Fabrication of an Anti-Reflective and Super-Hydrophobic Structure by Vacuum Ultraviolet Light-Assisted Bonding and Nanoscale Pattern Transfer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Design

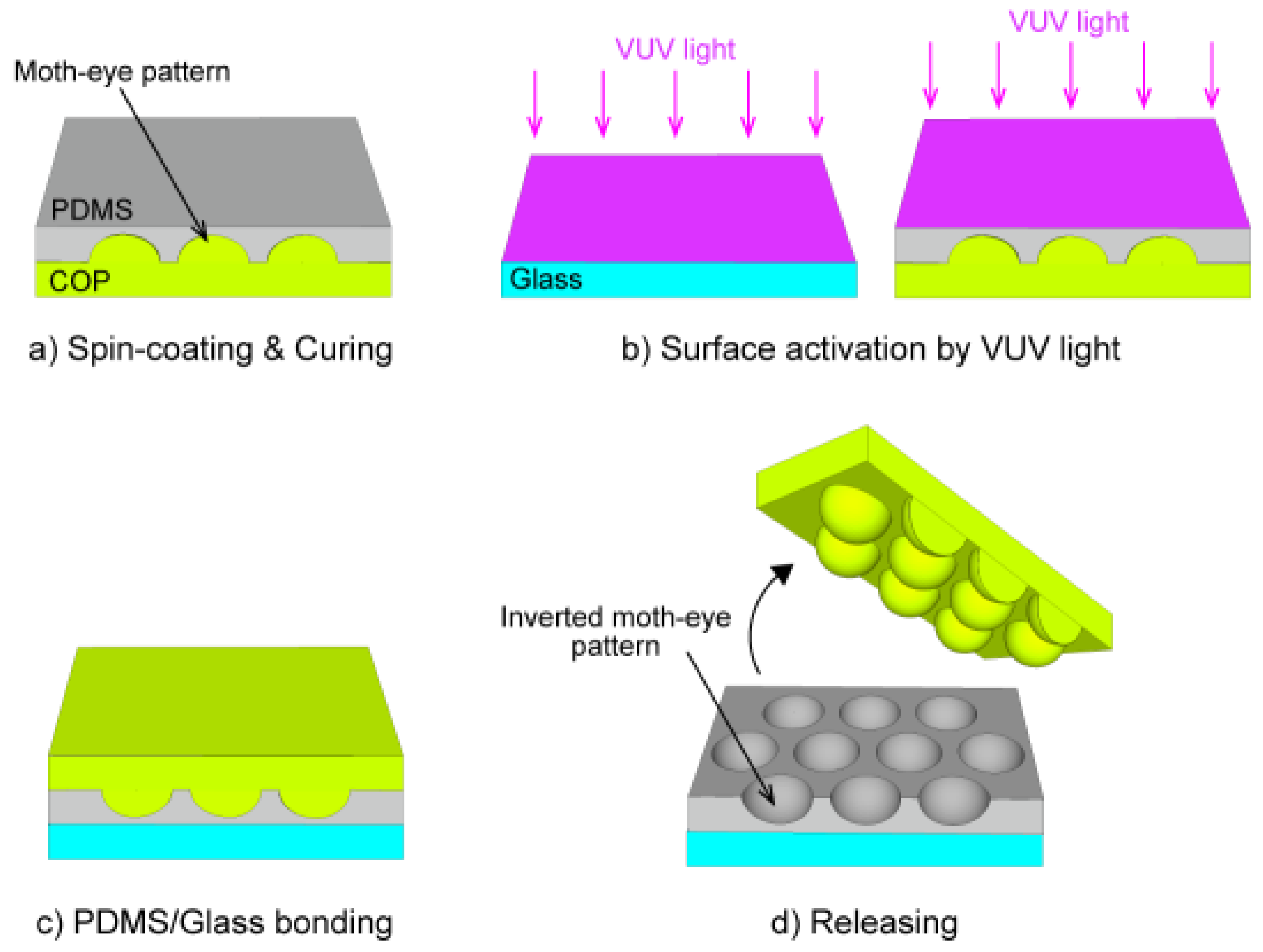

2.2. Fabrication

2.3. Optical Measurements

2.4. Contact Angle Measurements

3. Results and Discussion

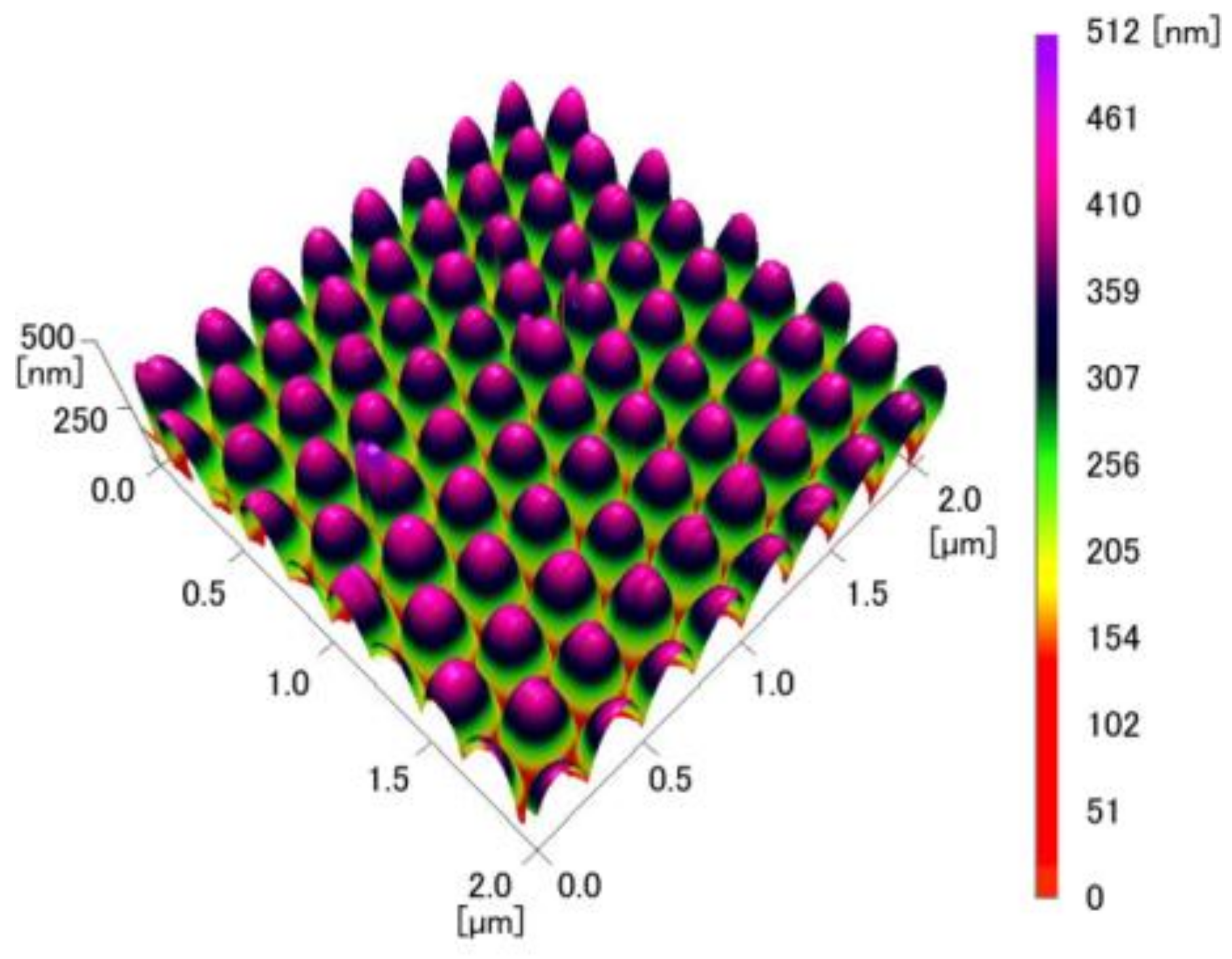

3.1. Fabrication

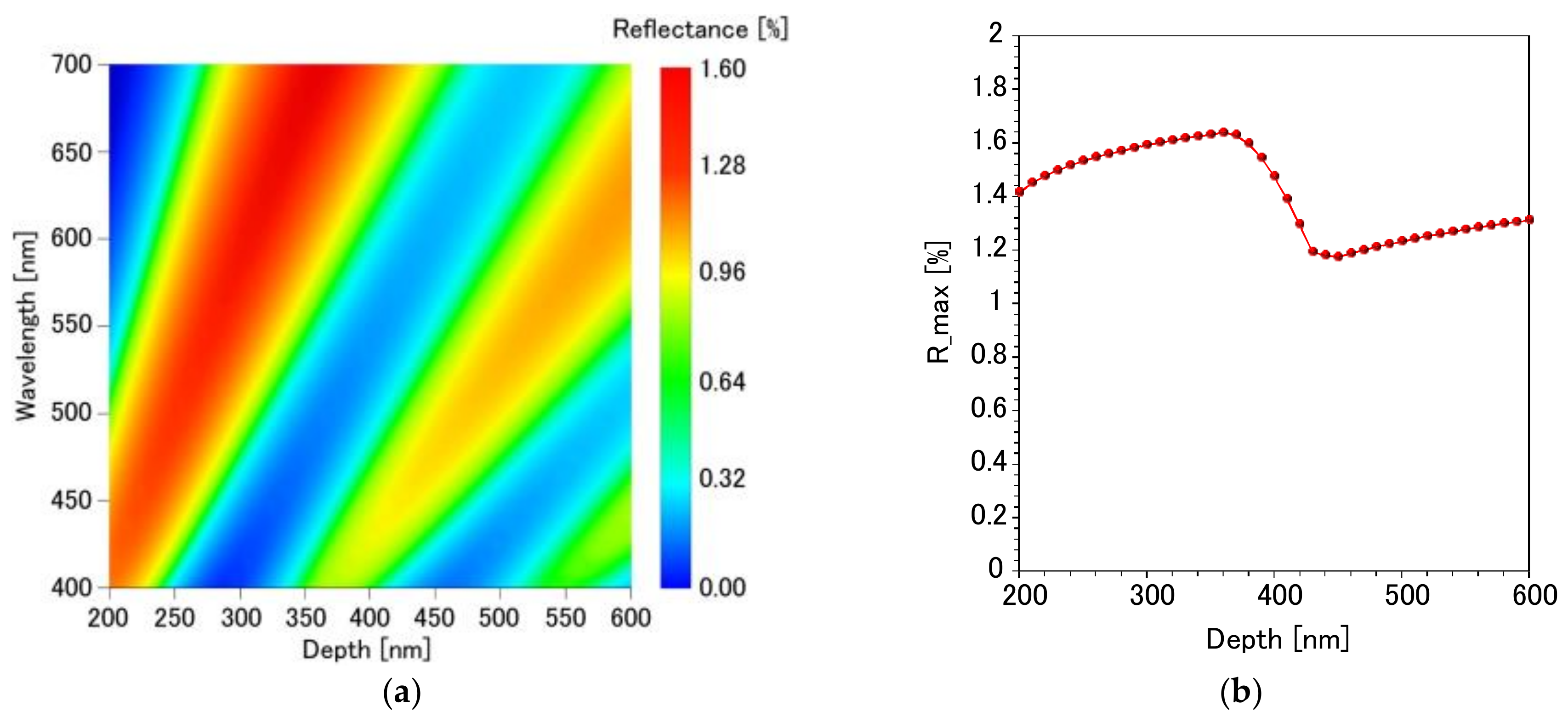

3.2. Optical Measurements

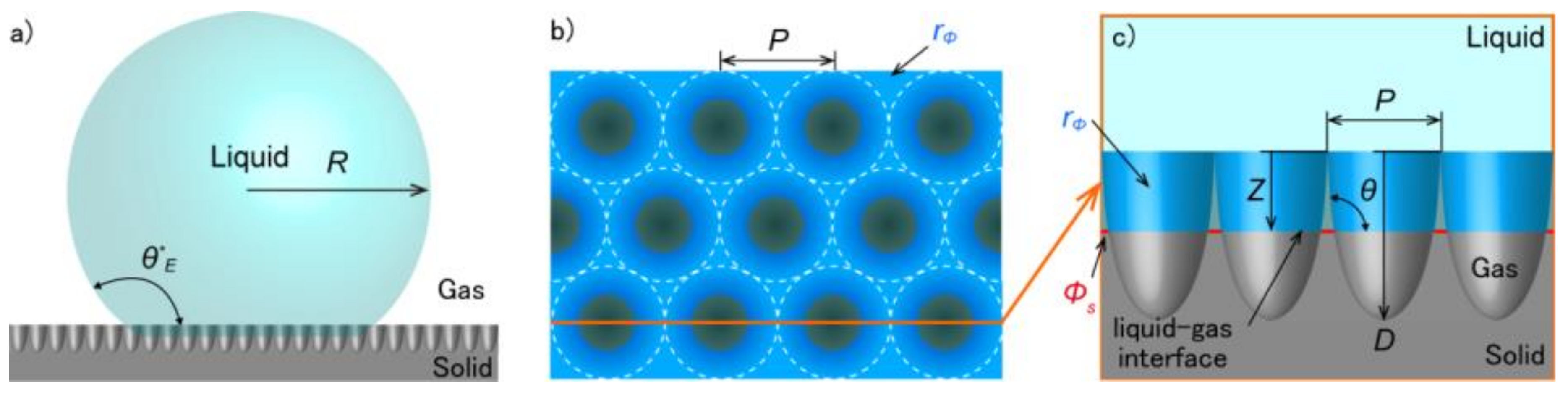

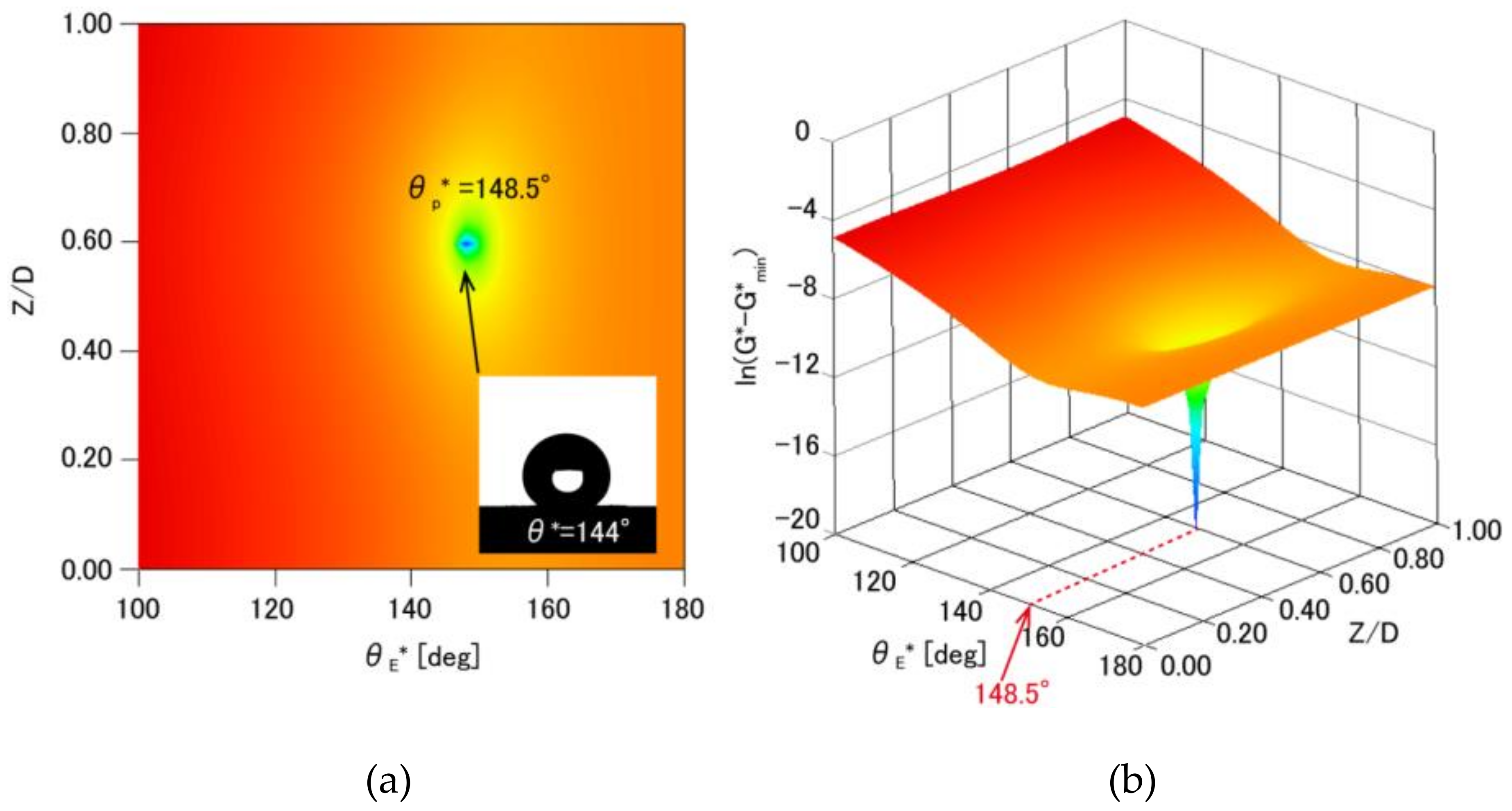

3.3. Contact Angle Measurements

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Raut, H.K.; Ganesh, V.A.; Nair, A.S.; Ramakrishna, S. Anti-reflective coatings: A critical, in-depth review. Energy Environ. Sci. 2011, 4, 3779–3804. [Google Scholar] [CrossRef]

- Bernhard, C.G. Structural and functional adaptation in a visual system. Endeavour 1967, 26, 79–84. [Google Scholar]

- Bhushan, B. Biomimetics: Lesson from nature—An overview. Philos. Trans. R. Soc. A 2009, 367, 1445–1486. [Google Scholar] [CrossRef] [PubMed]

- Parker, A.R. Natural photonics for industrial inspiration. Philos. Trans. R. Soc. A 2009, 367, 1759–1782. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.H.; Chattopadhyay, S.; Jen, Y.J.; Peng, C.Y.; Liu, T.A.; Hsu, Y.K.; Pan, C.L.; Lo, H.C.; Hsu, C.H.; Chang, Y.H.; et al. Improved broadband and quasi-omnidirectional anti-reflection properties with biomimetic silicon nanostructures. Nat. Nanotechnol. 2007, 2, 770–774. [Google Scholar] [CrossRef] [PubMed]

- Marmur, A. The Lotus effect: Superhydrophobicity and metastability. Langmuir 2004, 20, 3517–3519. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Tian, F.; Hu, A.; Li, M. A facile process for preparing superhydrophobic nickel films with stearic acid. Surf. Coat. Technol. 2013, 231, 88–92. [Google Scholar] [CrossRef]

- Toma, M.; Loget, G.; Corn, R.M. Flexible teflon nanocone array Surfaces with tunable superhydrophobicity for self-cleaning and aqueous droplet patterning. ACS Appl. Mater. Interfaces 2014, 6, 11110–11117. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.H.; Bae, B.J.; Han, K.S.; Hong, E.J.; Lee, H.; Choi, K.W. Imprinted moth-eye antireflection patterns on glass substrate. Electron. Mater. Lett. 2009, 5, 39–42. [Google Scholar] [CrossRef]

- Leem, J.W.; Kim, S.; Lee, S.H.; Rogers, J.A.; Kim, E.; Yu, J.S. Efficiency enhancement of organic solar cells using hydrophobic antireflective inverted moth-eye nanopatterned PDMS films. Adv. Energy Mater. 2014, 4, 1301315. [Google Scholar] [CrossRef]

- Mirotznik, M.S.; Good, B.L.; Ransom, P.; Wikner, D.; Mait, J.N. Broadband antireflective properties of inverse motheye surfaces. IEEE Trans. Antennas Propag. 2010, 58, 2969–2980. [Google Scholar] [CrossRef]

- Kim, J.G.; Choi, H.J.; Park, K.C.; Cohen, R.E.; McKinley, G.H.; Barbastathis, G. Multifunctional inverted nanocone arrays for non-wetting, self-cleaning transparent surface with high mechanical robustness. Small 2014, 10, 2487–2494. [Google Scholar] [CrossRef] [PubMed]

- Clapham, P.B.; Hutley, M.C. Reduction of lens reflection by the “MothEye” principle. Nature 1973, 244, 281–282. [Google Scholar] [CrossRef]

- Wilson, S.J.; Hutley, M.C. The optical properties of ‘Moth Eye’ antireflection surfaces. Opt. Acta 1982, 29, 993–1009. [Google Scholar] [CrossRef]

- Enger, R.C.; Case, S.K. Optical elements with ultrahigh spatial-frequency surface corrugation. Appl. Opt. 1983, 22, 3220–3228. [Google Scholar] [CrossRef] [PubMed]

- Lalanne, P.; Morris, G.M. Antireflection behavior of silicon subwavelength periodic structures for visible light. Nanotechnology 1997, 8, 53–56. [Google Scholar] [CrossRef]

- Toyota, H.; Takahara, K.; Okano, M.; Yotsuya, T.; Kikuta, H. Fabrication of microcone array for antireflection structured surface using metal dotted pattern. Jpn. J. Appl. Phys. 2001, 40, L747–L749. [Google Scholar] [CrossRef]

- Hsu, C.H.; Lo, H.C.; Chen, C.F.; Wu, C.T.; Hwang, J.S.; Das, D.; Tsai, J.; Chen, L.C.; Chen, K.H. Generally applicable self-masked dry etching technique for nanotip array fabrication. Nano Lett. 2004, 4, 471–475. [Google Scholar] [CrossRef]

- Sun, C.H.; Jiang, P.; Jiang, B. Broadband moth-eye antireflection coatings on silicon. Appl. Phys. Lett. 2008, 92, 061112. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, J.; Mao, G. Colloidal subwavelength nanostructures for antireflection optical coating. Opt. Lett. 2005, 30, 1885–1887. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Hubbard, G.; Shields, P.A.; Liu, C.; Allsopp, D.W.E.; Wang, W.N.; Abbott, S. Broadband moth-eye antireflection coatings fabricated by low-cost nanoimprinting. Appl. Phys. Lett. 2009, 94, 263118. [Google Scholar] [CrossRef]

- Bae, B.J.; Hong, S.H.; Hong, E.J.; Lee, H.; Jung, G.Y. Fabrication of moth-eye structure on glass by ultraviolet imprinting process with polymer template. Jpn. J. Appl. Phys. 2009, 48, 010207. [Google Scholar] [CrossRef]

- Yanagishita, T.; Endo, T.; Nishio, K.; Masuda, H. Fabrication of silica moth-eye structures by photo-nanoimprinting using ordered anodic porous alumina molds. Jpn. J. Appl. Phys. 2013, 53, 018002. [Google Scholar] [CrossRef]

- Taniguchi, J.; Otsuka, Y.; Nose, S.; Unno, N.; Hiwasa, S. Durability and transfer properties of a release-agent-free replica mold for ultraviolet nanoimprinting. J. Photopolym. Sci. Technol. 2015, 28, 563–568. [Google Scholar] [CrossRef]

- Vespini, V.; Coppola, S.; Todino, M.; Paturzo, M.; Bianco, V.; Grilli, S.; Ferraro, P. Forward electrohydrodynamic inkjet printing of optical microlenses on microfluidic devices. Lab Chip 2016, 16, 326–333. [Google Scholar] [CrossRef] [PubMed]

- Vespini, V.; Gennari, O.; Coppola, S.; Nasti, G.; Mecozzi, L.; Pagliarulo, V.; Grilli, S.; Carfagna, C.; Ferraro, P. Electrohydrodynamic assembly of multiscale PDMS microlens arrays. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 339–406. [Google Scholar] [CrossRef]

- Hashimoto, Y.; Mogi, K.; Yamamoto, T. Vacuum ultraviolet light assisted bonding and nanoscale pattern transfer method for polydimethylsiloxane. Microelectron. Eng. 2017, 176, 115–120. [Google Scholar] [CrossRef]

- Kuo, J.S.; Chiu, D.T. Disposable microfluidic substrates: Transitioning from the research laboratory into the clinic. Lab Chip 2011, 11, 2656–2665. [Google Scholar] [CrossRef] [PubMed]

- Nishi, Y.; Uyama, M.; Kawazu, H.; Takei, H.; Iwata, K.; Kudoh, H.; Mitsubayashi, K. Effects of electron beam irradiation on adhesive force of laminated sheet of high strength polytetrafluoroethylene (PTFE) and bio-adaptable polydimethylsiloxane (PDMS). Mater. Trans. 2012, 53, 1657–1664. [Google Scholar] [CrossRef]

- Lee, J.N.; Park, C.; Whitesides, G.M. Solvent Compatibility of poly(dimethylsiloxane)-based microfluidic devices. Anal. Chem. 2003, 75, 6544–6554. [Google Scholar] [CrossRef] [PubMed]

- Park, C.; Han, Y.; Joo, K.I.; Lee, Y.W.; Kang, S.W.; Kim, H.R. Optical detection of volatile organic compounds using selective tensile effects of a polymer-coated fiber Bragg grating. Opt. Express 2010, 18, 24753–24761. [Google Scholar] [CrossRef] [PubMed]

- Mogi, K.; Hashimoto, Y.; Tsukahara, T.; Terano, M.; Yoshino, M.; Yamamoto, T. Nanometer-level high-accuracy molding using a photo-curable silicone elastomer by suppressing thermal shrinkage. RSC Adv. 2015, 5, 10172–10177. [Google Scholar] [CrossRef]

- Hashimoto, Y.; Mogi, K.; Yamamoto, T. Nanoscale three-dimensional optical visualization method for a deformation of elastomer printing plate to realize soft nano-printing technology. Surf. Interface Anal. 2015, 47, 723–727. [Google Scholar] [CrossRef]

- COMSOL Multiphysics. RF Module User’s Guide, version 4.3b; COMSOL AB: Stockholm, Sweden, 2013. [Google Scholar]

- Alves, F.; Kearney, B.; Grbovic, D.; Lavrik, N.V.; Karunasiri, G. Strong terahertz absorption using SiO2/Al based metamaterial structures. Appl. Phys. Lett. 2012, 100, 111104. [Google Scholar] [CrossRef]

- Kearney, B.T.; Alves, F.; Grbovic, D.; Karunasiri, G. Al/SiOX/Al single and multiband metamaterial absorbers for terahertz sensor applications. Opt. Eng. 2013, 52, 013801. [Google Scholar] [CrossRef]

- Hashimoto, Y.; Yamamoto, T. Solid state direct bonding of polymers by vacuum ultraviolet light below 160 nm. Appl. Surf. Sci. 2017, 419, 319–327. [Google Scholar] [CrossRef]

- Marmur, A. Wetting on hydrophobic rough surfaces: To be heterogeneous or not to be? Langmuir 2003, 19, 8343–8348. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hashimoto, Y.; Yamamoto, T. Fabrication of an Anti-Reflective and Super-Hydrophobic Structure by Vacuum Ultraviolet Light-Assisted Bonding and Nanoscale Pattern Transfer. Micromachines 2018, 9, 186. https://doi.org/10.3390/mi9040186

Hashimoto Y, Yamamoto T. Fabrication of an Anti-Reflective and Super-Hydrophobic Structure by Vacuum Ultraviolet Light-Assisted Bonding and Nanoscale Pattern Transfer. Micromachines. 2018; 9(4):186. https://doi.org/10.3390/mi9040186

Chicago/Turabian StyleHashimoto, Yuki, and Takatoki Yamamoto. 2018. "Fabrication of an Anti-Reflective and Super-Hydrophobic Structure by Vacuum Ultraviolet Light-Assisted Bonding and Nanoscale Pattern Transfer" Micromachines 9, no. 4: 186. https://doi.org/10.3390/mi9040186