Fabrication and Characterization of Inhomogeneous Curved Artificial Compound Eye

Abstract

:1. Introduction

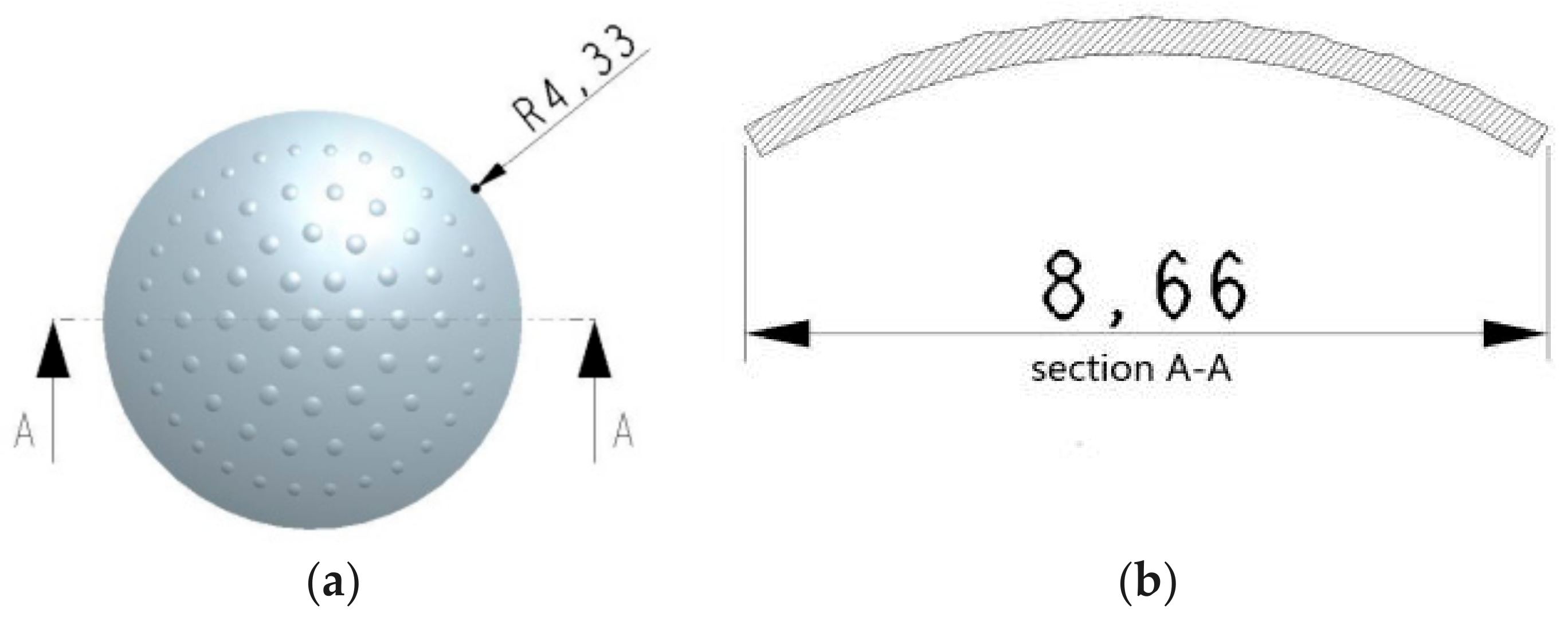

2. Structure Design for Curved Surface Compound Eyes

3. Light Tracing

4. Fabrication of Non-Uniform Artificial Compound Eyes

- (1)

- The raw material C45 steel was clamped on the precision five-axis CNC machine tools, and the rough machining process was carried out by a vertical spindle milling tool according to the structure and parameters. The convexity in the convex mold and the concavity in the concave mold were obtained respectively by micro-milling, as shown in Figure 9a,b.

- (2)

- The finish machining process was carried by a milling cutter with a smaller diameter ball end. The concave and convex mold for the curved compound eye was finished by the separate feeding of the cutter on every ommatidium’s position in the concavity, as shown in Figure 9c.

- (3)

- Four threaded holes on each corner in the concave and convex molds were tapped to fasten them after pouring the PDMS. The electric resistance wire can be put into the heating hole, which was located in the bottom of the concave mold, if the curing speed needed to be increased. One injecting hole with a 1-mm diameter and an 18.5-mm depth was drilled in the middle of the three ommatidia on the top of the cavity mold. A trace tunnel in the hole was formed after pouring the PDMS. The location of the pouring hole was optimized because it shaded the ommatidia and affected the image performance.

- (4)

- The mold was electrochemically polished, as shown in Figure 10.

- (1)

- Before operation, the module, beaker, and measuring cylinder were cleaned with deionized water by pressure syringe (LSP01-1BH, Longer Precision Pump Co., Ltd., Baoding, Hebei, China) to ensure that no particles remained on them. Then the mold was wrapped in plastic immediately to avoid surface oxidation by contact with the air.

- (2)

- Subsequently, 4 mL PDMS base and 0.4 mL curing agent were mixed in one breaker and a portion of the air bubbles were discharged by standing at least 10 min.

- (3)

- The mixture was injected into the syringe slowly to avoid producing air bubble. The syringe was put into the ultrasonic clearing machine (WN30-BXXW-040AL, Kamson ultrasonic equipment Co., Ltd., Taipei, Taiwan) and vibrated for 40 min to discharge a portion of the air bubbles, then it was left to stand for at least 10 min at room temperature to discharge all of the air bubbles.

- (4)

- The releasing agent (SP-751, Sansaikako, Osaka, Japan) was coated on the mold surface to release the sample from the module easily and thus obtain a smooth sample. Then the mold was fastened by a fastening screw to improve the sealing degree.

- (5)

- A screw syringe needle with a 0.9-mm diameter was put on the syringe and the syringe was inserted into the screw hole in the concave mold. Then the mixture was injected into the module, avoiding the generation of air bubbles.

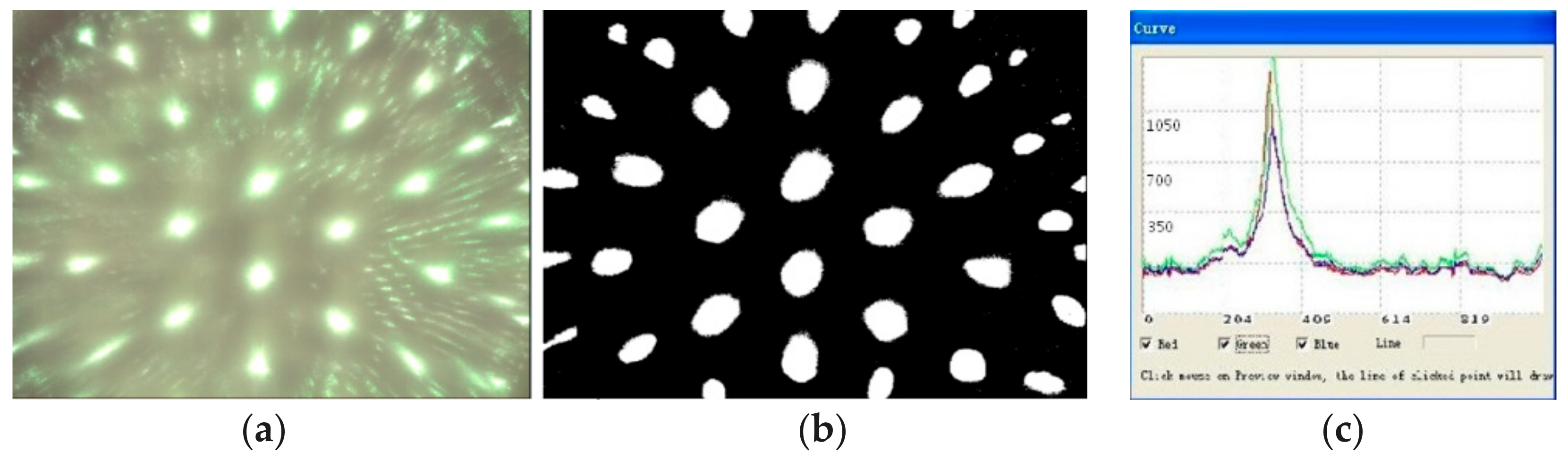

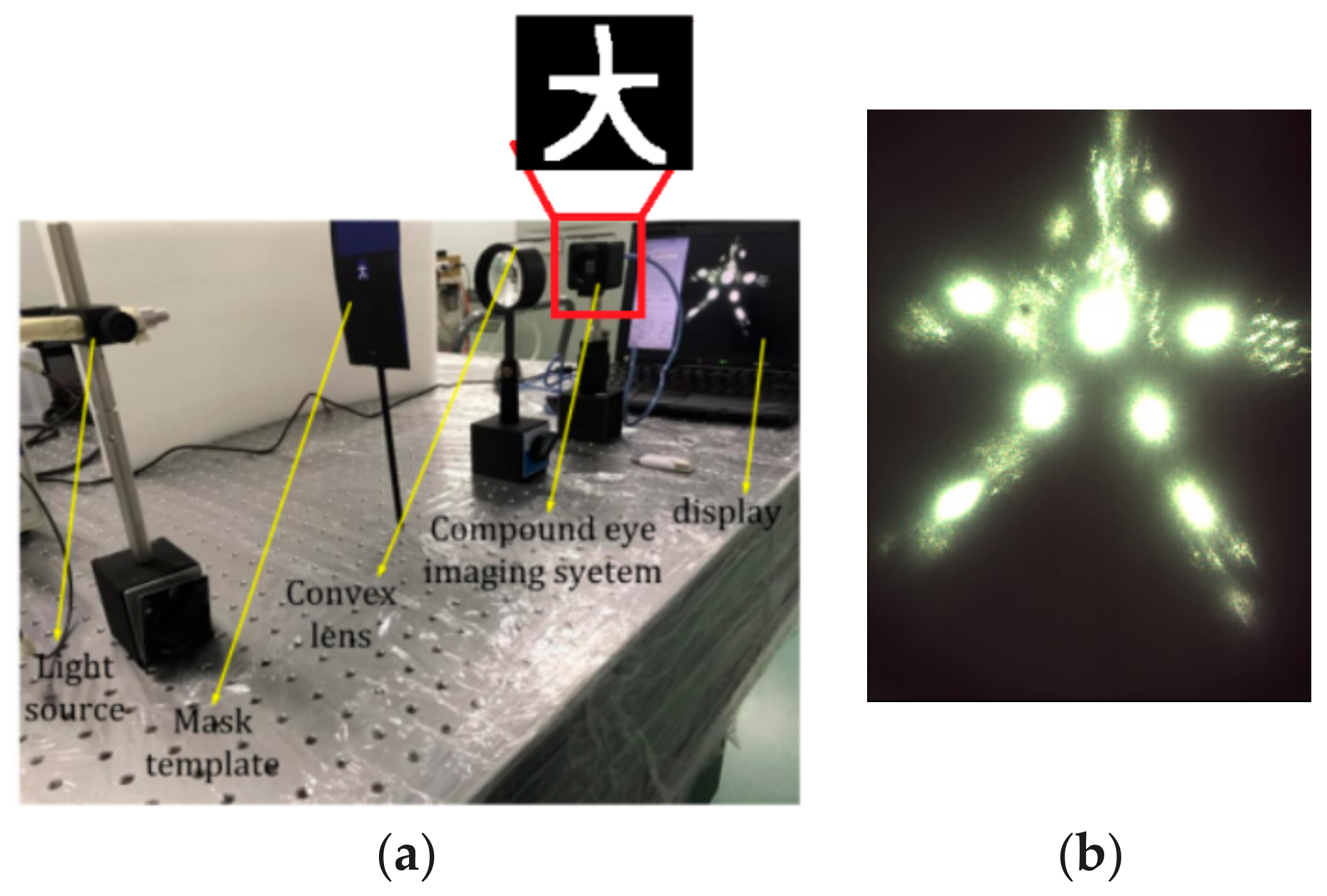

5. Optical Testing

6. Conclusions

Author Contributions

Conflicts of Interest

References

- Jeong, K.H.; Kim, J.; Lee, L.P. Biologically inspired artificial compound eyes. Science 2006, 312, 557–561. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.P.; Shen, X.J.; Li, X.F.; Jin, Y.S. Bionic mosaic method of panoramic image based on compound eye of fly. J. Bionic Eng. 2011, 8, 440–448. [Google Scholar] [CrossRef]

- Lichtensteiger, L.; Eggenberger, P. Evolving the morphology of a compound eye on a robot. In Proceedings of the Third European Workshop on Advanced Mobile Robots (Eurobot ’99), Zurich, Switzerland, 6–9 September 1999; Cat. No. 99EX355. Institute of Electrical and Electronics Engineers: Zurich, Switzerland, 1999; pp. 127–134. [Google Scholar]

- Duparré, J.; Dannberg, P.; Schreiber, P.; Bräuer, A.; Tünnermann, A. Thin compound-eye camera. Appl. Opt. 2005, 44, 2949–2956. [Google Scholar] [CrossRef] [PubMed]

- Zhu, D.F.; Li, C.H.; Zeng, X.F.; Jiang, H.G. Tunable-focused microlens arrays on curved surfaces. Appl. Phys. Lett. 2010, 16, 081111. [Google Scholar] [CrossRef]

- Radtke, D.; Duparré, J.; Zeitner, U.D.; Tünnermann, A. Laser lithographic fabrication and characterization of a spherical artificial compound eye. Opt. Express 2007, 15, 3067–3077. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.F.; Yan, X.; Yao, X.; Xu, L.; Zhang, K.; Zhang, J.H.; Yang, B.; Jiang, L. The dry-style antifogging properties of mosquito compound eyes and artificial analogues prepared by soft lithography. Adv. Mater. 2007, 19, 2213–2217. [Google Scholar] [CrossRef]

- Lee, L.P.; Szema, R. Inspirations from biological optics for advanced photonic systems. Science 2005, 310, 1148–1150. [Google Scholar] [CrossRef] [PubMed]

- Choi, C.; Choi, M.K.; Liu, S.Y.; Kim, M.S.; Park, O.K.; Im, C.; Kim, J.; Qin, X.L.; Lee, G.J.; Cho, K.W.; et al. Human eye-inspired soft optoelectronic device using high-density MoS2-graphene curved image sensor array. Nat. Commun. 2017, 8, 1664. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.H.; Xie, Y.J.; He, S.P.; Fu, S.; Lu, Z.W. Single step fabrication of microlens arrays with hybrid HfO2-SiO2 sol-gel glass on conventional lens surface. Opt. Express 2005, 13, 5846–5852. [Google Scholar] [CrossRef] [PubMed]

- Ko, H.C.; Stoykovich, M.P.; Song, J.; Malyarchuk, V.; Choi, W.M.; Yu, C.-J.; Geddes, J.B.; Xiao, J.; Wang, S.; Huang, Y.; et al. A Hemispherical electronic eye camera based on compressible silicon optoelectronics. Nature 2008, 454, 748–753. [Google Scholar] [CrossRef] [PubMed]

- Jung, I.; Xiao, J.; Malyarchuk, V.; Lub, C.; Li, M.; Liu, Z.; Yoon, J.; Huang, Y.; Rogers, J.A. Dynamically tunable hemispherical electronic eye camera system with adjustable zoom capability. Proc. Natl. Acad. Sci. USA 2011, 108, 1788–1793. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.M.; Xie, Y.Z.; Malyarchuk, V.R.; Xiao, J.L.; Jung, I; Choi, K.; Liu, Z.J.; Park, H.S.; Lu, C.F.; Kim, R.; et al. Digital cameras with designs inspired by the arthropod eye. Nature 2013, 497, 95–99. [Google Scholar] [CrossRef] [PubMed]

- Floreano, D.; Pericet-Camara, R.; Viollet, S.; Ruer, F.; Brückner, A.; Leitel, R.; Buss, W.; Menouni, M.; Expert, F.; Juston, R.; et al. Miniature curved artifcial compound eyes. Proc. Natl. Acad. Sci. USA 2013, 110, 9267–9272. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kuo, W.K.; Kuo, G.F.; Lin, S.Y.; Yu, H.H. Fabrication and characterization of artificial miniaturized insect compound eyes for imaging. Bioinspir. Biomim. 2015, 10, 056010. [Google Scholar] [CrossRef] [PubMed]

- Qu, P.B.; Chen, F.; Liu, H.W.; Yang, Q.; Lu, J.; Si, J.H.; Wang, Y.Q.; Hou, X. A simple route to fabricate artificial compound eye structures. Opt. Express 2012, 20, 5775–5782. [Google Scholar] [CrossRef] [PubMed]

- He, Q.; Liu, J.; Yang, B.; Dong, Y.; Yang, C. Fabrication and characteriza-tion of biologically inspired curved-surface artificial com-pound eyes. J. Microelectromech. Syst. 2013, 22, 4–6. [Google Scholar] [CrossRef]

- Li, Z.W.; Xiao, J.L. Mechanics and optics of stretchable elastomeric microlens array for artificial compound eye camera. J. Appl. Phys. 2015, 117, 014904. [Google Scholar] [CrossRef]

- Li, L.; Yi, A.Y. Development of a 3D artificial compound eye. Opt. Express 2010, 18, 18125–18137. [Google Scholar] [CrossRef] [PubMed]

- Scheiding, S.; Yi, A.Y.; Gebhardt, A.; Li, L.; Risse, S.; Eberhardt, R.; Tunnermann, A. Freeform manufacturing of a microoptical lens array on a steep curved substrate by use of a voice coil fast tool servo. Opt. Express 2011, 19, 23938. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H. Development of a low cost high precision three layer 3D artificial compound eye. Opt. Express 2013, 21, 22232–22245. [Google Scholar] [CrossRef] [PubMed]

- Leem, J.W.; Yu, J.S. Artificial inverted compound eye structured polymer films with light-harvesting and selfcleaning functions for encapsulated III–V solar cell applications. RSC Adv. 2015, 7, 60804–60813. [Google Scholar] [CrossRef]

- Cao, A.X.; Shi, L.F.; Deng, Q.L.; Pang, H.; Zhang, M.; Du, C.L. Structural design and image processing of a spherical artificial compound eye. Optik-Int. J. Light Electr. Opt. 2015, 126, 3099–3103. [Google Scholar] [CrossRef]

- Ding, X.N. Research on imaging system of artificial compound-eye and moving object detection. Int. J. Multimed. Ubiquitous Eng. 2016, 11, 79–90. [Google Scholar] [CrossRef]

- Lee, G.J.; Choi, C.; Kim, D.H.; Song, Y.M. Bioinspired artificial eyes: Optic components, digital cameras, and visual prostheses. Adv. Funct. Mater. 2018, 1705202. [Google Scholar] [CrossRef]

- Zhang, K.; Jung, Y.H.; Mikael, S.; Seo, J.H.; Kim, M.; Mi, H.Y.; Zhou, H.; Xia, Z.Y.; Zhou, W.D.; Gong, S.Q.; et al. Origami silicon optoelectronics for hemispherical electronic eye systems. Nat. Commun. 2017, 8, 1782. [Google Scholar] [CrossRef] [PubMed]

| Level | 0 | 1 | 2 | 3 | 4 |

|---|---|---|---|---|---|

| (°) | 0.0 | 14.0 | 28.0 | 41.0 | 52.0 |

| Parameter | Lever 0 | Lever 1 | Lever 2 | Lever 3 | Lever 4 |

|---|---|---|---|---|---|

| Radius (rn) | 1.2 | 1.19 | 1.16 | 1.11 | 1.03 |

| height of the ommatidia (hn) | 0.24 | 0.23 | 0.19 | 0.15 | 0.13 |

| focal length | 3.44 | 3.39 | 3.23 | 2.93 | 2.47 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Diao, X.; Li, L.; Hao, Y.; Jiao, Z. Fabrication and Characterization of Inhomogeneous Curved Artificial Compound Eye. Micromachines 2018, 9, 238. https://doi.org/10.3390/mi9050238

Liu F, Diao X, Li L, Hao Y, Jiao Z. Fabrication and Characterization of Inhomogeneous Curved Artificial Compound Eye. Micromachines. 2018; 9(5):238. https://doi.org/10.3390/mi9050238

Chicago/Turabian StyleLiu, Fengli, Xiaolei Diao, Lun Li, Yongping Hao, and Zhongyuan Jiao. 2018. "Fabrication and Characterization of Inhomogeneous Curved Artificial Compound Eye" Micromachines 9, no. 5: 238. https://doi.org/10.3390/mi9050238