Effect of Substrate Surface on Deposition of AlGaN: A Molecular Dynamics Simulation

Abstract

:1. Introduction

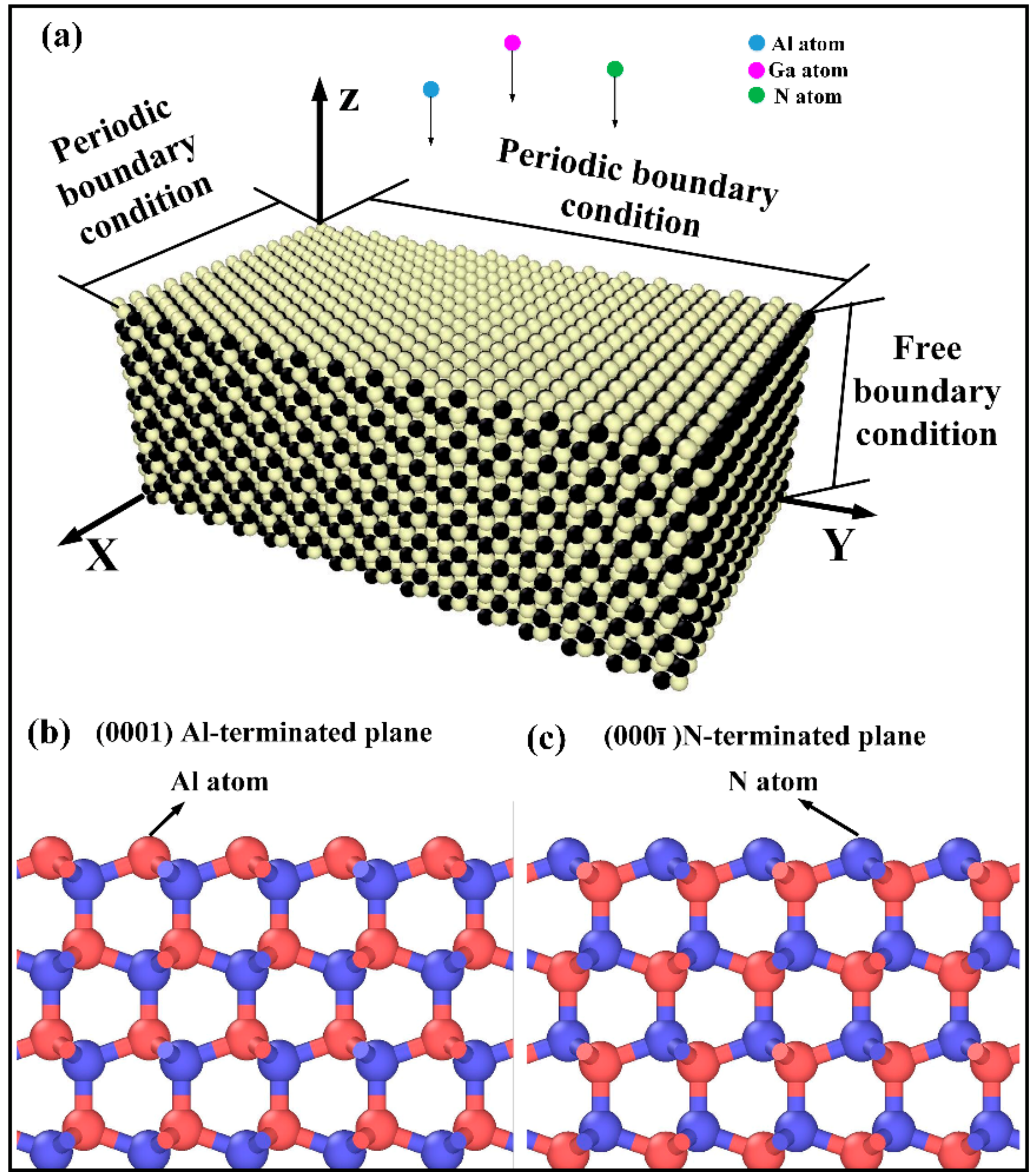

2. Calculation Methods

2.1. Interatomic Potential

2.2. Simulation Details

2.3. Analysis Methods

3. Results and Discussion

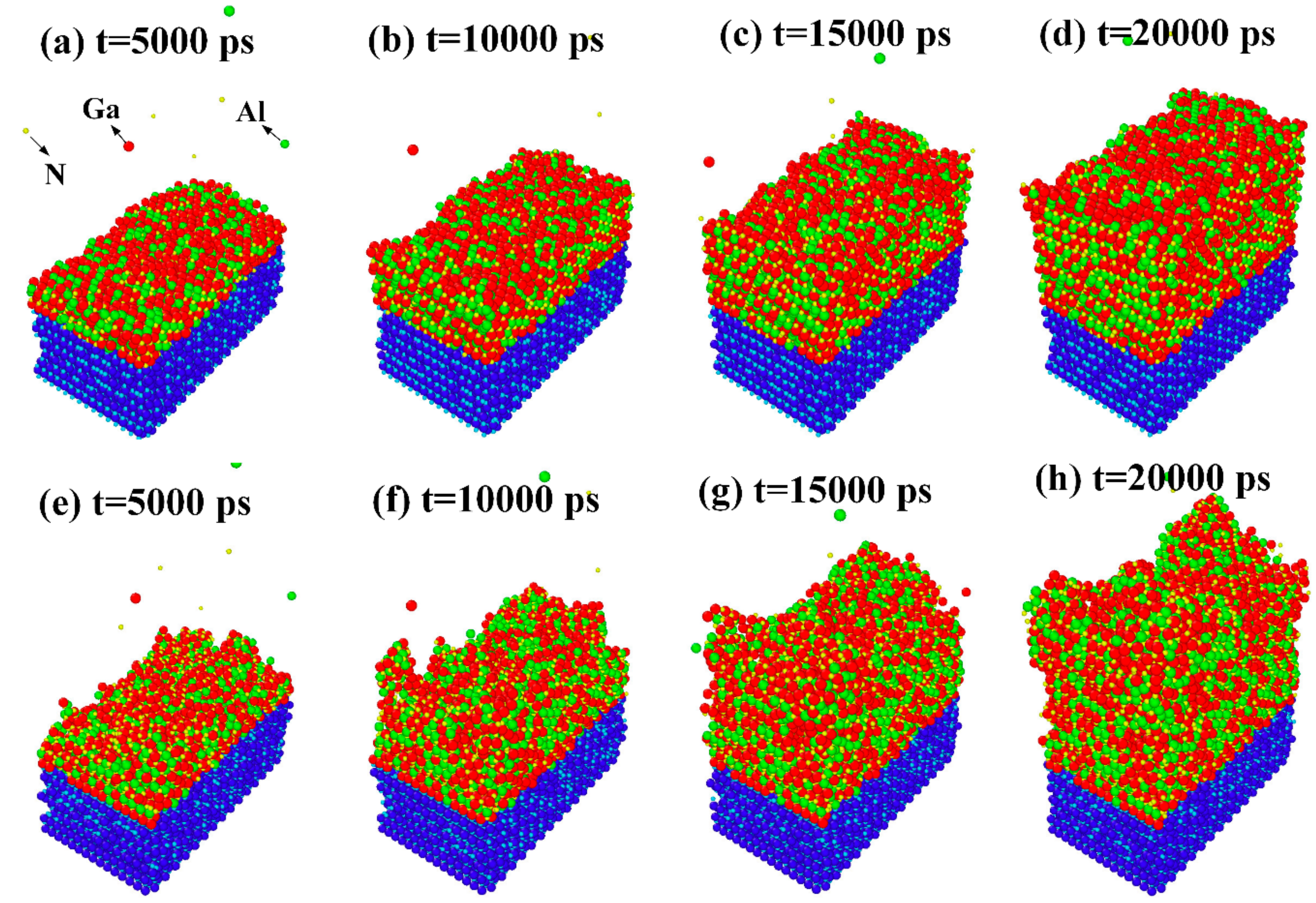

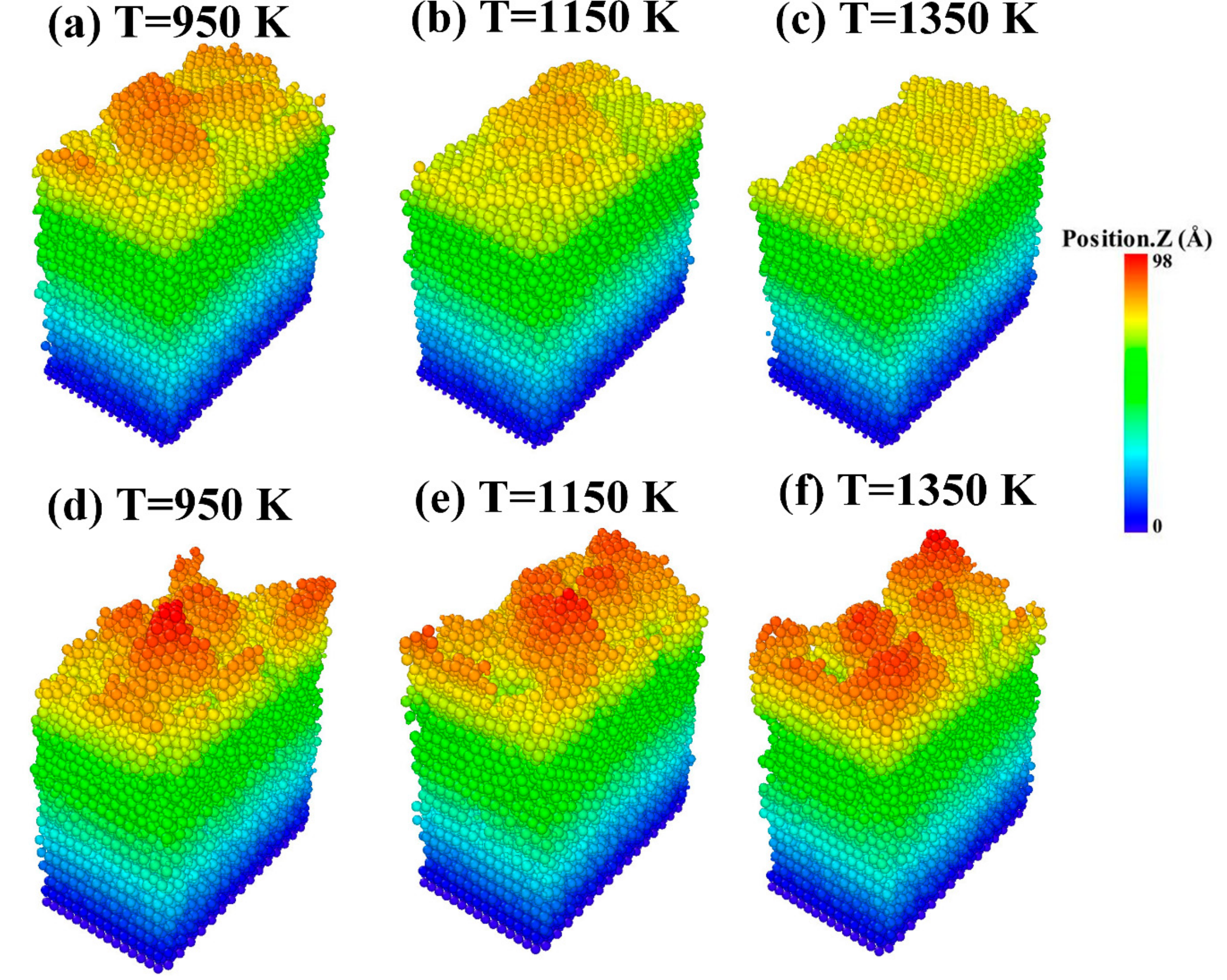

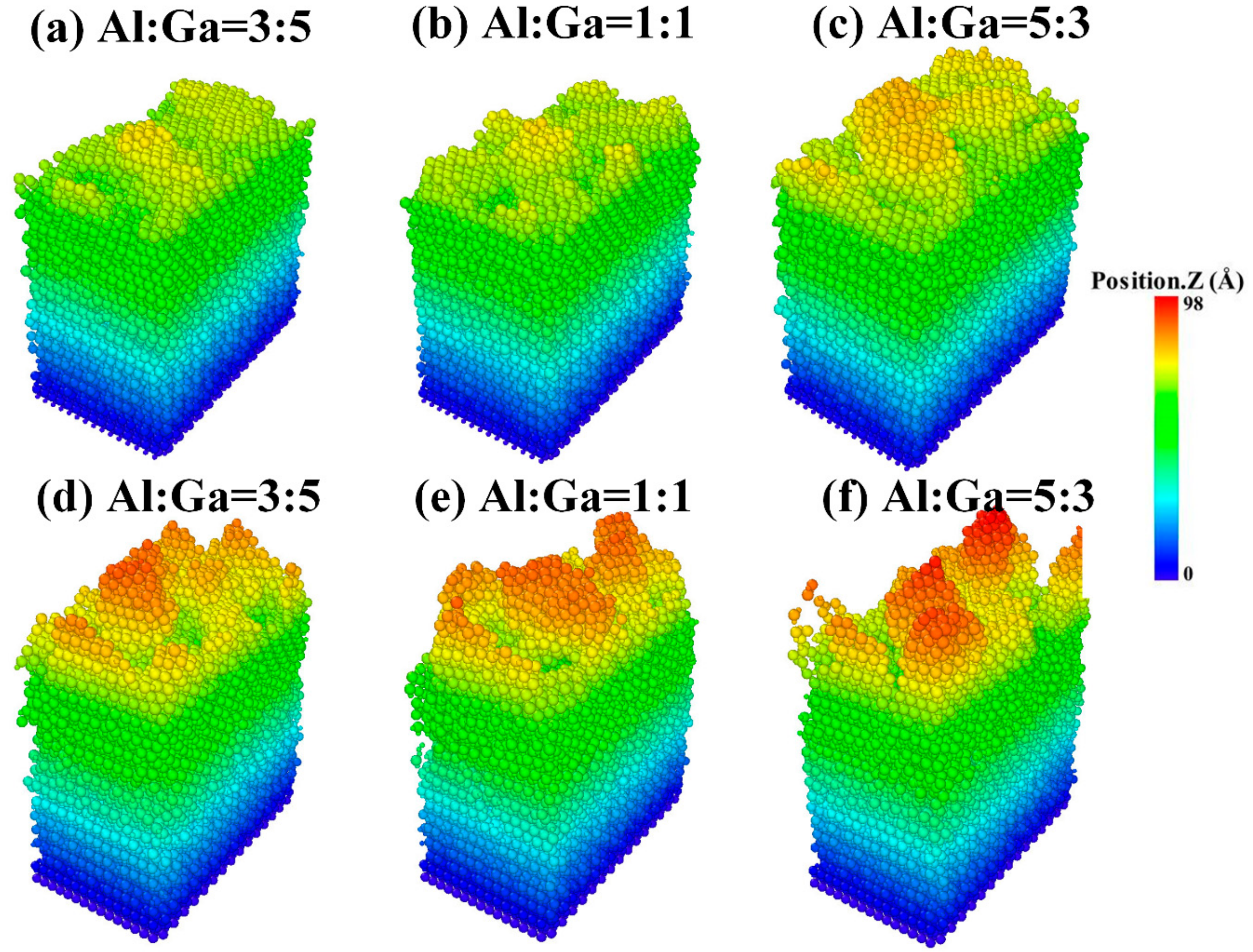

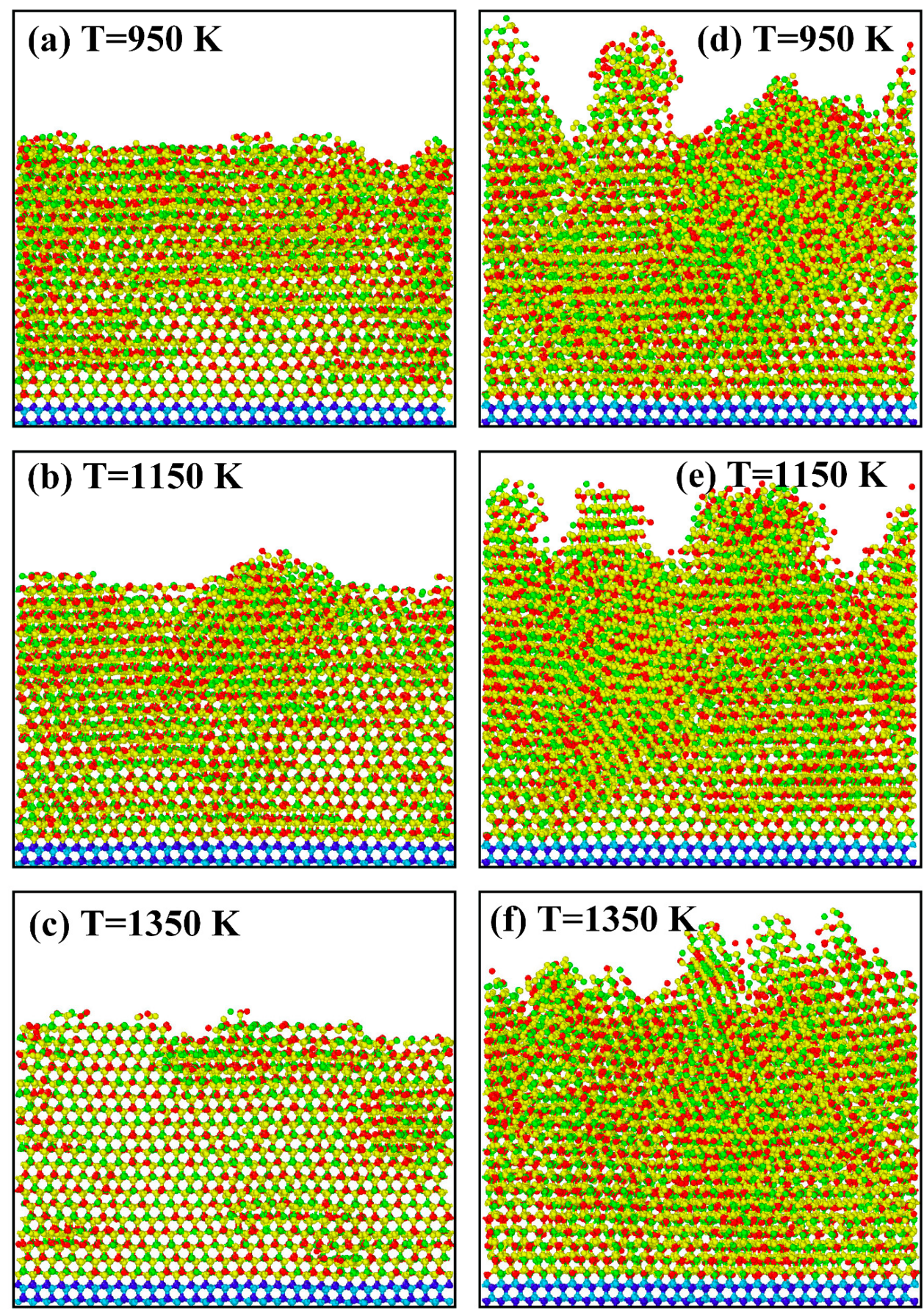

3.1. Surface Morphology

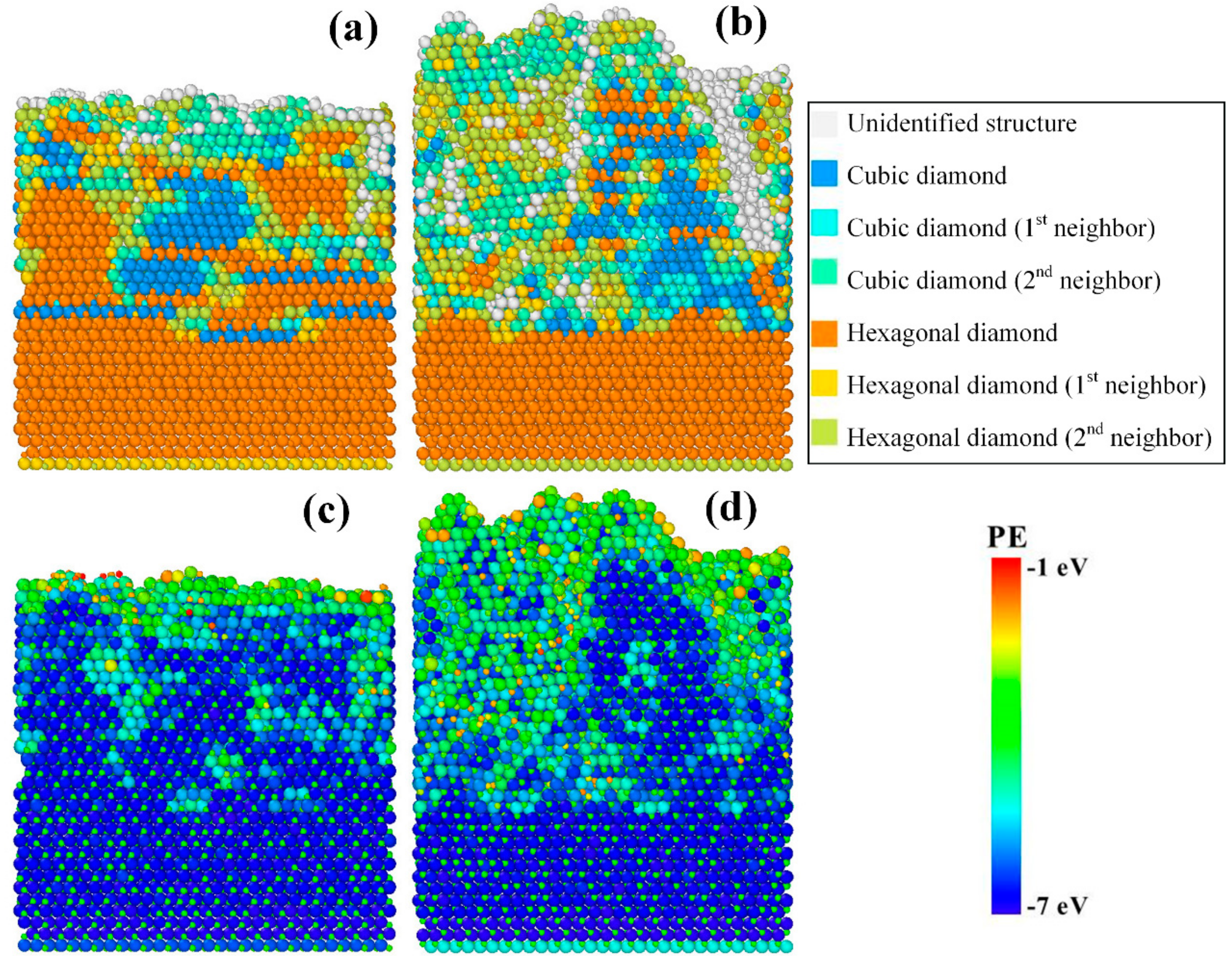

3.2. Atomic Structure

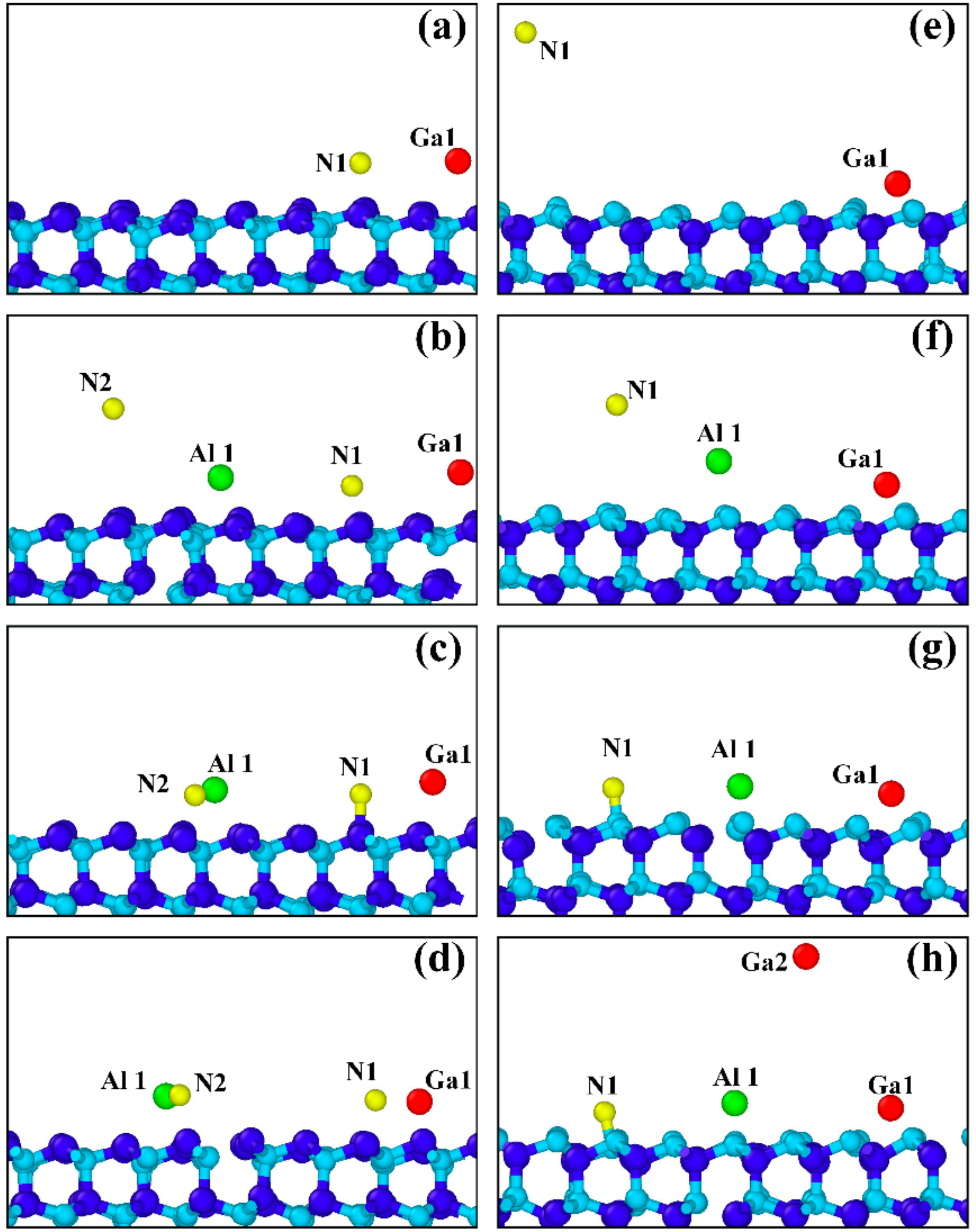

3.3. Atomic Migration Mechanisms

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, J.P.; Wang, H.M.; Gaevski, M.E.; Chen, C.Q.; Fareed, Q.; Yang, J.W.; Simin, G.; Khan, M.A. Crack-free thick AlGaN grown on sapphire using AlN/AlGaN superlattices for strain management. Appl. Phys. Lett. 2002, 80, 3542–3544. [Google Scholar] [CrossRef] [Green Version]

- Xiang, H.G.; Li, H.T.; Fu, T.; Zhao, Y.B.; Huang, C.; Zhang, G.; Peng, X.H. Molecular dynamics simulation of AlN thin films under nanoindentation. Ceram. Int. 2017, 43, 4068–4075. [Google Scholar] [CrossRef]

- Xiang, H.; Li, H.; Fu, T.; Huang, C.; Peng, X. Formation of prismatic loops in AlN and GaN under nanoindentation. Acta Mater. 2017, 138, 131–139. [Google Scholar] [CrossRef]

- Liang, F.; Zhao, D.-G.; Jiang, D.-S.; Liu, Z.-S.; Zhu, J.-J.; Chen, P.; Yang, J.; Liu, W.; Liu, S.-T.; Xing, Y.; et al. Output light power of InGaN-based violet laser diodes improved by using a u-InGaN/GaN/AlGaN multiple upper waveguide. Chin. Phys. B 2017, 26, 124210. [Google Scholar] [CrossRef] [Green Version]

- Lu, L.; Wan, Z.; Xu, F.J.; Shen, B.; Lv, C.; Jiang, M.; Chen, Q.G. Improving Performance of Algan-Based Deep-Ultraviolet Light-Emitting Diodes by Inserting a Higher Al-Content Algan Layer Within the Multiple Quantum Wells. Phys. Status Solidi A 2017, 214, 1700461. [Google Scholar] [CrossRef]

- Rathkanthiwar, S.; Kalra, A.; Solanke, S.V.; Mohta, N.; Muralidharan, R.; Raghavan, S.; Nath, D.N. Gain mechanism and carrier transport in high responsivity AlGaN-based solar blind metal semiconductor metal photodetectors. J. Appl. Phys 2017, 121, 164502. [Google Scholar] [CrossRef]

- Mastro, M.A.; Eddy, C.R.; Gaskill, D.K.; Bassim, N.D.; Casey, J.; Rosenberg, A.; Holm, R.T.; Henry, R.L.; Twigg, M.E. MOCVD growth of thick AlN and AlGaN superlattice structures on Si substrates. J. Cryst. Growth 2006, 287, 610–614. [Google Scholar] [CrossRef]

- Chichibu, S.F.; Miyake, H.; Ishikawa, Y.; Furusawa, K.; Hiramatsu, K. Spatio-time-resolved cathodoluminescence study on high AlN mole fraction AlxGa1−xN structures grown by metalorganic vapor phase epitaxy. Appl. Phys. Lett. 2015, 107, 121602. [Google Scholar] [CrossRef]

- Wang, L.; Li, R.; Li, D.; Liu, N.; Liu, L.; Chen, W.; Wang, C.; Yang, Z.; Hu, X. Strain modulation-enhanced Mg acceptor activation efficiency of Al0.14Ga0.86N/GaN superlattices with AlN interlayer. Appl. Phys. Lett 2010, 96, 061110. [Google Scholar] [CrossRef]

- Fujioka, A.; Misaki, T.; Murayama, T.; Narukawa, Y.; Mukai, T. Improved Efficiency of 255–280 nm AlGaN-Based Light-Emitting Diodes. Appl. Phys. Express 2010, 3, 061004. [Google Scholar] [CrossRef]

- Susilo, N.; Hagedorn, S.; Jaeger, D.; Miyake, H.; Zeimer, U.; Reich, C.; Neuschulz, B.; Sulmoni, L.; Guttmann, M.; Mehnke, F.; et al. AlGaN-based deep UV LEDs grown on sputtered and high temperature annealed AlN/sapphire. Appl. Phys. Lett. 2018, 112, 041110. [Google Scholar] [CrossRef]

- Koukitu, A.; Seki, H. unstable region of solid composition in ternary nitride alloys grown by metalorganic vapor-phase epitaxy. Jpn. J. Appl. Phys. 1996, 35, L1638–L1640. [Google Scholar] [CrossRef]

- Lu, D.C.; Duan, S. Quasi-thermodynamic analysis of MOVPE of AlGaN. J. Cryst. Growth 2000, 208, 73–78. [Google Scholar] [CrossRef]

- Xi, Y.A.; Chen, K.X.; Mont, F.W.; Kim, J.K.; Lee, W.; Schubert, E.F.; Liu, W.; Li, X.; Smart, J.A. Kinetic study of Al-mole fraction in AlxGa1−xN/AlxGa1−xN grown on c-plane sapphire and AlN bulk substrates by metal-organic vapor-phase epitaxy. Appl. Phys. Lett 2007, 90, 051104. [Google Scholar] [CrossRef]

- Lobanova, A.V.; Mazaev, K.M.; Talalaev, R.A.; Leys, M.; Boeykens, S.; Cheng, K.; Degroote, S. Effect of V/III ratio in AlN and AlGaN MOVPE. J. Cryst. Growth 2006, 287, 601–604. [Google Scholar] [CrossRef]

- Zúñiga-Pérez, J.; Consonni, V.; Lymperakis, L.; Kong, X.; Trampert, A.; Fernández-Garrido, S.; Brandt, O.; Renevier, H.; Keller, S.; Hestroffer, K.; et al. Polarity in GaN and ZnO: Theory, measurement, growth, and devices. Appl. Phys. Rev. 2016, 3, 041303. [Google Scholar] [CrossRef]

- Himmerlich, M.; Lymperakis, L.; Gutt, R.; Lorenz, P.; Neugebauer, J.; Krischok, S. GaN(0001) surface states: Experimental and theoretical fingerprints to identify surface reconstructions. Phys. Rev. B 2013, 88, 125304. [Google Scholar] [CrossRef]

- Zhou, X.W.; Murdick, D.A.; Gillespie, B.; Wadley, H.N.G. Atomic assembly during GaN film growth: Molecular dynamics simulations. Phys. Rev. B 2006, 73, 045337. [Google Scholar] [CrossRef]

- Leathersich, J.; Suvarna, P.; Tungare, M.; Shahedipour-Sandvik, F.S. Homoepitaxial growth of non-polar AlN crystals using molecular dynamics simulations. Surf. Sci. 2013, 617, 36–41. [Google Scholar] [CrossRef]

- Gruber, J.; Zhou, X.W.; Jones, R.E.; Lee, S.R.; Tucker, G.J. Molecular dynamics studies of defect formation during heteroepitaxial growth of InGaN alloys on (0001) GaN surfaces. J. Appl. Phys. 2017, 121, 195301. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chu, K.; Gruber, J.; Zhou, X.W.; Jones, R.E.; Lee, S.R.; Tucker, G.J. Molecular dynamics studies of InGaN growth on nonpolar (1120) GaN surfaces. Phys. Rev. Mater. 2018, 2, 013402. [Google Scholar] [CrossRef]

- Bryan, I.; Bryan, Z.; Washiyama, S.; Reddy, P.; Gaddy, B.; Sarkar, B.; Breckenridge, M.H.; Guo, Q.; Bobea, M.; Tweedie, J.; et al. Doping and compensation in Al-rich AlGaN grown on single crystal AlN and sapphire by MOCVD. Appl. Phys. Lett. 2018, 112, 062102. [Google Scholar] [CrossRef] [Green Version]

- Luo, W.; Li, L.; Li, Z.; Yang, Q.; Zhang, D.; Dong, X.; Peng, D.; Pan, L.; Li, C.; Liu, B.; et al. Influence of the nucleation layer morphology on the structural property of AlN films grown on c-plane sapphire by MOCVD. J. Alloys Compd. 2017, 697, 262–267. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.W.; Jones, R.E.; Kimmer, C.J.; Duda, J.C.; Hopkins, P.E. Relationship of thermal boundary conductance to structure from an analytical model plus molecular dynamics simulations. Phys. Rev. B 2013, 87, 094303. [Google Scholar] [CrossRef]

- Zhou, X.W.; Jones, R.E.; Duda, J.C.; Hopkins, P.E. Molecular dynamics studies of material property effects on thermal boundary conductance. Phys. Chem. Chem. Phys. 2013, 15, 11078–11087. [Google Scholar] [CrossRef] [PubMed]

- Nord, J.; Albe, K.; Erhart, P.; Nordlund, K. Modelling of compound semiconductors: Analytical bond-order potential for gallium, nitrogen and gallium nitride. J. Phys. Condens. Matter 2003, 15, 5649–5662. [Google Scholar]

- Béré, A.; Serra, A. On the atomic structures, mobility and interactions of extended defects in GaN: Dislocations, tilt and twin boundaries. Philos. Mag. 2006, 86, 2159–2192. [Google Scholar] [CrossRef]

- Zhou, X.W.; Foster, M.E.; Jones, R.; Yang, P.; Fan, H.; Doty, F.P. a modified Stillinger-Weber potential for TlBr, and its polymorphic extension. J. Mater. Sci. Res. 2015, 4, 15. [Google Scholar] [CrossRef]

- Tungare, M.; Shi, Y.; Tripathi, N.; Suvarna, P.; Shahedipour-Sandvik, F.S. A Tersoff-based interatomic potential for wurtzite AlN. Phys. Status Solidi A 2011, 208, 1569–1572. [Google Scholar] [CrossRef]

- Vashishta, P.; Kalia, R.K.; Nakano, A.; Rino, J.P. Interaction potential for aluminum nitride: A molecular dynamics study of mechanical and thermal properties of crystalline and amorphous aluminum nitride. J. Appl. Phys. 2011, 109, 033514. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—The Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2009, 18, 015012. [Google Scholar] [CrossRef]

- Maras, E.; Trushin, O.; Stukowski, A.; Ala-Nissila, T.; Jónsson, H. Global transition path search for dislocation formation in Ge on Si (001). Comput. Phys. Commun. 2016, 205, 13–21. [Google Scholar] [CrossRef]

- Ruffenach-Clur, S.; Briot, O.; Rouvière, J.; Gil, B.; Aulombard, R. MOVPE growth and characterization of AlxGa1−xN. Mater. Sci. Eng. B 1997, 50, 219–222. [Google Scholar] [CrossRef]

- Makaram, P.; Joh, J.; del Alamo, J.A.; Palacios, T.; Thompson, C.V. Evolution of structural defects associated with electrical degradation in AlGaN/GaN high electron mobility transistors. Appl. Phys. Lett. 2010, 96, 233509. [Google Scholar] [CrossRef]

- Neugebauer, J. Ab initio Analysis of Surface Structure and Adatom Kinetics of Group-III Nitrides. Phys. Status Solidi B 2001, 227, 93–114. [Google Scholar] [CrossRef]

- Keller, S.; DenBaars, S.P. Metalorganic chemical vapor deposition of group III nitrides—A discussion of critical issues. J. Cryst. Growth 2003, 248, 479–486. [Google Scholar] [CrossRef]

- Serrano, J.; Rubio, A.; Hernández, E.; Muñoz, A.; Mujica, A. Theoretical study of the relative stability of structural phases in group-III nitrides at high pressures. Phys. Rev. B 2000, 62, 16612–16623. [Google Scholar] [CrossRef]

- Siegel, A.; Parlinski, K.; Wdowik, U.D. Ab initio calculation of structural phase transitions in AlN crystal. Phys. Rev. B 2006, 74, 104116. [Google Scholar] [CrossRef]

- Ponce, F.A.; Bour, D.P.; Young, W.T.; Saunders, M.; Steeds, J.W. Determination of lattice polarity for growth of GaN bulk single crystals and epitaxial layers. Appl. Phys. Lett. 1996, 69, 337–339. [Google Scholar] [CrossRef]

- Rouviere, J.L.; Arlery, M.; Niebuhr, R.; Bachem, K.H.; Briot, O. Correlation between surface morphologies and crystallographic structures of GaN layers grown by MOCVD on sapphire. MRS Internet J. Nitride Semicond. Res. 1996, 1, 33. [Google Scholar] [CrossRef]

- Sumiya, M.; Yoshimura, K.; Ito, T.; Ohtsuka, K.; Fuke, S.; Mizuno, K.; Yoshimoto, M.; Koinuma, H.; Ohtomo, A.; Kawasaki, M. Growth mode and surface morphology of a GaN film deposited along the N-face polar direction on c-plane sapphire substrate. J. Appl. Phys. 2000, 88, 1158–1165. [Google Scholar] [CrossRef]

- Stutzmann, M.; Ambacher, O.; Eickhoff, M.; Karrer, U.; Pimenta, A.L.; Neuberger, R.; Schalwig, J.; Dimitrov, R.; Schuck, P.J.; Grober, R.D. Playing with Polarity. Phys. Status Solidi B 2001, 228, 505–512. [Google Scholar] [CrossRef]

| Parameter | GaGa | NN | AlAl | GaN | GaAl | NAl |

|---|---|---|---|---|---|---|

| ε (eV) | 1.2000 | 1.2000 | 0.5650 | 2.1700 | 0.5223 | 2.2614 |

| σ (Å) | 2.1000 | 1.3000 | 2.6674 | 1.6950 | 2.7322 | 1.7103 |

| α | 1.60 | 1.80 | 1.55 | 1.80 | 1.55 | 1.80 |

| λ | 32.5 | 32.5 | 0.0 | 32.5 | 0.0 | 40.5 |

| γ | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| A | 7.9170 | 7.9170 | 17.8118 | 7.9170 | 17.8118 | 7.917 |

| B | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Yan, H.; Zhu, G.; Liu, S.; Gan, Z.; Zhang, Z. Effect of Substrate Surface on Deposition of AlGaN: A Molecular Dynamics Simulation. Crystals 2018, 8, 279. https://doi.org/10.3390/cryst8070279

Zhang L, Yan H, Zhu G, Liu S, Gan Z, Zhang Z. Effect of Substrate Surface on Deposition of AlGaN: A Molecular Dynamics Simulation. Crystals. 2018; 8(7):279. https://doi.org/10.3390/cryst8070279

Chicago/Turabian StyleZhang, Libin, Han Yan, Guo Zhu, Sheng Liu, Zhiyin Gan, and Zili Zhang. 2018. "Effect of Substrate Surface on Deposition of AlGaN: A Molecular Dynamics Simulation" Crystals 8, no. 7: 279. https://doi.org/10.3390/cryst8070279