Statistical Technology Analysis for Competitive Sustainability of Three Dimensional Printing

Abstract

:1. Introduction

2. Statistical Approach to Patent Analysis

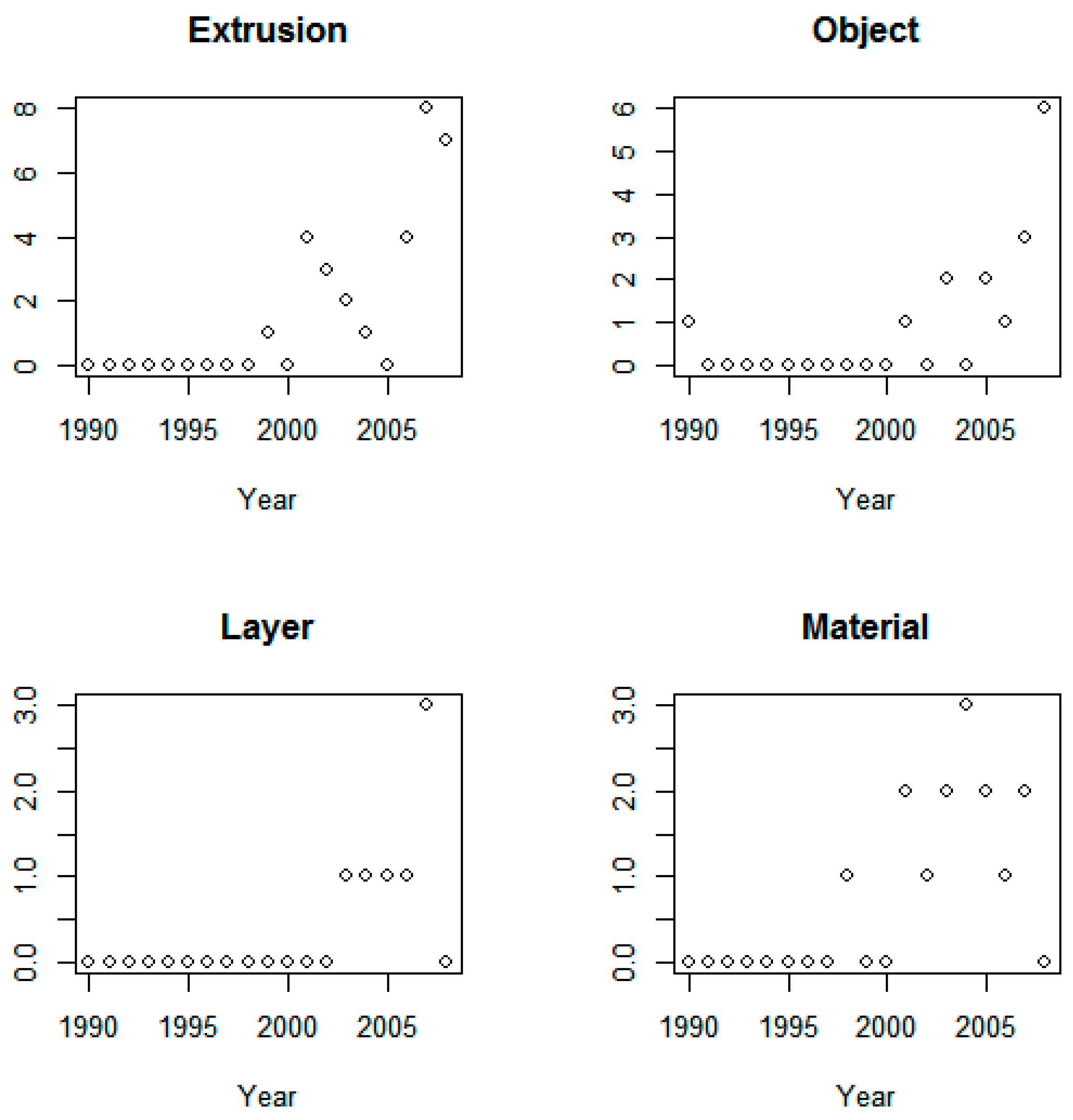

3. Statistical Technology Analysis for Competitive Sustainability

- Step 1.

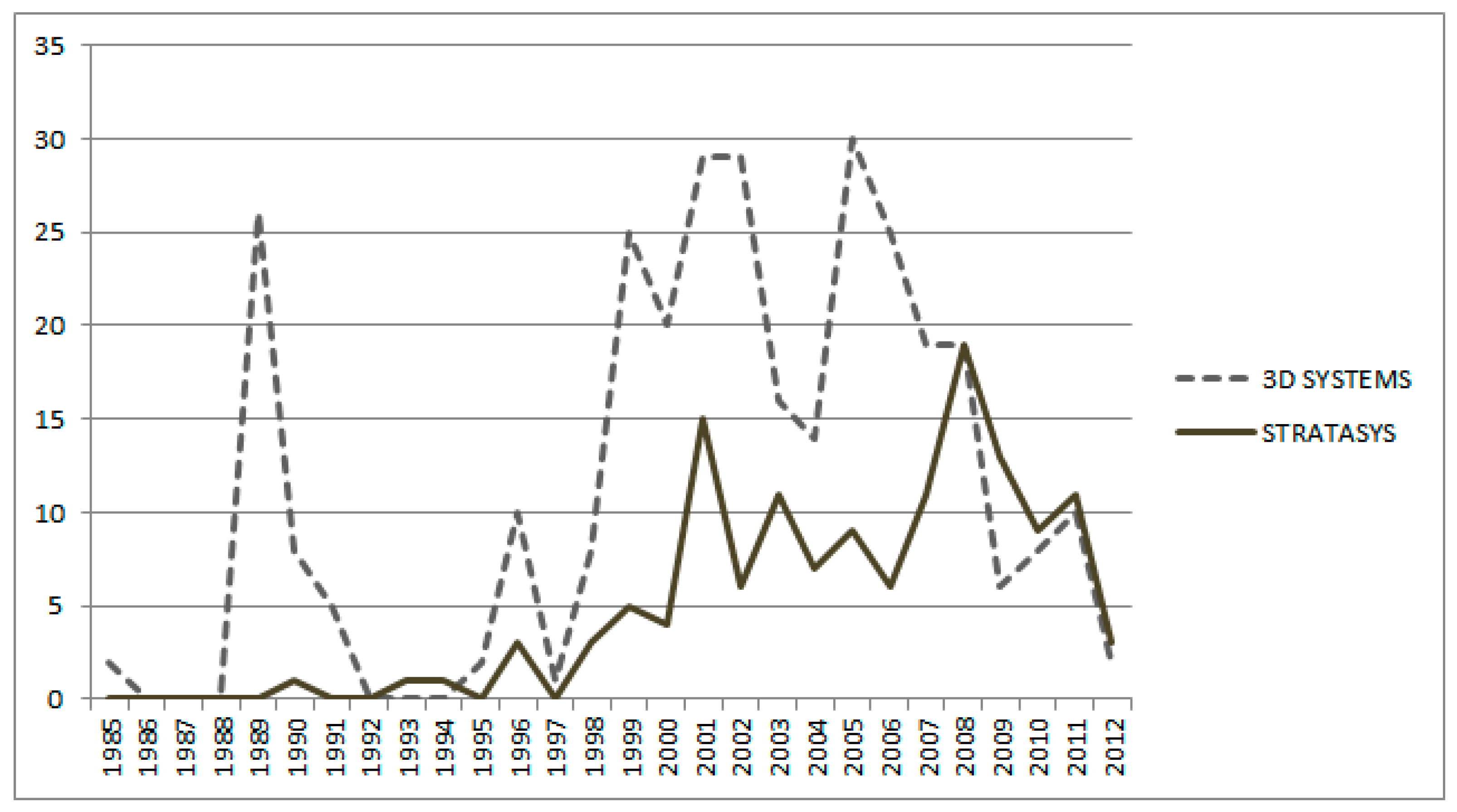

- Collect patent documents applied by Stratasys and 3D Systems from patent databases.

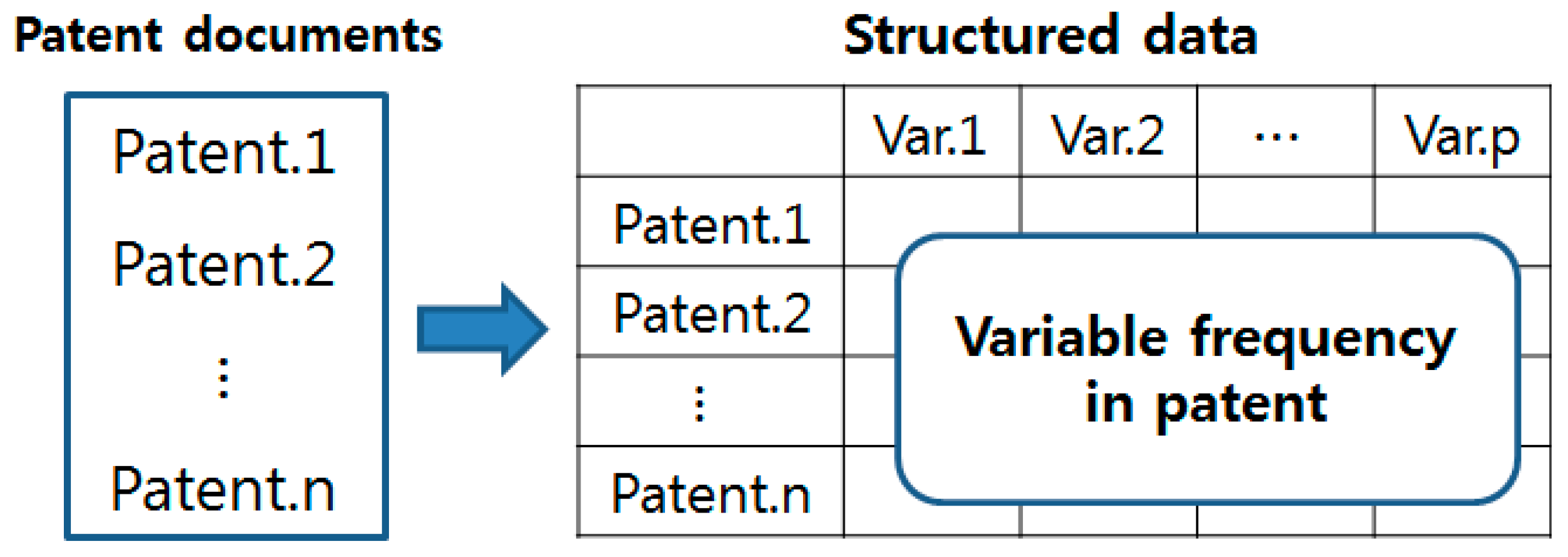

- Step 2.

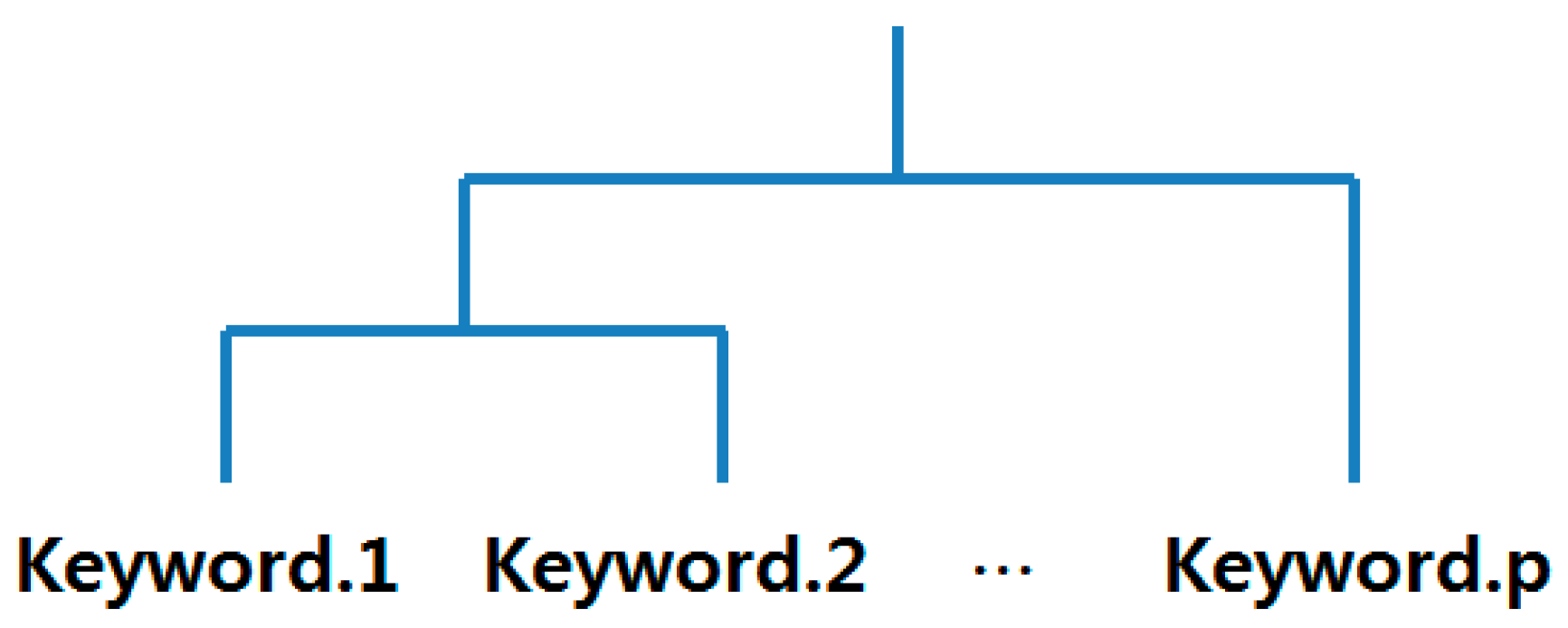

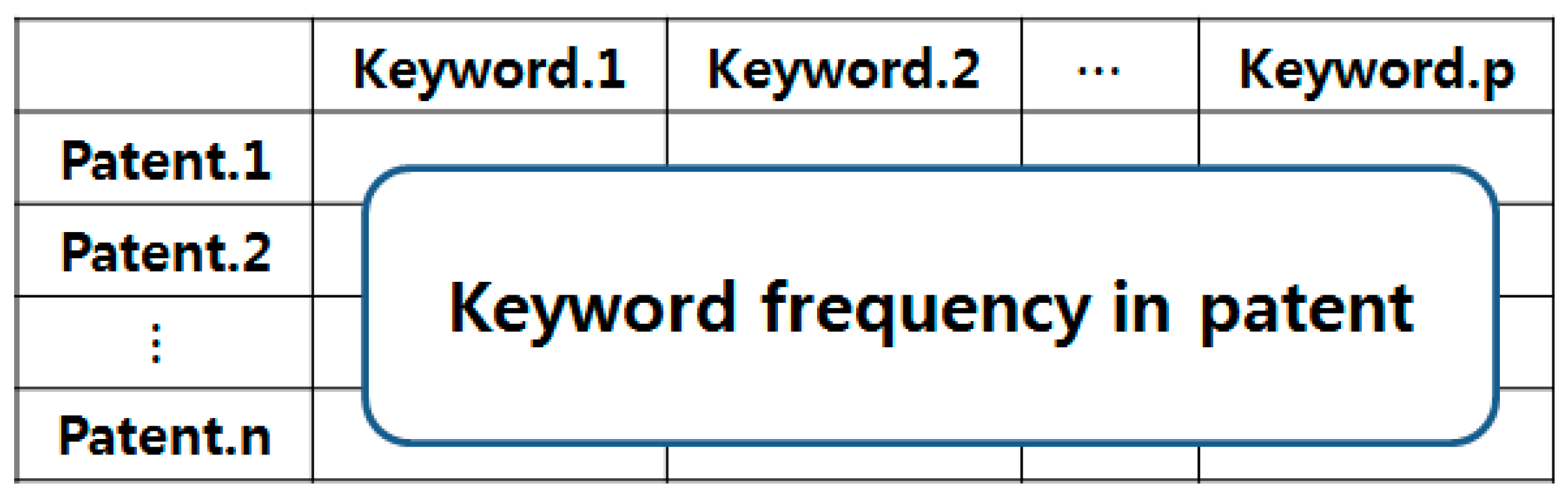

- Make structured patent data using text mining techniques.

- Step 3.

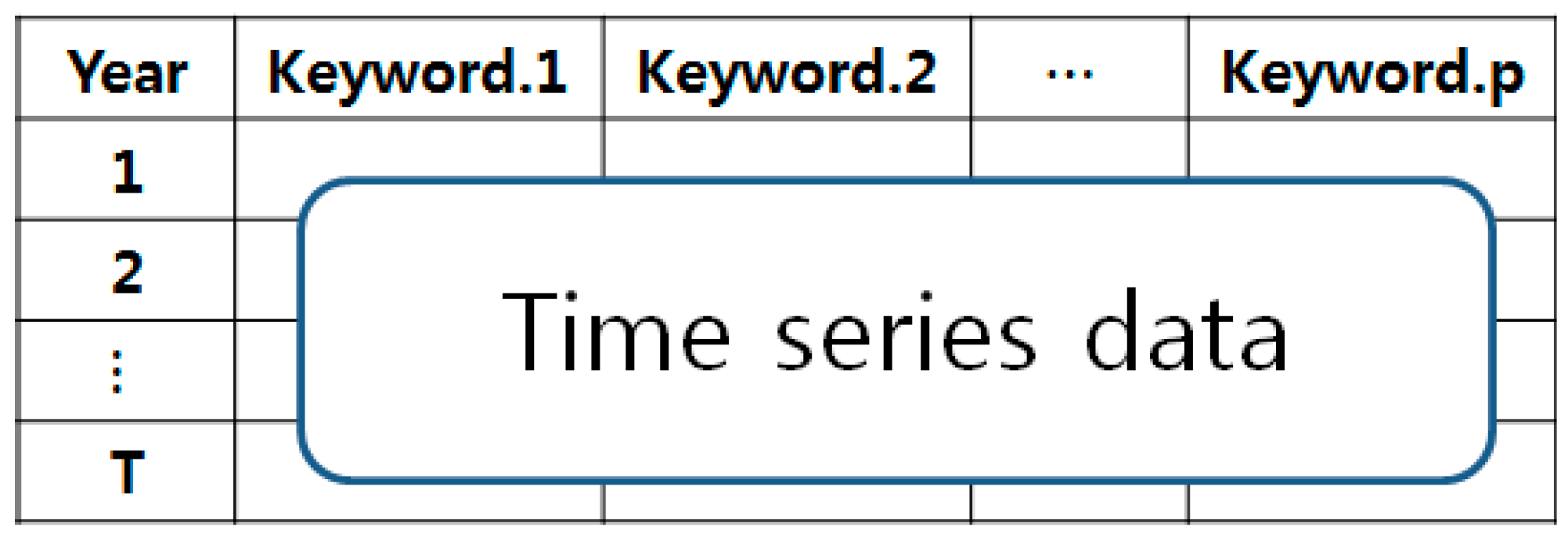

- Extract keywords from the structured patent data.

- Step 4.

- Analyze patent data to understand sustainable technology.

- 4-1.

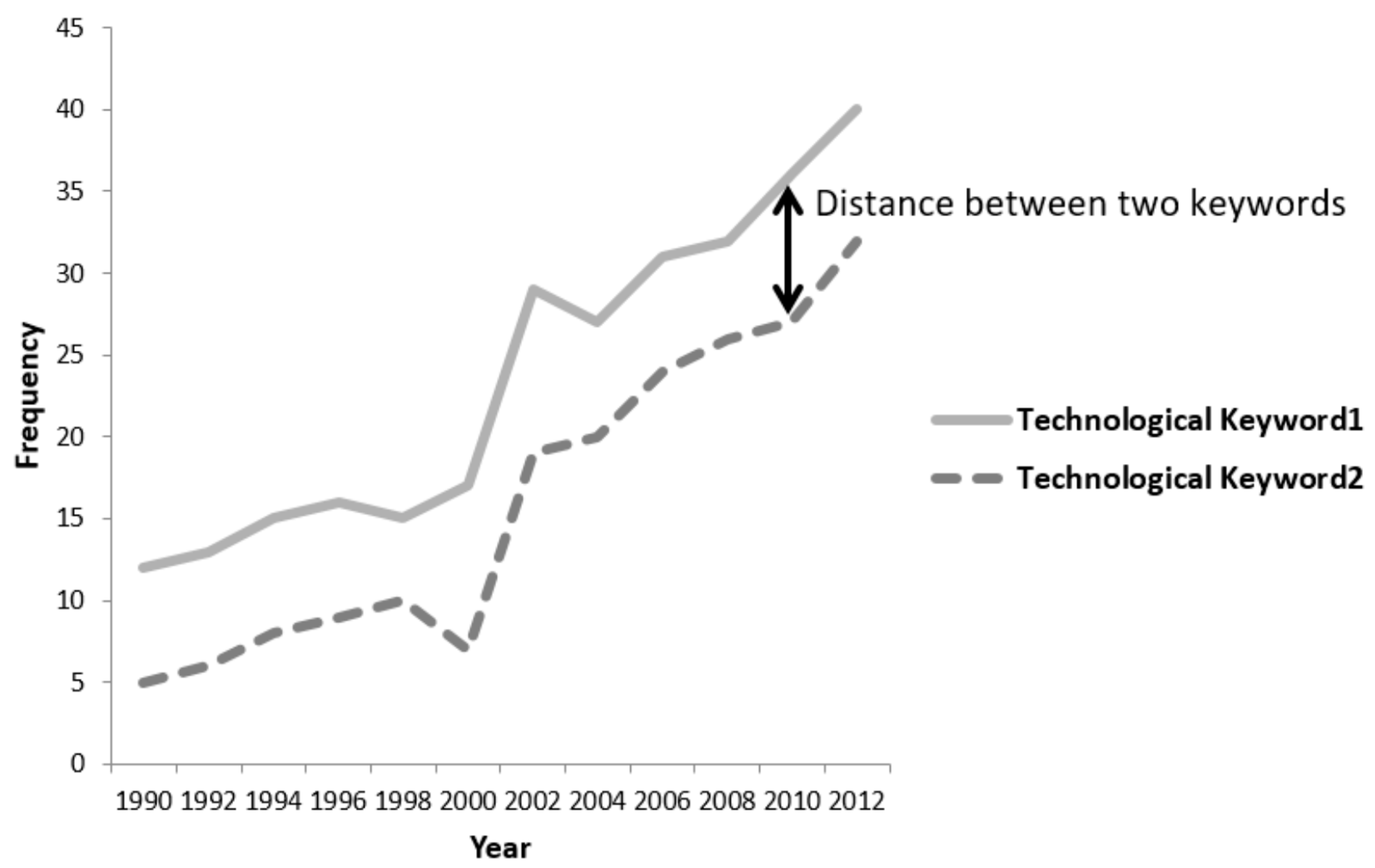

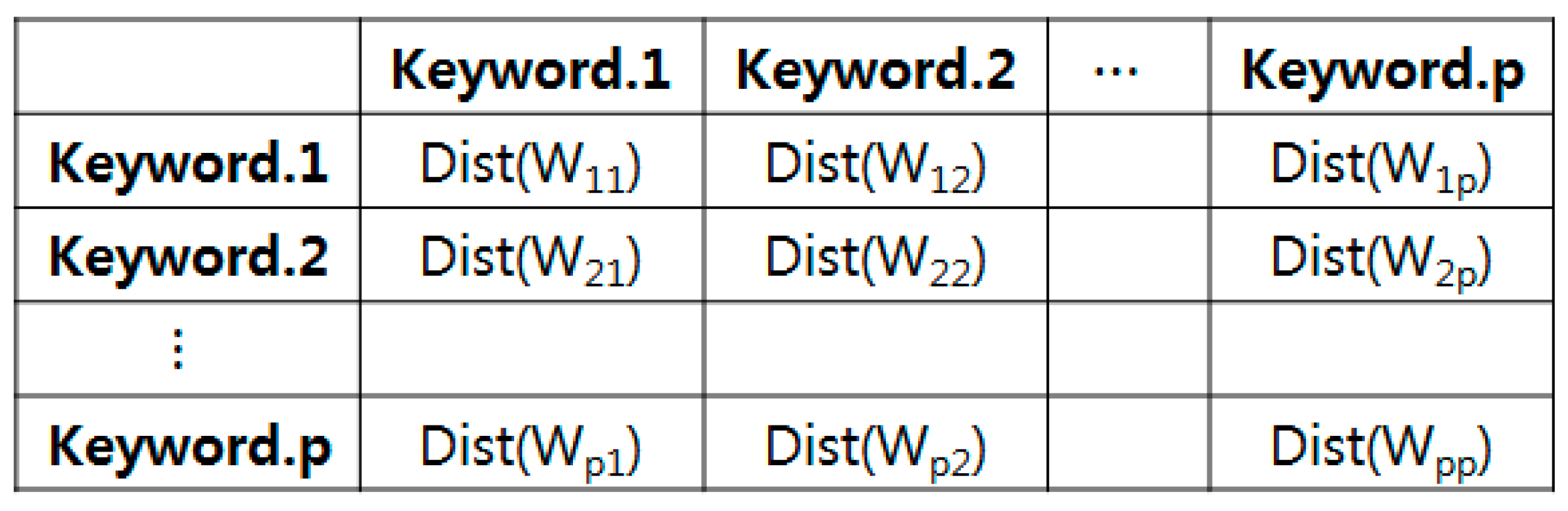

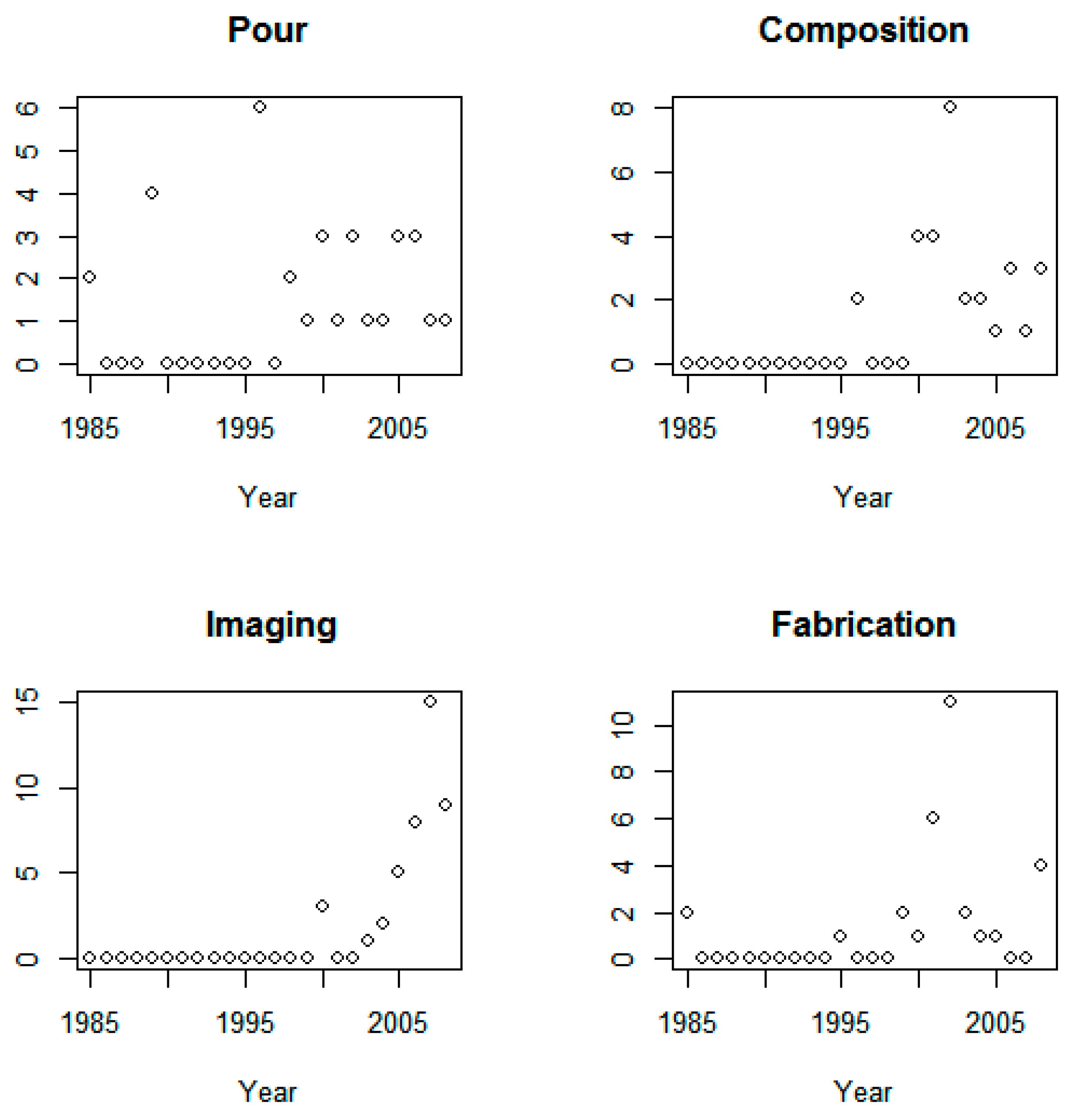

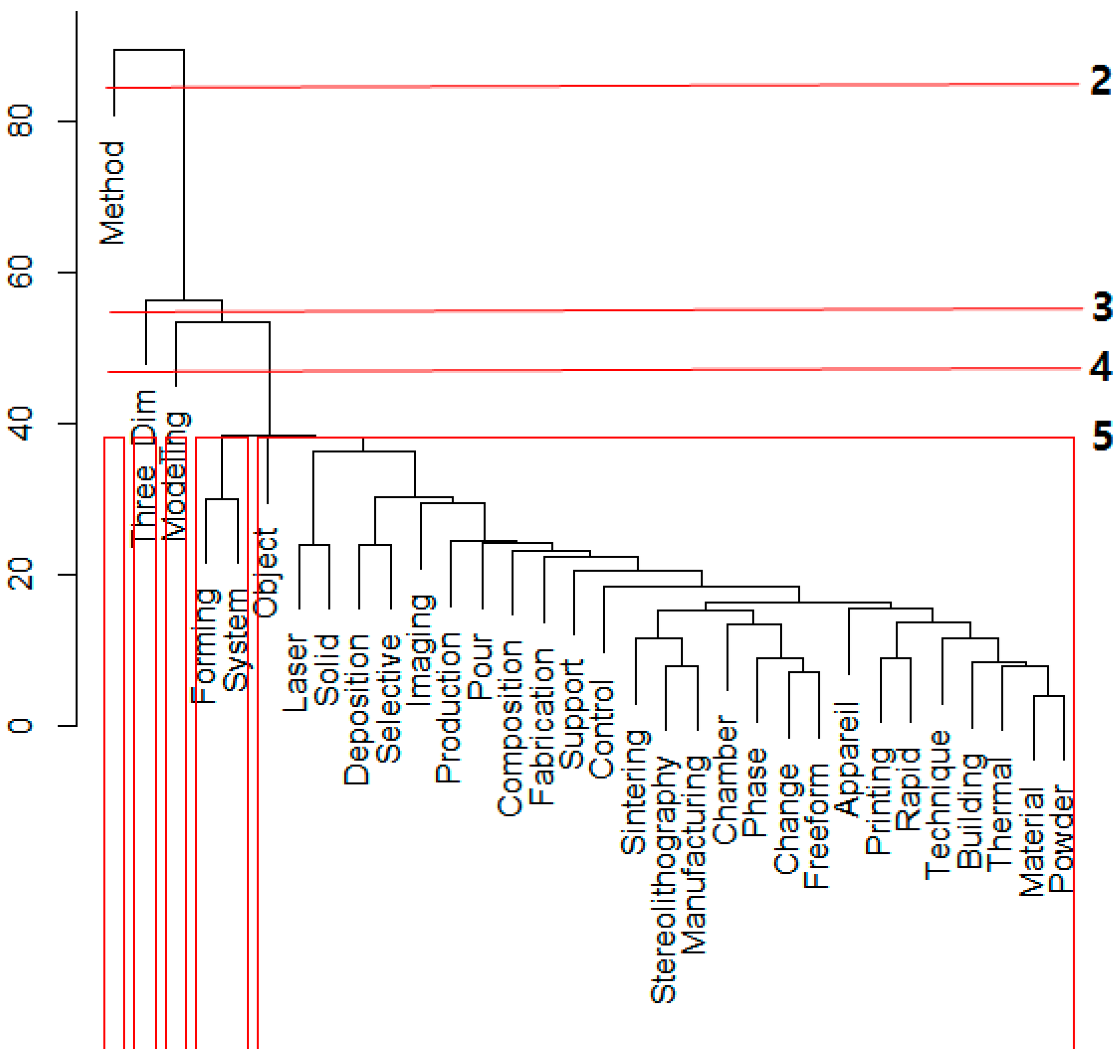

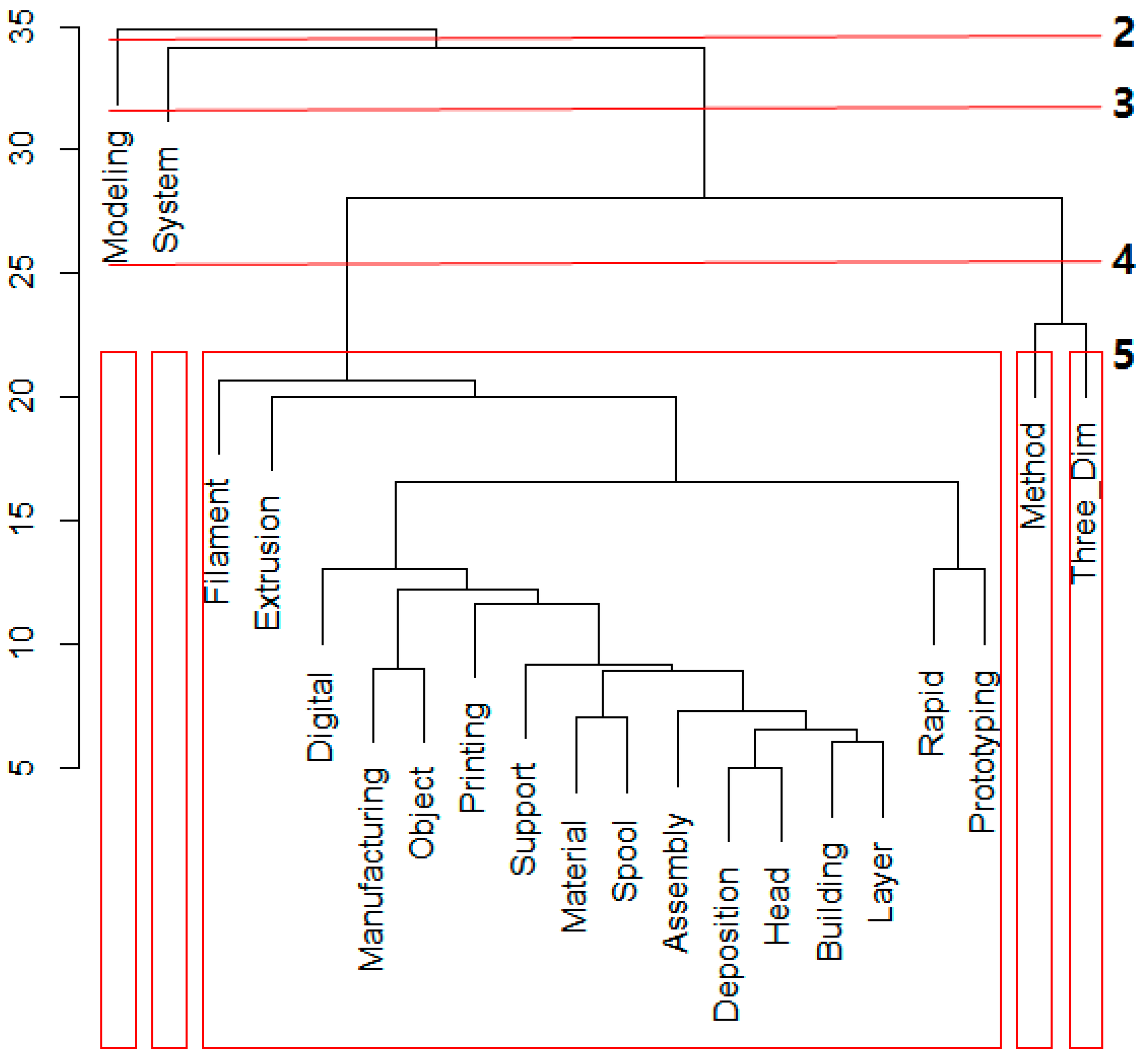

- Perform patent keyword clustering using TSC based on DTW.

- 4-2.

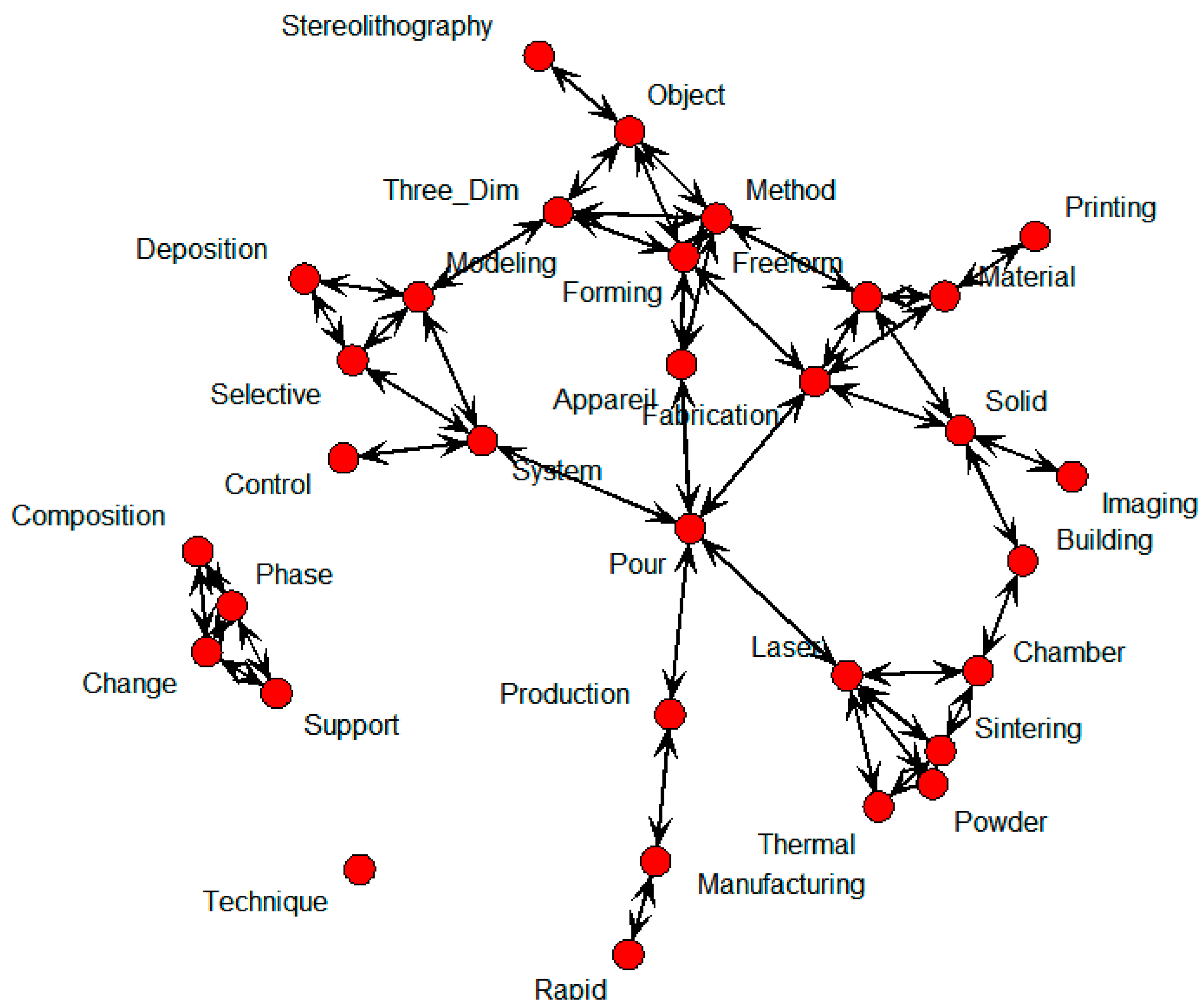

- Construct SNA graphs of patent keywords.

- Step 5.

- Test the result of the patent analysis.

- Step 6.

- Combine the results of TSC and SNA of technological keywords.

- Step 7.

- Compare sustainable technologies between competitors.

4. Case Study of Two Competitors

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mulder, K.; Ferrer, D.; Lente, H.V. What Is Sustainable Technology? Perceptions, Paradoxes and Possibilities; Greenleaf Publishing: Bradford, UK, 2011. [Google Scholar]

- Roper, A.T.; Cunningham, S.W.; Porter, A.L.; Mason, T.W.; Rossini, F.A.; Banks, J. Forecasting and Management of Technology; John Wiley & Sons: New York, NY, USA, 2011. [Google Scholar]

- Kim, S.; Jang, D.; Jun, S.; Park, S. A Novel Forecasting Methodology for Sustainable Management of Defense Technology. Sustainability 2015, 7, 16720–16736. [Google Scholar] [CrossRef]

- Choi, J.; Jang, D.; Jun, S.; Park, S. A Predictive Model of Technology Transfer using Patent Analysis. Sustainability 2015, 7, 16175–16195. [Google Scholar] [CrossRef]

- Park, S.; Lee, S.; Jun, S. A Network Analysis Model for Selecting Sustainable Technology. Sustainability 2015, 7, 13126–13141. [Google Scholar] [CrossRef]

- Choi, J.; Jun, S.; Park, S. A Patent Analysis for Sustainable Technology Management. Sustainability 2016, 8, 1–13. [Google Scholar] [CrossRef]

- Kim, J.; Lee, J.; Kim, G.; Park, S.; Jang, D. A Hybrid Method of Analyzing Patents for Sustainable Technology Management in Humanoid Robot Industry. Sustainability 2016, 8, 474. [Google Scholar] [CrossRef]

- Park, S. Analysis of Patents Issue Report—3D Printing; HIS Electronics & Media: Englewood, CO, USA, 2013. [Google Scholar]

- Kwak, K.; Park, S. Technology trend analysis of global 3D printing industry. J. KSME 2013, 53, 58–64. [Google Scholar]

- Geum, Y.; Lee, S.; Yoon, B.; Park, Y. Identifying and evaluating strategic partners for collaborative R&D: Index-based approach using patents and publications. Technovation 2013, 33, 211–224. [Google Scholar]

- Goetze, C. An empirical enquiry into co-patent networks and their stars: The case of cardiac pacemaker technology. Technovation 2010, 30, 436–446. [Google Scholar] [CrossRef]

- Jeong, Y.; Yoon, B. Development of patent roadmap based on technology roadmap by analyzing patterns of patent development. Technovation 2015, 39, 37–52. [Google Scholar] [CrossRef]

- Lee, S.; Yoon, B.; Park, Y. An approach to discovering new technology opportunities: Keyword-based patent map approach. Technovation 2009, 29, 481–497. [Google Scholar] [CrossRef]

- Jun, S. Central technology forecasting using social network analysis. Commun. Comput. Inf. Sci. 2012, 340, 1–8. [Google Scholar]

- Jun, S.; Park, S. Examining technological innovation of Apple using patent analysis. Ind. Manag. Data Syst. 2013, 113, 890–907. [Google Scholar] [CrossRef]

- Otte, E.; Rousseau, R. Social network analysis: a powerful strategy, also for the information sciences. J. Inf. Sci. 2002, 28, 441–453. [Google Scholar] [CrossRef]

- Sternitzke, C.; Bartkowski, A.; Schramm, R. Visualizing patent statistics by means of social network analysis tools. World Pat. Inf. 2008, 30, 115–131. [Google Scholar] [CrossRef]

- Jun, S. Technology network model using bipartite social network analysis. Commun. Comput. Inf. Sci. 2012, 340, 28–35. [Google Scholar]

- Jun, S.; Choi, J. A technology analysis model using dynamic time warping. J. Korea Soc. Comput. Inf. 2015, 20, 113–120. [Google Scholar]

- Chifu, A.G.; Hristea, F.; Mothe, J.; Popescu, M. Word sense discrimination in information retrieval: A spectral clustering-based approach. Inf. Process. Manag. 2015, 51, 16–31. [Google Scholar] [CrossRef]

- Jun, S.; Park, S.S.; Jang, D.S. Document clustering method using dimension reduction and support vector clustering to overcome sparseness. Expert Syst. Appl. 2014, 41, 3204–3212. [Google Scholar] [CrossRef]

- Liu, C.L.; Hsaio, W.H.; Lee, C.H.; Chen, C.H. Clustering tagged documents with labeled and unlabeled documents. Inf. Process. Manag. 2013, 49, 596–606. [Google Scholar] [CrossRef]

- Dao, V.T.; Zmud, B. The Influence of Technology-Related, Market-Related, and Standards-Related Strategic Signaling During a Standards War. IEEE Trans. Eng. Manag. 2015, 62, 300–310. [Google Scholar] [CrossRef]

- Jun, S.; Park, S.; Jang, D. Technology Forecasting using Matrix Map and Patent Clustering. Ind. Manag. Data Syst. 2012, 112, 786–807. [Google Scholar] [CrossRef]

- Lai, H.C.; Weng, C.S. Accessing External Technological Knowledge for Technological Development: When Technological Knowledge Distance Meets Slack Resources. IEEE Trans. Eng. Manag. 2014, 61, 80–89. [Google Scholar] [CrossRef]

- Tseng, Y.; Lin, C.; Lin, Y. Text mining techniques for patent analysis. Inf. Process. Manag. 2007, 43, 1216–1247. [Google Scholar] [CrossRef]

- Chen, D.; Lin, W.C.; Huang, M. Using essential patent index and essential technological strength to evaluate industrial technological innovation competitiveness. Scientometrics 2007, 71, 101–116. [Google Scholar] [CrossRef]

- Chen, Y.L.; Chiu, Y.T. An IPC-based vector space model for patent retrieval. Inf. Process. Manag. 2011, 47, 309–322. [Google Scholar] [CrossRef]

- Chen, Y.L.; Chang, Y.C. A three-phase method for patent classification. Inf. Process. Manag. 2012, 48, 1017–1030. [Google Scholar] [CrossRef]

- Guan, J.; Chen, Z. Patent collaboration and international knowledge flow. Inf. Process. Manag. 2012, 48, 170–181. [Google Scholar] [CrossRef]

- Hunt, D.; Nguyen, L.; Rodgers, M. Patent Searching Tools & Techniques; Wiley: New York, NY, USA, 2007. [Google Scholar]

- Berry, M.W.; Kogan, J. Text Mining Applications and Theory; Wiley: New York, NY, USA, 2010. [Google Scholar]

- Feinerer, I. A Text Mining Framework in R and Its Applications. Ph.D. Thesis, Vienna University of Economics and Business Administration, Vienna, Austria, 2008. [Google Scholar]

- Jun, S. A technology forecasting method using text mining and visual apriori algorithm. Appl. Math. Inf. Sci. Int. J. 2014, 8, 35–40. [Google Scholar] [CrossRef]

- Sun, Y.; Lu, Y.; Wang, T.; Ma, H.; He, G. Pattern of patent-based environmental technology innovation in China. Technol. Forecast. Soc. Chang. 2008, 75, 1032–1042. [Google Scholar] [CrossRef]

- Feinerer, I.; Hornik, K.; Meyer, D. Text mining infrastructure in R. J. Stat. Softw. 2008, 25, 1–54. [Google Scholar] [CrossRef]

- Butts, C.T. Social network analysis with SNA. J. Stat. Softw. 2008, 24, 1–51. [Google Scholar] [CrossRef]

- D’Aveni, R. The 3-D printing revolution. Harv. Bus. Rev. 2015, 93, 40–48. [Google Scholar]

- Bommel, V.T.; Mahieu, R.J.; Nijssen, E.J. Technology trajectories and the selection of optimal R&D project sequences. IEEE Trans. Eng. Manag. 2014, 61, 669–680. [Google Scholar]

- Liao, T.W. A clustering procedure for exploratory mining of vector time series. Pattern Recognit. 2007, 40, 2550–2562. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, J.; Du, Y.; Lv, T. A novel clustering method on time series data. Expert Syst. Appl. 2011, 38, 11891–11900. [Google Scholar] [CrossRef]

- Zhao, Y.R. Data Mining—Examples and Case Studies; Academic Press: Elsevier, Amsterdam, The Netherlands, 2013. [Google Scholar]

- Giorgino, T. Package ‘dtw’—Dynamic Time Warping Algorithms. 2014. Available online: dtw.r-forge.r-project.org (accessed on 15 October 2016).

- Keogh, E.J.; Pazzani, M.J. Derivative dynamic time warping. In Proceedings of the 2001 SIAM International Conference on Data Mining, Chicago, IL. USA, 2011; pp. 1–11. [Google Scholar]

- Salvador, S.; Chan, P. Toward accurate dynamic time warping in linear time and space. Intell. Data Anal. 2007, 11, 561–580. [Google Scholar]

- Mann, D.L. Better technology forecasting using systemic innovation methods. Technol. Forecast. Soc. Chang. 2003, 70, 779–795. [Google Scholar] [CrossRef]

- Trappey, A.J.C.; Trappey, C.V.; Wu, C.; Lin, C. A patent quality analysis for innovative technology and product development. Adv. Eng. Inf. 2012, 26, 26–34. [Google Scholar] [CrossRef]

- Feinerer, I.; Hornik, K. Text Mining Package—Package Tm. In CRAN R-Project; CRAN R-Project: Vienna, Austria, 2017. [Google Scholar]

- Butts, C.T. Tools for Social Network Analysis—Package Sna. In CRAN R-Project; CRAN R-Project: Vienna, Austria, 2017. [Google Scholar]

- R Development Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2017. [Google Scholar]

- USPTO. United States Patent and Trademark Office. Available online: http://www.uspto.gov/ (accessed on 1 June 2015).

- WIPSON. WIPS Corporation. Available online: http://www.wipson.com/ (accessed on 24 July 2015).

- Gridlogics Technologies Pvt. Ltd. Patent iNSIGHT Pro. 3D Printing Technology Insight Report; Gridlogics Technologies Pvt. Ltd.: Mumbai, India, 2014. [Google Scholar]

- UK Intellectual Property Office Patent Informatics Team. 3D Printing: A Patent Overview; Intellectual Property Office: Newport, UK, 2013. [Google Scholar]

- KISTA. Korea Intellectual Property Strategy Agency. 2016. Available online: www.kista.or.kr (accessed on 1 December 2016).

- Severyn, A.; Moschitti, A.; Uryupina, O.; Plank, B.; Filippova, K. Multi-lingual opinion mining on youtube. Inf. Process. Manag. 2016, 52, 46–60. [Google Scholar] [CrossRef]

- Medhat, W.; Hassan, A.; Korashy, H. Sentiment analysis algorithms and applications: A survey. Ain Shams Eng. J. 2014, 5, 1093–1113. [Google Scholar] [CrossRef]

- Blei, D.M. Probabilistic topic models. Commun. ACM 2012, 55, 77–84. [Google Scholar] [CrossRef]

- Park, S.; Lee, W.; Moon, I.C. Associative topic models with numerical time series. Inf. Process. Manag. 2015, 51, 737–755. [Google Scholar] [CrossRef]

| Company | Common Keywords | Representative Keywords |

|---|---|---|

| 3D Systems | Method, Modeling, System, Three_Dim, Manufacturing, Rapid, Building, Deposition, Material, Object, Support, Printing | Laser, Selective, Solid, Pour, Composition, Forming, Production, Control, Imaging, Sintering, Phase, Technique, Chamber, Stereolithography, Appareil, Change, Powder, Thermal, Fabrication, Freeform, |

| Stratasys | Extrusion, Filament, Head, Spool, Assembly, Digital, Layer, Prototyping |

| Number of Clusters | 3D Systems | Stratasys |

|---|---|---|

| 2 | (Method), (Three_Dim) | (Modeling), (System) |

| 3 | (Method), (Three_Dim), (Modeling) | (Modeling), (System), (Method) |

| 4 | (Method), (Three_Dim), (Modeling), (Forming) | (Modeling), (System), (Method), (Filament) |

| 5 | (Method), (Three_Dim), (Modeling), (Forming), (Object) | (Modeling), (System), (Method), (Filament), (Three_Dim) |

| Graph Test | 3D Systems | Stratasys |

|---|---|---|

| Test value | 0.9027 | 0.9235 |

| p (T ≥ test) | 0.6140 | 0.9140 |

| p (T < test) | 0.3860 | 0.0860 |

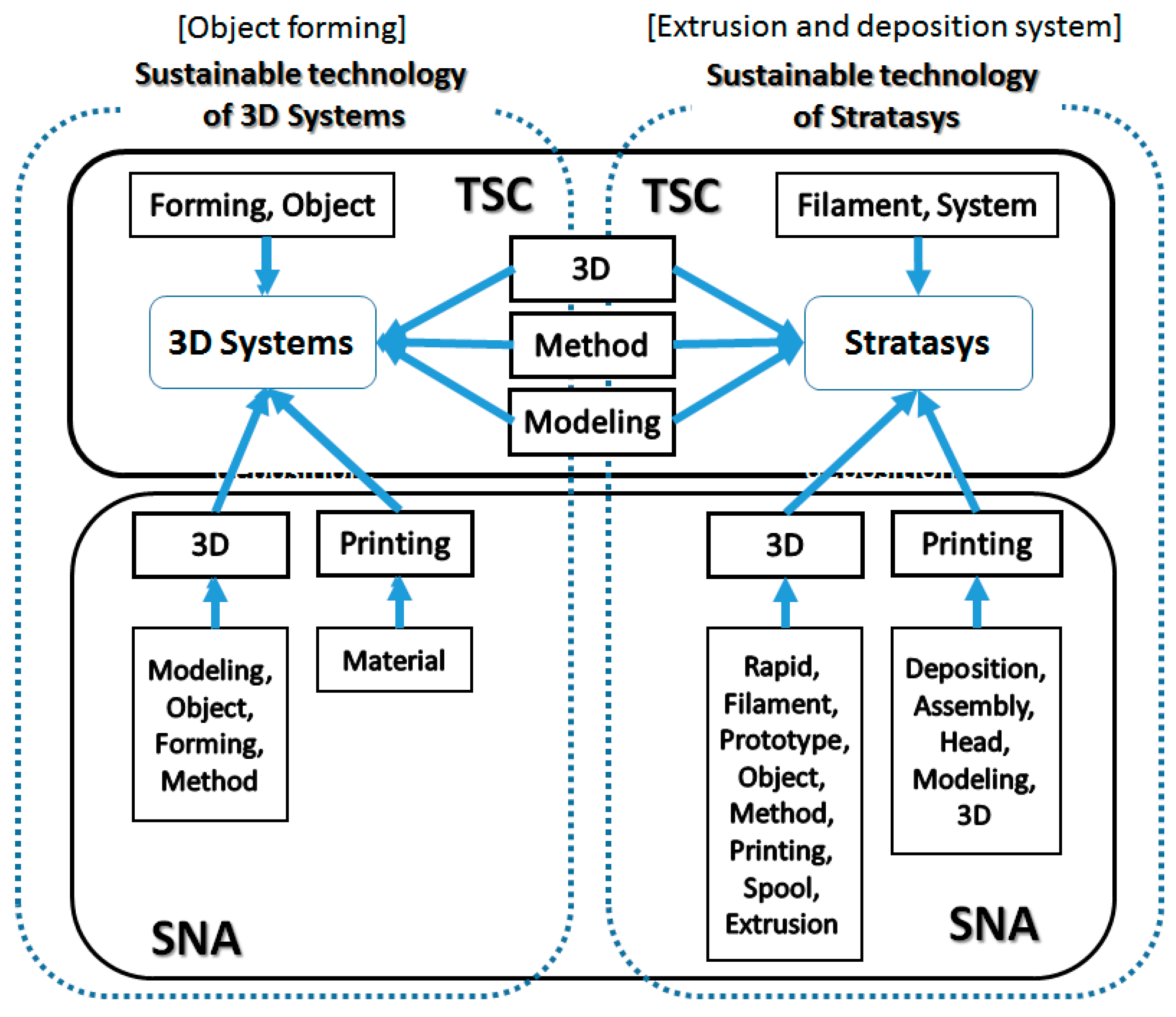

| Method | 3D Systems | Stratasys | |

|---|---|---|---|

| TSC | 3D, method, modeling | ||

| forming, object | filament, system | ||

| SNA | 3D | modeling, object, forming, method | rapid, filament, prototype, object, method, printing, spool, extrusion |

| Printing | material | deposition, assembly, head, modeling, 3D | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.; Jun, S. Statistical Technology Analysis for Competitive Sustainability of Three Dimensional Printing. Sustainability 2017, 9, 1142. https://doi.org/10.3390/su9071142

Park S, Jun S. Statistical Technology Analysis for Competitive Sustainability of Three Dimensional Printing. Sustainability. 2017; 9(7):1142. https://doi.org/10.3390/su9071142

Chicago/Turabian StylePark, Sangsung, and Sunghae Jun. 2017. "Statistical Technology Analysis for Competitive Sustainability of Three Dimensional Printing" Sustainability 9, no. 7: 1142. https://doi.org/10.3390/su9071142