Large-Scale Assembly and Mask-Free Fabrication of Graphene Transistors via Optically Induced Electrodeposition

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

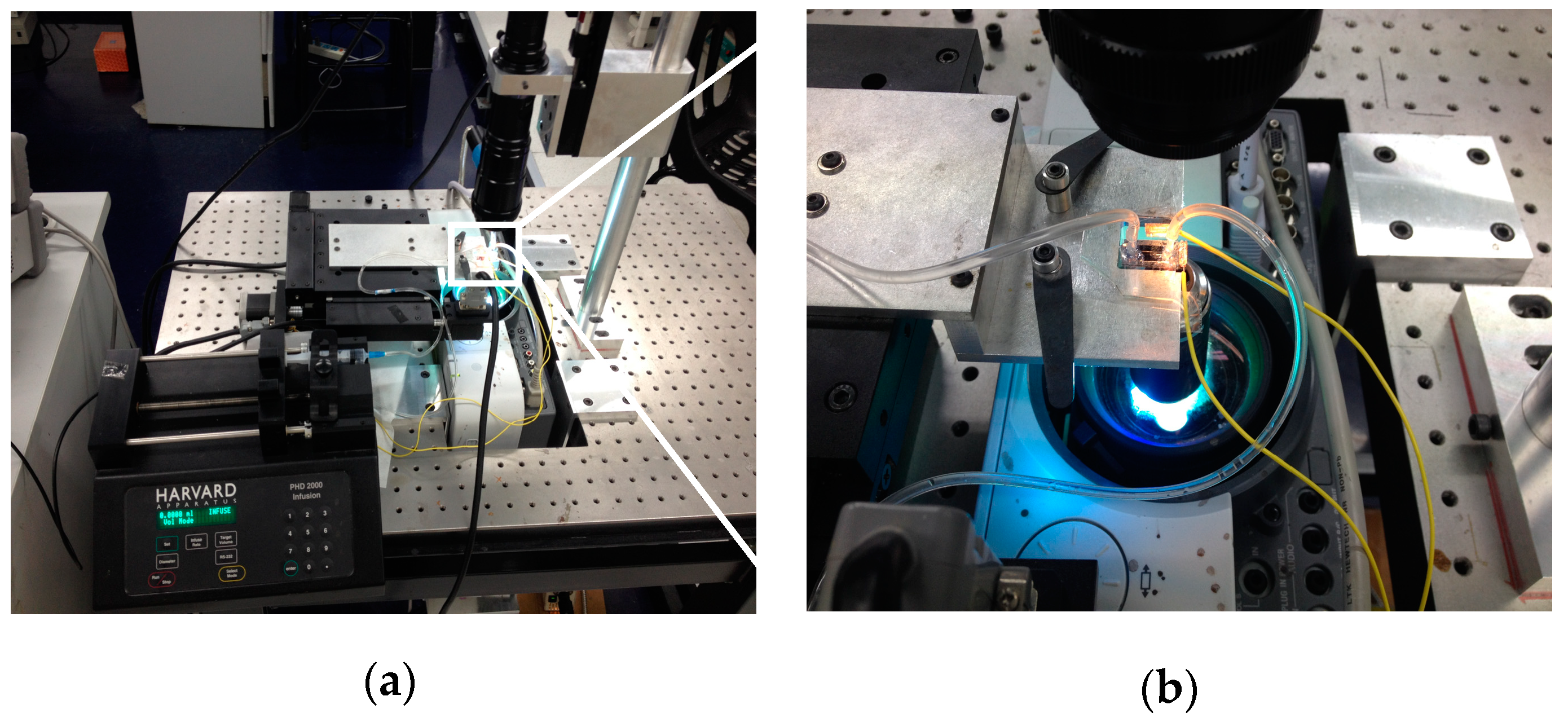

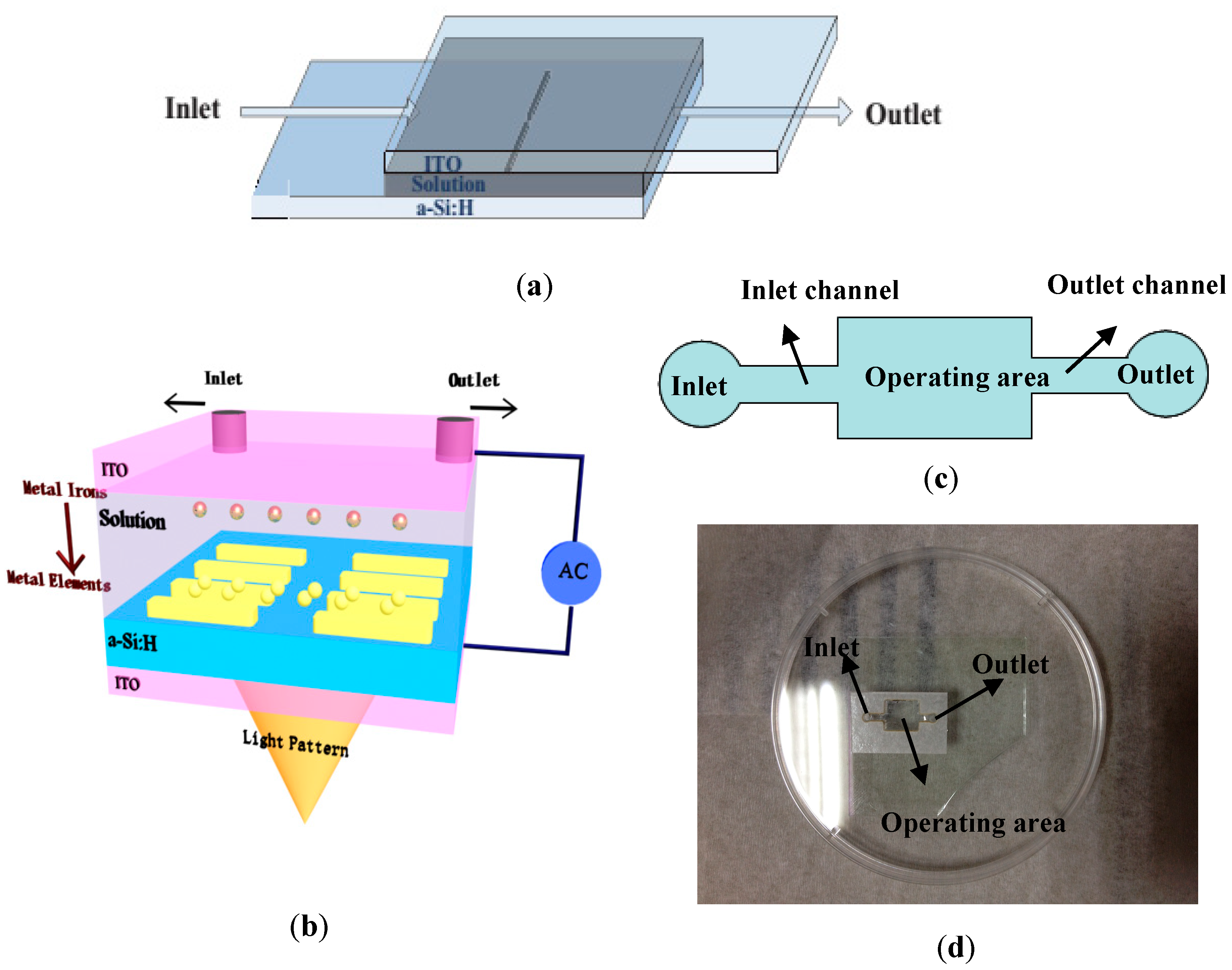

2.2. Apparatus

2.3. Methods

3. Results and Discussion

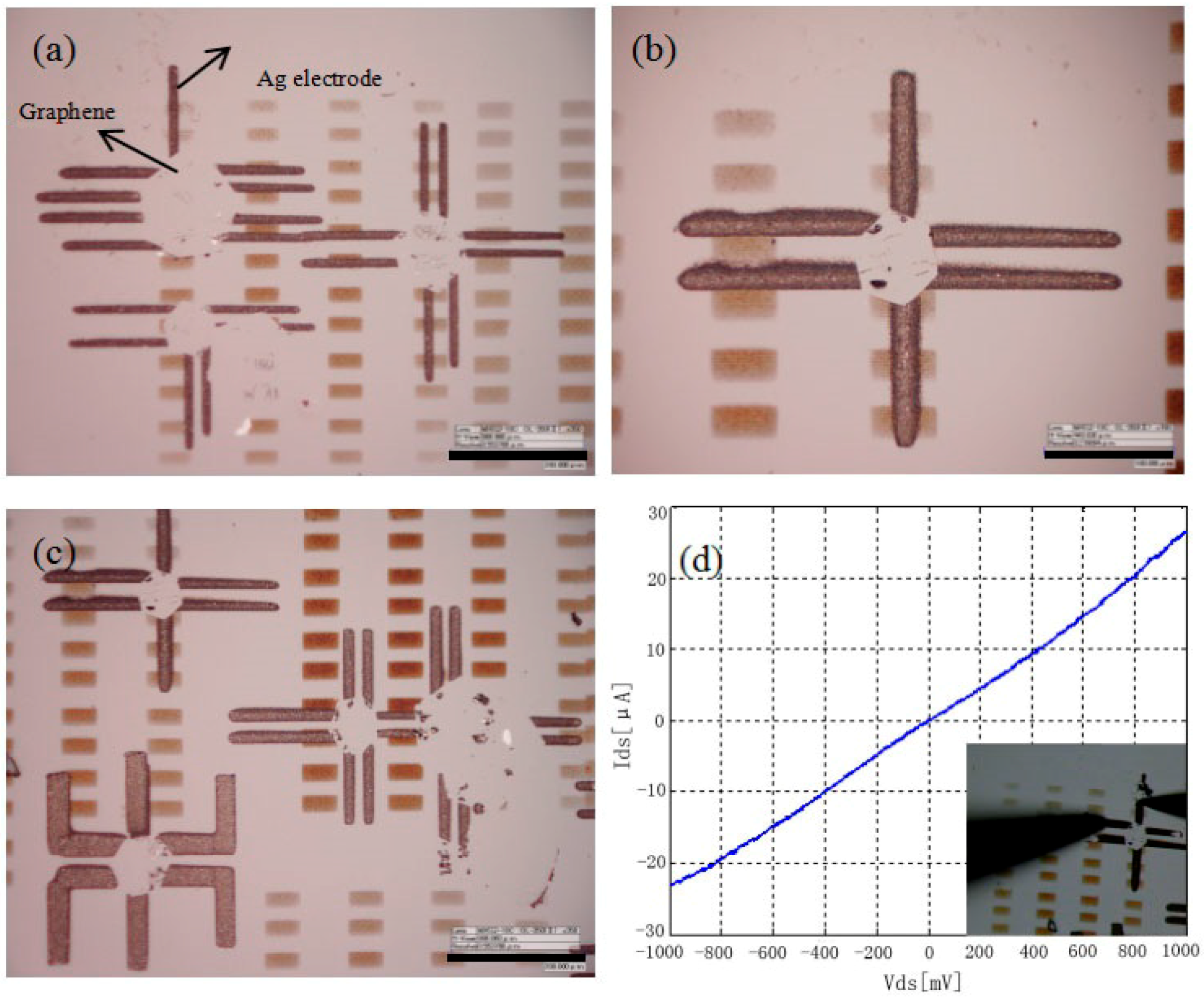

3.1. Growth of Ag Electrodes by OIED

3.2. Large-Scale Assembly of Graphene by OIED

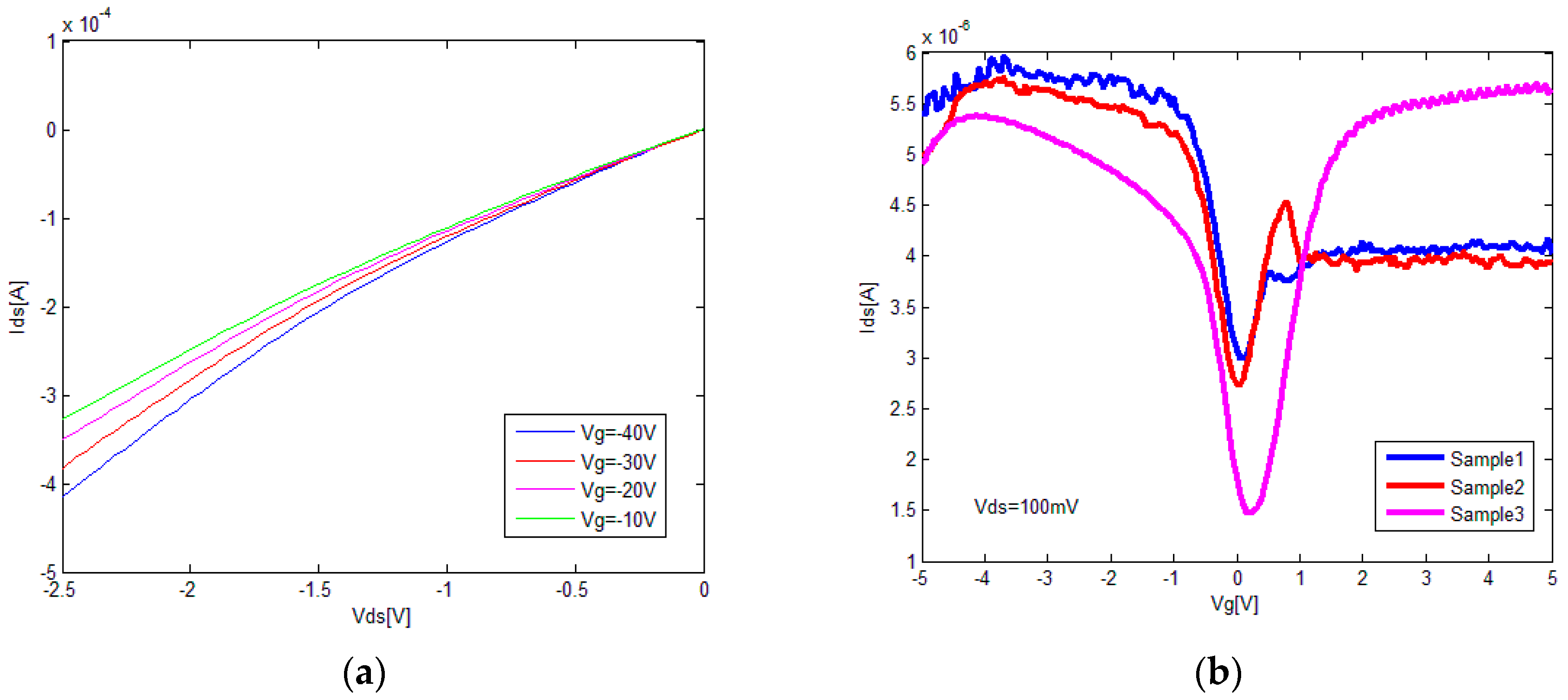

3.3. The Structure and Electrical Characteristics of Assembled Graphene-Based FETs

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Novoselov, K.S.; Falko, V.I.; Colombo, L.; Gellert, P.R.; Schwab, M.G.; Kim, K. A roadmap for graphene. Nature 2012, 490, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Yu, F.H.; Li, G.Y.; Liu, L.Q.; Liu, G.J.; Zhang, Z.Y.; Wang, Y.C.; Weijnya, U.C.; Xi, N. Online Determination of Graphene Lattice Orientation Through Lateral Forces. Nanoscale Res. Lett. 2016, 11, 353. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yang, T.; Lao, J.; Zhang, R.; Zhang, Y.; Zhu, M. Ultra-sensitive graphene strain sensor for sound signal acquisition and recognition. Nano Res. 2015, 8, 1627–1636. [Google Scholar] [CrossRef]

- Ghadiry, M.; Ismail, R.; Saeidmanesh, M.; Khaledian, M.; Manaf, A. Graphene nanoribbon field-effect transistor at high bias. Nanoscale Res. Lett. 2014, 9, 604. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lemme, M.C.; Bell, D.C.; Williams, J.R. Etching of Graphene Devices with a Helium Ion Beam. ACS Nano 2009, 3, 2674–2676. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, W.; Berthou, S.; Lu, X.; Wilmart, Q.; Denis, A.; Rosticher, M.; Taniguchi, T.; Watanabe, K.; Fève, G.; Berroir, J.; et al. A graphene Zener–Klein transistor cooled by a hyperbolic substrate. Nat. Nanotechnol. 2018, 13, 47–52. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, X.; Li, X.; Dai, H. Chemical self-assembly of graphene sheets. Nano Res. 2009, 2, 336–342. [Google Scholar] [CrossRef] [Green Version]

- Kang, H.; Kulkarni, A.; Stankovich, S.; Ruoff, R.S.; Baik, S. Restoring electrical conductivity of dielectrophoretically assembled graphite oxide sheets by thermal and chemical reduction techniques. Carbon 2009, 47, 1520–1525. [Google Scholar] [CrossRef]

- Burg, B.R.; Lutolf, F.; Schneider, J.; Schirmer, N.C.; Schwamb, T.; Poulikakos, D. High-yield dielectrophoretic assembly of two-dimensional graphene nanostructures. Appl. Phys. Lett. 2009, 94, 053110. [Google Scholar] [CrossRef]

- Joung, D.; Chunder, A.; Zhai, L.; Khondaker, S.I. High Yield Fabrication of Chemically Reduced Graphene Oxide Field Effect Transistors by Dielectrophoresis. Nanotechnology 2010, 21, 165202. [Google Scholar] [CrossRef] [PubMed]

- Burg, B.R.; Schneider, J.; Maurer, S.; Schimer, N.C.; Poulikakos, D. Dielectrophoretic integration of single and few layer graphenes. J. Appl. Phys. 2010, 107, 034302. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, L.; Xi, N.; Wang, Y.; Dong, Z.; Wejinya, U.C. Dielectrophoretic Assembly and AFM Modification of Reduced Graphene Oxide. J. Appl. Phys. 2011, 110, 114545. [Google Scholar] [CrossRef]

- Leiterer, C.; Deckert-Gaudig, T.; Singh, P.; Wirth, J.; Deckert, V.; Fritzsche, W. Dielectrophoretic positioning of single oparticles on atomnanic force microscope tips for tip-enhanced Raman spectroscopy. Electrophoresis 2015, 36, 1142–1148. [Google Scholar] [CrossRef] [PubMed]

- Shekhar, S.; Stokes, P.; Khondaker, S. Ultrahigh density alignment of carbon nanotube arrays by dielectrophoresis. ACS Nano 2011, 5, 1739–1746. [Google Scholar] [CrossRef] [PubMed]

- Viefhues, M.; Eichhorn, R. DNA dielectrophoresis theory and applications a review. Eelectrophoresis 2017, 38, 1483–1506. [Google Scholar] [CrossRef] [PubMed]

- Song, H.; Rosano, J.M.; Wang, Y.; Garson, C.J.; Prabhakarpandian, B.; Pant, K.; Klarmann, G.J.; Perantoni, A.; Alvarez, L.M.; Lai, E. Continuous-flow sorting of stem cells and differentiation products based on dielectrophoresis. Lab Chip 2015, 15, 1320–1328. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.; Wei, F.N.; Liu, L.Q.; Lai, H.S.S.; Yu, H.B.; Wang, Y.C.; Lee, G.; Li, W.J. Optically-controlled digital electrodeposition of thin-film metals for fabrication of nano-devices. Opt. Mater. Express 2015, 5, 838–848. [Google Scholar] [CrossRef]

- Liu, N.; Wang, F.F.; Liu, L.Q.; Yu, H.B.; Xie, S.; Wang, J.; Wang, Y.C.; Lee, G.; Li, W.J. Rapidly patterning micro/nano devices by directly assembling ions and nanomaterials. Sci. Rep. 2016, 6, 32106. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ma, T.; Ren, W.C.; Liu, Z.B.; Huang, L.; Ma, L.P.; Ma, X.L.; Zhang, Z.Y.; Peng, L.M.; Cheng, H.M. Repeated Growth-Etching-Regrowth for Large-Area Defect-Free Single-Crystal Graphene by Chemical Vapor Deposition. ACS Nano 2014, 8, 12806–12813. [Google Scholar] [CrossRef] [PubMed]

- Wang, S. Theoretical Analysis and Experimental Method of Optically Induced Dielectrophoresis for Micro/Nano Manipulation; Shenyang Institute of Automation, Chinese Academy of Sciences: Shenyang, China, 2011. [Google Scholar]

- Gao, L.B.; Ren, W.C.; Xu, H.L.; Jin, L.; Wang, Z.; Ma, T.; Ma, L.P.; Zhang, Z.; Fu, Q.; Peng, L.M.; et al. Repeated Growth and Bubbling Transfer of Graphene with Millimetre-size Single-crystal Grains Using Platinum. Nat. Commun. 2012, 3, 699. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Yang, Y.; Liu, N.; Yu, F.; Yu, H.; Jiao, N. Large-Scale Assembly and Mask-Free Fabrication of Graphene Transistors via Optically Induced Electrodeposition. Crystals 2018, 8, 239. https://doi.org/10.3390/cryst8060239

Zhang Y, Yang Y, Liu N, Yu F, Yu H, Jiao N. Large-Scale Assembly and Mask-Free Fabrication of Graphene Transistors via Optically Induced Electrodeposition. Crystals. 2018; 8(6):239. https://doi.org/10.3390/cryst8060239

Chicago/Turabian StyleZhang, Yu, Yong Yang, Na Liu, Fanhua Yu, Haibo Yu, and Niandong Jiao. 2018. "Large-Scale Assembly and Mask-Free Fabrication of Graphene Transistors via Optically Induced Electrodeposition" Crystals 8, no. 6: 239. https://doi.org/10.3390/cryst8060239