1. Introduction

In recent years, the rapid development of ultraprecision machining technology has led to higher positioning accuracy standards of the micropositioning platform driven by some functional materials such as piezoelectric ceramics. Piezoelectric ceramics actuators (PCAs) have been widely used in precision positioning applications, such as scanning and microscopic technologies [

1,

2], micromanipulators [

3], atomic force microscopes [

4,

5,

6], and ultraprecision machine tools [

7,

8]. This is because of their ability to achieve high precision and versatility to be implemented over a wide range of applications [

9]. However, the existence of hysteresis in PCAs often limits the operation performance of the actuators. Therefore, it is highly desirable to compensate for the hysteresis so that the piezoelectric devices can have a virtually linear relationship, or one-to-one mapping between the control signal and the output displacement [

10].

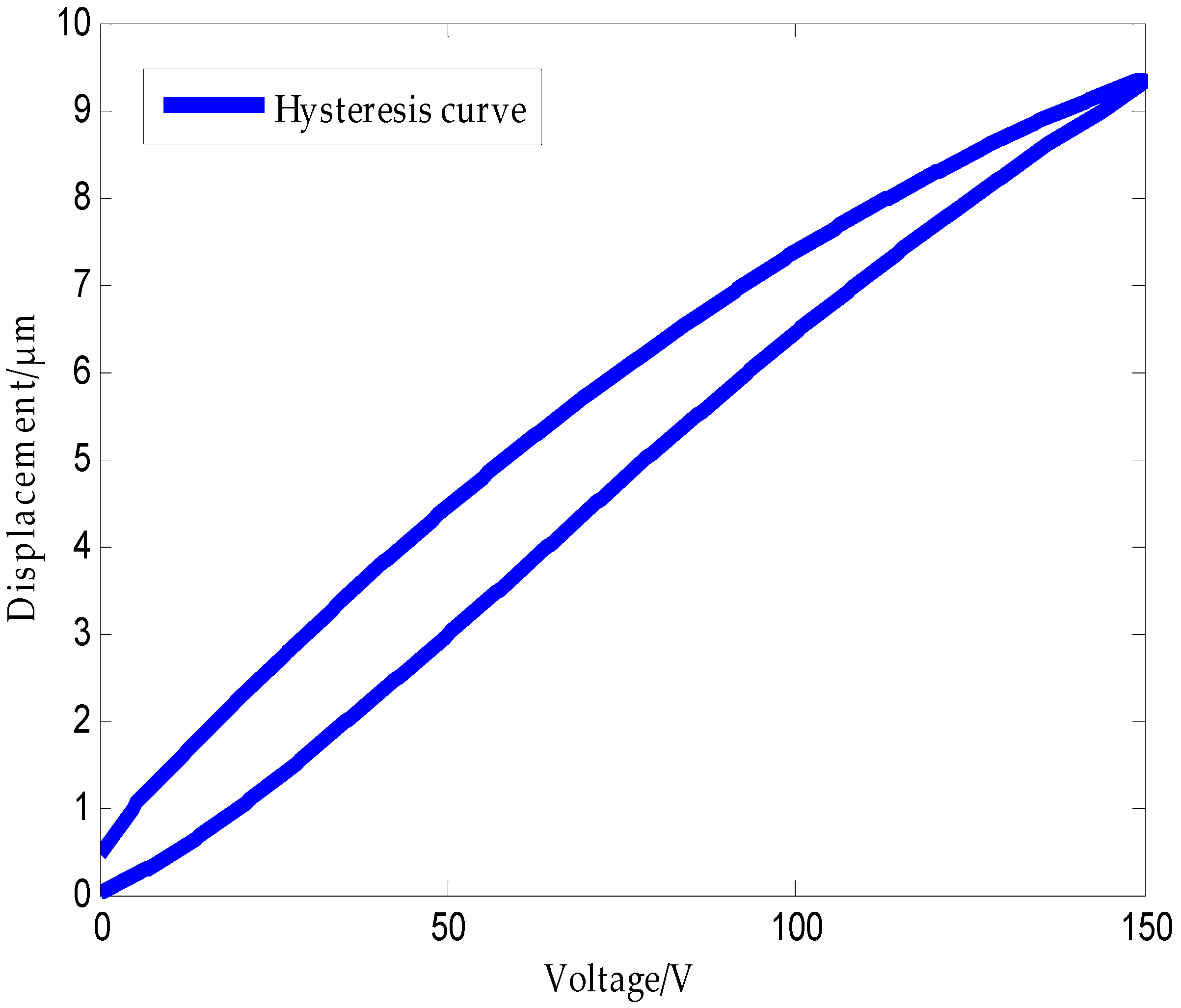

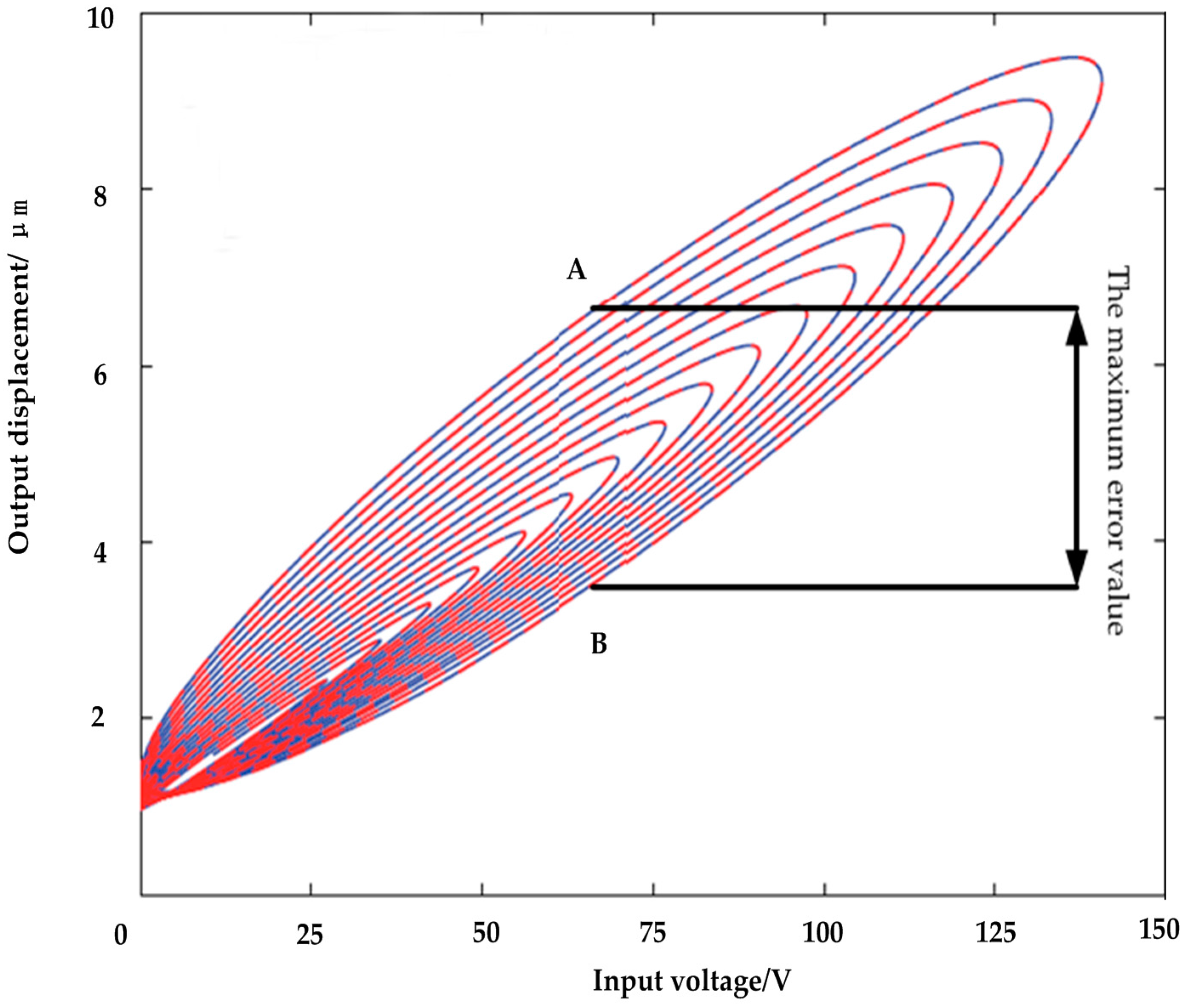

Figure 1 presents the relationship between the displacement and the voltage across a piezoelectric actuator. It can be seen from the figure that when the voltage is applied across the piezoelectric ceramic, the step-up displacement curve does not coincide with the step-down displacement curve, and the displacement does not return to zero after the applied voltage is reduced to zero. This phenomenon is called the piezoelectric ceramic hysteresis phenomenon. This means that the actuator output displacement depends not only on the input or applied voltage at the present time, but also on the input history [

11]. The intrinsic nonlinear and multivalued hysteresis in the piezoelectric actuator has the potential to cause an inaccuracy in, or even instability of, its applied system. The maximum error resulting from the hysteresis can be as much as 10–15% of the path covered [

12]. It is obvious from the above analysis that the available approaches for the identification of piezoelectric-actuated stages containing the hysteresis and linear dynamics are still an open problem [

13]. Therefore, establishing a precise control model of piezoelectric ceramics, and (based on this model) controlling the hysteresis nonlinearity of piezoelectric ceramics so as to improve the control precision of piezoelectric ceramics, has become a hot issue discussed by many scholars, globally [

14,

15].

As increasingly more researchers focus on PCAs, there have been numerous attempts to use models to compensate for hysteresis. These are broadly divisible into two, namely, physics-based models (white/gray box) and phenomenological models (black box) [

16]. The physics-based models are derived from the physical means of the hysteresis and can be strictly verified. The physical model refers to a scientific concept that is abstracted out from a large number of experiments for the convenience of research, excluding secondary factors and highlighting the main factors. One of the advantages of physics-based models is their clear physical meaning. However, due to the complicated form, physics-based models are not commonly used in the control of PCAs [

17]. The commonly used hysteresis models based on the hysteresis nonlinearity of piezoelectric ceramics are the Jiles–Atherton (J–A) model [

18] and the Maxwell model [

19]. Malczyk et al. proposed an extension of the J–A model, as the J–A magnetic hysteresis model, to describe the hysteresis curve narrowing phenomenon in ferrite ZnMn material. Their new model permits the inclusion of a wide variety of additional effects observed in ferromagnetic materials without invalidating the well known and broadly used J–A model parameters. Experiments prove the feasibility of this method [

20]. Liu et al. presented a Maxwell model to describe the hysteresis in a piezoelectric actuator. They studied the effect of the number of elements and presented both the forward and inverse algorithms. Further, they used the inverse Maxwell model and obtained almost linear performances of the hysteresis compensation. The results of their experiment validate the effectiveness of the proposed algorithm and showed a reduction in hysteresis nonlinearity from 13.8 to 0.4% [

21]. Phenomenon-based models are the ones in which researchers generalize and summarize input and output data and the phenomena of practical experiments, utilizing mathematical methods to directly build a mathematical model to satisfy the experiment rule regardless of the physical meaning, such as the Preisach model [

22], the Prandtle–Ishlinskii (PI) model [

23], the Duhem model [

24], and the Bouc–Wen model. Song et al. proposed a novel modified Preisach model to identify and simulate the hysteresis phenomenon observed in a piezoelectric stack actuator. Their approach can handle a varying-frequency dependence by employing a time-derivative correction technique. Parameter estimation and model verification demonstrated high accuracy of the derived model, keeping the deviation in a low percentage range (about 2–3%) [

16]. Lin et al. reformulated the Bouc–Wen model, the Dahl model and the Duhem model as a generalized Duhem model to compare the performances of variant hysteresis models with respect to the tracking reference. Since the Duhem model includes both the electrical and mechanical domains, it has a smaller modeling error compared to the other two hysteresis models. Finally, a real-time experiment confirmed the feasibility of their proposed method [

25]. Wang et al. proposed a novel modified Bouc–Wen (MBW) model to describe the asymmetric hysteresis of a piezoelectric actuator. They used a polynomial-based non-lag component to realize the asymmetric hysteresis property. The results demonstrate that their model is superior to its competitors’ models in describing the asymmetric hysteresis of a piezoelectric actuator [

26]. However, the lack of a physical meaning makes the above-mentioned model difficult to understand. Simultaneously, none of the abovementioned models reveal the cause of hysteresis from a microscopic point of view, thus, modeling errors in these modeling methods are inevitable.

In this study, we first analyze the causes of the hysteresis based on the micropolarization mechanism. Then, by observing the hysteresis curve of piezoelectric ceramic and establishing the deformation speed law of piezoelectric ceramics, we explain the deformation rate of piezoelectric ceramics at different stages, making use of the nucleation rate of microscopic domain evolution. After that, according to the proposed piezoelectric ceramic deformation speed law, we split and then recombined the play operator, and the improved PI model is proposed. Finally, the improved PI model is compared with the traditional PI model and Preisach model. The experimental results show that the accuracy of the improved PI model is increased by more than 80% as compared to the traditional PI model and Preisach model.

This paper is organized as follows:

Section 2 describes hysteresis based on the microscopic polarization mechanism and domain wall theory, and reveals the cause of hysteresis from the microscopic point of view. A novel piezoelectric ceramic deformation speed law is proposed, and its analysis presented in

Section 3.

Section 4 presents the proposed tripartite PI model based on the deformation rate law of piezoelectric ceramics. A contrast experiment with traditional PI model and Preisach model is presented in

Section 5. Finally,

Section 6 provides a summary of discussion and future works.

4. Hysteresis Modeling

Whether in scanning tunneling microscopes, atomic force microscopes, or other precision positioning systems, quick and accurate positioning of the probe is desired. However, due to hysteresis, it is difficult for the probes to locate the correct position quickly and accurately. Various ways to reduce errors and improve the positioning accuracy are currently in practice. In this paper, we discuss the use of modeling methods, as shown in

Figure 8.

From the piezoelectric ceramic hysteresis curve shown in

Figure 8, it can be seen that every time the voltage rises and reduces, a hysteresis error is introduced; however, the maximum error occurs in the main hysteresis loop (the distance from A to B in

Figure 8). Therefore, in this study, we only model the main hysteresis loop of the hysteresis curve. As a next step, we will conduct a study on the remaining displacements of the hysteresis curve.

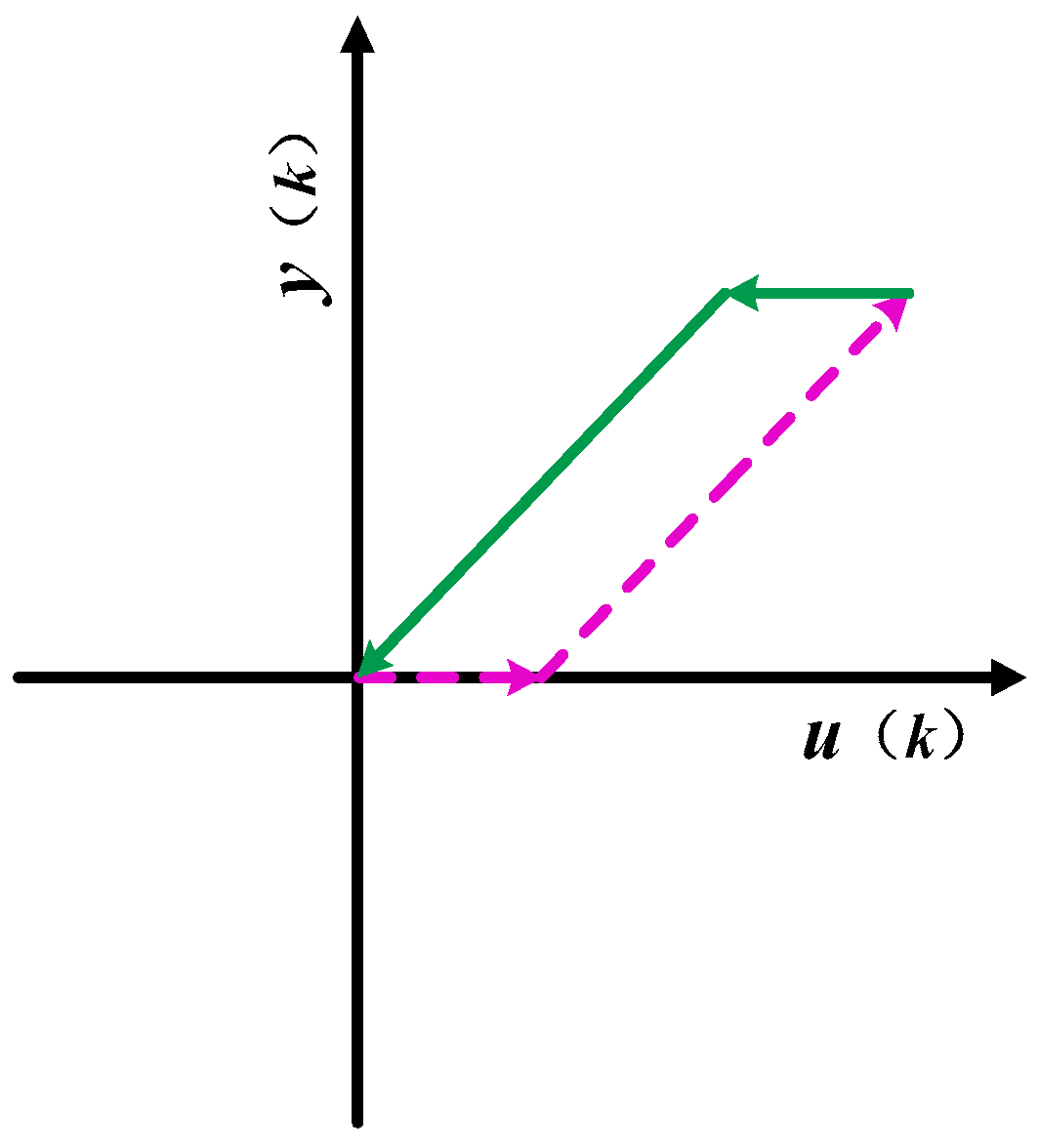

4.1. Play Operator and Prandtle–Ishlinskii Model

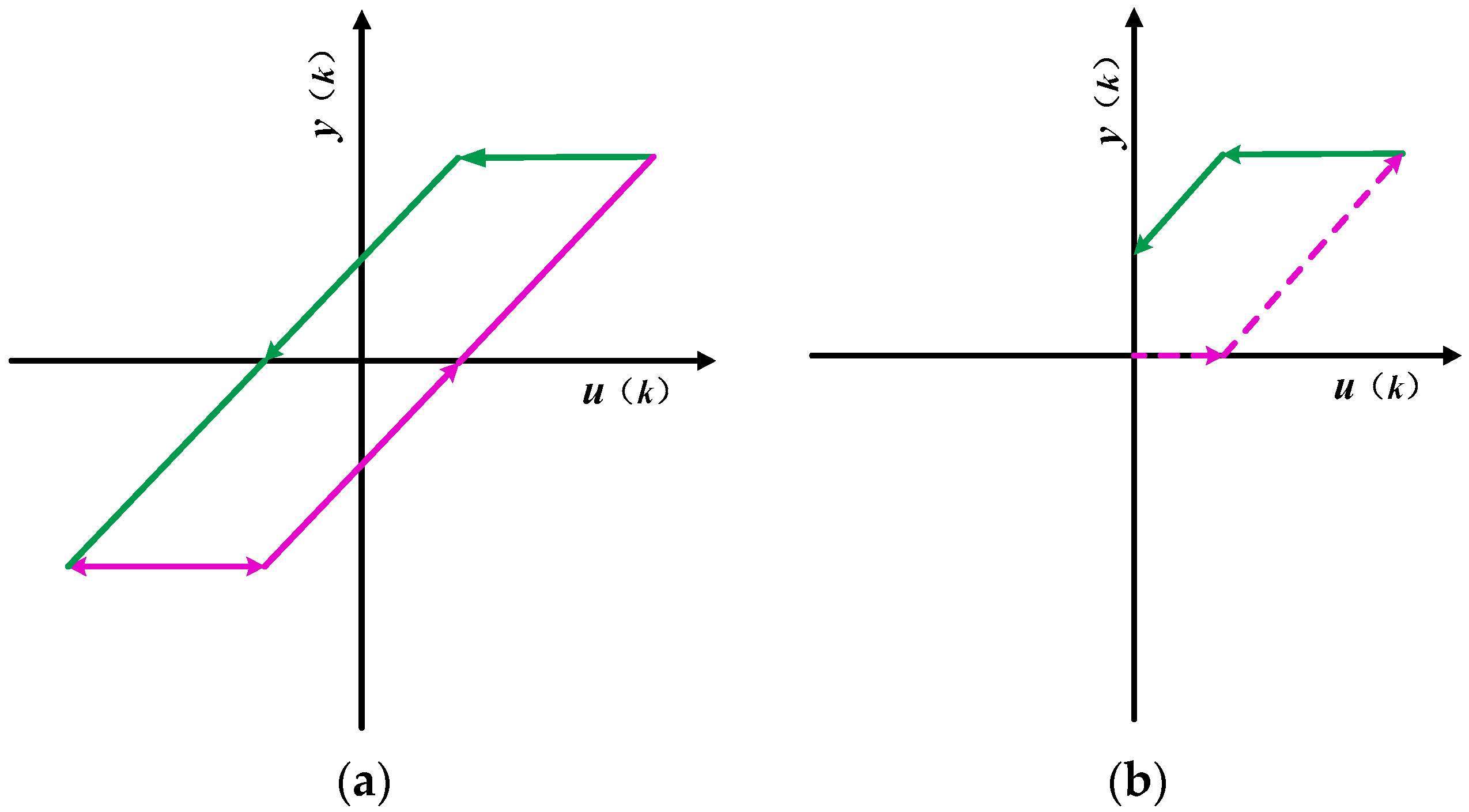

The PI hysteresis model can be thought of as consisting of a stack of hysteresis operators. The mathematical expression for the play hysteresis operator shown in

Figure 9a is

where

k is the input time,

r is the threshold of the play operator,

u(

k) is the input of the operator, and

y(

k) is the output of the operator. The initial value of hysteresis operator is defined as

If the piezoelectric actuator is started from the power off state, the value of h0 is 0.

The PI hysteresis model was established in 1970 by the Russian mathematician Krasnoselskii, developed from the Preisach model and it was referred to as the PI model. It is formed by different play operators with different thresholds. The play operator is similar to the hysteresis curve in shape. Different play operators are multiplied by different weighting values and superimposed on one another to obtain the piezoelectric ceramic hysteresis PI model. The mathematical expression for the PI model is

where

wi is the weight of each hysteresis operator in the mathematical sense,

n is the number of operators,

Y(

k) is the output of the model at the moment

k, and

ri is the threshold of the hysteresis operator. The vector form of Equation (11) is

where the threshold vector is

W = (

w1,···,

wi,···,

wn)

T, the state vector of the operator at the moment

k is

y(

k) = (

y1(

k),···,

yi(

k),···,

yn(

k))

T, and the state vector of the operator at initial time is

y(0) = (

y1(0),···,

yi(0),···,

yn(0))

T.

In the actual experiment, the step-down phase of the standard play operator is only partially present in the first quadrant, leading to its limited accuracy in describing the backhaul part of the hysteresis curve. The input voltage is always positive, which is increased from 0 V, therefore, in actual modeling, only a portion of the standard play operator is used. The input and output of the unilateral play operator are completely cuffed in the first quadrant, as shown in

Figure 9b. The dotted and solid lines shown in

Figure 9b are the output of the operator during increasing and decreasing voltage times. For

u(

k) ≤

r, the output

y(

k) always remains zero. For an input

r ≤

u(

k) ≤

umax, the operator output is

u(

k) −

r. When the input voltage drops from peak

umax to

umax − 2

r, the operator output is

umax −

r. After this, the operator output

y(

k) is

u(

k) +

r, until the voltage drops to zero. The output of the operator whose threshold

r ≥ 0.5

umax does not have an output of

u(

k) +

r.

4.2. Traditional PI Modeling and Inverse Model

We define

d(

k) as the output displacement that corresponds to the input voltage of the piezoelectric ceramic at time

; the expression of the error signal

e(

k) at time

k is

The square of the error

e(

k) is

In this study, the accuracy of modeling is measured by the addition of the squared errors

, where

n is the number of sampling points. The weight vector

w of the objective function is obtained from the quadratic programming algorithm, i.e.,

The cross-correlation function row vector

and autocorrelation function matrix

are defined as

Equation (15) can now be expressed as

This indicates that f(w) is a quadratic function of the weight coefficient vector w, which is an upwardly concave parabolic surface and a function with a unique minimum. The weight coefficient is adjusted so that f(w) is the minimum, i.e., we find the minimum drop along the curved surface corresponding to the parabolic path. Here, we use the gradient descent method to find this minimum.

For Equation (18), we take a derivative with respect to the weight coefficient

w, and we obtain the gradient of

f(

w) as

Make

= 0, and the optimal weight coefficient vector can be obtained.

In order to ensure the positive definite of the quadratic matrix, the principle of threshold selection is

,

. Using a program written in MATLAB software (R2017b, MathWorks, Inc., Natick, MA, USA) for the operation, the parameters of the traditional PI model are obtained. They are tabulated in

Table 1.

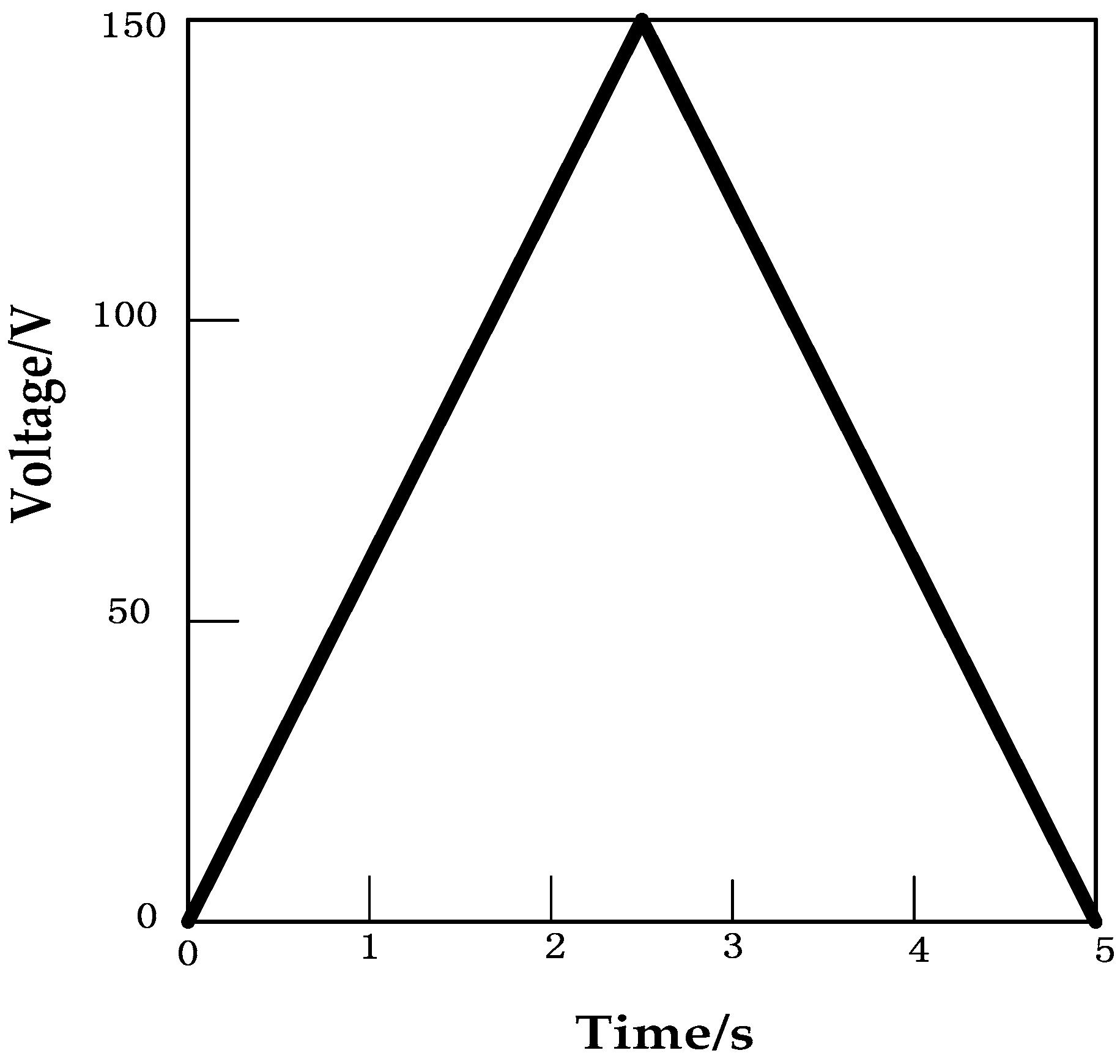

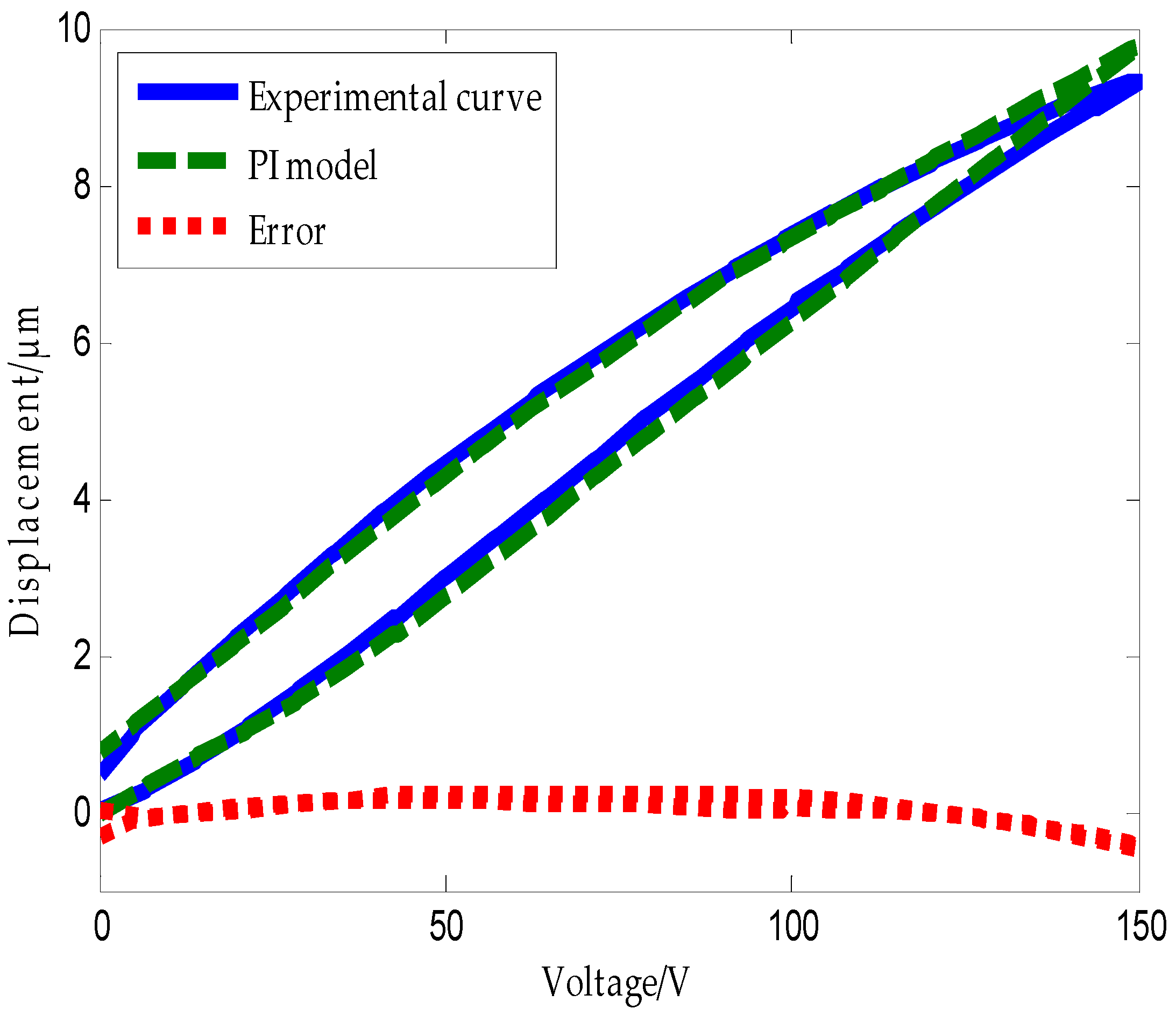

The triangular wave form shown in

Figure 10 was applied to the piezoelectric ceramic. The experimental hysteresis curve of the piezoelectric ceramic and the curve obtained using the traditional PI model along with the error plot are shown in

Figure 11. Error analysis using MATLAB software shows that the mean absolute error of the traditional PI model is

.

The inverse PI model is also a PI model. The threshold vector and the weight vector of the PI inverse model can be calculated using the relationship between the PI model and its inverse model. The PI model has an analytical inverse,

,

;

,

,

;

,

. Hence, the output expression of the PI inverse model at the time

k is

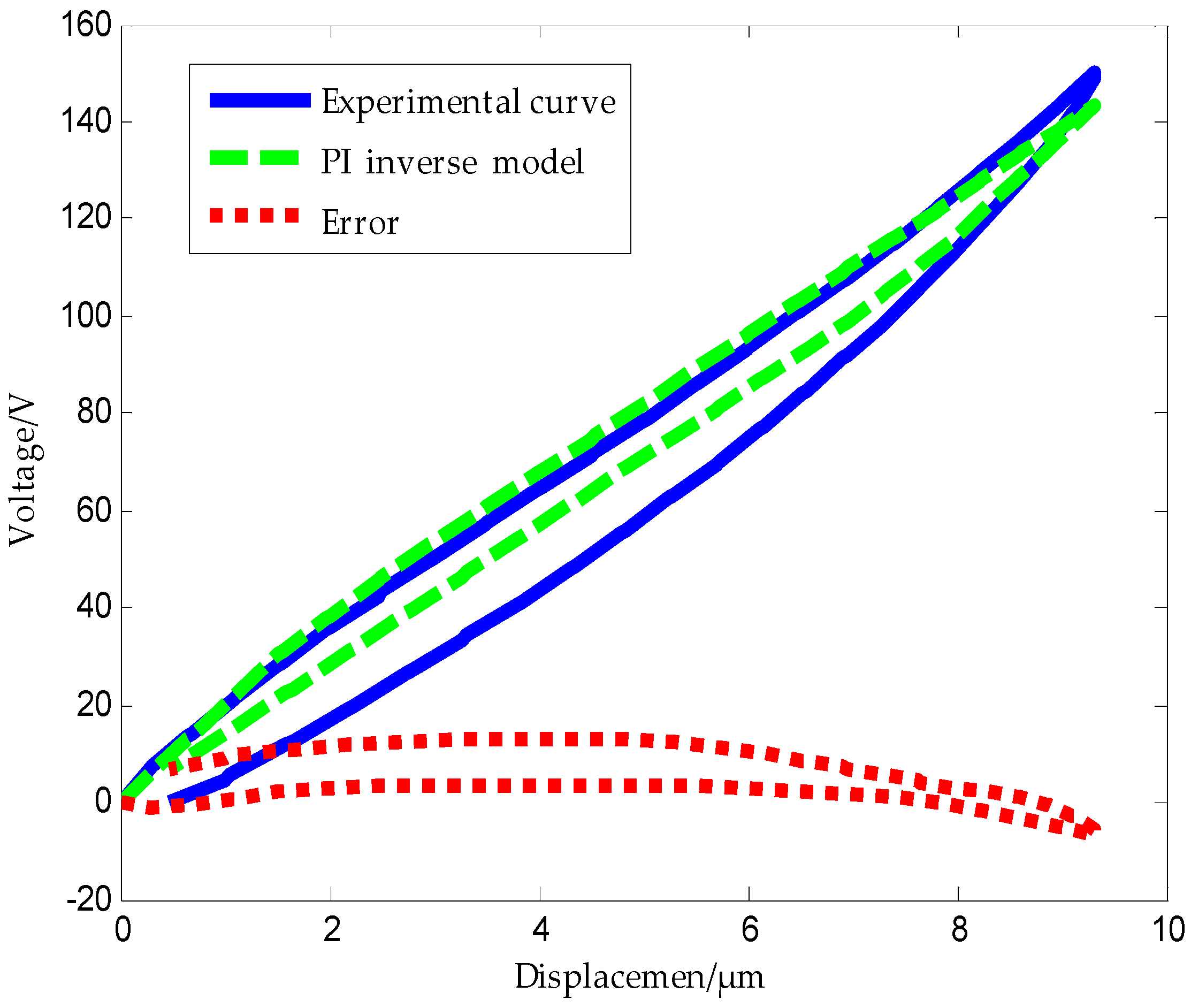

Figure 12 shows the experimental hysteresis curves of the piezoelectric ceramic and the ones obtained using the PI inverse model along with the error plot.

Error analysis using MATLAB software shows that the mean absolute error of the traditional PI inverse model is . From the above analysis, we can conclude that the traditional PI model and its inverse model exhibit large modeling errors.

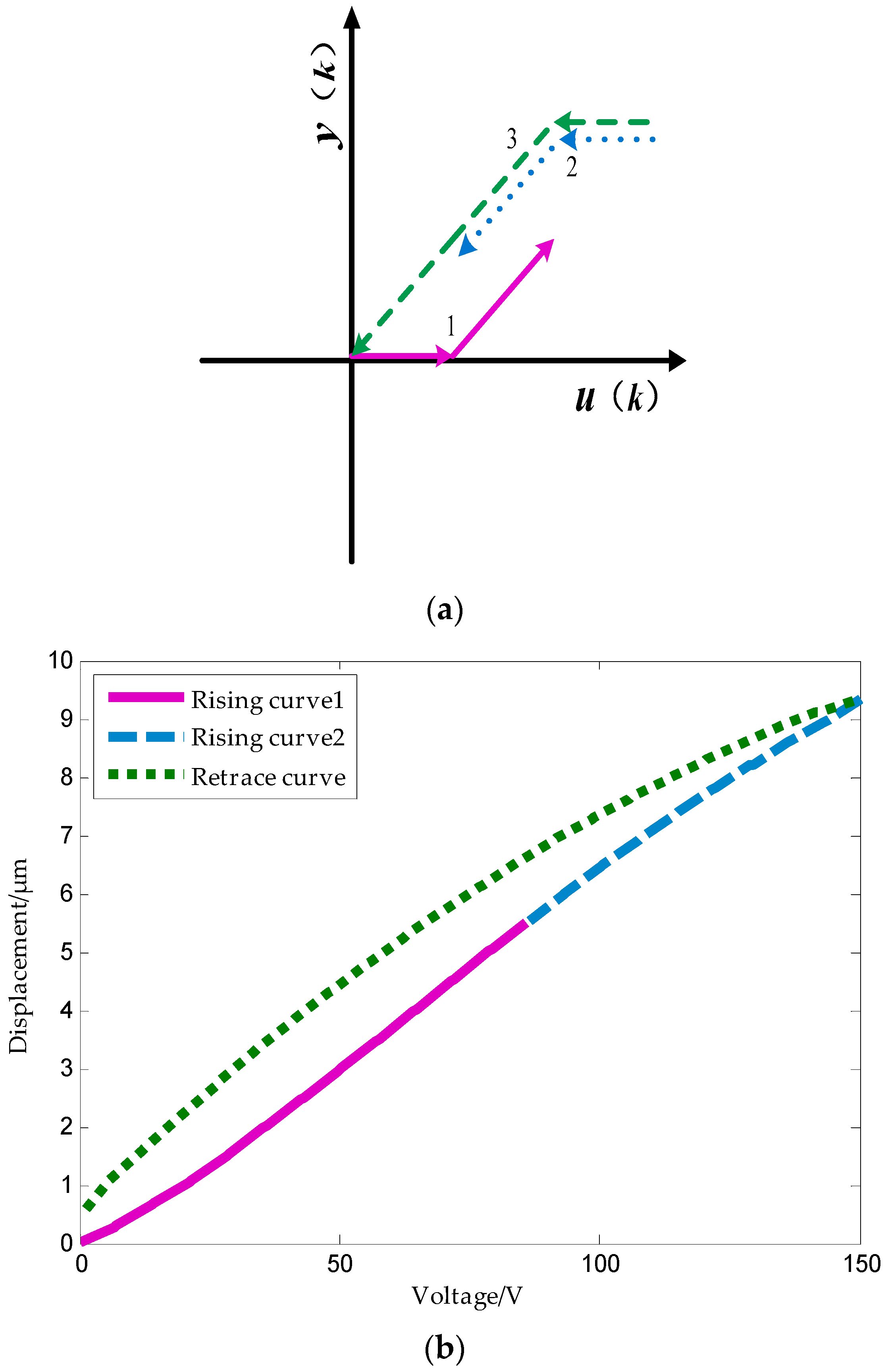

4.3. Tripartite PI Model Based on the Deformation Rate of Piezoelectric Ceramics

In

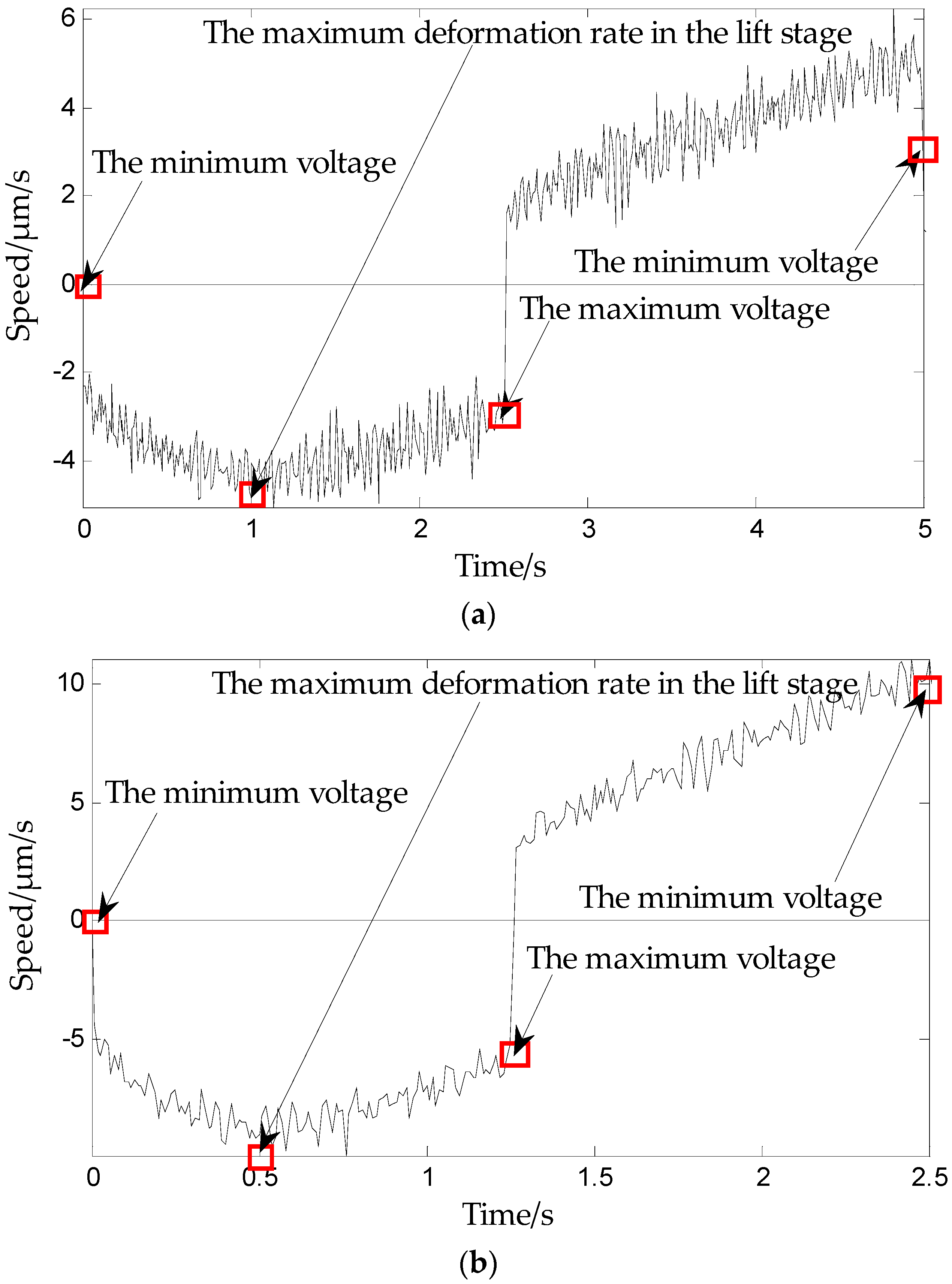

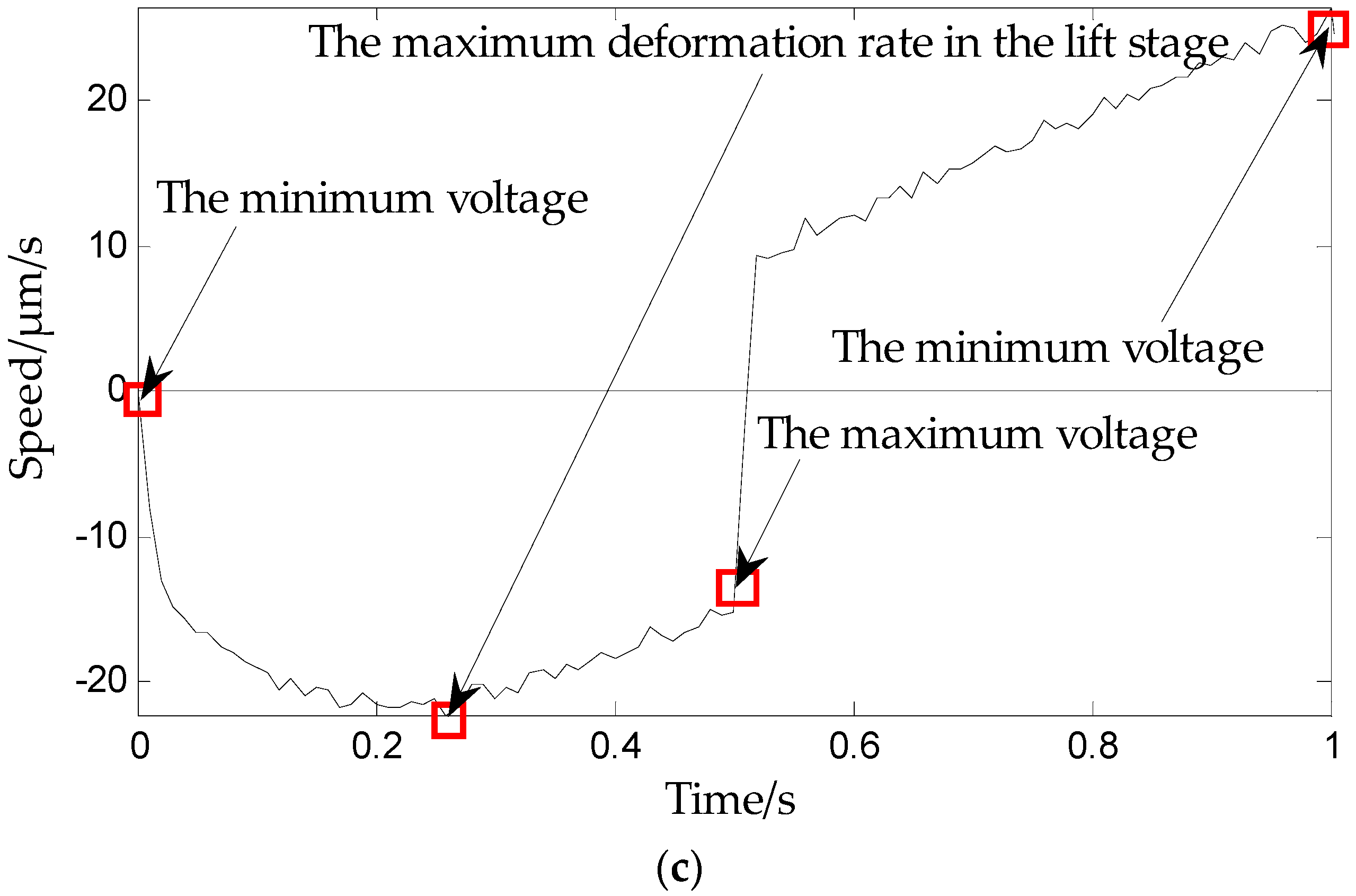

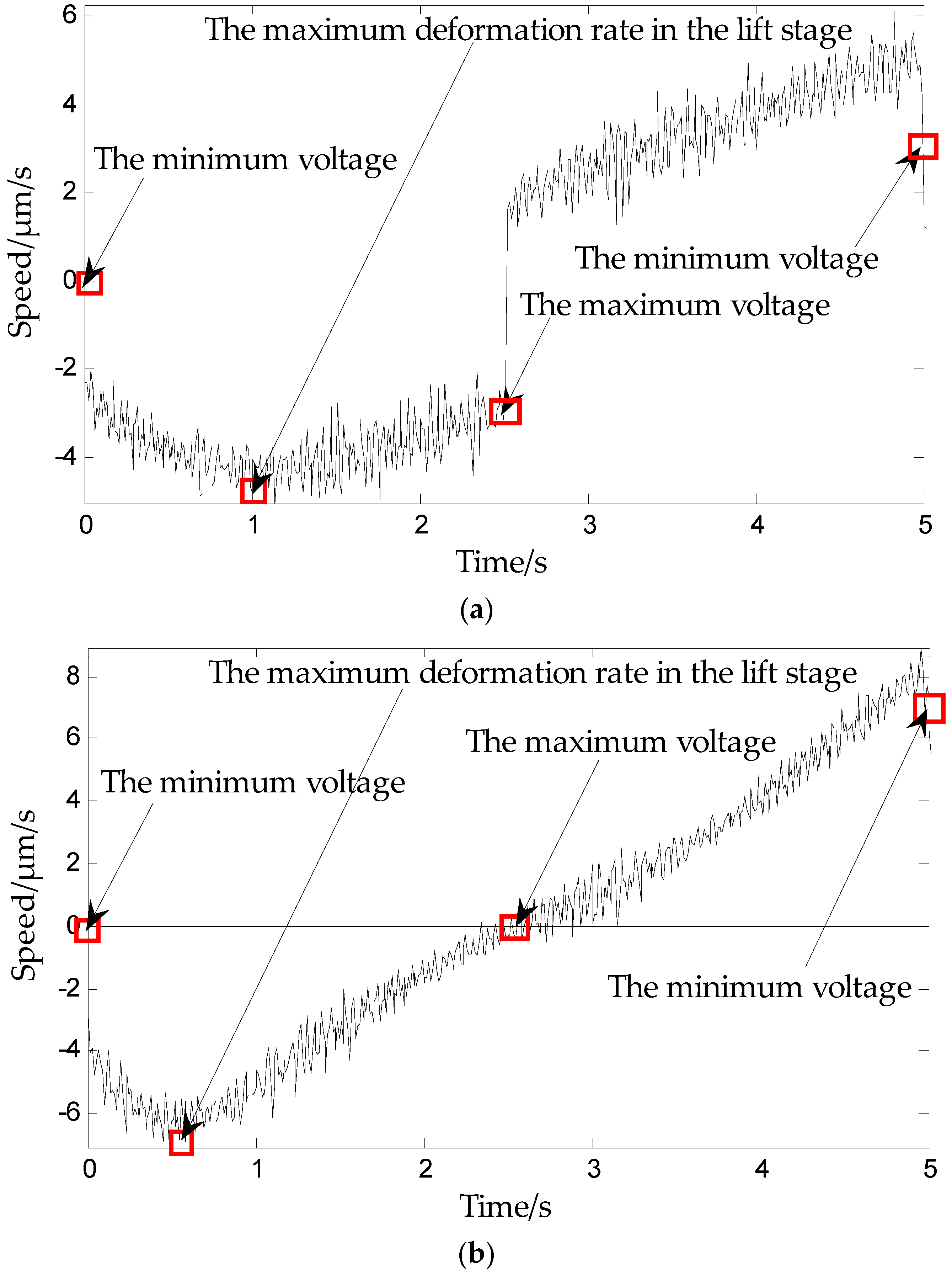

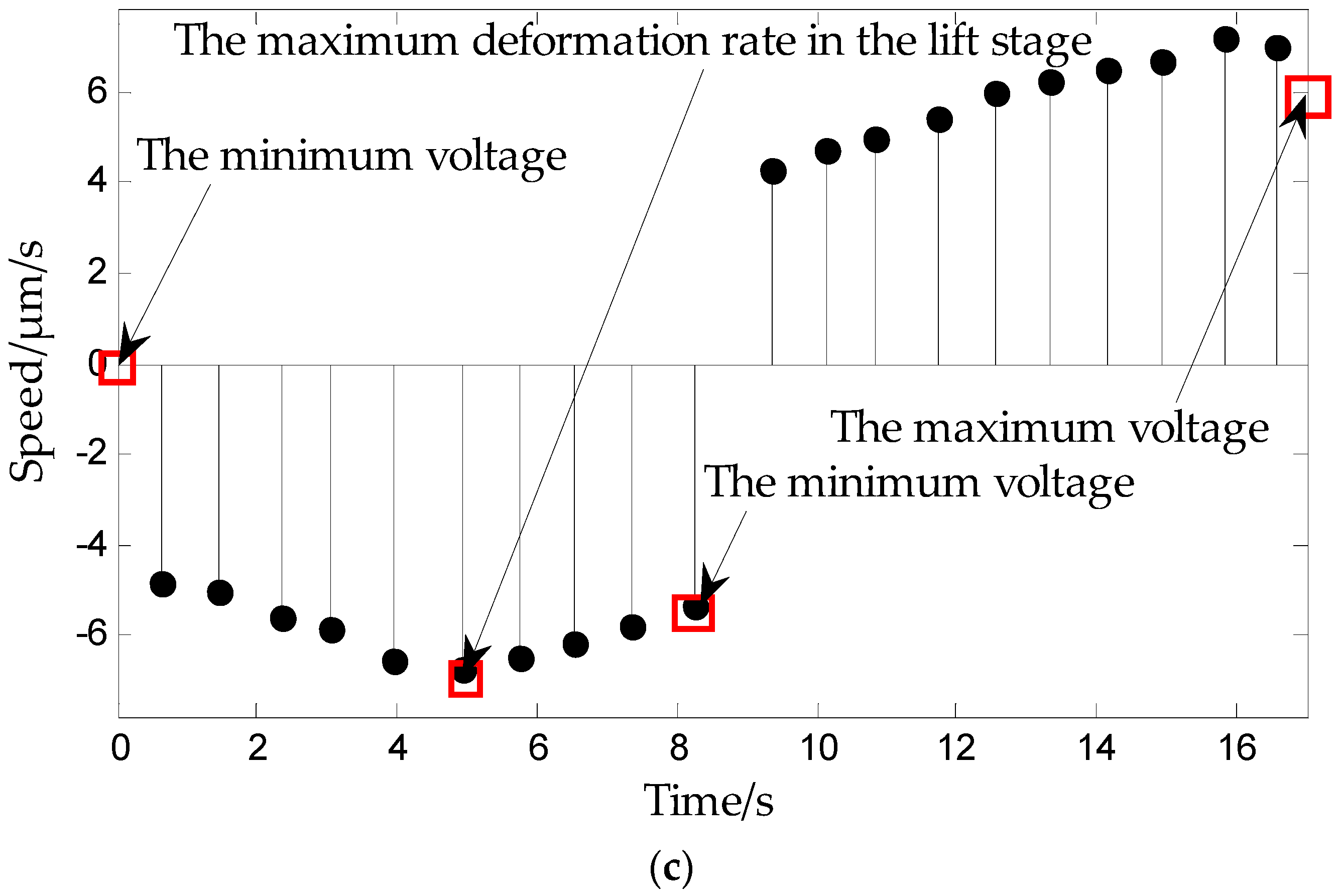

Section 3.1, we obtained the piezoelectric ceramic deformation speed law, and here, we propose a tripartite PI modeling method based on this law. As already mentioned in

Section 4.1, the step-down phase of the standard play operator is only partially present in the first quadrant, therefore, the standard play operator has a limited description of the backhaul of the hysteresis curve. The operator used in the tripartite PI modeling method is a unilateral play operator. The input and output of the unilateral play operator are completely limited to the first quadrant, as shown in

Figure 13.

The output expression of unilateral play operator is

The dashed part is the boost part and the solid part is the buck part. The model is based on the theory presented in

Section 3. A data collection experiment of the piezoelectric ceramic hysteresis curve under the triangle wave pressure provides support for modeling. The inflection point is captured based on

Figure 6 and

Figure 7, which show the maximum deformation speed in the rising process.

Modeling steps:

- (1)

The selection of operators is based on the principles of concave-convex consistency, which means that in the hysteresis curve, the concave and convex parts of the curve correspond to the boost part and the depressurization part of the play operator, respectively.

- (2)

The rising curve rises from zero voltage to the inflection point voltage

uif (

uif refers to the voltage indicated by the arrows in

Figure 6 and

Figure 7), i.e., when the deformation speed rises from 0 to the maximum. The relationship between the voltage and displacement is described by a single lateral play operator as shown in

Figure 13 (the dotted portion).

- (3)

The rising curve rises from the inflection voltage

uif to maximum voltage

umax (

umax refers to the maximum point voltage applied to the piezoelectric ceramic during the whole rising cycle. It is 150 V here). Voltage–position relation in this part is described by a single lateral play operator as shown in

Figure 13 (the solid line). One side play operators and hysteresis curves have a counter clock directivity. The reducing portion and rising process in the second part manifest the epirelief characteristic. The reducing portion of play operators point to the origin of coordinates while the second rising hysteresis curve deviates from it. Therefore, we need to model in reverse when we use play operators in the reducing part to describe the second rising process of the hysteresis curve.

- (4)

The retraced curve’s relation that reduces from the maximum to zero voltage is described by a single lateral play operator as shown in

Figure 13 (the solid line).

The application of operators in respective parts of the hysteresis curves during the model process are shown in

Figure 14.

The weight identification algorithm and threshold selection principle are consistent with

Section 4.2.

Table 2 shows the identification parameters of the tripartite PI model.

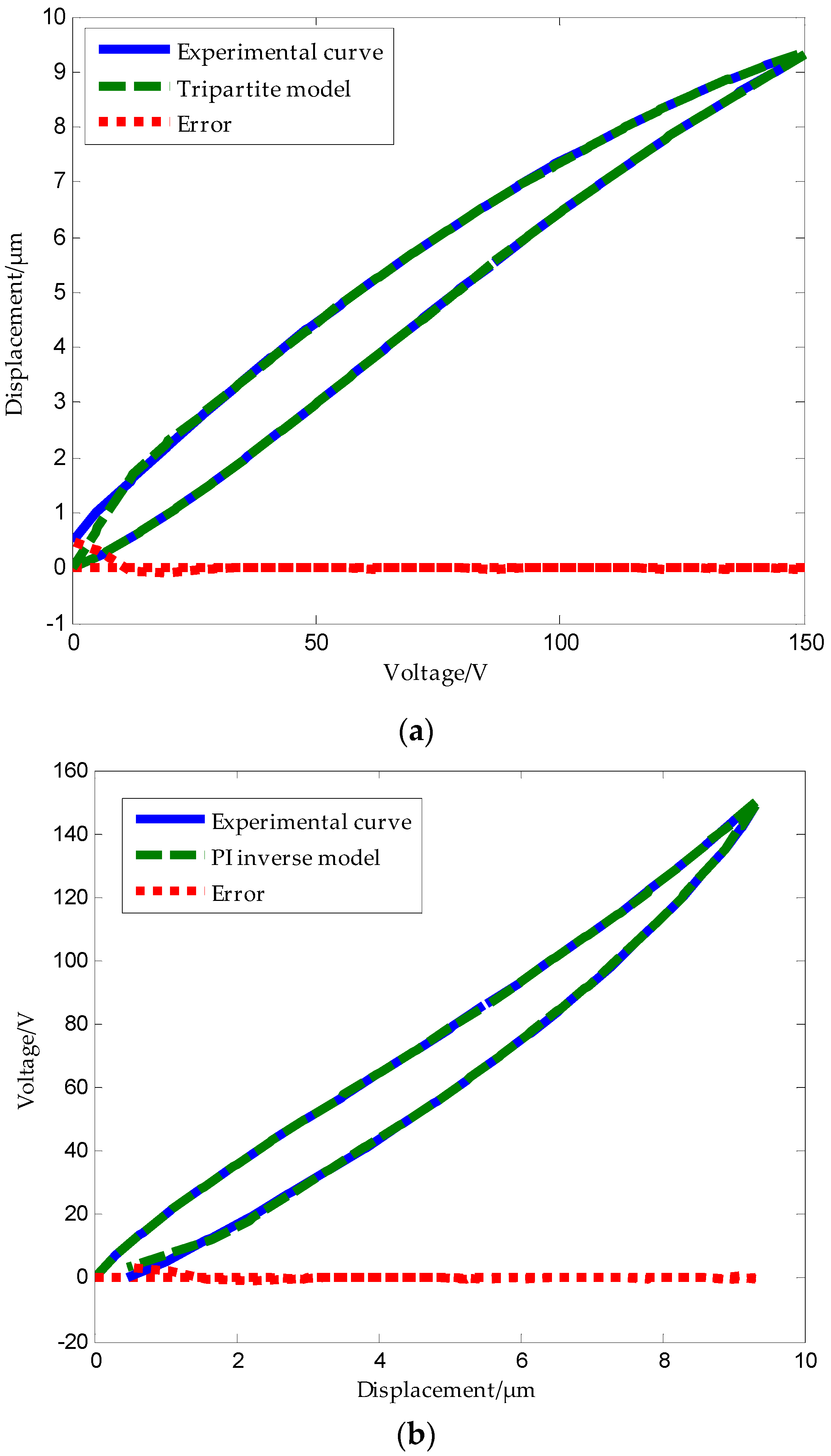

The tripartite PI model also includes the tripartite PI inverse model.

Figure 15a,b show the modeling result of the tripartite PI model and its inverse model, respectively. Through MATLAB software modeling, we obtained the mean absolute error of the tripartite PI model as

.

It should be noted that the unilateral play operator used for modeling returns to the origin when the voltage comes back to zero, and the displacement of the tripartite PI model obtained by the weighted addition of the unilateral play operator is also forced to zero when the voltage drops to zero. Since the actual hysteresis curve does not return to zero when the voltage drops to zero, the tripartite PI model shows a high error when the voltage is close to 0 only during the process of reducing pressure.

5. Experiment Results and Discussion

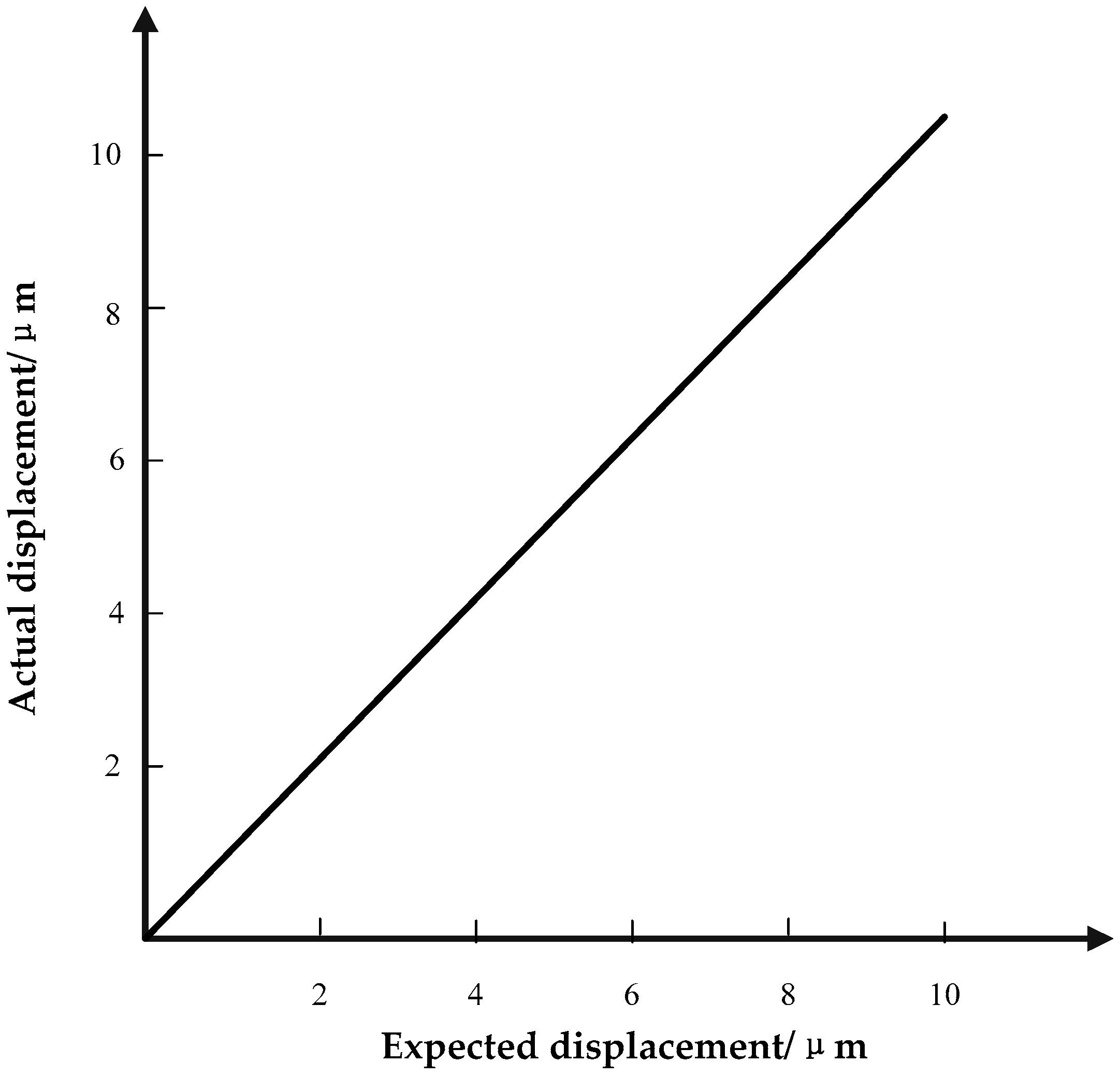

The purpose of the microdisplacement positioning system is to make the expected piezoelectric ceramic output displacement equal to its actual displacement, as shown in

Figure 16.

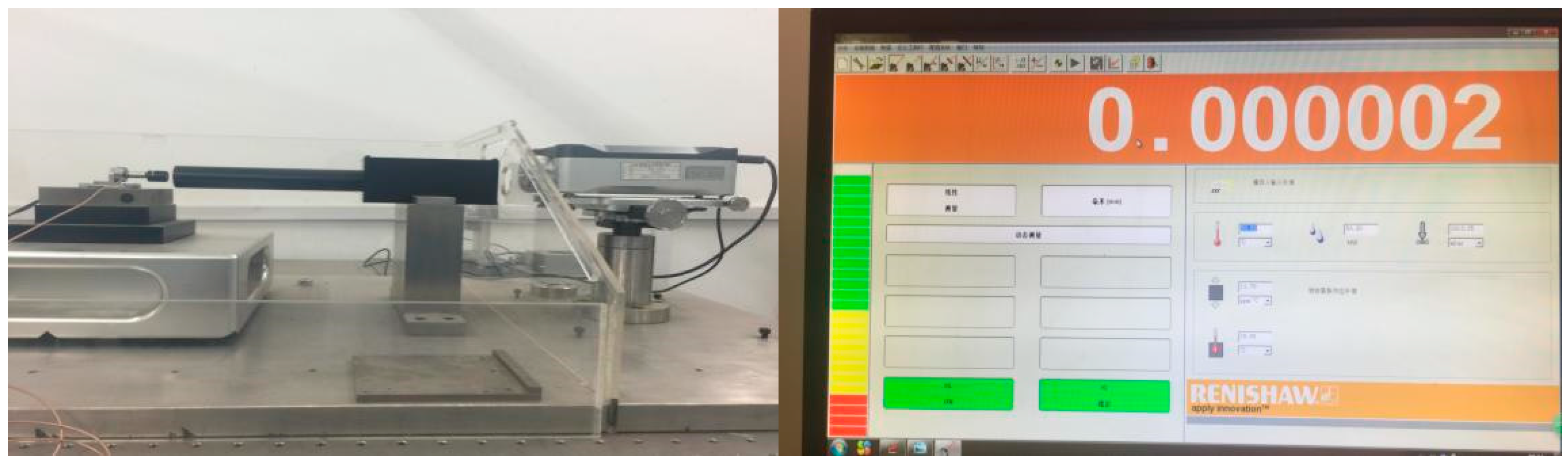

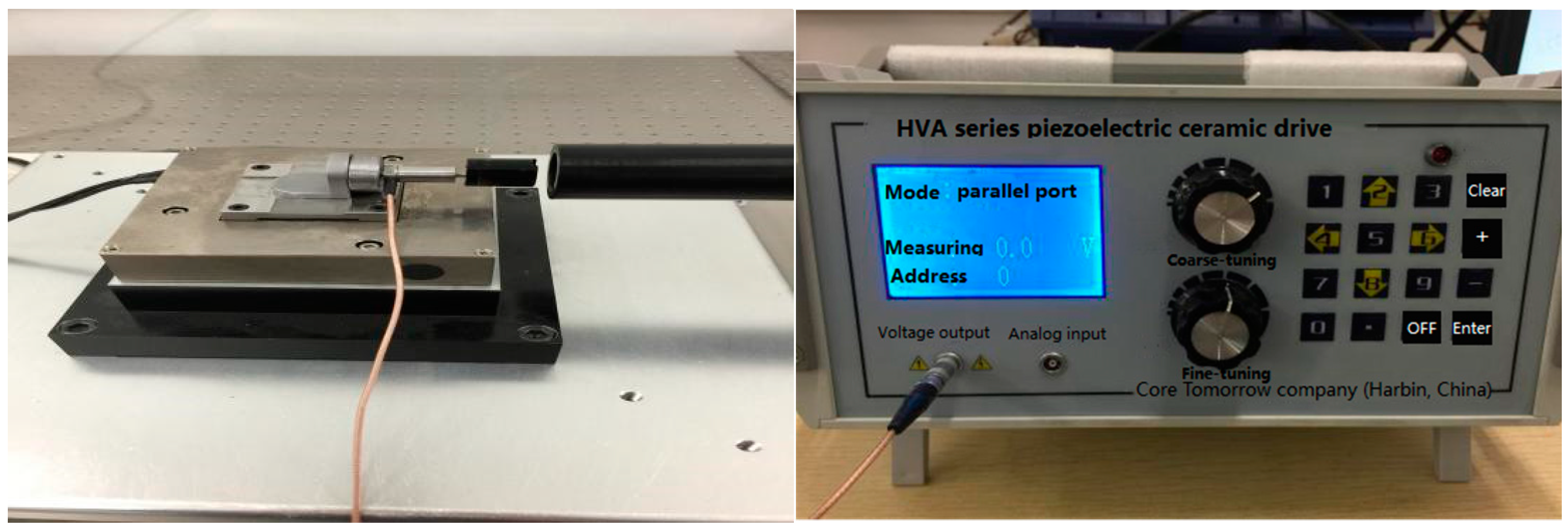

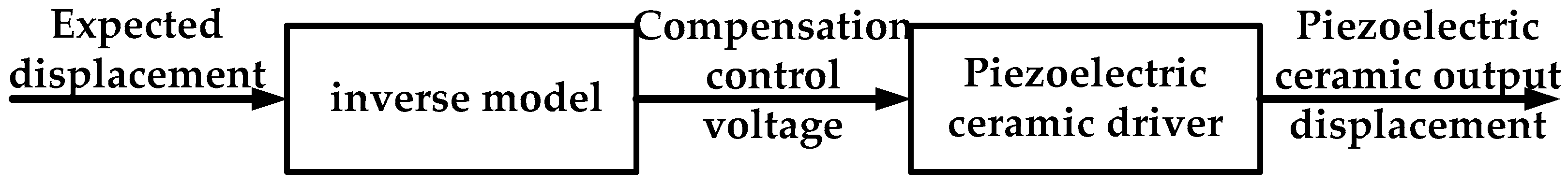

Hence, in order to verify the effect of tripartite PI inverse model on the piezoelectric ceramic driver’s hysteresis compensation, we designed a piezoelectric ceramic hysteresis model control effect comparison experiment. The PCA used for this study was the PSt150/4/7VS9 piezoelectric ceramic made by Core Tomorrow company (Harbin, China). We used the driving power HVA-150D. A3, made by Harbin Core Tomorrow Science & Technology Co., Ltd., to generate driving power (the input voltage was in the range of 0 to 150 V and the output displacement was in the range of 0 μm to 9.5 μm) to drive the piezoelectric ceramic and a Renishaw XL-80 laser interferometer to measure the displacement. The equipment used for the experiment was as shown in

Figure 17. The driving power communicated with the host computer through the standard parallel port (SPP) parallel communication port. Here, we refer to the Preisach model parameters used in Song et al.’s study [

16] and we used the experimental data in this study to establish the PCAs Preisach model. The desired displacement was taken as the input of the PI inverse model, the Preisach inverse model, and the tripartite PI inverse model. Thus, we got three sets of control voltages. These three sets of voltages were used to control the piezoelectric ceramic via the driving power. The output displacement was collected and recorded in real time by the laser interferometer. The control block diagram is shown in

Figure 18. After the experiment, the data was processed and compared.

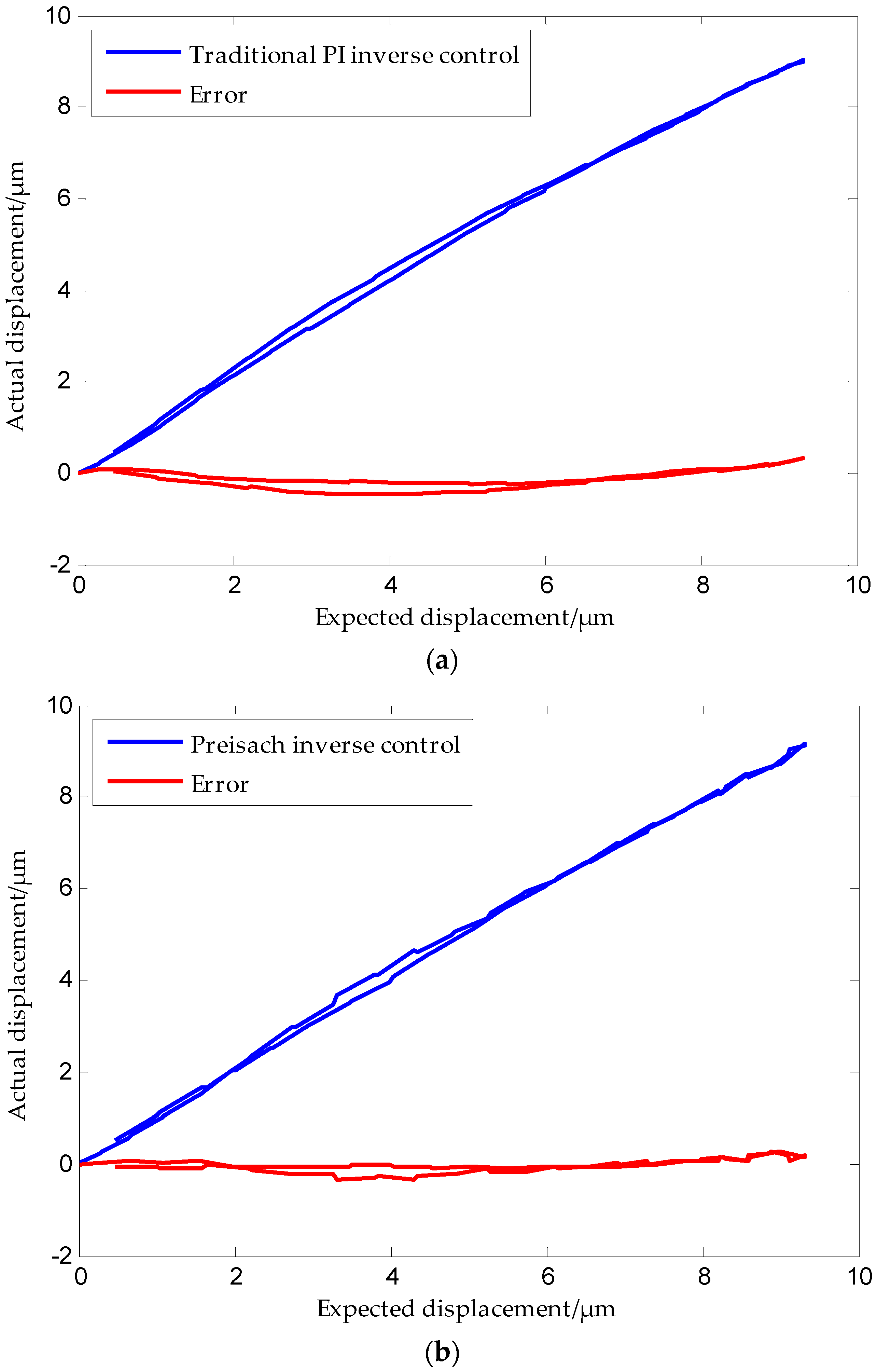

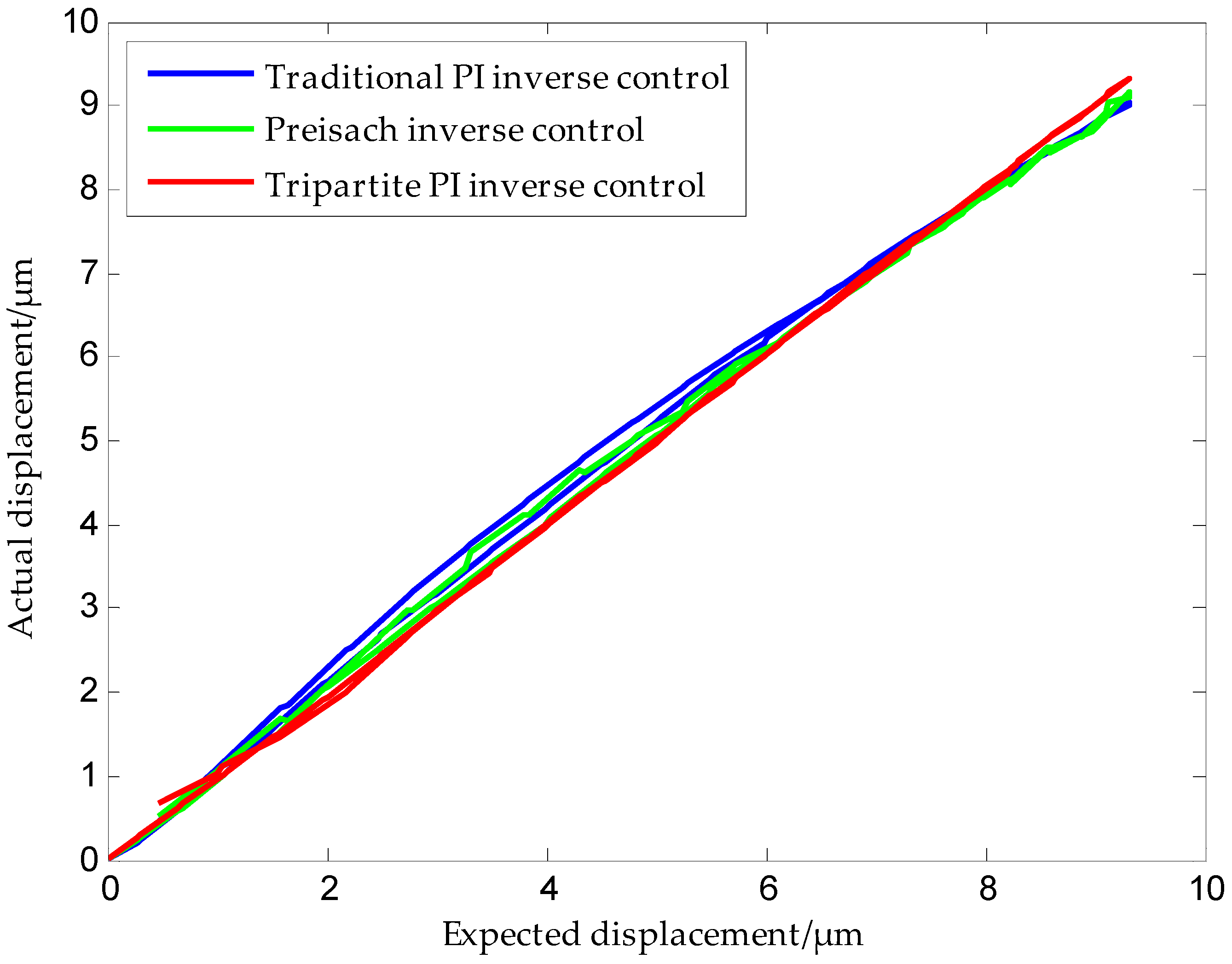

The results obtained are shown in

Figure 19. The mean absolute errors (

MAE) of the traditional inverse PI model, the Preisach inverse model, and the tripartite PI inverse model compensation controllers are

MAE = 0.19019 μm,

MAE = 0.10893 μm, and

MAE = 0.03549 μm, respectively.

Figure 20 shows a comparison of the positioning accuracies of the three models. It can be seen from the figure that the positioning accuracy of the tripartite PI model was higher than that of the traditional PI model and the Preisach model. Error analysis shows that the positioning accuracy was improved by more than 80% in the case of the tripartite inverse model when compared to the other two models. Experiments confirm that the proposed modeling method was effective.