Vickers Hardness of Diamond and cBN Single Crystals: AFM Approach

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

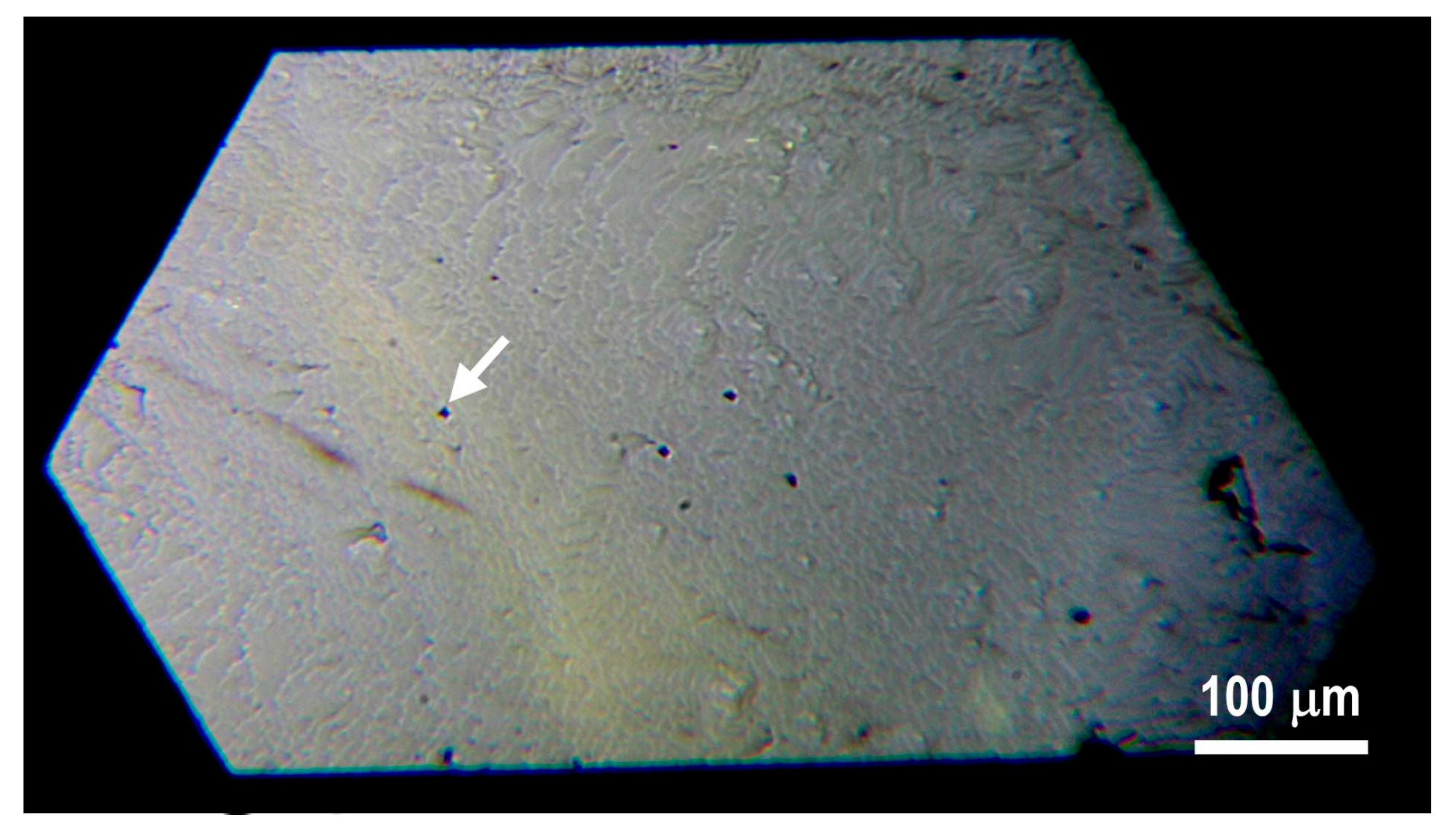

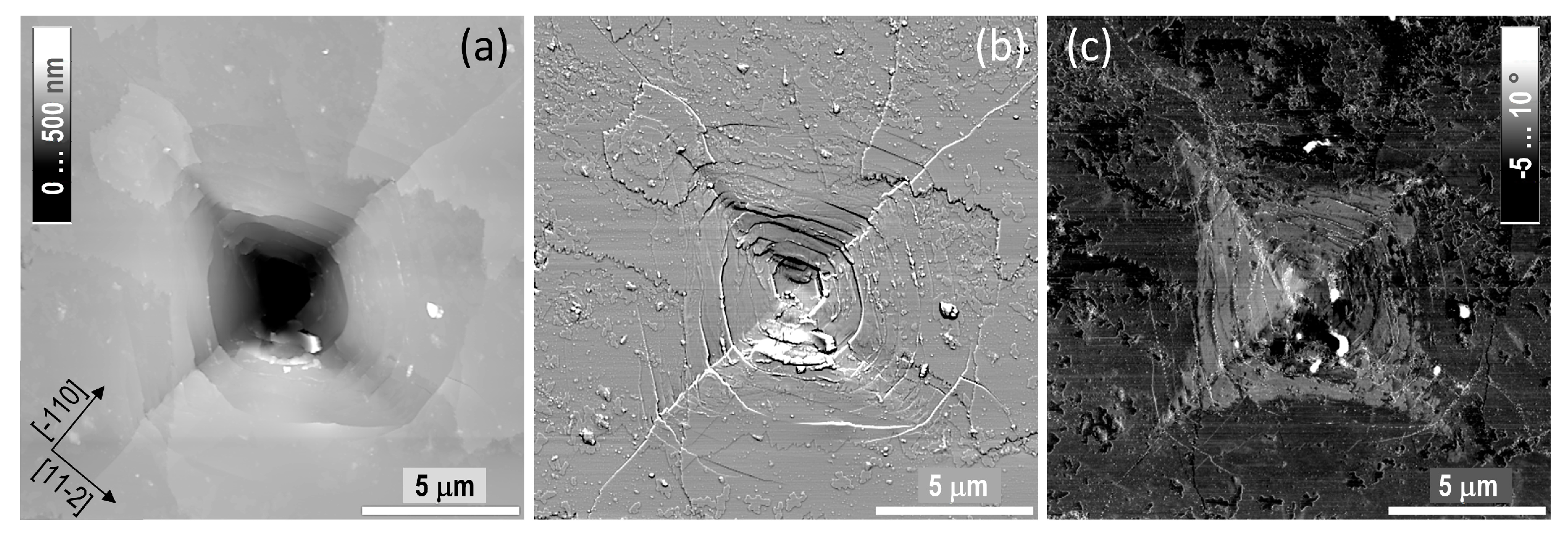

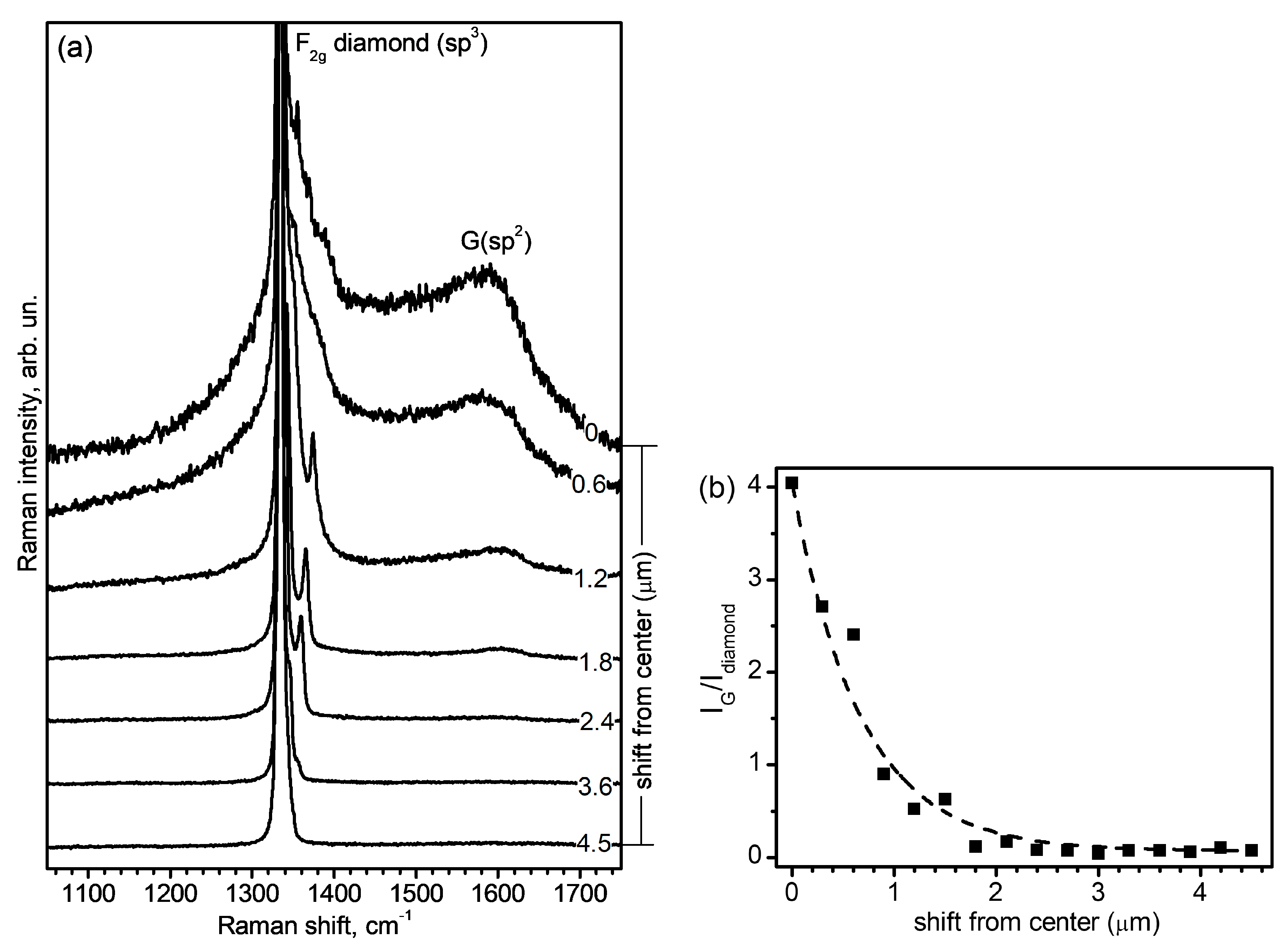

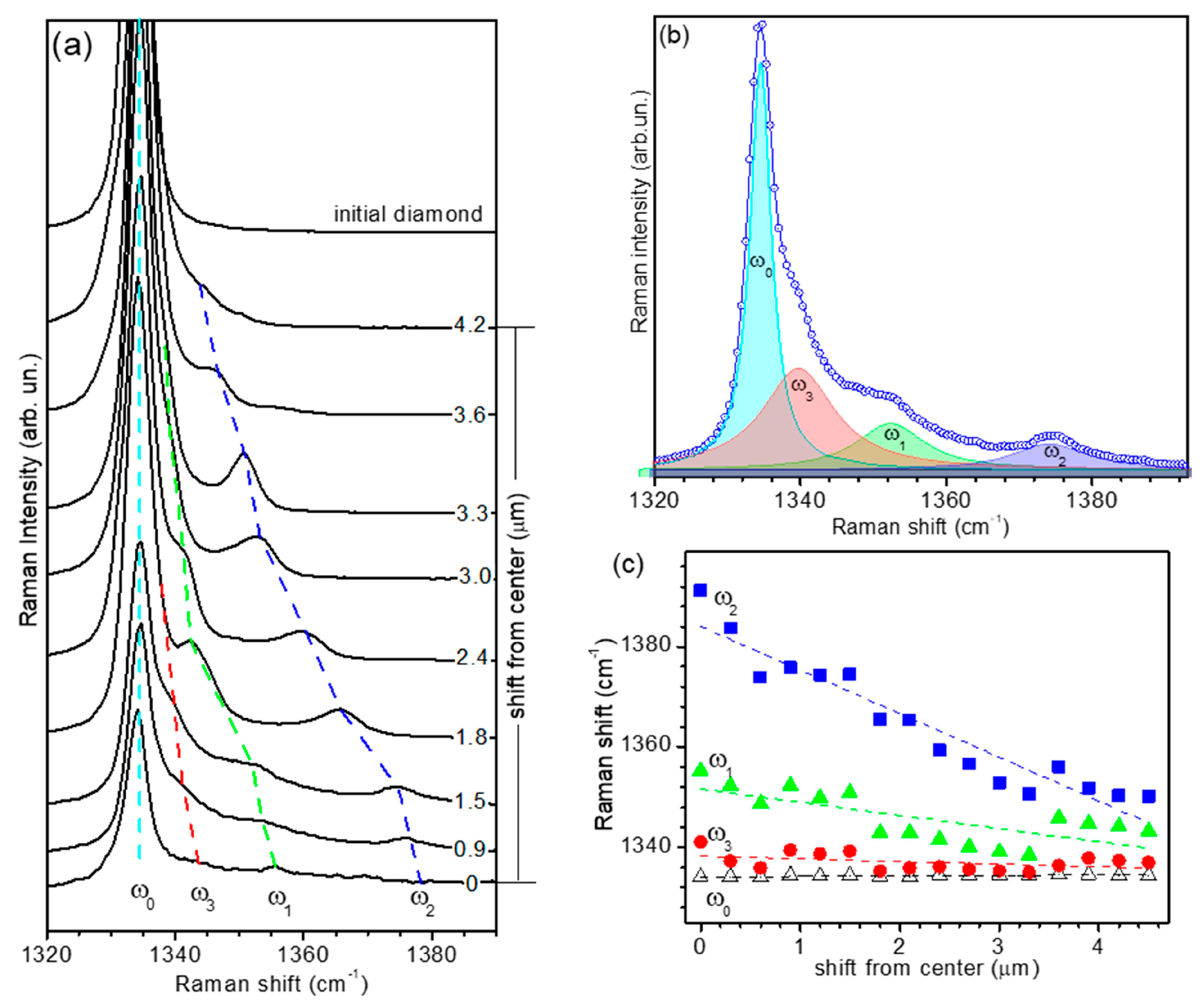

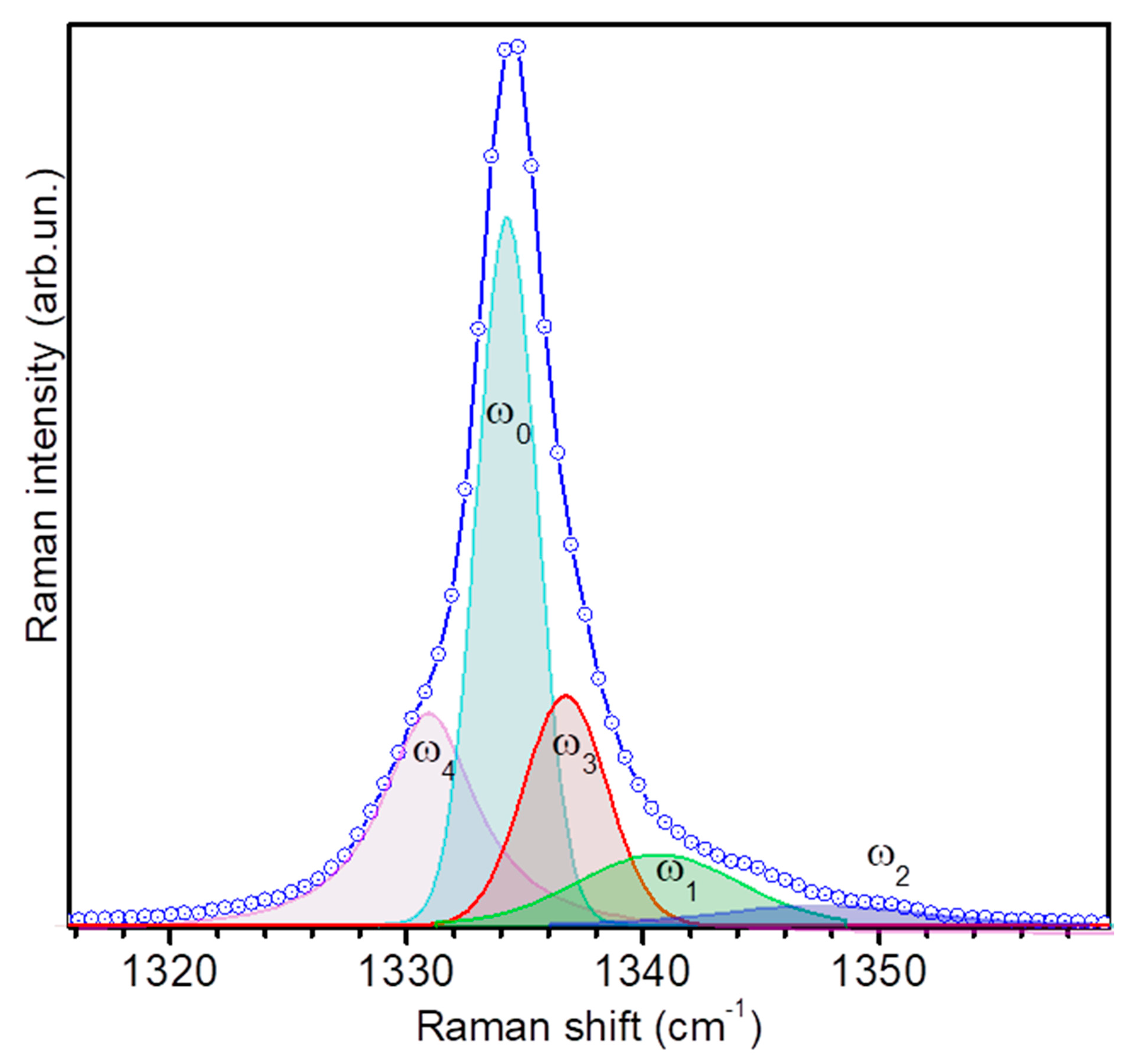

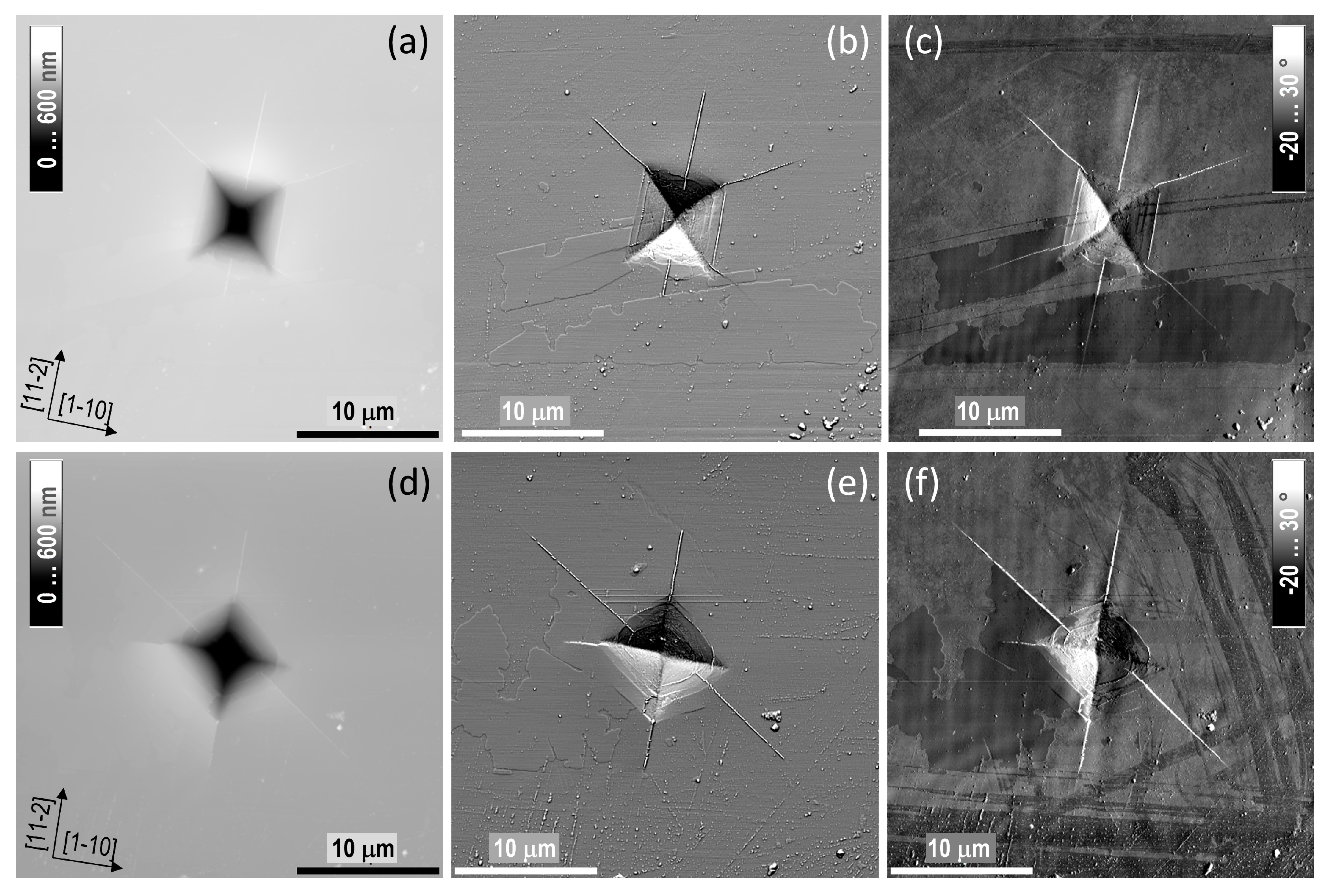

3.1. AFM Imaging and Micro-Raman Spectroscopy of Vickers Indents in Synthetic Ib Diamond Single Crystal

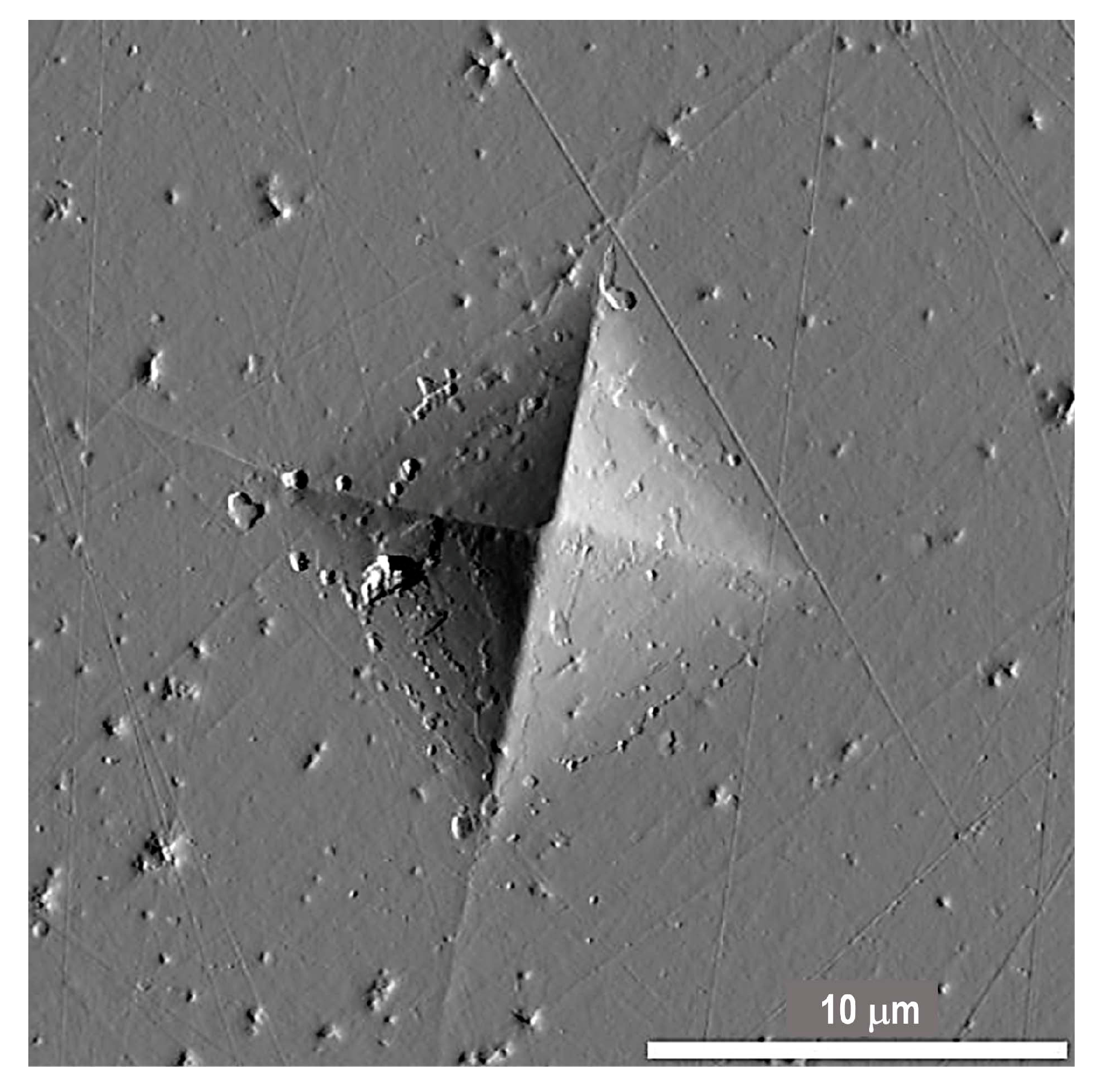

3.2. AFM Imaging of Vickers Indents on (111) and (001) cBN Single Crystals

3.3. Vickers Hardness and Fracture Toughness of Diamond and cBN Single Crystals

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Chowdhury, S.; de Barra, E.; Laugier, M.T. Hardness measurement of CVD diamond coatings on SiC substrates. Surf. Coat. Technol. 2005, 193, 200–205. [Google Scholar] [CrossRef]

- Irifune, T.; Kurio, A.; Sakamoto, S.; Inoue, T.; Sumiya, H. Materials: Ultrahard polycrystalline diamond from graphite. Nature 2003, 421, 599–600. [Google Scholar] [CrossRef] [PubMed]

- Sumiya, H.; Irifune, T. Indentation hardness of nano-polycrystalline diamond prepared from graphite by direct conversion. Diam. Relat. Mater. 2004, 13, 1771–1776. [Google Scholar] [CrossRef]

- Sumiya, H.; Uesaka, S.; Satoh, S. Mechanical properties of high purity polycrystalline cBN synthesized by direct conversion sintering method. J. Mater. Sci. 2000, 35, 1181–1186. [Google Scholar] [CrossRef]

- Huang, Q.; Yu, D.; Xu, B.; Hu, W.; Ma, Y.; Wang, Y.; Zhao, Z.; Wen, B.; He, J.; Liu, Z.; et al. Nanotwinned diamond with unprecedented hardness and stability. Nature 2013, 510, 250–253. [Google Scholar] [CrossRef] [PubMed]

- Dubrovinskaia, N.; Solozhenko, V.L.; Miyajima, N.; Dmitriev, V.; Kurakevych, O.O.; Dubrovinsky, L. Superhard nanocomposite of dense polymorphs of boron nitride: Noncarbon material has reached diamond hardness. Appl. Phys. Lett. 2007, 90, 101912. [Google Scholar] [CrossRef]

- Solozhenko, V.L.; Kurakevych, O.O.; Le Godec, Y. Creation of nanostuctures by extreme conditions: High-pressure synthesis of ultrahard nanocrystalline cubic boron nitride. Adv. Mater. 2012, 24, 1540–1544. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Xu, B.; Yu, D.; Ma, Y.; Wang, Y.; Jiang, Y.; Hu, W.; Tang, C.; Gao, Y.; Luo, K.; et al. Ultrahard nanotwinned cubic boron nitride. Nature 2013, 493, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Nagakubo, A.; Ogi, H.; Sumiya, H.; Hirao, M. Elasticity and hardness of nano-polycrystalline boron nitrides: The apparent Hall-Petch effect. Appl. Phys. Lett. 2014, 105, 081906. [Google Scholar] [CrossRef]

- Liu, X.; Chang, Y.-Y.; Tkachev, S.N.; Bina, C.R.; Jacobsen, S.D. Elastic and mechanical softening in boron-doped diamond. Sci. Rep. 2017, 7, 42921. [Google Scholar] [CrossRef] [PubMed]

- Sumiya, H.; Ishida, Y.; Arimoto, K.; Harano, K. Real indentation hardness of nano-polycrystalline cBN synthesized by direct conversion sintering under HPHT. Diam. Relat. Mater. 2014, 48, 47–51. [Google Scholar] [CrossRef]

- Xu, B.; Tian, Y. Ultrahardness: Measurement and enhancement. J. Phys. Chem. C 2015, 119, 5633–5638. [Google Scholar] [CrossRef]

- Drory, M.D.; Dauskardt, R.H.; Kant, A.; Ritchie, R.O. Fracture of synthetic diamond. J. Appl. Phys. 1995, 78, 3083–3088. [Google Scholar] [CrossRef]

- Solozhenko, V.L.; Dub, S.N.; Novikov, N.V. Mechanical properties of cubic BC2N, a new superhard phase. Diam. Relat. Mater. 2001, 10, 2228–2231. [Google Scholar] [CrossRef]

- Zerr, A.; Kempf, M.; Schwarz, M.; Kroke, E.; Göken, M.; Riedel, R. Elastic moduli and hardness of cubic silicon nitride. J. Am. Ceram. Soc. 2002, 85, 86–90. [Google Scholar] [CrossRef]

- Dub, S.N.; Petrusha, I.A. Mechanical properties of polycrystalline cBN obtained from pyrolytic gBN by direct transformation technique. High Press. Res. 2006, 26, 71–77. [Google Scholar] [CrossRef]

- Dub, S.N.; Petrusha, I.A.; Bushlya, V.M.; Taniguchi, T.; Belous, V.A.; Tolmachova, G.N.; Andreev, A.V. Theoretical shear strength and the onset of plasticity in nanodeformation of cubic boron nitride. J. Superhard Mater. 2017, 39, 88–98. [Google Scholar] [CrossRef]

- Richter, A.; Ries, R.; Smith, R.; Henkel, M.; Wolf, B. Nanoindentation of diamond, graphite and fullerene films. Diam. Relat. Mater. 2000, 9, 170–184. [Google Scholar] [CrossRef]

- Sawa, T.; Tanaka, K. Nanoindentation of natural diamond. Philos. Mag. A 2002, 82, 1851–1856. [Google Scholar] [CrossRef]

- Dubrovinskaia, N.; Dub, S.; Dubrovinsky, L. Superior wear resistance of aggregated diamond nanorods. Nano Lett. 2006, 6, 824–826. [Google Scholar] [CrossRef] [PubMed]

- Dub, S.N.; Brazhkin, V.V.; Belous, V.A.; Tolmacheva, G.N.; Konevskii, P.V. Comparative nanoindentation of single crystals of hard and superhard oxides. J. Superhard Mater. 2014, 36, 217–230. [Google Scholar] [CrossRef]

- Gogotsi, Y.G.; Kailer, A.; Nickel, K.G. Pressure-induced phase transformations in diamond. J. Appl. Phys. 1998, 84, 1299–1304. [Google Scholar] [CrossRef]

- Gogotsi, Y.G.; Kailer, A.; Nickel, K.G. Transformation of diamond to graphite. Nature 1999, 401, 663–664. [Google Scholar] [CrossRef]

- Suprun, O.M.; Ilnitskaya, G.D.; Kalenchuk, V.A.; Zanevskii, O.A.; Shevchuk, S.N.; Lysakovskii, V.V. Change of dislocations density in single crystals of various types diamonds depending on the growth temperature and rate. Funct. Mater. 2016, 23, 552–556. [Google Scholar] [CrossRef]

- Khvostantsev, L.G.; Slesarev, V.N. Large-volume high-pressure devices for physical investigations. UFN 2008, 51, 1059–1063. [Google Scholar] [CrossRef]

- Anstis, G.R.; Chantikul, P.; Lawn, B.R.; Marshal, D.B. A critical evaluation of indentation techniques for measuring fracture toughness: I, direct crack measurements. J. Am. Ceram. Soc. 1981, 64, 533–538. [Google Scholar] [CrossRef]

- Zhong, Q.; Inniss, D.; Kjoller, K.; Elings, V.B. Fractured polymer/silica fiber surface studied by tapping mode atomic force microscopy. Surf. Sci. 1993, 290, L688–L692. [Google Scholar] [CrossRef]

- Radmacher, M.; Tillmann, R.W.; Gaub, H.E. Imaging viscoelasticity by force modulation with the atomic force microscope. Biophys. J. 1993, 64, 735–742. [Google Scholar] [CrossRef]

- Magonov, S.N.; Elings, V.; Whangbo, M.-H. Phase imaging and stiffness in tapping-mode atomic force microscopy. Surf. Sci. 1997, 375, L385–L391. [Google Scholar] [CrossRef]

- Nonnenmacher, M.; O’Boyle, M.P.; Wickramasinghe, H.K. Kelvin probe force microscopy. Appl. Phys. Lett. 1991, 58, 2921–2923. [Google Scholar] [CrossRef]

- Domnich, V.; Gogotsi, Y.; Dub, S. Effect of phase transformations on the shape of unloading curve in the nanoindentation of silicon. Appl. Phys. Lett. 2000, 76, 2214–2216. [Google Scholar] [CrossRef]

- Diederich, L.; Küttel, O.M.; Aebi, P.; Schlapbach, L. Electron affinity and work function of differently oriented and doped diamond surfaces determined by photoelectron spectroscopy. Surf. Sci. 1998, 418, 219–239. [Google Scholar] [CrossRef]

- Robrieux, B.; Faure, R.; Dussaulcy, J.P. Resistivity and electronic work function of very thin film carbon. C. R. Acad. Sci. Ser. B 1974, 278, 659–662. [Google Scholar]

- Xu, C.; Liu, C.; Wang, H. Incipient plasticity of diamond during nanoindentation. RSC Adv. 2017, 7, 36093–36100. [Google Scholar] [CrossRef]

- Denisov, V.N.; Mavrin, B.N.; Serebryanaya, N.R.; Dubitsky, G.A.; Aksenenkov, V.V.; Kirichenko, A.N.; Kuzmin, N.V.; Kulnitskiy, B.A.; Perezhogin, I.A.; Blank, V.D. First-principles, UV Raman, X-ray diffraction and TEM study of the structure and lattice dynamics of the diamond—Lonsdaleite system. Diam. Relat. Mater. 2011, 20, 951–953. [Google Scholar] [CrossRef]

- Goryainov, S.V.; Likhacheva, A.Y.; Rashchenko, S.V.; Shubin, A.S.; Afanas’ev, V.P.; Pokhilenko, N.P. Raman identification of lonsdaleite in Popigai impactites. J. Raman Spectrosc. 2014, 45, 305–313. [Google Scholar] [CrossRef]

- Boteler, J.M.; Gupta, Y.M. Shock induced splitting of the triply degenerate Raman line in diamond. Phys. Rev. Lett. 1993, 71, 3497. [Google Scholar] [CrossRef] [PubMed]

- Boteler, J.M.; Gupta, Y.M. Raman spectra of shocked diamond single crystals. Phys. Rev. B 2002, 66, 014107. [Google Scholar] [CrossRef]

- Novikov, N.V.; Dub, S.N. Fracture toughness of diamond single crystals. J. Hard Mater. 1991, 2, 3–11. [Google Scholar]

- Novikov, N.V.; Dub, S.N.; Mal’nev, V.I.; Beskrovanov, V.V. Mechanical properties of diamond at 1200 °C. Diam. Relat. Mater. 1994, 3, 198–204. [Google Scholar] [CrossRef]

- Brookes, C.A.; Hooper, R.M.; Lambert, W.A. Identification of slip systems in cubic boron nitride. Philos. Mag. A 1983, 47, L.9–L.12. [Google Scholar] [CrossRef]

- Galanov, B.A.; Milman, Y.V.; Chugunova, S.I.; Goncharova, I.V. Investigation of mechanical properties of high-hardness materials by indentation. J. Superhard Mater. 1999, 21, 23–35. [Google Scholar]

- Lim, Y.Y.; Chaudhri, M.M. The effect of the indenter load on the nanohardness of ductile metals: An experimental study on polycrystalline work-hardened and annealed oxygen-free copper. Philos. Mag. A 1999, 79, 2979–3000. [Google Scholar] [CrossRef]

- Dub, S.N. Fracture Toughness Determination of Superhard Single Crystals by Indentation. Ph.D. Thesis, Institute for Superhard Materials of the Academy of Sciences of Ukraine, Kiev, Ukraine, 1 November 1984. [Google Scholar]

- Novikov, N.V.; Dub, S.N. Hardness and fracture toughness of CVD diamond film. Diam. Relat. Mater. 1996, 5, 1026–1030. [Google Scholar] [CrossRef]

- Novikov, N.V.; Dub, S.N.; Malnev, V.I. Microhardness and fracture toughness of cubic boron nitride single crystals. Sov. J. Superhard Mater. 1983, 5, 16–20. [Google Scholar]

| Sample | E, GPa | Poisson’s Ratio | HM, GPa | φ/2, ° | 2sin(φ/2) |

|---|---|---|---|---|---|

| Al | 72 | 0.35 | 0.36 | 68.04 | 1.8549 |

| SiO2 | 71 | 0.17 | 9 | 68.79 | 1.8646 |

| Al2O3 | 400 | 0.22 | 22 | 69.94 | 1.8787 |

| cBN | 850 | 0.12 | 62 | 73.58 | 1.9184 |

| Diamond | 1136 | 0.07 | 100 | 77.17 | 1.9501 |

| Sample | Load P, N | Projected Contact Area A, 106 nm2 | Equivalent Diagonal deq, μm | Vickers Hardness HV, GPa | Meyer Hardness HM, GPa | Radial Crack Length C, μm | Fracture Toughness KIC, MPa m0.5 |

|---|---|---|---|---|---|---|---|

| (111) Synthetic diamond | 4.91 | 60.05 | 10.96 | 79.7 | 81.7 | 14.2 [44] | 5.6 |

| Nano cBN compact | 4.91 | 81.40 | 12.51 | 60.2 | 61.5 | 11.40 | 7.9 |

| (111) cBN orientation A | 1.96 | 38.46 | 8.77 | 48.9. | 51.0 | 10.65 | 3.2 |

| (111) cBN orientation B | 1.96 | 39.05 | 8.84 | 48.2 | 50.2 | 11.37 | 3.5 |

| (001) cBN, orientation <100> | 1.96 | 38.04 | 8.72 | 49.4 | 51.5 | - | - |

| (001) cBN, orientation <110> | 1.96 | 43.36 | 9.31 | 43.4 | 45.2 | - | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dub, S.; Lytvyn, P.; Strelchuk, V.; Nikolenko, A.; Stubrov, Y.; Petrusha, I.; Taniguchi, T.; Ivakhnenko, S. Vickers Hardness of Diamond and cBN Single Crystals: AFM Approach. Crystals 2017, 7, 369. https://doi.org/10.3390/cryst7120369

Dub S, Lytvyn P, Strelchuk V, Nikolenko A, Stubrov Y, Petrusha I, Taniguchi T, Ivakhnenko S. Vickers Hardness of Diamond and cBN Single Crystals: AFM Approach. Crystals. 2017; 7(12):369. https://doi.org/10.3390/cryst7120369

Chicago/Turabian StyleDub, Sergey, Petro Lytvyn, Viktor Strelchuk, Andrii Nikolenko, Yurii Stubrov, Igor Petrusha, Takashi Taniguchi, and Sergey Ivakhnenko. 2017. "Vickers Hardness of Diamond and cBN Single Crystals: AFM Approach" Crystals 7, no. 12: 369. https://doi.org/10.3390/cryst7120369