Nb-Doped 0.8BaTiO3-0.2Bi(Mg0.5Ti0.5)O3 Ceramics with Stable Dielectric Properties at High Temperature

Abstract

:1. Introduction

2. Experimental Procedure

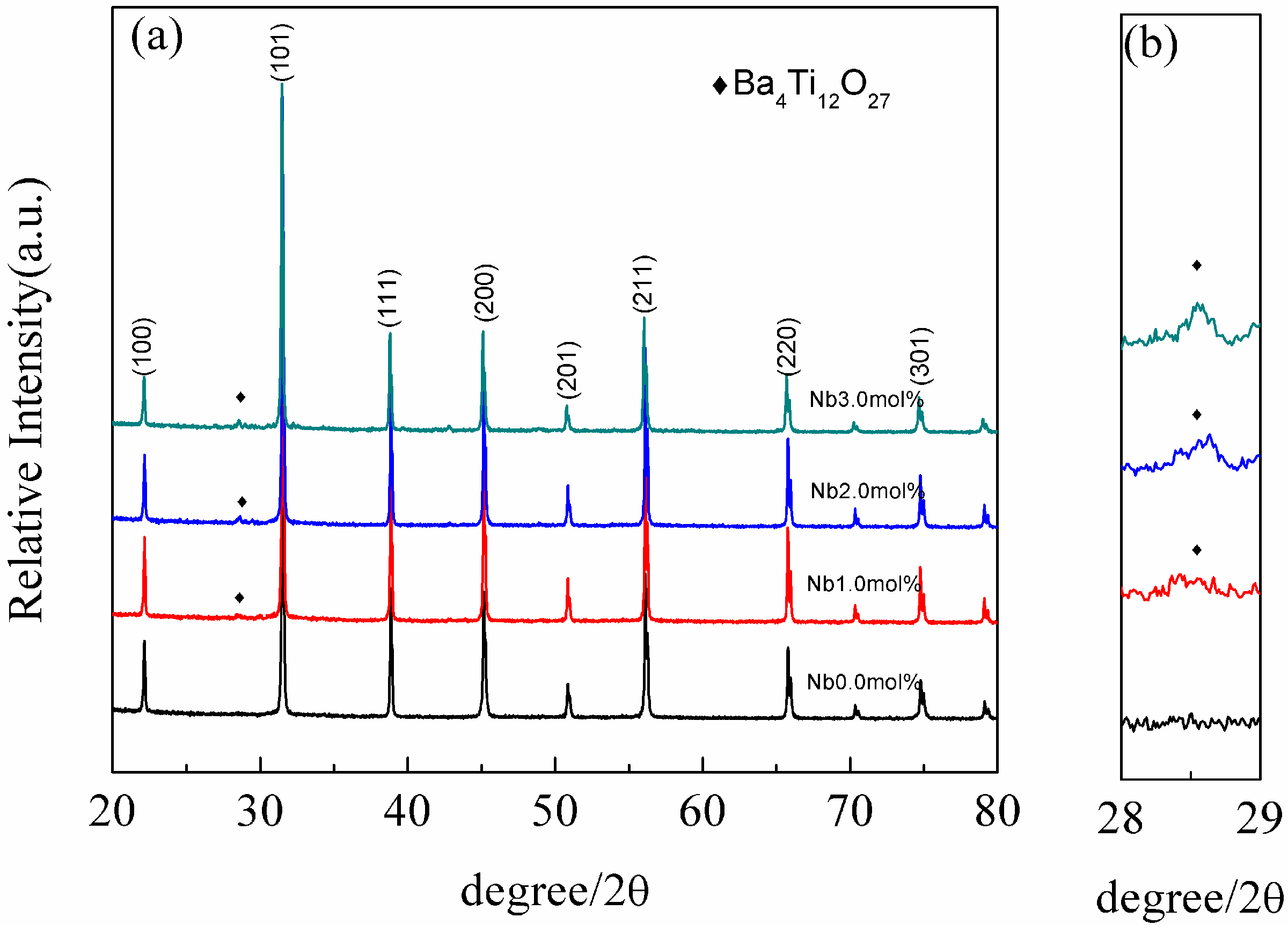

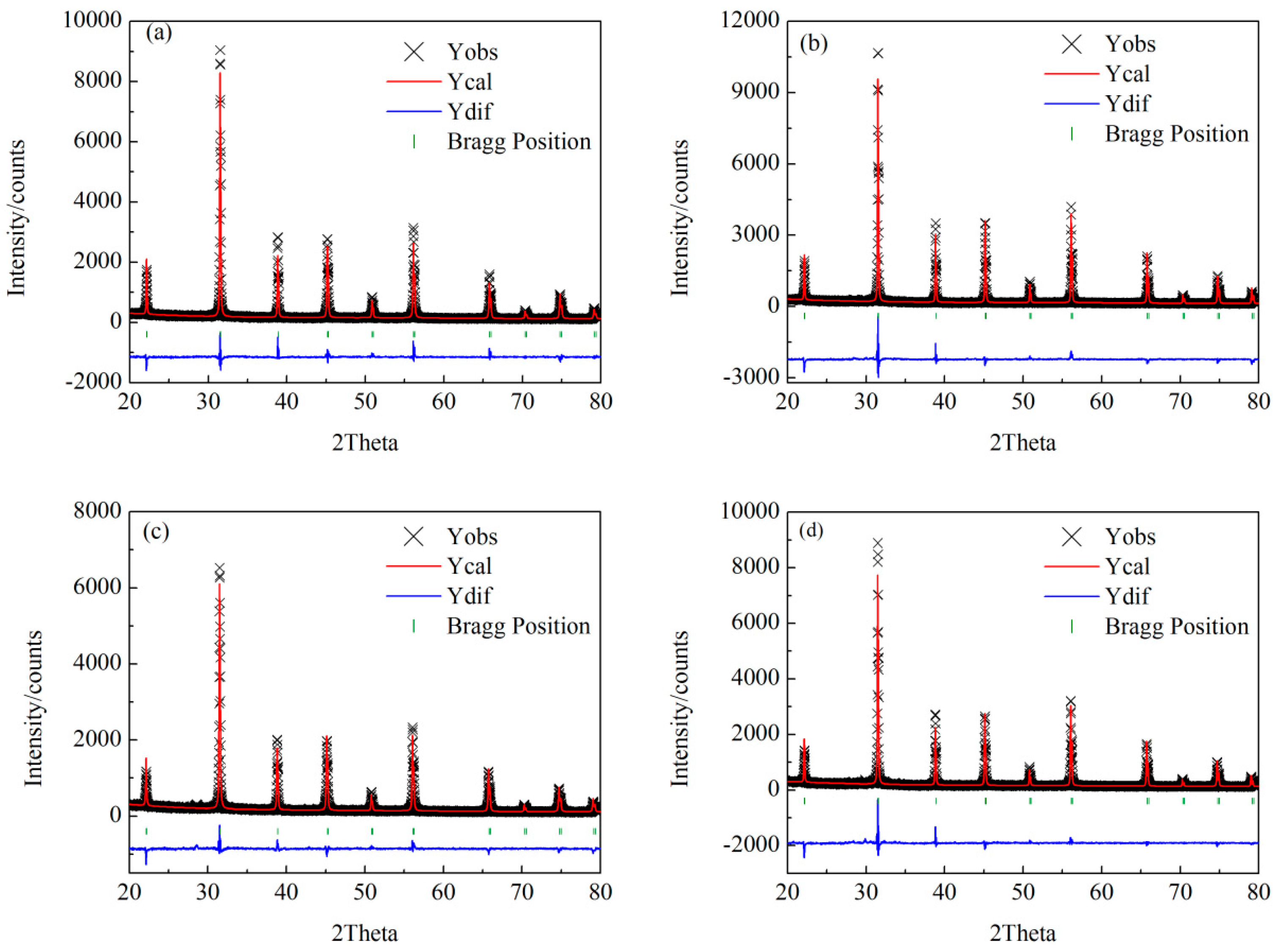

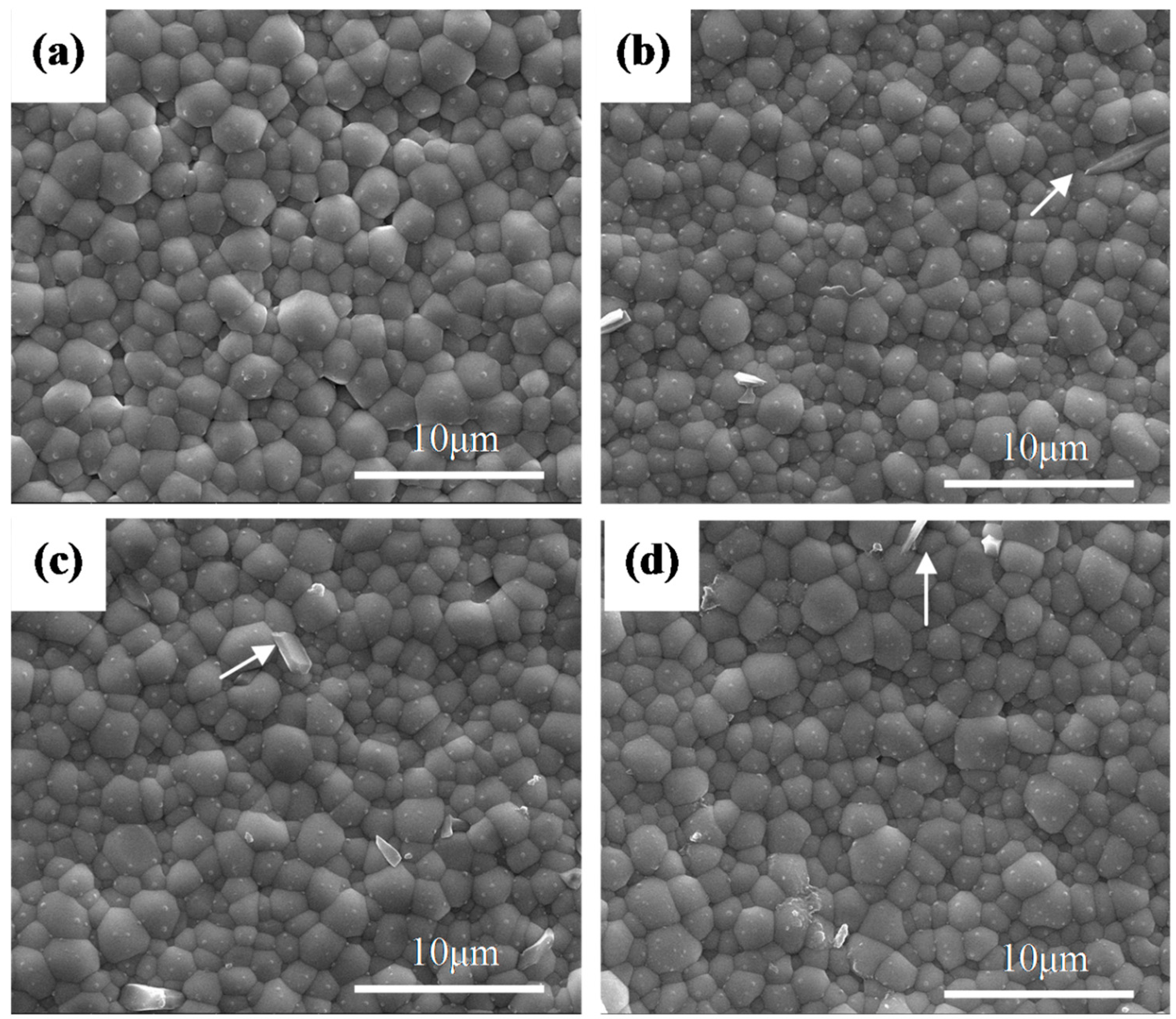

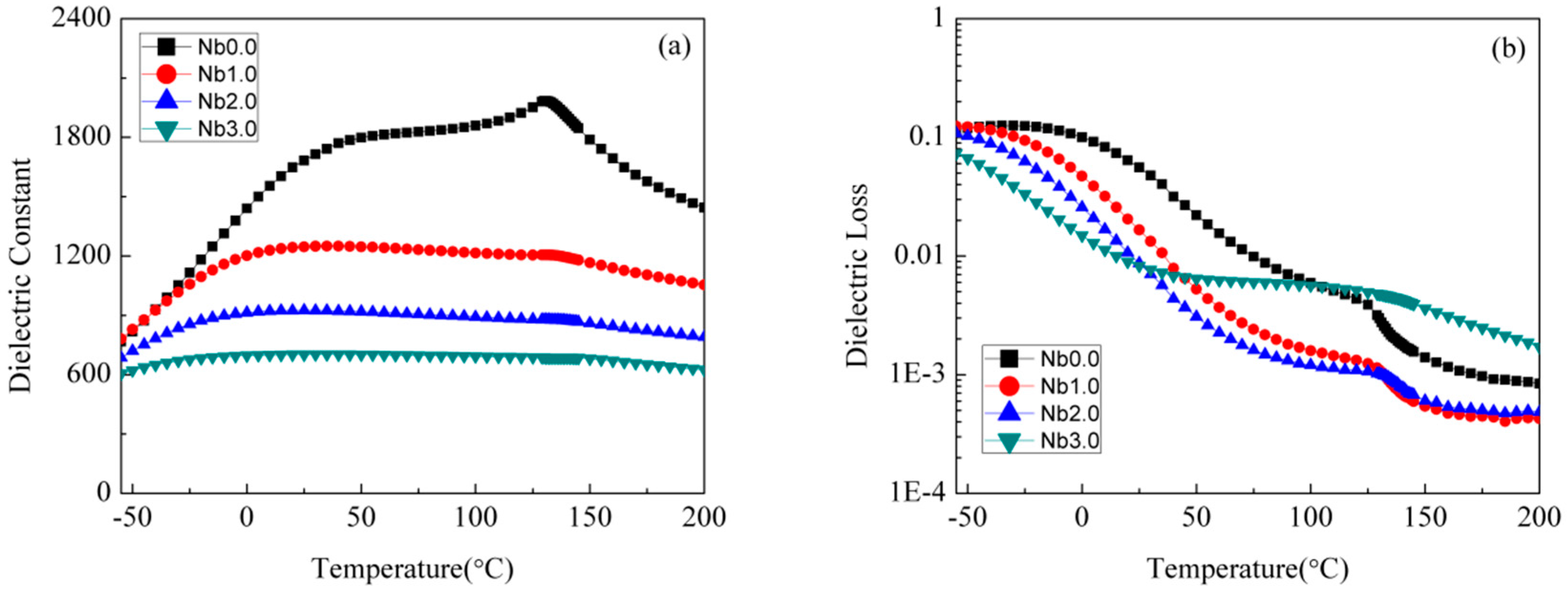

3. Results and Discussion

4. Conclusions

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Johnson, R.W.; Evans, J.L.; Jacobsen, P. The changing automotive environment: High-temperature electronics. IEEE Trans. Electron. Pack. Manuf. 2004, 27, 164–176. [Google Scholar] [CrossRef]

- Werner, M.R.; Fahrner, W.R. Review on materials, microsensors, systems, and devices for high-temperature and harsh-environment applications. IEEE Trans. Ind. Electron. 2001, 48, 249–257. [Google Scholar] [CrossRef]

- Lee, W.H.; Su, C.Y. Improvement in the temperature stability of a BaTiO3-Based multilayer ceramic capacitor by constrained sintering. J. Am. Ceram. Soc. 2007, 90, 3345–3348. [Google Scholar] [CrossRef]

- Wang, S.F.; Dayton, G.O. Dielectric properties of fine-grained barium titanate based X7R materials. J. Am. Ceram. Soc. 1999, 82, 2677–2682. [Google Scholar] [CrossRef]

- Sakayori, K.; Matsui, Y.; Abe, H. Curie-Temperature of Batio3. Jpn. J. Appl. Phys. 1995, 34, 5443–5445. [Google Scholar] [CrossRef]

- Datta, K.; Thomas, P.A. Structural investigation of a novel perovskite-based lead-free ceramics: xBiScO3-(1-x)BaTiO3. J. Appl. Phys. 2010, 107, 043516. [Google Scholar] [CrossRef]

- Raengthon, N.; Cann, D.P. Dielectric Relaxation in BaTiO3-Bi(Zn1/2Ti1/2)O3 Ceramics. J. Am. Ceram. Soc. 2012, 95, 1604–1612. [Google Scholar] [CrossRef]

- Liu, M.Y.; Hao, H.; Zhen, Y.C. Temperature stability of dielectric properties for xBiAlO3-(1-x)BaTiO3 ceramics. J. Eur. Ceram. Soc. 2015, 35, 2303–2311. [Google Scholar] [CrossRef]

- Wang, Y.R.; Pu, Y.P.; Zheng, H.Y. Enhanced dielectric relaxation in (1-x)BaTiO3-xBiYO3 ceramics. Mater. Lett. 2016, 181, 358–361. [Google Scholar] [CrossRef]

- Zeb, A.; Milne, S.J. High temperature dielectric ceramics: A review of temperature-stable high-permittivity perovskites. J. Mater. Sci. Mater. Electron. 2015, 26, 9243–9255. [Google Scholar] [CrossRef]

- Ren, P.R.; Wang, X.; Fan, H.Q. Structure, relaxation behaviors and nonlinear dielectric properties of BaTiO3-Bi(Ti0.5Mg0.5)O3 ceramics. Ceram. Int. 2015, 41, 7693–7697. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, H.X.; Hao, H. Structure Property Relationship in BaTiO3-Na0.5Bi0.5TiO3-Nb2O5-NiO X8R System. J. Am. Ceram. Soc. 2015, 98, 1574–1579. [Google Scholar] [CrossRef]

- Hennings, D.F.K. Dielectric materials for sintering in reducing atmospheres. J. Eur. Ceram. Soc. 2001, 21, 1637–1642. [Google Scholar] [CrossRef]

- Chazono, H.; Kishi, H. Sintering characteristics in the BaTiO3-Nb2O5-Co3O4 ternary system: II, stability of so-called “core–shell” structure. J. Am. Ceram. Soc. 2000, 83, 101–106. [Google Scholar] [CrossRef]

- Liu, X.A.; Cheng, S.G.; Randall, C.A. The core–shell structure in ultrafine X7R dielectric ceramics. J. Korean Phys. Soc. 1998, 32, S312–S315. [Google Scholar]

- Toby, B.H. EXPGUI, a graphical user interface for GSAS. J. Appl. Crystallogr. 2001, 34, 210–213. [Google Scholar] [CrossRef]

- Wang, T.; Jin, L.; Li, C.C. Relaxor Ferroelectric BaTiO3-Bi(Mg2/3Nb1/3)O3 Ceramics for Energy Storage Application. J. Am. Ceram. Soc. 2015, 98, 559–566. [Google Scholar] [CrossRef]

- Park, Y.; Kim, H.G. Dielectric temperature characteristics of cerium-modified barium titanate based ceramics with core–shell grain structure. J. Am. Ceram. Soc. 1997, 80, 106–112. [Google Scholar] [CrossRef]

- Brzozowski, E.; Castro, M.S.; Foschini, C.R. Secondary phases in Nb-doped BaTiO3 ceramics. Ceram. Int. 2002, 28, 773–777. [Google Scholar] [CrossRef]

- Kowalski, K.; Ijjaali, M.; Bak, T. Electrical properties of Nb-doped BaTiO3. J. Phys. Chem. Solid. 2001, 62, 543–551. [Google Scholar] [CrossRef]

- Li, W.; Qi, J.Q.; Wang, Y.L. Doping behaviors of Nb2O5 and Co2O3 in temperature stable BaTiO3-based ceramics. Mater. Lett. 2002, 57, 1–5. [Google Scholar] [CrossRef]

- Smyth, D.M. The defect chemistry of donor-doped BaTiO3: A rebuttal. J. Electroceram. 2002, 9, 179–186. [Google Scholar] [CrossRef]

| Samples | Lattice Parameters | Reliability Factors | ||||

|---|---|---|---|---|---|---|

| a (Å) | c (Å) | V (Å3) | Rwp | Rp | χ2 | |

| +0.0 mol% Nb2O5 | 4.0096 | 4.0131 | 64.5182 | 0.0786 | 0.0598 | 1.678 |

| +1.0 mol% Nb2O5 | 4.0112 | 4.0140 | 64.5842 | 0.0873 | 0.0651 | 2.187 |

| +2.0 mol% Nb2O5 | 4.0131 | 4.0165 | 64.6856 | 0.0780 | 0.0579 | 1.555 |

| +3.0 mol% Nb2O5 | 4.0150 | 4.0179 | 64.7695 | 0.0847 | 0.0621 | 1.943 |

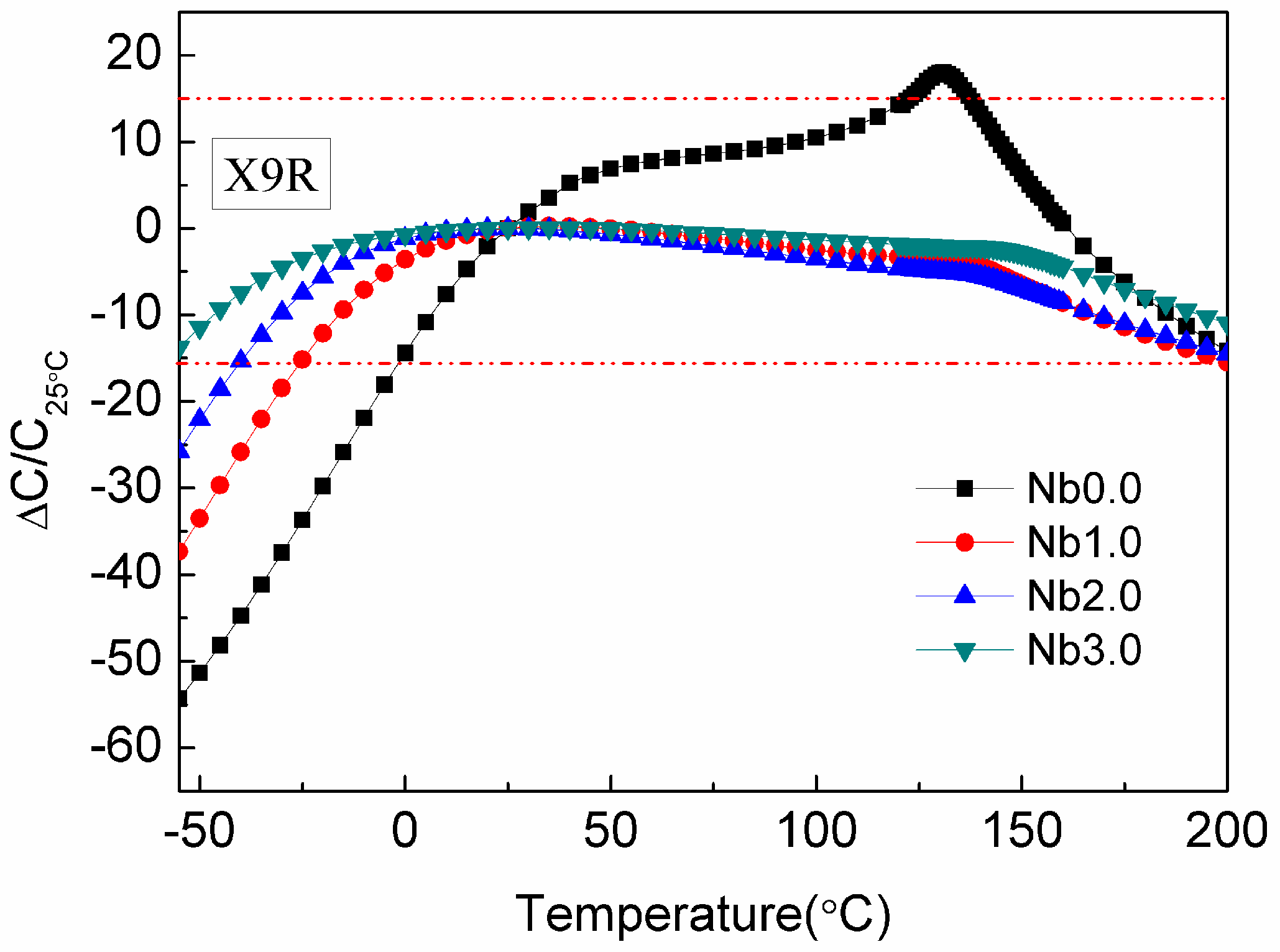

| Sample | εr | tan δ | ΔC/C25 °C < ±15% | Resistivity (Ω·cm) | Density (g/cm3) |

|---|---|---|---|---|---|

| +0.0 mol% Nb2O5 | 1683 | 5.0% | - | 1.0 × 1013 | 6.214 |

| +1.0 mol% Nb2O5 | 1247 | 1.5% | −26~197 °C | 6.4 × 1011 | 6.219 |

| +2.0 mol% Nb2O5 | 925 | 0.7% | −40~200 °C | 5.9 × 1012 | 6.148 |

| +3.0 mol% Nb2O5 | 764 | 0.5% | −55~200 °C | 1.3 × 1013 | 6.159 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Si, F.; Tang, B.; Fang, Z.; Zhang, S. Nb-Doped 0.8BaTiO3-0.2Bi(Mg0.5Ti0.5)O3 Ceramics with Stable Dielectric Properties at High Temperature. Crystals 2017, 7, 168. https://doi.org/10.3390/cryst7060168

Si F, Tang B, Fang Z, Zhang S. Nb-Doped 0.8BaTiO3-0.2Bi(Mg0.5Ti0.5)O3 Ceramics with Stable Dielectric Properties at High Temperature. Crystals. 2017; 7(6):168. https://doi.org/10.3390/cryst7060168

Chicago/Turabian StyleSi, Feng, Bin Tang, Zixuan Fang, and Shuren Zhang. 2017. "Nb-Doped 0.8BaTiO3-0.2Bi(Mg0.5Ti0.5)O3 Ceramics with Stable Dielectric Properties at High Temperature" Crystals 7, no. 6: 168. https://doi.org/10.3390/cryst7060168