1. Introduction

With sustainability becoming integral to the decision making of industries and policy making [

1], assessment of the positive and negative impacts of resource recovery operations has become common. Until recently, these assessments have been limited to the accounting of only environmental impacts as supported by Life Cycle Analysis (LCA). With increasing calls for sustainability assessment to become a truly integrated science [

2,

3], concerted efforts have been made to develop methods that align the practice of sustainability assessment of resource recovery processes with the three-pillars of sustainability, namely environmental, economic and social [

4,

5]. As such, Life Cycle Sustainability Assessment (LCSA) has extended LCA by integrating it with social Life Cycle Analysis (sLCA) and Life Cycle Costing (LCC) that account for the social and economic domains of resource recovery systems, respectively, alongside the environmental [

4,

5]. Nonetheless, the implementation of LCSA as a way to inform transformative, systemic changes towards sustainability, has presented an important challenge [

6,

7]. The inclusion of social and economic dimensions further complicated the already difficult task of drawing consistent system boundaries [

8], requiring consideration of the socio-economic context within which resource recovery systems are embedded.

A number of frameworks have been proposed to deal with the complexities of combining LCA, LCC and sLCA. Guinée et al. [

4] developed a framework that integrates models from different disciplines relevant to sustainability, to allow the examination of environmental, economic and social aspects at different levels of analysis (product, meso, or economy). This framework was adapted and implemented by Hu et al. [

9] through the development of a five-step procedure. These authors showed that modelling the technological system at the micro-level, and scaling it up with realistic scenarios generated with the knowledge gained from material flow analysis (MFA) at the meso-level and policy/economic studies at the macro-level is a practical approach towards its implementation. Another framework was developed by Bachmann et al. [

10] who used multi-criteria decision analysis (MCDA) for the examination of all three domains, an approach also applied by Halog and Manik [

11], who integrated MCDA and dynamic system modelling for LCSA [

12]. These frameworks, however, require significant resources and expertise to implement. The relative rarity of LCSA studies that include all three domains of sustainability suggests that the use of LCSA is too complicated to be practical in many decision making contexts [

13,

14].

Most developments in LCSA have focused on the individual LCA, LCC and sLCA methods [

15] or integrative frameworks [

16]. Reconciling these different methods, and extending their capabilities to account for the interdependency of environmental, economic and social systems remains an on-going project for the LCSA community [

13]. The complexity this entails is widely recognised, but relatively little work addresses the consequent challenge posed by the resources and expertise required to implement LCSA. Pesonen and Horn [

15] sought to address LCSA complexity with a sustainability Strengths Weaknesses Opportunities and Threats (SWOT) analysis tool combined with conventional LCA. Ziout et al. [

17] suggested the use of Political, Economic, Social, Technological, Environmental and Legal (PESTEL) analysis to inform end-of-life (EoL) processing decisions in a way that captures the perspectives of different stakeholders.

PESTEL analysis (also known as PEST or PESTLE) was originally designed as an assessment tool of the external macro environment in which an industry or business operates. This tool was found to be useful in identifying and understanding the key political parameters that are likely to affect the industry; the key environmental and economic considerations and associated societal aspects; the technological innovations that are likely to occur; as well as the current and impending legislation that may affect the industry [

18]. The PESTEL analysis, being generic in nature, is not likely to relate directly to sustainability assessment procedures; yet it is a useful intermediary step in identifying specific contextual domains. It can provide more detailed guidance to decision-makers on issues that are likely to impact on the success of their initiatives [

19]. Despite its relative strength on describing multi-dimensional aspects, the use of PESTEL analysis is necessarily narrative; restricted to the identification and conceptual evaluation of the relative importance of contextual issues in order to determine those that should be subject to a more detailed analysis. Such issues include, for example, political drivers of change, social values that must be protected, environmental systems sensitive to adverse impacts, and legal or regulatory requirements. As such, its usefulness lies in the assumption that the optimisation of a management solution cannot be realised without having all the information relevant to the specific “environment” [

20]. Thus far, PESTEL analysis has rarely been applied in a sustainability assessment context; examples include the analysis of obstacles to energy efficient retrofit of buildings in China [

21], an assessment of agricultural product service systems [

22], and an assessment of EoL processing decisions [

17].

This paper aims to develop a new approach with which current LCSA frameworks can be supplemented with PESTEL analysis to support their goal and scope definition stages which, as argued by Stefanova et al. [

8], are more important in LCSA that in LCA. To achieve this,

Section 2 provides a detailed description of how PESTEL can be embedded in the existing LCSA framework and a structured conceptual representation of the food waste management system in the UK which is used as an illustrative case study (

Section 2.1). In

Section 3, the conceptual analysis of the case study is presented, primarily focusing on the description and analysis of the food waste management system and the parameters identified therefrom, by also providing a reflection on their relevant importance based upon existing literature. Then, in

Section 4, a discussion of the benefits and limitations of the methodology is presented, followed by reflections on further development of the approach in the conclusions (

Section 4).

2. Materials and Methods

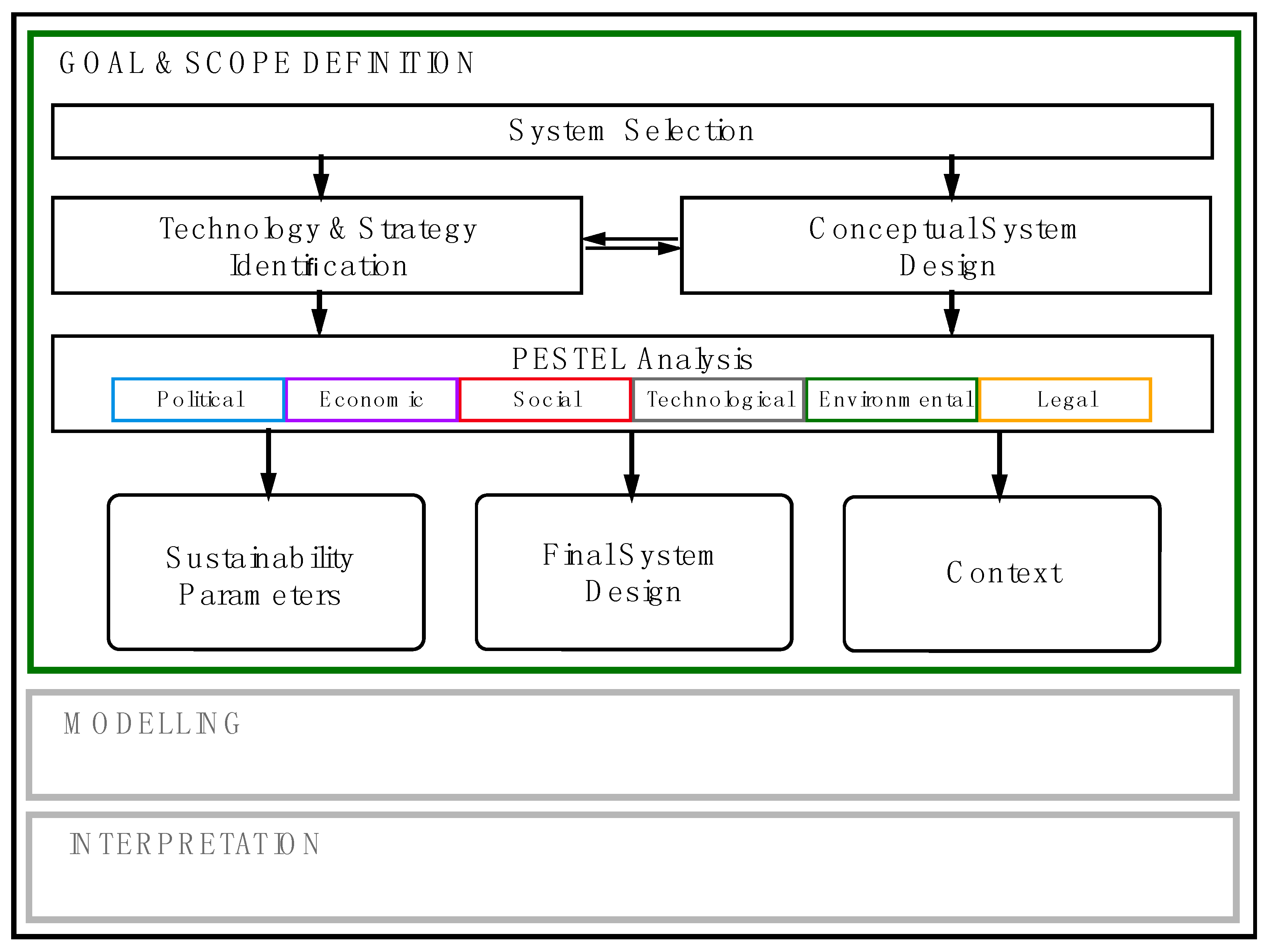

Figure 1 shows how PESTEL analysis is embedded in the goal and scope definition stage of an LCSA framework. This approach results in three key outputs that form the basis of the subsequent modelling and interpretation stages of LCSA:

a set of sustainability parameters that are to be used in the LCSA;

a final system design that outlines the entities and processes that are to be modelled; and

a description of the context that determines relevant aspects that govern the system/process under assessment.

The implementation of this approach depends on the thoroughness of the background research and the collection of information across all the parameter categories from a variety of sources, including peer-reviewed articles, technical reports and other grey literature.

The first step of the framework is to select the system and describe the problem that is to be addressed (

Figure 1). Following this, alternative technologies or strategies that could be implemented are identified, and a conceptual system diagram is constructed. At this stage, a functional system boundary—including core system processes—is defined. Such a functional system boundary is sufficient for a PESTEL analysis, whereas a complete system boundary definition, including exchanges with the background system, must follow the PESTEL analysis as part of the subsequent LCSA; hence, this does not constitute part of our analysis.

Once the system has been conceptually described, the PESTEL analysis is then performed to identify and assess the importance of different parameters associated with the resource recovery from waste system/process under investigation. The identification of parameters is achieved in reference to the goal of the sustainability assessment (i.e., resource recovery from waste) based on system and technology selection, strategy identification, and conceptual system design, but also in recognition for the potential of this goal to be subsequently revised. Even though a number of parameters may arise through this process, justifying the selection of those that are most meaningful in terms of systemic evaluation is a gap that needs to be explored. An intermediate way of dealing with this gap is by ranking of the parameters identified based on their relative contribution in achieving the sustainability goal based on participatory approaches that involve all stakeholders of the resource recovery system under study. The results of the PESTEL analysis provide the three outputs listed above. The goal and scope of the LCSA should subsequently be refined to be consistent with the final system design and decision making context.

Since PESTEL is used to support the selection of key impact parameters for an LCSA, it was considered prudent for the environmental, economic and social parameters to be informed based on the predefined impact categories proposed for LCA, LCC and sLCA as shown in

Table 1.

The parameters used in LCA are standardized and aimed at addressing the environmental aspects and potential environmental impacts throughout a material, component, and product’s (MCP) lifecycle (ISO 14044-2006, 2006). LCC is defined as the assessment of all costs and revenues associated with the MCP lifecycle and with all actors in the MCP supply chain (supplier, producer, user/consumer, and EoL actor) distinguished into five categories as shown in

Table 1 [

23,

24]. Acquisition costs, costs of use, maintenance costs, and EoL costs are those borne by the contracting authority/stakeholder. External environmental costs, i.e., those imputed by environmental externalities linked to the MCP during its lifecycle, are not included as these would amount to a double counting of the environmental impact parameters.

Although several sets of indicators have been proposed for sLCA [

25,

26], a commonly accepted set of indicators has not yet been fully established [

13,

27,

28]. Five main stakeholder groups involved and affected by the MCP lifecycle are introduced by sLCA guidelines: workers, consumers, society, local community, and value chain actors not including consumers [

29]. For each of these groups, several impact subcategories have been introduced (e.g., job opportunities, working conditions, and health impact).

Alongside the environmental, economic and social parameters described above, the PESTEL analysis also includes political, technological and legal parameters. Political parameters relevant to resource recovery from waste may include government attitudes to consumer protection, the environment, taxation, trade restrictions and societal reforms as well as the burden of bureaucracy and level of corruption [

30]. Technological parameters may be associated with waste infrastructure (i.e., collection, waste management facilities and resources available) and technologies that can promote the better recovery of commercially valuable resources from waste. Legal parameters may include current and impending legislation that affect the uptake and performance of waste management processes, and how these legislations and other regulatory measures can impact the recovery of resource from waste.

To implement the PESTEL analysis, a systematic literature review is employed, using appropriate search terms to identify relevant documents, and systematically coding them to identify the frequency and perceived importance of relevant parameters. For environmental, economic and social parameters the categories listed in

Table 1 are used as the basis for the coding scheme; for the political, technological and legal parameters the coding scheme emerges from issues identified in the analysis.

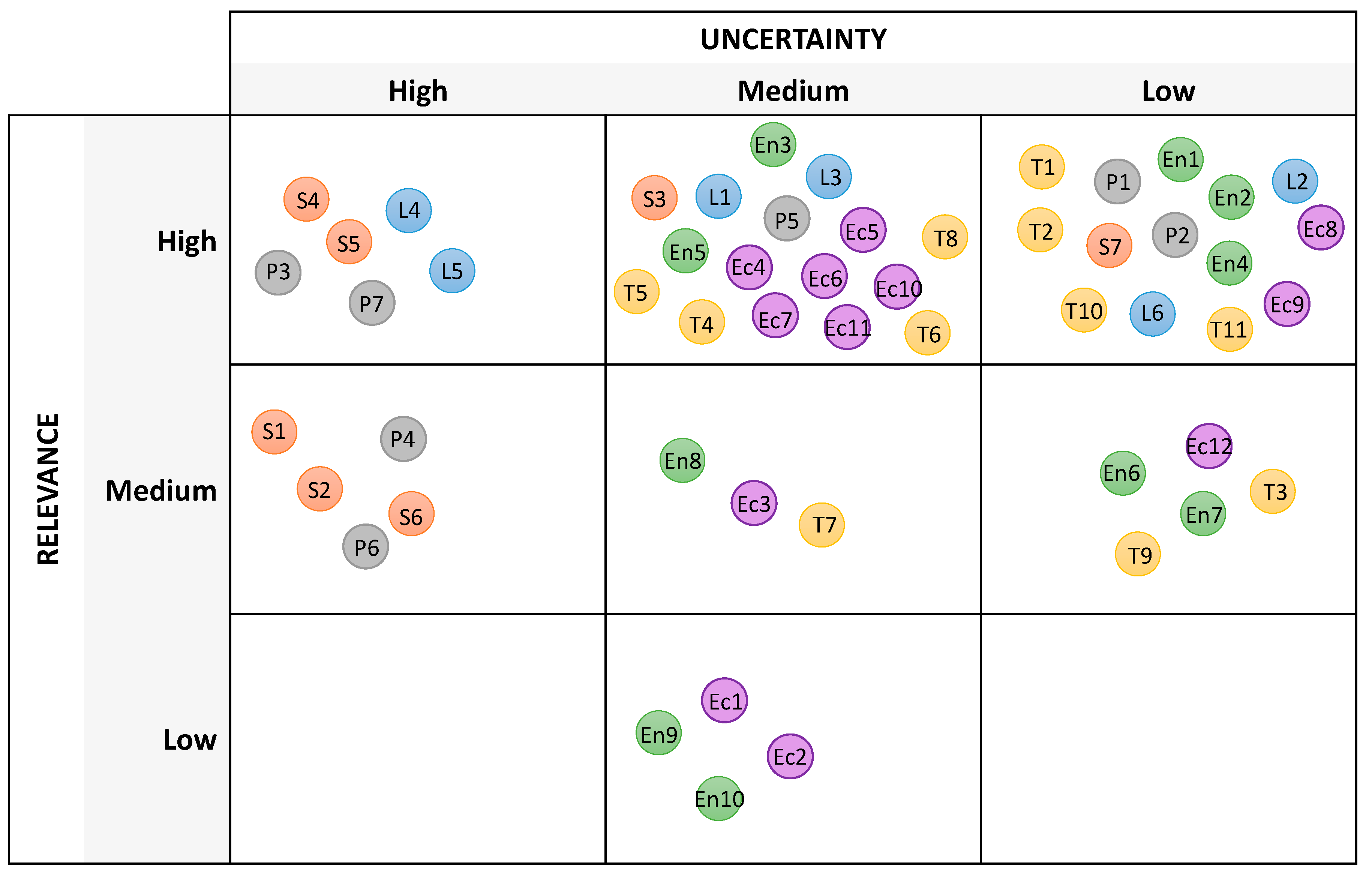

The parameters identified for each of the six PESTEL domains, as derived from the literature review process, are categorized according to their relevance to the resource recovery system/process under investigation and the uncertainty in this ranking, both using a high, medium and low scale. The relevance rankings are intended to denote how important it is for that parameter to be included in a LCSA with respect to the other identified parameters. The uncertainty ranking for each parameter denotes the confidence in the relevance ranking, resulting from two factors:

the parameter is inherently uncertain, e.g., legislative changes are possible as a result of which the importance of a parameter could change; and

there is insufficient or ambiguous information leading to an unreliable assessment of the importance of the parameter, e.g., there is often little information on social impacts and what information there is highly context dependent.

The rankings that result from this analysis are derived from a synthesis of existing literature with potentially conflicting perspectives that include common elements and statements of importance. This necessitates a qualitative ranking of importance into high, medium and low categories and the inclusion of uncertainty estimation to avoid a false impression of consensus or numerical accuracy. The quantification of parameters is beyond the scope of this analysis and should be part of the assessment phase of a subsequent LCSA.

In the following case study, an abridge version of the methodology described was implemented for illustrative purposes.

Introduction to the Case Study

Food waste consists of raw or cooked food materials and includes food loss before, during or after meal preparation in the household, as well as food discarded in the process of manufacturing, distribution, retail and food service activities [

31]. In the UK alone, total food and drink waste accounts for about 15 Mt per year, approximately one-quarter of the total food distributed for human consumption in the country [

32].

Anaerobic digestion (AD) of food waste has become increasingly popular in policy making in recent years, in the UK and worldwide, as a promising food waste management option and a sustainable energy alternative. However, the collection of food waste has been suggested as a determining factor of the performance of AD [

33]. There are two potential pathways for food waste collection: (i) commingled collection, i.e., with other municipal solid waste in what is called the residual waste stream; and (ii) source-separated collection. While the latter provides a quality feedstock for AD due to a reduction in contamination, commingled collection introduces high concentrations of potentially toxic elements (PTEs) and lowers the nutrient content of food waste, which may affect the performance of AD and the quality of the biogas and digestate produced [

34,

35].

As such, source-separated collection of food waste is considered to be the most suitable way to access a high quality (i.e., free from physical impurities) waste stream and ensure a stable operation of the AD process [

36]. In the following analysis, only systems and strategies that use source-segregated collection of food waste have been considered. Digestate produced from the AD of source-separated food waste can be used as a fertiliser, opening up opportunities for new market creation while also facilitating maximisation of the value recovery from food waste. Nonetheless, implementation of source-separation is a complex decision process based on several parameters including: policy targets; local needs and conditions; technologies availability; quality and quantity of collected wastes; and applicable socio-economic effects. For this reason, source-separated collection method may not always be feasible [

37].

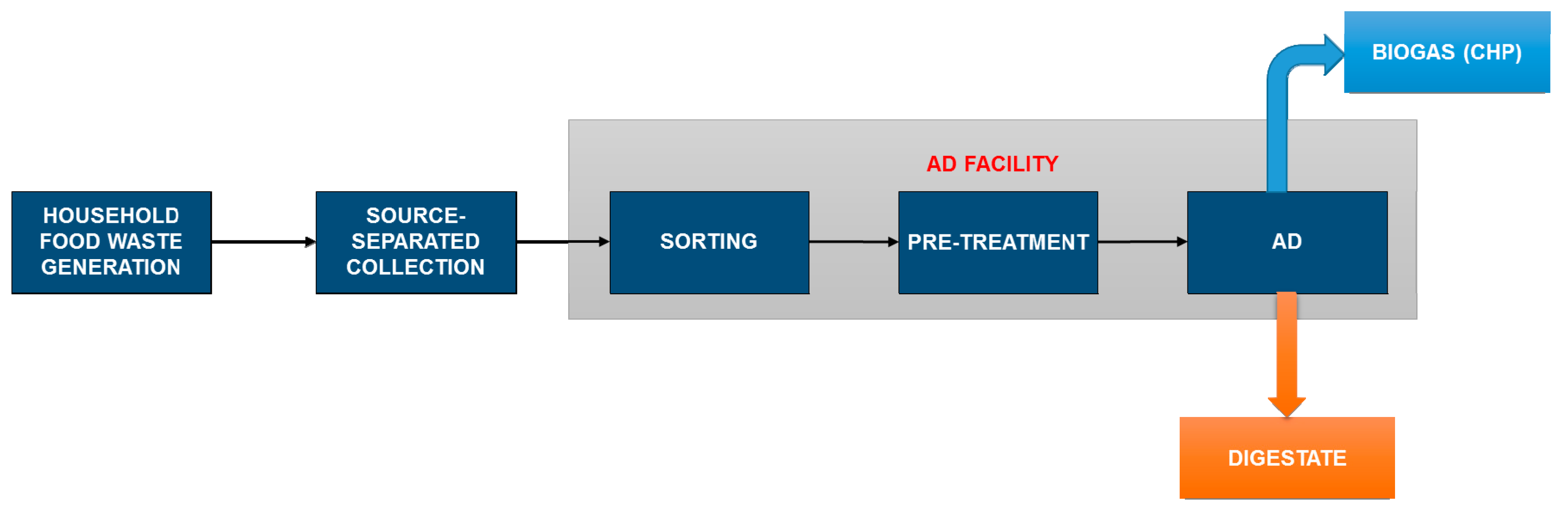

Assessing the sustainability of source-separated food waste management via AD and its potential to maximise the recovery of resources (i.e., biogas and digestate) from food waste is a prerequisite in supporting its large-scale uptake as a viable resource recovery alternative. A system flow diagram for conceptualising the source-separated food waste management via AD (

Figure 2) was constructed to depict its pathway; from generation towards treatment and disposal.

3. Results

The UK government considers AD to have an important role in the wider sustainable resource management system [

38]. It is regarded as a means of dealing with food waste while tackling climate change, energy security, economic security, food security and air quality, via producing:

renewable energy in the form of biogas that can be used on site in combined heat and power (CHP) engines that generate heat and electricity, treated and injected directly into the gas grid, or liquefied for use as a transport fuel; and

digestate that contains all the nitrogen, phosphorus and potassium present in the original feedstock (in this case food waste) and as a consequence has value as an organic fertiliser and soil conditioner for agriculture and land use.

Besides the recovery of resources, AD can also divert food waste from landfill, in a way that is beneficial to the environment, society and economy. A PESTEL analysis was performed to conceptualise the potential parameters that could be used in supporting the sustainability assessment of food waste management via AD and its potential recovery of value. The relevant political, economic, social, technological, environmental and legal domains associated with the food waste management system were identified and analysed on their relevance and respective outputs on maximising the recovery of value are listed below.

3.1. Political

The UK government’s commitment to renewable energy generation and climate change policy has been a key driver to increasing renewable energy from waste [

38]. To meet the targets set by these policies, the UK has decided to depart from the waste hierarchy (WH) defined in Article 4 of the Waste Framework Directive (WFD), and, instead of using composting for the treatment of food waste that is higher up in the WH, support the uptake of AD technology. This is because AD based LCA is considered to be a more beneficial option than composting, and one with the potential to underpin the transition to a resource-efficient and renewable energy future (see

Table S1 in Supplementary Materials for detailed sources).

To promote the development and implementation of AD technology, DECC (Department for Energy and Climate Change) and Defra launched the AD Strategy and Action Plan in 2012 [

38]. This plan was intended to create the supportive landscape and the right regulatory environment required for promoting and implementing AD for the treatment of organic waste, including food waste. It includes key provisions for the planning, taxation and financial incentives (more details in Section 4.6) that support the deployment of AD. For instance, landfill tax policy has encouraged the industry to invest in a range of alternative treatment facilities for recycling and recovering value from waste, including AD, while the environmental permitting regulations have put pressure towards ensuring that the installation of facilities for recovering value from waste pose no harm to human health and the environment. In regards to the sustainable development of AD capacity, an additional aspect of great importance was the rate at which feedstock becomes available, which in the case of food waste source-separated collection was considered to be key [

39].

Collaboration between Local Authorities (LAs) and investors/developers in AD was found to be critical in supporting the sustainability of AD. LAs interest stems from the expected opportunities for economic growth and employment; thereby tackling the on-going pressure to reduce food waste arising at source and meeting their waste management targets. In regards to job creation, it is estimated that investment in the AD process may generate 35,000 new jobs in the UK [

38]. Indicatively, in a 2015 ADBA (the Anaerobic Digestion & Bioresources Association) study it was reported that there will be 4500 jobs in the sector, and the increase is expected to continue in the coming years (with fewer in the construction sector, but more in the on-going maintenance sector). However, these figures are not specific to food waste management via AD, but general to the AD sector and thus it is unclear how many jobs the AD of food waste can actually create. Further studies and new data is needed to better quantify this, particularly in view of the rapid development of the AD industry in recent years (see

Table S1 in Supplementary Materials).

3.2. Economic

The

acquisition, operational, maintenance, EoL disposal, and

external environmental cost categories of LCC (

Table 1) were used in identifying the key economic values associated with the AD of source-separated food waste. Under acquisition costs, the cost savings from the elimination of avoidable food waste generated by an average UK household in 2012 had an estimated value of £470 per year [

32]. Cost savings from food waste storage efficiency, lowering fridge temperatures and refrigerating foods which are predominantly stored at ambient temperatures has been estimated to have a net economic benefit (taking into account the additional energy used) of around £200 million [

40]. The collection and transport costs of food waste are also classed under acquisition. Food waste can be collected on a weekly or fortnightly basis with each having a different economic impact due to the number and intensity of collection rounds and vehicular movements required [

41].

The operational costs of AD include pre-treatment costs, AD facility costs, post-treatment costs, labour costs and the revenues from digestate and biogas. In compliance with EU regulations (i.e., Animal By-Products Regulations), food waste needs to be pasteurized or sterilized before and/or after AD. A suite of different pre-treatments methods are available, such as mechanical, thermal, chemical, and biological pre-treatments [

42], with different associated costs [

43]. The investment, capital and operational (utility) costs of AD facilities vary based on the technology used (e.g., wet vs. dry, batch vs. continuous, and mesophilic vs. thermophilic) and scale [

44]. In regards to indirect economic costs, feedstock availability is considered to be an important factor in the economic viability of AD. Post-treatment costs include costs for biogas cleaning/scrubbing processes, feeding into the national gas grid or storing [

45], and digestate preliminary post-treatment and enhancement. The preliminary post-treatment involves mechanical separation into a liquid and solid fraction. The solid fraction is then used to produce a high quality fertilizer [

46].

The commercial value of digestate is determined by its nutrient content (primarily Nitrogen and Phosphorous), and compliance with the End-of-Waste criteria [

47]. The nutrients content in digestate depends on the feedstock and on the technology used in the separation process [

48]. As there are concerns for the future availability of phosphorus [

49], digestate is regarded as a valuable supply that can reduce reliance on its primary production. The commercial value of biogas is determined by its methane content and the market price of its final end-use(s) (or products from its processing such as electricity and heat). Biogas that is used on site or is cleaned and exported to the grid, may be eligible for a number of financial incentives which vary depending on the type of technologies used and capacity of AD plant. When biogas is used on site it can replace grid-supplied heat and/or electricity, thus reducing associated utility costs. The labour requirements of an AD operation is proportional to the complexity of the system adopted [

45].

The cost of maintaining the pre-treatment and AD processes tends to be relatively low in comparison to its capital cost. Maintenance costs are not negligible, but a well maintained plant is more economically efficient, in the medium- and long-term, than one that is not maintained regularly. When digestate fails to meet the EoW criteria, it is regarded as a waste and thus additional costs are incurred for its disposal.

3.3. Social

The social parameters that influence food wastage and treatment, and their impacts on the various stakeholders (i.e.,

workers,

consumers,

society,

local community, and

other value chain actors) outlined in

Table 1, are complex. They range from macro (e.g., cultural, economic, etc.) to micro (e.g., knowledge of what can be frozen, portion sizes, etc.), and relate to individuals, families, firms and industry sectors. Household generation of food waste is influenced by parameters including cultural contexts [

50], advertising [

51], government interventions [

52], lack of food preparation and storage knowledge [

53], and labelling [

54]. Food waste separation at source is an important parameter that displays consumers’ responsibility towards the implementation of a particular waste collection practice and acceptability of the overall waste management option for food waste. Impurities in food waste can bring the AD process to a halt, leading to serious economic and environmental impacts, associated with inefficient operations, loss of economic value and disposal of untreated waste into landfill. The collection regime selected by LAs (weekly/fortnightly), the container provided (kerbside containers and/or kitchen caddies) can impact household health and attitudes to food wastage and method of disposal [

41].

At the upstream part of the food supply chain, food waste generation in sources other than household can be affected by the promotion of alternative and improved food and food waste management practices. While firms may benefit from taking action through improved corporate social responsibility, and redistribution of surplus food to small businesses, the impact of such initiatives on the sustainability of AD in the medium- and long-term is largely unknown.

At the downstream part of the supply chain, trial studies of source-separated food waste collection carried out by Wrap in the UK in year 2009 [

41] indicated improved job satisfaction for collection crew employees, as well as reduction in vermin attraction and malodours in domestic areas, creating benefits both for the waste collectors, the householders and the community At treatment level, AD of food waste has been estimated to create employment for more than 4,000 people in the UK, and the digestate produced can reduce synthetic fertilizer use, potentially mitigating the health impacts of its production. The possibility of locating AD plants close to urban centres can reduce the transport requirements for waste treatment, reducing transport disruption. In some cases, this has also resulted in enabling weekly collection of food waste which is otherwise un-economical (see the Lower Reule Farm case study in [

38].

3.4. Technological

In the UK, there is an advanced level of knowledge and experience in technologies related to the storage of food, as well as on the AD technologies for the treatment of food waste. Technologies for preserving food for longer at the production, distribution, and consumption stages have been introduced, and are used in the UK. It has been suggested that in households lowering the average temperatures of refrigerators (2–5 °C) can have a net environmental and economic benefit while leading to a reduction in food wastage [

40]. In addition, technological advances that seek to optimise food packaging by introducing “intelligent/smart” materials, is considered to be making a considerable difference in sustaining the freshness of food products for longer periods of time and preventing its spoilage [

40,

55].

In 2015, there were 91 operational food waste AD facilities in the UK, with many more in the pipeline [

56]. AD technologies can be wet or dry, mesophilic (35–40 °C) or thermophilic (55–60 °C), single or multistage, and incorporate a range of filtering mechanisms to remove contaminants. A waste pre-treatment step is often a key requirement prior to AD to ensure the removal of impurities, and the homogenisation and pasteurisation/sterilisation of the mixture [

57]. This step aims to remove undesirable materials such as large items and inert materials (e.g., plastic, glass, etc.) to enhance feedstock digestibility, thus obtaining a higher energy recovery and ensuring a good overall performance [

58]. The effect of various pre-treatment methods however, can differ widely based on the characteristics of the substrates and the pre-treatment type. More specifically, selection of the appropriate macerating technology at the pre-treatment step has been found to be important to the reliable processing of the organic material, and the production of a substrate that can be easily pumped into the digester [

59]. Flexibility in the use of a macerator (so that it can be adapted based on the nature of the organic waste and the particle size), and reliability when it comes to the prevention of damages and corrosion, can prolong its operational life and hence maximise the value of the asset. In the digestion process, the position of the gas holder has been suggested to be of significant importance [

60]. Given the mechanical and bio-chemical complexity of AD schemes, significant technical and financial due diligence is required at project conception to ensure that the correct plant components for an AD scheme are specified [

45].

The cleaning/scrubbing of biogas is a critical step in ensuring effective and efficient utilisation. The major gas cleaning steps involve removing carbon dioxide from the gas stream and scrubbing out sulphur compounds, which are highly corrosive to downstream plants. There are a number of different technologies used for this purpose, and the selection of the most efficient one is important criterion for ensuring high biogas quality and reliability [

45]. Post-treatment of digestate can also involve a range of technologies depending on the final product desired [

38]. The selection of a post-digestion enhancement technology can be an important part of the optimisation of value recovery from digestate, the creation of new markets for digestate products, and the establishment of more secure and sustainable outlets for digestate products [

46].

3.5. Environmental

Environmental parameters are based on the impact categories of LCA, as listed in

Table 1. The AD of food waste can lead to GHG associated with the collection, transport, pre-treatment, AD operation and post-treatment, and distribution/utilization of end products. However, AD can contribute to savings in GHG emissions achieved via the use of renewable energy generation (biogas) and the digestate, which can replace conventional energy use and synthetic fertilizer production and use [

61]. AD is reported to contribute minimally to acidification with the emissions of NO

x only reported from the collection system and CHP plants [

61], and the combustion of biogas in CHP units is the only significant contributor to photo-oxidation [

61]. Digestate application to land bears the risk of nutrient leaching to surface and ground water [

48]. This risk can be mitigated by using appropriate fertilizer management techniques and application technologies [

47,

62].

Due to the risks to human health from toxic materials, dealing with food waste, and the processing of food waste via AD, is highly regulated. The waste derived fuel classification includes quantification of mercury (Hg), cadmium (Cd) and other heavy metal content as these have implications for environmental pollution and human health [

63]. Stringent treatment is required, particularly where animal by-products are present, such as pasteurization at 70 °C for 1 h or with thermophilic digestion, with a guaranteed retention of 5 h at 53 °C. This ensures the destruction of communicable diseases such as spongiform encephalopathy and foot and mouth disease, and also results in a reduction in viable weed seeds, reducing the need for herbicide use [

47]. As such human, terrestrial and aquatic toxicity are of low concern when it comes to the use of AD treatment of food waste and its by-products [

48,

62,

64,

65].

Construction materials (e.g., manufacturing, transport, EoL management) used for AD schemes and the fossil fuels used in development and operation stages are significant factors in the depletion of abiotic resources. The fossil fuel used for the collection and transport of food waste and any grid based demand for plant operation should be accounted for [

64,

65,

66]. The energy requirements associated with the collections, transport, pre-treatment, operation and post-treatment stages of an AD scheme can vary significantly depending on the technical configuration of the plant and its operating conditions. However, such energy demand can be offset by the export of biogas derived power to the grid [

38] or by producing transport fuel grade liquefied gas from biogas, which would serve to reduce lifecycle GHG emissions associated with an equivalent energy content of diesel fuel by 80% [

38].

3.6. Legal

The legal framework surrounding AD is relatively complex, involving a number of regulations stemming from EU legislation and translated at national level. According to European Union Regulation EC1772/2002, food waste needs to be pasteurized or sterilized before (and/or after) AD. Taking this into account, pre-treatment processes are considered to be an important pre-step in the successful implementation of AD (as explained in Section 4.2). The Industrial Emissions Directive (IED) has brought changes to the Environmental Permitting Regulations that includes activities such as AD (see

Table S6 in Supplementary Materials).

A number of legal requirements have to be met to enable the use of biogas and digestate outputs from an AD scheme. The End-of-Waste (EoW) criteria for AD digestate, as defined in the

Anaerobic Digestate Quality Protocol [

67], constitutes one of the most important legal requirements that has to be met. This protocol sets out a pathway to fully recover wastes and turn them into quality products. It defines the point at which waste ceases to be waste and can be used as a product without the requirement for waste management controls. Compliance with Quality Protocols is voluntary, but only its compliance can give the digestate “by-product” status. In the UK, there is an additional guidance for digestate quality control called the Publicly Available Specification (PAS110) (PAS110 is for the digestate product, whilst the Quality Protocol is about safeguards and processes needed to achieve PAS110) that is used to certify that the digested materials are of consistent quality and fit for purpose [

68]. Digestate that meets the specifications set in PAS110 can be sold under the “Bio-fertiliser” tag, increasing its commercial value. Biogas is also subject to EoW criteria which are based on the

Quality Protocol for Biomethane from Waste [

69]. This protocol sets out EoW criteria for the production and use of biomethane arising from the degradation of organic wastes in a landfill site or anaerobic digestion plant, for injection into the gas grid or use in an appliance suitably designed and operated for natural gas. Meeting the criteria set in the protocol enables biomethane to be marketed as a product.

A number of financial incentives are included in regulation to support the utilisation of biogas from AD for the generation and export of low carbon electricity, gas and heat: the Renewables Obligation Order (ROO), Contracts for Difference (CfD), Feed-in Tariffs (FITs) and the Renewable Heat Incentive (RHI). In additional, the Renewable Transport Fuels Obligation (RTFO) supports the use of biogas for transport.

Table 2 lists the core parameters extracted from the analysis of the six PESTEL domains of value above. These parameters are ranked in importance (H: high, M: medium, L: low) based on the authors understanding of their relevance and impact on the resource recovery system in the UK context. These judgments are necessarily subjective as the purpose of this study is to create a qualitative basis to streamline LCSA.

4. Discussion

The results presented in this study demonstrate that the PESTEL analysis contributes to sustainability assessment in two ways: (1) by providing a comprehensive understanding of the context within which decisions must be made; and (2) by identifying the key parameters that can form the basis for a formal streamlined LCSA.

It emerged from our results that a better understanding of the context is important in determining what the appropriate system boundary for LCSA should be. The issue of food waste reduction is a good example of this; it appears as a parameter in both the economic and social domains, and indirectly in the technological domain through better food packaging design and food preservation technologies efficiency. Food waste is one of the world’s greatest challenges and its reduction is considered to be a necessity; yet such measures can directly and indirectly affect the viability and sustainability of AD of source-separated food waste. Investment in AD for food waste management makes sense only if there is feedstock availability (i.e., food waste); if food waste is reduced because of the prominence of other alternatives (e.g., lower food production, surplus redistribution and use as animal feed) then the investment is at risk, as well as the benefits accruing from it (e.g., job creation, biogas used for electricity/heat that powers/heats the nearby community, fertiliser that is environmentally friendly, etc.). As a result, it no longer appears justified to exclude food waste reduction measures from the system boundary used for a subsequent LCSA.

A number of shortcomings associated with the use of PESTEL analysis for supporting LCSA have also emerged. These are as follows:

The lack of a material flow analysis (MFA) that balances the flow of food waste within the system under consideration in the PESTEL analysis bears the risk of an incomplete system definition.

The ranking of parameters can be challenging due to differing ideologies, interests and needs of the various actors involved in the food waste management system under consideration.

Interactions and trade-offs between different domains of value are overlooked owing to PESTEL analysing each domain separately.

The translation of political, technological and legal parameters into the LCSA domains of social, economic and environmental impacts is ambiguous.

The first two of these shortcomings relate primarily to the process of carrying out the PESTEL analysis itself, whereas the second two have implications for the subsequent streamlined LCSA. We now discuss each of these in more detail.

MFA is a useful method of tracking material flow between and within (as stocks) processes throughout the MCP’s lifecycle within a defined system [

70]. This method is widely applied in waste management contexts [

71] as it can fully account for the physical extent of the resource recovery system. As such, using the MFA to illustrate food waste flow and accumulation within the system makes it possible to identify where losses occur, enabling a more informed analysis of the system’s performance and optimisation, providing a robust basis for considering the creation or destruction of value (e.g., changes in technical quality, economic value, environmental impact or social benefit) [

72].

A standard PESTEL analysis provides little guidance on the ranking of parameters according to their importance. The ranking of each parameter has been associated with a degree of uncertainty that was defined based upon existing literature and empirical studies. This kind of “valuation” reflects the quality of information available for each parameter as well as the inherent variability of the parameters importance according to the context of the study.

Figure 3 shows the “conceptual” interplay between the uncertainty and relevance rankings of the parameters. This “subjective conceptualisation” can be alleviated by participatory approaches through which the various stakeholders involved in the particular food waste management option could have a voice in the selection and ranking of parameters. This is a beneficial way of capturing their insights, experience and preference on the importance of the different parameters, which are likely to be varied due to their specific interests and needs. The inclusion of parameters from such a process should err on the side of caution; controversial issues should be included. A decision of the relative weighting of impact parameters—as must be made in the assessment phase of LCSA that is outside the scope of this paper —will be able to draw on more information generated by the LCSA’s modelling phase.

In the food waste management system, the involvement of representatives from the waste management sector, households, LAs, interested third sector organisations and food retailers would be a constructive way of selecting parameters that inform a streamlined LCSA for a systemic evaluation. The use of the proposed approach and framework by actors in silos (e.g., government, LAs, and waste management operators), or by a group of actors that want to serve their own interests and needs, must be avoided.

The interactions and trade-offs between different domains of value are neglected by both the PESTEL analysis we have used and by standard LCSA frameworks [

73]. In the food waste management system, there is a clear trade-off between efforts to reduce food waste, and the economic viability and sustainability of an AD industry that relies on food waste as a feedstock which have been touched upon but not investigated further herein, as they fall outside of the scope of this study. Other trade-offs may include implications by the displacement of synthetic fertiliser by digestate, and the social misconception that food wastage is not bad. PESTEL analysis is an appropriate basis for identifying trade-offs because it does not attempt to collapse parameters from different domains of value to a single metric (e.g., money), but it should be supplemented by a methodology that systematically identifies the interactions between different system parameters. This is a routine practice, for example, in the system mapping exercises used to construct system dynamics models [

74].

A further significant shortcoming is associated with the translation of the political, technological and legal parameters into the LCSA environmental, economic and social impact domains. A reductive solution would be to integrate political, legal and technological parameters through their direct impacts on associated environmental, economic and social parameters. For example, regulations on diverting biodegradable waste from landfill, can reduce food waste disposed of to landfill and associated environmental impacts, while the quality protocols on both digestate and biogas produced from AD, can be associated with direct environmental and economic benefits. This is not an easy task to preform and the interconnections between the different domains over the different processes should be an integral part of such analysis. Moreover, it loses the benefits of the initial widening of the contextual understanding that the PESTEL analysis provides. Any alternative, however, entails a reconceptualization of the LCSA framework to account for interactions and trade-offs between a wider and less strongly delineated spectrum of domains of value. We believe that such developments are important, but beyond the scope of this paper.