Effect of Process Parameters on Flow Length and Flash Formation in Injection Moulding of High Aspect Ratio Polymeric Micro Features

Abstract

:1. Introduction

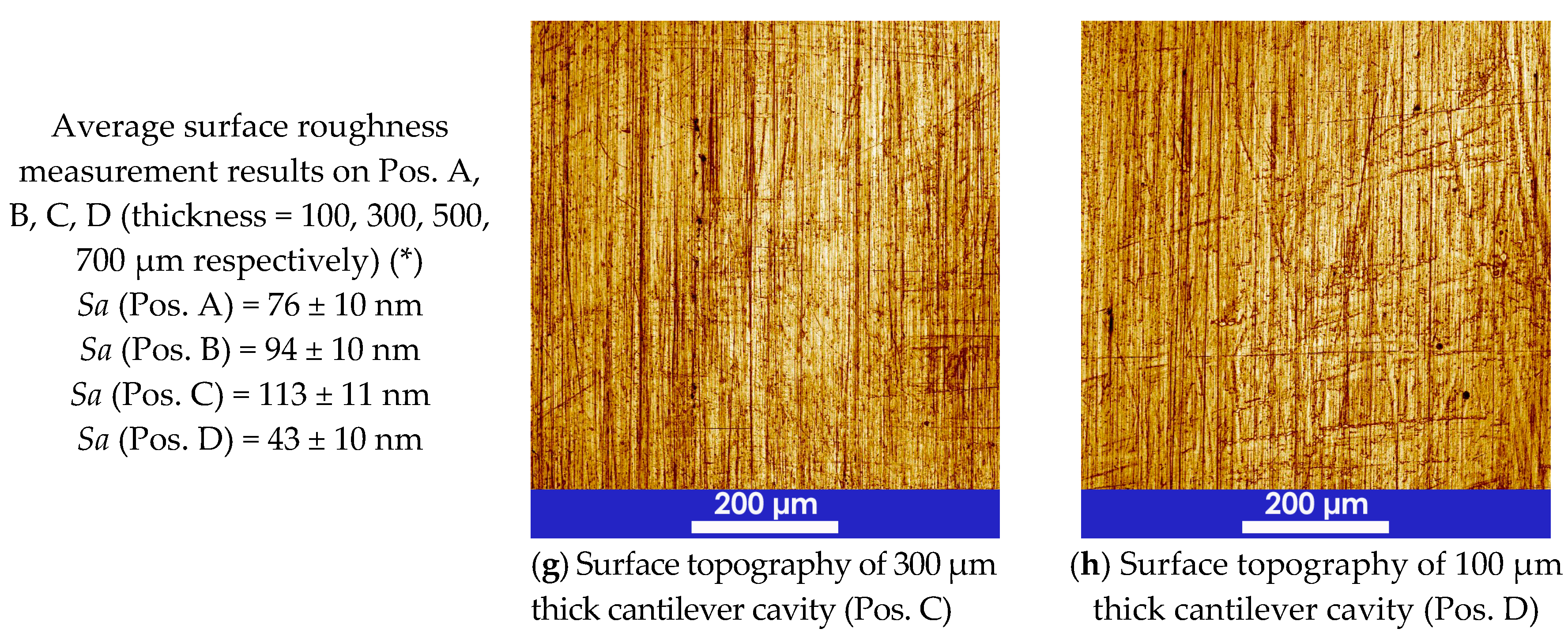

2. Materials and Methods

2.1. Polymeric Materials

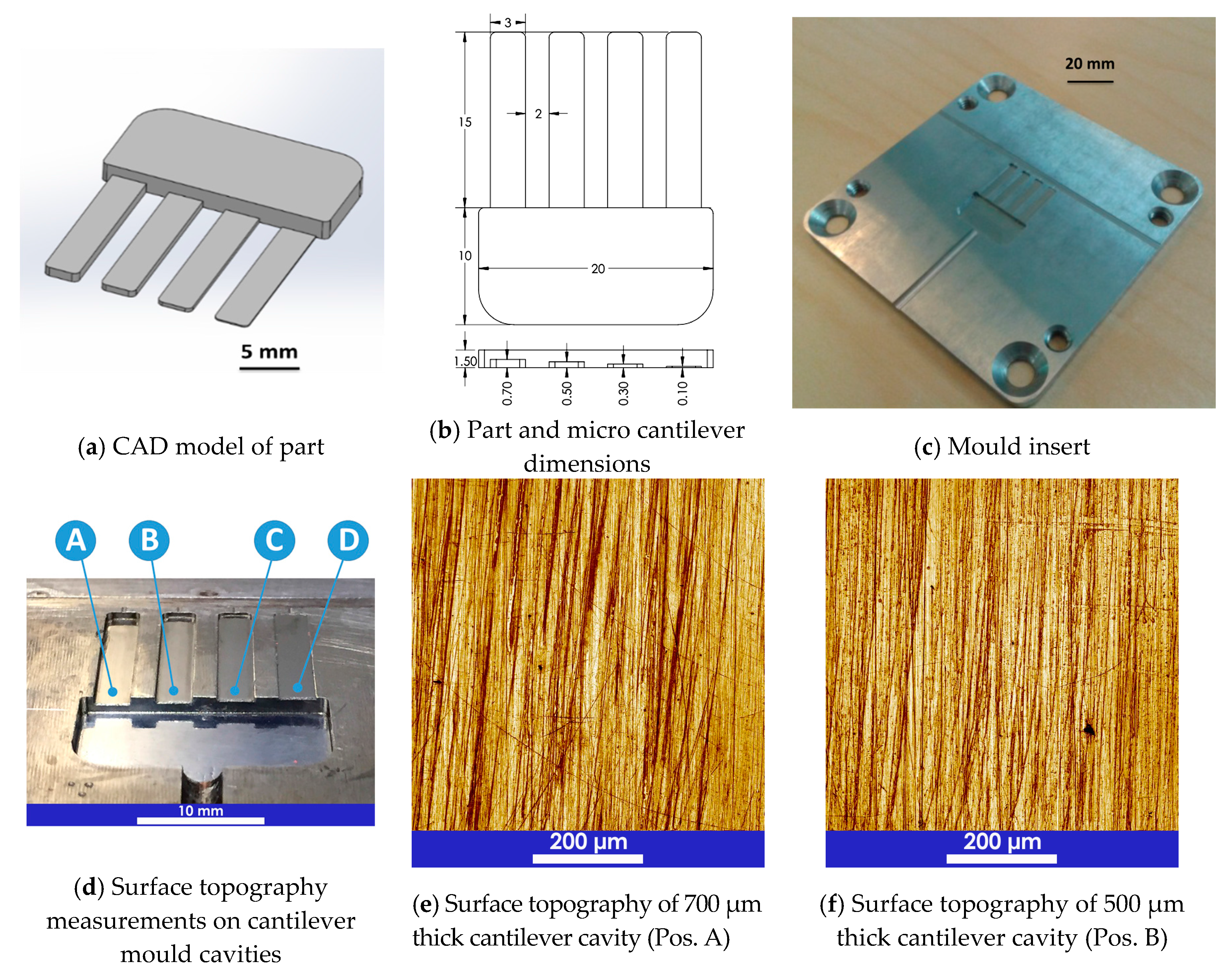

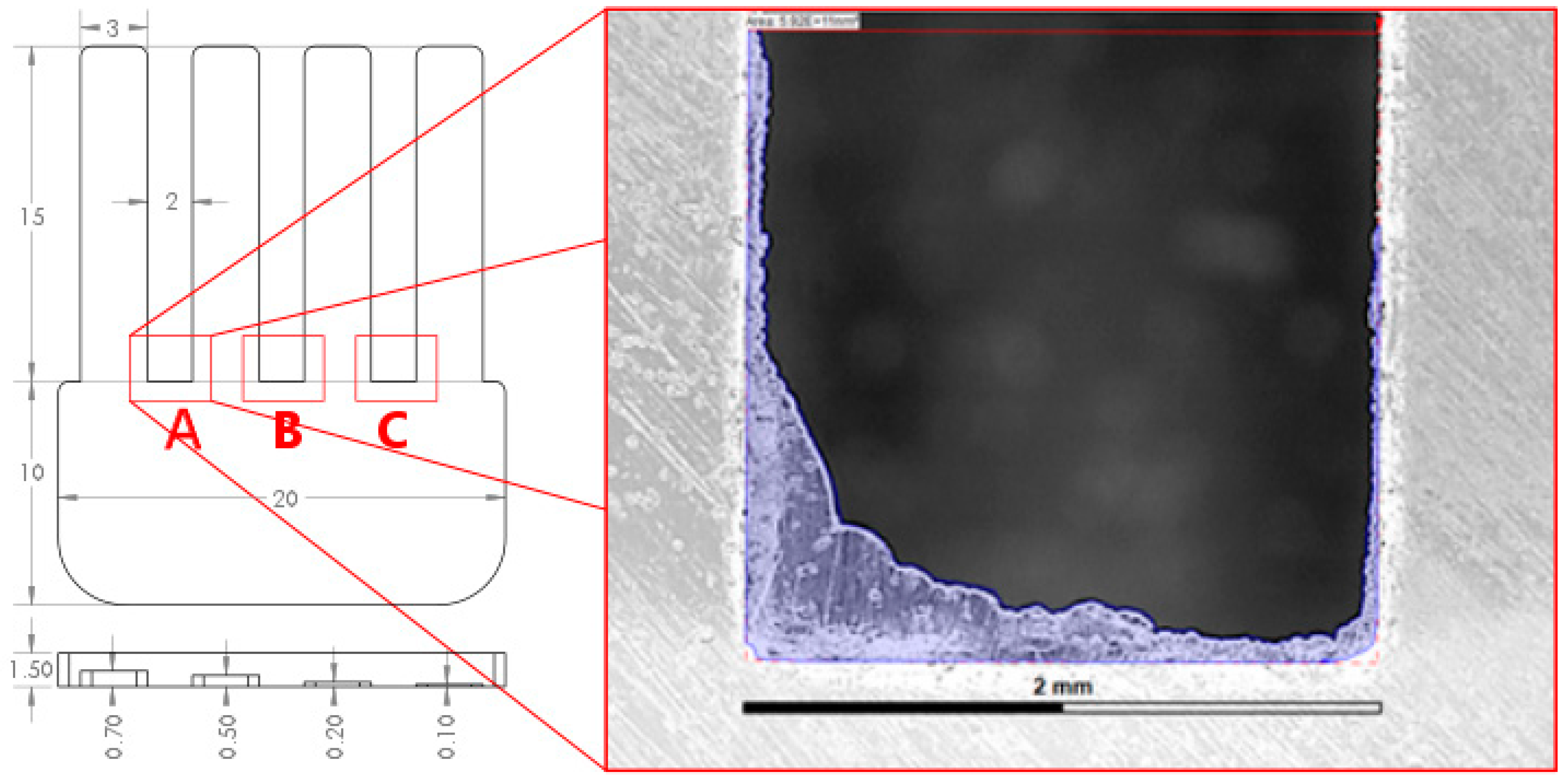

2.2. Part Geometry and Tooling

2.3. Experimentation

- Melt temperature:

- -

- (Min) 240 °C was selected as the lowest melt temperature following the recommendation of the material supplier.

- -

- (Max) 270 °C was selected as the highest melt temperature following the recommendation of the material supplier.

- Mould temperature:

- -

- (Min) 20 °C was the lowest temperature allowing micro finger replication and complete filling of the cavity.

- -

- (Max) 60 °C was selected as the highest melt temperature following the recommendation of the material supplier, in order to allow successful demoulding of the part from the cavity.

- Holding pressure:

- -

- (Min) 10 MPa for PP materials and 20 MPa for ABS materials, which provided acceptable shrinkage compensation and dimensional accuracy.

- -

- (Max) 60 MPa for PP materials and 70 MPa for ABS materials were the maximum values allowing automatic demoulding without distortion.

- Injection velocity:

- -

- (Min) 140 mm/s was selected based on experimentation. This was the minimum injection speed that allowed the part to fill completely.

- -

- (Max) 220 mm/s was selected based on experimentation. This was the highest injection speed at which a continuous injection moulding process could be achieved.

3. Analysis of the Results

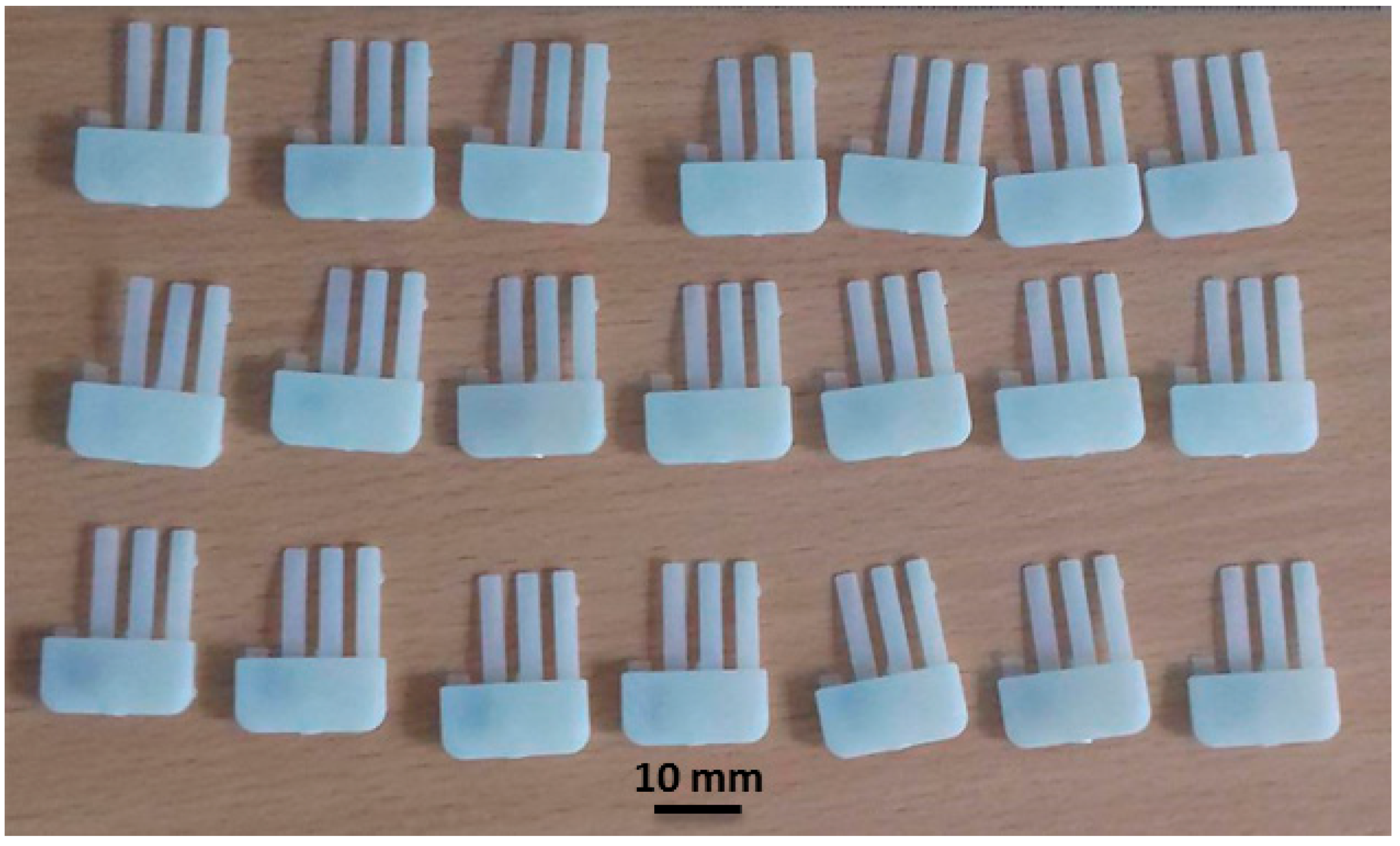

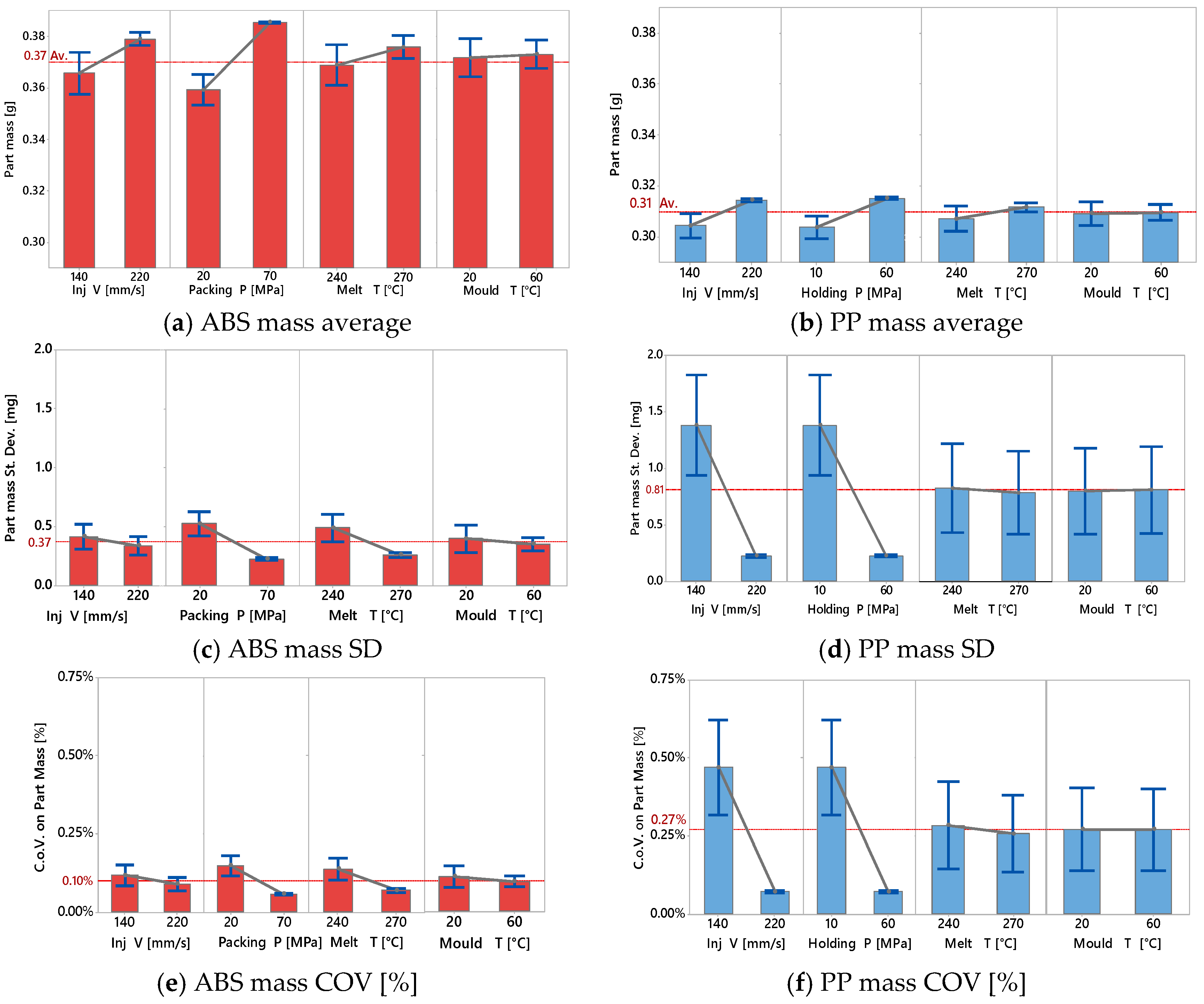

3.1. Factors Affecting Part Mass

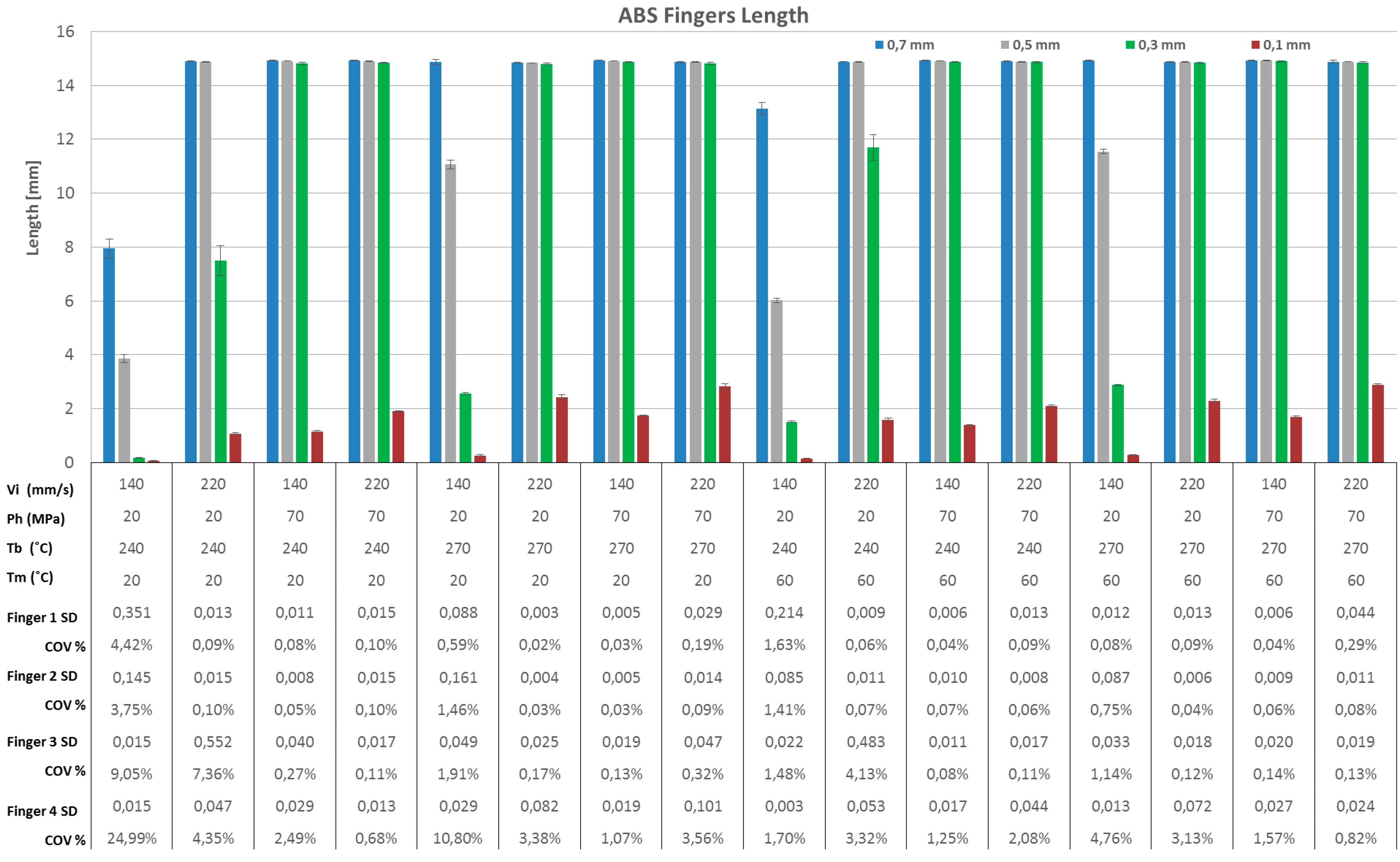

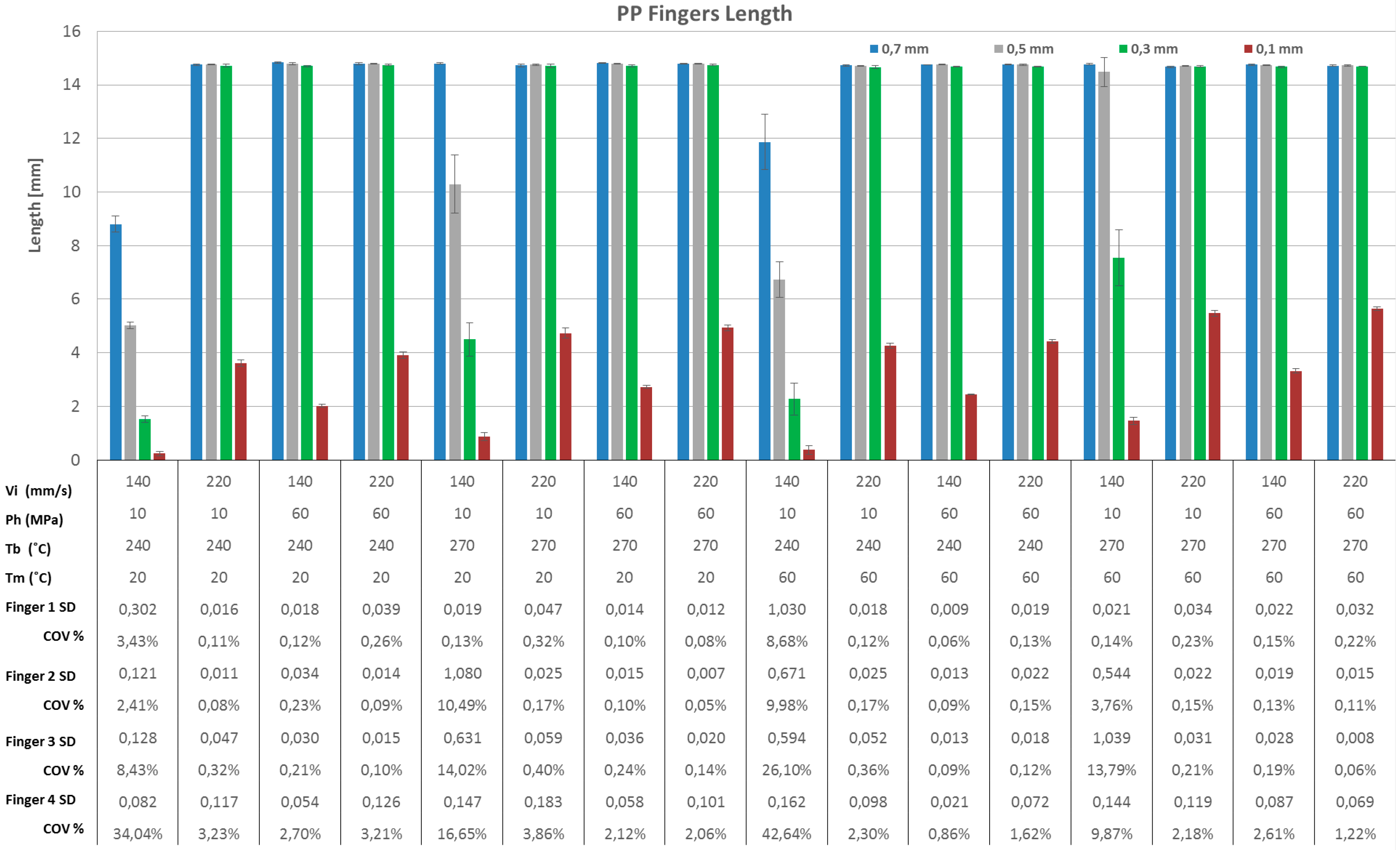

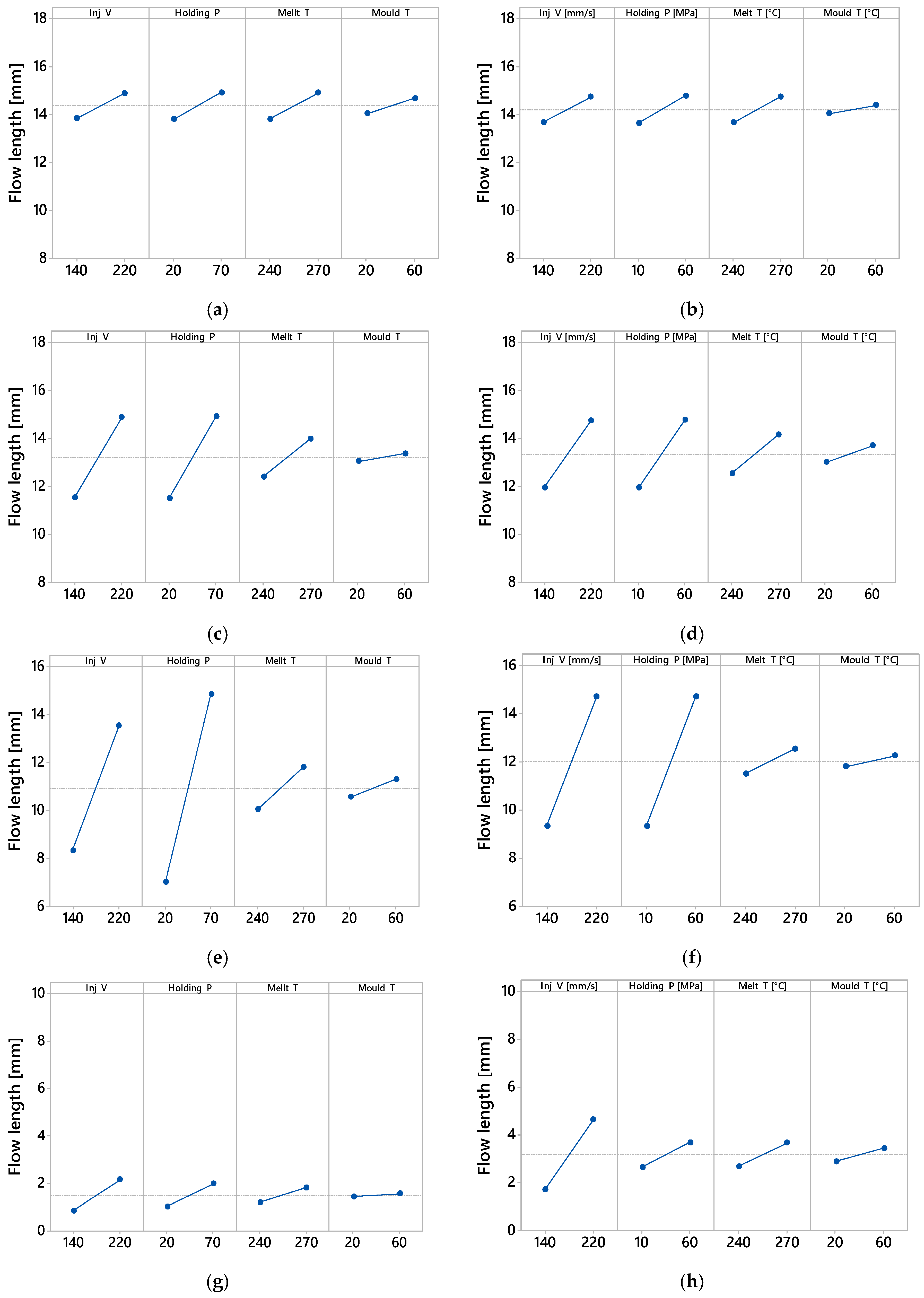

3.2. Factors Affecting Finger Filling Flow Length

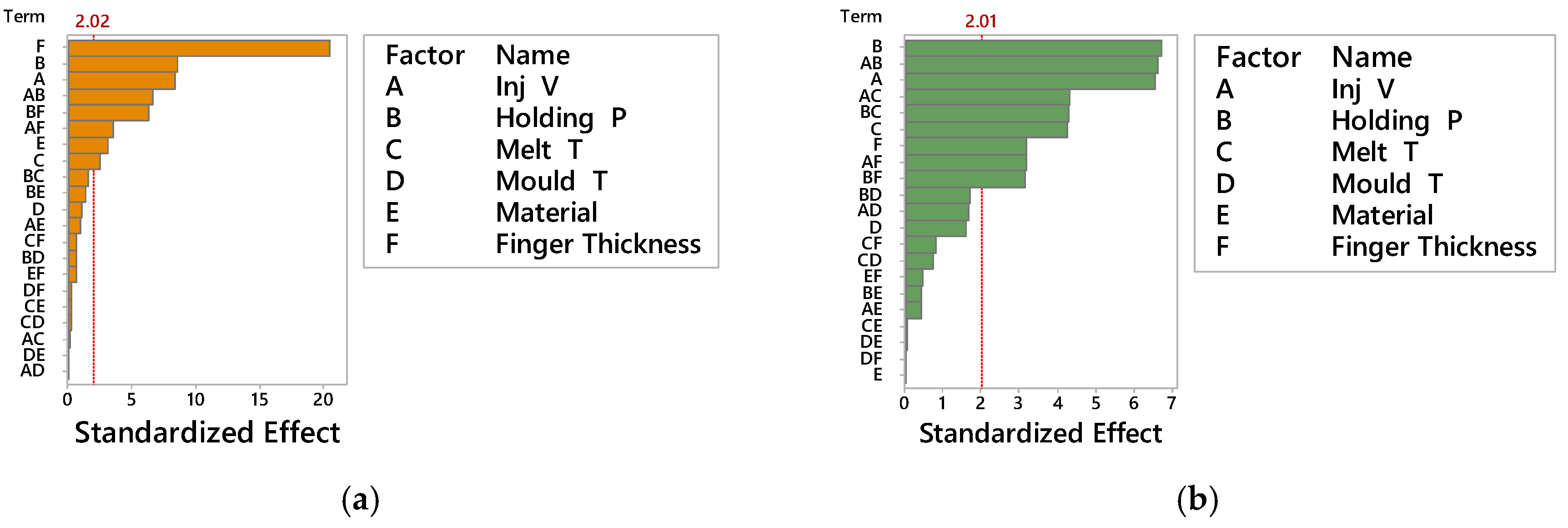

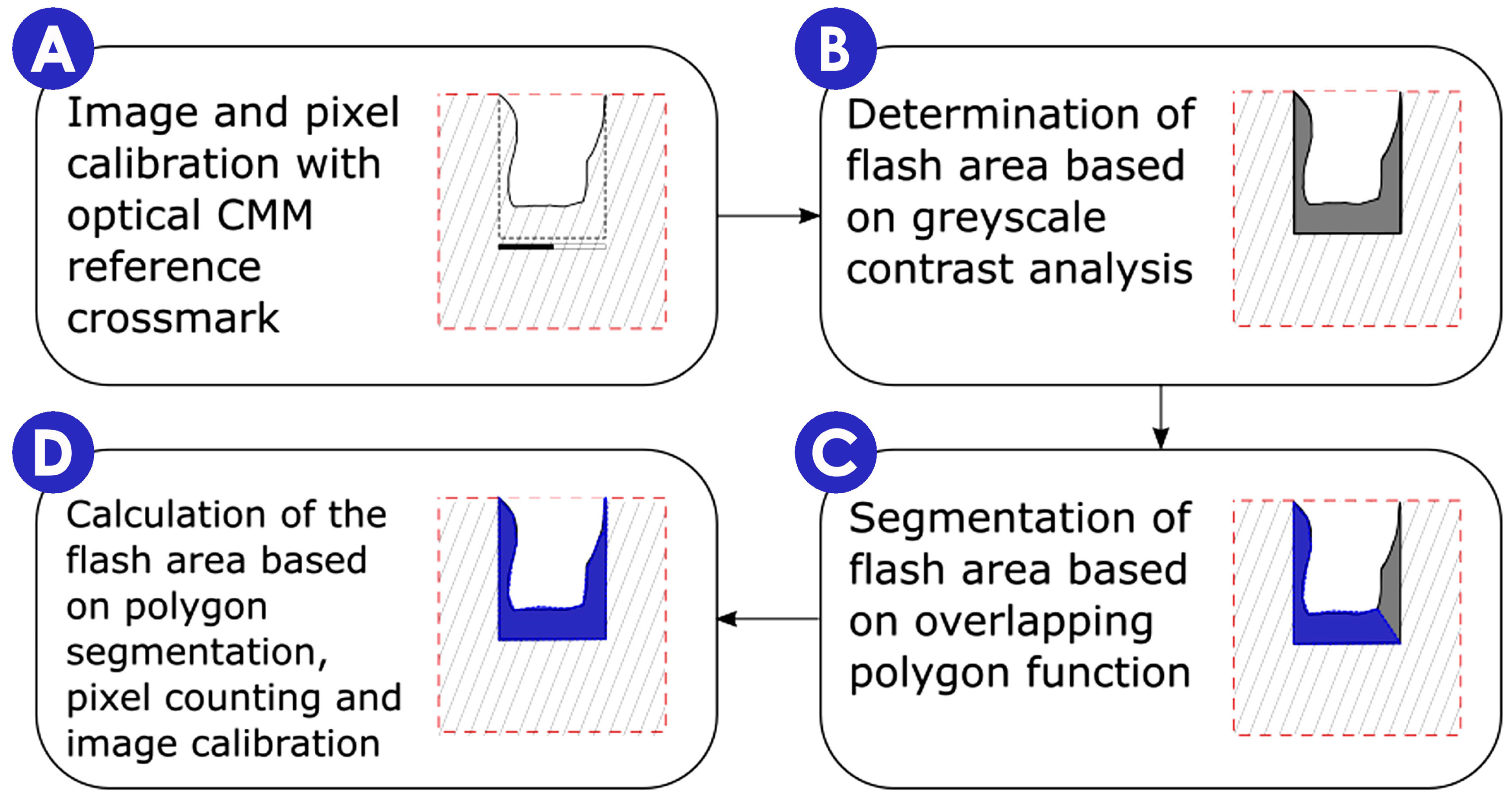

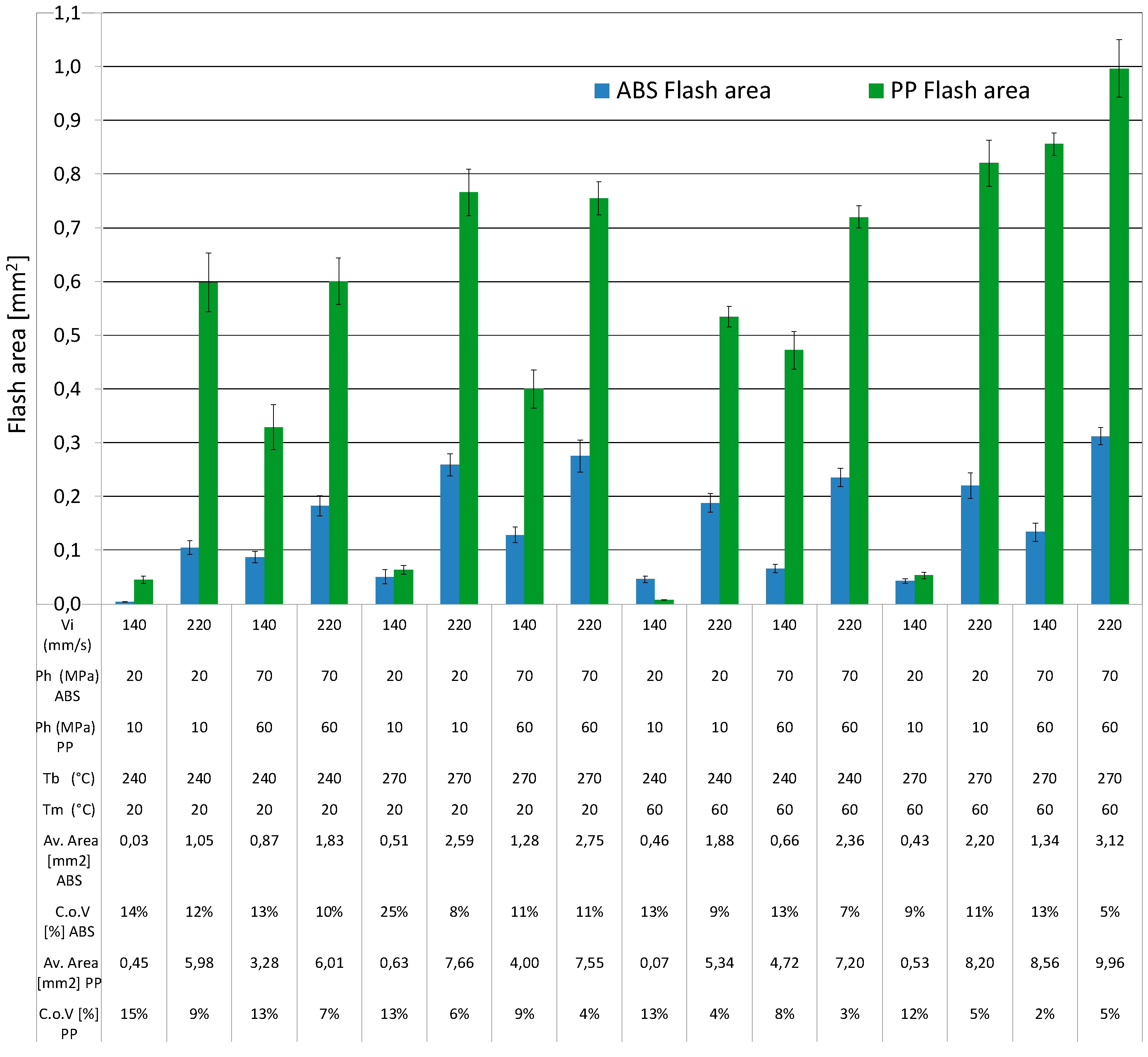

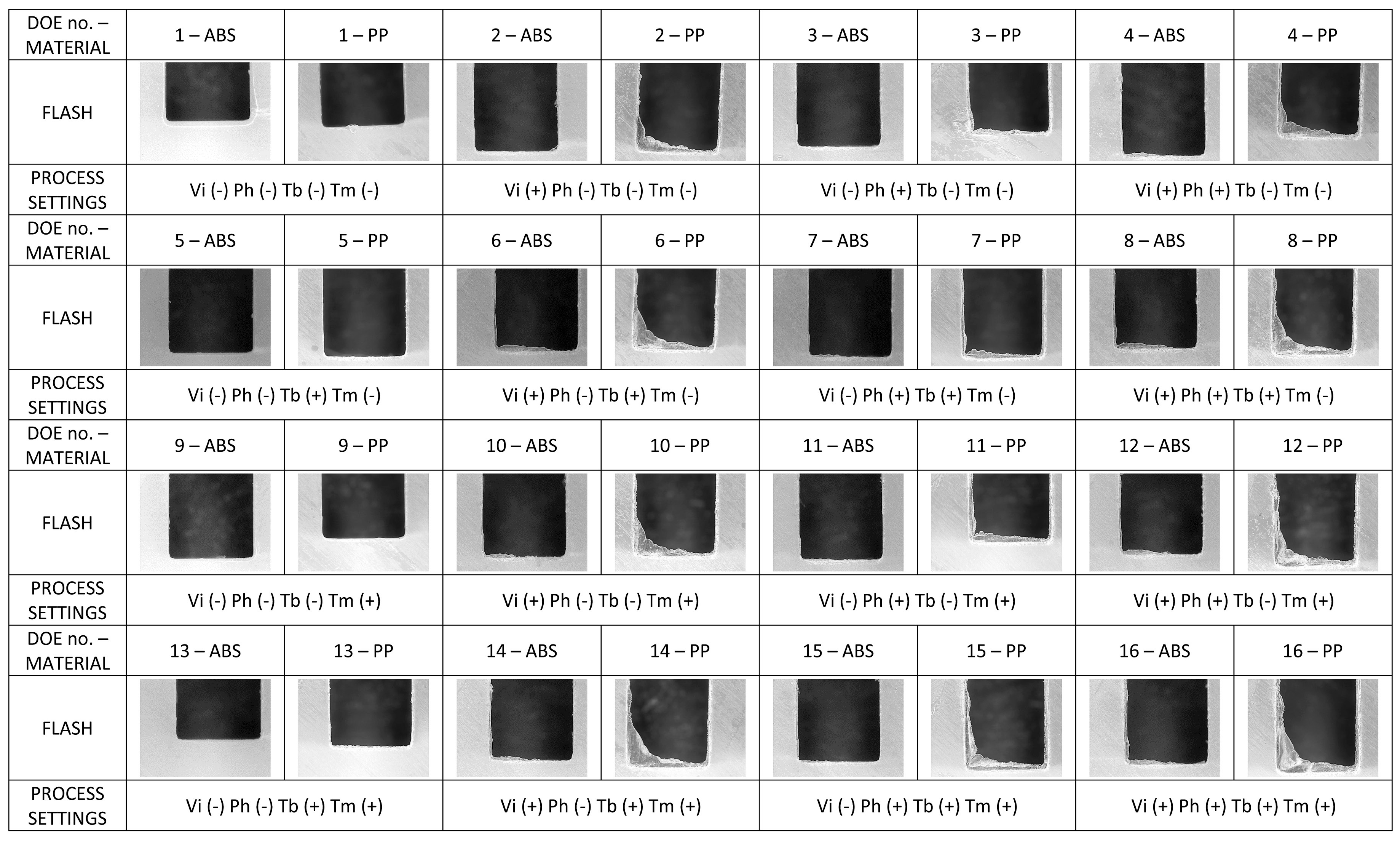

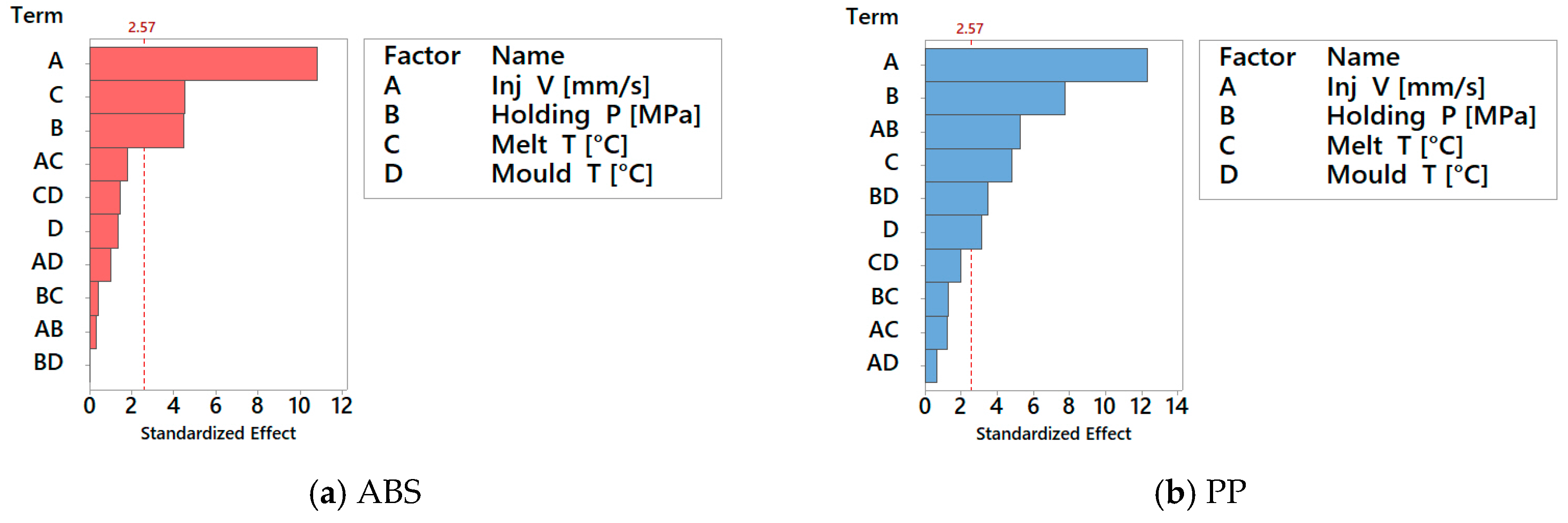

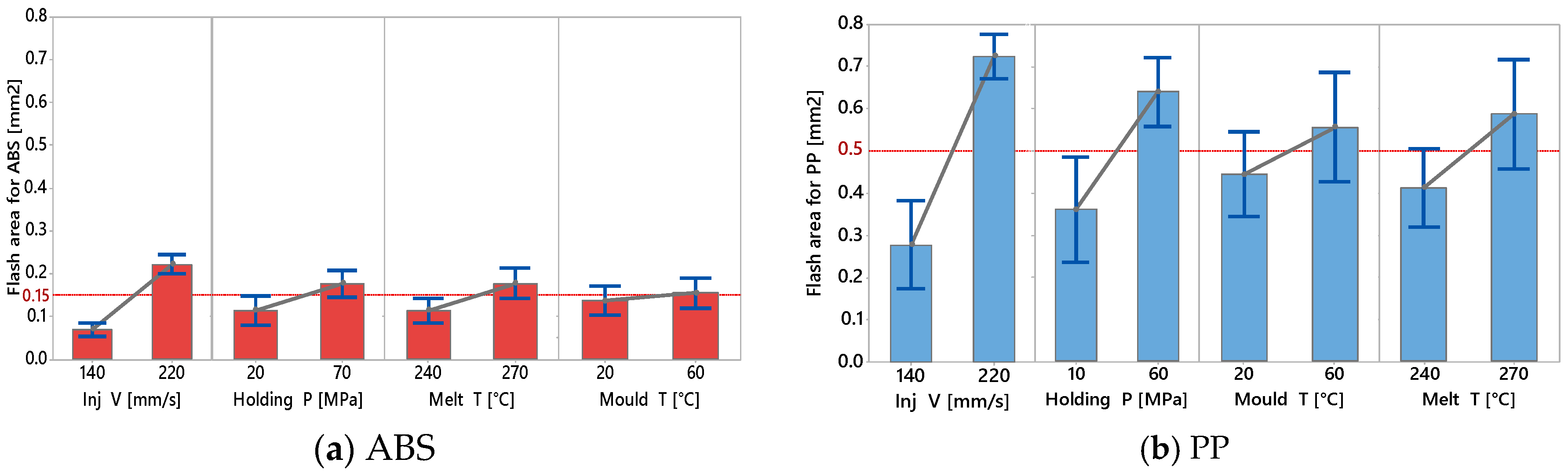

3.3. Factors Affecting Flash Formation

4. Conclusions

- Among the four process parameters considered in this research (injection velocity, holding pressure, melt temperature and mould temperature), results showed that the holding pressure and injection speed were the most effective on mass and flow length for both the used materials (ABS and PP) and the for all considered micro cantilever geometries.

- Flow length was inversely proportional to the thickness of the fingers high aspect ratio features. However, a non-linear behaviour was observed across the micro geometries analysed. For finger having thickness of 500 μm and above, both ABS and PP had similar flow length across the entire process window with similar filling behaviours. For finger thickness of 300 μm and below, PP had an increasingly better filling performance than ABS as the thickness decreased down to 100 μm. ABS flowability was severely challenged due to its higher viscosity with respect to PP. The decreasing of thickness gave raise to higher effect of injection speed and packing pressure in increasing the flow length, both for PP and ABS.

- The flash amount created when moulding the PP material was generally larger than the flash amount for the ABS material when considering corresponding processing conditions. Injection speed and holding pressure had higher effects than melt and mould temperature and revealed to be the most affective parameters on increasing the amount of flash for both material when set at high levels. The area of flash generated when moulding PP was in average 3.3 larger than that of ABS. However, the relative importance of the four process parameters in promoting flash formation was the same for ABS and PP, indicating similarity among the two materials in their relative sensitivity to changes in moulding parameters settings.

Acknowledgment

Author Contributions

Conflicts of Interest

References

- Hansen, H.N.; Hocken, R.J.; Tosello, G. Replication of micro and nano surface geometries. CIRP Ann.-Manuf. Technol. 2011, 60, 695–714. [Google Scholar] [CrossRef]

- Kim, W.W.; Gang, M.G.; Min, B.K.; Kim, W.B. Experimental and numerical investigations of cavity filling process in injection moulding for microcantilever structures. Int. J. Adv. Manuf. Technol. 2014, 75, 293–304. [Google Scholar] [CrossRef]

- Calaon, M.; Hansen, H.N.; Tosello, G.; Garnaes, J.; Nørregaard, J.; Li, W. Microfluidic chip designs process optimization and dimensional quality control. Microsyst. Technol. J. 2013, 21, 561–570. [Google Scholar] [CrossRef]

- Packianather, M.; Griffiths, C.; Kadir, W. Micro injection moulding process parameter tuning. Procedia CIRP 2015, 33, 400–405. [Google Scholar] [CrossRef]

- Fu, G.; Tor, S.B.; Hardt, D.E.; Loh, N.H. Effects of processing parameters on the micro-channels replication in microfluidic devices fabricated by micro injection molding. Microsyst. Technol. 2011, 17, 1791–1798. [Google Scholar] [CrossRef]

- Yang, D.; Liu, C.; Xu, Z.; Wang, J.Z.; Wang, L.D. Effect of microinjection molding process parameters for various micro-channels. Key Eng. Mater. 2011, 483, 53–57. [Google Scholar] [CrossRef]

- Mani, M.R.; Surace, R.; Ferreira, P.; Segal, J.; Fassi, I.; Ratchev, S. Process Parameter Effects on Dimensional Accuracy of Microinjection Moulded Part. J. Micro- Nano-Manuf. 2013, 1, 031003-1–031003-8. [Google Scholar] [CrossRef]

- Attia, U.M.; Alcock, J.R. Optimising process conditions for multiple quality criteria in microinjection moulding. Int. J. Adv. Manuf. Technol. 2010, 50, 533–542. [Google Scholar] [CrossRef] [Green Version]

- Yang, C.; Li, L.; Huang, H.; Castro, J.M.; Yi, A.Y. Replication Characterization of Microribs Fabricated by Combining Ultraprecision Machining and Microinjection Molding. Polym. Eng. Sci. 2010. [Google Scholar] [CrossRef]

- Bellantone, V.; Surace, R.; Trotta, G.; Fassi, I. Replication capability of micro injection moulding process for polymeric parts manufacturing. Int. J. Adv. Manuf. Technol. 2013, 67, 1407–1421. [Google Scholar] [CrossRef]

- Metwally, K.; Barriere, T. Replication of micronic and submicronic structured surfaces using micro-injection and micro-injection compression moulding. Int. J. Adv. Manuf. Technol. 2013, 83, 779–789. [Google Scholar] [CrossRef]

- Zhang, N.; Browne, D.J.; Gilchrist, M.D. Characterization of Micro Injection Molding Process for the Replication of Micro/Nano Features Using Bulk Metallic Glass Insert. IACSIT Int. J. Eng. Technol. 2013, 5, 198. [Google Scholar] [CrossRef]

- Lee, J.G.; Lee, B.K.; Kang, T.G.; Kwon, T.H. Experimental and Numerical Investigation of Injection Molding with Microribs Patterns. Polym. Eng. Sci. 2010, 5, 1186–1198. [Google Scholar] [CrossRef]

- Rodgers, J.W.; Casey, M.E.; Jedlicka, S.S.; Coulter, J.P. Effect of Micro-Injection Molding Processing Conditions on the Replication and Consistency of a Dense Network of High Aspect Ratio Microstructures. J. Micro- Nano-Manuf. 2014, 2, 011006-1–011006-8. [Google Scholar] [CrossRef]

- Qiu, Z.J.; Ma, Z.; Gao, S. Effects of process parameters on the molding quality of the micro-needle array. In Proceedings of the Global Conference on Polymer and Composite Materials, Hangzhou, China, 20–23 May 2016; Volume 137. [Google Scholar] [CrossRef]

- Matschuk, M.; Larsen, N.B. Injection molding of high aspect ratio sub-100 nm nanostructures. J. Micromech. Microeng. 2013, 23, 1–10. [Google Scholar] [CrossRef]

- Baruffi, F.; Calaon, M.; Tosello, G. Effects of micro-injection moulding process parameters on accuracy and precision of thermoplastic elastomer micro rings. Precis. Eng. 2018, 51, 353–361. [Google Scholar] [CrossRef]

- Stormonth-Darling, J.M.; Pedersen, R.H.; How, C.; Gadegaard, N. Injection moulding of ultra-high aspect ratio nanostructures using coated polymer tooling. J. Micromech. Microeng. 2014, 24, 075019. [Google Scholar] [CrossRef]

- Han, S.; Kim, W. Microinjection moulding of miniaturised polymeric ortho-planar springs. Microsyst. Technol. 2016, 22, 1991–1999. [Google Scholar] [CrossRef]

- Yang, C.; Huang, H.X.; Castro, J.M.; Yi, A.Y. Replication Characterization in Injection Molding of Microfeatures with High Aspect Ratio: Influence of Layout and Shape Factor. Polym. Eng. Sci. 2011, 51, 959–968. [Google Scholar] [CrossRef]

- Packianather, M.; Chana, F.; Griffiths, C.; Dimov, S.; Pham, D.T. Optimizations of micro injection moulding process through design of experiments. In Proceedings of the 8th CIRP Conference on Intelligent Computation in Manufacturing Engineering, Munich, Germany, 6–9 October 2013. [Google Scholar] [CrossRef]

- Pina-Estany, J.; Colominas, C.; Fraxedas, J.; Llobet, J.; Perez-Murano, F.; Puigoriol-Forcada, J.M.; Ruso, D.; Garcia-Granada, A.A. A statistical analysis of nanocavities replication applied to injection moulding. Int. Commun. Heat Mass Transf. 2016, 81, 131–140. [Google Scholar] [CrossRef]

- Autodesk Moldflow Insight®. Database, 2016, Autodesk: San Rafael, CA, USA, 2016.

- Bellantone, V.; Surace, R.; Modica, F.; Fassi, I. Evaluation of mold roughness influence on injected thin micro-cavities. Int. J. Adv. Manuf. Technol. 2017, 1–11. [Google Scholar] [CrossRef]

- Zhang, H.L.; Ong, N.S.; Lam, Y.C. Mold surface roughness effects on cavity filling of polymer melt in micro injection molding. Int. J. Adv. Manuf. Technol. 2008, 37, 1105–1112. [Google Scholar] [CrossRef]

- Stanek, M.; Manas, M.; Manas, D.; Senkerik, V. How Surface Roughness Influence the Polymer Flow. RECENT ADVANCES IN MECHANICAL ENGINEERING and MECHANICS. In Proceedings of the 2014 International Conference on Theoretical Mechanics and Applied Mechanics (TMAM ‘14) and the 2014 International Conference on Mechanical (ME ’14), Venice, Italy, 15–17 March 2014; Volume 10, ISBN 978-1-61804-226-2. [Google Scholar]

- Griffiths, C.A.; Dimov, S.S.; Scholz, S.; Hirshy, H.; Tosello, G. Process Factors Influence on Cavity Pressure Behavior in Microinjection Moulding. J. Manuf. Sci. Eng. 2011, 133, 031007-1–031007-10. [Google Scholar] [CrossRef]

- Chen, Z.; Giacomin, A.J.; Turng, L.-S. Flash. Polym. Eng. Sci. 2006, 46, 235–383. [Google Scholar] [CrossRef]

| Standard Order | Vi | Ph (PP/ABS) | Tb | Tm |

|---|---|---|---|---|

| 1 | −(140 mm/s) | −(10/20 MPa) | −(240 °C) | −(240 °C) |

| 2 | +(220 mm/s) | −(10/20 MPa) | −(240 °C) | −(240 °C) |

| 3 | −(140 mm/s) | +(60/70 MPa) | −(240 °C) | −(240 °C) |

| 4 | +(220 mm/s) | +(60/70 MPa) | −(240 °C) | −(240 °C) |

| 5 | −(140 mm/s) | −(10/20 MPa) | +(270 °C) | −(240 °C) |

| 6 | +(220 mm/s) | −(10/20 MPa) | +(270 °C) | −(240 °C) |

| 7 | −(140 mm/s) | +(60/70 MPa) | +(270 °C) | −(240 °C) |

| 8 | +(220 mm/s) | +(60/70 MPa) | +(270 °C) | −(240 °C) |

| 9 | −(140 mm/s) | −(10/20 MPa) | −(240 °C) | +(270 °C) |

| 10 | +(220 mm/s) | −(10/20 MPa) | −(240 °C) | +(270 °C) |

| 11 | −(140 mm/s) | +(60/70 MPa) | −(240 °C) | +(270 °C) |

| 12 | +(220 mm/s) | +(60/70 MPa) | - (240 °C) | +(270 °C) |

| 13 | −(140 mm/s) | −(10/20 MPa) | +(270 °C) | +(270 °C) |

| 14 | +(220 mm/s) | −(10/20 MPa) | +(270 °C) | +(270 °C) |

| 15 | −(140 mm/s) | +(60/70 MPa) | +(270 °C) | +(270 °C) |

| 16 | +(220 mm/s) | +(60/70 MPa) | +(270 °C) | +(270 °C) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eladl, A.; Mostafa, R.; Islam, A.; Loaldi, D.; Soltan, H.; Hansen, H.N.; Tosello, G. Effect of Process Parameters on Flow Length and Flash Formation in Injection Moulding of High Aspect Ratio Polymeric Micro Features. Micromachines 2018, 9, 58. https://doi.org/10.3390/mi9020058

Eladl A, Mostafa R, Islam A, Loaldi D, Soltan H, Hansen HN, Tosello G. Effect of Process Parameters on Flow Length and Flash Formation in Injection Moulding of High Aspect Ratio Polymeric Micro Features. Micromachines. 2018; 9(2):58. https://doi.org/10.3390/mi9020058

Chicago/Turabian StyleEladl, Abdelkhalik, Rania Mostafa, Aminul Islam, Dario Loaldi, Hassan Soltan, Hans N. Hansen, and Guido Tosello. 2018. "Effect of Process Parameters on Flow Length and Flash Formation in Injection Moulding of High Aspect Ratio Polymeric Micro Features" Micromachines 9, no. 2: 58. https://doi.org/10.3390/mi9020058