Single-Wall Carbon Nanotube-Coated Cotton Yarn for Electrocardiography Transmission

Abstract

:1. Introduction

2. Materials and Methods

2.1. Ethical Statement

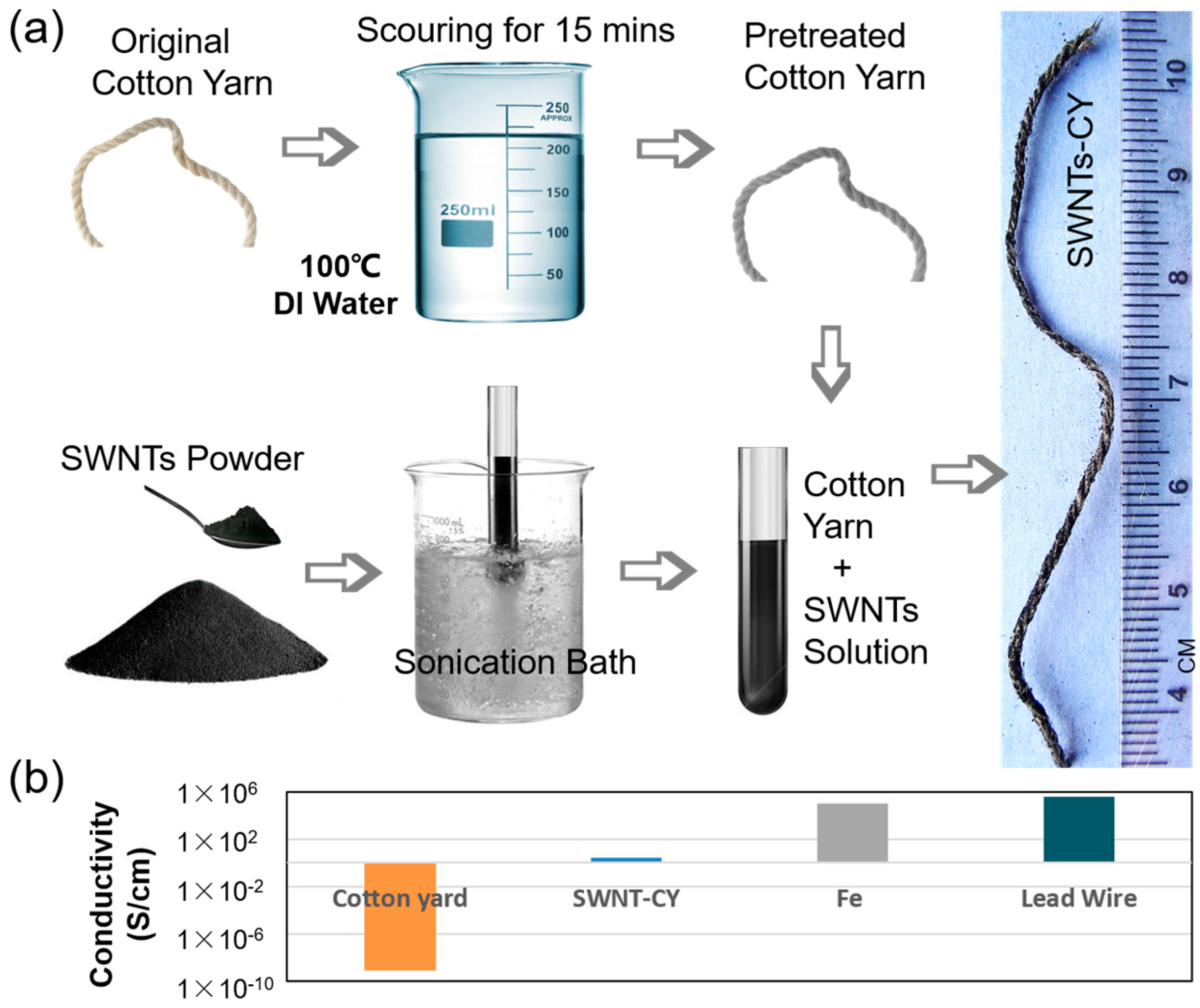

2.2. Materials Fabrication Process for Conductive Cotton Yarns

2.3. Measurement of Electromechanical Properties

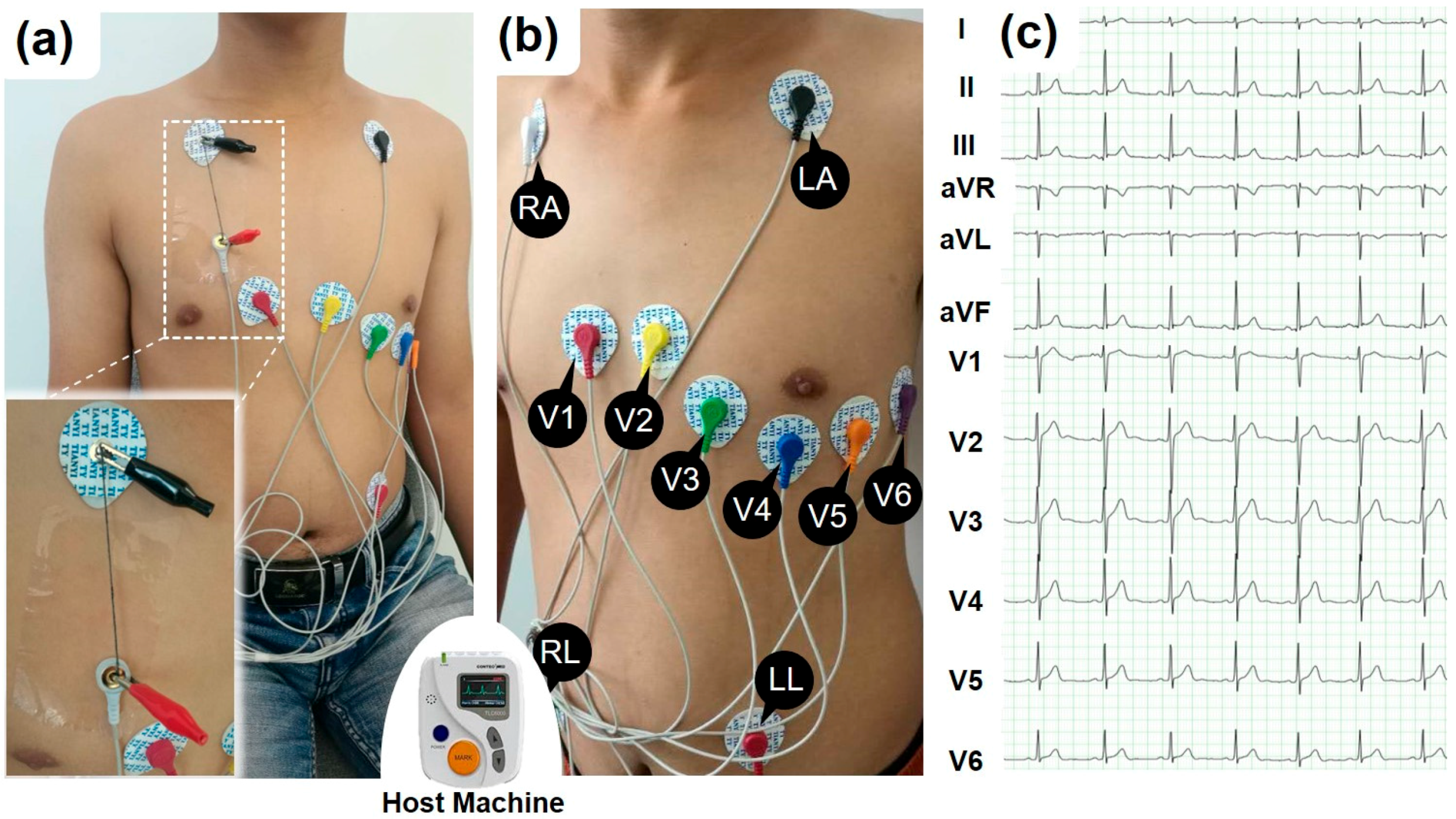

2.4. Electrocardiography (ECG) Monitoring

3. Results

3.1. Morphology of Cotton Yarn before and after SWNT Coating

3.2. Electrical Conductivity Properties of SWNT-CYs

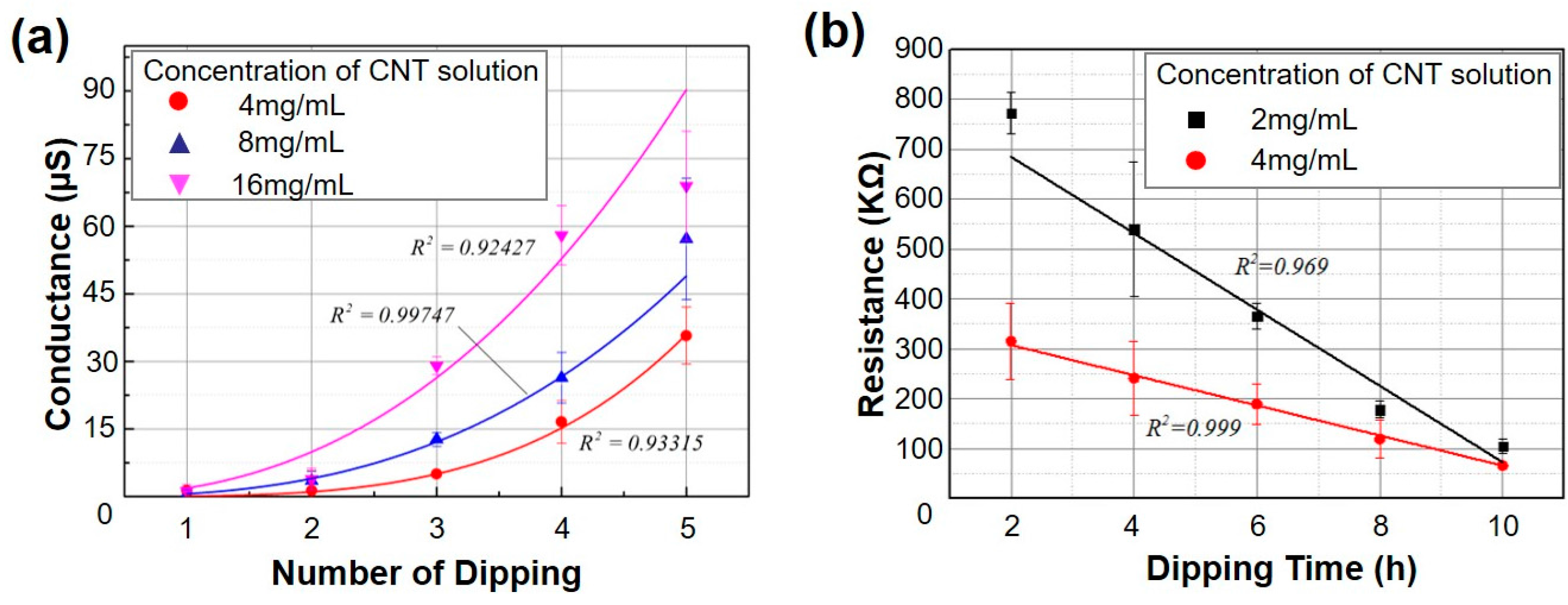

3.2.1. Conductivity Control of SWNT-CYs

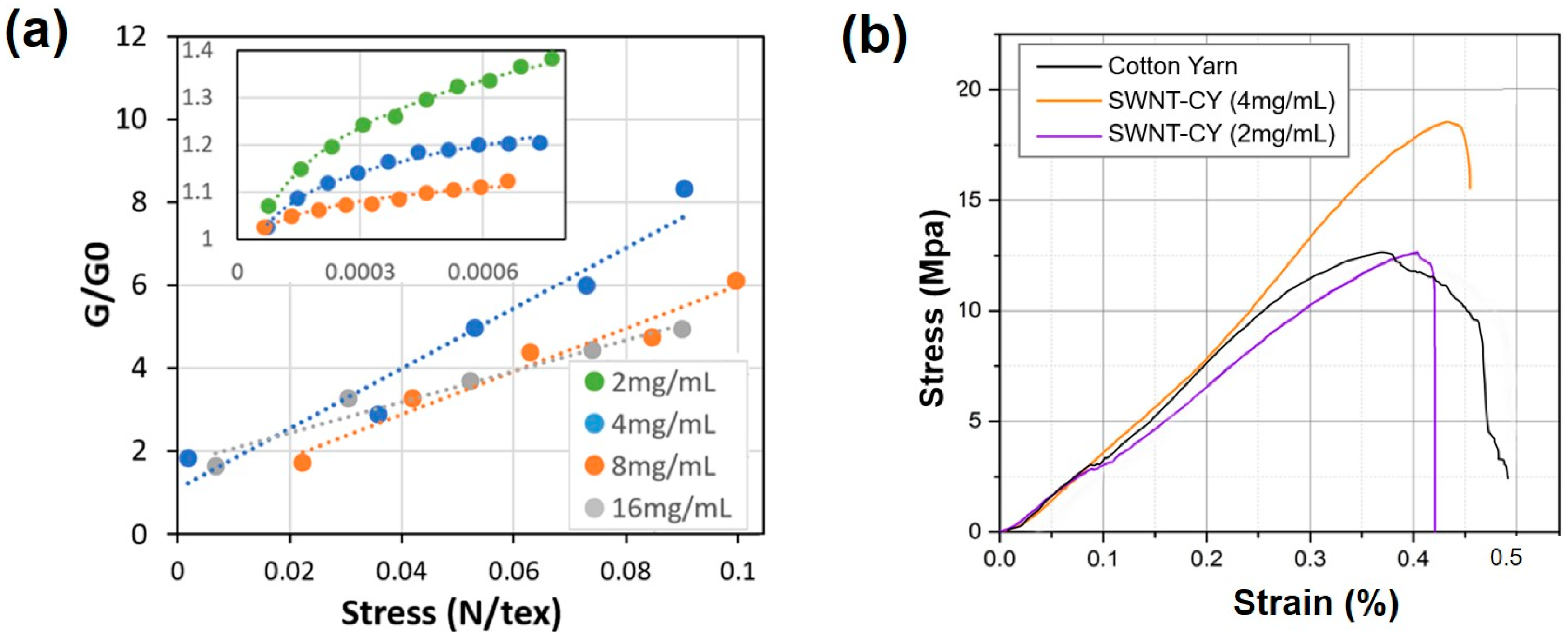

3.2.2. Conductivity and Mechanical Characteristics

3.3. Electrocardiography (ECG) Transmission

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shaikh, T.N.; Chaudhari, S.; Patel, B.H.; Patel, M. Study of conductivity behavior of nano copper loaded nonwoven polypropylene based textile electrode for ECG. Int. J. Emerg. Sci. Eng. 2015, 3, 11–14. [Google Scholar]

- Pani, D.; Dessi, A.; Saenz-Cogollo, J.F.; Barabino, G.; Fraboni, B.; Bonfiglio, A. Fully Textile, PEDOT:PSS based electrodes for wearable ECG monitoring systems. IEEE Trans. Biomed. Eng. 2016, 63, 540–549. [Google Scholar] [CrossRef] [PubMed]

- Yapici, M.K.; Alkhidir, T.; Samad, Y.A.; Liao, K. Graphene-clad textile electrodes for electrocardiogram monitoring. Sens. Actuators B Chem. 2015, 221, 1469–1474. [Google Scholar] [CrossRef]

- Haghdoost, F.; Mottaghitalab, V.; Haghi, A.K. Comfortable textile-based electrode for wearable electrocardiogram. Sens. Rev. 2015, 35, 20. [Google Scholar] [CrossRef]

- Liang, G.; Zhu, L.; Xu, J.; Fang, D.; Bai, Z.; Xu, W. Investigations of poly(pyrrole)-coated cotton fabrics prepared in blends of anionic and cationic surfactants as flexible electrode. Electrochim. Acta 2013, 103, 9–14. [Google Scholar] [CrossRef]

- Bhat, N.V.; Seshadri, D.T.; Nate, M.M.; Gore, A.V. Development of conductive cotton fabrics for heating devices. J. Appl. Polym. Sci. 2006, 102, 4690–4695. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, A.; Wang, Q.; Fan, X.; Cavaco-Paulo, A.; Zhang, Y. Conductive cotton prepared by polyaniline in situ polymerization using laccase. Appl. Biochem. Biotechnol. 2014, 174, 820–831. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pani, D.; Dessi, A.; Gusai, E.; Saenz-Cogollo, J.F.; Barabino, G.; Fraboni, B.; Bonfiglio, A. Evaluation of novel textile electrodes for ECG signals monitoring based on PEDOT:PSS-treated woven fabrics. In Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology Society, EMBS, Milan, Italy, 25–29 August 2015; pp. 3197–3200. [Google Scholar]

- Khodagholy, D.; Gelinas, J.N.; Thesen, T.; Doyle, W.; Devinsky, O.; Malliaras, G.G.; Buzsaki, G. NeuroGrid: Recording action potentials from the surface of the brain. Nat. Neurosci. 2015, 18, 310–315. [Google Scholar] [CrossRef] [PubMed]

- Takamatsu, S.; Lonjaret, T.; Crisp, D.; Badier, J.-M.; Malliaras, G.G.; Ismailova, E. Direct patterning of organic conductors on knitted textiles for long-term electrocardiography. Sci. Rep. 2015, 5, 15003. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tsukada, S.; Nakashima, H.; Torimitsu, K. Conductive polymer combined silk fiber bundle for bioelectrical signal recording. PLoS ONE 2012, 7. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Chang, H.; Li, Y.; Huck, W.T.S.; Zheng, Z. Polyelectrolyte-bridged metal/cotton hierarchical structures for highly durable conductive yarns. ACS Appl. Mater. Interfaces 2010, 2, 529–535. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Wu, C.W.; Tan, Y.Y.; Silva, S.R.P. Functionalisation of nylon with carbon nanotubes to make thermally stable fabric and wearable capacitor. Micro Nano Lett. 2012, 7, 193–195. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Zuo, X.; Wu, C. Wetting of carbon nanotube functionalised nylon and its usage as flexible electrode in electrowetting on dielectric. Micro Nano Lett. 2013, 8, 722–725. [Google Scholar] [CrossRef]

- Alimohammadi, F.; Gashti, M.P.; Shamei, A. A novel method for coating of carbon nanotube on cellulose fiber using 1,2,3,4-butanetetracarboxylic acid as a cross-linking agent. Prog. Org. Coat. 2012, 74, 470–478. [Google Scholar] [CrossRef]

- Hu, L.; Pasta, M.; La Mantia, F.; Cui, L.; Jeong, S.; Deshazer, H.D.; Choi, J.W.; Han, S.M.; Cui, Y. Stretchable, porous, and conductive energy textiles. Nano Lett. 2010, 10, 708–714. [Google Scholar] [CrossRef] [PubMed]

- Jang, E.Y.; Kang, T.J.; Im, H.; Baek, S.J.; Kim, S.; Jeong, D.H.; Park, Y.W.; Kim, Y.H. Macroscopic single-walled-carbon-nanotube fiber self-assembled by dip-coating method. Adv. Mater. 2009, 21, 4357–4361. [Google Scholar] [CrossRef] [PubMed]

- Di Rienzo, M.; Racca, V.; Rizzo, F.; Bordoni, B.; Parati, G.; Castiglioni, P.; Meriggi, P.; Ferratini, M. Evaluation of a textile-based wearable system for the electrocardiogram monitoring in cardiac patients. Europace 2013, 15, 607–612. [Google Scholar] [CrossRef] [PubMed]

- Jafar, A.; Alshatti, Y.; Ahmad, A. Carbon nanotube toxicity: The smallest biggest debate in medical care. Cogent Med. 2016, 3, 1–12. [Google Scholar] [CrossRef]

- Firme, C.P.; Bandaru, P.R. Toxicity issues in the application of carbon nanotubes to biological systems. Nanomed. Nanotechnol. Biol. Med. 2010, 6, 245–256. [Google Scholar] [CrossRef] [PubMed]

- Madani, S.Y.; Mandel, A.; Seifalian, A.M. A concise review of carbon nanotube’s toxicology. Nano Rev. 2013, 4, 21521. [Google Scholar] [CrossRef] [PubMed]

- Lacerda, L.; Bianco, A.; Prato, M.; Kostarelos, K. Carbon nanotubes as nanomedicines: From toxicology to pharmacology. Adv. Drug Deliv. Rev. 2006, 58, 1460–1470. [Google Scholar] [CrossRef] [PubMed]

- Huczko, A.; Lange, H. Carbon nanotubes: Experimental evidence for a null risk of skin irritation and allergy. Fuller. Sci. Technol. 2001, 9, 247–250. [Google Scholar] [CrossRef]

- De Volder, M.; Tawfick, S.; Baughman, R.; Hart, A. Carbon nanotubes: Present and future commercial applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.X.; Feng, C.; Zhai, Y.C.; Jiang, K.L.; Li, Q.Q.; Fan, S.S. Cross-stacked carbon nanotube sheets uniformly loaded with SnO2 nanoparticles: A novel binder-free and high-capacity anode material for lithium-ion batteries. Adv. Mater. 2009, 21, 2299–2304. [Google Scholar] [CrossRef]

- Technical Data for Iron. Available online: http://periodictable.com/Elements/026/data.html (accessed on 24 August 2017).

- Mahmoud, S.A.; Salem, H.A.; Albalooshi, H.M. An 8-bit, 10 KS/s,1.87 µW successive approximation analog to digital converter in 0.25 µm CMOS technology for ECG detection systems. Circuits Syst. Signal Process. 2015, 34, 2419–2439. [Google Scholar] [CrossRef]

- Sun, C.-Y.; Lee, S.-Y. A fifth-order butterworth OTA-C LPF with multiple-Output differential-Input OTA for ECG applications. IEEE Trans. Circuits Syst. II Express Briefs 2017. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Cao, Y.; Liu, J.; Zhan, Z.; Li, X.; Li, W.J. Single-Wall Carbon Nanotube-Coated Cotton Yarn for Electrocardiography Transmission. Micromachines 2018, 9, 132. https://doi.org/10.3390/mi9030132

Zhao Y, Cao Y, Liu J, Zhan Z, Li X, Li WJ. Single-Wall Carbon Nanotube-Coated Cotton Yarn for Electrocardiography Transmission. Micromachines. 2018; 9(3):132. https://doi.org/10.3390/mi9030132

Chicago/Turabian StyleZhao, Yuliang, Yuying Cao, Junshan Liu, Zhikun Zhan, Xiaoli Li, and Wen Jung Li. 2018. "Single-Wall Carbon Nanotube-Coated Cotton Yarn for Electrocardiography Transmission" Micromachines 9, no. 3: 132. https://doi.org/10.3390/mi9030132