Statistical Comparison between Low-Cost Methods for 3D Characterization of Cut-Marks on Bones

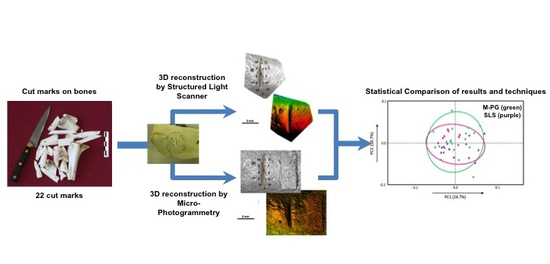

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample

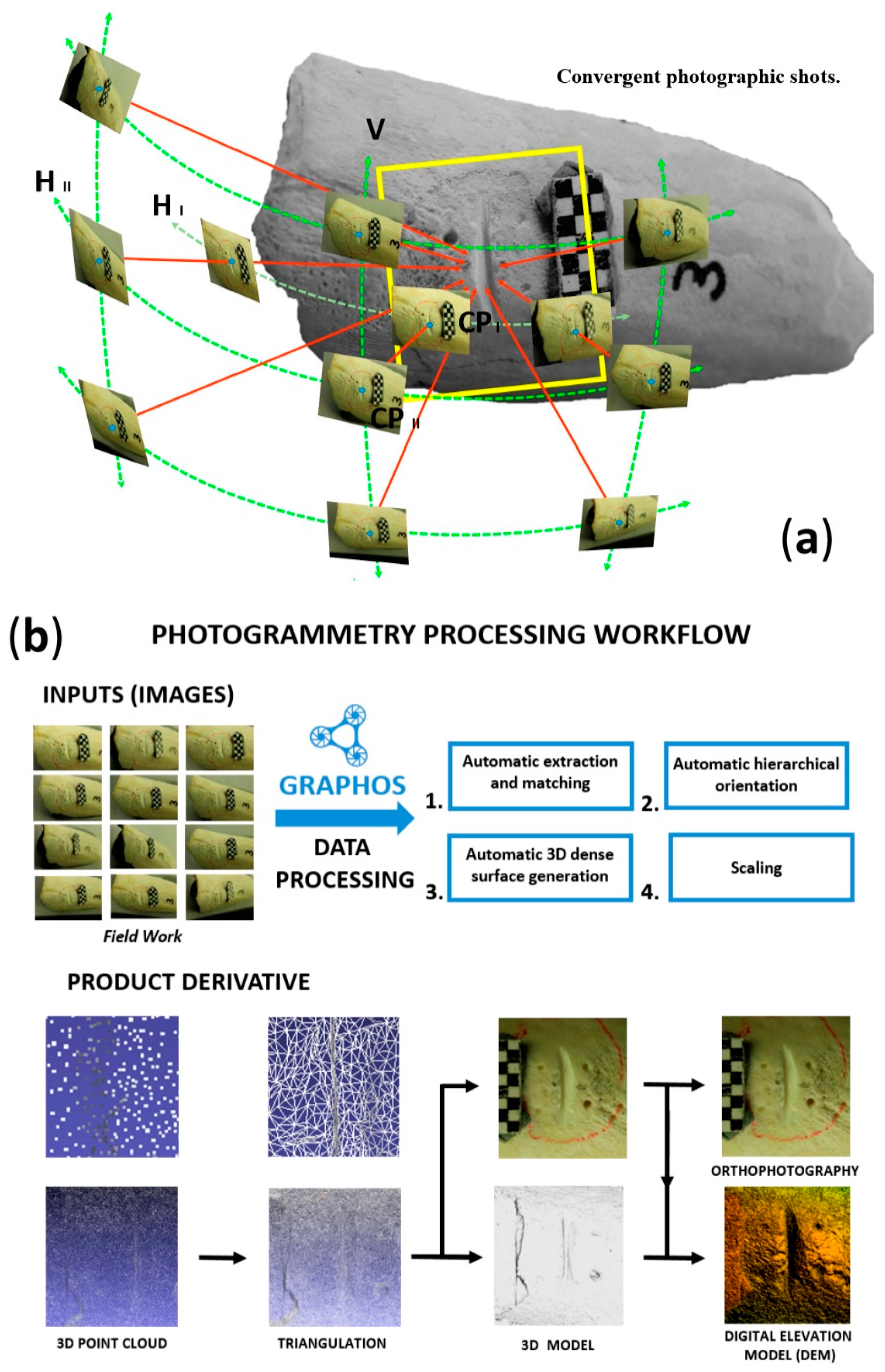

2.2. Reflex Camera and Macro-Lens

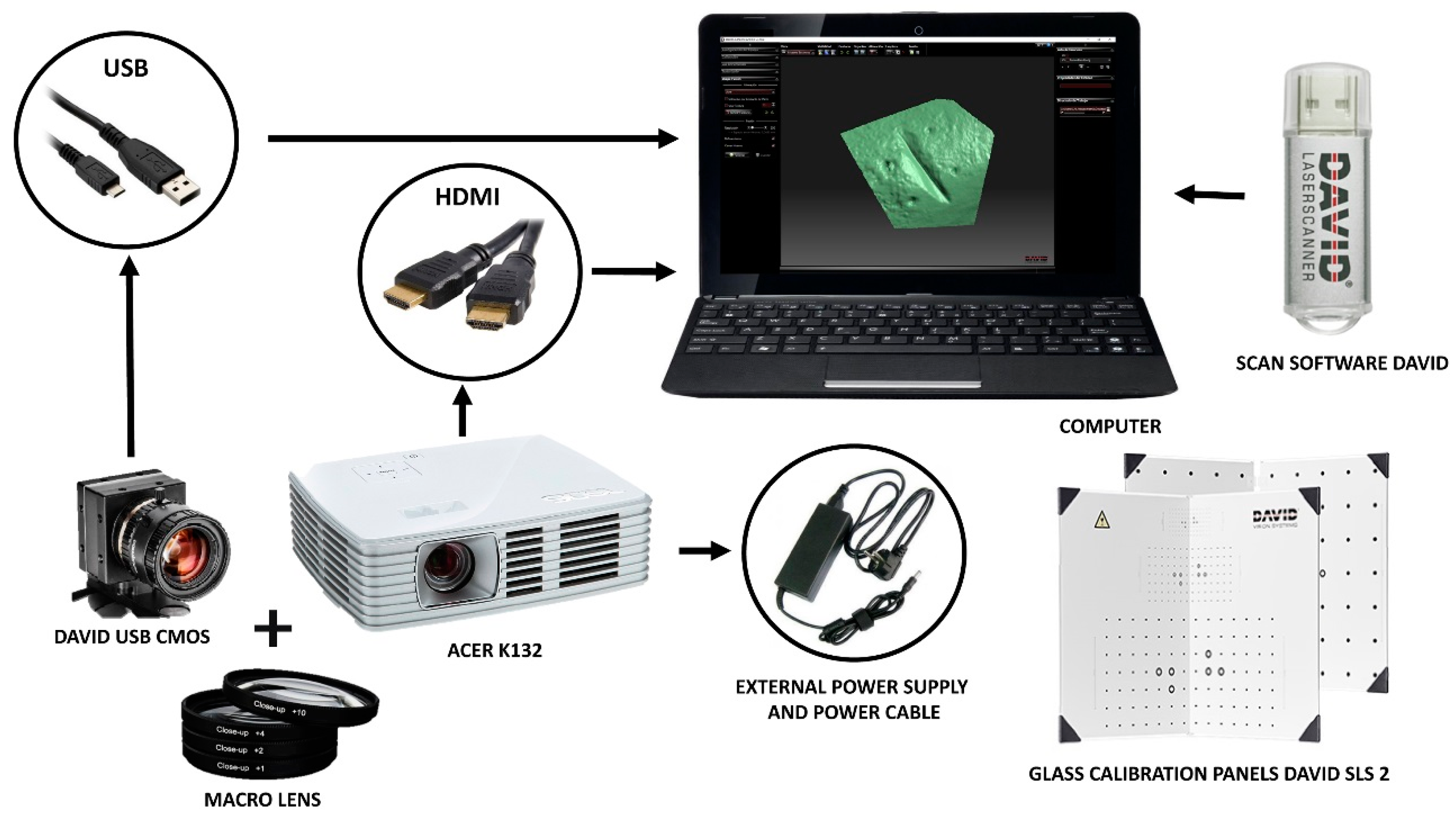

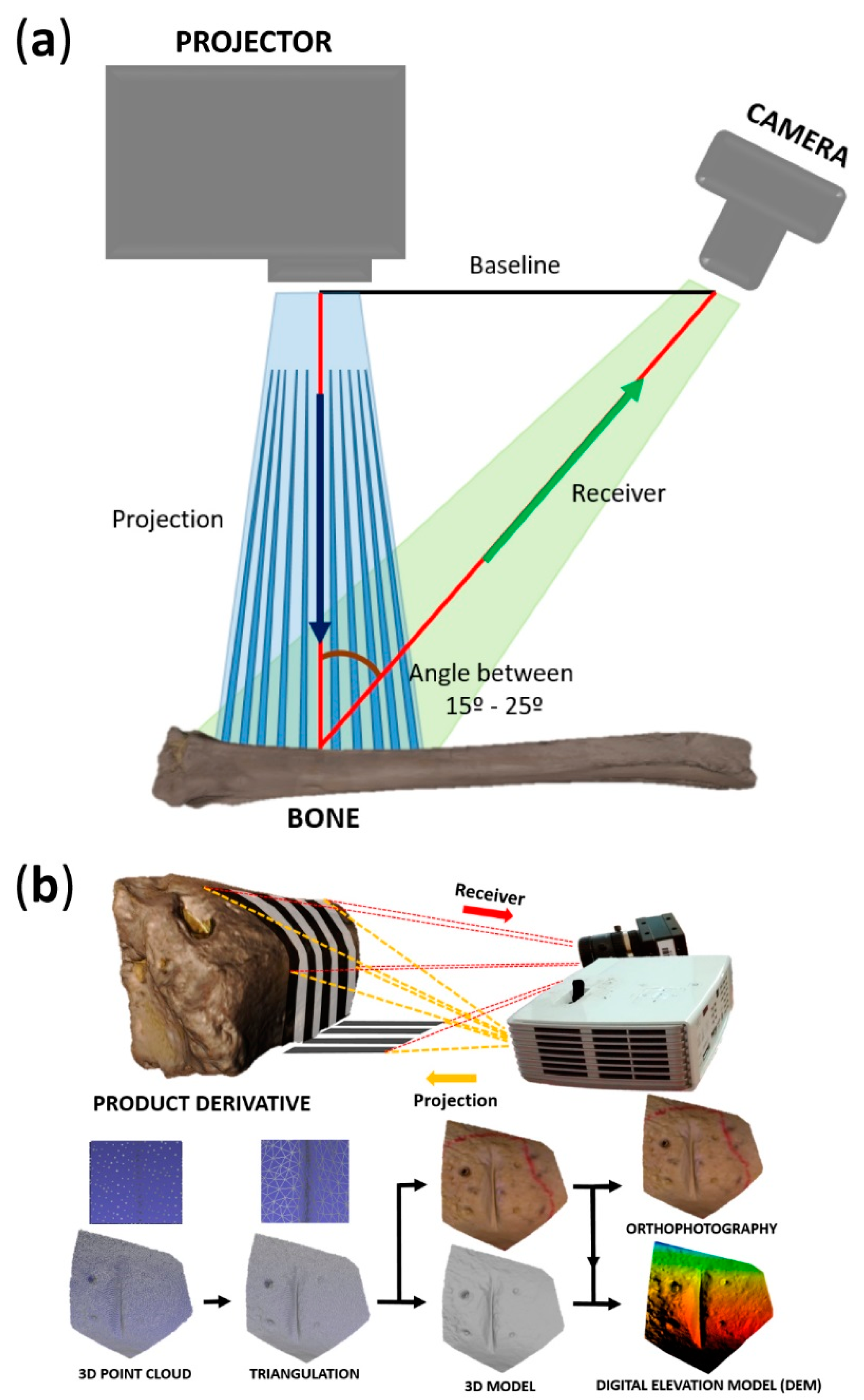

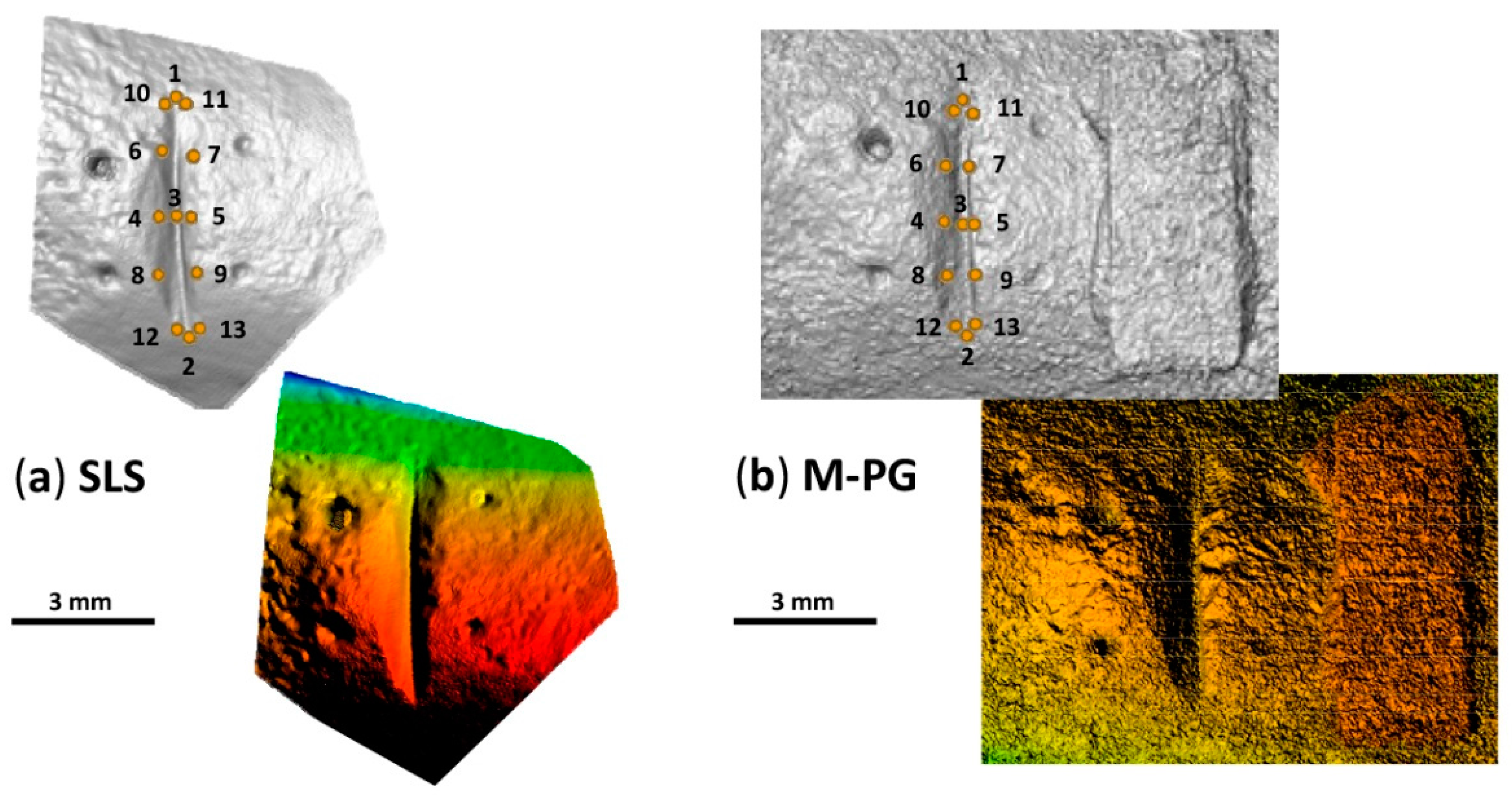

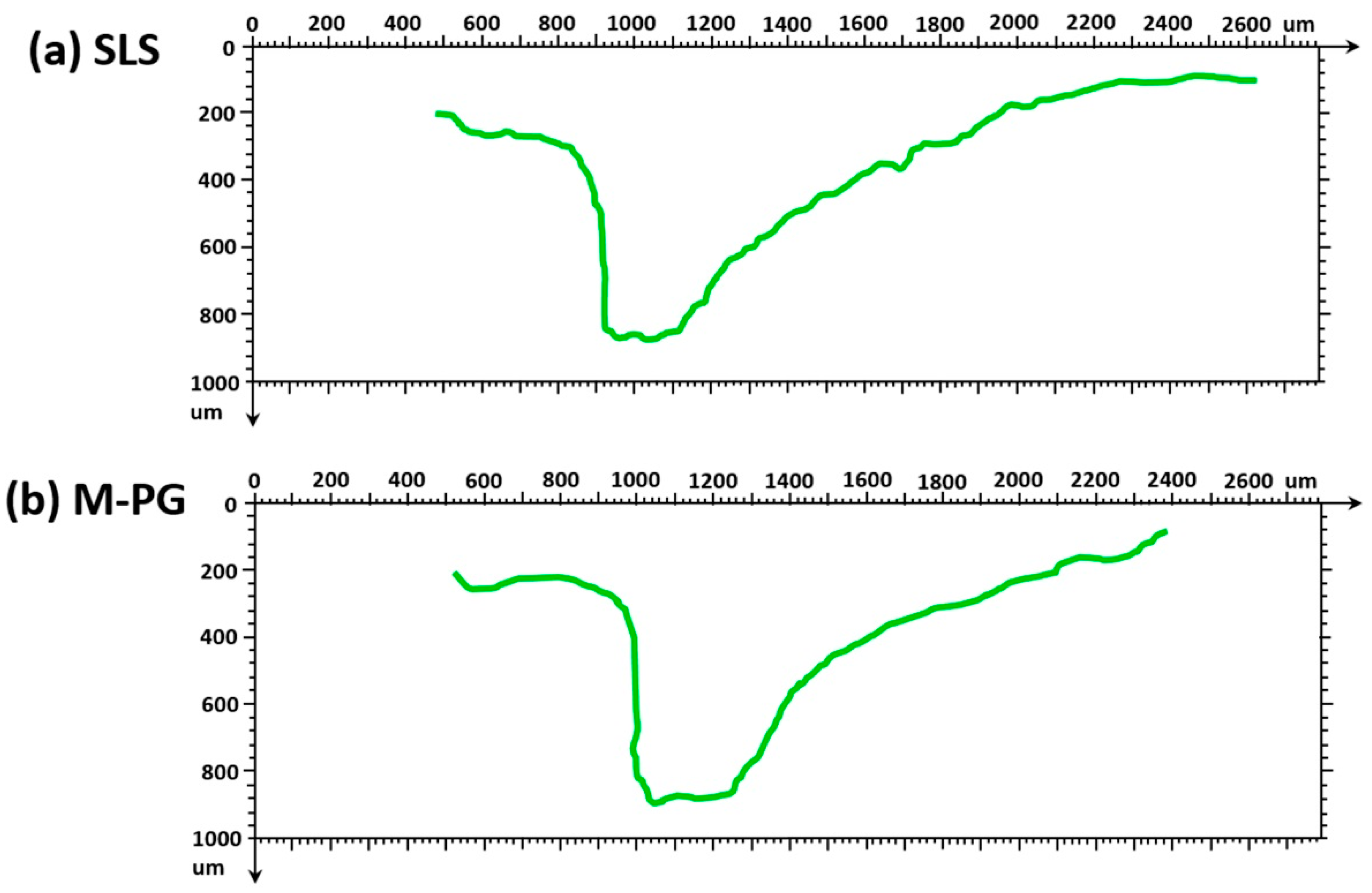

2.3. Structured Light Scanner

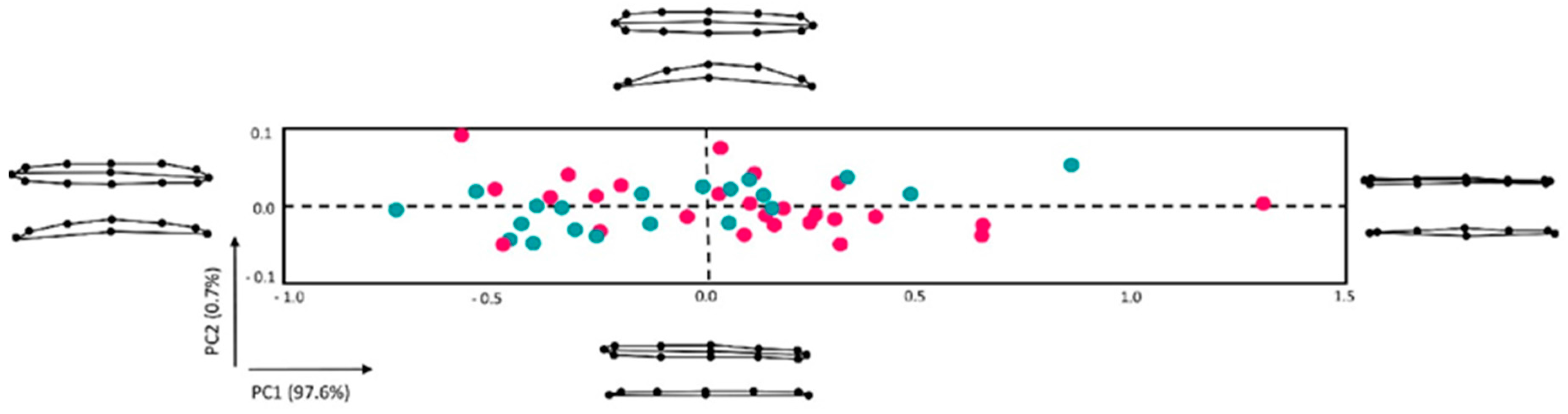

2.4. Statistical Comparison

3. Results and Discussion

3.1. SLS vs. M-PG

3.2. Cut Marks on Long Bone Diaphyses vs. Cut Marks on Flat Bones

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kersten, T.P.; Lindstaedt, M. Image-Based Low-Cost Systems for Automatic 3D Recording and Modelling of Archaeological Finds and Objects. In ICP in Cultural Heritage Preservation; Springer: Berlin/Heidelberg, Germany, 2012; pp. 1–10. [Google Scholar]

- Tiano, P.; Tapete, D.; Matteini, M.; Ceccaroni, F. The microphotogrammetry: A new diagnostic tool for on site monitoring of monumental surfaces. In Proceedings of the International Workshop SMW08, Florence, Italy, 27–29 October 2008; pp. 97–106. [Google Scholar]

- Aramendi, J.; Maté-González, M.A.; Yravedra, J.; Ortega, M.C.; Arriaza, M.C.; González-Aguilera, D.; Baquedano, E.; Domínguez-Rodrigo, M. Discerning carnivore agency through the three-dimensional study of tooth pits: Revisiting crocodile feeding behaviour at FLK-Zinj and FLK NN3 (Olduvai Gorge, Tanzania). Palaeogeogr. Palaeoclimatol. Palaeoecol. 2017. [Google Scholar] [CrossRef]

- Gajski, D.; Solter, A.; Gašparović, M. Applications of macro photogrammetry in archaeology. In Proceedings of the XXIII ISPRS Congress, Prague, Czech Republic, 12–19 July 2016. [Google Scholar]

- Cachero, R.; Abello, C. Stereo-photometric techniques for scanning micrometer scale. Virtual Archaeol. Rev. 2015, 6, 72–76. [Google Scholar] [CrossRef]

- Reu, J.D.; Plets, G.; Verhoeven, G.; Smedt, P.D.; Bats, M.; Cherretté, B.; Maeyer, W.D.; Deconynck, J.; Herremans, D.; Laloo, P. Towards a three-dimensional cost-effective registration of the archaeological heritage. J. Archaeol. Sci. 2013, 40, 1108–1121. [Google Scholar] [CrossRef]

- Chandler, J.H.; Fryer, J.G. Recording aboriginal rock art using cheap digital cameras and digital photogrammetry. In Proceedings of the CIPA XX International Symposium, Torino, Italy, 26 September–1 October 2005. [Google Scholar]

- Koutsoudis, A.; Vidmar, B.; Ioannakis, G.; Arnaoutoglou, F.; Pavlidis, G.; Chamzas, C. Multi-image 3D reconstruction data evaluation. J. Cult. Herit. 2014, 15, 73–79. [Google Scholar] [CrossRef]

- Dhonju, H.; Xiao, W.; Sarhosis, V.; Mills, J.P.; Wilkinson, S.; Wang, Z.; Thapa, L.; Panday, U.S. Feasibility Study of Low-Cost Image-Based Heritage Documentation in Nepal. In International Archives of the Photogrammetry; Remote Sensing and Spatial Information Sciences: Göttingen, Germany, 2017; pp. 237–242. [Google Scholar]

- González-Aguilera, D.; Muñoz-Nieto, Á.; Rodríguez-Gonzálvez, P.; Menéndez, M. New tools for rock art modelling: Automated sensor integration in Pindal Cave. J. Archaeol. Sci. 2011, 38, 120–128. [Google Scholar] [CrossRef]

- El-Hakim, S.F.; Beraldin, J.A.; Picard, M.; Godin, G. Detailed 3D reconstruction of large-scale heritage sites with integrated techniques. IEEE Comput. Graph. Appl. 2004, 24, 21–29. [Google Scholar] [CrossRef] [PubMed]

- Bello, S.M.; Soligo, C. A new method for the quantitative analysis of cutmark micromorphology. J. Archaeol. Sci. 2008, 35, 1542–1552. [Google Scholar] [CrossRef]

- Bello, S.M. New Results from the Examination of Cut-Marks Using Three-Dimensional Imaging. In The Ancient Human Occupation of Britain; Ashton, N., Lewis, S.G., Stringer, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2011; pp. 249–262. ISBN 9780444535986. [Google Scholar]

- Boschin, F.; Crezzini, J. Morphometrical Analysis on Cut Marks Using a 3D Digital Microscope. Int. J. Osteoarch. 2012, 22, 549–562. [Google Scholar] [CrossRef]

- Archer, W.; Braun, D.R. Investigating the signature of aquatic resource use within Pleistocene hominin dietary adaptations. PLoS ONE 2013, 8, e69899. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Crezzini, J.; Boschin, F.; Wierer, U. Wild cats and cut marks: Exploitation of Felis silvestris in the Mesolithic of Galgenbühel/Dos de la Forca (South Tyrol, Italy). Q. Int. 2014, 330, 52–60. [Google Scholar] [CrossRef]

- Bonney, H. An investigation of the use of discriminant analysis for the classification of blade edge type from cut marks made by metal and bamboo blades. Am. J. Phys. Anthropol. 2014, 154, 575–584. [Google Scholar] [CrossRef] [PubMed]

- Maté-González, M.Á.; Yravedra, J.; González-Aguilera, D.; Palomeque-González, J.F.; Domínguez-Rodrigo, M. Micro-photogrammetric characterization of cut marks on bones. J. Archaeol. Sci. 2015, 62, 128–142. [Google Scholar] [CrossRef]

- Maté-González, M.Á.; Aramendi, J.; Yravedra, J.; Blasco, R.; Rosell, J.; González-Aguilera, D.; Domínguez-Rodrigo, M. Assessment of Statistical Agreement of Three Techniques for the Study of Cut Marks: 3D Digital Microscope, Laser Scanning Confocal Microscopy and Micro-Photogrammetry. J. Micro Technol. 2017. [Google Scholar] [CrossRef] [PubMed]

- Calvache, A.T.M.; García, J.L.P.; Colmenero, V.B.; Arenas, A.L. Estudio geométrico de piezas arqueológicas a partir de un modelo virtual 3D. Virtual Archaeol. Rev. 2011, 2, 109–113. [Google Scholar] [CrossRef]

- Kersten, T.P.; Przybilla, H.J.; Lindstaedt, M.; Tschirschwitz, F.; Misgaiski-Hass, M. Comparative Geometrical Investigations of Hand-Held Scanning Systems. Int. Soc. Photogram. Remote Sens. 2016. [Google Scholar] [CrossRef]

- Remondino, F. Heritage recording and 3D modeling with photogrammetry and 3D scanning. Remote Sens. 2011, 3, 1104–1138. [Google Scholar] [CrossRef] [Green Version]

- Allard, T.; Sitchon, M.; Sawatzky, R.; Hoppa, R. Use of hand-held laser scanning and 3D printing for creation of a museum exhibit. In Proceedings of the 6th International Symposium on Virtual Reality, Archaelogy and Cultural Heritage, Pisa, Italy, 8–11 November 2005. [Google Scholar]

- Park, H.K.; Chung, J.W.; Kho, H.S. Use of hand-held laser scanning in the assessment of craniometry. Forensic Sci. Int. 2006, 160, 200–206. [Google Scholar] [CrossRef] [PubMed]

- Munkelt, C.; Bräuer-Burchardt, C.; Kühmstedt, P.; Schmidt, I.; Notni, G. Cordless hand-held optical 3D sensor. Proc. SPIE 2007. [Google Scholar] [CrossRef]

- Cano, P.; Lamolda, F.; Torres, J.C.; del Mar Villafranca, M. Uso de escáner láser 3D para el registro del estado previo a la intervención de la Fuente de los Leones de La Alhambra. Virtual Archaeol. Rev. 2010, 1, 89–94. [Google Scholar] [CrossRef]

- Melero, F.J.; León, A.; Torres, J.C. Digitalización y reconstrucción de elementos cerámicos arqueológicos de torno. Virtual Archaeol. Rev. 2010, 1, 137–141. [Google Scholar] [CrossRef]

- Escarcena, J.C.; de Castro, E.M.; García, J.L.P.; Calvache, A.M.; del Castillo, T.F.; García, J.D.; Cámara, M.U.; Castillo, J.C. Integration of photogrammetric and terrestrial laser scanning techniques for heritage documentation. Virtual Archaeol. Rev. 2011, 2, 53–57. [Google Scholar] [CrossRef]

- Kühmstedt, P.; Bräuer-Burchardt, C.; Schmidt, I.; Heinze, M.; Breitbarth, A.; Notni, G. Hand-held 3D Sensor for Documentation of Fossil and Archaeological Excavations. 2011. Avaliable online: http://olymp.inf-cv.uni-jena.de:6680/pdf/Kuhmstedt11:HHT.pdf (accessed on 22 August 2017).

- Boyd, C.P.; Marín, F.M.; Goodmaster, C.; Johnson, A.; Castaneda, A.; Dwyer, B. Digital Documentation and the Archaeology of the Lower Pecos Canyonlands. Virtual Archaeol. Rev. 2012, 3, 98–103. [Google Scholar] [CrossRef]

- Komar, D.A.; Davy-Jow, S.; Decker, S.J. The Use of a 3-D Laser Scanner to Document Ephemeral Evidence at Crime Scenes and Postmortem Examinations. J. Forensic Sci. 2012, 57, 188–191. [Google Scholar] [CrossRef] [PubMed]

- Neamtu, C.; Popescu, S.; Popescu, D.; Mateescu, R. Using reverse engineering in archaeology: Ceramic pottery reconstruction. J. Autom. Mobile Robot. Intell. Syst. 2012, 6, 55–59. [Google Scholar]

- Comes, R.; Buna, Z.; Badiu, I. Creation and preservation of digital cultural heritage. J. Am. Heart Assoc. 2014, 1, 10–15. [Google Scholar]

- Manferdini, A.M.; Gasperoni, S.; Guidi, F.; Marchesi, M. Unveiling Damnatio Memoriae. The use of 3D digital technologies for the virtual reconstruction of archaeological finds and artefacts. Virtual Archaeol. Rev. 2016, 7, 9–17. [Google Scholar] [CrossRef]

- Rodríguez-Martín, M.; Rodríguez-Gonzálvez, P.; González-Aguilera, D.; Fernández-Hernández, J. Feasibility Study of a Structured Light System Applied to Welding Inspection Based on Articulated Coordinate Measure Machine Data. IEEE Sens. J. 2017, 17, 4217–4224. [Google Scholar] [CrossRef]

- Santoso, F.; Garratt, M.A.; Pickering, M.R.; Asikuzzaman, M. 3D Mapping for Visualization of Rigid Structures: A Review and Comparative Study. IEEE Sens. J. 2016, 16, 1484–1507. [Google Scholar] [CrossRef]

- Blais, F.; Rioux, M.; Beraldin, J.A. Practical considerations for a design of a high precision 3D laser scanner system. Proc. SPIE 1988, 959, 225–246. [Google Scholar]

- Stumpfel, J.; Tchou, C.; Yun, N.; Martinez, P.; Hawkins, T.; Jones, A.; Debevec, P.E. Digital Reunification of the Parthenon and its Sculptures. In Proceedings of the 4th International conference on Virtual Reality, Archaeology and Intelligent Cultural Heritage, Brighton, UK, 5–7 November 2003; Volume 1, pp. 41–50. [Google Scholar]

- Akca, D.; Remondino, F.; NovÃ, D.; Hanusch, T.; Schrotter, G. Recording and modeling of cultural heritage objects with coded structured light projection systems. In Proceedings of the 2nd International Conference on Remote Sensing in Archaeology, Rome, Italy, 4–7 December 2006; pp. 375–382. [Google Scholar]

- McPherron, S.P.; Gernat, T.; Hublin, J.J. Structured light scanning for high-resolution documentation of in situ archaeological finds. J. Archaeol. Sci. 2009, 36, 19–24. [Google Scholar] [CrossRef]

- Niven, L.; Steele, T.E.; Finke, H.; Gernat, T.; Hublin, J.J. Virtual skeletons: Using a structured light scanner to create a 3D faunal comparative collection. J. Archaeol. Sci. 2009, 36, 2018–2023. [Google Scholar] [CrossRef]

- Georgopoulos, A.; Ioannidis, C.; Valanis, A. Assessing the performance of a structured light scanner. ISPRS Int. Arch. Photogram. Remote Sen. Spat. Inf. Sci. 2010, 38, 250–255. [Google Scholar]

- Slizewski, A.; Friess, M.; Semal, P. Surface scanning of anthropological specimens: Nominal-actual comparison with low cost laser scanner and high end fringe light projection surface scanning systems. Quartär 2010, 57, 179–187. [Google Scholar]

- Ahmed, N.; Carter, M.; Ferris, N. Sustainable archaeology through progressive assembly 3D digitization. World Archaeol. 2014, 46, 137–154. [Google Scholar] [CrossRef]

- Neiß, M.; Sholts, S.B.; Wärmländer, S.K. New applications of 3D modeling in artefact analysis: Three case studies of Viking Age brooches. Archaeol. Anthropol. Sci. 2016, 8, 651–662. [Google Scholar] [CrossRef]

- Errickson, D.; Grueso, I.; Griffith, S.J.; Setchell, J.M.; Thompson, T.J.U.; Thompson, C.E.L.; Gowland, R.L. Towards a Best Practice for the Use of Active Non-contact Surface Scanning to Record Human Skeletal Remains from Archaeological Contexts. Inter. J. Osteoarchaeol. 2017. [Google Scholar] [CrossRef]

- Kuzminsky, S.C.; Tung, T.A.; Hubbe, M.; Villaseñor-Marchal, A. The application of 3D geometric morphometrics and laser surface scanning to investigate the standardization of cranial vault modification in the Andes. J. Archaeol. Sci. Rep. 2017, 10, 507–513. [Google Scholar] [CrossRef]

- Gonzalez-Jorge, H.; Rodríguez-Gonzálvez, P.; Martínez-Sánchez, J.; González-Aguilera, D.; Arias, P.; Gesto, M.; Díaz-Vilariño, L. Metrological comparison between Kinect I and Kinect II sensors. Measurement 2015, 70, 21–26. [Google Scholar] [CrossRef]

- Kersten, T.P.; Omelanowsky, D.; Lindstaedt, M. Investigations of Low-Cost Systems for 3D Reconstruction of Small Objects. In Euro-Mediterranean Conference; Springer International Publishing: Cham, Switzerland, 2016; pp. 521–532. [Google Scholar]

- Pomaska, G. Monitoring the deterioration of stone at Mindener Museum’s Lapidarium. ISPRS Int. Arch. Photogram. Remote Sens. Spatial Inf. Sci. 2013, XL-5/W2, 495–500. [Google Scholar] [CrossRef]

- Yravedra, J.; Maté-González, M.Á.; Palomeque-González, J.F.; Aramendi, J.; Estaca-Gómez, V.; San Juan Blazquez, M.; García Vargas, E.; Organista, E.; González-Aguilera, D.; Arriaza, M.C.; et al. A new approach to raw material use in the exploitation of animal carcasses at BK (Upper Bed II, Olduvai Gorge, Tanzania): A micro-photogrammetric and geometric morphometric analysis of cut marks. Boreas 2017. [Google Scholar] [CrossRef]

- Fraser, C. Multiple focal setting self-calibration of close-range metric cameras. Photogram. Eng. Remote Sens. 1980, 46, 1161–1171. [Google Scholar]

- González-Aguilera, D.; López-Fernández, L.; Rodríguez-González, P.; Guerrero-Sevilla, D.; Hernández-López, D.; Menna, F.; Nocerino, E.; Toschi, I.; Remondino, F.; Ballabeni, A.; et al. Development of an All-Purpose Free Photogrammetric Tool; ISPRS International Archives: Prague, Czech Republic, 2016. [Google Scholar]

- González-Aguilera, D.; López-Fernández, L.; Rodríguez-González, P.; Guerrero-Sevilla, D.; Hernández-López, D.; Menna, F.; Nocerino, E.; Toschi, I.; Remondino, F.; Ballabeni, A.; et al. InteGRAted Photogrammetric Suite, GRAPHOS. In Proceedings of the Congress: CATCON7-ISPRS, Prague, Czech Republic, 12–19 July 2016. [Google Scholar]

- Courtenay, L.; Yravedra, J.; Mate-González, M.Á.; Aramendi, J.; González-Aguilera, D. 3D Analysis of Cut Marks Using a New Geometric Morphometric Methodological Approach. Archaeol. Anthropol. Sci. 2017. Accepted. [Google Scholar]

- O’Higgins, P.; Johnson, D. The Quantitative Description and Comparison of Biological Forms. Critic. Rev. Anatom. Sci. 1988, 1, 149–170. [Google Scholar]

- Bookstein, F. Types of Landmarks, Morphometric Tools for Landmark Data: Geometry and Biology; Cambridge University Press: New York, NY, USA, 1991; pp. 63–64. [Google Scholar]

- Hall, B. Descent with Modification: The unity underlying homology and homoplasy as seen through an analysis of development and evolution. Biol. Rev. 2003, 78, 409–433. [Google Scholar] [CrossRef] [PubMed]

- Klingenberg, C. Novelty and “Homology-Free” Morphometrics: What’s in a Name? Evol. Biol. 2008, 35, 186–190. [Google Scholar] [CrossRef]

- Richtsmeier, J.T.; Deleon, V.B.; Lele, S.R. The promise of geometric morphometrics. Am. J. Phys. Anthropol. 2002, 45, 63–91. [Google Scholar] [CrossRef]

- Rohlf, F.J. Shape Statistics: Procrustes Superimpositions and Tangent Spaces. J. Classif. 1999, 16, 197–223. [Google Scholar] [CrossRef]

- Slice, D.E. Landmark Coordinates Aligned by Procrustes Analysis Do Not Lie in Kendall’s Shape Space. Syst. Biol. 2001, 50, 141–149. [Google Scholar] [CrossRef] [PubMed]

- Klingenberg, H. MorphoJ: An integrated software package for geometric morphometrics. Mol. Ecol. Resour. 2011, 11, 353–357. [Google Scholar] [CrossRef] [PubMed]

- Bookstein, F. Principal Warps: Thin-Plate Spline and the Decomposition of Deformations. Trans. Pattern A Mach. Intell. 1989, 11, 567–585. [Google Scholar] [CrossRef]

- Core-Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2015; Available online: https://www.Rproject.org/ (accessed on 25 May 2017).

- Timm, N.H. Applied Multivariate Analysis; Springer: New York, NY, USA, 2002. [Google Scholar]

| Technical | Measuring Procedure | Classification | System | Portability | Speed (min) | Range | Usage Way | Resolution | Cost [EUR] |

|---|---|---|---|---|---|---|---|---|---|

| Microscopy | 3D digital microscope | Active sensor | KH-8700 | low | >1 | 1–10 mm | Automatic | 0.15–0.01 μm | <100.000 |

| confocal laser microscope | Active sensor | Olympus LEXT OLS3000 | low | >1 | 1–20 mm | Automatic | 0.12–0.01 μm | <100.000 | |

| Laser scanners | Triangulation-based | Active sensor | ShapeGrabber | medium | >1 | 21–120 cm | Automatic | 0.02 mm | <30.000 |

| Structured Light | Active sensor | Creaform EXAscan | high | >1 | 0.17–0.40 m | Automatic | 0.05 mm | <20.000 | |

| Structured Light | Active sensor | David Scanner SLS2 | medium | >1 | 0.15–5.00 m | Semiautomatic | 0.02 mm | 3.000 | |

| Time-of-flight | Active sensor | Google Tango | high | >1 | 0.50–4.00 m | Automatic | 8 mm | 450 | |

| Photogrammetry | Micro-photogrammetry | Passive sensor | Reflex + macro objective | high | ≅25 | 10–50 cm | Semiautomatic | 0.02 mm | 1000 |

| Canon EOS 700D | |

|---|---|

| Type | CMOS |

| Sensor size | 22.3 × 14.9 mm |

| Pixel size | 4.3 μm |

| Image size | 5184 × 3456 pixels |

| Total pixels | 18.0 MP |

| Focal length | 60 mm |

| Focused distance to object | 100–120 mm |

| DAVID Structured-Light Scanner SLS-2 | |

|---|---|

| Workpiece size | 16 × 500 mm |

| Resolution | Up to 0.1% of scan size (down to 0.016 mm) |

| Scanning time | One single scan within a few seconds |

| Mesh density | Up to 12,000,000 vertices per scan |

| Sample | F | p-Value | |

|---|---|---|---|

| MANOVA in shape space | SLS-2 vs. M-PG | 0.4904 | 0.7812 |

| MANOVA in form space | SLS-2 vs. M-PG | 1.33 | 0.2739 |

| ANOVA in shape space | SLS-2 vs. M-PG | 0.5242 | 0.718 |

| Welch t-test in form space | SLS-2 vs. M-PG | 3.345 | 0.998 |

| MANOVA in shape space | CM on LB vs. CM on FB | 1.414 | 0.2395 |

| MANOVA in form space | CM on LB vs. CM on FB | 0.7747 | 0.536 |

| Welch t-test in shape space | CM on LB vs. CM on FB | 0.9202 | 0.4552 |

| Welch t-test in form space | CM on LB vs. CM on FB | 1.076 | 0.989 |

| CM a on LB b with SLS-2 | CM a on LB b with M-PG | CM a on LB b | CM a on FB c | Total | |

|---|---|---|---|---|---|

| CM a on LB b with SLS-2 | 13 (61.9%) | 8 (38.1%) | 21 | ||

| CM a on LB b with M-PG | 8 (38.1%) | 13 (61.9%) | 21 | ||

| CM a on LB b | 14 (66.7%) | 7 (33.3%) | 21 | ||

| CM a on FBc | 7 (26.9%) | 19 (73.1%) | 26 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maté-González, M.Á.; Aramendi, J.; González-Aguilera, D.; Yravedra, J. Statistical Comparison between Low-Cost Methods for 3D Characterization of Cut-Marks on Bones. Remote Sens. 2017, 9, 873. https://doi.org/10.3390/rs9090873

Maté-González MÁ, Aramendi J, González-Aguilera D, Yravedra J. Statistical Comparison between Low-Cost Methods for 3D Characterization of Cut-Marks on Bones. Remote Sensing. 2017; 9(9):873. https://doi.org/10.3390/rs9090873

Chicago/Turabian StyleMaté-González, Miguel Ángel, Julia Aramendi, Diego González-Aguilera, and José Yravedra. 2017. "Statistical Comparison between Low-Cost Methods for 3D Characterization of Cut-Marks on Bones" Remote Sensing 9, no. 9: 873. https://doi.org/10.3390/rs9090873