An Electrically Tunable Liquid Crystal Lens with Coaxial Bi-Focus and Single Focus Switching Modes

Abstract

:1. Introduction

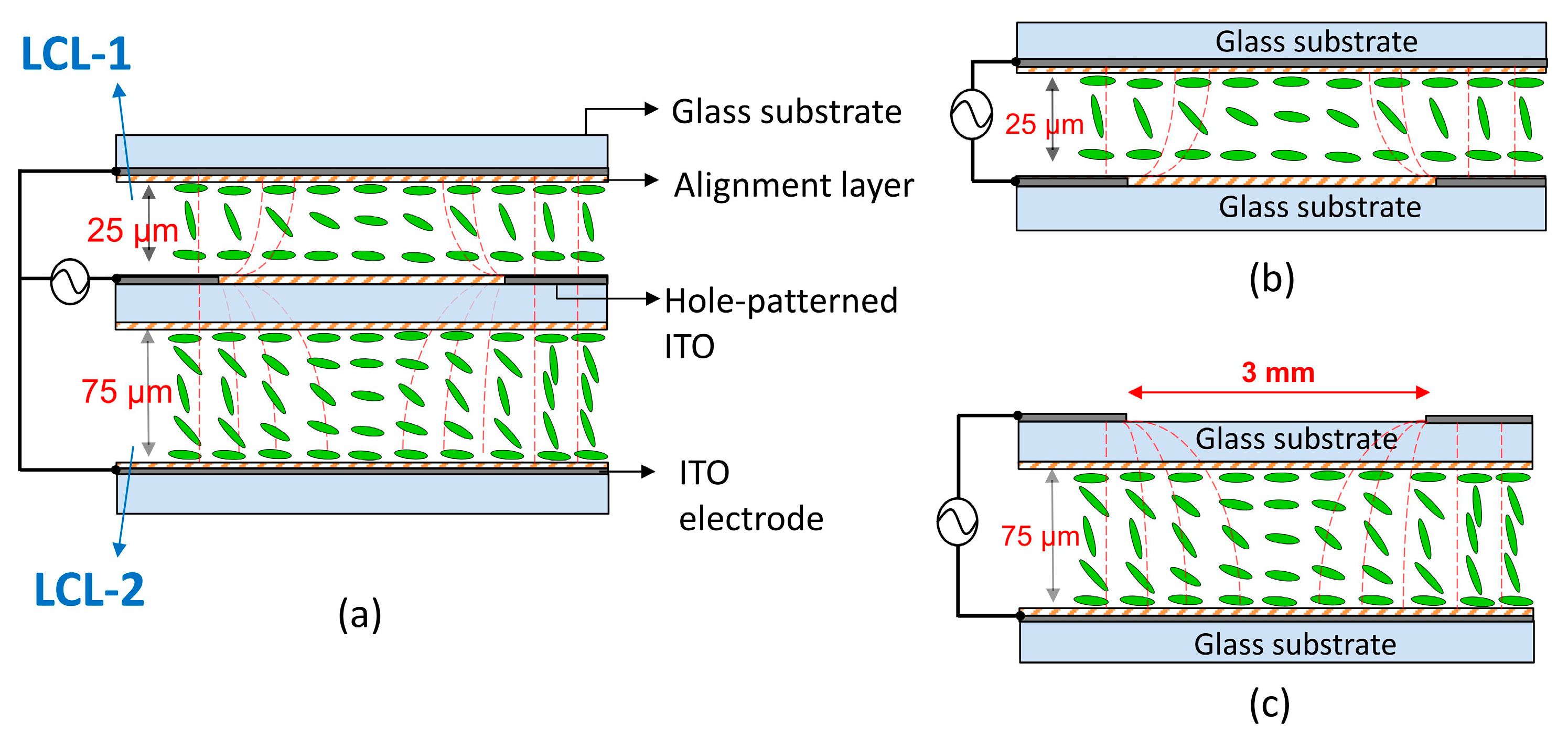

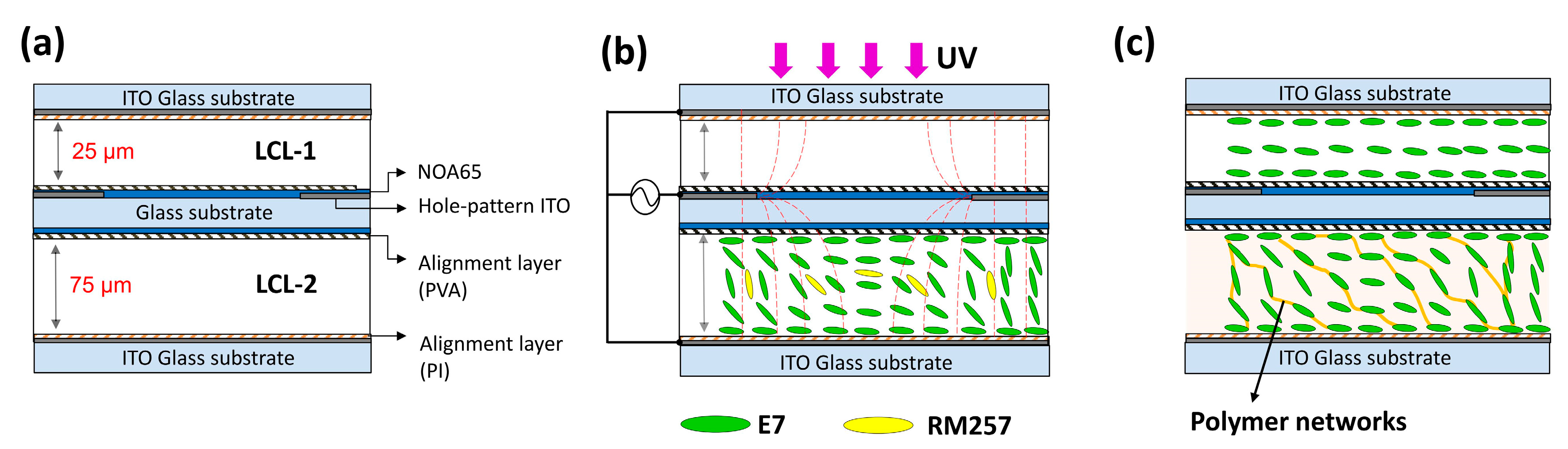

2. Simulation Design and Fabrication of the Proposed LC Lens

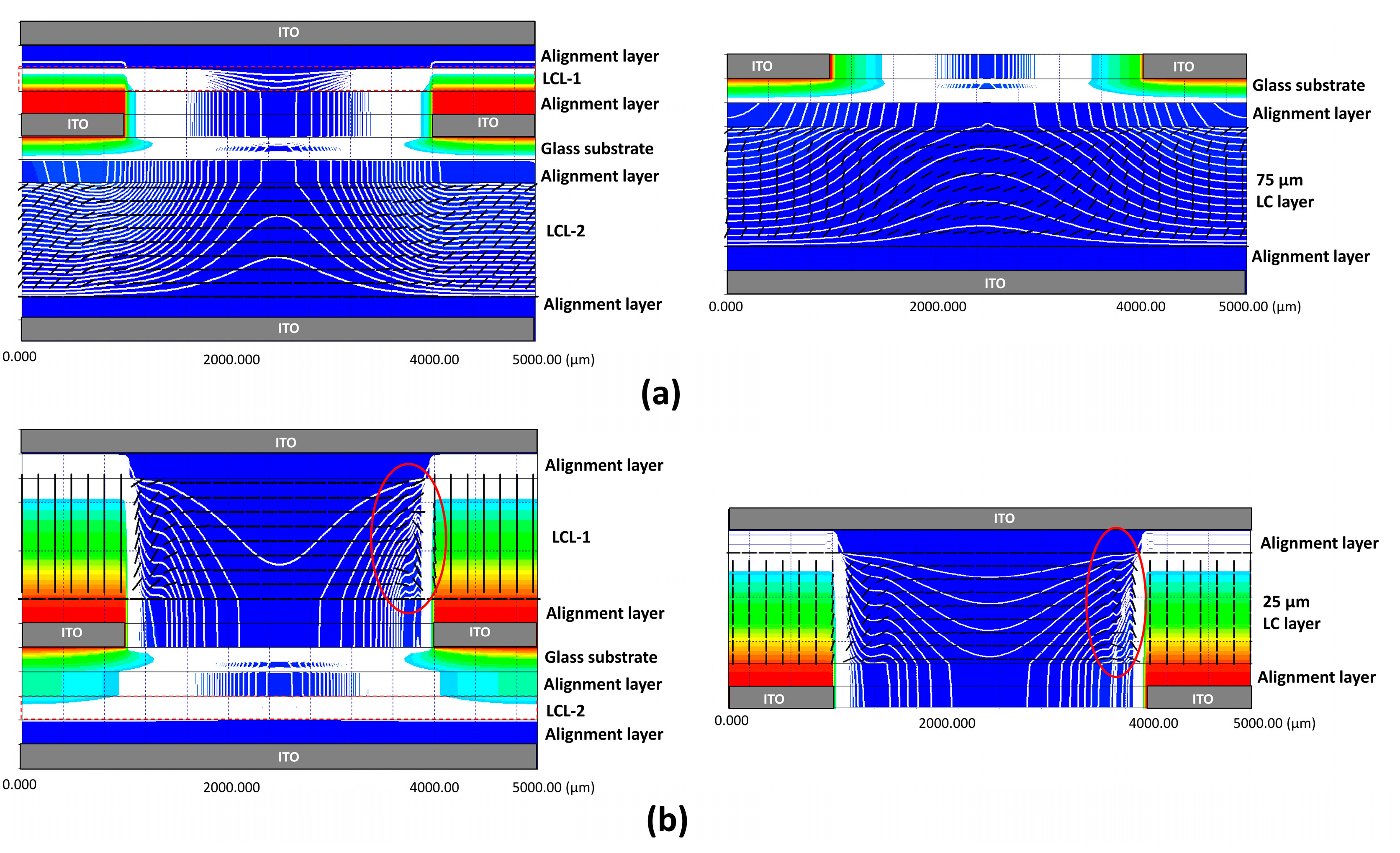

2.1. Simulation Design

2.2. LC Lens Fabrication

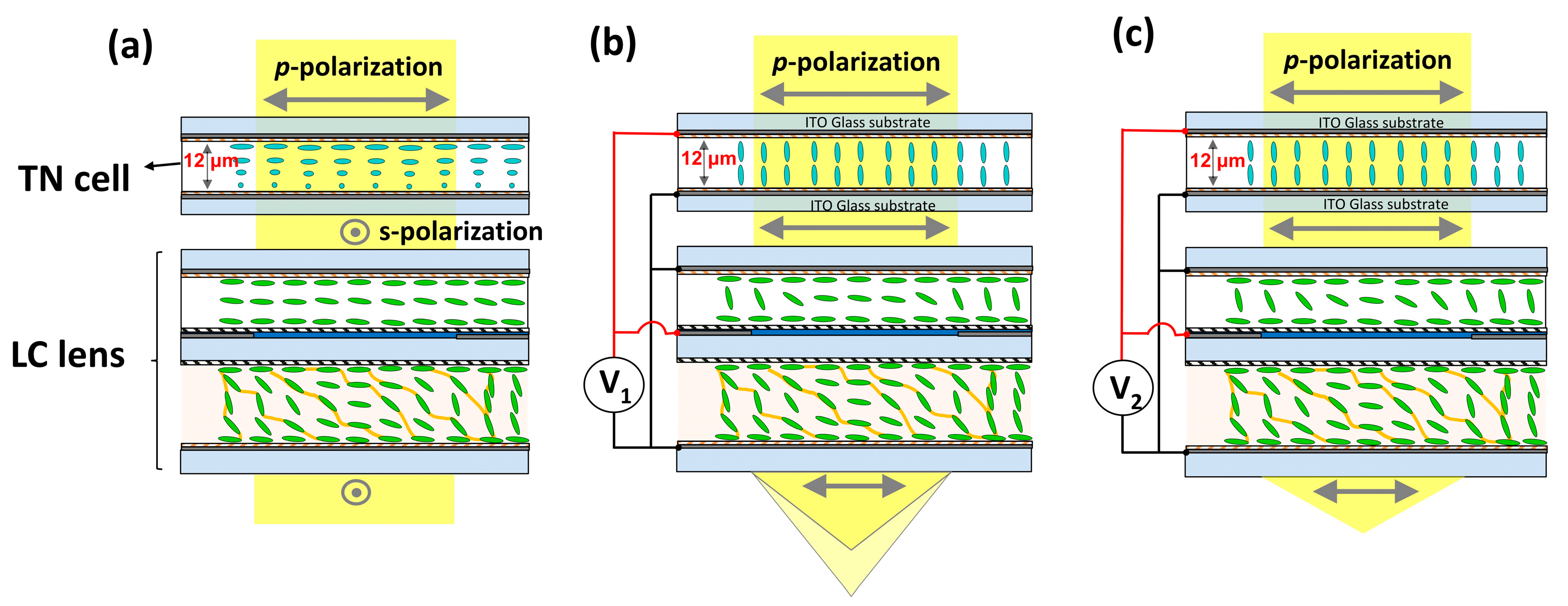

2.3. Electric Operation Versus Switching Focal Modes in Proposed LC Lenses

3. Experimental Results

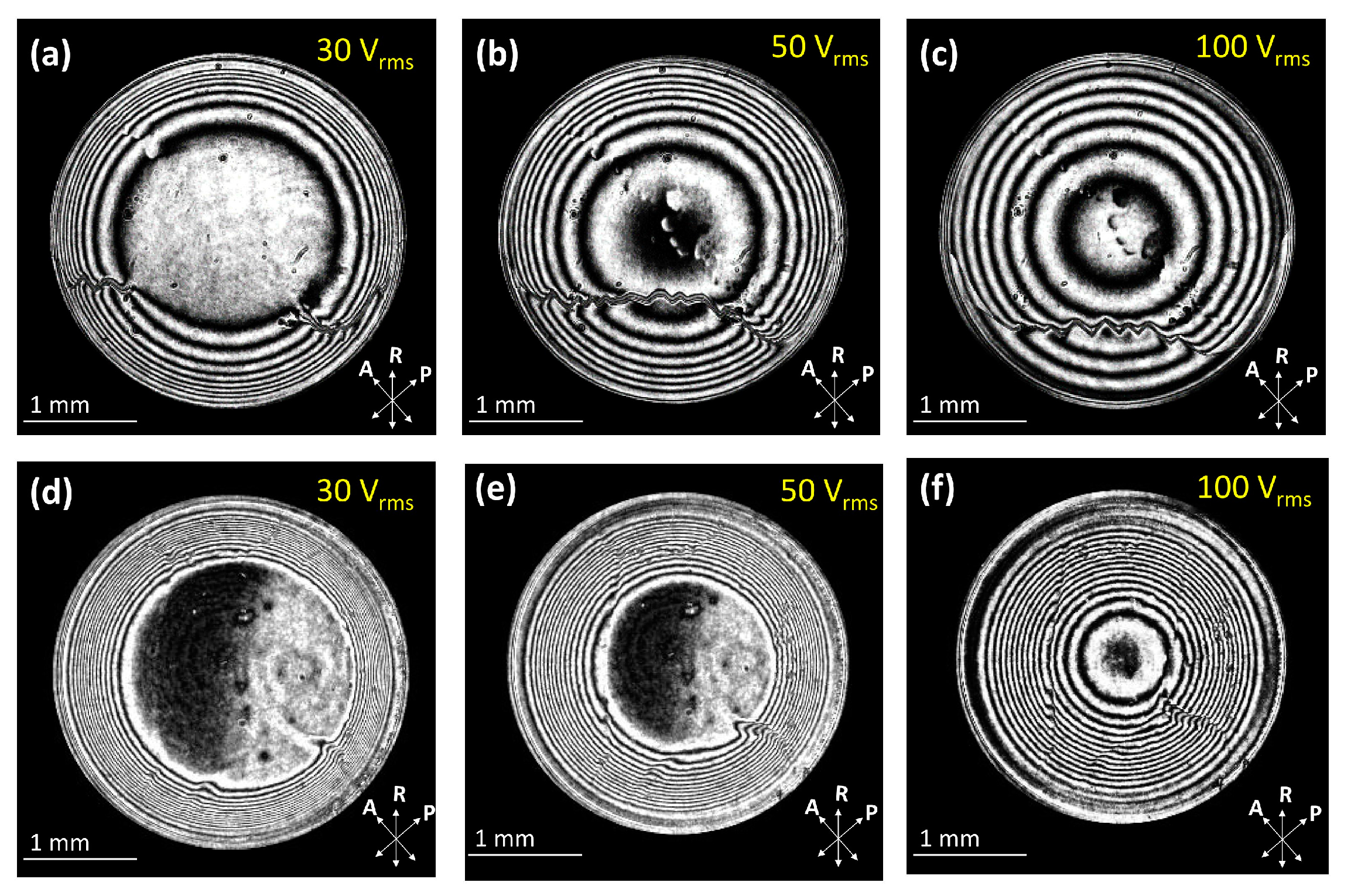

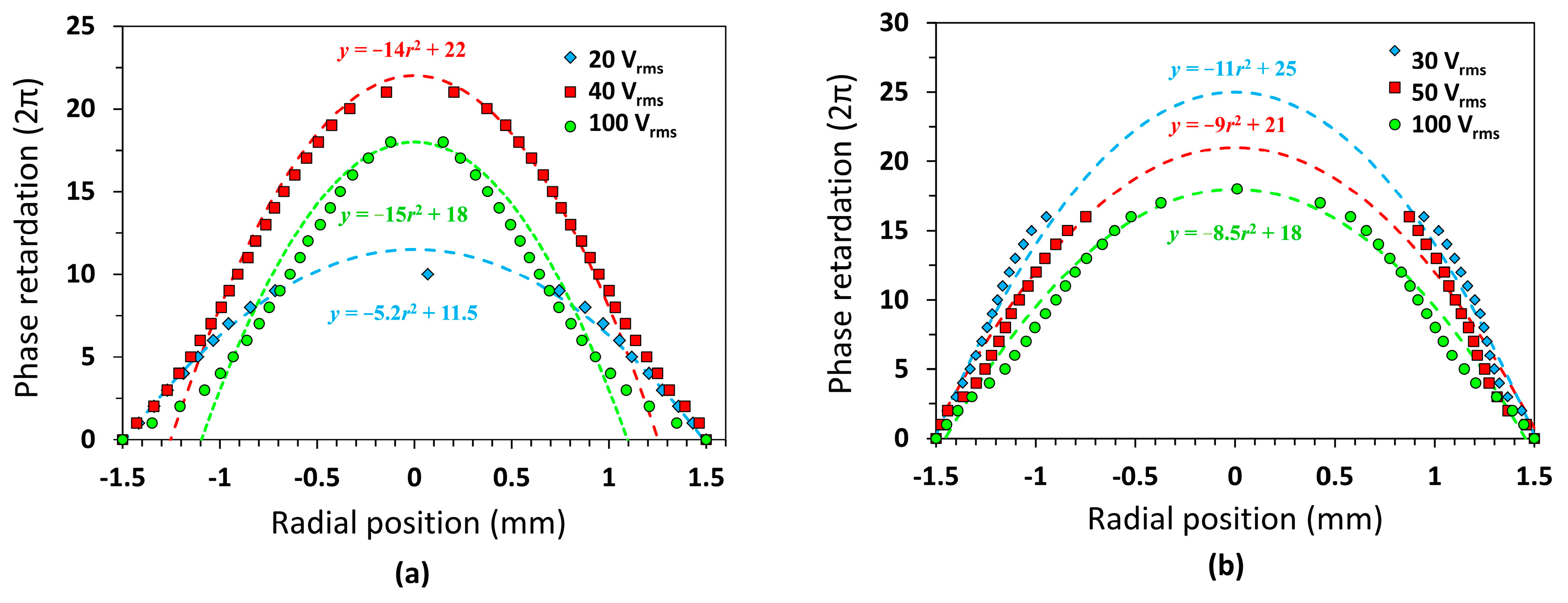

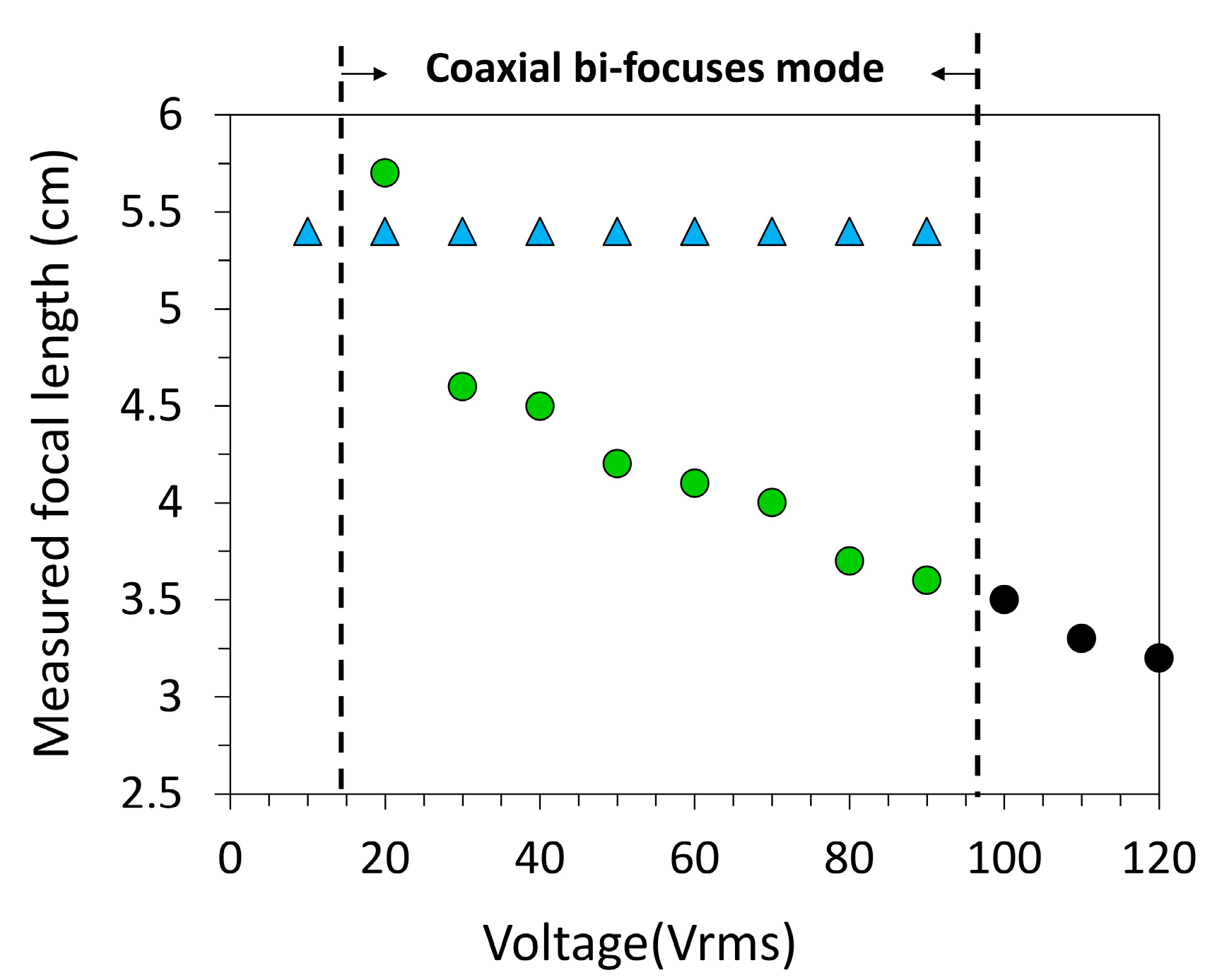

3.1. Comparisons Between the TLCL Lenses and Conventional LC Lenses

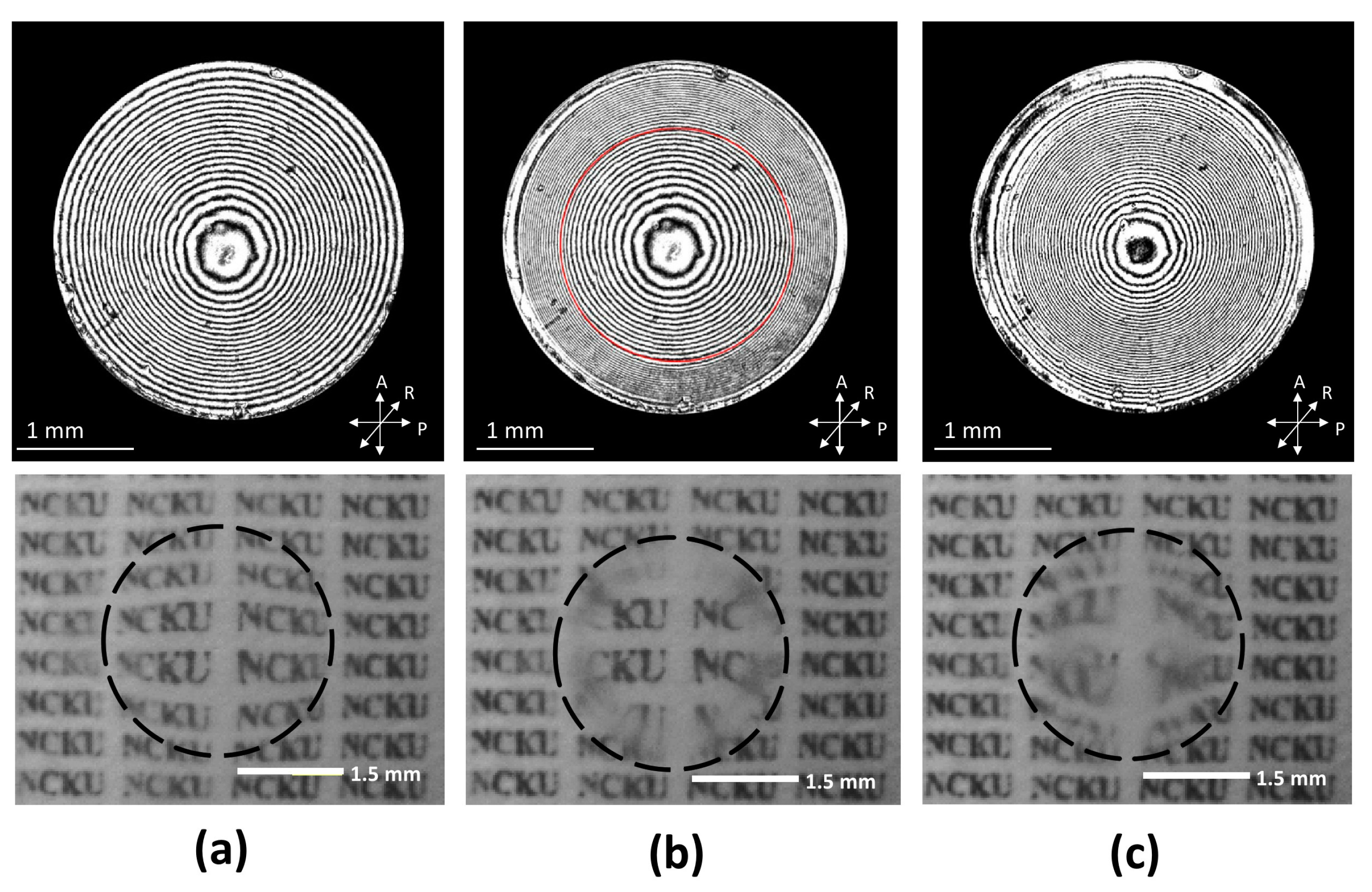

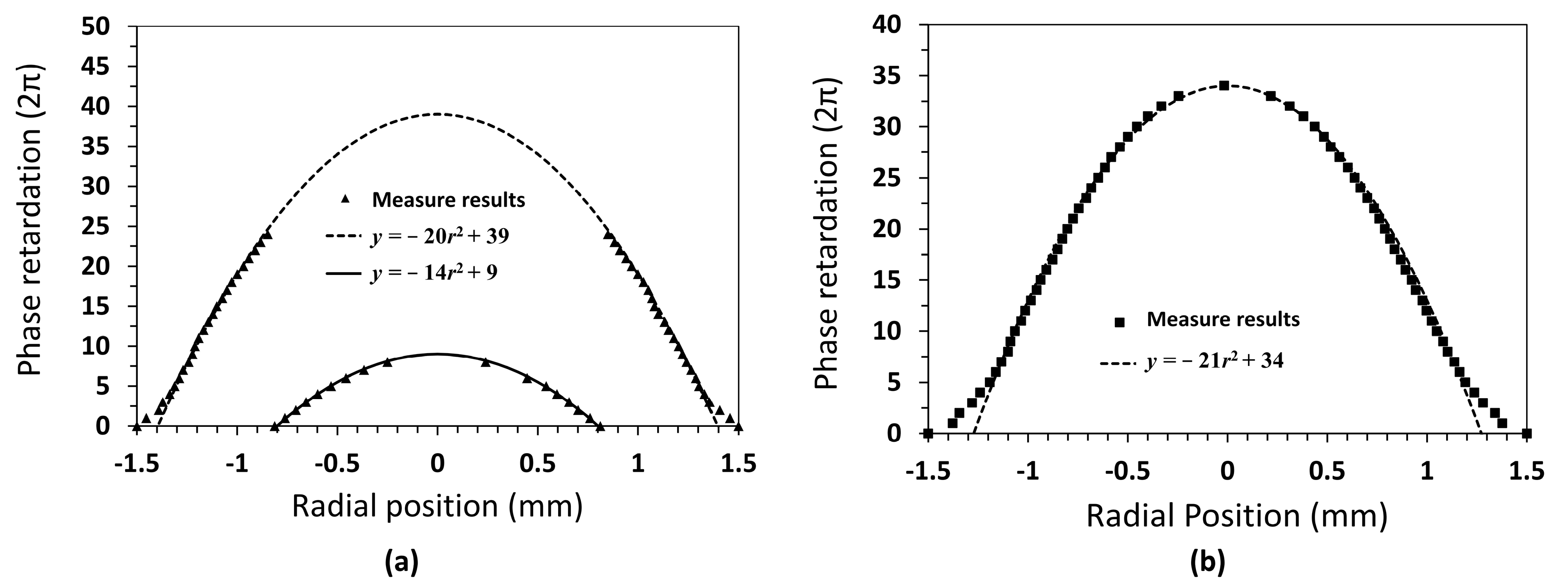

3.2. Optical Characteristics of TLCL Lenses

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, L.; Bryant, D.; Heugten, T.V.; Bos, P.J. Near-diffraction-limited and low-haze electro optical tunable liquid crystal lens with floating electrodes. Opt. Express 2013, 21, 8371–8381. [Google Scholar] [CrossRef] [PubMed]

- Chien, C.Y.; Hsu, C.J.; Chen, Y.W.; Tseng, S.H.; Sheu, C.R. Holographic polymer networks formed in liquid crystal phase modulators via a He-Ne laser to achieve ultra-fast optical response. Opt. Express 2016, 24, 7534–7542. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Peng, F.; Luo, Z.; Xu, D.; Wu, S.T.; Li, M.C.; Lee, S.L.; Tsai, W.C. High performance liquid crystal displays with a low dielectric constant material. Opt. Mater. Express 2014, 4, 2262–2273. [Google Scholar] [CrossRef]

- Chien, C.Y.; Sheu, C.R. Small dosage of holographic exposure via a He-Ne laser to fabricate tunable liquid crystal phase gratings operated with low electric voltages. Liq. Cryst. 2017, 44, 854–862. [Google Scholar] [CrossRef]

- Tan, J.; Song, Y.; Zhu, J.L.; Ni, S.B.; Wang, Y.J.; Sun, X.Y.; Lu, J.G.; Yang, B.R.; Shieh, H.P.D. Blue phase LC/polymer Fresnel lens fabricated by holographics. J. Disp. Technol. 2014, 10, 157–161. [Google Scholar] [CrossRef]

- Lin, S.H.; Huang, B.Y.; Li, C.Y.; Yu, K.Y.; Chen, J.L.; Kuo, C.T. Electrically and optically tunable Fresnel lens in a liquid crystal cell with a rewritable photoconductive layer. Opt. Mater. Express 2016, 6, 2229–2235. [Google Scholar] [CrossRef]

- Li, G.; Valley, P.; Giridhar, M.S.; Mathine, D.L.; Meredith, G.; Haddock, J.N.; Kippelen, B.; Peyghambarian, N. Large-aperture switchable thin diffractive lens with interleaved electrode patterns. Appl. Phys. Lett. 2006, 89, 141120. [Google Scholar] [CrossRef]

- Lou, Y.; Chen, L.; Wang, C.; Shen, S. Tunable-focus liquid crystal Fresnel zone lens based on harmonic diffraction. Appl. Phys. Lett. 2012, 101, 221121. [Google Scholar] [CrossRef]

- Ren, H.; Wu, S.T. Adaptive liquid crystal lens with large focal length tenability. Opt. Express 2006, 14, 11292–11298. [Google Scholar] [CrossRef] [PubMed]

- Serra, F.; Gharbi, M.A.; Luo, Y.; Liu, I.B.; Bade, N.D.; Kamien, R.D.; Yang, S.; Stebe, K.J. Curvature-driven, one-step assembly of reconfigurable smectic liquid crystal “compound eye” lenses. Adv. Opt. Mater. 2015, 3, 1287–1292. [Google Scholar] [CrossRef]

- Popov, P.; Honaker, L.W.; Mirheydari, M.; Mann, E.K.; Jákli, A. Chiral nematic liquid crystal microlenses. Sci. Rep. 2017, 7, 1603. [Google Scholar] [CrossRef] [PubMed]

- Ye, M.; Sato, S. Optical properties of liquid crystal lens of any size. Jpn. J. Appl. Phys. 2002, 41, L571–L573. [Google Scholar] [CrossRef]

- Hsu, C.J.; Jhang, J.J.; Huang, C.Y. Large aperture liquid crystal lens with an imbedded floating ring electrode. Opt. Express 2016, 24, 16722–16731. [Google Scholar] [CrossRef] [PubMed]

- Shibuya, G.; Yoshida, H.; Ozaki, M. High-speed driving of liquid crystal lens with weakly conductive thin films and voltage booster. Appl. Opt. 2015, 54, 8145–8151. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.S.; Chen, P.J.; Chen, M.; Lin, Y.H. An electrically tunable imaging system with separable focus and zoom functions using composite liquid crystal lenses. Opt. Express 2014, 22, 11427–11435. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.H.; Chen, H.S. Electrically tunable-focusing and polarizer-free liquid crystal lenses for ophthalmic applications. Opt. Express 2013, 21, 9428–9436. [Google Scholar] [CrossRef] [PubMed]

- Ye, M.; Wang, B.; Uchida, M.; Yanase, S.; Takahashi, S.; Sato, S. Focus tuning by liquid crystal lens in imaging system. Appl. Opt. 2012, 51, 7630–7635. [Google Scholar] [CrossRef] [PubMed]

- Lei, Y.; Tong, Q.; Zhang, X.; Sang, H.; Ji, A.; Xie, C. An electrically tunable plenoptic camera using a liquid crystal microlens array. Rev. Sci. Instrum. 2015, 86, 053100. [Google Scholar] [CrossRef] [PubMed]

- Algorri, J.F.; Urruchi, V.; Bennis, N.; Morawiak, P.; Sánchez-Pena, M.J.; Otón, J.M. Integral imaging capture system with tunable field of view based on liquid crystal microlenses. IEEE Photonics Technol. Lett. 2016, 28, 1854–1857. [Google Scholar] [CrossRef]

- Wang, Y.J.; Shen, X.; Lin, Y.H.; Javidi, B. Extended depth-of-field 3D endoscopy with synthetic aperture integral imaging using an electrically tunable focal-length liquid-crystal lens. Opt. Lett. 2015, 40, 3564–3567. [Google Scholar] [CrossRef] [PubMed]

- Hassanfiroozi, A.; Huang, Y.P.; Javidi, B.; Shieh, H.P.D. Dual layer electrode liquid crystal lens for 2D/3D tunable endoscopy imaging system. Opt. Express 2016, 24, 8527–8538. [Google Scholar] [CrossRef] [PubMed]

- Hassanfiroozi, A.; Huang, Y.P.; Javidi, B.; Shieh, H.P.D. Hexagonal liquid crystal lens array for 3D endoscopy. Opt. Express 2015, 23, 971–981. [Google Scholar] [CrossRef] [PubMed]

- Ye, M.; Wang, B.; Sato, S. Liquid-crystal lens with a focal length that is variable in a wide range. Appl. Opt. 2004, 43, 6407–6412. [Google Scholar] [CrossRef] [PubMed]

- Hsu, C.J.; Sheu, C.R. Preventing occurrence of disclination lines in liquid crystal lenses with a large aperture by means of polymer stabilization. Opt. Express 2011, 19, 14999–15008. [Google Scholar] [CrossRef] [PubMed]

- Kao, Y.Y.; Chao, P.C.P. A New dual-frequency liquid crystal lens with ring-and-pie electrodes and a driving scheme to prevent disclination lines and improve recovery time. Sensors 2011, 11, 5402–5415. [Google Scholar] [CrossRef] [PubMed]

- Ye, M.; Wang, B.; Sato, S. Driving of liquid crystal lens without disclination occurring by applying in-plane electric field. Jpn. J. Appl. Phys. 2003, 42, 5086–5089. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, C.; Zhang, D.; Luo, Y. Tunable liquid crystal microlens array using hole patterned electrode structure with ultrathin glass slab. Appl. Opt. 2012, 51, 3024–3030. [Google Scholar] [PubMed]

- Shen, X.; Wang, Y.J.; Chen, H.S.; Xiao, X.; Lin, Y.H.; Javidi, B. Extended depth-of-focus 3D micro integral imaging display using a bifocal liquid crystal lens. Opt. Lett. 2015, 40, 538–541. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Hua, H. Time-multiplexed dual-focal plane head-mounted display with a liquid lens. Opt. Lett. 2009, 34, 1642–1644. [Google Scholar] [CrossRef] [PubMed]

- Ren, H.; Fox, D.W.; Wu, B.; Wu, S.T. Liquid crystal lens with large focal length tunability and low operating voltage. Opt. Express 2007, 15, 11328–11335. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.C.; Lin, Y.H. A fast response and large electrically tunable-focusing imaging system based on switching of two modes of a liquid crystal lens. Appl. Phys. Lett. 2010, 97, 063505. [Google Scholar] [CrossRef]

- Wang, B.; Ye, M.; Honma, M.; Nose, T.; Sato, S. Liquid crystal lens with spherical electrode. Jpn. J. Appl. Phys. 2002, 41, L1232–L1233. [Google Scholar] [CrossRef]

- Lin, H.C.; Lin, Y.H. An electrically tunable focusing liquid crystal lens with a built-in planar polymeric lens. Appl. Phys. Lett. 2011, 98, 083503. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, D.; Luo, Y.; Liu, C. Numerical analysis and design of patterned electrode liquid crystal microlens array with dielectric slab. Opt. Laser Technol. 2012, 44, 1834–1839. [Google Scholar]

- Hsu, C.J.; Sheu, C.R. Using photopolymerization to achieve tunable liquid crystal lenses with coaxial bifocals. Opt. Express 2012, 20, 4738–4746. [Google Scholar] [CrossRef] [PubMed]

- Choi, H.; Park, J.H.; Hong, J.; Lee, B. Depth-enhanced integral imaging with a stepped lens array or a composite lens array for three-dimensional display. Jpn. J. Appl. Phys. 2004, 43, 5330–5336. [Google Scholar] [CrossRef]

- Jang, J.S.; Javidi, B. Large depth-of-focus time-multiplexed three-dimensional integral imaging by use of lenslets with nonuniform focal lengths and aperture sizes. Opt. Lett. 2003, 28, 1924–1926. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chien, C.-Y.; Li, C.-H.; Sheu, C.-R. An Electrically Tunable Liquid Crystal Lens with Coaxial Bi-Focus and Single Focus Switching Modes. Crystals 2017, 7, 209. https://doi.org/10.3390/cryst7070209

Chien C-Y, Li C-H, Sheu C-R. An Electrically Tunable Liquid Crystal Lens with Coaxial Bi-Focus and Single Focus Switching Modes. Crystals. 2017; 7(7):209. https://doi.org/10.3390/cryst7070209

Chicago/Turabian StyleChien, Chun-Yu, Cheng-Hau Li, and Chia-Rong Sheu. 2017. "An Electrically Tunable Liquid Crystal Lens with Coaxial Bi-Focus and Single Focus Switching Modes" Crystals 7, no. 7: 209. https://doi.org/10.3390/cryst7070209