Experimental Investigations and Numerical Simulation of Thermal Performance of a Horizontal Slinky-Coil Ground Heat Exchanger

Abstract

:1. Introduction

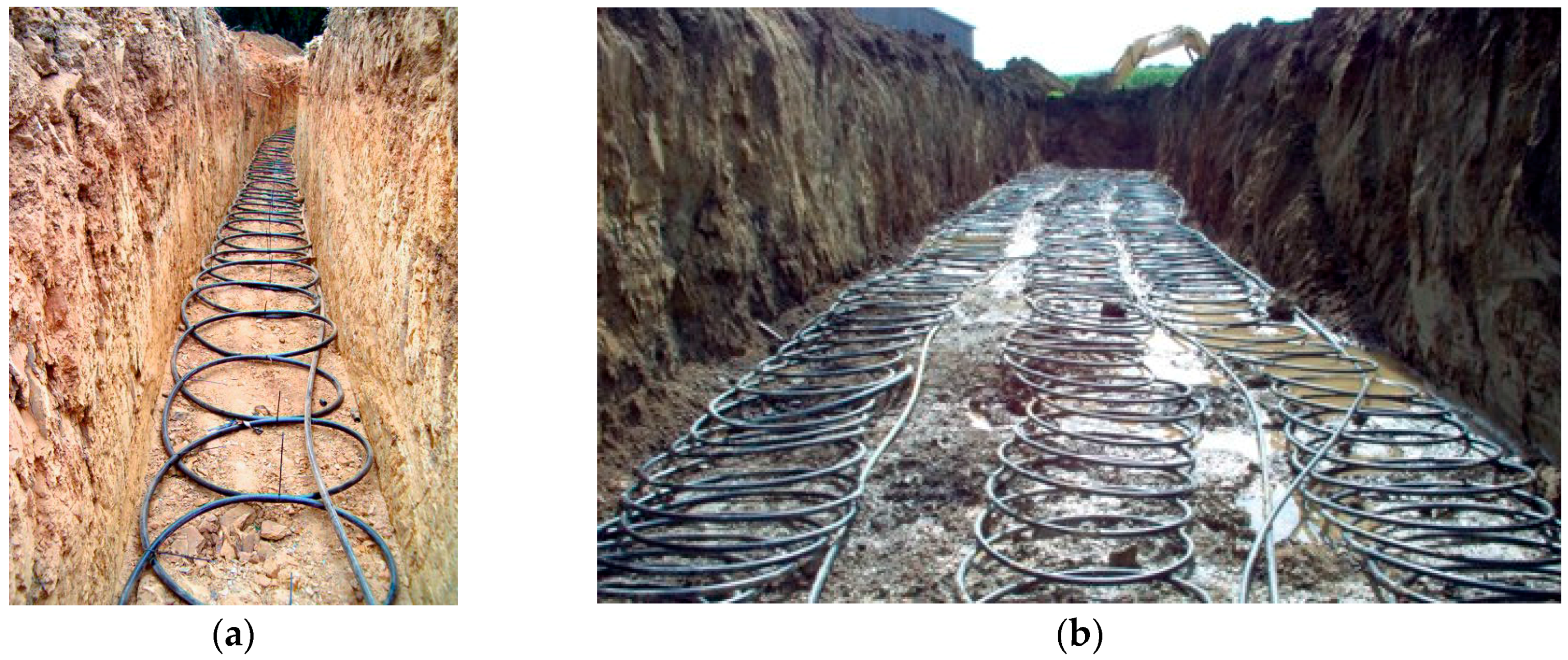

2. Experimental Investigation

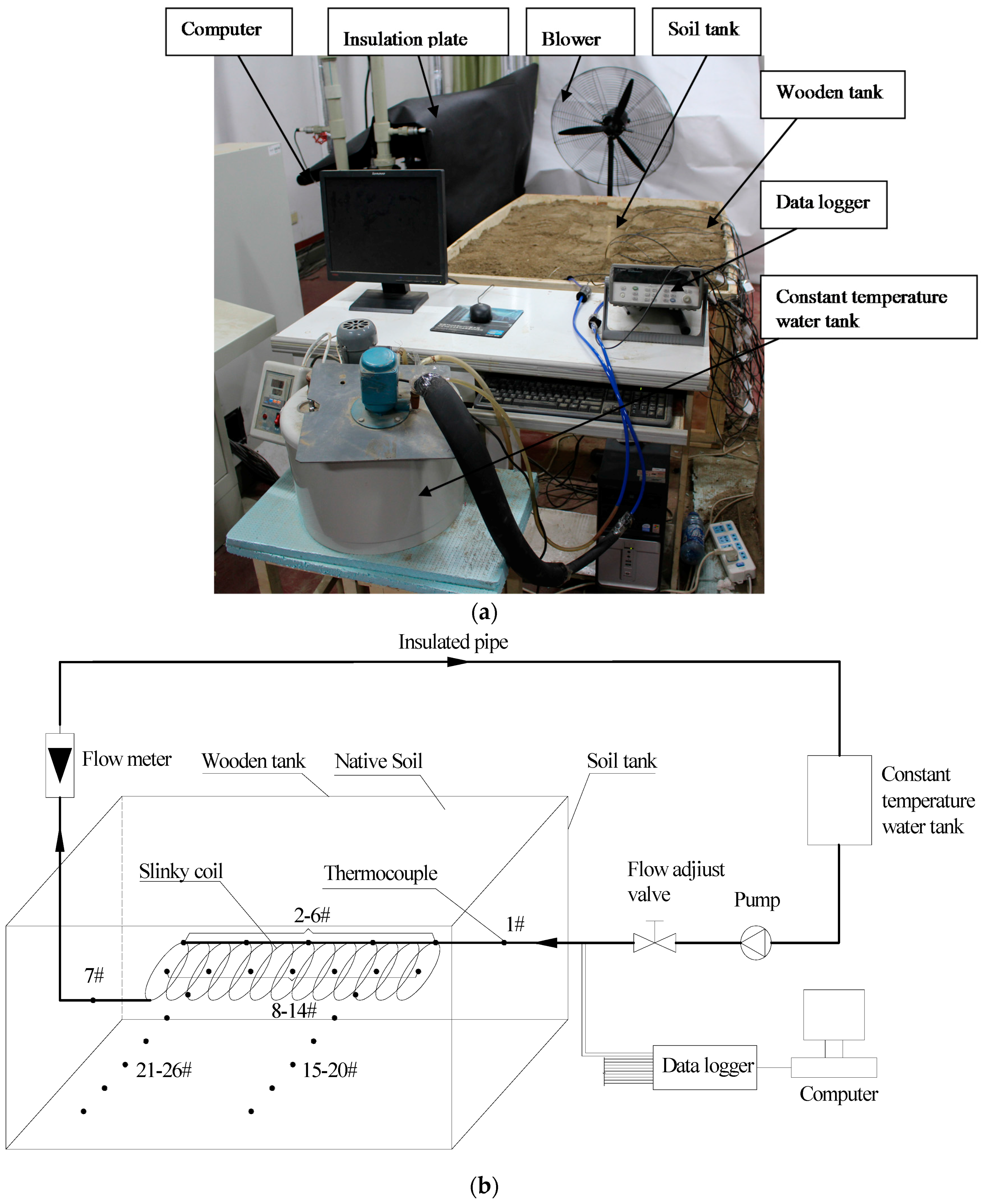

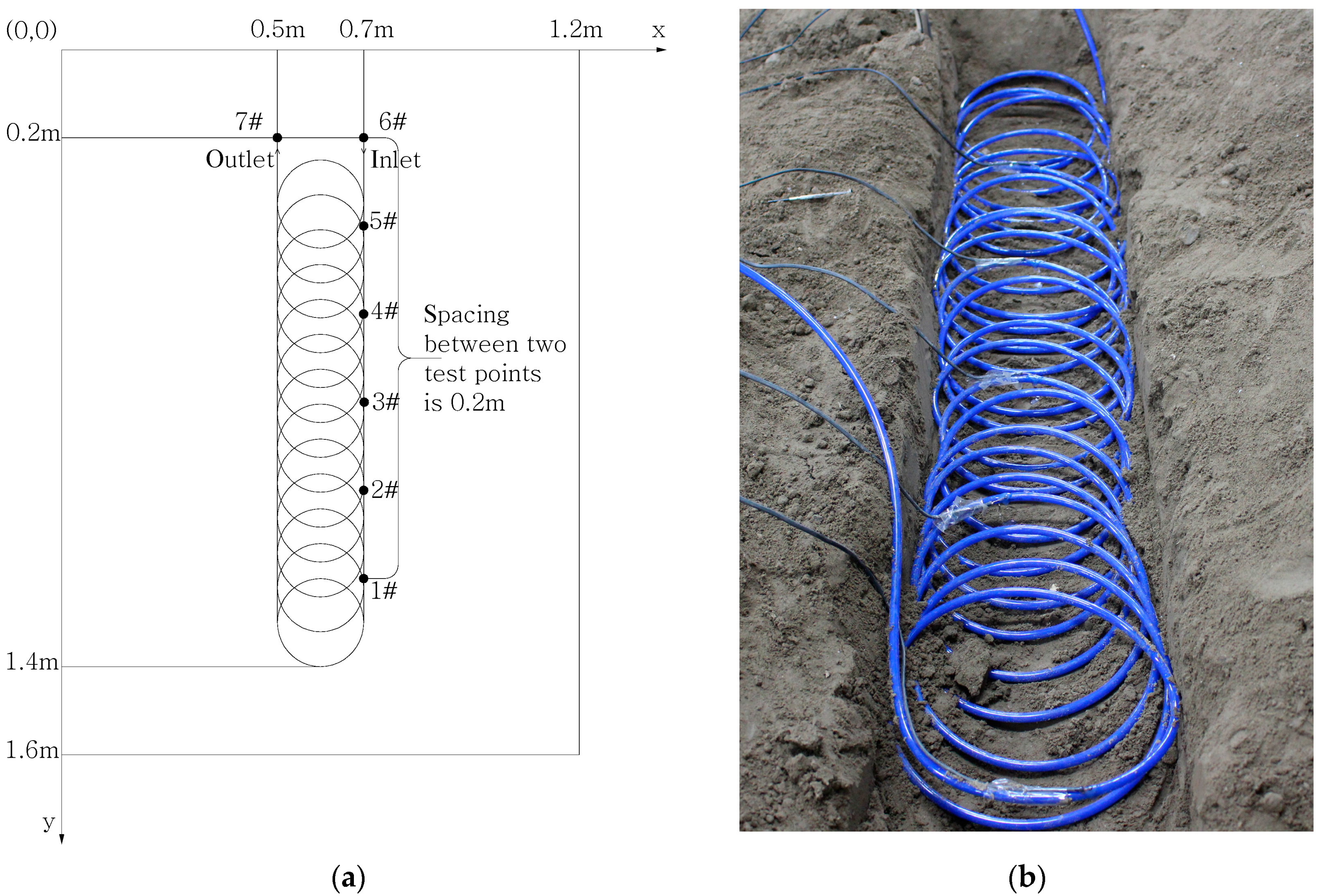

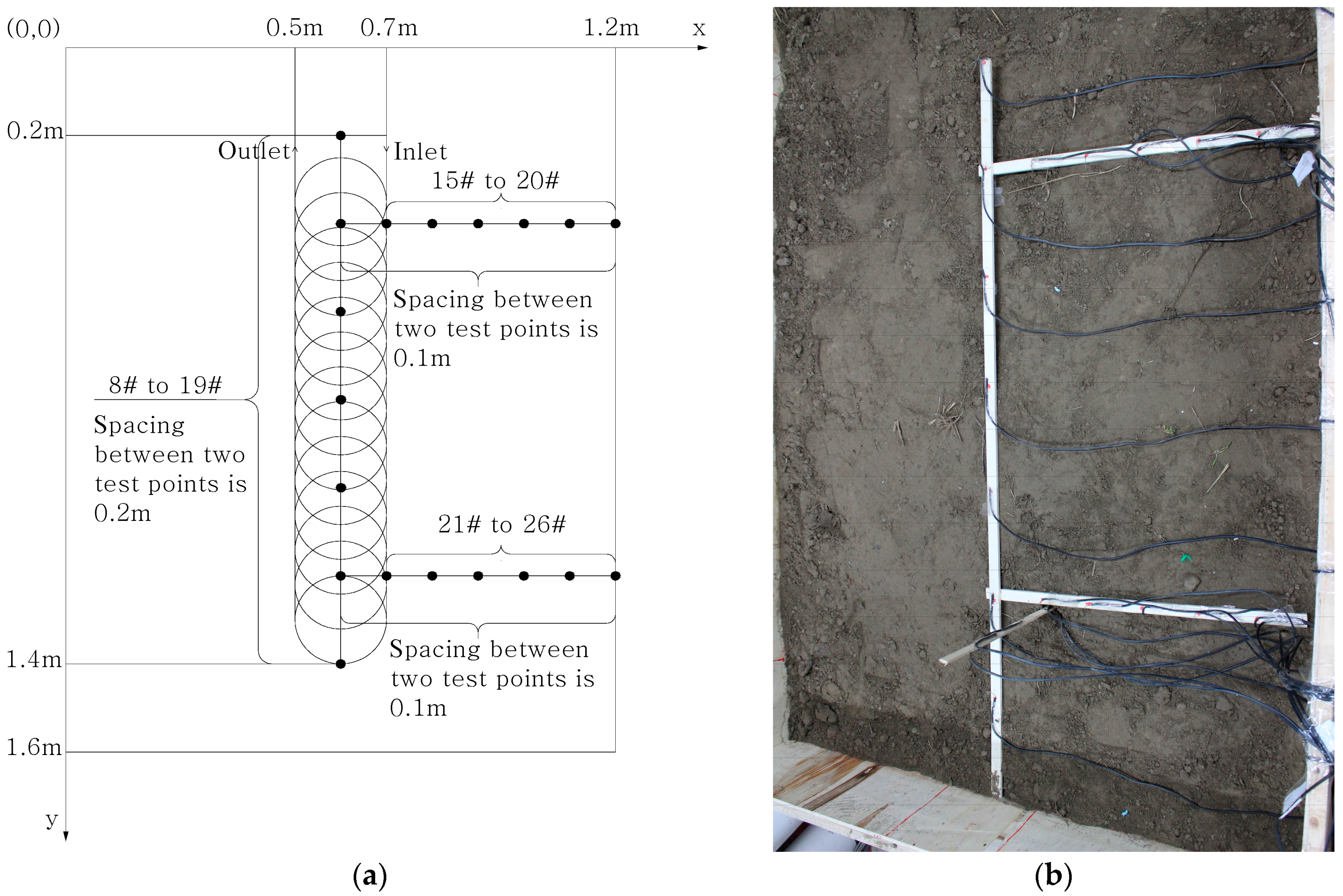

2.1. Experimental Device

2.2. Temperature Measurement System

2.3. Experimental Performance Analysis

2.3.1. Experimental Data Processing

2.3.2. Error Analysis

2.4. Experimental Results and Discussions

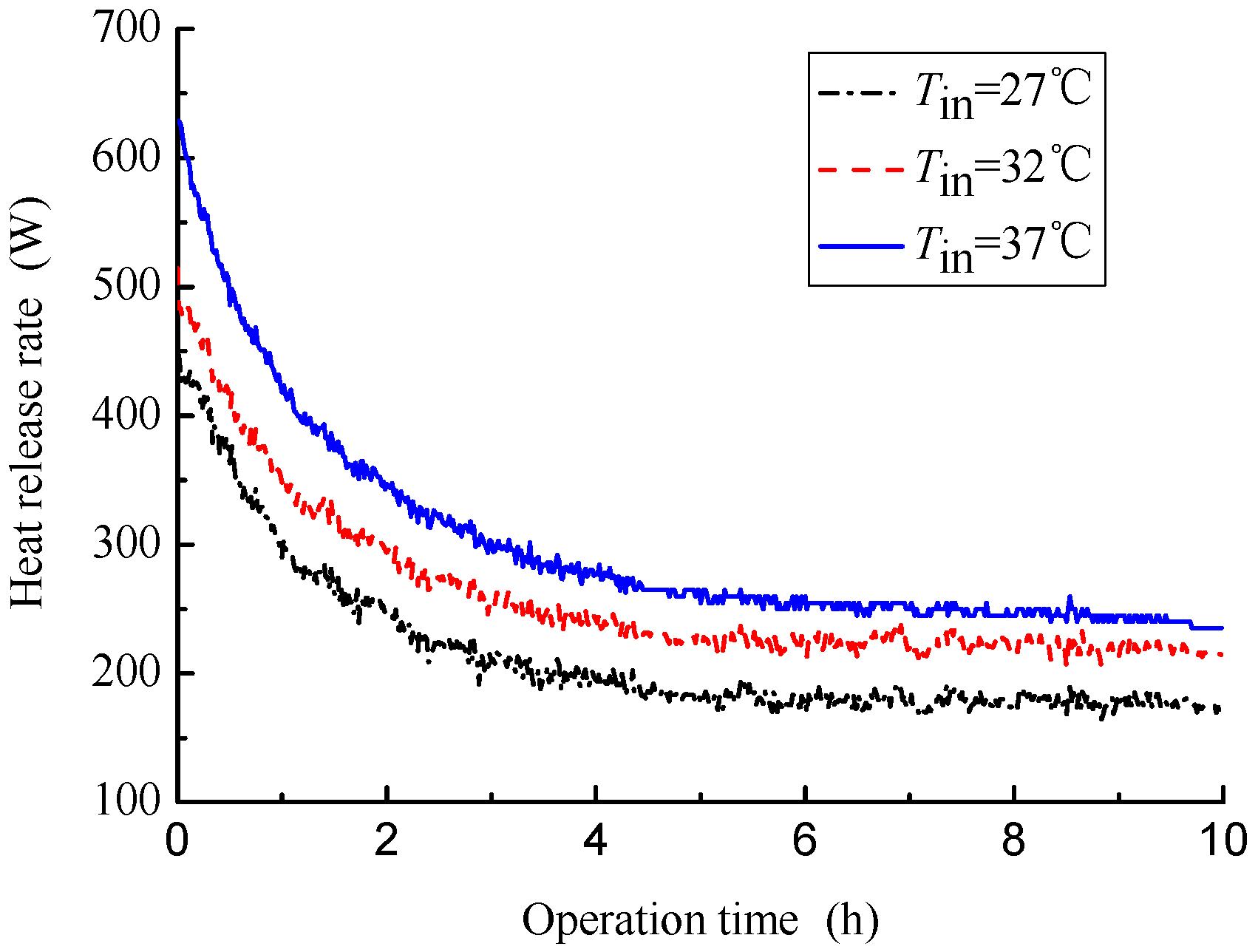

2.4.1. Effects of Inlet Water Temperature

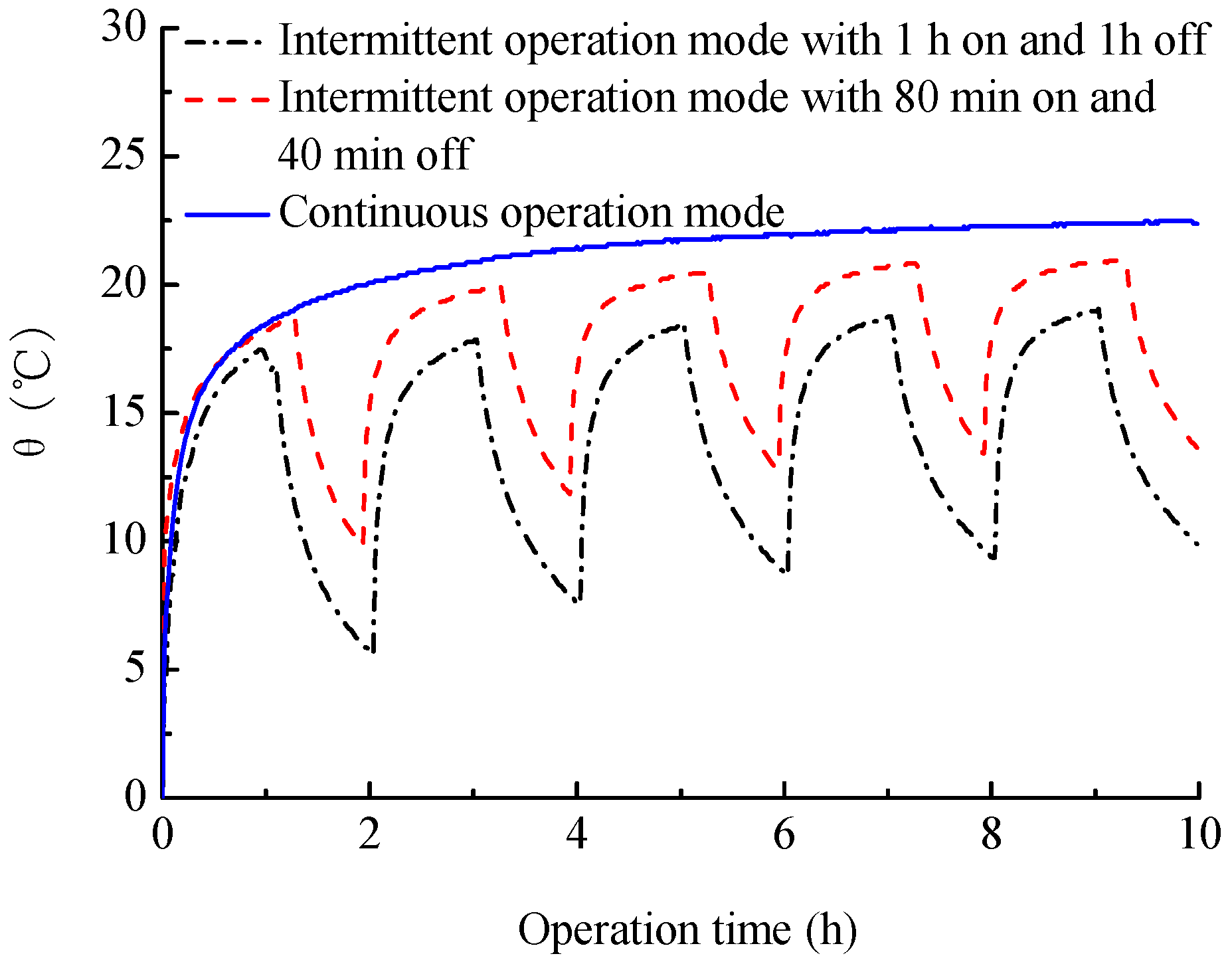

2.4.2. Effect of the Intermittent Operating Mode

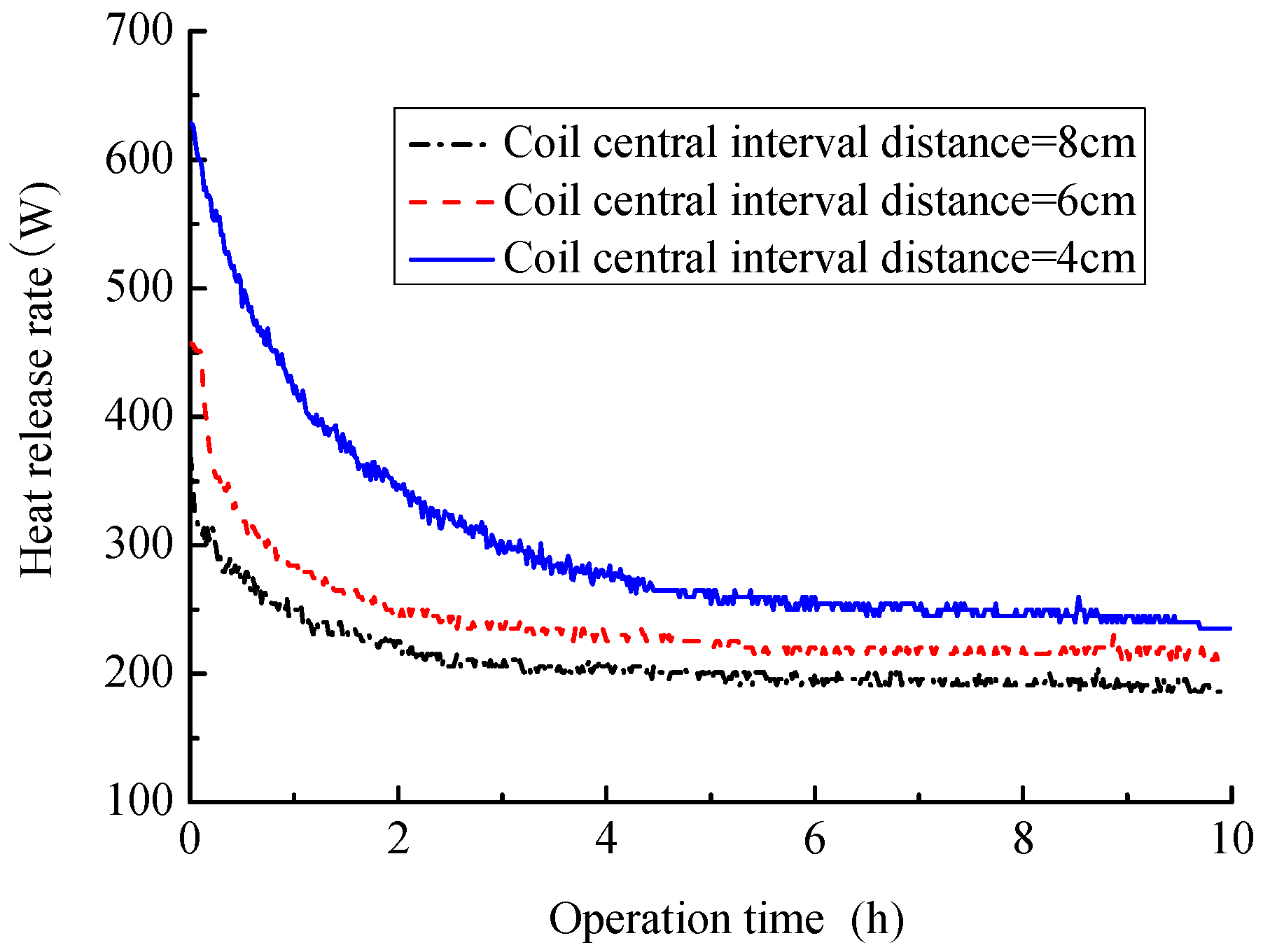

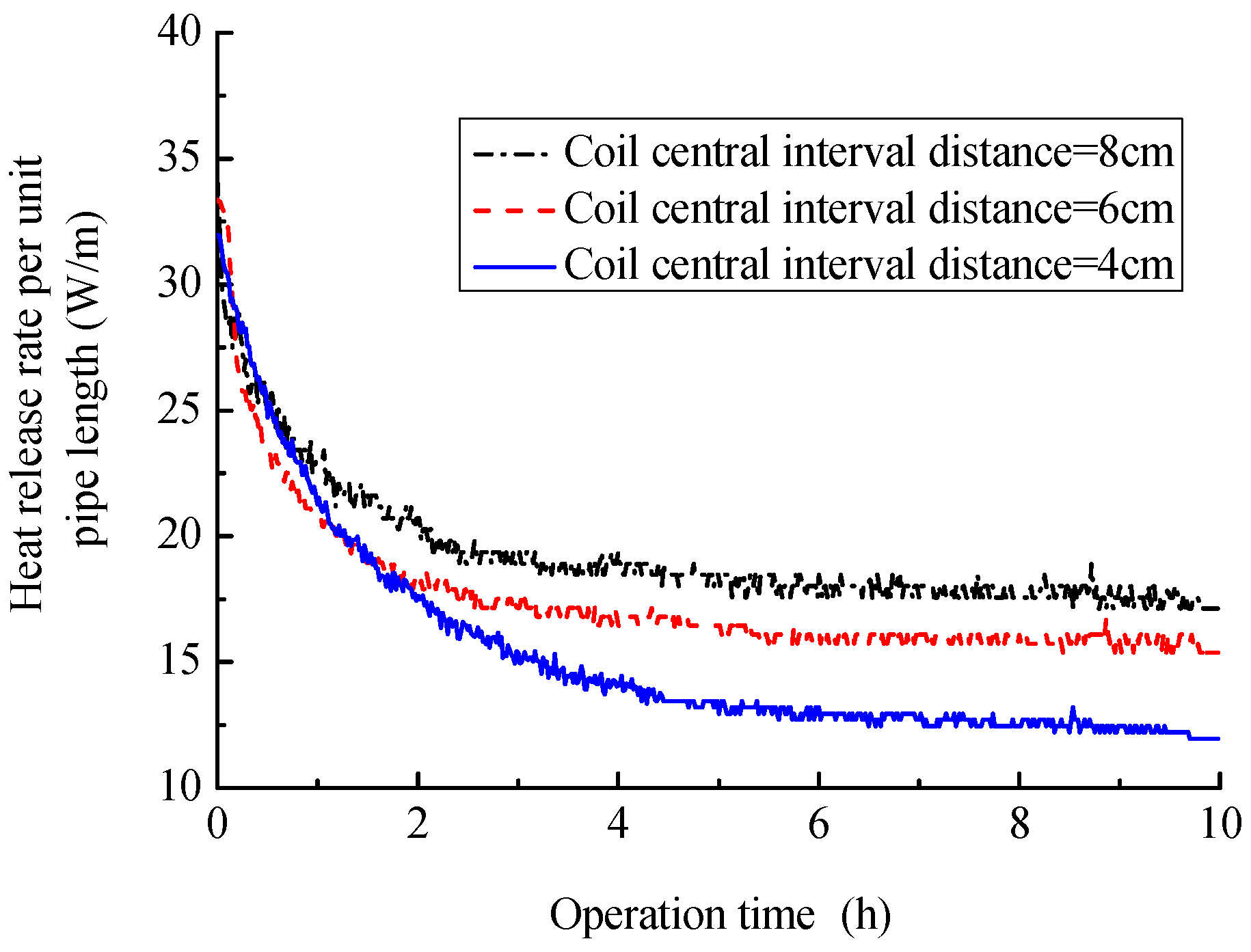

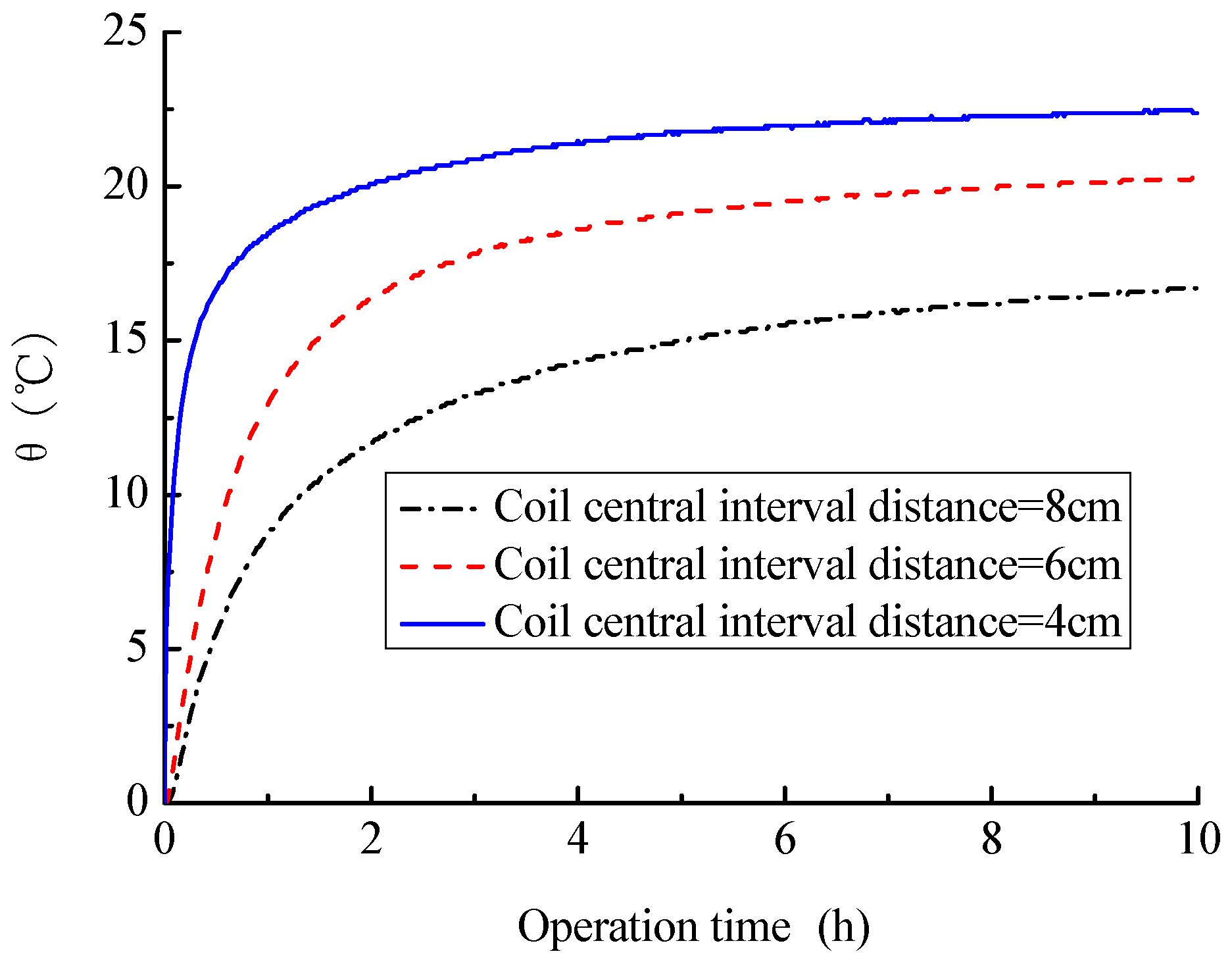

2.4.3. Effect of the Coil Central Interval Distance

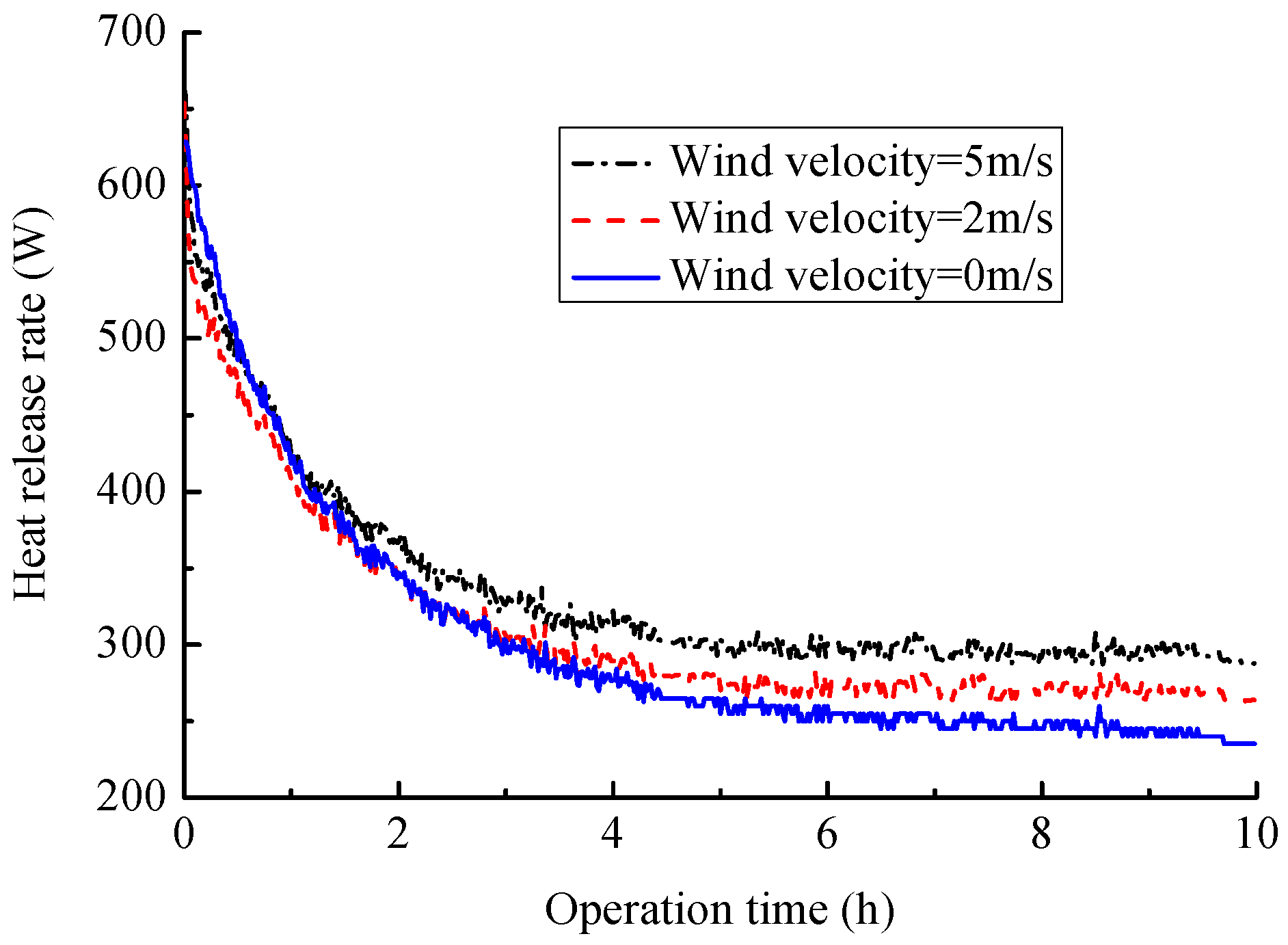

2.4.4. Effect of the Ground Surface Wind Velocity

3. Numerical Simulation

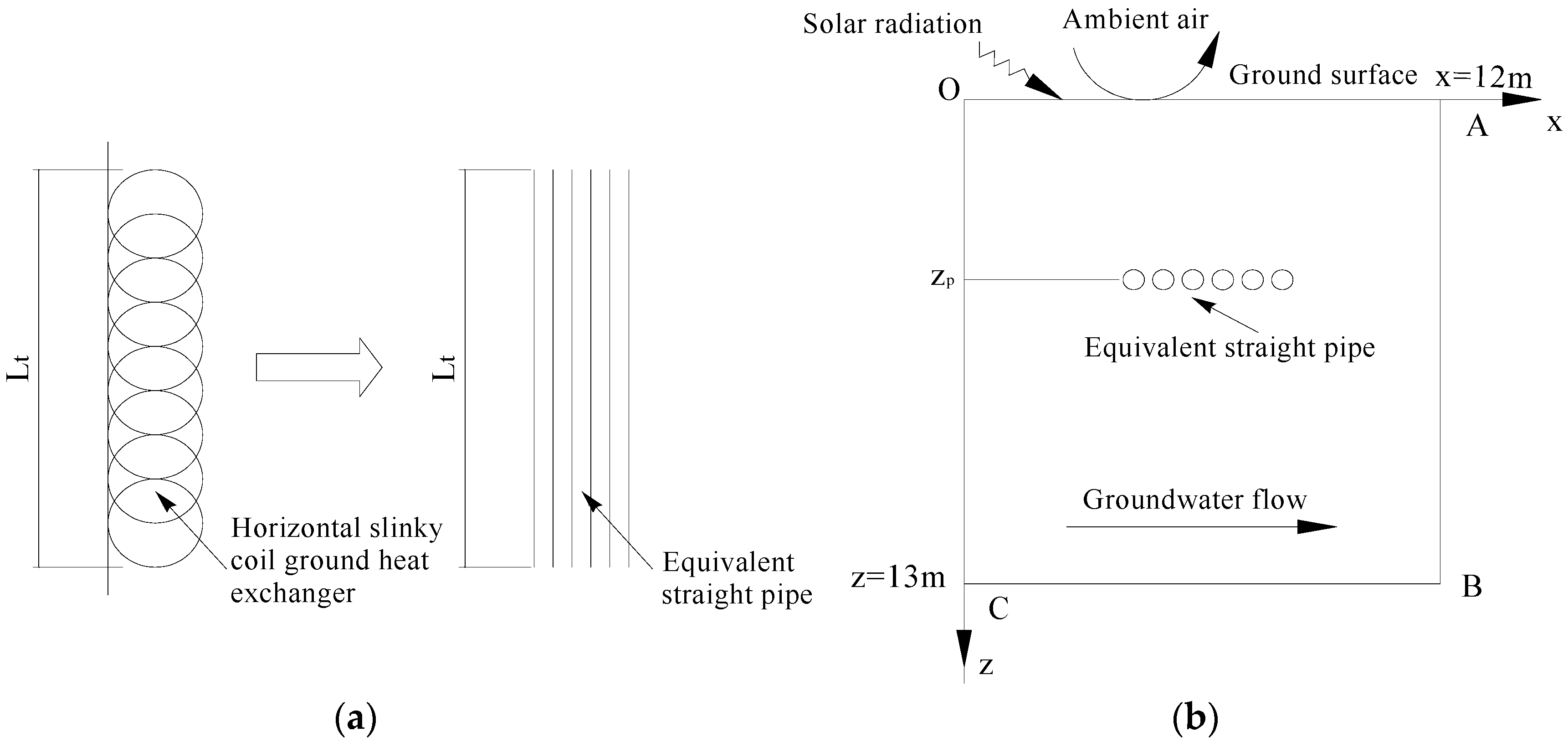

3.1. Physical Model

- The initial temperature of the soil at the same depth is uniform and the soil is viewed as a type of isotropic, homogeneous rigid porous media.

- The HSCGHE is treated as a series of equally spaced straight pipes located in the same trench as slinky coil.

- The thermal properties of slinky coil, soil and fluid are constant.

- Groundwater flows only in the horizontal direction perpendicular to the trench.

3.2. Mathematical Model

3.2.1. Heat Transfer Model of Soil outside Pipe

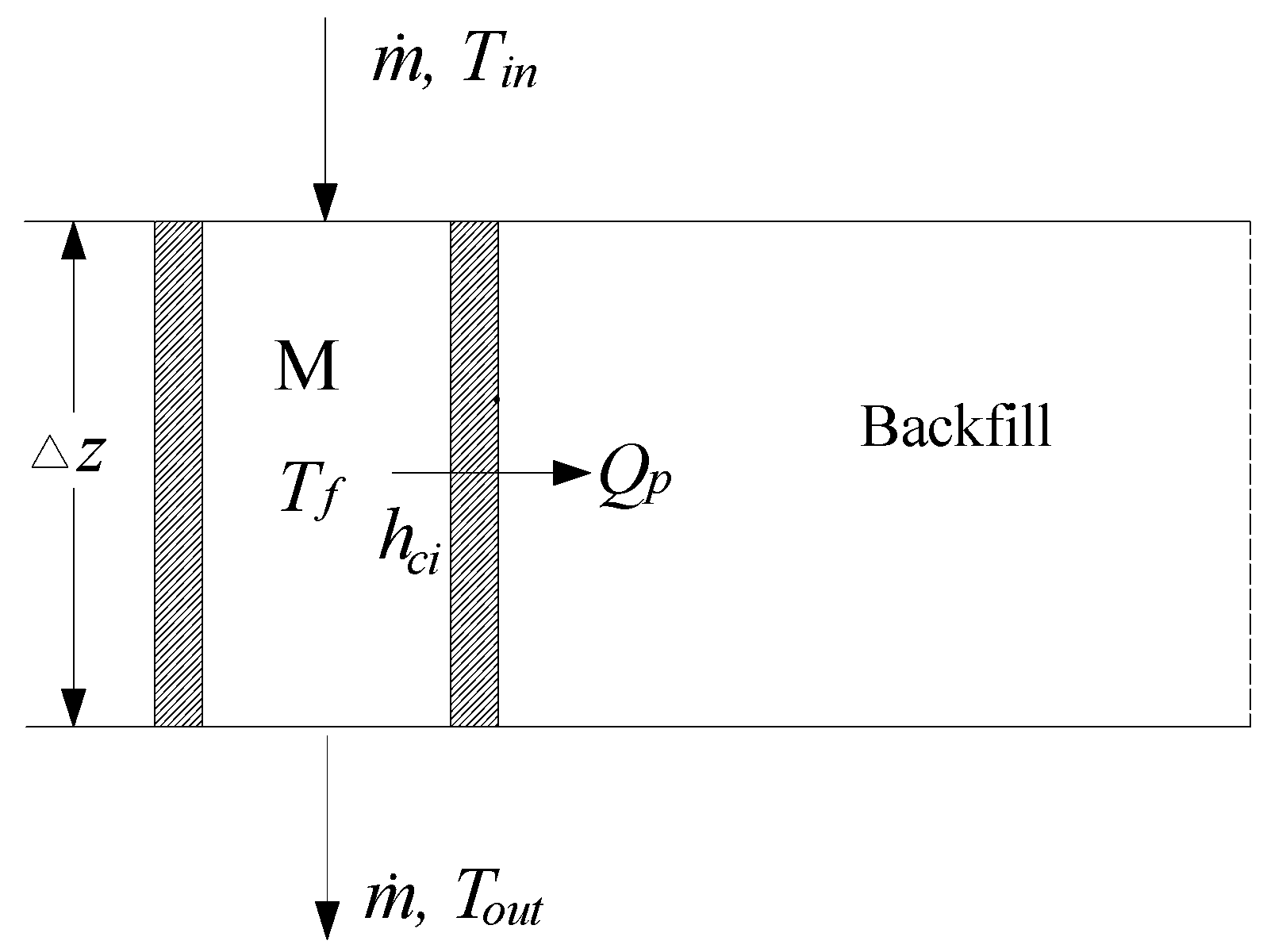

3.2.2. Heat Transfer Model of Fluid along the Pipe Direction

3.3. Initial and Boundary Conditions

3.3.1. Initial Conditions

3.3.2. Boundary Conditions

- (1)

- AB:

- (2)

- BC:

- (3)

- CO:

- (4)

- OA:where Qs is the surface heat flux into the ground. αs is the solar absorptivity. Qsun is the solar radiation intensity on the ground. ha is the convective heat transfer coefficient of the air. Ta is the temperature of the air.

3.4. Experimental Validation of the Model

3.5. Calculated Results and Discussion

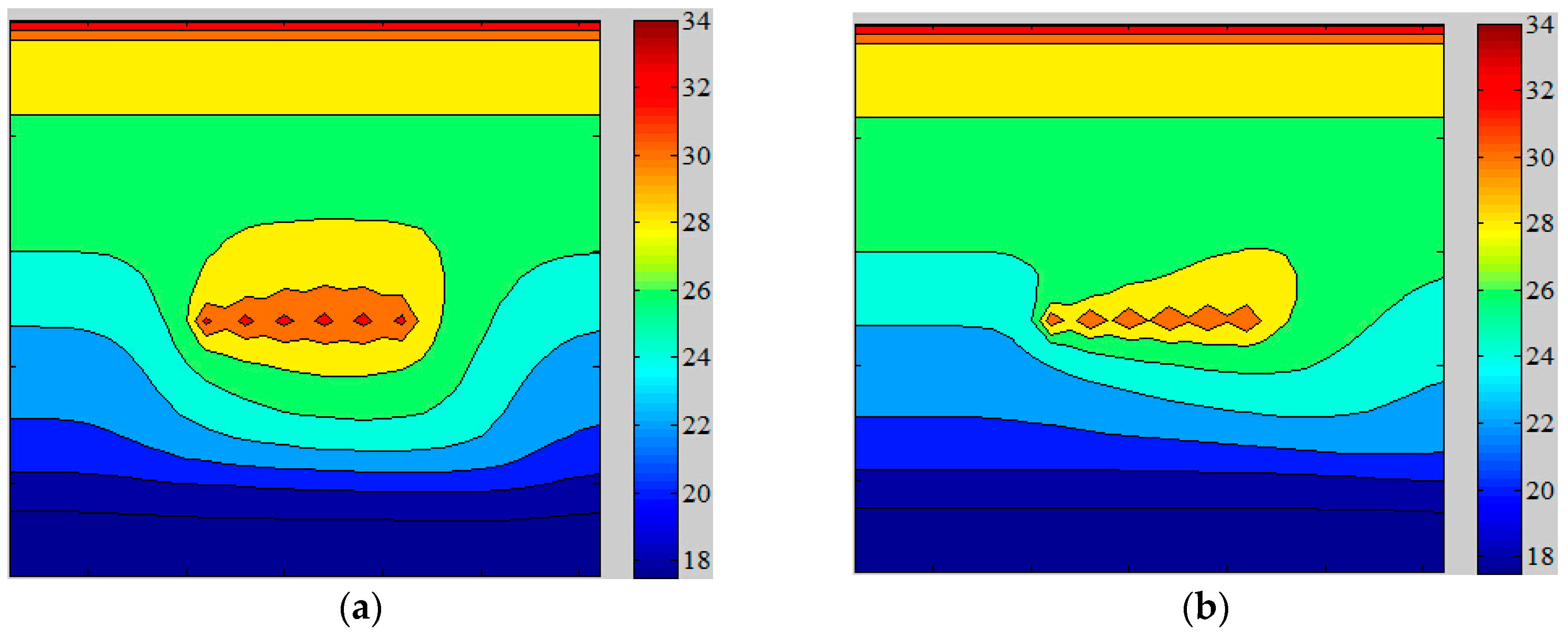

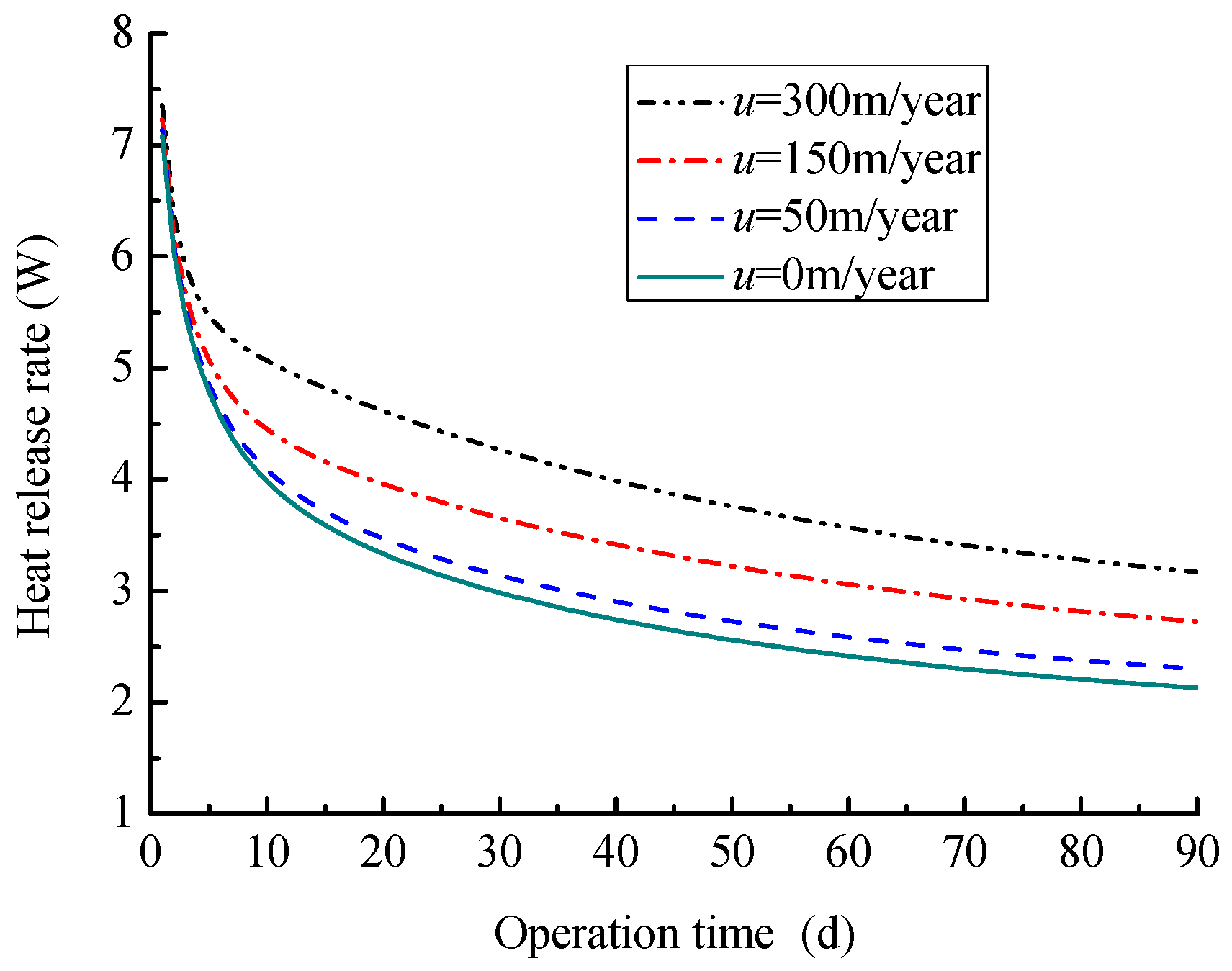

3.5.1. Effects of Groundwater Advection Velocity

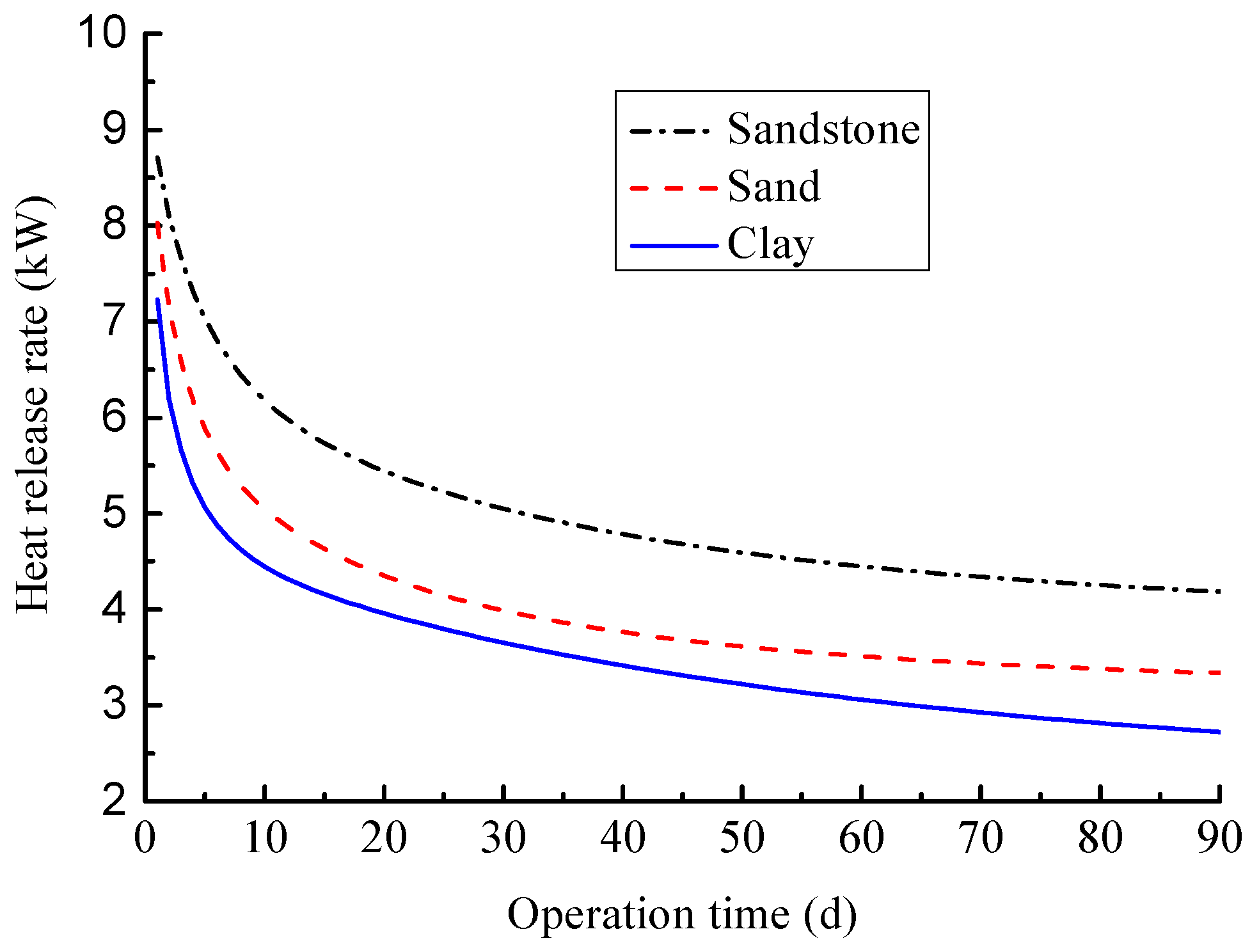

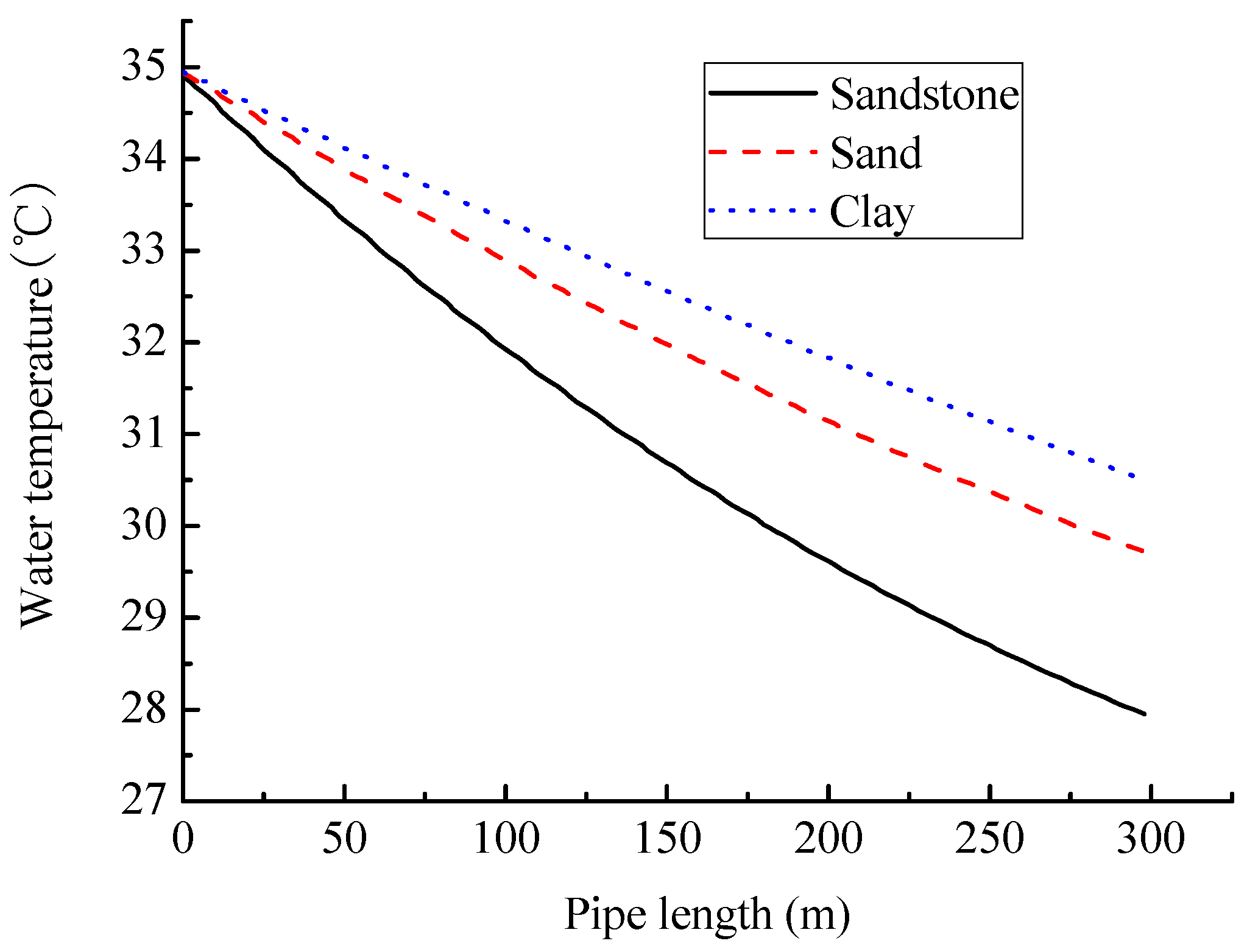

3.5.2. Effects of Soil Type

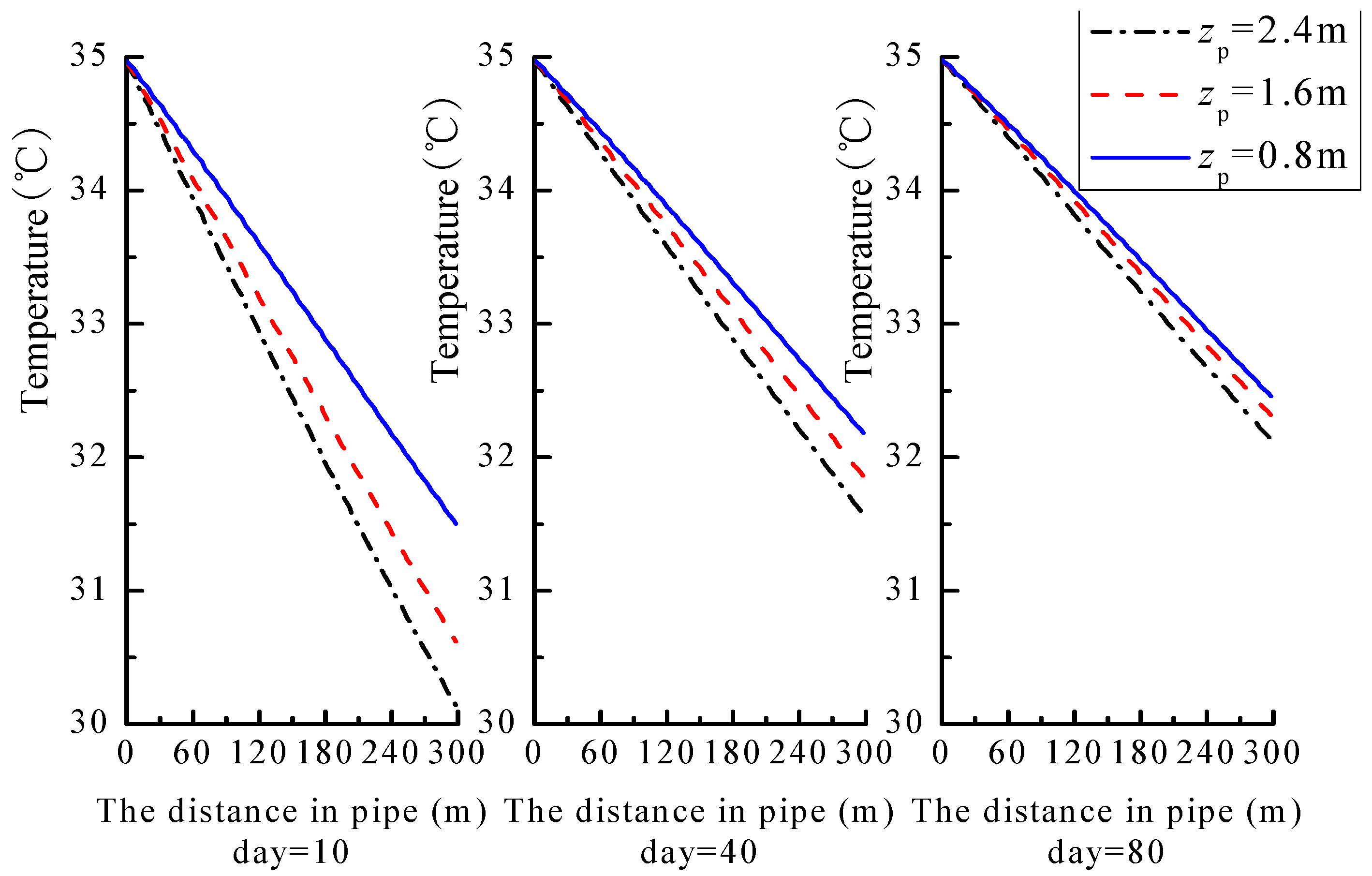

3.5.3. Effects of the Buried Depth

4. Conclusions

- (1)

- The heat release rate of HSCGHE increases as the inlet temperature increases, and thus the thermal performance of HSCGHE can be enhanced effectively. Meanwhile, the increase of inlet temperature can also lead to an increase in soil excess temperature, and the increase degree becomes smaller as the distance from center line of coil increases.

- (2)

- The soil temperature operated in intermittent mode can recover: during each interval, the soil temperature restoration rate increases as the intermittent time increases, and thus the temperature rise rate of soil around the HSCGHE can be delayed. Therefore, under the condition of intermittent operation control strategy, the soil temperature rise rate can be reduced, and thus the heat release efficiency of the HSCGHE and system operation performance can be improved effectively.

- (3)

- A smaller coil central interval distance can contribute to a larger heat release rate, but also results in a smaller heat release rate per unit length of coil. Thus, the coil central interval distance cannot be too small and should be determined through considering the heat release rate, coil cost and available land area. At the same time, with the increase of the coil central interval distance, the sable value of soil excess temperature decreases and the corresponding time for stabling are shortened.

- (4)

- Thermal performance of the HSCGHE is related to the ground surface wind velocity. The heat release rate of HSCGHE increases as surface wind velocity grow. For the experimental conditions used in the paper, compared with 0 wind velocity condition, the heat release rate of coil operated in wind velocities of 2 and 5 m/s increases by 3.4% and 11.4%, respectively.

- (5)

- The existence of groundwater advection is conductive to the improvement of thermal performance of the HSCGHE. The greater the groundwater advection velocity, the more heat is taken away by the groundwater, the smaller the soil temperature rise, and thus the better the thermal performance of coil.

- (6)

- Thermal performance of slinky coil is greatly affected by the soil type. Under the same conditions, the slinky coil with sandstone has a maximum water temperature drop along length direction, followed by sand and clay. This results in the heat exchange rate being the largest for sandstone, then sand, and the lowest clay.

- (7)

- The energy released into ground by the coil increases with the buried depth, and the influence of buried depth change on thermal performance is reduced with the increase of buried depth. Thus, the buried depth cannot be too deep and should be determined through considering the heat exchange performance, installation cost and safety requirements.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yuan, Y.P.; Cao, X.L.; Sun, L.L.; Lei, B.; Yu, N.Y. Ground source heat pump system: A review of simulation in China. Renew. Sustain. Energy Rev. 2012, 16, 6814–6822. [Google Scholar] [CrossRef]

- Beier, R.A. Transient heat transfer in a U-tube borehole heat exchanger. Appl. Therm. Eng. 2014, 62, 256–266. [Google Scholar] [CrossRef]

- Hong, T.; Kim, J.; Chae, M.; Park, J.; Jeong, J.; Lee, M. Sensitivity analysis on the impact factors of the GSHP system considering energy generation and environmental impact using LCA. Sustainability 2016, 8, 376. [Google Scholar] [CrossRef]

- Tota-Maharaj, K.; Paul, P. Sustainable approaches for stormwater quality improvements with experimental geothermal paving systems. Sustainability 2015, 7, 1388–1410. [Google Scholar] [CrossRef]

- Yuan, Y.P.; Cao, X.L.; Wang, J.Q.; Sun, L.L. Thermal interaction of multiple ground heat exchangers under different intermittent ratio and separation distance. Appl. Therm. Eng. 2016, 108, 277–286. [Google Scholar] [CrossRef]

- Lee, J.U.; Kim, T.; Leigh, S.B. Applications of building-integrated coil-type ground-coupled heat exchangers-comparison of performances of vertical and horizontal installations. Energy Build. 2015, 93, 99–109. [Google Scholar] [CrossRef]

- Pulat, E.; Coskun, S.; Unlu, K.; Yamankaradeniz, N. Experimental study of horizontal ground source heat pump performance for mild climate in Turkey. Energy 2009, 34, 1284–1295. [Google Scholar] [CrossRef]

- Cui, P.; Li, X.; Man, Y.; Fang, Z.H. Heat transfer analysis of pile geothermal heat exchangers with spiral coils. Appl. Energy 2011, 88, 4113–4119. [Google Scholar] [CrossRef]

- Xiong, Z.Y.; Fisher, D.E.; Spitler, J.D. Development and validation of a slinky™ ground heat exchanger model. Appl. Energy 2015, 141, 57–69. [Google Scholar] [CrossRef]

- Go, G.H.; Lee, S.R.; Yoon, S.; Kim, M.J. Optimum design of horizontal ground-coupled heat pump systems using spiral-coil-loop heat exchangers. Appl. Energy 2016, 162, 330–345. [Google Scholar] [CrossRef]

- Li, C.F.; Mao, J.F.; Zhang, H.; Xing, Z.L.; Li, Y.; Zhou, J. Numerical simulation of horizontal spiral-coil ground source heat pump system: Sensitivity analysis and operation characteristics. Appl. Therm. Eng. 2017, 110, 424–435. [Google Scholar] [CrossRef]

- Wang, D.Q.; Lu, L.; Cui, P. A new analytical solution for horizontal geothermal heat exchangers with vertical spiral coils. Int. J. Heat Mass Transf. 2016, 100, 111–120. [Google Scholar] [CrossRef]

- Yoon, S.; Lee, S.R.; Go, G.H. Evaluation of thermal efficiency in different types of horizontal ground heat exchangers. Energy Build. 2015, 105, 100–105. [Google Scholar] [CrossRef]

- Kupiec, K.; Larwa, B.; Gwadera, M. Heat transfer in horizontal ground heat exchangers. Appl. Therm. Eng. 2015, 75, 270–276. [Google Scholar] [CrossRef]

- Kim, M.J.; Lee, S.R.; Yoon, S.; Go, G.H. Thermal performance evaluation and parametric study of a horizontal ground heat exchanger. Geothermics 2016, 60, 134–143. [Google Scholar] [CrossRef]

- Dasare, R.R.; Saha, S.K. Numerical study of horizontal ground heat exchanger for high energy demand applications. Appl. Therm. Eng. 2015, 85, 252–263. [Google Scholar] [CrossRef]

- Congedo, P.M.; Colangelo, G.; Starace, G. CFD simulations of horizontal ground heat exchangers: A comparison among different configurations. Appl. Therm. Eng. 2012, 33–34, 24–32. [Google Scholar] [CrossRef]

- Go, G.H.; Lee, S.R.; Nikhil, N.V.; Yoon, S. A new performance evaluation algorithm for horizontal GCHPs (ground coupled heat pump systems) that considers rainfall infiltration. Energy 2015, 83, 766–777. [Google Scholar] [CrossRef]

- Sofyan, S.E.; Hu, E.; Kotousov, A. A new approach to modelling of a horizontal geo-heat exchanger with an internal source term. Appl. Energy 2016, 164, 963–971. [Google Scholar] [CrossRef]

- Chong, C.S.A.; Gan, G.; Verhoef, A.; Garcia, R.G.; Vidale, P.L. Simulation of thermal performance of horizontal slinky-loop heat exchangers for ground source heat pumps. Appl. Energy 2013, 104, 603–610. [Google Scholar] [CrossRef]

- Wu, Y.P.; Gan, G.H.; Verhoef, A.; Vidale, P.L.; Gonzalez, R.G. Experimental measurement and numerical simulation of horizontal-coupled slinky ground source heat exchangers. Appl. Therm. Eng. 2010, 30, 2574–2583. [Google Scholar] [CrossRef]

- Fujii, H.; Nishi, K.; Komaniwa, Y.; Chou, N. Numerical modeling of slinky-coil horizontal ground heat exchangers. Geothermics 2012, 41, 55–62. [Google Scholar] [CrossRef]

- Fujii, H.; Yamasaki, S.; Maehara, T.; Ishikami, T.; Chou, N. Numerical simulation and sensitivity study of double-layer slinky-coil horizontal ground heat exchangers. Geothermics 2013, 47, 61–68. [Google Scholar] [CrossRef]

- Li, H.; Nagano, K.; Lai, Y.X. Heat transfer of a horizontal spiral heat exchanger under groundwater advection. Int. J. Heat Mass Transf. 2012, 55, 6819–6831. [Google Scholar] [CrossRef]

- Selamat, S.; Miyara, A.; Kariya, K. Numerical study of horizontal ground heat exchangers for design optimization. Renew. Energy 2016, 95, 561–573. [Google Scholar] [CrossRef]

- Naili, N.; Hazami, M.; Kooli, S.; Farhat, A. Energy and exergy analysis of horizontal ground heat exchanger for hot climatic condition of northern Tunisia. Geothermics 2015, 53, 270–280. [Google Scholar] [CrossRef]

- Gao, Y.; Fan, R.; Li, H.S.; Liu, R.; Lin, X.X.; Guo, H.B.; Gao, Y.T. Thermal performance improvement of a horizontal ground-coupled heat exchanger by rainwater harvest. Energy Build. 2016, 110, 302–313. [Google Scholar] [CrossRef]

- Verda, V.; Cosentino, S.; Lo Russo, S.; Sciacovelli, A. Second law analysis of horizontal geothermal heat pump systems. Energy Build. 2016, 124, 236–240. [Google Scholar] [CrossRef]

- Kong, L. Study on the Heat Exchange Performance of Spiral Ground Heat Changer. Master’s Thesis, Yangzhou University, Yangzhou, China, 2015. [Google Scholar]

- Yang, S.M.; Tao, W.Q. Heat Transfer; Higher Education Press: Beijing, China, 2006; pp. 229–300. [Google Scholar]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Morrison, A. Finite Difference Model of a Spiral Ground Heat Exchanger for Ground Source Heat Pump. Master’s Thesis, Carleton University, Ottawa, ON, USA, 1999. [Google Scholar]

- Kong, X.Y. Advanced Seepage Mechanics; China University of Science and Technology Press: Hefei, China, 1999. [Google Scholar]

| Parameters | Central Distance/m | Coil Diameter/m | Inside Diameter of Coil/m | Flow Velocity/m/s | Re |

|---|---|---|---|---|---|

| Prototype | 0.2 | 1 | 0.025 | 0.12 | 3731 |

| Model | 0.04 | 0.2 | 0.005 | 0.6 | 3731 |

| Parameters | Type of Data | Typical Value | Unit | Relative Uncertainty |

|---|---|---|---|---|

| Average soil temperature | Measured | 28 | °C | 4.2% |

| Average inlet water temperature for the slinky coil | Measured | 32 | °C | 4.3% |

| Average outlet fluid temperature for the slinky coil | Measured | 27 | °C | 4.6% |

| Average flow rate of water | Measured | 0.04 | m3/h | 5.4% |

| Average heat release rate of coil | Calculated | 274 | W | 4.6% |

| Average heat flux per unit pipe length | Calculated | 16.5 | W/m | 4.4% |

| Average excess soil temperature | Calculated | 16 | °C | 4.7% |

| Parameters | Value |

|---|---|

| Thermal conductivity of pipe, λp/W·m−1·K−1 | 0.48 |

| Inside diameter of equivalent pipe, din/m | 0.022 |

| Outside diameter of equivalent pipe, dout/m | 0.024 |

| Lp/Lt, n | 6 |

| Thermal conductivity of soil, λs/W·m−1·K−1 | 0.9 |

| Density of soil, ρs/kg·m−3 | 1500 |

| Specific heat of soil, cs/J·kg−1·K−1 | 1100 |

| Solar absorptivity, αs | 0.8 |

| Density of fluid, ρf /kg·m−3 | 1000 |

| Specific heat of fluid, cp/J·kg−1·K−1 | 4100 |

| Thermal conductivity of fluid, λf/W·m−1·K−1 | 0.56 |

| Flow rate, v/L·s−1 | 0.2 |

| Burial depth, zp/m | 2.4 |

| Length of trench, L/m | 50 |

| Width of computation region/m | 12 |

| Depth of computation region/m | 13 |

| Inlet water temperature of coil, Tin/°C | 35 |

| Mean ground temperature, TM/°C | 17.5 |

| Amplitude of annual temperature, A0/°C | 14.5 |

| Day from January 1st at which the minimum temperature occurs, τ0/day | 340 |

| Total operation time/day | 90 |

| Groundwater table/m | 2 |

| Porosity ε | 0.4 |

| Groundwater advection velocity, m·a−1 | 150 |

| Soil Type | Density/kg/m3 | Specific Heat/J/(kg·K) | Thermal Conductivity/W/(m·K) | Thermal Diffusivity/m2/s |

|---|---|---|---|---|

| Clay | 1500 | 1100 | 0.9 | 0.545 × 10−6 |

| Sand | 2000 | 700 | 2.0 | 1.430 × 10−6 |

| Sandstone | 2500 | 1400 | 3.2 | 0.900 × 10−6 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Yang, W.; Yang, J.; Wu, S.; Chen, Y. Experimental Investigations and Numerical Simulation of Thermal Performance of a Horizontal Slinky-Coil Ground Heat Exchanger. Sustainability 2017, 9, 1362. https://doi.org/10.3390/su9081362

Zhang C, Yang W, Yang J, Wu S, Chen Y. Experimental Investigations and Numerical Simulation of Thermal Performance of a Horizontal Slinky-Coil Ground Heat Exchanger. Sustainability. 2017; 9(8):1362. https://doi.org/10.3390/su9081362

Chicago/Turabian StyleZhang, Chengbin, Weibo Yang, Jingjing Yang, Suchen Wu, and Yongping Chen. 2017. "Experimental Investigations and Numerical Simulation of Thermal Performance of a Horizontal Slinky-Coil Ground Heat Exchanger" Sustainability 9, no. 8: 1362. https://doi.org/10.3390/su9081362