Effects of In0.82Ga0.18As/InP Double Buffers Design on the Microstructure of the In0.82G0.18As/InP Heterostructure

Abstract

:1. Introduction

2. Results and Discussion

3. Materials and Methods

3.1. Sample Preparation

3.2. Characterization Techniques

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Vurgaftman, I.; Meyer, J.R.; Ram-Mohan, L.R. Band parameters for iii-v compound semiconductors and their alloys. J. Appl. Phys. 2001, 89, 5815–5875. [Google Scholar] [CrossRef]

- Del Alamo, J.A. Nanometre-scale electronics with iii-v compound semiconductors. Nature 2011, 479, 317–323. [Google Scholar] [CrossRef] [PubMed]

- Arslan, Y.; Oguz, F.; Besikci, C. Extended wavelength swir ingaas focal plane array: Characteristics and limitations. Infrared Phys. Technol. 2015, 70, 134–137. [Google Scholar] [CrossRef]

- Ajayan, J.; Nirmal, D. A review of inp/inalas/ingaas based transistors for high frequency applications. Superlattices Microstruct. 2015, 86, 1–19. [Google Scholar] [CrossRef]

- Kim, J.; Fischetti, M.V. Electronic band structure calculations for biaxially strained Si, Ge, and III-V semiconductors. J. Appl. Phys. 2010, 108, 013710. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Y.; Wang, K.; Gu, Y.; Li, H.; Li, Y. Distinction investigation of ingaas photodetectors cutoff at 2.9 μm. Infrared Phys. Technol. 2010, 53, 173–176. [Google Scholar] [CrossRef]

- Chen, X.Y.; Gu, Y.; Zhang, Y.G.; Xi, S.P.; Guo, Z.X.; Zhou, L.; Li, A.Z.; Li, H. Optimization of inalas buffers for growth of gaas-based high indium content ingaas photodetectors. J. Cryst. Growth 2015, 425, 346–350. [Google Scholar] [CrossRef]

- Tsai, C.L.; Cheng, K.Y.; Chou, S.T.; Lin, S.Y. Ingaas quantum wire infrared photodetector. Appl. Phys. Lett. 2007, 91, 181105. [Google Scholar] [CrossRef]

- Xia, H.; Li, T.X.; Tang, H.J.; Zhu, L.; Li, X.; Gong, H.M.; Lu, W. Nanoscale imaging of the photoresponse in pn junctions of ingaas infrared detector. Sci. Rep. 2016, 6, 21544. [Google Scholar] [CrossRef] [PubMed]

- Tzeng, T.E.; Chuang, K.Y.; Lay, T.S.; Chang, C.H. Broadband ingaas quantum dot-in-a-well solar cells of p-type wells. J. Cryst. Growth 2013, 378, 583–586. [Google Scholar] [CrossRef]

- Gao, F.; Wen, L.; Li, J.; Guan, Y.; Zhang, S.; Li, G. Achieving high-quality In0.3Ga0.7As films on gaas substrates by low-temperature molecular beam epitaxy. CrystEngComm 2014, 16, 10774–10779. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, Y.; Tian, Z.; Li, A.; Zhu, X.; Zheng, Y. Wavelength extended 2.4μm heterojunction ingaas photodiodes with inalas cap and linearly graded buffer layers suitable for both front and back illuminations. Infrared Phys. Technol. 2008, 51, 316–321. [Google Scholar] [CrossRef]

- Tounsi, N.; Habchi, M.M.; Chine, Z.; Rebey, A.; El Jani, B. Optical properties study of In.08Ga.92As/gaas using spectral reflectance, photoreflectance and near-infrared photoluminescence. Superlattices Microstruct. 2013, 59, 133–143. [Google Scholar] [CrossRef]

- Tsai, J.-H. Investigation of inp/ingaas metamorphic co-integrated complementary doping-channel field-effect transistors for logic application. Superlattices Microstruct. 2014, 65, 256–263. [Google Scholar] [CrossRef]

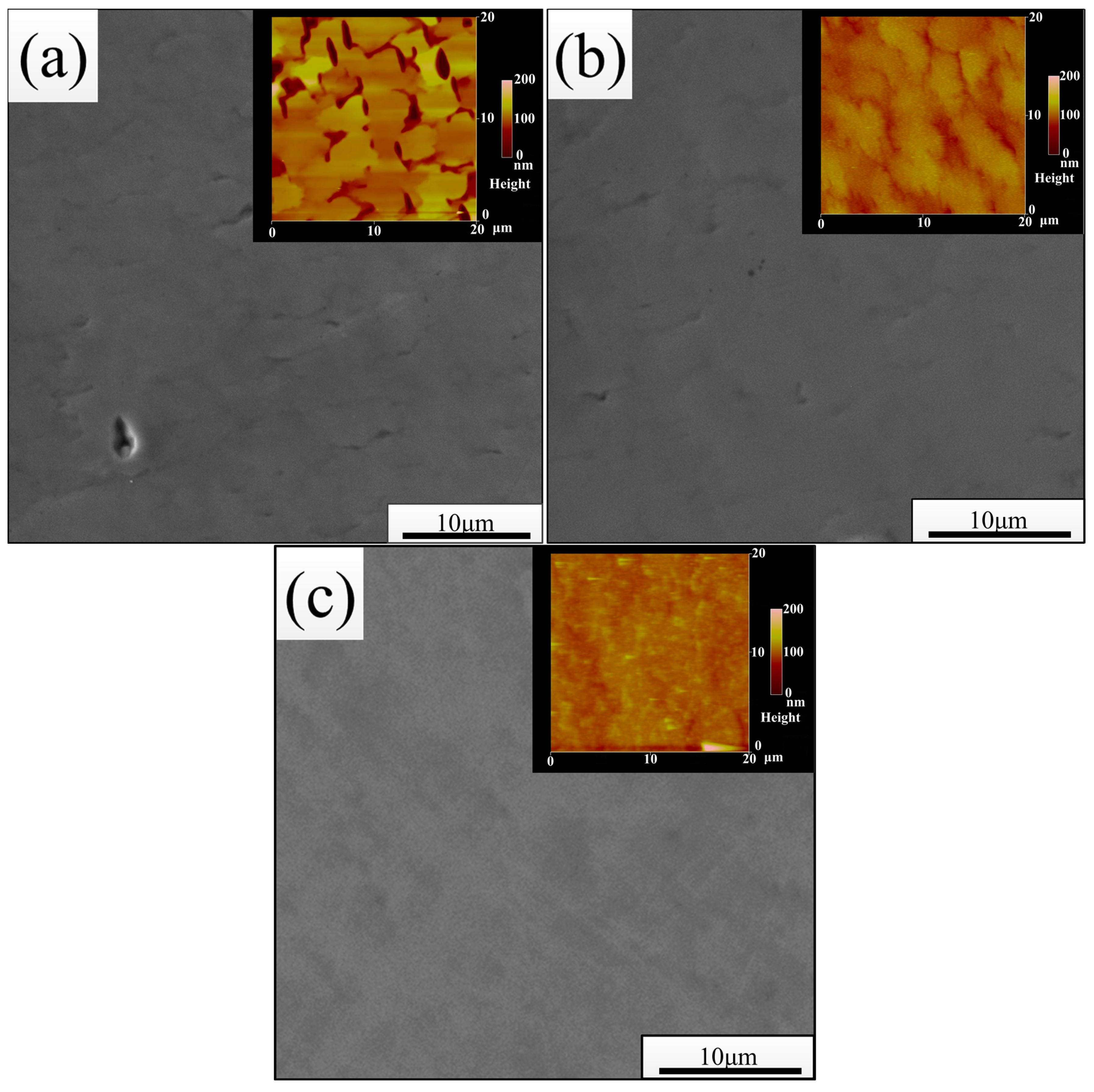

- Samonji, K.; Yonezu, H.; Takagi, Y.; Ohshima, N. Evolution process of cross-hatch patterns and reduction of surface roughness in (inas)[sub m](gaas)[sub n] strained short-period superlattices and ingaas alloy layers grown on gaas. J. Appl. Phys. 1999, 86, 1331. [Google Scholar] [CrossRef]

- Chang, S.Z.; Chang, T.C.; Lee, S.C. The growth of highly mismatched inxga1−xas (0.28 ≤ x ≤ 1) on gaas by molecular-beam epitaxy. J. Appl. Phys. 1993, 73, 4916–4926. [Google Scholar] [CrossRef]

- Li, J.; Miao, G.; Zhang, Z.; Zeng, Y. Experiments and analysis of the two-step growth of ingaas on gaas substrate. CrystEngComm 2015, 17, 5808–5813. [Google Scholar] [CrossRef]

- Zhang, T.; Miao, G.; Jin, Y.; Jiang, H.; Li, Z.; Song, H. Effect of buffer growth temperature on crystalline quality and optical property of In0.82Ga0.18As/InP grown by lp-mocvd. J. Alloy. Compd. 2008, 458, 363–365. [Google Scholar] [CrossRef]

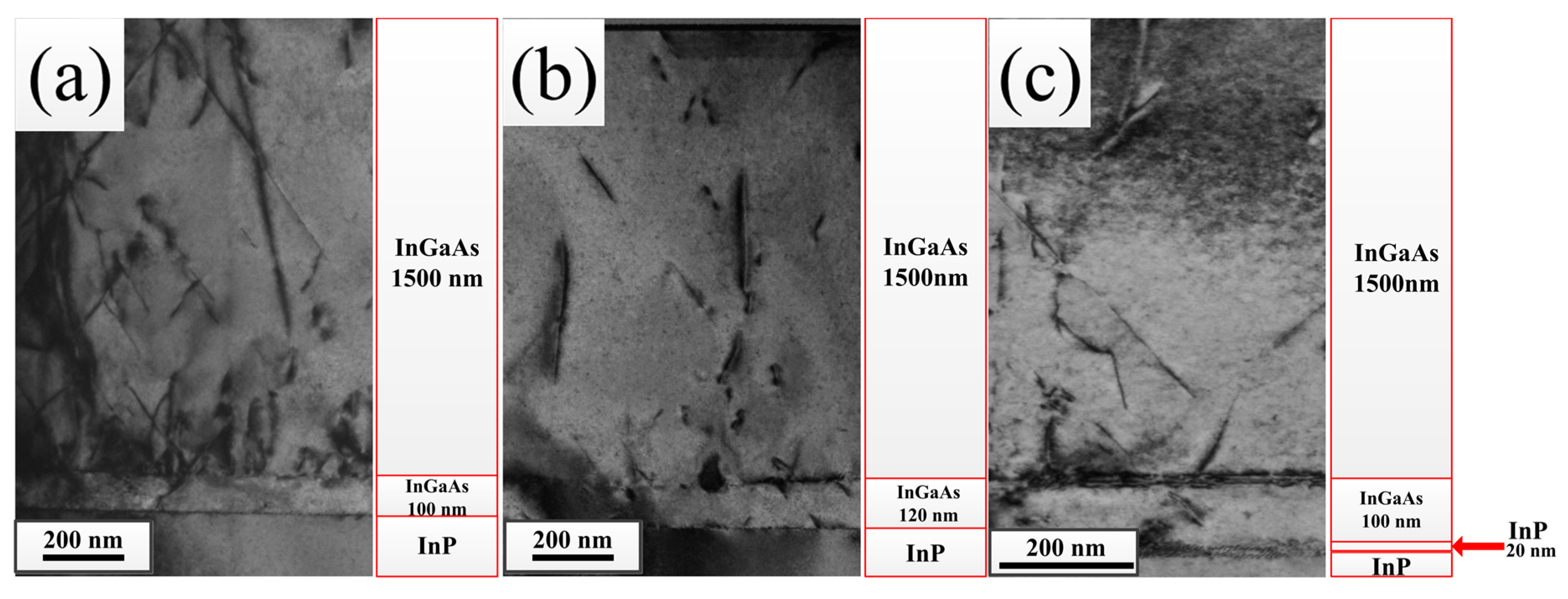

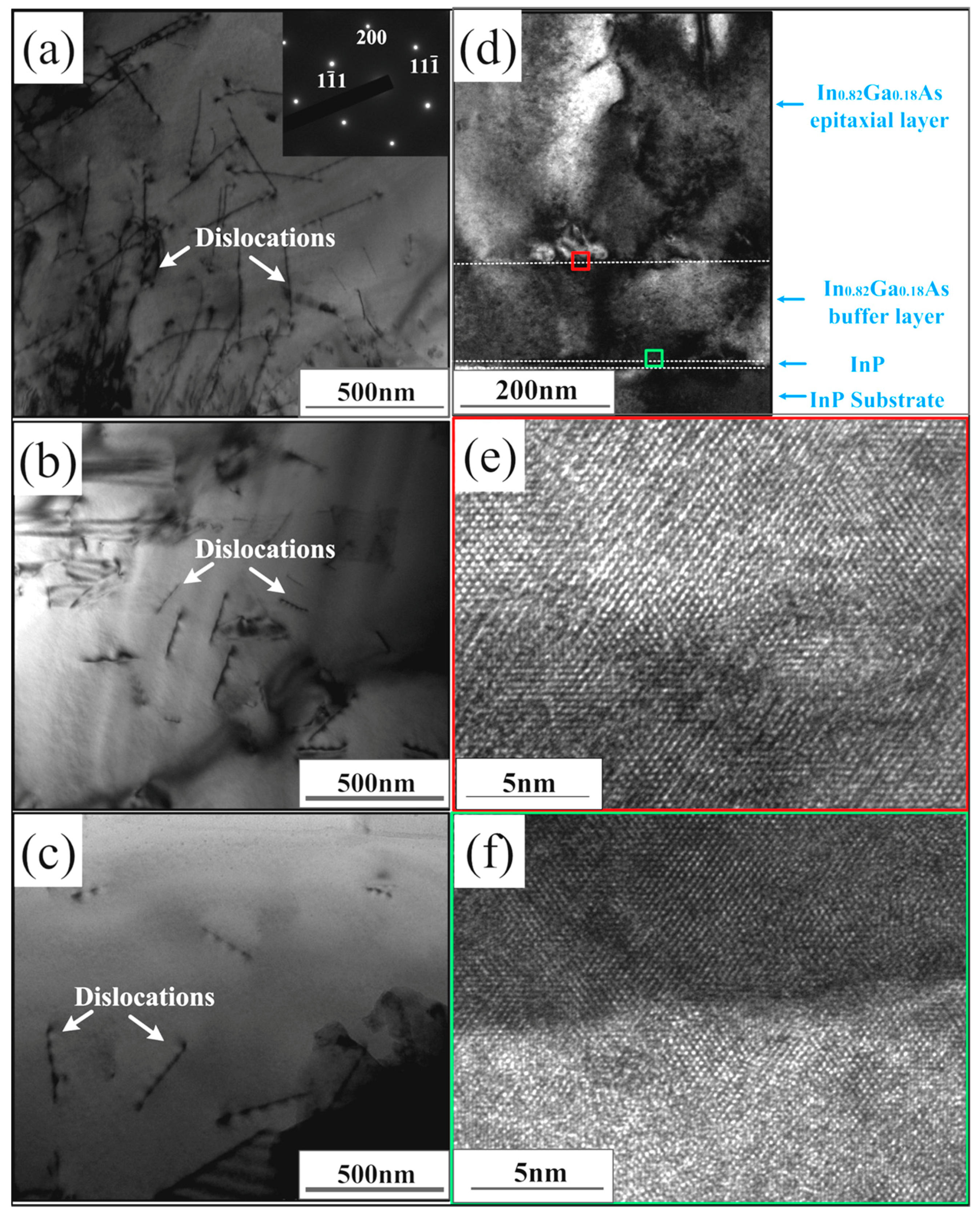

- Zhao, L.; Guo, Z.; Wei, Q.; Miao, G.; Zhao, L. The relationship between the dislocations and microstructure in In0.82Ga0.18As/Inp heterostructures. Sci. Rep. 2016, 6, 35139. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Song, H.; Miao, G.; Jiang, H.; Cao, L.; Li, D.; Sun, X.; Chen, Y. Influence of thermal annealing duration of buffer layer on the crystalline quality of In0.82Ga0.18As grown on inp substrate by lp-mocvd. Appl. Surf. Sci. 2011, 257, 1996–1999. [Google Scholar] [CrossRef]

- Chang, S.Z.; Chang, T.C.; Shen, J.L.; Lee, S.C.; Chen, Y.F. Material and electrical properties of highly mismatched in x ga1-x as on gaas by molecular-beam epitaxy. J. Appl. Phys. 1993, 74, 6912–6918. [Google Scholar] [CrossRef]

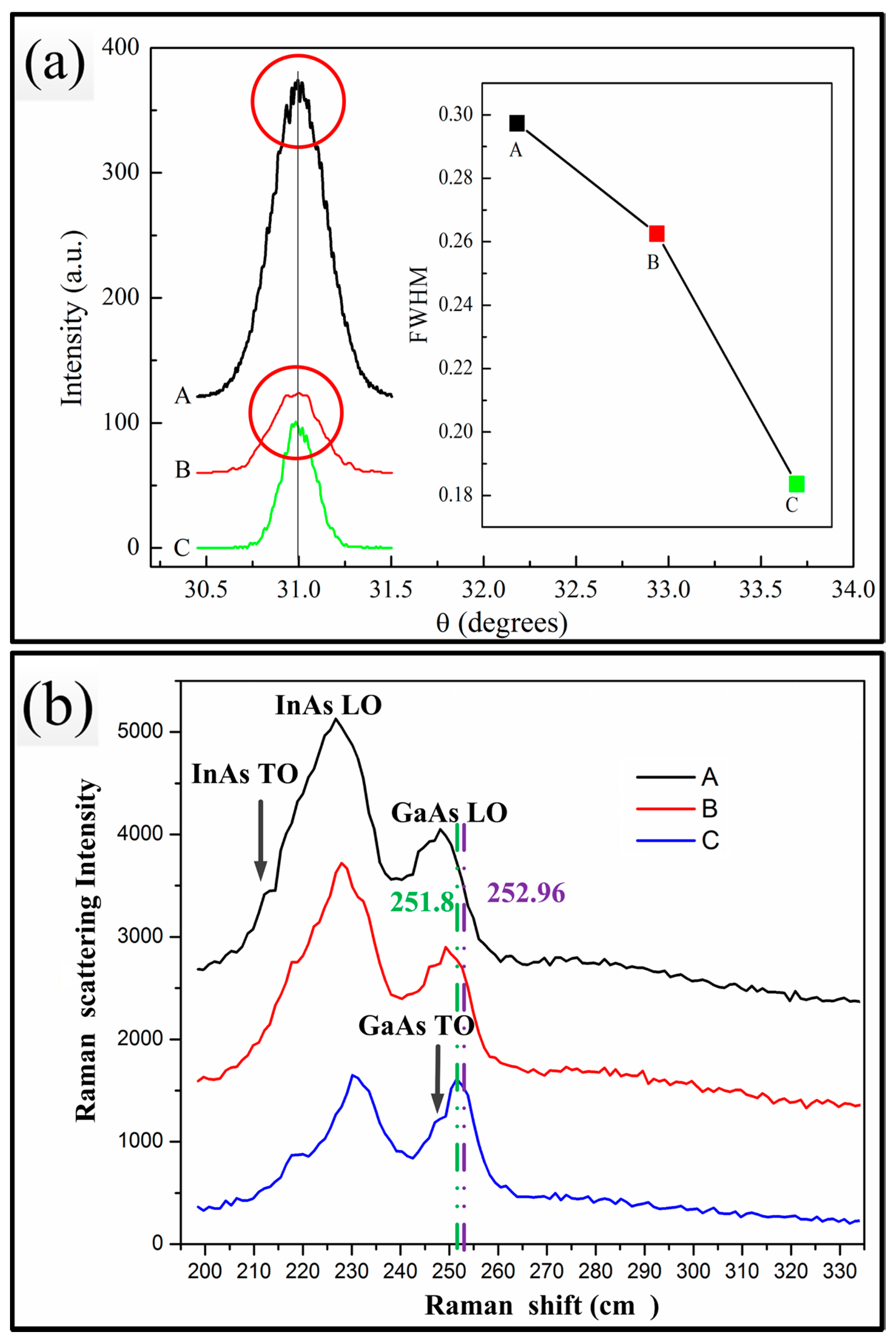

- Emura, S.; Gonda, S.-I.; Matsui, Y.; Hayashi, H. Internal-stress effects on raman spectra of inxga1-xas on inp. Phys. Rev. B 1988, 38, 3280–3286. [Google Scholar] [CrossRef]

- Nicholas, R.J.; Brunel, L.C.; Huant, S.; Karrai, K.; Portal, J.C.; Brummell, M.A.; Razeghi, M.; Cheng, K.Y.; Cho, A.Y. Frequency-shifted polaron coupling in Ga0.47In0.53As heterojunctions. Phys. Rev. Lett. 1985, 55, 883–886. [Google Scholar] [CrossRef] [PubMed]

- Feng, Z.C.; Allerman, A.A.; Barnes, P.A.; Perkowitz, S. Raman scattering of ingaas/inp grown by uniform radial flow epitaxy. Appl. Phys. Lett. 1992, 60, 1848–1850. [Google Scholar] [CrossRef]

- Jusserand, B.; Voisin, P.; Voos, M.; Chang, L.L.; Mendez, E.E.; Esaki, L. Raman scattering in gasb-alsb strained layer superlattices. Appl. Phys. Lett. 1985, 46, 678–680. [Google Scholar] [CrossRef]

- Cerdeira, F.; Buchenauer, C.J.; Pollak, F.H.; Cardona, M. Stress-induced shifts of first-order raman frequencies of diamond- and zinc-blende-type semiconductors. Phys. Rev. B 1972, 5, 580–593. [Google Scholar] [CrossRef]

- Zhao, L.; Sun, J.G.; Guo, Z.X.; Miao, G.Q. Tem dislocations characterization of inxga1-xas/inp (100) (x = 0.82) on mismatched inp substrate. Mater. Lett. 2013, 106, 222–224. [Google Scholar] [CrossRef]

- Dimitrakopulos, G.P.; Bazioti, C.; Grym, J.; Gladkov, P.; Hulicius, E.; Pangrác, J.; Pacherová, O.; Komninou, P. Misfit dislocation reduction in ingaas epilayers grown on porous gaas substrates. Appl. Surf. Sci. 2014, 306, 89–93. [Google Scholar] [CrossRef]

| Samples | FWHM (Degree) | Ndis (×109 cm−2) | (cm−1) | (cm−1) | F (×106N·cm−2) | ρi (×1010 cm−2) | ρs (×1010 cm−2) |

|---|---|---|---|---|---|---|---|

| A | 0.298 | 1.69 | 248.7 | 4.26 | −1.917 | 5.44 | 2.78 |

| B | 0.262 | 1.31 | 250.5 | 2.46 | −1.106 | 3.43 | 1.54 |

| C | 0.183 | 0.64 | 251.8 | 1.16 | −0.4901 | 12.7 (ρi1) | 0.69 |

| 2.44 (ρi2) |

| Samples | Resistivity (×10−6 Ω/cm) | Hall Coefficient/RH (×10−2 cm−3C−1) | Carrier Density/nH (×1020 cm−3) | Hall Mobility/uH (×103 cm2(V·s)−1) | Type |

|---|---|---|---|---|---|

| A | 6.6782 | −1.1105 | 5.6214 | 1.6718 | n |

| B | 6.5794 | −1.0880 | 5.7390 | 1.6331 | n |

| C | 6.5581 | −1.0559 | 5.9133 | 1.5973 | n |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Guo, Z.; Ding, X.; Li, J.; Yang, S.; Zhang, M.; Zhao, L. Effects of In0.82Ga0.18As/InP Double Buffers Design on the Microstructure of the In0.82G0.18As/InP Heterostructure. Crystals 2017, 7, 155. https://doi.org/10.3390/cryst7060155

Zhao L, Guo Z, Ding X, Li J, Yang S, Zhang M, Zhao L. Effects of In0.82Ga0.18As/InP Double Buffers Design on the Microstructure of the In0.82G0.18As/InP Heterostructure. Crystals. 2017; 7(6):155. https://doi.org/10.3390/cryst7060155

Chicago/Turabian StyleZhao, Liang, Zuoxing Guo, Xiangdong Ding, Jingjuan Li, Shen Yang, Min Zhang, and Lei Zhao. 2017. "Effects of In0.82Ga0.18As/InP Double Buffers Design on the Microstructure of the In0.82G0.18As/InP Heterostructure" Crystals 7, no. 6: 155. https://doi.org/10.3390/cryst7060155