Two-Directional Tuning of Distributed Feedback Film Dye Laser Devices

Abstract

:1. Introduction

2. Materials and Methods

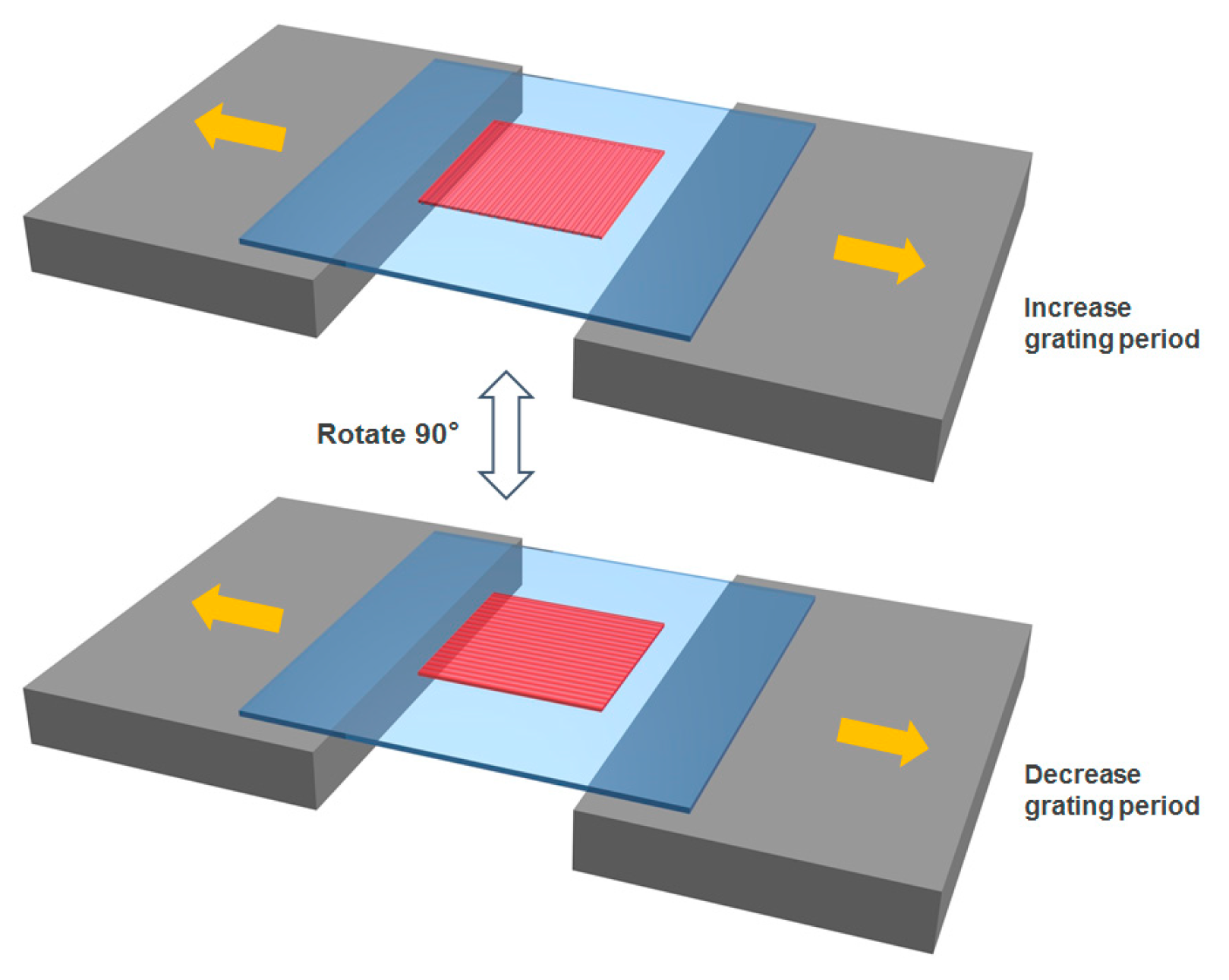

2.1. Device Structure

2.2. Fabrication

3. Results and Discussion

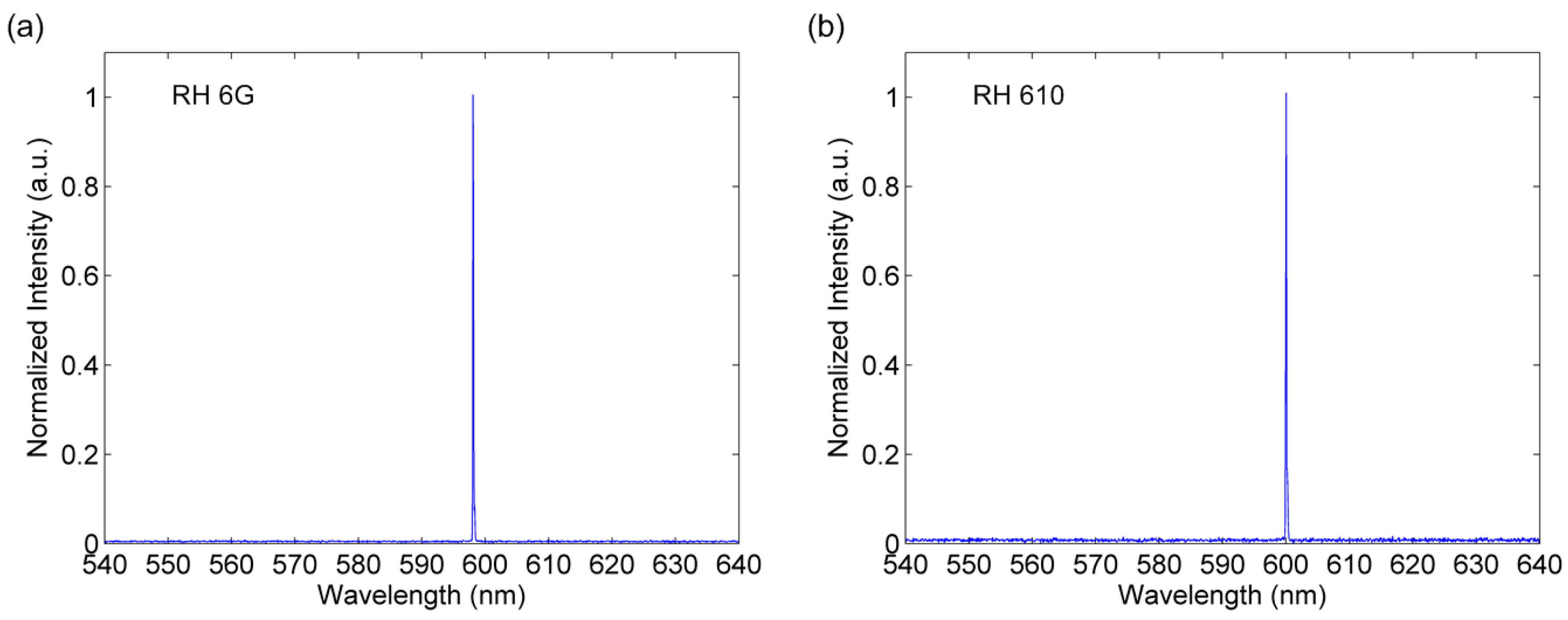

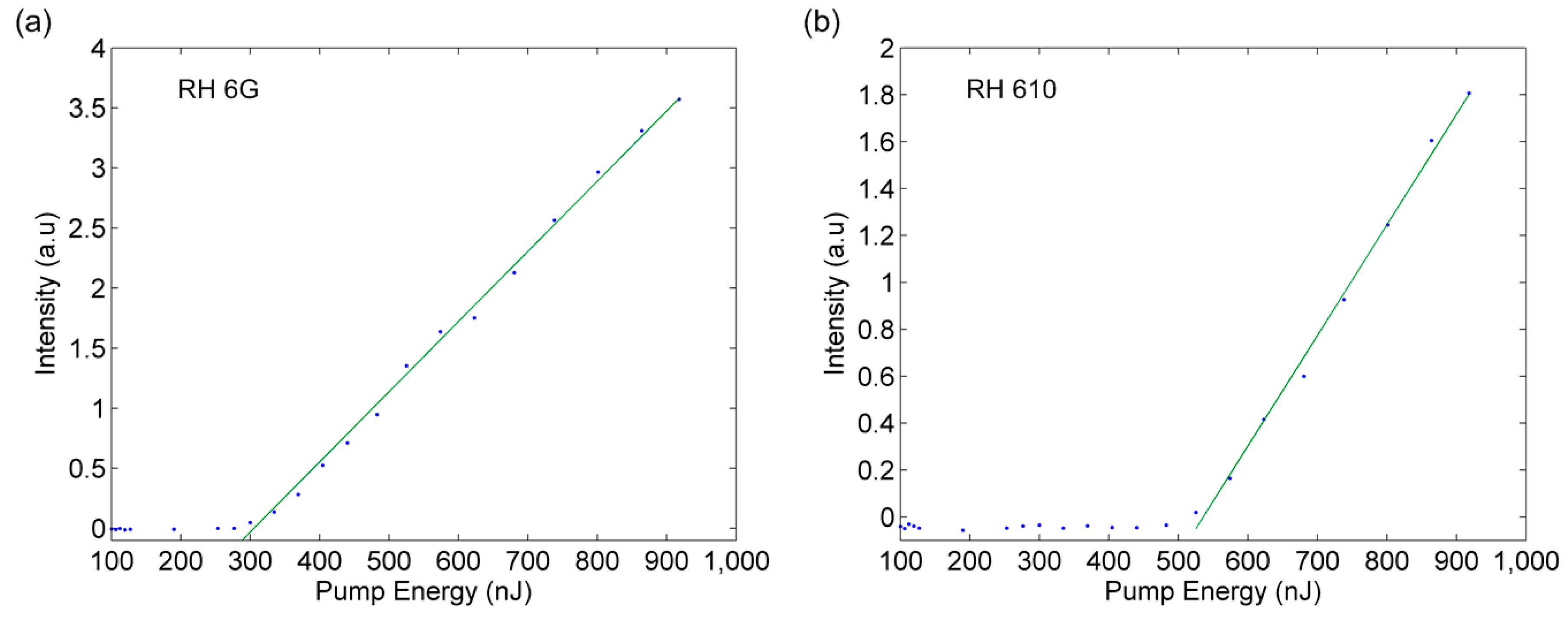

3.1. Laser Characterization

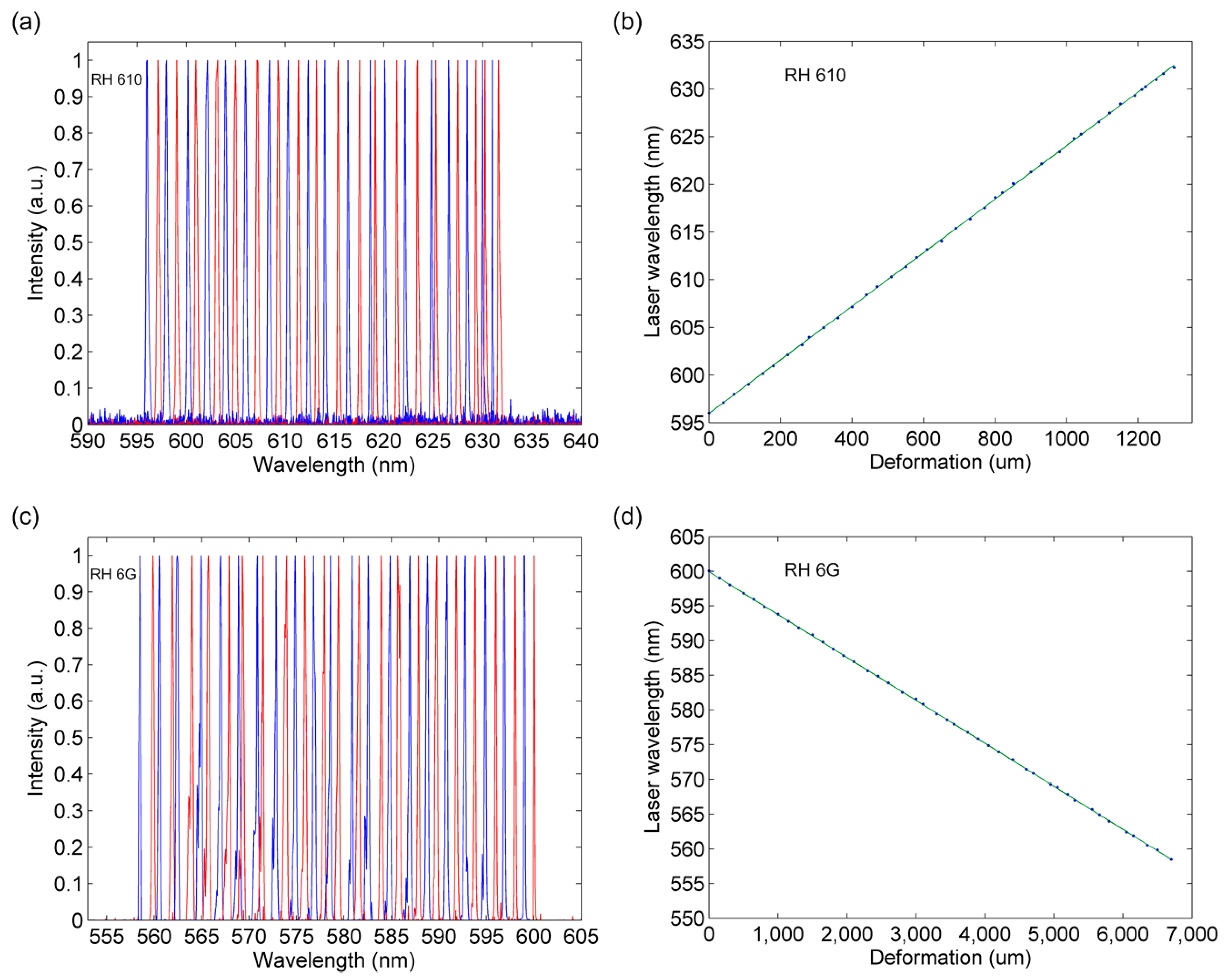

3.2. Laser Wavelength Tuning

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Song, M.H.; Wenger, B.; Friend, R.H. Tuning the wavelength of lasing emission in organic semiconducting laser by the orientation of liquid crystalline conjugated polymer. J. Appl. Phys. 2008, 104, 033107. [Google Scholar] [CrossRef]

- Missinne, J.; Kalathimekkad, S.; Van Hoe, B.; Bosman, E.; Vanfleteren, J.; Van Steenberge, G. Stretchable optical waveguides. Opt. Express 2014, 22, 4168–4179. [Google Scholar] [CrossRef] [PubMed]

- Song, W.Z.; Psaltis, D. Pneumatically tunable optofluidic dye laser. Appl. Phys. Lett. 2010, 96, 081101. [Google Scholar] [CrossRef]

- Li, Z.Y.; Zhang, Z.Y.; Scherer, A.; Psaltis, D. Mechanically tunable optofluidic distributed feedback dye laser. Opt. Express 2006, 14, 10494–10499. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.J.; Zhou, C.H.; Zhang, T.T.; Chen, J.D.; Liu, S.D.; Fan, X.D. Optofluidic laser array based on stable high-q fabry-perot microcavities. Lab Chip 2015, 15, 3862–3869. [Google Scholar] [CrossRef] [PubMed]

- Vezenov, D.V.; Mayers, B.T.; Conroy, R.S.; Whitesides, G.M.; Snee, P.T.; Chan, Y.; Nocera, D.G.; Bawendi, M.G. A low-threshold, high-efficiency microfluidic waveguide laser. J. Am. Chem. Soc. 2005, 127, 8952–8953. [Google Scholar] [CrossRef] [PubMed]

- Shopova, S.I.; Zhou, H.Y.; Fan, X.D.; Zhang, P. Optofluidic ring resonator based dye laser. Appl. Phys. Lett. 2007, 90, 221101. [Google Scholar] [CrossRef]

- Chen, Q.S.; Zhang, X.W.; Sun, Y.Z.; Ritt, M.; Sivaramakrishnan, S.; Fan, X.D. Highly sensitive fluorescent protein fret detection using optofluidic lasers. Lab Chip 2013, 13, 2679–2681. [Google Scholar] [CrossRef] [PubMed]

- Lu, M.; Cunningham, B.T.; Park, S.J.; Eden, J.G. Vertically emitting, dye-doped polymer laser in the green (lambda similar to 536 nm) with a second order distributed feedback grating fabricated by replica molding. Opt. Commun. 2008, 281, 3159–3162. [Google Scholar] [CrossRef]

- Morales-Vidal, M.; Boj, P.G.; Quintana, J.A.; Villalvilla, J.M.; Retolaza, A.; Merino, S.; Diaz-Garcia, M.A. Distributed feedback lasers based on perylenediimide dyes for label-free refractive index sensing. Sens. Actuators B 2015, 220, 1368–1375. [Google Scholar] [CrossRef] [Green Version]

- Retolaza, A.; Juarros, A.; Otaduy, D.; Merino, S.; Navarro-Fuster, V.; Ramirez, M.G.; Boj, P.G.; Quintana, J.A.; Villalvilla, J.M.; Diaz-Garcia, M.A. Thermal-nanoimprint lithography for perylenediimide-based distributed feedback laser fabrication. Microelectron. Eng. 2014, 114, 52–56. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Li, Z.; Zhang, Z.; Psaltis, D.; Scherer, A. Nanoimprinted circular grating distributed feedback dye laser. Appl. Phys. Lett. 2007, 91, 051109. [Google Scholar]

- Chen, Y.; Li, Z.Y.; Henry, M.D.; Scherer, A. Optofluidic circular grating distributed feedback dye laser. Appl. Phys. Lett. 2009, 95, 031109. [Google Scholar]

- Shank, C.V.; Bjorkholm, J.E.; Kogelnik, H. Tunable distributed-feedback dye laser. Appl. Phys. Lett. 1971, 18, 395. [Google Scholar] [CrossRef]

- Diaz-Garcia, M.A.; Morales-Vidal, M.; Ramirez, M.G.; Villalvilla, J.M.; Boj, P.G.; Quintana, J.A.; Retolaza, A.; Merino, S. Solution-processable, photo-stable, low-threshold, and broadly tunable thin film organic lasers based on novel high-performing laser dyes. Org. Light Emit. Mater. Devices XIX 2015, 9566, 95660Q. [Google Scholar]

- Riedl, T.; Rabe, T.; Johannes, H.H.; Kowalsky, W.; Wang, J.; Weimann, T.; Hinze, P.; Nehls, B.; Farrell, T.; Scherf, U. Tunable organic thin-film laser pumped by an inorganic violet diode laser. Appl. Phys. Lett. 2006, 88, 241116. [Google Scholar] [CrossRef]

- Wang, J.; Weimann, T.; Hinze, P.; Ade, G.; Schneider, D.; Rabe, T.; Riedl, T.; Kowalsky, Y. A continuously tunable organic dfb laser. Microelectron. Eng. 2005, 78–79, 364–368. [Google Scholar] [CrossRef]

- Kim, J.H.; Inoue, M.; Zhao, L.; Komino, T.; Seo, S.; Ribierre, J.C.; Adachi, C. Tunable and flexible solvent-free liquid organic distributed feedback lasers. Appl. Phys. Lett. 2015, 106, 053302. [Google Scholar] [CrossRef]

- Suzuki, K.; Takahashi, K.; Seida, Y.; Shimizu, K.; Kumagai, M.; Taniguch, Y. A continuously tunable organic solid-state laser based on a flexible distributed-feedback resonator. Jpn. J. Appl. Phys. Part 2 2003, 42, L249–L251. [Google Scholar] [CrossRef]

- Weinberger, M.R.; Langer, G.; Pogantsch, A.; Haase, A.; Zojer, E.; Kern, W. Continuously color-tunable rubber laser. Adv. Mater. 2004, 16, 130. [Google Scholar] [CrossRef]

- Doring, S.; Kollosche, M.; Rabe, T.; Kofod, G.; Stumpe, J. Voltage tunable polymer laser device. Solid State Lasers XXI Technol. Devices 2012, 8235, 82351N. [Google Scholar]

- And, M.D.; Whitesides, G.M. Poly (dimethylsiloxane) as a material for fabricating microfluidic devices. Acc. Chem. Res. 2002, 35, 491–499. [Google Scholar]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Imprint lithography with 25-nanometer resolution. Science 1996, 272, 85–87. [Google Scholar] [CrossRef]

- Li, Z.W.; Gu, Y.N.; Wang, L.; Ge, H.X.; Wu, W.; Xia, Q.F.; Yuan, C.S.; Chen, Y.; Cui, B.; Williams, R.S. Hybrid nanoimprint-soft lithography with sub-15 nm resolution. Nano. Lett. 2009, 9, 2306–2310. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, H.; Shu, W.; Xu, H.; Zhang, B.; Huang, B.; Wang, J.; Jin, W.; Chen, Y. Two-Directional Tuning of Distributed Feedback Film Dye Laser Devices. Micromachines 2017, 8, 362. https://doi.org/10.3390/mi8120362

Feng H, Shu W, Xu H, Zhang B, Huang B, Wang J, Jin W, Chen Y. Two-Directional Tuning of Distributed Feedback Film Dye Laser Devices. Micromachines. 2017; 8(12):362. https://doi.org/10.3390/mi8120362

Chicago/Turabian StyleFeng, Hongtao, Weiliang Shu, Hong Xu, Baoyue Zhang, Bin Huang, Jingjing Wang, Wei Jin, and Yan Chen. 2017. "Two-Directional Tuning of Distributed Feedback Film Dye Laser Devices" Micromachines 8, no. 12: 362. https://doi.org/10.3390/mi8120362