The Evaluation and Application of the TRIZ Method for Increasing Eco-Innovative Levels in SMEs

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sustainability-Oriented Innovation (SOI)

2.1.1. Sustainability-Oriented Innovation Concept

- Both environmental regulations at national and supranational levels are growing, as well as the external pressure of the different stakeholders (NGOs, clients, local communities) requiring companies to tackle issues related to sustainability.

- Much more importantly, in terms of business, SOI may generate a competitive edge through more effective production from the standpoint of cost, stable relationships, and access to resources (e.g., supply contracts on a long-term basis), as well as new business opportunities through the differentiation of products and new markets [18].

- Regulations and laws in the social and environmental fields increase the pressure for innovation [3].

- Target dimension examines the innovation effects depending on their impact on sustainability objectives. Target size distinguishes three criteria for assessing the effects of innovations, sometimes linked together: economic effects, social effects, and environmental effects.

- Life cycle dimension. Target dimension alone is not sufficient to provide an evaluation structure for the sustainability effects of innovations that spread widely in time and space. For example, biofuels have a reduced environmental impact on use, but critical effects during production. Accordingly, specialty literature concerning the sustainability effects of product innovation focuses in particular on the role of the life cycle, taking into account parameters such as manufacture, use and reuse, and end of life.

- Innovation type dimension consists of four criteria relating to innovations from the fields of Technology, Product-service system, Business model innovations, and Strategy.

- How could we ensure that sustainability is part of our creative process?

- How can we ensure that sustainability is part of the business process management?

- When and how can an outside opinion be incorporated into the creative process?

- What processes are most suitable for increasing the value of the company’s intellectual capital?

2.1.2. Sustainability-Oriented Innovation in SMEs

- What practices of product and process innovations are implemented in SMEs and how do they interact?

- What factors facilitate and/or are involved in the practice of product and process innovations?

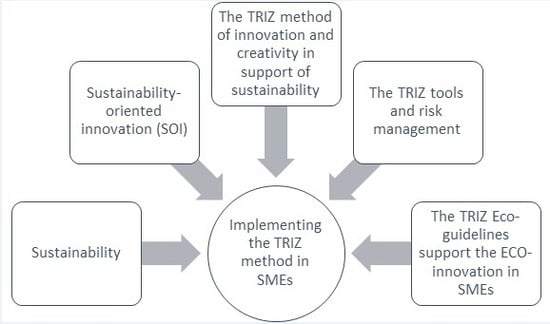

2.2. The TRIZ Method of Innovation and Creativity in Support of Sustainability

2.2.1. The TRIZ Laws of Evolution and Eco-Design

2.2.2. Other Areas Where TRIZ Support Sustainability

- It is an effective way to forecast future trends and developments.

- An innovative method of eco-design was designed by incorporating the rules of eco evolution and the ideality laws in order to create innovative and environment-friendly products and processes.

- The idea of biological evolution was integrated with TRIZ models of evolution and inventive principles to develop and to predict future ecological products.

2.2.3. The Need for Using the TRIZ Method in SMEs

2.2.4. Implementing the TRIZ Method in SMEs

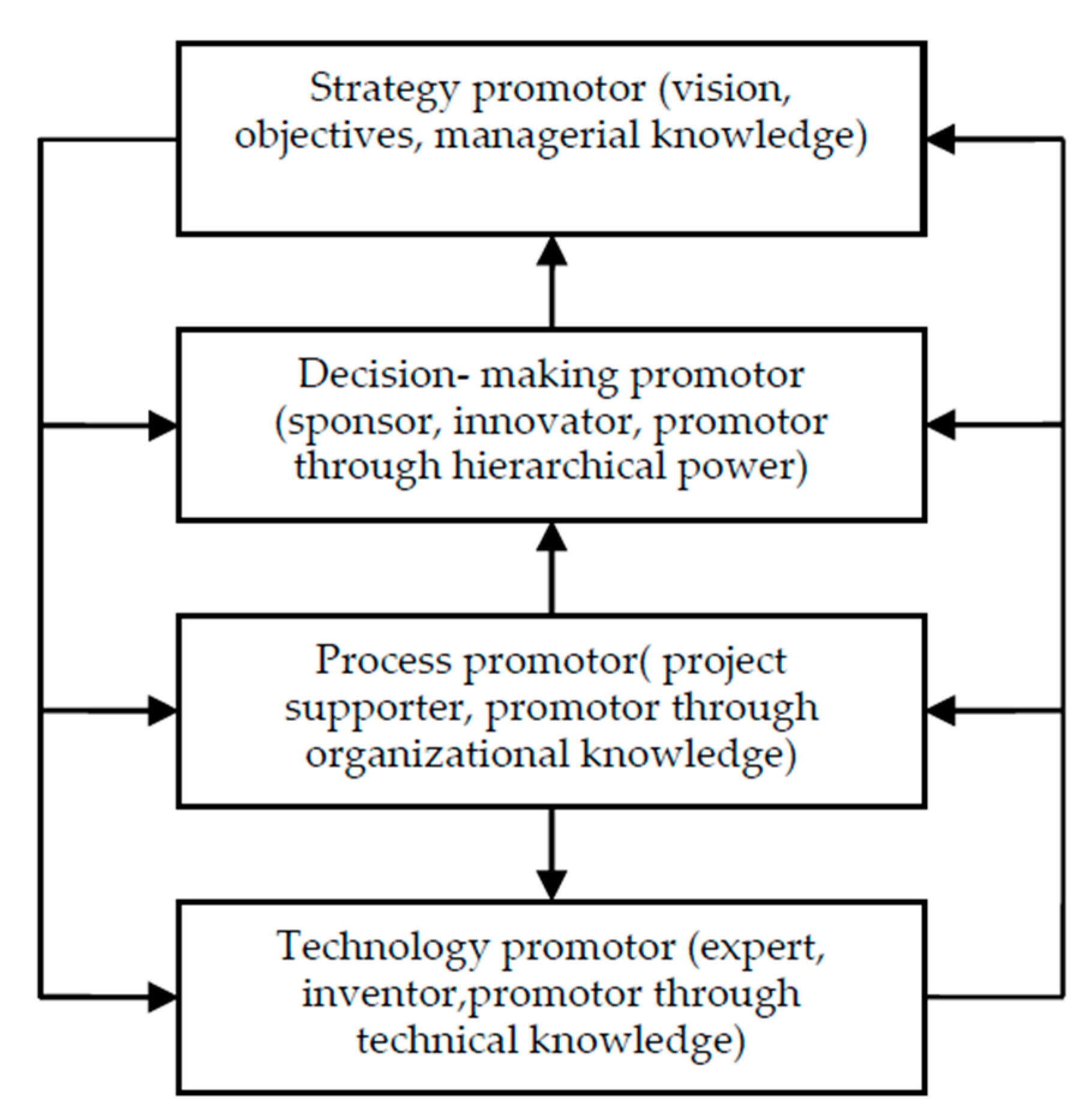

- 1.

- The strategic promoter has expertise in the field of planning, organization, coordination, and supervision. He plays an essential role inside the projects as he contributes to achieving the objectives of the organization in accordance with the established plan [52].

- 2.

- The decision-making promotor has the required hierarchical power to lead the project, to ensure the necessary resources and to help overcome the obstacles which may appear during the project. The decision-making promotor will overcome potential obstacles through authority bestowed within the organization. Due to the fact that the decision-making power belongs to management, it has to be said that the statement according to which higher-level management support is a success factor in innovation projects, should be nuanced.

- 3.

- The technology promotor, also called expert, has a vast technical expertise in the area where the innovation takes place. He or she plays an important role in the project because it has the knowledge necessary for applying the innovation.

- 4.

- The process promotor connects the decision-making promotor with the technology promotor (the expert) and has the ability to bring together the human resources required for the innovation process. The process promotor must overcome the administrative barriers through his or her knowledge about the organization, by recognizing and removing organizational obstacles [49,53].

- They have undergone a one-year master program in innovative design based on the TRIZ approach, and have a very good knowledge of the company, each having been employed for ten years in the company;

- They have adapted the TRIZ method to the SMEs’ needs and resources by choosing a simplified approach based on a selection of key-principles (contradictions, ideality and evolution laws);

- In both cases, we can talk about assimilating TRIZ to the extent that promotors transformed their knowledge in competences dedicated to the development of the innovation function;

- By applying the TRIZ-inspired methods, they became involved in an active attempt to change the designers’ practices, that is, in a form of organizational innovation;

- Full autonomy regarding the TRIZ application. This autonomy is reflected in the organization chart—both being directly subordinated to the entrepreneur—but actually having a significant action freedom;

3. Case Study on the Possibility of Using TRIZ in a Medium-Sized Enterprise in the Center Region, Romania

3.1. Overview of Organization

3.2. The Moby’s Innovation Context

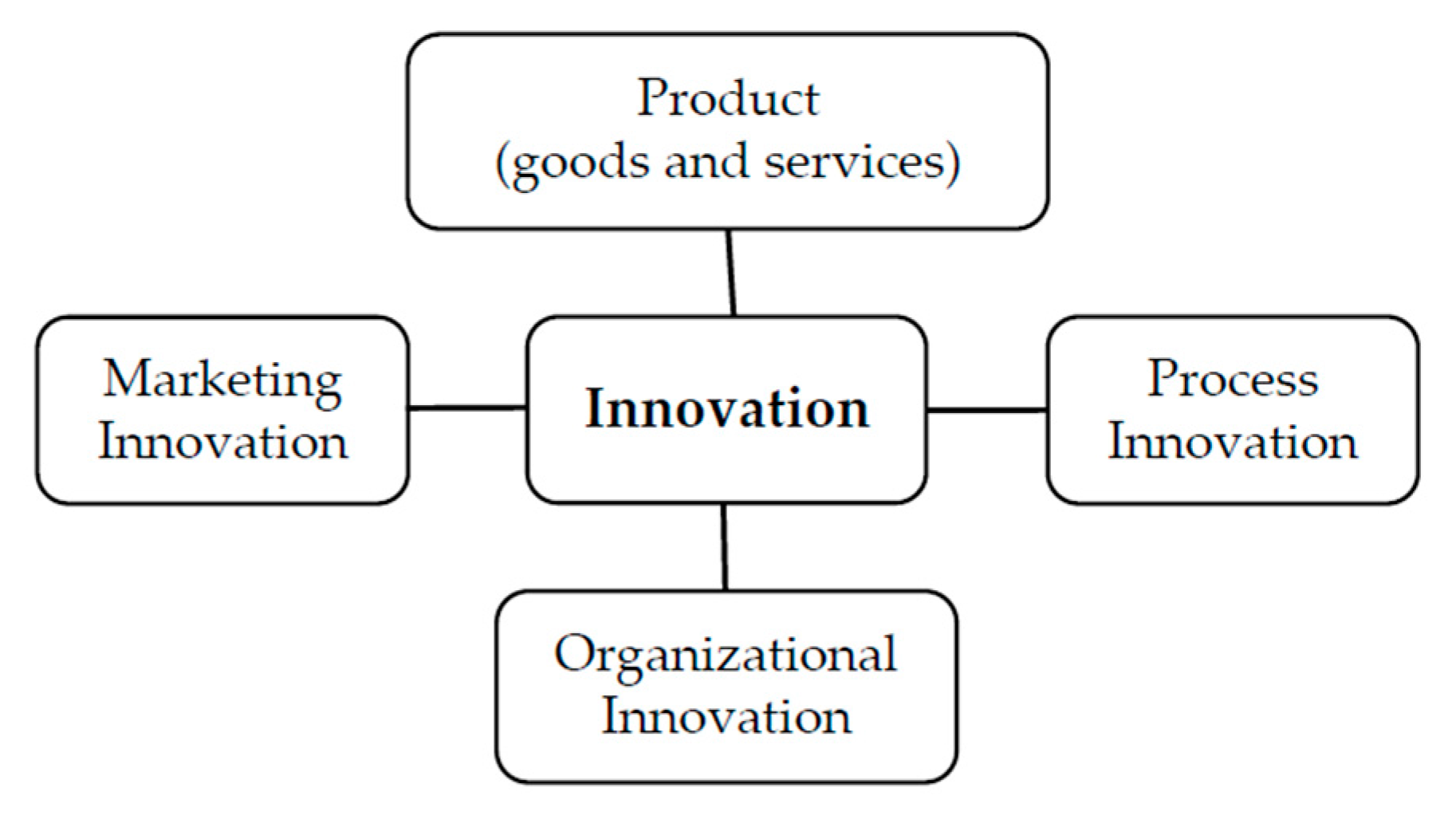

- Goods and services innovations (Product innovation)

- a1.

- Changes in components, materials or other elements which improve performance significantly

- a2.

- Adding new functions or characteristics to the existing goods, which result in a significantly improved performance.

- b.

- Process innovations

- b1.

- New or improved equipment (orbital polishing machine, drilling machine in two planes) and software used to make a product or provide a service, for reducing the unit cost or to increase the quality of an existing product/service.

- b2.

- First time introduction of computer aided design by using the AutoCAD software to digitize the customer’s profile for the requested products

- b3.

- Significantly improved methods and/or competences used to make/deliver a product/service or for reducing the unit cost or to increase the quality of an existing product/service.

- b4.

- New or significantly improved methods, equipment, and software for logistic activities by utilizing a stock management software.

- b5.

- New or significantly improved methods, equipment, and software for ancillary activities (accounting, calculus, maintenance) through the use of a modular software adapted to the field of activity of the company and which may be updated according to the requirements of regulatory authorities.

- c.

- Marketing innovations

- c1.

- A new geographic market area or a new market segment. Over the last years, the company has entered markets in Austria and Germany.

- d.

- Organizational innovations

- Due to on-line sales, the number of product handling movements increases. If the protection level of the packaging increases, the number of complaints regarding product damage decreases, but the costs increase;

- If the number of elements made from solid wood is reduced, the costs are reduced, but the mechanical resistance of the furniture decreases.

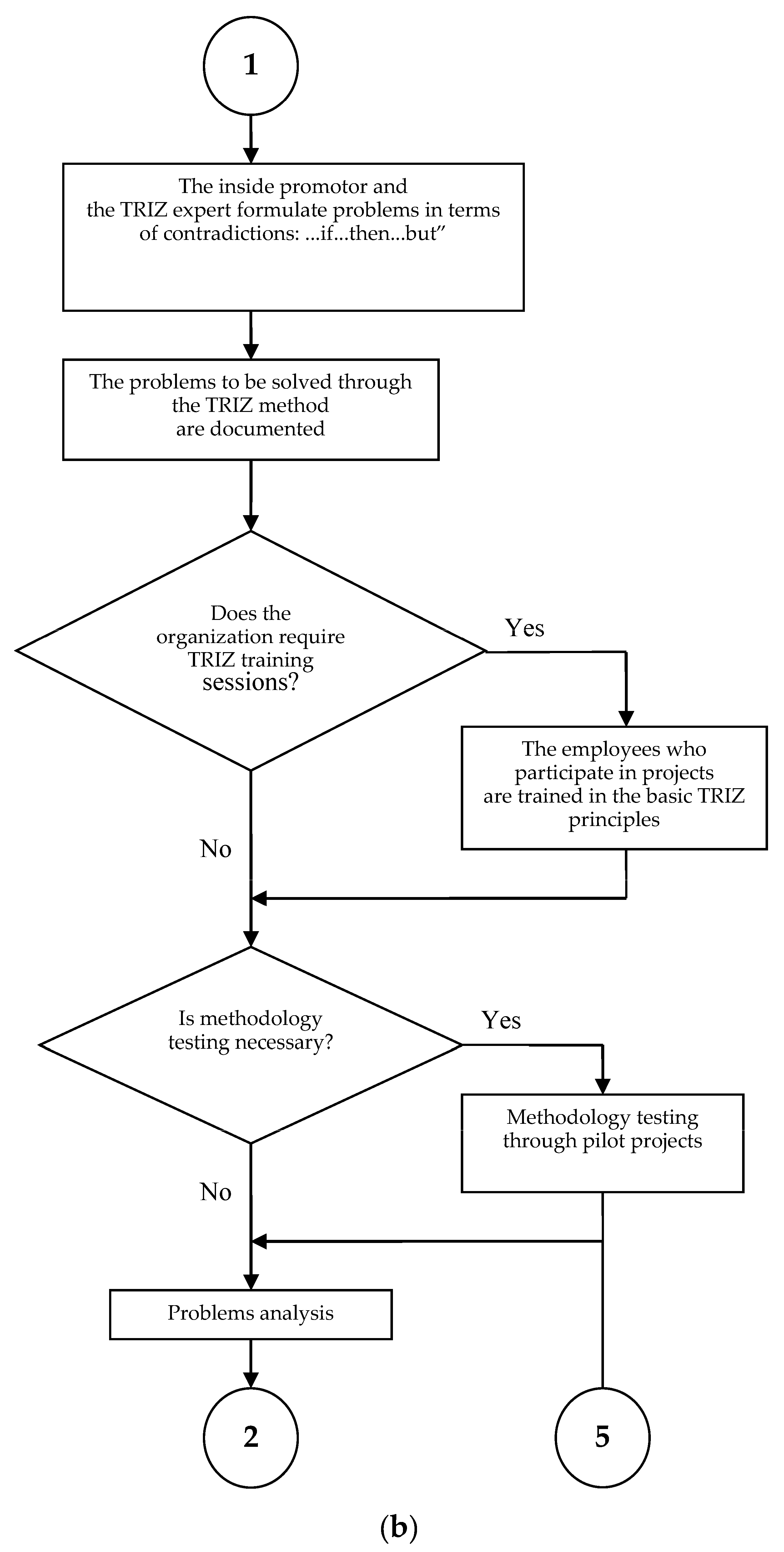

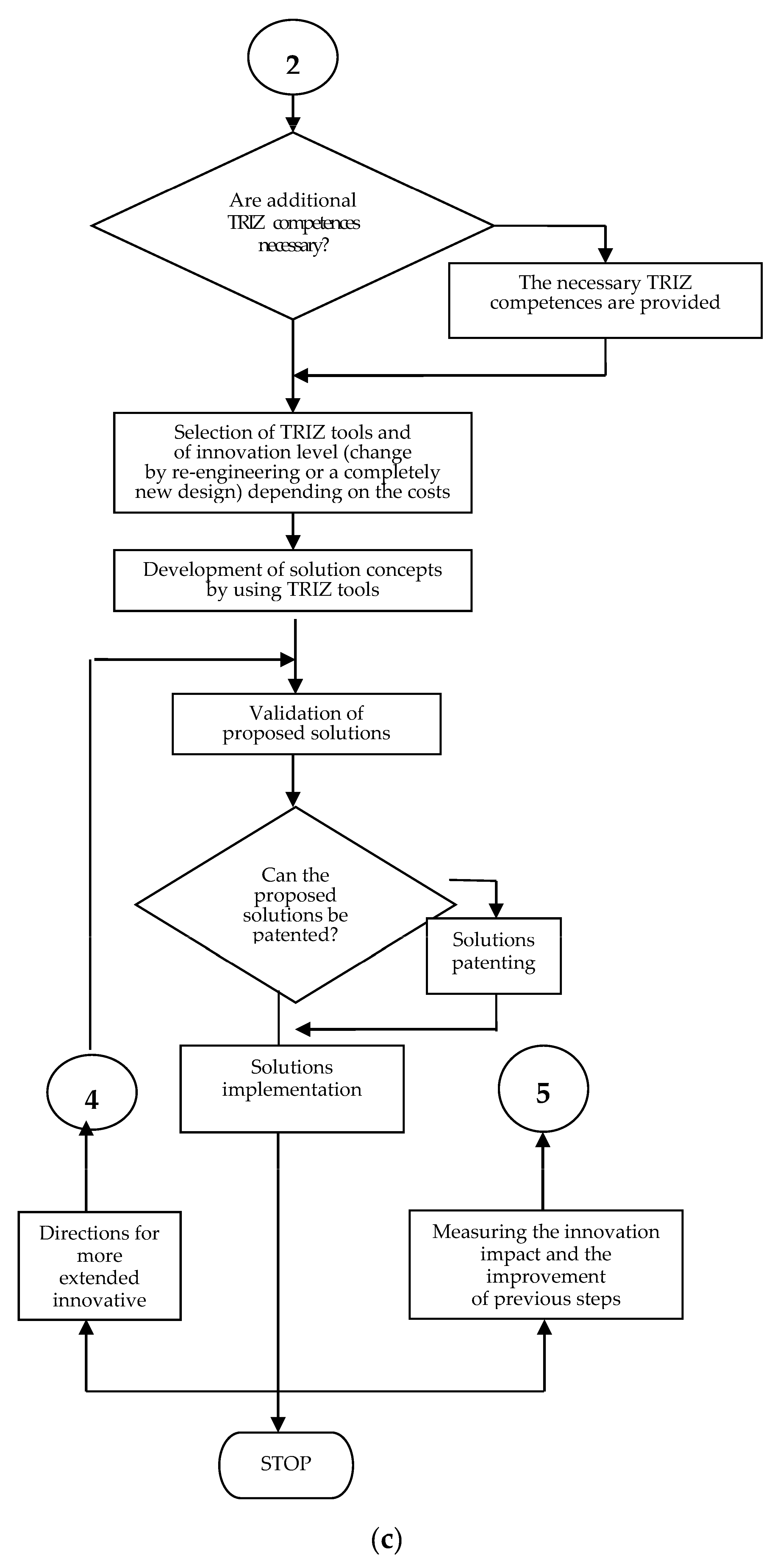

3.3. Necessary Steps in Implementing TRIZ Method in the Company Moby

- (1). TRIZ expert (the consultant from outside the organization) presents the background and experience of organizations that have tested and adopted TRIZ methodology and “success stories”—so basically he presents a portfolio of his or others’ achievements.

- (2). The organization identifies the explicit or implicit problems faced by that organization this means that the organization must submit both explicit and implicit problems (i.e., those that were not explained).

- (3). The organization recognizes the need for innovation, proposes projects (from the problems shown) and provides technical expertise (specialists from inside).

- (4). Innovation cannot happen if it is not promoted, thus somehow things have to be pushed. The SME manager assumes the role of promoter from the inside? If not, then an inside promoter is designated and invested with decision making.

- (5). To the promoter from within the organization there are presented, first, three core concepts of TRIZ: the contradictions, the ideality and the patterns of evolution.

- (6). The promoter from the inside of the organization and the TRIZ expert formulate problems in terms of contradiction, that means TRIZ specific terms: “if... then... but”.

- (7). The problems to be solved by the TRIZ method are documented, that means they are described in the documents to be made: contracts, minutes, etc.(8). If the organization wants a broader and with a perspective approach, it can request training in TRIZ.

- (9). If it is deemed necessary the methodology is tested by pilot projects.

- (10). The proposed problems to be solved are analyzed, and if difficulty or quantity requires, additional TRIZ skills are mobilized (specialists).

- (11). The appropriate TRIZ tools are identified, and the organization defines the innovation level they want (change through redesign or completely new concept) based on costs that may incur and allocates a budget.

- (12). Using the TRIZ tools the solutions are developed.(13). If the resulting solutions are patentable then it will be proceeded accordingly.

- (14). Validation of the proposed solutions: the solutions are supported by management and their implementation approved.

- (15). The implementation of the solutions.

- (16). In the process, taking into account that TRIZ provide solutions with a high degree of generality, ways to achieve larger innovative solutions can be identified.

- (17). Feed-back: measurement the impact of innovation and improvement of previous steps.

4. Discussion

- SME innovation is geared toward incremental improvements rather than radical innovations.

- The innovation effort of SMEs is reactive, being heavily influenced by customer requirements in general and in the particular case of sustainability-oriented innovation of regulations.

- SME protects its market niche through competitive prices and through incremental innovations.

- In SMEs it is possible to use TRIZ, however its implementation hits the lack of resources specific to this type of company, considering that Romania does not have an advanced innovation system, such as, for example, Taiwan or Hong Kong.

- The innovative directions seen, mainly in SMEs are: product, service, process, marketing, and organizational innovations. These directions are essential in order to become competitive and sustainable companies.

- Goods and services innovations confirm the fact that in the case of SMEs which innovate without research, the relationship with the clients is the most important external knowledge source when it comes to performance in good innovation [42], especially in the case of a company like Moby that does not collaborate with Research Centers or Universities.

- The quadruple of promoters proposed for large enterprises is considered to be an important pillar in attaining the objectives of the organization through the inclusion of a strategic promoter within the implementation process.

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Christiansen, A.; Buen, J. Managing environmental innovation in the energy sector: the case of photovoltaic and wave power development in Norway. Int. J. Innov. Manag. 2002, 6, 233–256. [Google Scholar] [CrossRef]

- Preuss, L. Contribution of purchasing and supply management to ecological innovation. Int. J. Innov. Manag. 2007, 11, 515–537. [Google Scholar] [CrossRef]

- Hansen, E.G.; Grosse-Dunker, F.; Reichwald, R. Sustainability innovation cube—A framework to evaluate sustainability—oriented innovations. Int. J. Innov. Manag. 2009, 13, 683–713. [Google Scholar] [CrossRef]

- Gabriel, M.; Schöggl, J.-P.; Posch, A. Early front-end innovation decisions for self-organized industrial symbiosis dynamics—A case study on lignin utilization. Sustainability 2017, 9, 515. [Google Scholar] [CrossRef]

- Siqueira, R.P.; Pitassib, C. Sustainability-oriented innovations: Can mindfulness make a difference? J. Clean. Prod. 2016, 139, 1181–1190. [Google Scholar] [CrossRef]

- Hede, S.; Ferreira, P.V.; Lopes, M.N.; Rocha, L.A. TRIZ and the paradigms of social sustainability in product development endeavors. Procedia Eng. 2015, 131, 522–538. [Google Scholar] [CrossRef]

- Chulvi, V.; González-Cruz, M.C.; Mulet, E.; Aguilar-Zambrano, J. Influence of the type of idea-generation method on the creativity of solutions. Res. in Eng. Des. 2013, 24, 33–41. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Dempsey, N.; Bramley, G.; Power, S.; Brown, C. The social dimension of sustainable development: Defining urban social sustainability. Sustain. Dev. 2011, 19, 289–300. [Google Scholar] [CrossRef]

- Regazzoni, D.; Russo, D. TRIZ tools to enhance risk management. Procedia Eng. 2011, 9, 40–51. [Google Scholar] [CrossRef]

- Mann, D.; Poon, J.; Driver, M. Case studies from a breakthrough innovation product design programme for local industries. Triz J. 2006, 2, 35. [Google Scholar]

- Luthraa, S.; Govindanb, K.; Kannanb, D.; Manglac, S.-K.; Gargd, C.-P. An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- Cioca, L.-I.; Ivascu, L.; Rada, E.-C.; Torretta, V.; Ionescu, G. The study of sustainable development and technological impact on co2 reducing conditions: Case study of Romania. Sustainability 2015, 7, 1637–1650. [Google Scholar] [CrossRef]

- Cheng, C.C.J.; Yang, C.-L.; Sheu, C. The Link Between eco-innovation and business performance: A taiwanese industry context. J. Clean. Prod. 2014, 64, 81–90. [Google Scholar] [CrossRef]

- Barbieri, J.C.; Vasconcelos, I.F.-G.; Andreassi, T.; Vasconcelos, F.-C. Innovation and sustainability: New models and propositions. R. Adm. Empr. 2010, 50, 146–154. [Google Scholar] [CrossRef]

- Feng, T.; Wang, D. The Influence of Environmental Management Systems on Financial Performance: A moderated-mediation analysis. J. Bus. Ethics 2016, 135, 265–278. [Google Scholar] [CrossRef]

- Weng, H.-H.R.; Chen, J.-S.; Chen, P.-C. Effects of green innovation on environmental and corporate performance: a stakeholder perspective. Sustainability 2015, 7, 4997–5026. [Google Scholar] [CrossRef]

- Klewitz, J.; Hansen, E.-G. Sustainability-oriented innovation of SMEs: A systematic review. J. Clean. Prod. 2014, 65, 57–75. [Google Scholar] [CrossRef]

- Ben Moussaa, F.-Z.; Rasovskab, I.; Duboisc, S.; Guioc, S.; Benmoussaa, R. Reviewing the use of the theory of inventive problem solving (TRIZ) in green supply chain problems. J. Clean. Prod. 2017, 142, 2677–2692. [Google Scholar] [CrossRef]

- Salzmann, O.-U.; Steger, A.; Ionescu-Somers, A. Determinants of corporate sustainability management: An empirical contingency approach. In Corporate Social Responsibility; Springer Gabler: Wiesbaden, Germany, 2008. [Google Scholar]

- Perrini, F.; Tencati, A. Sustainability and stakeholder management: The need for new corporate performance evaluation and reporting systems. Bus. Strategy Environ. 2006, 15, 296–308. [Google Scholar] [CrossRef]

- Kölsch, D.; Saling, P. How to measure social impacts? A socio-eco-efficiency analysis by the seebalance method. Int. J. Sustain. Dev. 2009, 11, 1–23. [Google Scholar] [CrossRef]

- Gauthier, C. Measuring corporate, social and environmental performance: The extended life-cycle assessment. J. Bus. Ethics 2005, 59, 199–206. [Google Scholar] [CrossRef]

- Zetterlund, H.; Hallstedt, S.; Broman, G. Implementation potential of sustainability-oriented decision support in product development. Proc. CIRP 2016, 50, 287–292. [Google Scholar] [CrossRef]

- Ayyagari, M.; Thorsten, B.; Demirguc-Kunt, A. Small and medium enterprises across the globe: A new database. Small Bus. Econ. 2007, 29, 415–434. [Google Scholar] [CrossRef]

- Boons, F.; Lüdeke-Freund, F. Business models for sustainable innovation: State-of-the-art and steps towards a research agenda. J. Clean. Prod. 2012, 45, 9–19. [Google Scholar] [CrossRef]

- D’Anna, W.; Cascini, G. Supporting sustainable innovation through TRIZ system thinking. Procedia Eng. 2011, 9, 145–156. [Google Scholar] [CrossRef]

- Chulvi, V.; Vidal, R. Usefulness of evolution lines in eco-design. Procedia Eng. 2011, 9, 135–144. [Google Scholar] [CrossRef]

- Prajogo, D.; Tang, A.K.Y.; Lai, K.-H. The diffusion of environmental management system and its effect on environmental management practices. Int. J. Oper. Prod. Manag. 2014, 34, 565–585. [Google Scholar] [CrossRef]

- Russo, D.; Regazzoni, D.; Montecchi, T. Eco-design with TRIZ laws of evolution. Procedia Eng. 2011, 9, 311–322. [Google Scholar] [CrossRef]

- Fresner, J.; Jantschgi, J.; Birkel, S.; Bärnthaler, J.; Krenn, C. The theory of inventive problem solving (TRIZ) as option generation tool within cleaner production projects. J. Clean. Prod. 2010, 18, 128–136. [Google Scholar] [CrossRef]

- Chang, D.; Lee, C.; Chen, C. Review of life cycle assessment towards sustainable product development. J. Clean. Prod. 2014, 83, 48–60. [Google Scholar] [CrossRef]

- Yang, C.-J.; Chen, J.-L. Forecasting the design of eco-products by integrating TRIZ evolution patterns with CBR and Simple LCA methods. Expert Syst. Appl. 2012, 39, 2884–2892. [Google Scholar] [CrossRef]

- Fitzgerald, D.-P.; Herrmann, J.-W.; Schmidt, L.-C. A Conceptual Design Tool for Resolving Conflicts between Product Functionality and Environmental Impact. J. Mech. Des. 2010, 132, 1–16. [Google Scholar] [CrossRef]

- Russo, D.; Schöfer, M.; Bersano, G. Supporting ECO-innovation in SMEs by TRIZ eco-guidelines. Procedia Eng. 2015, 131, 831–839. [Google Scholar] [CrossRef]

- Machiba, T. Eco-innovation for enabling resource efficiency and green growth: Development of an analytical framework and preliminary analysis of industry and policy practices. Int. Econ. Econ. Policy 2011, 7, 357–370. [Google Scholar] [CrossRef]

- Kong, T.; Feng, T.; Ye, C. Advanced manufacturing technologies and green innovation: the role of internal environmental collaboration. Sustainability 2016, 8, 1056. [Google Scholar] [CrossRef]

- Burz, G.; Marian, L. Case study on the implementation of the TRIZ innovation method in SMEs. Rev. Manag. Econ. Eng. 2014, 13, 81. [Google Scholar]

- Ortega-Argiles, R.; Vivarelli, M.; Voigt, P. R&D in SMEs: A paradox? Small Bus. Econ. 2009, 33, 3–11. [Google Scholar] [CrossRef]

- Bougrain, F.; Haudeville, B. Innovation, collaboration and SMEs internal research capacities. Res. Policy 2002, 31, 735–747. [Google Scholar] [CrossRef]

- Organisation for Economic Co-operation and Development. Oslo Manual: Guidelines for Collecting and Interpreting Innovation Data. Available online: http://www.oecd:sti/inno/oslomanualguidelinesforcollectingandinterpretinginnovationdata3rdedition.htm (accessed on 10 March 2017).

- Moilanen, M.; Østbye, S.; Woll, K. Non-R&D SMEs: External knowledge, absorptive capacity and product innovation. Small Bus. Econ. 2014, 43, 447–462. [Google Scholar] [CrossRef]

- European Commission. Renewable Energy Directive—National Action Plans. Available online: https://ec.europa.eu/energy/node/71 (accessed on 10 January 2017).

- Rada, E.-C.; Bresciani, C.; Girelli, E.; Ragazzi, M.; Schiavon, M.; Torretta, V. Analysis and measures to improve waste management in schools. Sustainability 2016, 8, 840. [Google Scholar] [CrossRef]

- Torretta, V.; Rada, E.-C.; Ragazzi, M.; Trullic, E.; Istrated, I.A.; Cioca, L.I. Treatment and disposal of tyres: Two EU approaches. A review. Waste Manag. 2015, 45, 152–160. [Google Scholar] [CrossRef] [PubMed]

- Xavier, A.-F.; Naveiroa, R.-M.; Aoussatb, A.; Reyesc, T. Systematic literature review of eco-innovation models: Opportunities and recommendations for future research. J. Clean. Prod. 2017, 149, 1278–1302. [Google Scholar] [CrossRef]

- Campodall’Orto, S. TRIZ—Innovazione Sistematica per le Pmi Lombarde. Introduzione. Available online: http://lazio-side.it/showdocument.php?id=6248 (accessed on 17 January 2017).

- Bhushan, N. The Elegant Solution and TRIZ. Available online: http://www.triz-journal.com/archives/2008/10/03/ (accessed on 17 January 2017).

- Goduscheit, R.-C. Innovation promoters—A multiple case study. Ind. Mark. Manag. 2014, 43, 525–534. [Google Scholar] [CrossRef]

- Cioca, L.-I.; Moraru, R.-I.; Babut, G.-B. A Framework for Organisational Characteristic Assessment and their Influences on Safety and Health at Work. In Proceedings of the 15th International Conference the Knowledge-Based Organization, Sibiu, Romania, 26–28 November 2009; Volume 2, pp. 43–48. [Google Scholar]

- Ivascu, L.; Cioca, L.-I. Opportunity Risk: Integrated Approach to Risk Management for Creating Enterprise Opportunities. In Proceedings of the 2nd International Conference on Psychology, Management and Social Science, Shenzhen, China, 23–24 January 2014. [Google Scholar]

- Ryszko, A. Proactive Environmental Strategy, Technological Eco-Innovation and Firm Performance—Case of Poland. Sustainability 2016, 8, 156. [Google Scholar] [CrossRef]

- Hauschildt, J.; Kirchmann, E. Teamwork for Innovation—The ‘Troika’ of Promotors. R&D Manag. 2001, 31, 10–34. [Google Scholar] [CrossRef]

- Lerch, C.; Schenk, E.; Cavallucci, D. Emergence d’une fonction d’innovation en PME: Le rôle de l’intrapreneur. Manag. Int. 2012, 16, 71–84. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feniser, C.; Burz, G.; Mocan, M.; Ivascu, L.; Gherhes, V.; Otel, C.C. The Evaluation and Application of the TRIZ Method for Increasing Eco-Innovative Levels in SMEs. Sustainability 2017, 9, 1125. https://doi.org/10.3390/su9071125

Feniser C, Burz G, Mocan M, Ivascu L, Gherhes V, Otel CC. The Evaluation and Application of the TRIZ Method for Increasing Eco-Innovative Levels in SMEs. Sustainability. 2017; 9(7):1125. https://doi.org/10.3390/su9071125

Chicago/Turabian StyleFeniser, Cristina, Gheorghe Burz, Marian Mocan, Larisa Ivascu, Vasile Gherhes, and Calin Ciprian Otel. 2017. "The Evaluation and Application of the TRIZ Method for Increasing Eco-Innovative Levels in SMEs" Sustainability 9, no. 7: 1125. https://doi.org/10.3390/su9071125