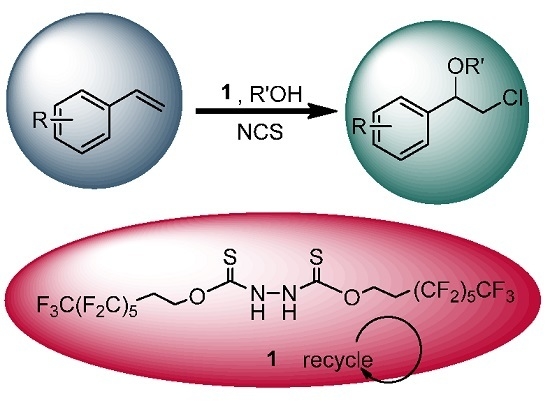

A Recyclable Fluorous Hydrazine‐1,2Bis(Carbothioate) Organocatalyst for the Synthesis of ꞵ‐Chloroethers with N‐Chlorosuccinimide

Abstract

:1. Introduction

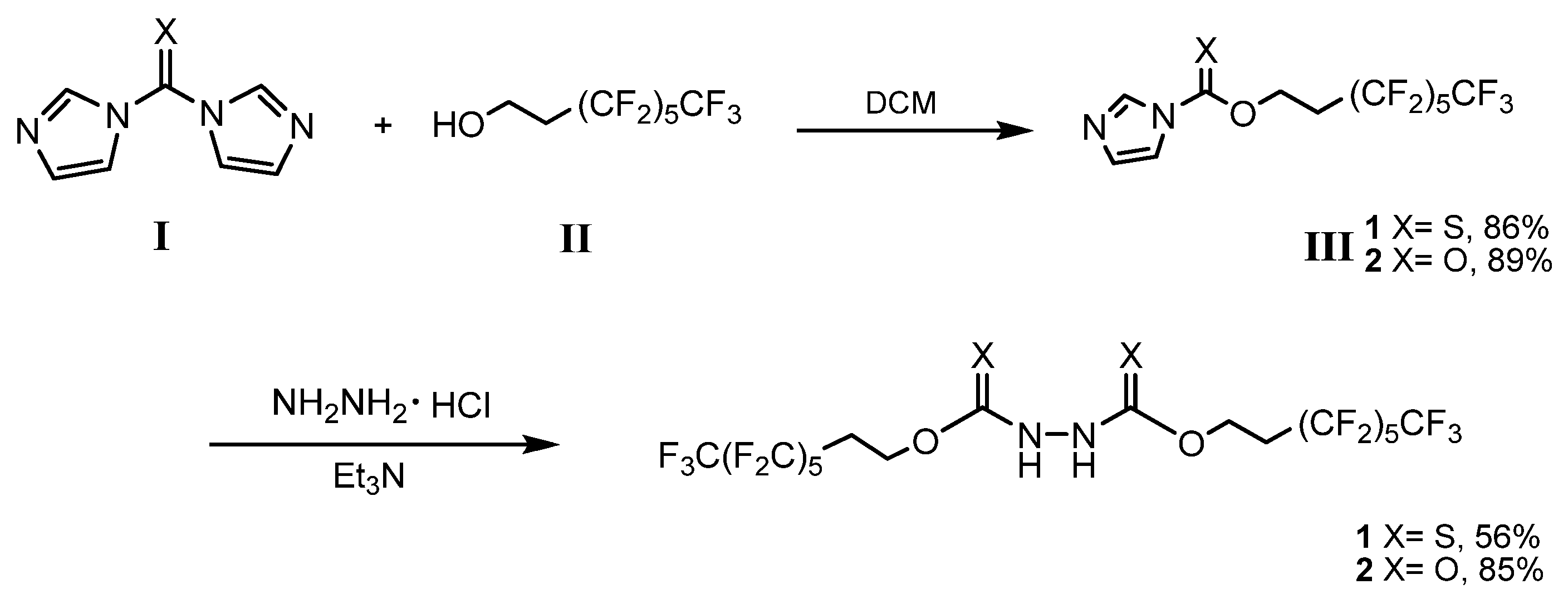

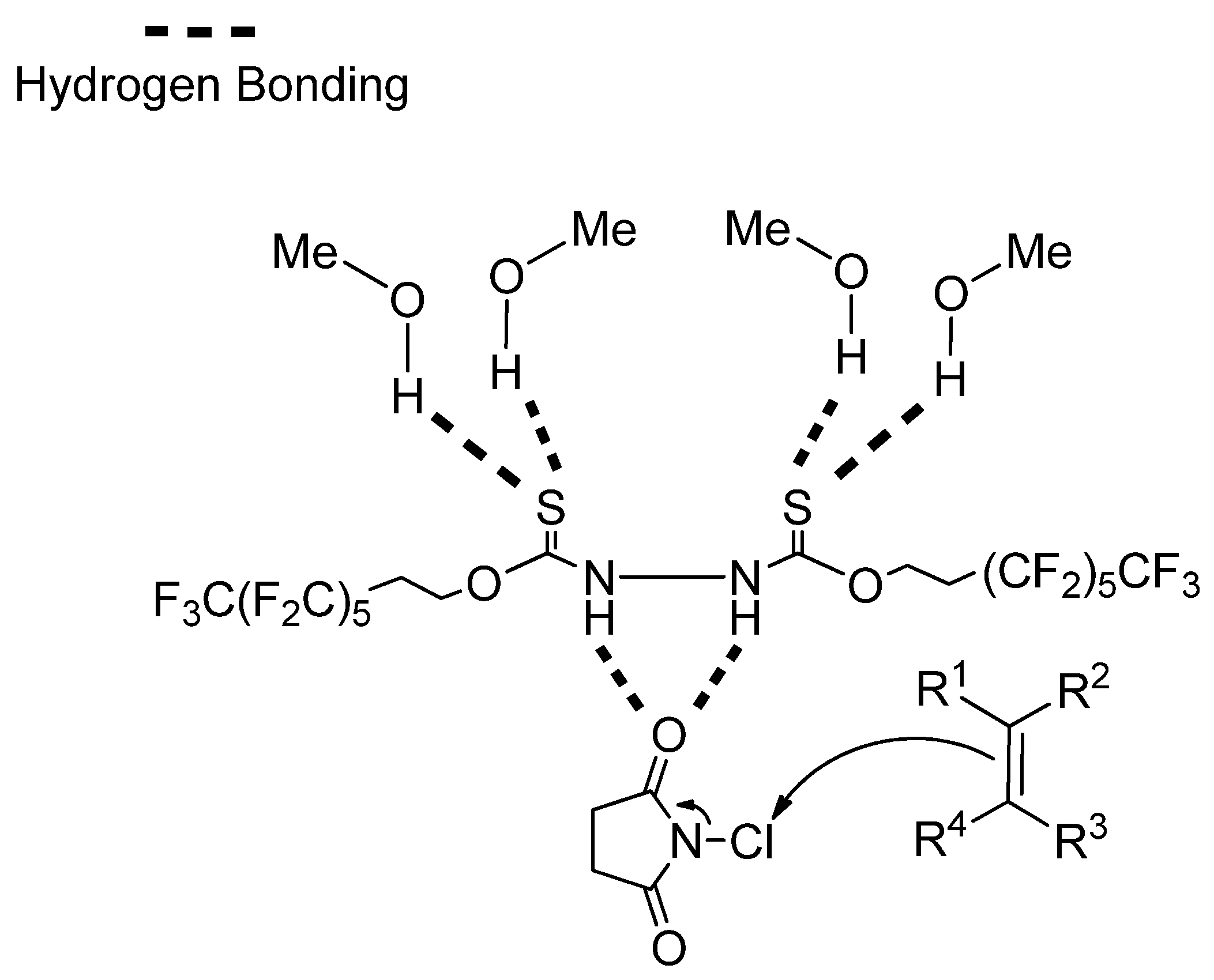

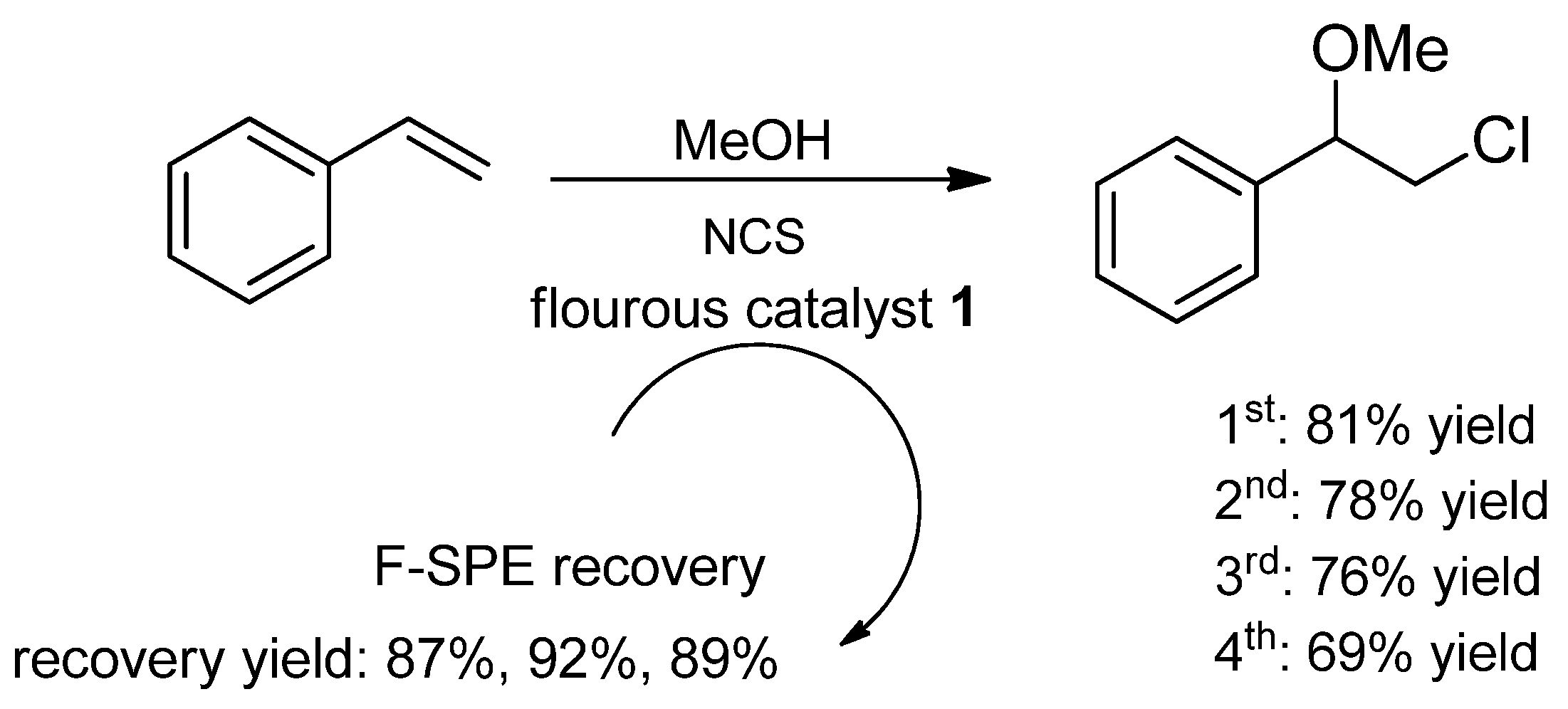

2. Results and Discussion

3. Experimental Section

3.1. General

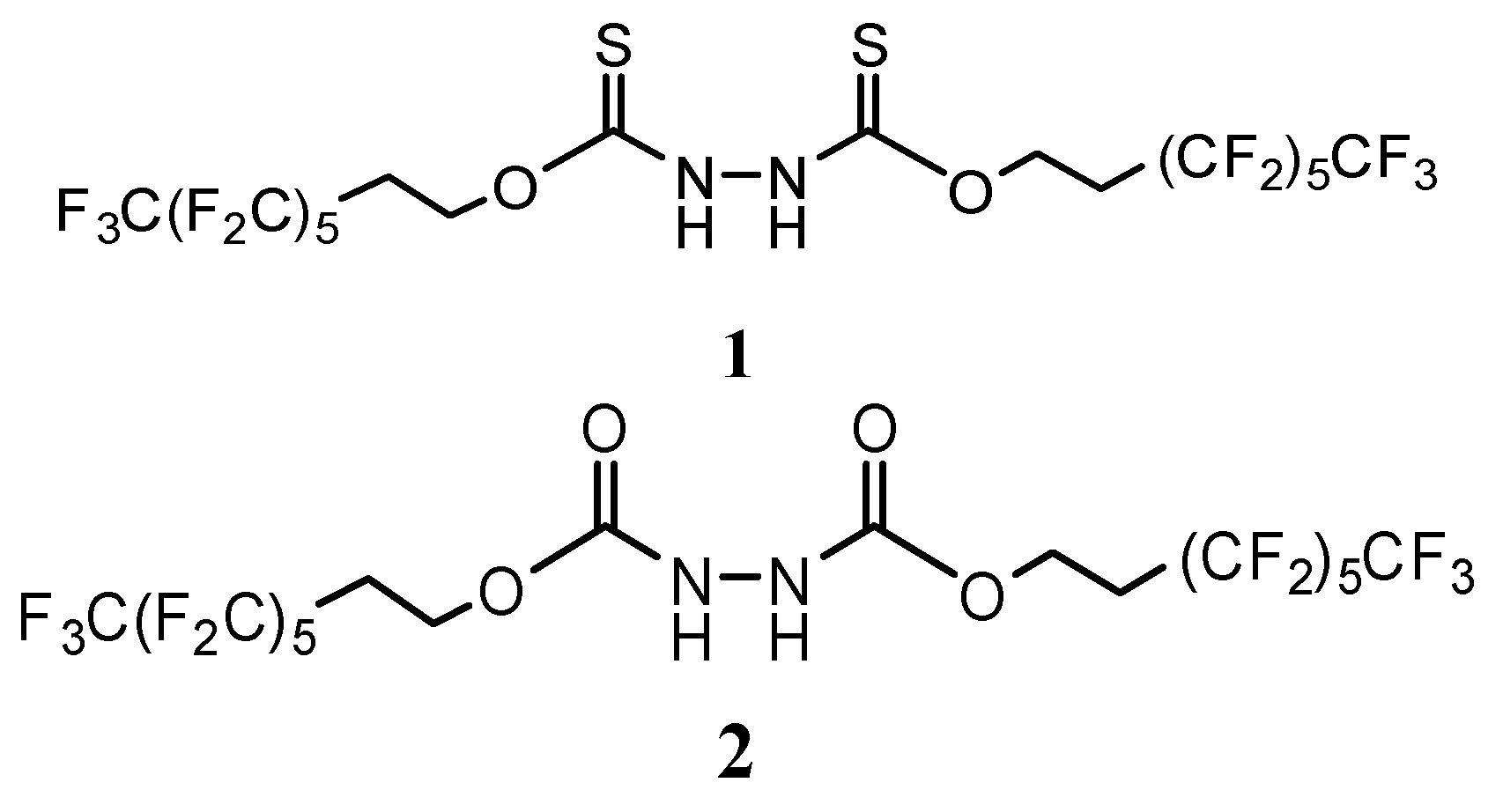

3.2. The Synthesis of Fluorous Catalyst 1

3.3. The Synthesis of β-Chloroethers Catalyzed by 1 and the Catalyst Recycling Experiment

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jimeno, C.; Cao, L.; Renaud, P. Trichloromethanesulfonyl chloride: A chlorinating reagent for aldehydes. J. Org. Chem. 2016, 3, 1251–1255. [Google Scholar] [CrossRef] [PubMed]

- Coffey, K.E.; Murphy, G.K. Dichlorination of α-diazo-β-dicarbonyls using (dichloroiodo)benzene. Synlett 2015, 8, 1003–1007. [Google Scholar]

- Coffey, K.E.; Moreira, R.; Abbas, F.Z. Synthesis of 3,3-dichloroindolin-2-ones from isatin-3-hydrazones and (dichloroiodo)benzene. Org. Biomol. Chem. 2015, 3, 682–685. [Google Scholar] [CrossRef] [PubMed]

- Faisca, P.; Ana, M.; Barros, M.T.; Pacheco, M. Synthesis and biological evaluation of alpha-hydroxyalkylphosphonates as new antimicrobial agents. Bioorg. Med. Chem. Lett. 2014, 1, 49–53. [Google Scholar] [CrossRef] [PubMed]

- Tsuchida, K.; Kochi, T.; Kakiuchi, F. Copper-catalyzed electrochemical chlorination of 1,3-dicarbonyl compounds using hydrochloric acid. Asian J. Org. Chem. 2013, 11, 935–937. [Google Scholar] [CrossRef]

- Wang, L.; Wang, J.-W.; Cui, A.-J. Regioselective 2,6-dihalogenation of BODIPYs in 1,1,1,3,3,3-hexafluoro-2-propanol and preparation of novel meso-alkyl polymeric BODIPY dyes. RSC Adv. 2013, 24, 9219–9222. [Google Scholar] [CrossRef]

- Bentley, P.A.; Mel, Y.; Du, J. Thiourea catalysis of NCS in the synthesis of β-chloroethers. Tetrahedron Lett. 2008, 16, 2653–2655. [Google Scholar] [CrossRef]

- Bentley, P.A.; Mel, Y.; Du, J. Thiourea catalysis of NCS in the synthesis of chlorohydrins. Tetrahedron Lett. 2008, 49, 1425–1427. [Google Scholar] [CrossRef]

- Mel, Y.; Bentley, P.A.; Du, J. Thiourea catalysis of NCS in the synthesis of α-chloroketones. Tetrahedron Lett. 2008, 49, 3802–3804. [Google Scholar]

- Karmakar, R.; Mal, D. Total synthesis of chlorocyclinone A, a PPAR-γ antagonist. J. Org. Chem. 2012, 22, 10235–10248. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Nie, J.; Wu, J.-W. Stereoselective synthesis of fluorinated 2,3-dihydroquinolin-4(1H)-ones via a one-pot multistep transformation. J. Org. Chem. 2012, 5, 2398–2406. [Google Scholar] [CrossRef] [PubMed]

- Cui, H.-F.; Dong, K.-Y.; Nie, J. Lewis acid-catalyzed one-pot sequential reaction for the synthesis of alpha-halogenated beta-keto esters. Tetrahedron Lett. 2010, 17, 2374–2377. [Google Scholar] [CrossRef]

- Studer, A.; Hadida, S.; Ferritto, R. Fluorous synthesis: A fluorous-phase strategy for improving separation efficiency in organic synthesis. Science 1997, 5301, 823–826. [Google Scholar] [CrossRef]

- Luo, Z.Y.; Zhang, Q.S.; Oderaotoshi, Y. Fluorous mixture synthesis: A fluorous-tagging strategy for the synthesis and separation of mixtures of organic compounds. Science 2001, 5509, 1766–1769. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, H.; Linclau, B.; Curran, D.P. Fluorous triphasic reactions: Transportative deprotection of fluorous silyl ethers with concomitant purification. J. Am. Chem. Soc. 2001, 41, 10119–10120. [Google Scholar] [CrossRef]

- Curran, D.P. Chemistry—Fluorous tags unstick messy chemical biology problems. Science 2008, 5896, 1645–1646. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Qian, J.G.; Yi, W.-B. Direct trifluoromethylthiolation and perfluoroalkylthiolation of C(sp2)–H bonds with CF3SO2Na and RfSO2Na. Angew. Chem. Int. Ed. 2015, 49, 14965–14969. [Google Scholar] [CrossRef] [PubMed]

- Cai, C.; Yi, W.-B.; Zhang, W. Fluorous Lewis acids and phase transfer catalysts. Mol. Divers. 2009, 2, 209–239. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Cai, C. New chemical and biological applications of fluorous technologies. Chem. Commun. 2008, 44, 5686–5694. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.-W.; Qian, J.-L.; Yi, W.-B.; Cai, C. Highly efficient synthesis of polysubstituted 1,2-dihydroquinolines via tandem reaction of α-ketoesters and arylamines catalyzed by fluorous hydrazine-1,2-bis(carbothioate) and NCS. Tetrahedron Lett. 2013, 54, 638–641. [Google Scholar] [CrossRef]

- Zhu, Y.-W.; Yi, W.-B.; Cai, C. A recyclable fluorous hydrazine-1,2-bis(carbothioate) with NCS as efficient catalysts for acetalization of aldehydes. New J. Chem. 2013, 37, 890–892. [Google Scholar] [CrossRef]

- Wang, L.; Yi, W.-B.; Cai, C. A green and highly selective oxidation of alcohols by fluorous silica gel-supported gold nanoparticles in aqueous H2O2 under base-free conditions. ChemSusChem 2010, 3, 1280–1284. [Google Scholar] [CrossRef] [PubMed]

| Entry | NCS (mmol) | Catalyst (mol %) | Time (h) | Yield (%) |

|---|---|---|---|---|

| 1 | 4 | - | 120 | 37 |

| 2 | 4 | 1 (20) | 1 | 88 |

| 3 | 4 | 1 (10) | 1 | 89 |

| 4 | 4 | 1 (5) | 2 | 85 |

| 5 | 4 | 1 (2) | 2 | 82 |

| 6 | 2 | 1 (5) | 2 | 81 |

| 7 | 1.5 | 1 (5) | 4 | 68 |

| 8 | 2 | 2 (5) | 48 | 33 |

| Entry | Olefin | ROH | Reaction Time (h) | Chloride | Yield (%) |

|---|---|---|---|---|---|

| 1 |  | MeOH | 2 |  | 81 |

| 2 |  | EtOH | 6 |  | 75 |

| 3 |  |  | 48 |  | 63 |

| 4 |  |  | 48 |  | 54 |

| 5 |  |  | 24 |  | 34 |

| 6 |  | MeOH | 6 |  | 90 |

| 7 |  | MeOH | 4 |  | 89 |

| 8 |  | MeOH | 0.5 |  | 93 |

| 9 |  | MeOH | 0.5 |  | 52 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Shi, Y.; Yin, Y. A Recyclable Fluorous Hydrazine‐1,2Bis(Carbothioate) Organocatalyst for the Synthesis of ꞵ‐Chloroethers with N‐Chlorosuccinimide. Catalysts 2017, 7, 66. https://doi.org/10.3390/catal7020066

Zhu Y, Shi Y, Yin Y. A Recyclable Fluorous Hydrazine‐1,2Bis(Carbothioate) Organocatalyst for the Synthesis of ꞵ‐Chloroethers with N‐Chlorosuccinimide. Catalysts. 2017; 7(2):66. https://doi.org/10.3390/catal7020066

Chicago/Turabian StyleZhu, Yi‐Wei, Yi‐Xin Shi, and Yu‐Qi Yin. 2017. "A Recyclable Fluorous Hydrazine‐1,2Bis(Carbothioate) Organocatalyst for the Synthesis of ꞵ‐Chloroethers with N‐Chlorosuccinimide" Catalysts 7, no. 2: 66. https://doi.org/10.3390/catal7020066