Thermal Stability of Epitaxial Graphene Electrodes for Conductive Polymer Nanofiber Devices

Abstract

:1. Introduction

2. Results and Discussion

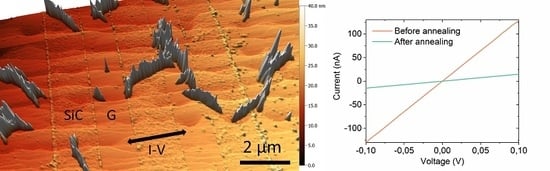

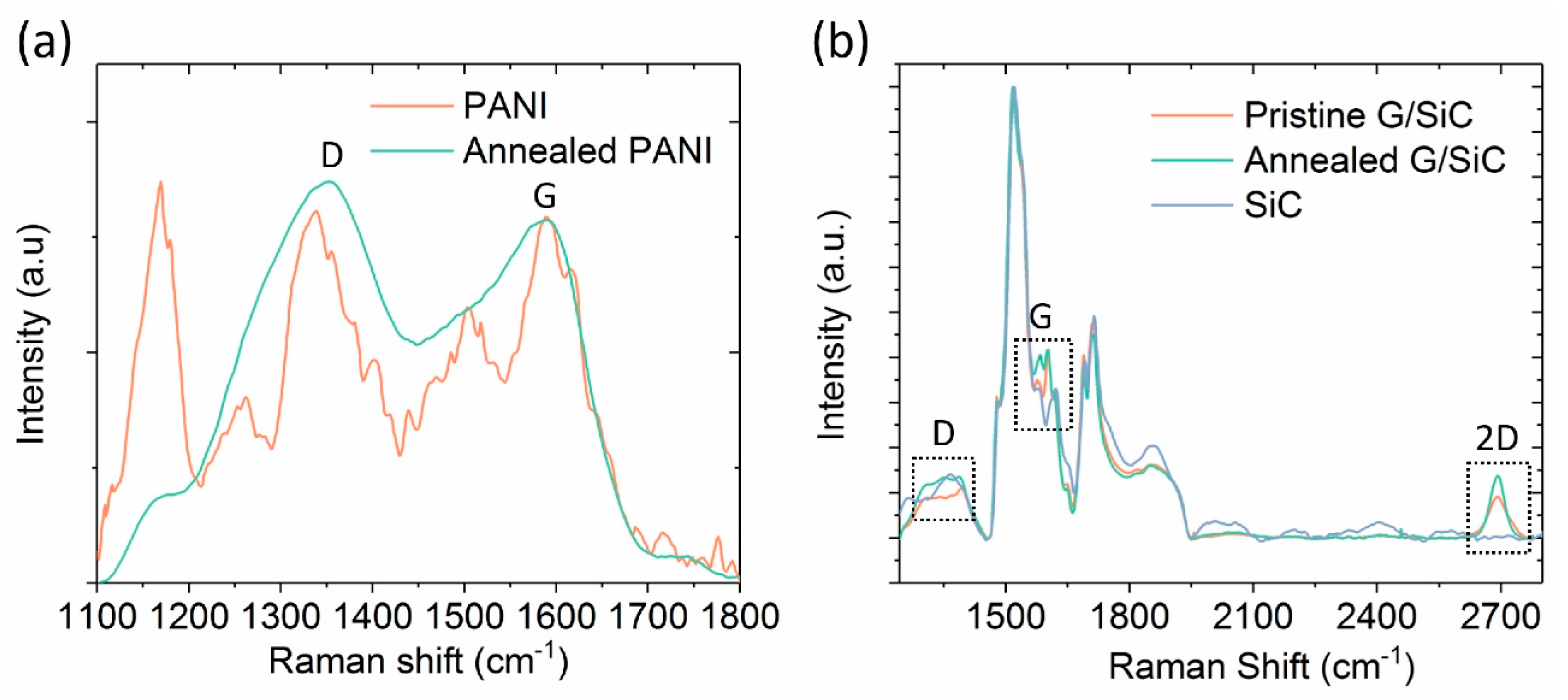

2.1. Characterization of Graphene Electrodes

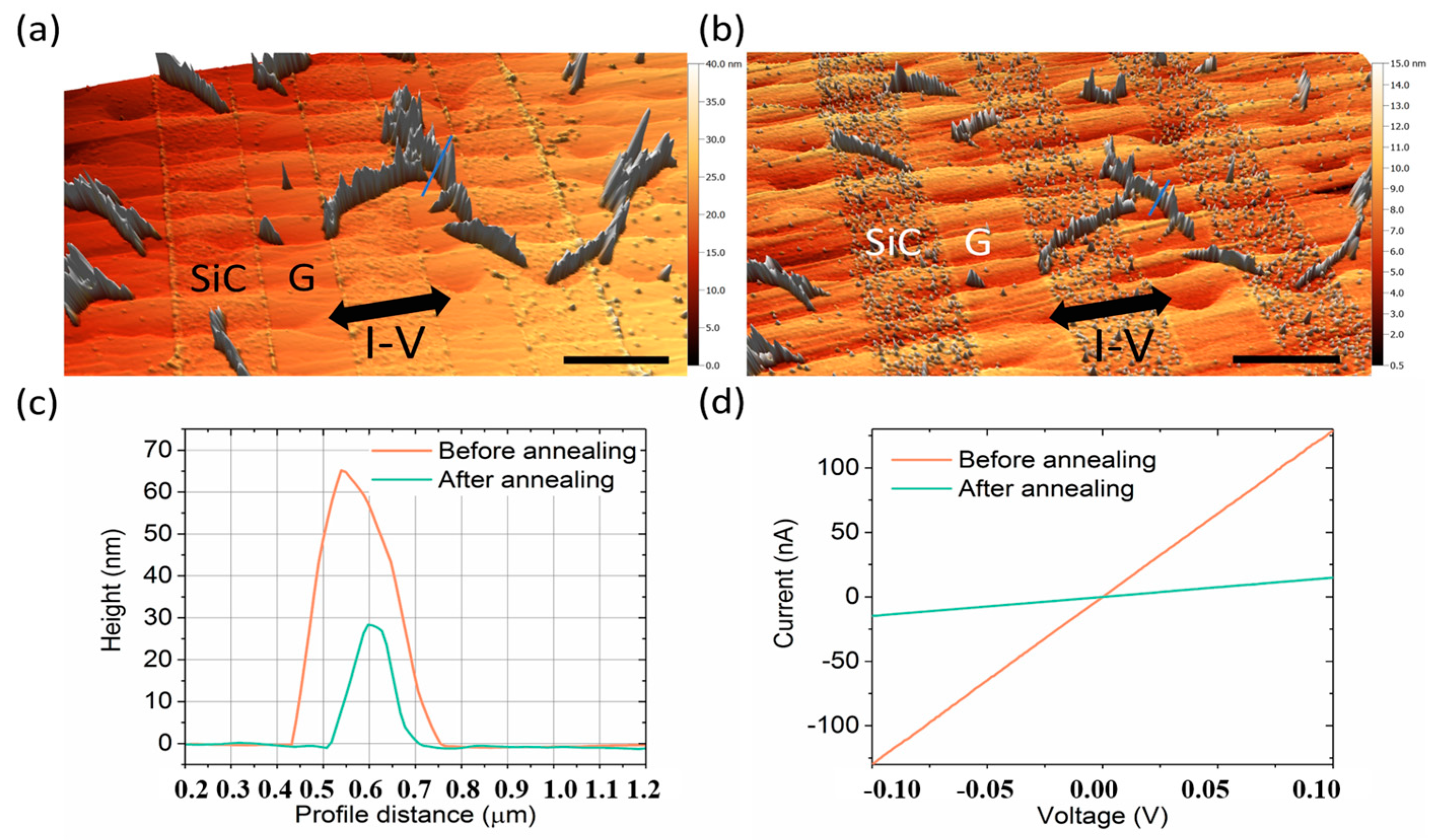

2.2. Characterization of Graphene-Nanofiber Devices before and after Thermal Annealing Step

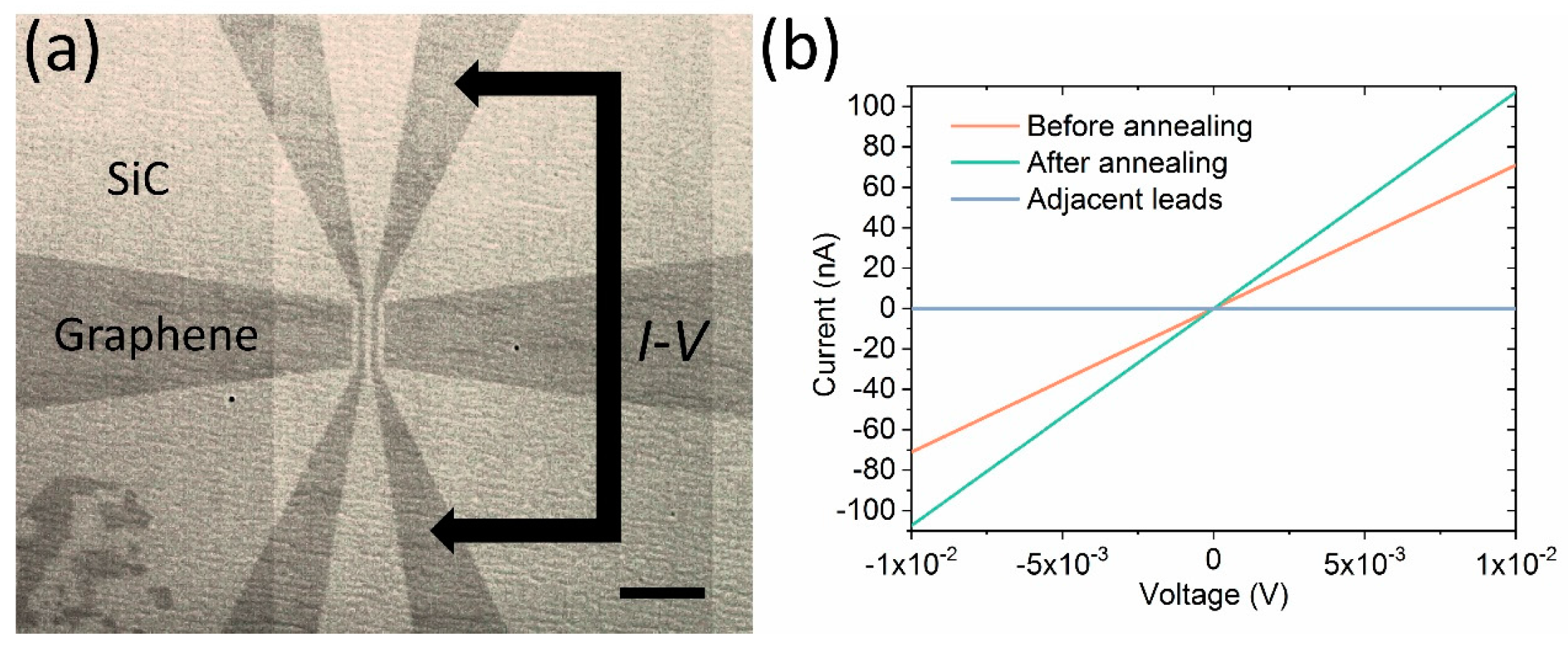

2.3. Comparison of Graphene with Gold as a Contact for PANI Nanofibers

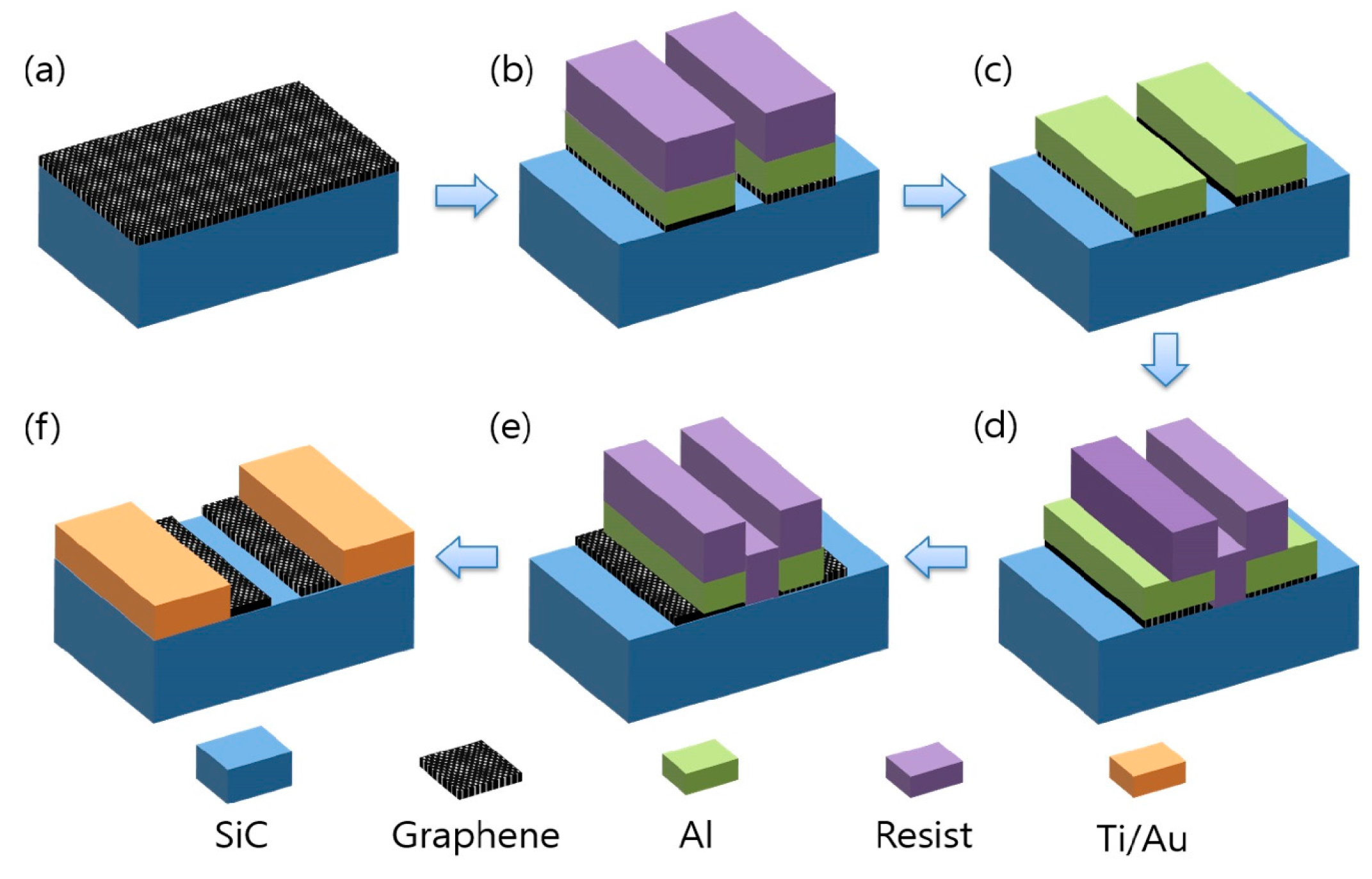

3. Materials and Methods

3.1. Growth of Epitaxial Graphene on SiC

3.2. Fabrication of Graphene and Au Electrodes

3.2.1. Fabrication of Graphene Electrodes

3.2.2. Fabrication of Gold Electrodes

3.3. Synthesis of Polyaniline Nanofibers and Contacting to Graphene and Au Electrodes

3.4. Electrical Characterization, Raman Spectroscopy and Carbonization

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chen, D.; Lei, S.; Chen, Y. A single polyaniline nanofiber field effect transistor and its gas sensing mechanisms. Sensors 2011, 11, 6509–6516. [Google Scholar] [CrossRef] [PubMed]

- Baker, C.O.; Shedd, B.; Innis, P.C.; Whitten, P.G.; Spinks, G.M.; Wallace, G.G.; Kaner, R.B. Monolithic actuators from flash-welded polyaniline nanofibers. Adv. Mater. 2008, 20, 155–158. [Google Scholar] [CrossRef]

- Chen, X.; Wong, C.K.Y.; Yuan, C.A.; Zhang, G. Nanowire-based gas sensors. Sens. Actuators B Chem. 2013, 177, 178–195. [Google Scholar] [CrossRef]

- Yu, H.; Li, B. Wavelength-converted wave-guiding in dye-doped polymer nanofibers. Sci. Rep. 2013, 3, 1674. [Google Scholar] [CrossRef] [PubMed]

- Park, J.U.; Nam, S.; Lee, M.S.; Lieber, C.M. Synthesis of monolithic graphene–graphite integrated electronics. Nat. Mater. 2011, 11, 120–125. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, W.; Wei, J.; Sun, X.; Yu, H. A Study on graphene—metal contact. Crystals 2013, 3, 257–274. [Google Scholar] [CrossRef]

- Lin, Y.M.; Valdes-Garcia, A.; Han, S.J.; Farmer, D.B.; Meric, I.; Sun, Y.N.; Wu, Y.Q.; Dimitrakopoulos, C.; Grill, A.; Avouris, P.; et al. Wafer-scale graphene integrated circuit. Science 2011, 332, 1294–1298. [Google Scholar] [CrossRef] [PubMed]

- Neto, A.H.C.; Guinea, F.; Peres, N.M.R.; Novoselov, K.S.; Geim, A.K. The electronic properties of graphene. Rev. Mod. Phys. 2009, 81, 109–162. [Google Scholar] [CrossRef] [Green Version]

- Banszerus, L.; Schmitz, M.; Engels, S.; Dauber, J.; Oellers, M.; Haupt, F.; Watanabe, K.; Taniguchi, T.; Beschoten, B.; Stampfer, C. Ultrahigh-mobility graphene devices from chemical vapor deposition on reusable copper. Sci. Adv. 2015, 1, e1500222. [Google Scholar] [CrossRef] [PubMed]

- Yager, T.; Webb, M.J.; Grennberg, H.; Yakimova, R.; Lara-Avila, S.; Kubatkin, S. High mobility epitaxial graphene devices via aqueous-ozone processing. Appl. Phys. Lett. 2015, 106, 063503. [Google Scholar] [CrossRef]

- Boyd, D.A.; Lin, W.H.; Hsu, C.C.; Teague, M.L.; Chen, C.C.; Lo, Y.Y.; Chan, W.Y.; Su, W.B.; Cheng, T.C.; Chang, C.S.; et al. Single-step deposition of high-mobility graphene at reduced temperatures. Nat. Commun. 2015, 6, 6620. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef] [PubMed]

- Nair, R.R.; Blake, P.; Grigorenko, A.N.; Novoselov, K.S.; Booth, T.J.; Stauber, T.; Peres, N.M.R.; Geim, A.K. Fine structure constant defines visual transparency of graphene. Science 2008, 320, 1308. [Google Scholar] [CrossRef] [PubMed]

- Bonaccorso, F.; Sun, Z.; Hasan, T.; Ferrari, A.C. Graphene photonics and optoelectronics. Nat. Photonics 2010, 4, 611–622. [Google Scholar] [CrossRef]

- Mansour, A.E.; Said, M.M.; Dey, S.; Hu, H.; Zhang, S.; Munir, R.; Zhang, Y.; Moudgil, K.; Barlow, S.; Marder, S.R.; et al. Facile doping and work-function modification of few-layer graphene using molecular oxidants and reductants. Adv. Funct. Mater. 2017, 27, 1602004. [Google Scholar] [CrossRef]

- Hong, S.K.; Song, S.M.; Sul, O.; Cho, B.J. Reduction of metal-graphene contact resistance by direct growth of graphene over metal. Carbon Lett. 2013, 14, 171–174. [Google Scholar] [CrossRef]

- Lee, S.; Jo, G.; Kang, S.J.; Park, W.; Kahng, Y.H.; Kim, D.Y.; Lee, B.H.; Lee, T. Characterization on improved effective mobility of pentacene organic field-effect transistors using graphene electrodes. Jpn. J. Appl. Phys. 2012, 51, 02BK09. [Google Scholar] [CrossRef]

- Liu, W.; Jackson, B.L.; Zhu, J.; Miao, C.; Park, Y.; Sun, K.; Woo, J.; Xie, Y. Large scale pattern graphene electrode for high performance in transparent organic single crystal field-effect transistors. ACS Nano 2010, 4, 3927–3932. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Liu, S.; Shen, Q.; Yan, K.; Li, P.; Xu, J.; Yu, D.; Steigerwald, M.L.; Nuckolls, C.; Liu, Z.; et al. High-performance photoresponsive organic nanotransistors with single-layer graphenes as two-dimensional electrodes. Adv. Funct. Mater. 2009, 19, 2743–2748. [Google Scholar] [CrossRef]

- Park, J.K.; Song, S.M.; Mun, J.H.; Cho, B.J. Graphene gate electrode for MOS structure-based electronic devices. Nano Lett. 2011, 11, 5383–5386. [Google Scholar] [CrossRef] [PubMed]

- Di, C.A.; Wei, D.; Yu, G.; Liu, Y.; Guo, Y.; Zhu, D. Patterned graphene as source/drain electrodes for bottom-contact organic field-effect transistors. Adv. Mater. 2008, 20, 3289–3293. [Google Scholar] [CrossRef]

- Pang, S.; Tsao, H.N.; Feng, X.; Mullen, K. Patterned graphene electrodes from solution-processed graphite oxide films for organic field-effect transistors. Adv. Mater. 2009, 21, 3488–3491. [Google Scholar] [CrossRef]

- Henrichsen, H.H.; Bøggild, P. Graphene electrodes for n-type organic field-effect transistors. Microelectron. Eng. 2010, 87, 1120–1122. [Google Scholar] [CrossRef]

- Wang, X.; Zhi, L.; Müllen, K. Transparent, conductive graphene electrodes for dye-sensitized solar cells. Nano Lett. 2008, 8, 323–327. [Google Scholar] [CrossRef] [PubMed]

- Jo, G.; Choe, M.; Cho, C.Y.; Kim, J.H.; Park, W.; Lee, S.; Hong, W.K.; Kim, T.W.; Park, S.J.; Hong, B.H.; et al. Large-scale patterned multi-layer graphene films as transparent conducting electrodes for GaN light-emitting diodes. Nanotechnol. 2010, 21, 175201. [Google Scholar] [CrossRef] [PubMed]

- Qian, Z.; Hui, Y.; Liu, F.; Kang, S.; Kar, S.; Rinaldi, M. Graphene–aluminum nitride NEMS resonant infrared detector. Microsyst. Nanoeng. 2016, 2, 16026. [Google Scholar] [CrossRef]

- Kuzum, D.; Takano, H.; Shim, E.; Reed, J.C.; Juul, H.; Richardson, A.G.; de Vries, J.; Bink, H.; Dichter, M.A.; Lucas, T.H.; et al. Transparent and flexible low noise graphene electrodes for simultaneous electrophysiology and neuroimaging. Nat. Commun. 2014, 5, 5259. [Google Scholar] [CrossRef] [PubMed]

- Park, D.W.; Brodnick, S.K.; Ness, J.P.; Atry, F.; Krugner-Higby, L.; Sandberg, A.; Mikael, S.; Richner, T.J.; Novello, J.; Kim, H.; et al. Fabrication and utility of a transparent graphene neural electrode array for electrophysiology, in vivo imaging, and optogenetics. Nat. Protoc. 2016, 11, 2201–2222. [Google Scholar] [CrossRef] [PubMed]

- Vashist, S.K.; Luong, J.H.T. Recent advances in electrochemical biosensing schemes using graphene and graphene-based nanocomposites. Carbon 2015, 84, 519–550. [Google Scholar] [CrossRef]

- Vashist, S.K.; Luppa, P.B.; Yeo, L.Y.; Ozcan, A.; Luong, J.H.T. Emerging Technologies for Next-Generation Point-of-Care Testing. Trends Biotechnol. 2015, 33, 692–705. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Sun, Z.; Yan, Z.; Jin, Z.; Tour, J.M. Rational design of hybrid graphene films for high-performance transparent electrodes. ACS Nano 2011, 5, 6472–6479. [Google Scholar] [CrossRef] [PubMed]

- Yager, T.; Lartsev, A.; Yakimova, R.; Lara-Avila, S.; Kubatkin, S. Wafer-scale homogeneity of transport properties in epitaxial graphene on SiC. Carbon 2015, 87, 409–414. [Google Scholar] [CrossRef]

- Yazdi, G.; Iakimov, T.; Yakimova, R. Epitaxial graphene on SiC: A review of growth and characterization. Crystals 2016, 6, 53. [Google Scholar] [CrossRef]

- Shih, F.Y.; Chen, S.Y.; Liu, C.H.; Ho, P.H.; Wu, T.S.; Chen, C.W.; Chen, Y.F.; Wang, W.H. Residue-free fabrication of high-performance graphene devices by patterned PMMA stencil mask. AIP Adv. 2014, 4, 67129. [Google Scholar] [CrossRef]

- Kybert, N.J.; Han, G.H.; Lerner, M.B.; Dattoli, E.N.; Esfandiar, A.; Charlie Johnson, A.T. Scalable arrays of chemical vapor sensors based on DNA-decorated graphene. Nano Res. 2014, 7, 95–103. [Google Scholar] [CrossRef]

- Yong, K.; Ashraf, A.; Kang, P.; Nam, S. Rapid stencil mask fabrication enabled one-step polymer-free graphene patterning and direct transfer for flexible graphene devices. Sci. Rep. 2016, 6, 24890. [Google Scholar] [CrossRef] [PubMed]

- Hsu, A.; Wang, H.; Kim, K.K.; Kong, J.; Palacios, T. Impact of graphene interface quality on contact resistance and RF device performance. IEEE. Electron. Device Lett. 2011, 32, 1008–1010. [Google Scholar] [CrossRef]

- Xie, W.; Weng, L.T.; Ng, K.M.; Chan, C.K.; Chan, C.M. Clean graphene surface through high temperature annealing. Carbon 2015, 94, 740–748. [Google Scholar] [CrossRef]

- Yager, T.; Lartsev, A.; Mahashabde, S.; Charpentier, S.; Davidovikj, D.; Danilov, A.; Yakimova, R.; Panchal, V.; Kazakova, O.; Tzalenchuk, A.; et al. Express optical analysis of epitaxial graphene on SiC: Impact of morphology on quantum transport. Nano Lett. 2013, 13, 4217–4223. [Google Scholar] [CrossRef] [PubMed]

- Kopylov, S.; Tzalenchuk, A.; Kubatkin, S.; Fal’Ko, V.I. Charge transfer between epitaxial graphene and silicon carbide. Appl. Phys. Lett. 2010, 97, 112109. [Google Scholar] [CrossRef]

- Janssen, T.J.B.M.; Tzalenchuk, A.; Yakimova, R.; Kubatkin, S.; Lara-Avila, S.; Kopylov, S.V.; Fal’Ko, V.I. Anomalously strong pinning of the filling factor ν = 2 in epitaxial graphene. Phys. Rev. B. 2011, 83, 233402. [Google Scholar] [CrossRef]

- Leong, W.S.; Nai, C.T.; Thong, J.T.L. What does annealing do to metal-graphene contacts? Nano Lett. 2014, 14, 3840–3847. [Google Scholar] [CrossRef] [PubMed]

- Yager, T.; Lartsev, A.; Cedergren, K.; Yakimova, R.; Panchal, V.; Kazakova, O.; Tzalenchuk, A.; Kim, K.H.; Park, Y.W.; Lara-Avila, S.; et al. Low contact resistance in epitaxial graphene devices for quantum metrology. AIP Adv. 2015, 5, 087134. [Google Scholar] [CrossRef]

- Tran, H.D.; Wang, Y.; D’Arcy, J.M.; Kaner, R.B. Toward an understanding of the formation of conducting polymer nanofibers. ACS Nano 2008, 2, 1841–1848. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Kaner, R.B. The intrinsic nanofibrillar morphology of polyaniline. Chem. Commun. 2006, 0, 367–376. [Google Scholar] [CrossRef] [PubMed]

- Tran, H.D.; Norris, I.; D’Arcy, J.M.; Tsang, H.; Wang, Y.; Mattes, B.R.; Kaner, R.B. Substituted polyaniline nanofibers produced via rapid initiated polymerization. Macromolecular 2008, 41, 7405–7410. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, X.; Zhu, S.; Zhou, Z.; Yao, Y.; Quan, W.; Liu, B. Enhanced sensitivity of ammonia sensor using graphene/polyaniline nanocomposite. Sens. Actuators B Chem. 2013, 178, 485–493. [Google Scholar] [CrossRef]

- Crowley, K.; Smyth, M.; Killard, A.; Morrin, A. Printing polyaniline for sensor applications. Chem. Pap. 2013, 67, 771–780. [Google Scholar] [CrossRef]

- Goto, A.; Kyotani, M.; Tsugawa, K.; Piao, G.; Akagi, K.; Yamaguchi, C.; Matsui, H.; Koga, Y. Nanostructures of pyrolytic carbon from a polyacetylene thin film. Carbon 2003, 41, 131–138. [Google Scholar] [CrossRef]

- Kyotani, M.; Matsushita, S.; Nagai, T.; Matsui, Y.; Shimomura, M.; Kaito, A.; Akagi, K. Helical carbon and graphitic films prepared from iodine-doped helical polyacetylene film using morphology-retaining carbonization. J. Am. Chem. Soc. 2008, 130, 10880–10881. [Google Scholar] [CrossRef] [PubMed]

- Matsushita, S.; Akagi, K. Macroscopically aligned graphite films prepared from iodine-doped stretchable polyacetylene films using morphology-retaining carbonization. J. Am. Chem. Soc. 2015, 137, 9077–9087. [Google Scholar] [CrossRef] [PubMed]

- Bober, P.; Trchová, M.; Morávková, Z.; Kovářová, J.; Vulić, I.; Gavrilov, N.; Pašti, I.A.; Stejskal, J. Phosphorus and nitrogen-containing carbons obtained by the carbonization of conducting polyaniline complex with phosphites. Electrochem. Acta 2017, 246, 443–450. [Google Scholar] [CrossRef]

- Maiyalagan, T.; Viswanathan, B.; Varadaraju, U.V. Nitrogen containing carbon nanotubes as supports for Pt-Alternate anodes for fuel cell applications. Electrochem. Commun. 2005, 7, 905–912. [Google Scholar] [CrossRef]

- Rozlívková, Z.; Trchová, M.; Exnerová, M.; Stejskal, J. The carbonization of granular polyaniline to produce nitrogen-containing carbon. Synth. Met. 2011, 161, 1122–1129. [Google Scholar] [CrossRef]

- Trchová, M.; Konyushenko, E.N.; Stejskal, J.; Kovářová, J.; Ćirić-Marjanović, G. The conversion of polyaniline nanotubes to nitrogen-containing carbon nanotubes and their comparison with multi-walled carbon nanotubes. Polym. Degrad. Stab. 2009, 94, 929–938. [Google Scholar] [CrossRef]

- Quílez-Bermejo, J.; González-Gaitan, C.; Morallón, E.; Cazorla-Amorós, D. Effect of carbonization conditions of polyaniline on its catalytic activity towards ORR. Some insights about the nature of the active sites. Carbon 2017, 119, 62–71. [Google Scholar] [CrossRef]

- Shen, W.; Fan, W. Nitrogen-containing porous carbons: synthesis and application. J. Mater. Chem. A 2013, 1, 999–1013. [Google Scholar] [CrossRef]

- Mentus, S.; Ćirić-Marjanović, G.; Trchová, M.; Stejskal, J. Conducting carbonized polyaniline nanotubes. Nanotechnology 2009, 20, 245601. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.H.; Lara-Avila, S.; Kang, H.; He, H.; Eklӧf, J.; Hong, S.J.; Park, M.; Moth-Poulsen, K.; Matsushita, S.; Akagi, K.; et al. Apparent power law scaling of variable range hopping conduction in carbonized polymer nanofibers. Sci. Rep. 2016, 6, 37783. [Google Scholar] [CrossRef] [PubMed]

- Fromm, F.; Oliveira, M.H.; Molina-Sánchez, A.; Hundhausen, M.; Lopes, J.M.J.; Riechert, H.; Wirtz, L.; Seyller, T. Contribution of the buffer layer to the Raman spectrum of epitaxial graphene on SiC(0001). New J. Phys. 2013, 15, 043031. [Google Scholar] [CrossRef]

- Lee, D.S.; Riedl, C.; Krau, B.; Klitzing, K.V.; Starke, U.; Smet, J.H.; Festkörperforschung, M.; Stuttgart, D. Raman spectra of epitaxial graphene on SiC and of epitaxial graphene transferred to SiO2. Nano Lett. 2008, 8, 4320–4325. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, R.; Lippmaa, M. Thermally Stable Sr2RuO4 Electrode for Oxide Heterostructures. ACS Appl. Mater. Interfaces 2017, 9, 21314–21321. [Google Scholar] [CrossRef] [PubMed]

- Park, K.Y.; Kim, H.; Lee, S.; Kim, J.; Hong, J.; Lim, H.D.; Park, I.; Kang, K. Thermal structural stability of multi-component olivine electrode for lithium ion batteries. CrystEngComm 2016, 18, 7463–7470. [Google Scholar] [CrossRef]

- Choi, A.J. Magneto Resistance of One-Dimensional Polymer Nanofibers. Ph.D. Thesis, Seoul National University, Seoul, Korea, February 2012. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.H.; Lara-Avila, S.; He, H.; Kang, H.; Park, Y.W.; Yakimova, R.; Kubatkin, S. Thermal Stability of Epitaxial Graphene Electrodes for Conductive Polymer Nanofiber Devices. Crystals 2017, 7, 378. https://doi.org/10.3390/cryst7120378

Kim KH, Lara-Avila S, He H, Kang H, Park YW, Yakimova R, Kubatkin S. Thermal Stability of Epitaxial Graphene Electrodes for Conductive Polymer Nanofiber Devices. Crystals. 2017; 7(12):378. https://doi.org/10.3390/cryst7120378

Chicago/Turabian StyleKim, Kyung Ho, Samuel Lara-Avila, Hans He, Hojin Kang, Yung Woo Park, Rositsa Yakimova, and Sergey Kubatkin. 2017. "Thermal Stability of Epitaxial Graphene Electrodes for Conductive Polymer Nanofiber Devices" Crystals 7, no. 12: 378. https://doi.org/10.3390/cryst7120378