Morphological and Crystallographic Characterization of Primary Zinc-Rich Crystals in a Ternary Sn-Zn-Bi Alloy under a High Magnetic Field

Abstract

:1. Introduction

2. Results and Discussion

3. Materials and Methods

4. Conclusions

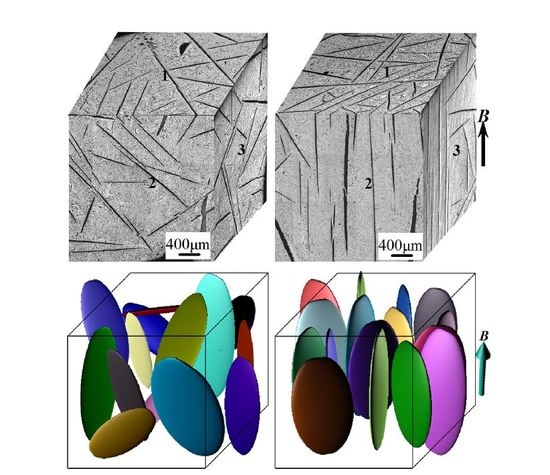

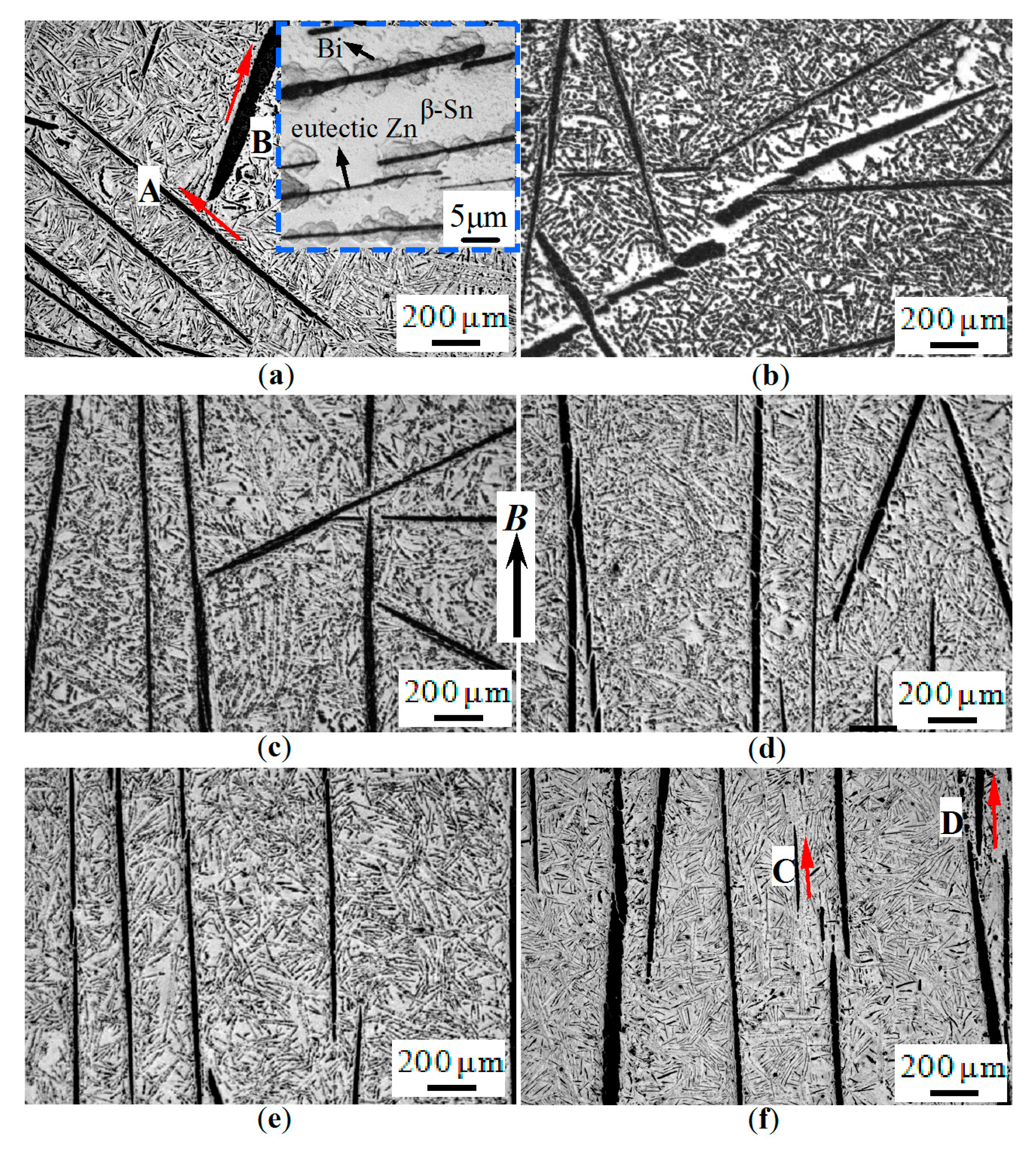

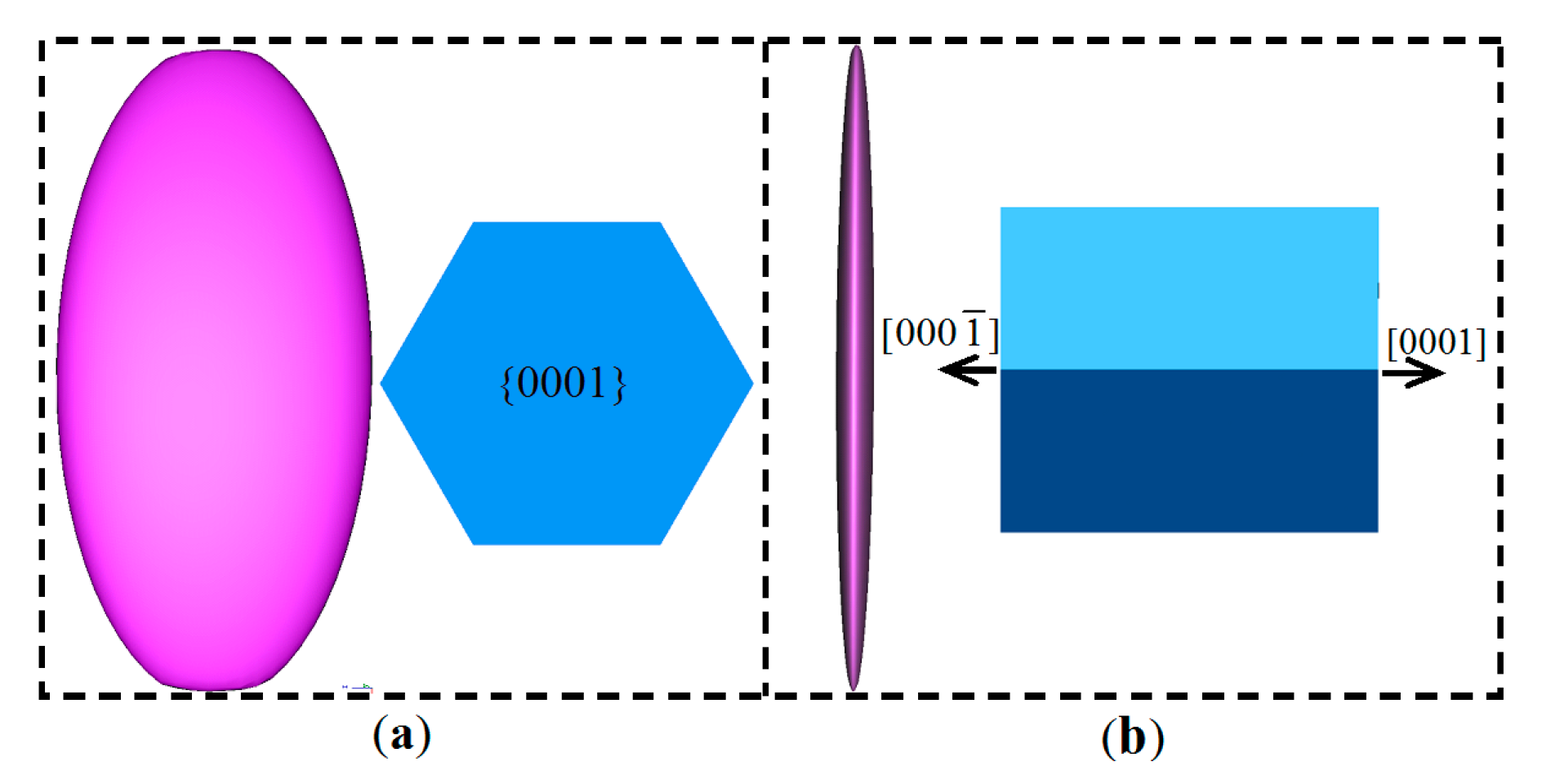

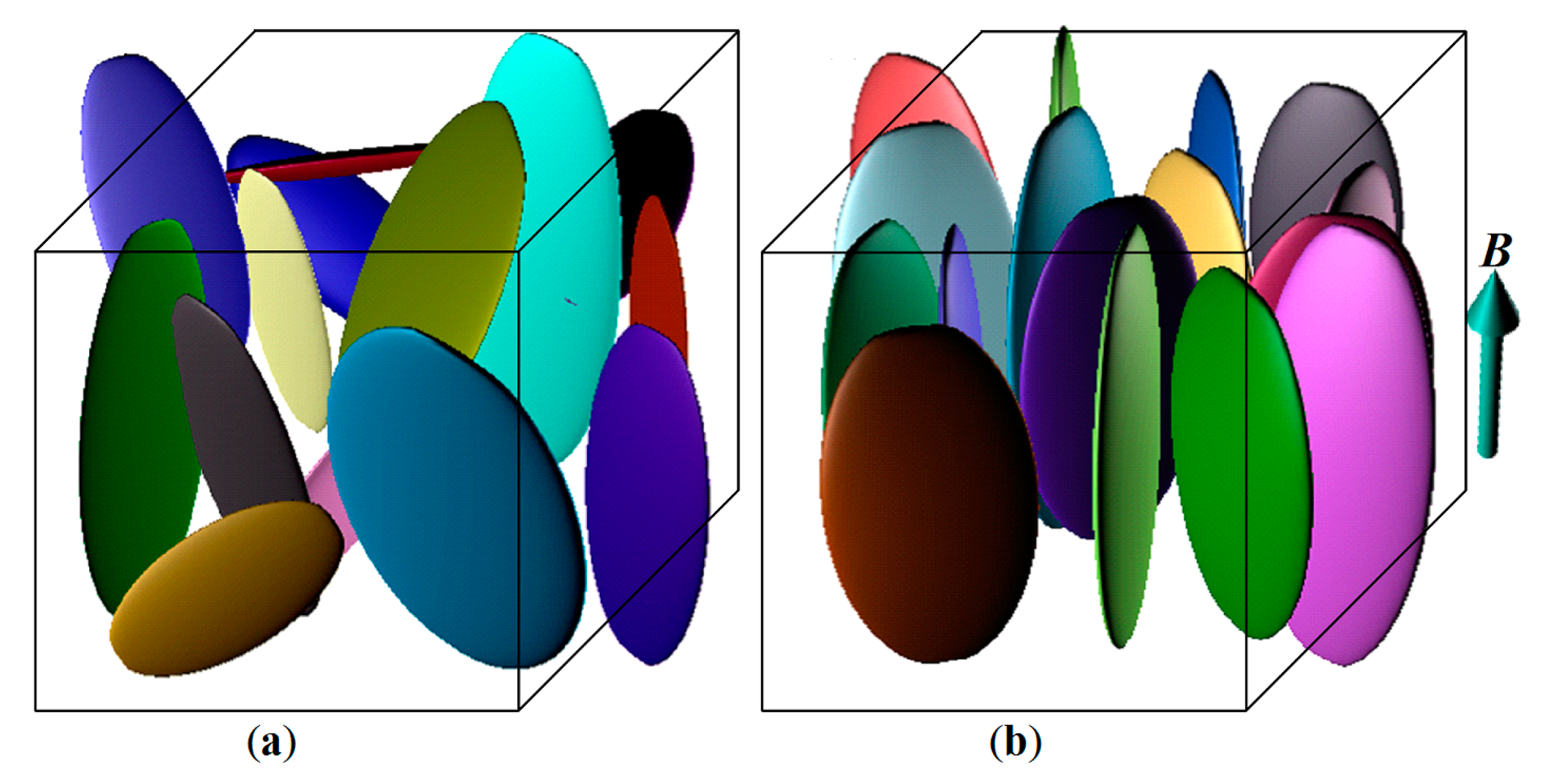

- Irrespective of whether the HMF is applied, the primary zinc-rich crystals reveal a plate-shaped form and grow in three dimensions, as follows: spreading rapidly in the {0001} basal plane and then decreasing the thickness at the edges gradually;

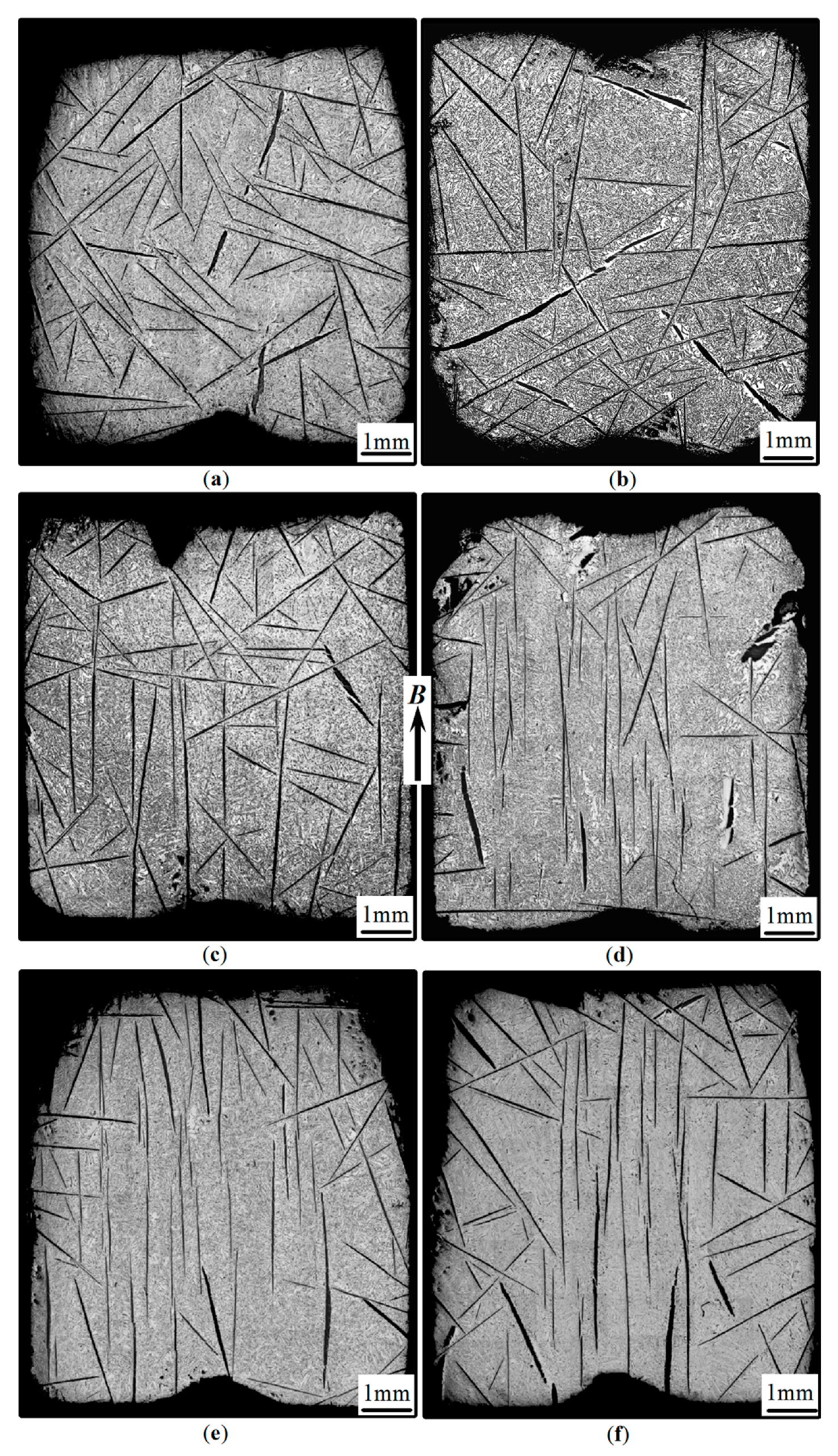

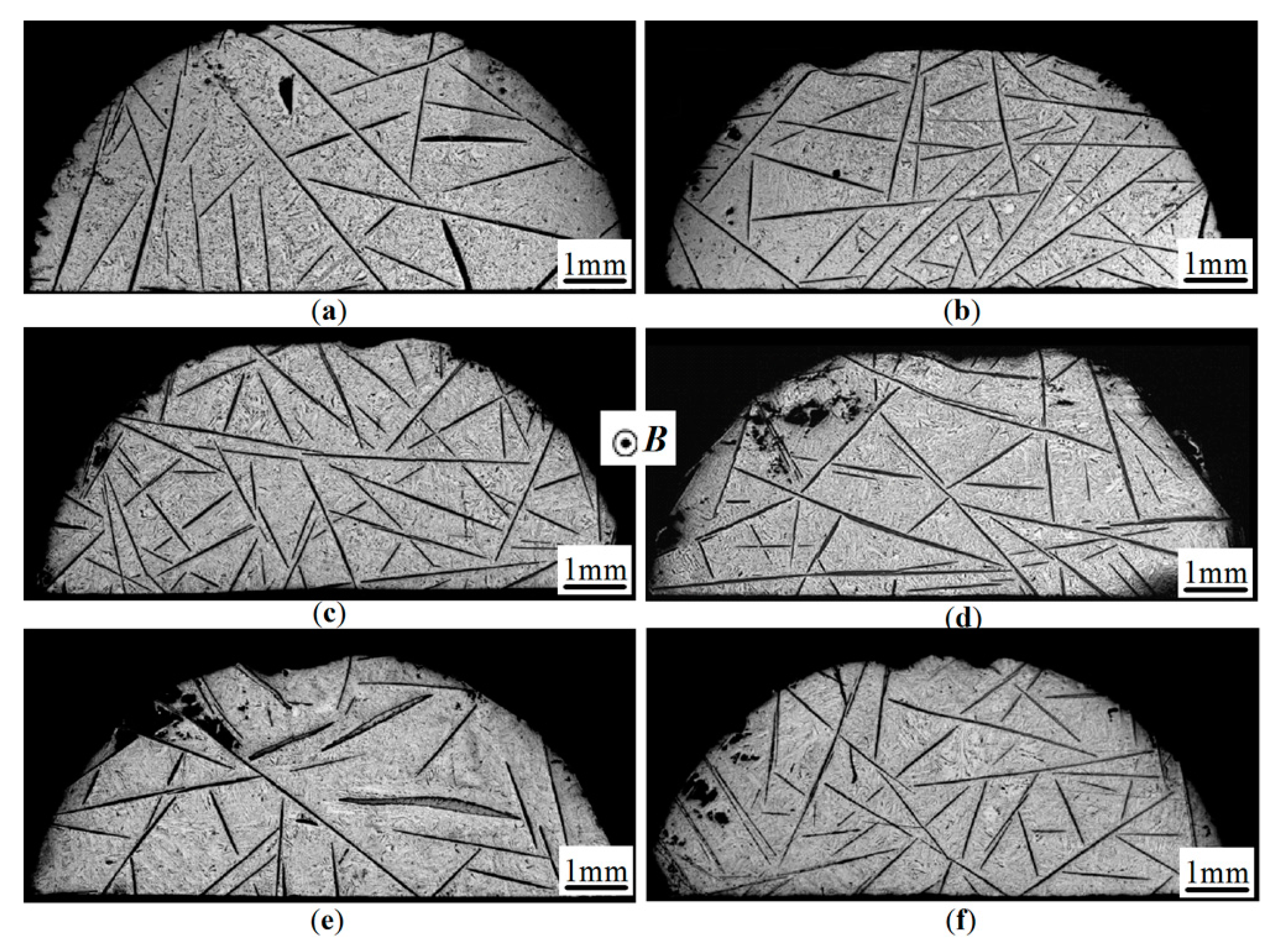

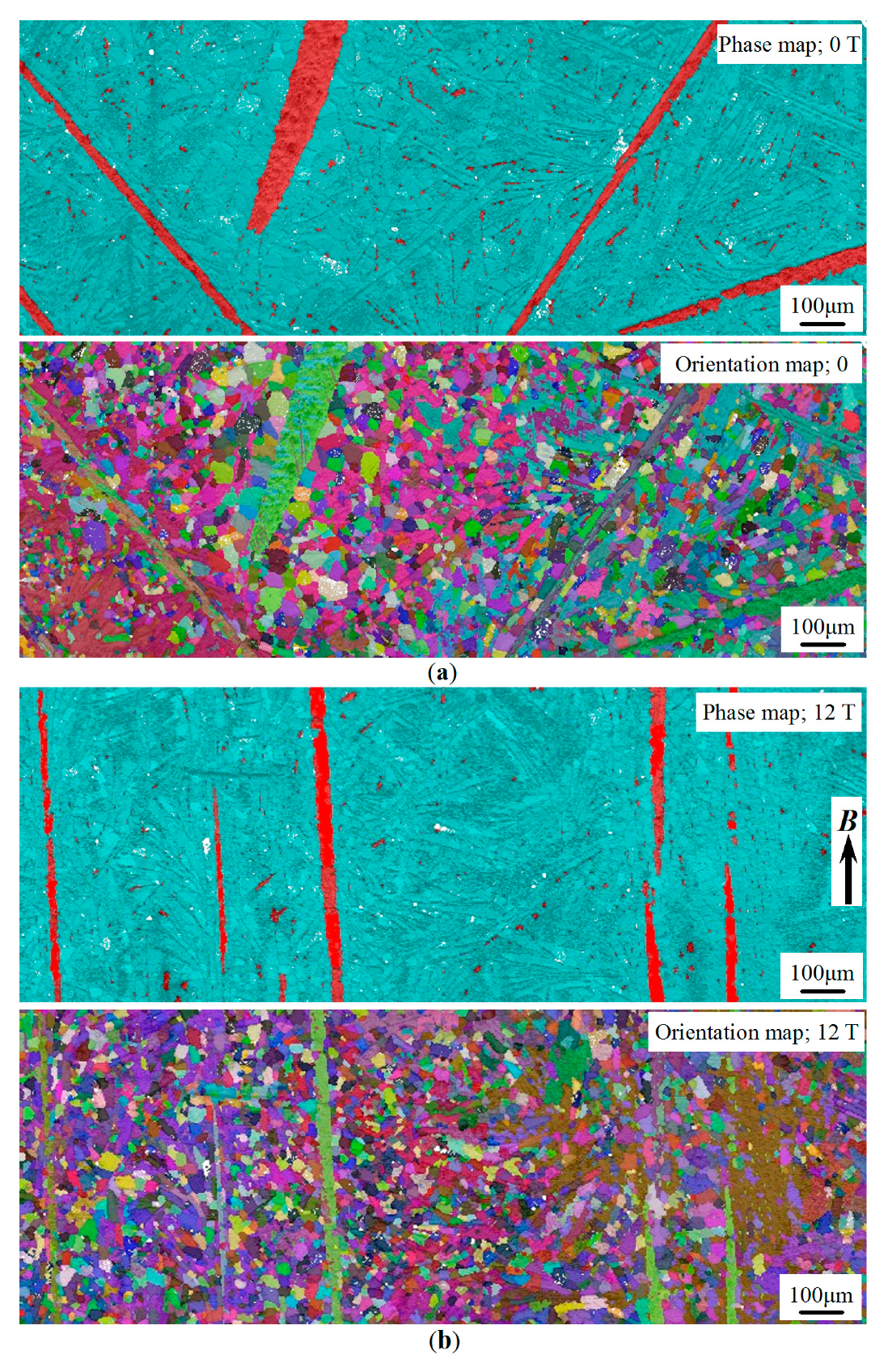

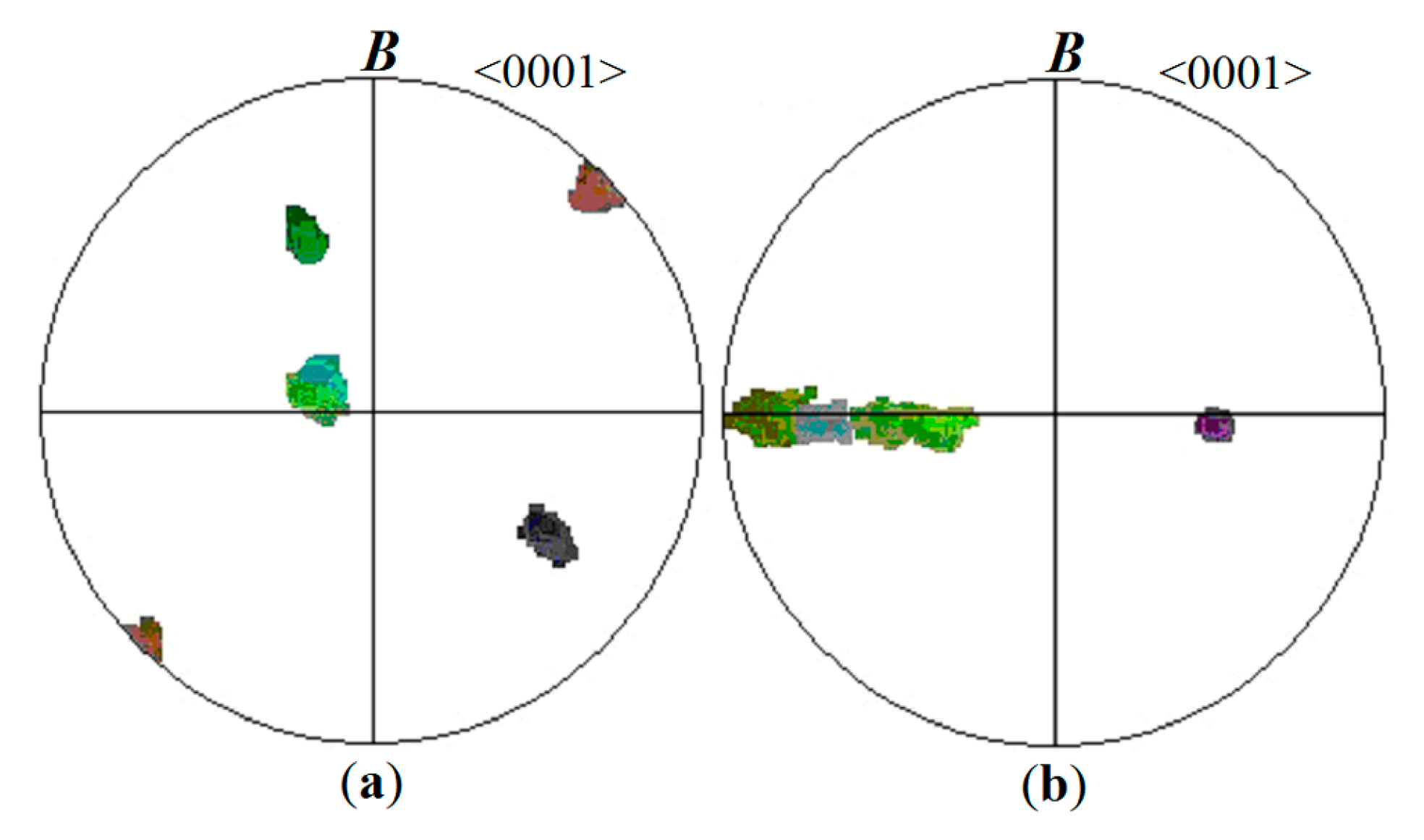

- In the absence of the HMF, the plate-shaped primary zinc-rich crystals align randomly, whereas in the presence of the HMF, those in the central regions of the specimens tend to align vertically;

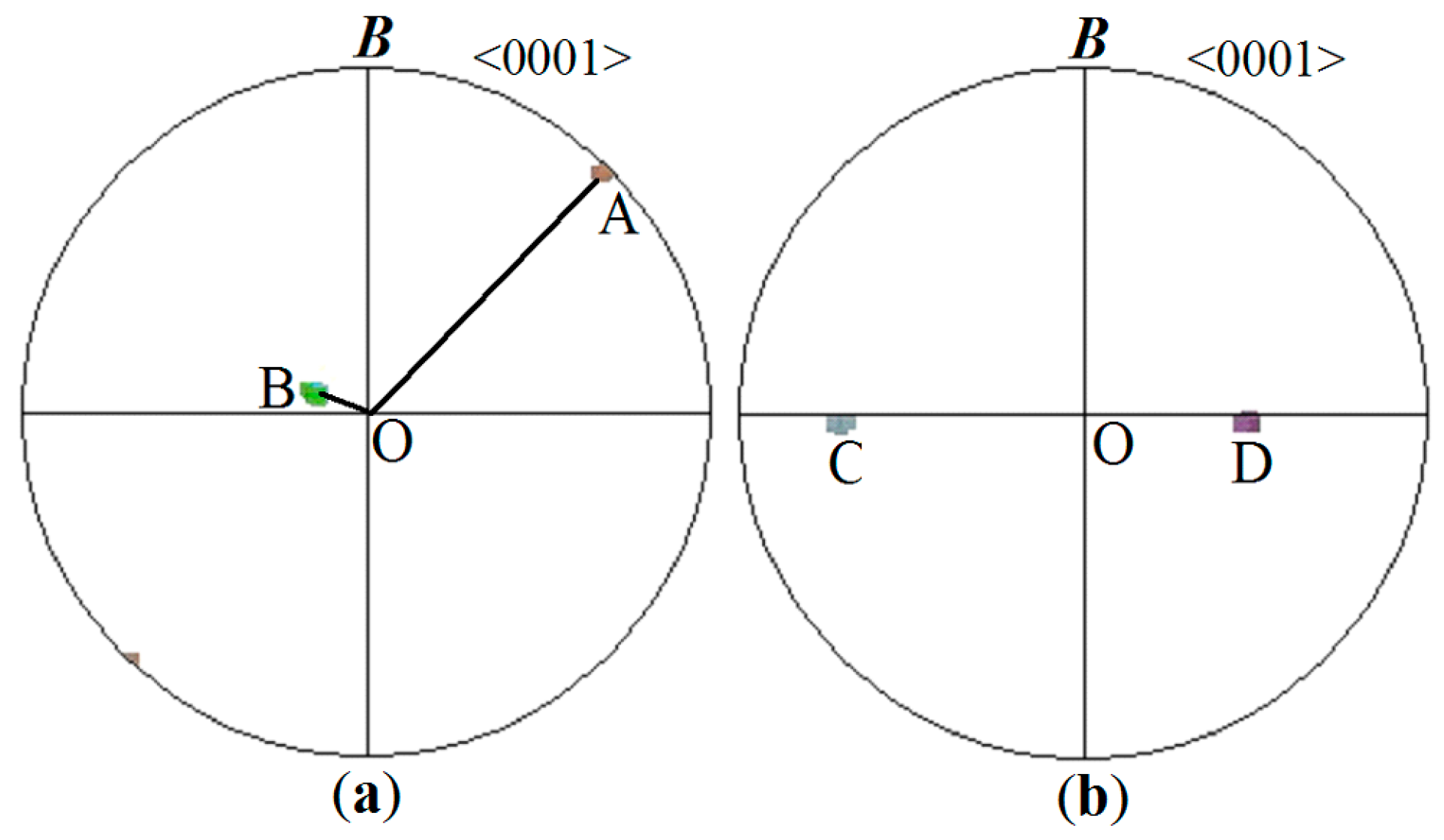

- Crystallographic analyses indicate that the vertically aligned primary zinc-rich crystals orient preferentially with the c-axis perpendicular to B;

- The preferential orientation and thus the regular vertical alignment should be related to the magnetocrystalline anisotropy of the diamagnetic primary zinc-rich crystals.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, L.; Zhang, Y.D.; Esling, C.; Zhao, Z.H.; Zuo, Y.B.; Zhang, H.T.; Cui, J.Z. Formation of feathery grains with the application of a static magnetic field during direct chill casting of Al-9.8 wt % Zn alloy. J. Mater. Sci. 2009, 44, 1063–1068. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.D.; Esling, C.; Zhao, Z.H.; Zuo, Y.B.; Zhang, H.T.; Cui, J.Z. Formation of twinned lamellas with the application of static magnetic fields during semi-continuous casting of Al-0.24 wt % Fe alloy. J. Cryst. Growth 2009, 311, 3211–3215. [Google Scholar] [CrossRef]

- Vives, C. Effects of forced electromagnetic vibrations during the solidification of aluminum alloys: Part II. solidification in the presence of colinear variable and stationary magnetic fields. Metall. Trans. B 1996, 27, 457–464. [Google Scholar] [CrossRef]

- Vives, C. Effects of forced electromagnetic vibrations during the solidification of aluminum alloys: Part I. solidification in the presence of crossed alternating electric fields and stationary magnetic fields. Metall. Trans. B 1996, 27, 445–455. [Google Scholar] [CrossRef]

- Singh, R.; Thomas, B.G.; Vanka, S.P. Effects of a magnetic field on turbulent flow in the mold region of a steel caster. Metall. Trans. B 2013, 44, 1201–1221. [Google Scholar] [CrossRef]

- Hu, S.D.; Dai, Y.C.; Gagnoud, A.; Fautrelle, Y.; Moreau, R.; Ren, Z.M.; Deng, K.; Li, C.J.; Li, X. Effect of a magnetic field on macro segregation of the primary silicon phase in hypereutectic Al-Si alloy during directional solidification. J. Alloy. Compd. 2017, 722, 108–115. [Google Scholar] [CrossRef]

- Li, H.X.; Fautrelle, Y.; Hou, L.; Du, D.F.; Zhang, Y.K.; Ren, Z.M.; Lu, X.G.; Moreau, R.; Li, X. Effect of a weak transverse magnetic field on the morphology and orientation of directionally solidified Al–Ni alloys. J. Cryst. Growth 2016, 436, 68–75. [Google Scholar] [CrossRef]

- Du, D.F.; Guan, G.; Gagnoud, A.; Fautrelle, Y.; Ren, Z.M.; Lu, X.G.; Wang, H.; Dai, Y.M.; Wang, Q.L.; Li, X. Effect of a high magnetic field on the growth of å-CuZn5 dendrite during directionally solidified Zn-rich Zn–Cu alloys. Mater. Charact. 2016, 111, 31–42. [Google Scholar] [CrossRef]

- Li, X.; Wang, J.; Du, D.F.; Zhang, Y.K.; Fautrelle, Y.; Nguyen-Thi, H.; Gagnoud, A.; Ren, Z.M.; Moreau, R. Effect of a transverse magnetic field on the growth of equiaxed grains during directional solidification. Mater. Lett. 2015, 161, 595–600. [Google Scholar] [CrossRef]

- Li, L.; Zhu, Q.F.; Zhang, H.; Zuo, Y.B.; Ban, C.Y.; He, L.Z.; Liu, H.T.; Cui, J.Z. Morphological and crystallographic characterization of solidified Al–3Ti–1B master alloy under a high magnetic field. Mater. Charact. 2014, 95, 1–11. [Google Scholar] [CrossRef]

- Xuan, W.D.; Liu, H.; Lan, J.; Li, C.J.; Zhong, Y.B.; Li, X.; Cao, G.H.; Ren, Z.M. Effect of a transverse magnetic field on stray grain formation of Ni-Based single crystal superalloy during directional solidification. Metall. Trans. B 2016, 6, 3231–3236. [Google Scholar] [CrossRef]

- Xuan, W.D.; Liu, H.; Li, C.J.; Ren, Z.M.; Zhong, Y.B.; Li, X.; Cao, G.H. Effect of a high magnetic field on microstructures of Ni-Based single crystal superalloy during seed melt-back. Metall. Trans. B 2016, 47, 828–833. [Google Scholar] [CrossRef]

- Li, L.; Li, Z.B.; Zhang, Y.D.; Esling, C.; Liu, H.T.; Zhao, Z.H.; Zhu, Q.F.; Zuo, Y.B.; Cui, J.Z. Crystallographic effect of a high magnetic field on hypoeutectic Zn-Al during solidification process. J. Appl. Crystallogr. 2014, 47, 606–612. [Google Scholar] [CrossRef]

- Li, L.; Ban, C.Y.; Shi, X.C.; Zhang, H.T.; Cai, M.H.; Liu, H.T.; Cui, J.Z.; Nagaumi, H. Crystallographic growth pattern of zinc-rich plate-like cells under a high magnetic field. Mater. Lett. 2016, 185, 447–451. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.D.; Esling, C.; Jiang, H.X.; Zhao, Z.H.; Zuo, Y.B.; Cui, J.Z. Influence of a high magnetic field on the precipitation behaviors of the primary Al3Fe phase during the solidification of hypereutectic Al-3.31 wt % Fe alloy. J. Cryst. Growth 2012, 339, 61–69. [Google Scholar] [CrossRef]

- Li, L.; Zhao, Z.H.; Zuo, Y.B.; Zhu, Q.F.; Cui, J.Z. Effect of a high magnetic field on the morphological and crystallographic features of primary Al6Mn phase formed during solidification process. J. Mater. Res. 2013, 28, 1567–1573. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.D.; Esling, C.; Qin, K.; Zhao, Z.H.; Zuo, Y.B.; Cui, J.Z. A microstructural and crystallographic investigation on the precipitation behaviour of primary Al3Zr phase under high magnetic field. J. Appl. Crystallogr. 2013, 46, 421–429. [Google Scholar] [CrossRef]

- Wang, C.J.; Wang, Q.; Wang, Z.Y.; Li, H.T.; Nakajima, K.; He, J.C. Phase alignment and crystal orientation of Al3Ni in Al–Ni alloy by imposition of a uniform high magnetic field. J. Cryst. Growth 2008, 310, 1256–1263. [Google Scholar] [CrossRef]

- Li, X.; Ren, Z.M.; Fautrelle, Y. The alignment, aggregation and magnetization behaviors in MnBi–Bi composites solidified under a high magnetic field. Intermetallics 2007, 15, 845–855. [Google Scholar] [CrossRef]

- Li, X.; Ren, Z.M.; Fautrelle, Y. Effect of high magnetic fields on the microstructure in directionally solidified Bi–Mn eutectic alloy. J. Cryst. Growth 2007, 299, 41–47. [Google Scholar] [CrossRef]

- Li, L.; Xu, B.; Tong, W.P.; He, L.Z.; Ban, C.Y.; Zhang, H.; Zuo, Y.B.; Zhu, Q.F.; Cui, J.Z. Directional growth behavior of α(Al) dendrites during concentration-gradient-controlled solidification process in static magnetic field. Trans. Nonferrous Met. Soc. China 2015, 25, 2438–2445. [Google Scholar] [CrossRef]

- Du, D.F.; Fautrelle, Y.; Ren, Z.M.; Moreau, R.; Li, X. Effect of a high magnetic field on the growth of ternary Al-Cu-Ag alloys during directional solidification. Acta Mater. 2016, 121, 240–256. [Google Scholar] [CrossRef]

- Li, X.; Fautrelle, Y.; Ren, Z.M. Influence of thermoelectric effects on the solid–liquid interface shape and cellular morphology in the mushy zone during the directional solidification of Al–Cu alloys under a magnetic field. Acta Mater. 2007, 55, 3803–3813. [Google Scholar] [CrossRef]

- Rhême, M.; Gonzales, F.; Rappaz, M. Growth directions in directionally solidified Al–Zn and Zn–Al alloys near eutectic composition. Scripta Mater. 2008, 59, 440–443. [Google Scholar]

- Haxhimali, T.; Karma, A.; Gonzales, F.; Rappaz, M. Orientation selection in dendritic evolution. Nat. Mater. 2006, 5, 660–664. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Ban, C.Y.; Shi, X.C.; Zhang, H.T.; Zuo, Y.B.; Zhu, Q.F.; Wang, X.J.; Zhang, H.; Cui, J.Z.; Nagaumi, H. Effects of a high magnetic field on the primary zinc-rich crystals in hypoeutectic Zn-Sn alloy. J. Cryst. Growth 2017, 463, 59–66. [Google Scholar] [CrossRef]

- Kima, Y.S.; Kim, K.S.; Hwang, C.W.; Suganuma, K. Effect of composition and cooling rate on microstructure and tensile properties of Sn–Zn–Bi alloys. J. Alloy. Compd. 2003, 352, 237–245. [Google Scholar] [CrossRef]

- Asai, S. Crystal orientation of non-magnetic materials by imposition of a high magnetic field. Sci. Technol. Adv. Mater. 2003, 4, 455–460. [Google Scholar] [CrossRef]

- Marcus, J.A. Magnetic Susceptibility of Zinc at Liquid Hydrogen Temperatures. Phys. Rev. 1949, 76, 413–416. [Google Scholar] [CrossRef]

- Sugiyama, T.; Tahashi, M.; Sassa, K.; Asai, S. The control of crystal orientation in non-magnetic metals by imposition of a high magnetic field. ISIJ. Int. 2003, 43, 855–861. [Google Scholar] [CrossRef]

- Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Indirect two-trace method to determine a faceted low-energy interface between two crystallographically correlated crystals. J. Appl. Cryst. 2007, 40, 436–440. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.D.; Esling, C.; Jiang, H.; Zhao, Z.H.; Zuo, Y.B.; Cui, J.Z. Crystallographic features of primary Al3Zr phase. J. Cryst. Growth 2011, 316, 172–176. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Ban, C.; Zhang, R.; Zhang, H.; Cai, M.; Zuo, Y.; Zhu, Q.; Wang, X.; Cui, J. Morphological and Crystallographic Characterization of Primary Zinc-Rich Crystals in a Ternary Sn-Zn-Bi Alloy under a High Magnetic Field. Crystals 2017, 7, 204. https://doi.org/10.3390/cryst7070204

Li L, Ban C, Zhang R, Zhang H, Cai M, Zuo Y, Zhu Q, Wang X, Cui J. Morphological and Crystallographic Characterization of Primary Zinc-Rich Crystals in a Ternary Sn-Zn-Bi Alloy under a High Magnetic Field. Crystals. 2017; 7(7):204. https://doi.org/10.3390/cryst7070204

Chicago/Turabian StyleLi, Lei, Chunyan Ban, Ruixue Zhang, Haitao Zhang, Minghui Cai, Yubo Zuo, Qingfeng Zhu, Xiangjie Wang, and Jianzhong Cui. 2017. "Morphological and Crystallographic Characterization of Primary Zinc-Rich Crystals in a Ternary Sn-Zn-Bi Alloy under a High Magnetic Field" Crystals 7, no. 7: 204. https://doi.org/10.3390/cryst7070204