Milling Positive Master for Polydimethylsiloxane Microfluidic Devices: The Microfabrication and Roughness Issues

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Protocol of the Fabrication of PDMS Microchannel Device through Milling Positive Master and Molding

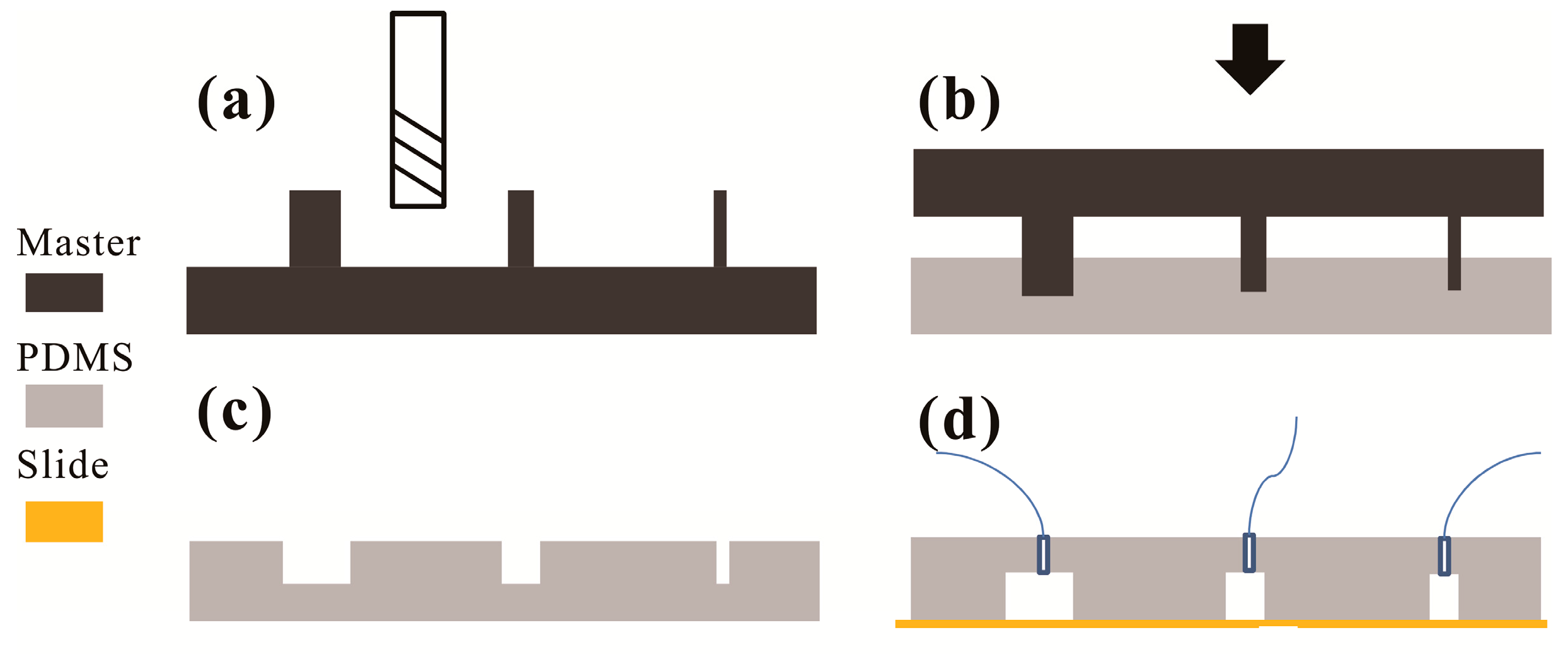

- (i)

- The geometrical pattern of the microchannels is designed using computer-aided design software such as Autodesk (AutoCAD 2017, Autodesk, Inc., San Rafael, CA, USA).

- (ii)

- The convex of the pattern is milled on a PMMA sheet using a CNC mini-engraving machine (custom-made based on Tonsen CNC (Dongda Electrical Control Company, Jiangyin, China) and see also below) with an end-mill (ϕ = 0.4 mm, double-edged, tungsten steel) for the positive master (Figure 1a), which is to be used in the subsequent steps.

- (iii)

- The block of the above positive master is cleaned with mild detergents, and washed in pure water for 15 min with ultrasonic, and then flushed dry.

- (iv)

- Liquid PDMS mixture (prepolymer: curing agent = 10:1 w/w) is poured into a dish to the predefined depth, then degassed for ~10 min, and pre-cured for 30 min at 55 °C in an oven. Then, on the top surface of the pre-cured PDMS the cleaned positive master block is covered with the convex pattern top-down, and the whole dish is placed in the oven for curing again 90 min at 55 °C (Figure 1b).

- (v)

- After curing, the block of the positive master is removed, leaving the solidified PDMS block with the negative pattern (Figure 1c). This PDMS block is then bonded onto a glass slide via O2 plasma treatment (O2 pressure 0.1 MPa, power 25 W, processing time 10–20 s, Diener Prep2, Diener electronic GmbH, Ebhausen, Germany) (Figure 1d).

3. Results and Discussions

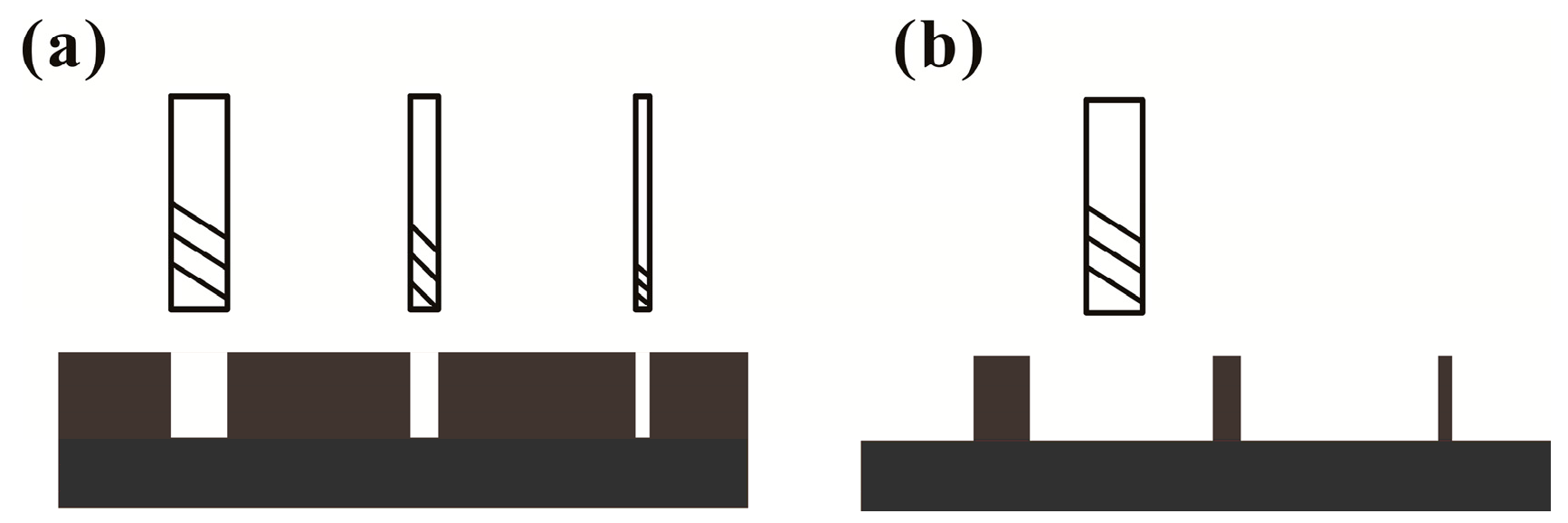

3.1. 2D Positive Master Fabrication

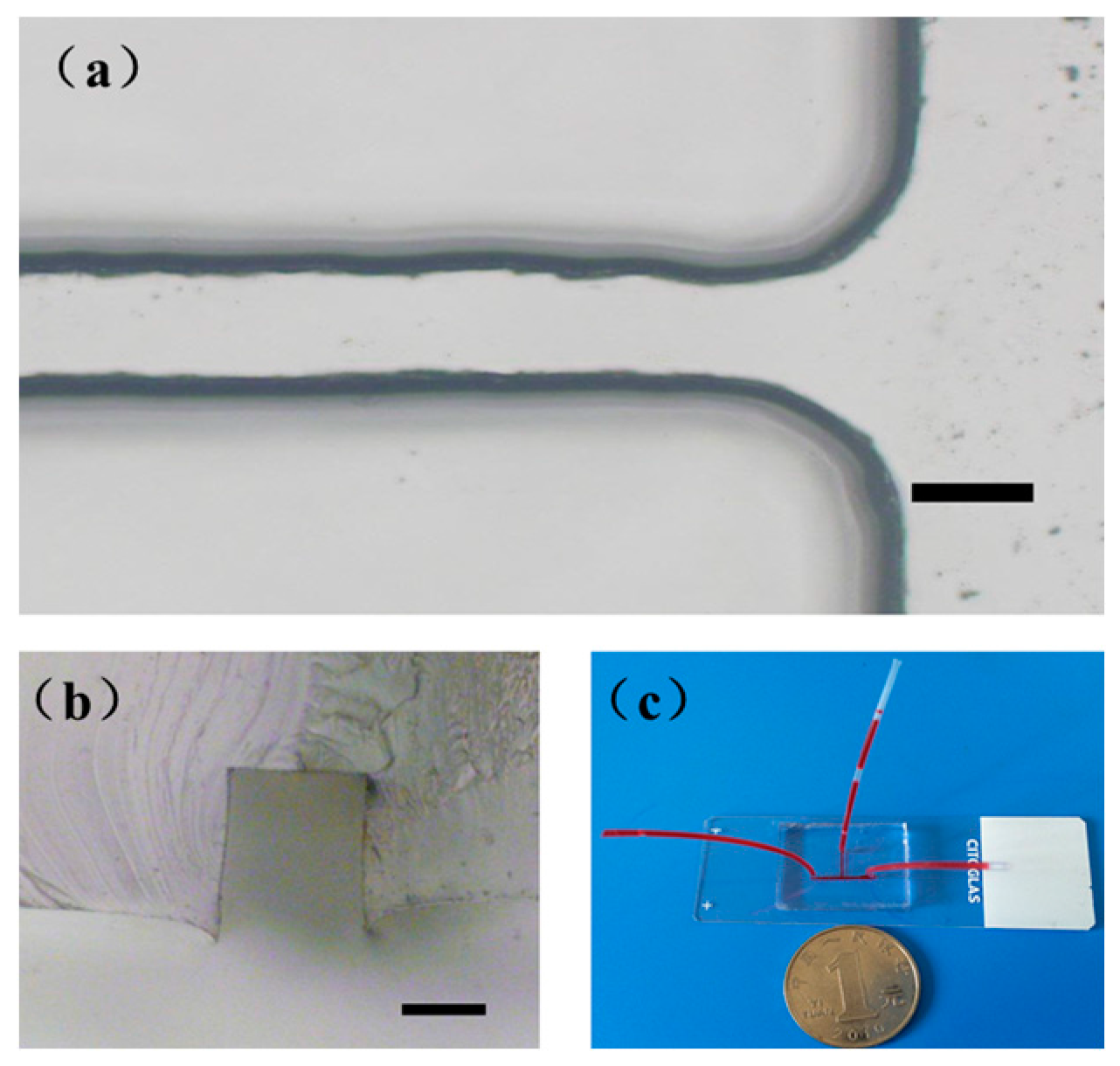

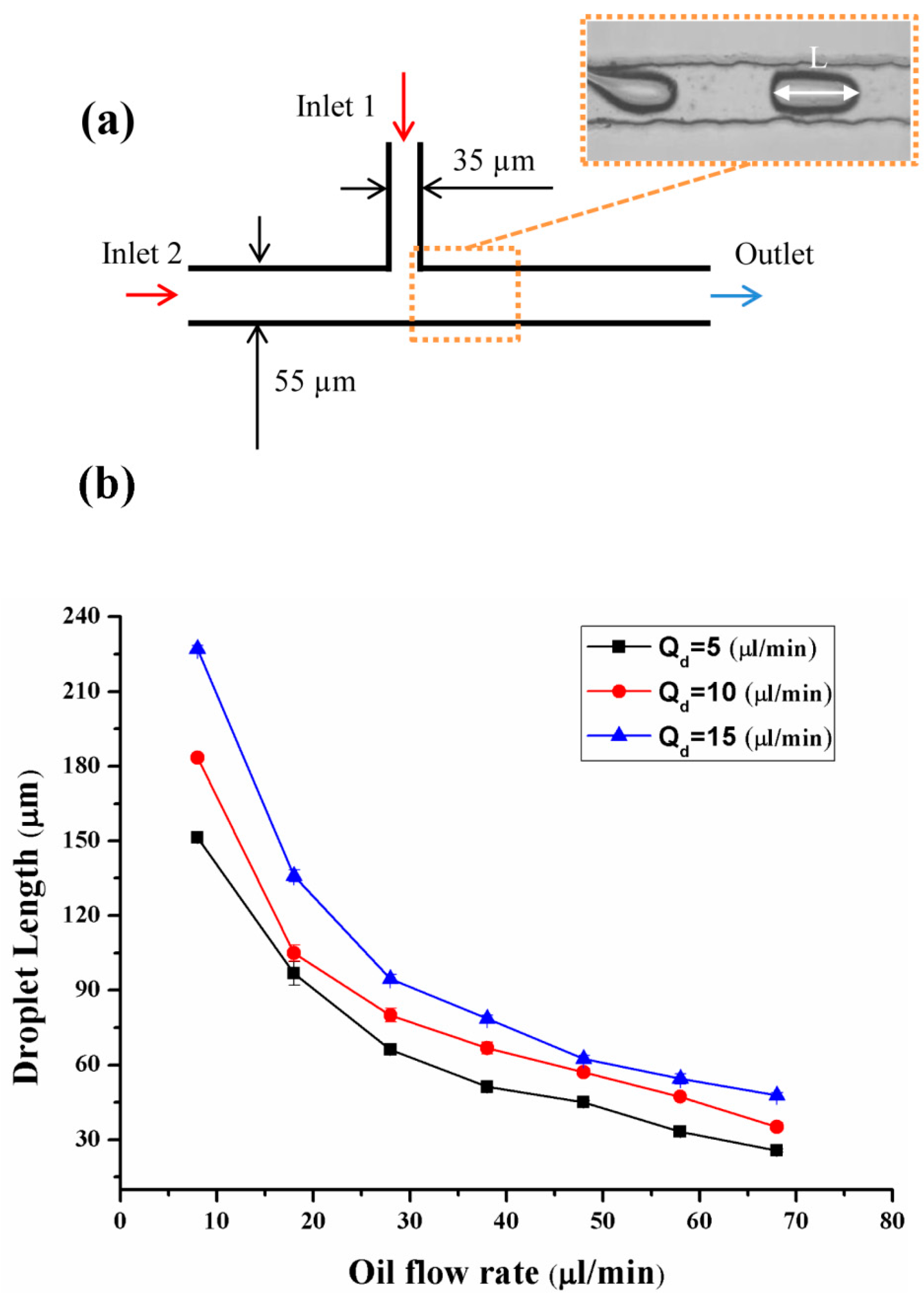

3.2. Measurement of Microchannels

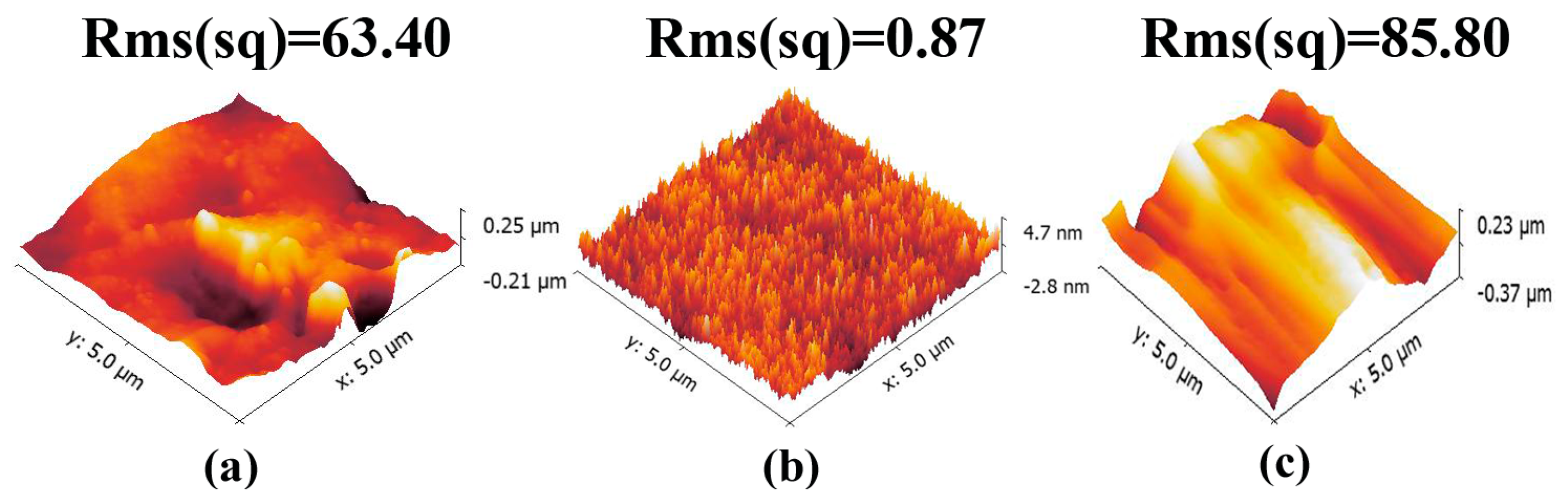

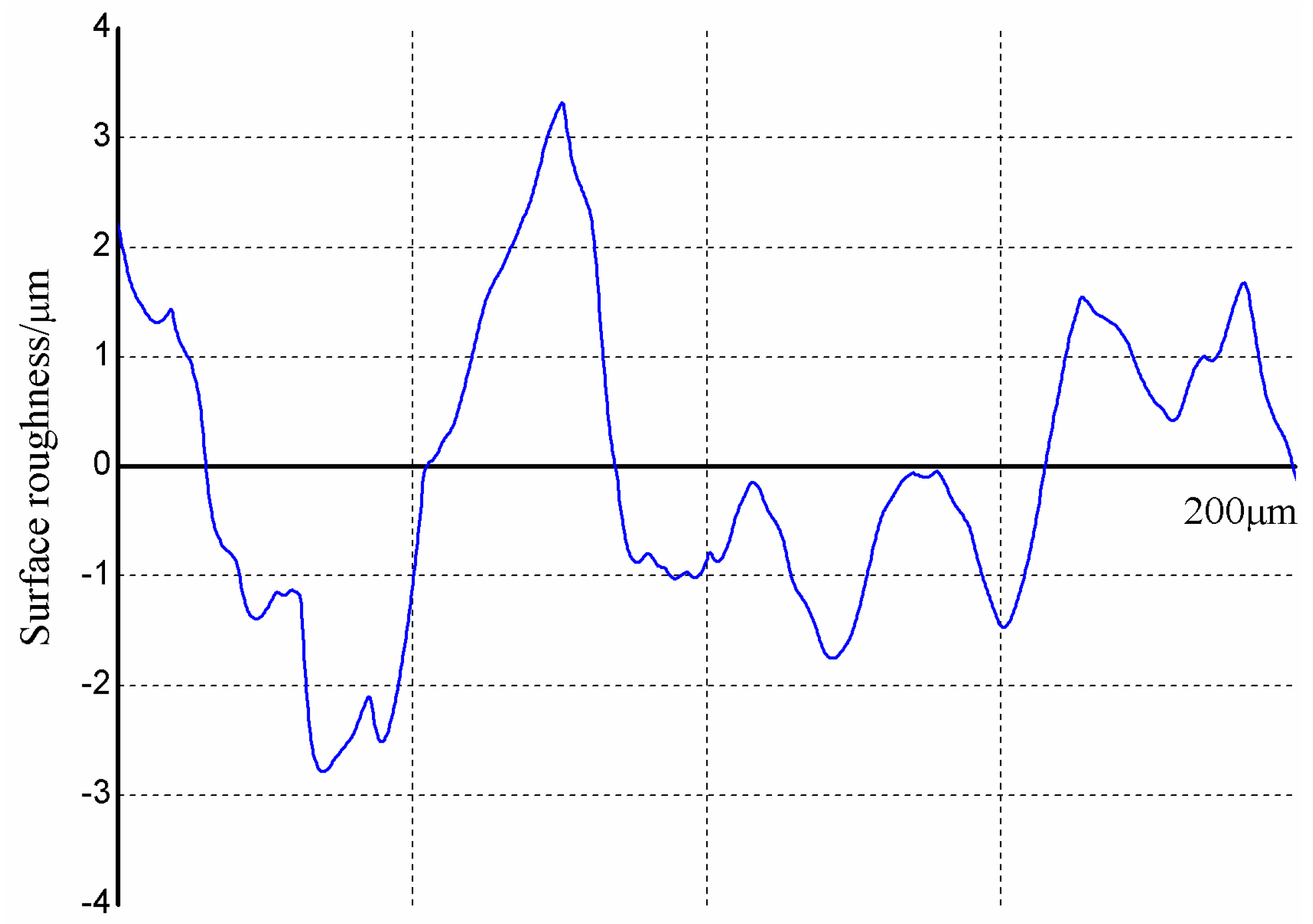

3.3. Atomic Force Microscopy (AFM) and Profilometer Images of Surface Roughness Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Whitesides, G.M. The origins and the future of microfluidics. Nature 2006, 442, 368–373. [Google Scholar] [CrossRef] [PubMed]

- Sackmann, E.K.; Fulton, A.L.; Beebe, D.J. The present and future role of microfluidics in biomedical research. Nature 2014, 507, 181–189. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.N.; Whitesides, G.M. Soft lithography. Angew. Chem. Int. Ed. 1998, 28, 153–184. [Google Scholar]

- Tomazelli Coltro, W.K.; de Jesus, D.P.; Fracassi da Silva, J.A.; do Lago, C.L.; Carrilho, E. Toner and paper-based fabrication techniques for microfluidic applications. Electrophoresis 2010, 31, 2487–2498. [Google Scholar] [CrossRef] [PubMed]

- Tan, A.M.; Rodgers, K.; Murrihy, J.P.; O’Mathuna, C.; Glennon, J.D. Rapid fabrication of microfluidic devices in poly(dimethylsiloxane) by photocopying. Lab Chip 2001, 1, 7–9. [Google Scholar] [CrossRef] [PubMed]

- Branham, M.L.; Tran-Son-Tay, R.; Schoonover, C.; Davis, P.S.; Allen, S.D.; Shyy, W. Rapid prototyping of micropatterned substrates using conventional laser printers. J. Mater. Res. 2002, 17, 1559–1562. [Google Scholar] [CrossRef]

- Do Lago, C.L.; da Silva, H.D.T.; Neves, C.A.; Brito-Neto, J.G.A.; da Silva, J.A.F. A dry process for production of microfluidic devices based on the lamination of laser-printed polyester films. Anal. Chem. 2003, 75, 3853–3858. [Google Scholar] [CrossRef] [PubMed]

- Coltro, W.K.T.; da Silva, J.A.F.; da Silva, H.D.T.; Richter, E.M.; Furlan, R.; Angnes, L.; do Lago, C.L.; Mazo, L.H.; Carrilho, E. Electrophoresis microchip fabricated by a direct-printing process with end-channel amperometric detection. Electrophoresis 2004, 25, 3832–3839. [Google Scholar] [CrossRef] [PubMed]

- Bao, N.; Zhang, Q.; Xu, J.J.; Chen, H.Y. Fabrication of poly(dimethylsiloxane) microfluidic system based on masters directly printed with an office laser printer. J. Chromatogr. A 2005, 1089, 270–275. [Google Scholar] [CrossRef] [PubMed]

- Liu, A.L.; He, F.Y.; Wang, K.; Zhou, T.; Lu, Y.; Xia, X.H. Rapid method for design and fabrication of passive micromixers in microfluidic devices using a direct-printing process. Lab Chip 2005, 5, 974–978. [Google Scholar] [CrossRef] [PubMed]

- Vullev, V.I.; Wan, J.D.; Heinrich, V.; Landsman, P.; Bower, P.E.; Xia, B.; Millare, B.; Jones, G. Nonlithographic fabrication of microfluidic devices. J. Am. Chem. Soc. 2006, 128, 16062–16072. [Google Scholar] [CrossRef] [PubMed]

- Kaigala, G.V.; Ho, S.; Penterman, R.; Backhouse, C.J. Rapid prototyping of microfluidic devices with a wax printer. Lab Chip 2007, 7, 384–387. [Google Scholar] [CrossRef] [PubMed]

- Abdelgawad, M.; Watson, M.W.L.; Young, E.W.K.; Mudrik, J.M.; Ungrin, M.D.; Wheeler, A.R. Soft lithography: Masters on demand. Lab Chip 2008, 8, 1379–1385. [Google Scholar] [CrossRef] [PubMed]

- Lobo Júnior, E.O.; Duarte, L.C.; Braga, L.E.P.; Gobbi, A.L.; de Jesus, D.P.; Coltro, W.K.T. High fidelity prototyping of PDMS electrophoresis microchips using laser-printed masters. Microsyst. Technol. 2015, 21, 1345–1352. [Google Scholar] [CrossRef]

- Do Lago, C.L.; Neves, C.A.; de Jesus, D.P.; da Silva, H.D.T.; Brito-Neto, J.G.A.; da Silva, J.A.F. Microfluidic devices obtained by thermal toner transferring on glass substrate. Electrophoresis 2004, 25, 3825–3831. [Google Scholar] [CrossRef] [PubMed]

- Coltro, W.K.T.; Piccin, E.; da Silva, J.A.F.; do Lago, C.L.; Carrilho, E. A toner-mediated lithographic technology for rapid prototyping of glass microchannels. Lab Chip 2007, 7, 931–934. [Google Scholar] [CrossRef] [PubMed]

- Grimes, A.; Breslauer, D.N.; Long, M.; Pegan, J.; Lee, L.P.; Khine, M. Shrinky-Dink microfluidics: Rapid generation of deep and rounded patterns. Lab Chip 2008, 8, 170–172. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.Z.; Li, L.H.; Li, F.Y.; Zhou, H.H.; Song, Y.L. Inkjet print microchannels based on a liquid template. Lab Chip 2015, 15, 1759–1764. [Google Scholar] [CrossRef] [PubMed]

- Guckenberger, D.J.; de Groot, T.E.; Wan, A.M.D.; Beebe, D.J.; Young, E.W.K. Micromilling: A method for ultra-rapid prototyping of plastic microfluidic devices. Lab Chip 2015, 15, 2364–2378. [Google Scholar] [CrossRef] [PubMed]

- Aurich, J.C.; Reichenbach, I.G.; Schuler, G.M. Manufacture and application of ultra-small micro end mills. Cirp Ann. Manuf. Technol. 2012, 61, 83–86. [Google Scholar] [CrossRef]

- Berthier, E.; Guckenberger, D.J.; Cavnar, P.; Huttenlocher, A.; Keller, N.P.; Beebe, D.J. Kit-On-A-Lid-Assays for accessible self-contained cell assays. Lab Chip 2013, 13, 424–431. [Google Scholar] [CrossRef] [PubMed]

- Guckenberger, D.J.; Berthier, E.; Beebe, D.J. High-Density Self-Contained Microfluidic KOALA Kits for Use by Everyone. J. Lab. Autom. 2015, 20, 146–153. [Google Scholar] [CrossRef] [PubMed]

- Casavant, B.P.; Guckenberger, D.J.; Berry, S.M.; Tokar, J.T.; Lang, J.M.; Beebe, D.J. The VerIFAST: An integrated method for cell isolation and extracellular/intracellular staining. Lab Chip 2013, 13, 391–396. [Google Scholar] [CrossRef] [PubMed]

- Strotman, L.; O’Connell, R.; Casavant, B.P.; Berry, S.M.; Sperger, J.M.; Lang, J.M.; Beebe, D.J. Selective Nucleic Acid Removal via Exclusion (SNARE): Capturing mRNA and DNA from a Single Sample. Anal. Chem. 2013, 85, 9764–9770. [Google Scholar] [CrossRef] [PubMed]

- Bischel, L.L.; Mader, B.R.; Green, J.M.; Huttenlocher, A.; Beebe, D.J. Zebrafish Entrapment by Restriction Array (ZEBRA) device: A low-cost, agarose-free zebrafish mounting technique for automated imaging. Lab Chip 2013, 13, 1732–1736. [Google Scholar] [CrossRef] [PubMed]

- Carney, C.M.; Muszynski, J.L.; Strotman, L.N.; Lewis, S.R.; O’Connell, R.L.; Beebe, D.J.; Theberge, A.B.; Jorgensen, J.S. Cellular Microenvironment Dictates Androgen Production by Murine Fetal Leydig Cells in Primary Culture. Biol. Reprod. 2014, 91, 85. [Google Scholar] [CrossRef] [PubMed]

- Wilson, M.E.; Kota, N.; Kim, Y.; Wang, Y.D.; Stolz, D.B.; LeDuc, P.R.; Ozdoganlar, O.B. Fabrication of circular microfluidic channels by combining mechanical micromilling and soft lithography. Lab Chip 2011, 11, 1550–1555. [Google Scholar] [CrossRef] [PubMed]

- Okagbare, P.I.; Emory, J.M.; Datta, P.; Goettert, J.; Soper, S.A. Fabrication of a cyclic olefin copolymer planar waveguide embedded in a multi-channel poly(methyl methacrylate) fluidic chip for evanescence excitation. Lab Chip 2010, 10, 66–73. [Google Scholar] [CrossRef] [PubMed]

- Carugo, D.; Lee, J.Y.; Pora, A.; Browning, R.J.; Capretto, L.; Nastruzzi, C.; Stride, E. Facile and cost-effective production of microscale PDMS architectures using a combined micromilling-replica moulding (μMi-REM) technique. Biomed. Microdevices 2016, 18, 4. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.W.; Lin, C.C.; Hwang, S.M.; Chang, Y.J.; Lee, G.B. A microfluidic device for chemical and mechanical stimulation of mesenchymal stem cells. Microfluid. Nanofluid. 2011, 11, 545–556. [Google Scholar] [CrossRef]

- Singhal, J.; Pinho, D.; Lopes, R.; Sousa, P.C.; Garcia, V.; Schütte, H.; Lima, R.; Gassmann, S. Blood Flow Visualization and Measurements in Microfluidic Devices Fabricated by a Micromilling Technique. Micro Nanosyst. 2015, 7, 148–153. [Google Scholar] [CrossRef]

- Gitlin, L.; Schulze, P.; Belder, D. Rapid replication of master structures by double casting with PDMS. Lab Chip 2009, 9, 3000–3002. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.C.; Pan, C.W.; Lee, W.C.; Li, K.M. An experimental study of micromilling parameters to manufacture microchannels on a PMMA substrate. Int. J. Adv. Manuf. Technol. 2014, 71, 1623–1630. [Google Scholar] [CrossRef]

- Ogilvie, I.R.G.; Sieben, V.J.; Floquet, C.F.A.; Zmijan, R.; Mowlem, M.C.; Morgan, H. Reduction of surface roughness for optical quality microfluidic devices in PMMA and COC. J. Micromech. Microeng. 2010, 20, 065016. [Google Scholar] [CrossRef]

| Axis Travel | Parameter |

|---|---|

| X-, Y-, and Z-axes travel (mm) | 180 × 220 × 30 |

| Table working area (mm) | 270 × 350 |

| Table weight (kg) | 17 |

| Feed per tooth (fz) | 0.04 |

| Spindle motor (kw) | 0.2 |

| Spindle speed (rpm) | 0–2000 |

| Cutting feed rate (mm/min) | 0–3000 |

| Position precision (mm) | 0.05 |

| Position Repeatability (mm) | 0.02 |

| Control | TS-2518C |

| Lubrication | No use |

| Diameter of Mills (in mm) | Minimum Width (in mm) | Reference |

|---|---|---|

| ~1 | ~1 | [27] |

| 0.1 | ~0.1 | [29] |

| 0.03 | ~0.03 | [31] |

| 0.4 | ~0.03 | This work |

| Types of Master | End Mill | Replica Time | Roughness Surface | Microstructure | Ref. |

|---|---|---|---|---|---|

| Negative | Several | Twice | Side and bottom | Dependent on mill size | [29] |

| Positive | Only one | Once | Side | Independent on mill size (except cross-junction) | This work |

| Types of Master | Master Fabrication | PDMS Moulding | Ref. |

|---|---|---|---|

| Negative | ~100 min | Over night | [29] |

| Positive | ~30 min | 120 min | This work |

| Positive Master | PDMS | PDMS after Bonding |

|---|---|---|

| Width (µm) | ||

| 105.6 ± 5.2 | 107.3 ± 7.6 | 95.5 ± 8.5 |

| Depth (µm) | ||

| - | 55.2 ± 3.8 | 60.3 ± 5.8 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Chen, D.; Wang, X.; Jiang, J. Milling Positive Master for Polydimethylsiloxane Microfluidic Devices: The Microfabrication and Roughness Issues. Micromachines 2017, 8, 287. https://doi.org/10.3390/mi8100287

Zhou Z, Chen D, Wang X, Jiang J. Milling Positive Master for Polydimethylsiloxane Microfluidic Devices: The Microfabrication and Roughness Issues. Micromachines. 2017; 8(10):287. https://doi.org/10.3390/mi8100287

Chicago/Turabian StyleZhou, Zhizhi, Dong Chen, Xiang Wang, and Jiahuan Jiang. 2017. "Milling Positive Master for Polydimethylsiloxane Microfluidic Devices: The Microfabrication and Roughness Issues" Micromachines 8, no. 10: 287. https://doi.org/10.3390/mi8100287