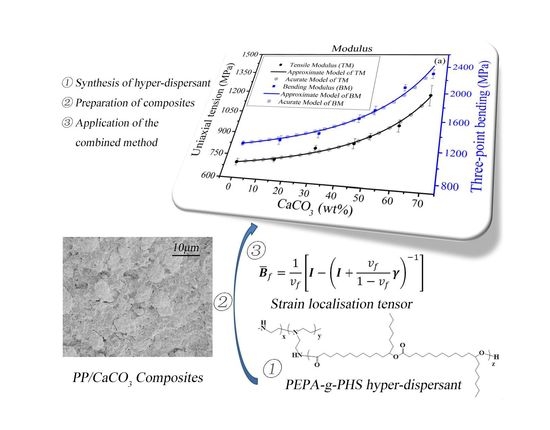

A Combined Self-Consistent Method to Estimate the Effective Properties of Polypropylene/Calcium Carbonate Composites

Abstract

:1. Introduction

2. Combined Self-Consistent Method

3. Discussion of the Combined Self-Consistent Method

3.1. Solutions of the Combined Equation

3.1.1. The Anisotropic Case

3.1.2. The Isotropic Case

3.2. Verifications of These Solutions

3.2.1. Comparison with the Mori-Tanaka Method

3.2.2. Comparison with the SP Model

4. Applications in Experiments

4.1. Experiments

4.1.1. Synthesis of Polyethylene Polyamine Hyper-Dispersant: Polyethylene Polyamine Grafted Poly(12-Hydroxy Stearate) (PEPA-g-PHS)

4.1.2. Preparation of the PP/CaCO3 Composites

4.1.3. Test Procedure and Characterization of PP/CaCO3 Composites

4.2. Applications of the Combined Self-Consistent Method

4.2.1. The Variation Tendency of Moduli

4.2.2. The Variation Tendency of Yield Strength

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Ingredients | PEPA | PHS | PEPA-g-PHS |

|---|---|---|---|

| Time (s) | 75.3 | 628.7 | 4471.5 |

Appendix B

Appendix C

References

- Jones, F.R. A review of interphase formation and design in fibre-reinforced composites. J. Adhes. Sci. Technol. 2010, 24, 171–202. [Google Scholar] [CrossRef]

- Awad, Z.K.; Aravinthan, T.; Yan, Z.G.; Gonzalez, F. A review of optimization techniques used in the design of fibre composite structures for civil engineering applications. Mater. Des. 2012, 33, 534–544. [Google Scholar] [CrossRef] [Green Version]

- Thoniyot, P.; Tan, M.J.; Karim, A.A.; Young, D.J.; Loh, X.J. Nanoparticle-hydrogel composites: Concept, design, and applications of these promising, multi-functional materials. Adv. Sci. 2015, 2, 13. [Google Scholar] [CrossRef] [PubMed]

- Nascimento, E.M.D.; Eiras, D.; Pessan, L.A. Effect of thermal treatment on impact resistance and mechanical properties of polypropylene/calcium carbonate nanocomposites. Compos. B 2016, 91, 228–234. [Google Scholar] [CrossRef]

- Thio, Y.S.; Argon, A.S.; Cohen, R.E. Role of interfacial adhesion strength on toughening polypropylene with rigid particles. Polymer 2004, 45, 3139–3147. [Google Scholar] [CrossRef]

- Zare, Y.; Garmabi, H. A developed model to assume the interphase properties in a ternary polymer nanocomposite reinforced with two nanofillers. Compos. B 2015, 75, 29–35. [Google Scholar] [CrossRef]

- Iyer, K.A.; Torkelson, J.M. Green composites of polypropylene and eggshell: Effective biofiller size reduction and dispersion by single-step processing with solid-state shear pulverization. Compos. Sci. Technol. 2014, 102, 152–160. [Google Scholar] [CrossRef]

- Xu, J.; Mittal, V.; Bates, F.S. Toughened isotactic polypropylene: Phase behavior and mechanical properties of blends with strategically designed random copolymer modifiers. Macromolecules 2016, 49, 6497–6506. [Google Scholar] [CrossRef]

- Chen, S.; Wang, X.; Ma, X.; Wang, K. Morphology and properties of polypropylene/nano-CaCO3 composites prepared by supercritical carbon dioxide-assisted extrusion. J. Mater. Sci. 2016, 51, 708–718. [Google Scholar] [CrossRef]

- Hassinger, I.; Li, X.L.; Zhao, H.; Xu, H.Y.; Huang, Y.H.; Prasad, A.; Schadler, L.; Chen, W.; Brinson, L.C. Toward the development of a quantitative tool for predicting dispersion of nanocomposites under non-equilibrium processing conditions. J. Mater. Sci. 2016, 51, 4238–4249. [Google Scholar] [CrossRef]

- Liang, J.Z. Toughening and reinforcing in rigid inorganic particulate filled poly(propylene): A review. J. Appl. Polym. Sci. 2002, 83, 1547–1555. [Google Scholar] [CrossRef]

- Thio, Y.S.; Argon, A.S.; Cohen, R.E.; Weinberg, M. Toughening of isotactic polypropylene with CaCO3 particles. Polymer 2002, 43, 3661–3674. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, H.; Chan, C.M.; Wu, J. The toughening mechanism of polypropylene/calcium carbonate nanocomposites. Polymer 2010, 51, 3277–3284. [Google Scholar] [CrossRef]

- Helbig, M.; van der Giessen, E.; Clausen, A.H.; Seelig, T. Continuum-micromechanical modeling of distributed crazing in rubber-toughened polymers. Eur. J. Mech. A Solids 2016, 57, 108–120. [Google Scholar] [CrossRef]

- Zuiderduin, W.C.J.; Westzaan, C.; Huétink, J.; Gaymans, R.J. Toughening of polypropylene with calcium carbonate particles. Polymer 2003, 44, 261–275. [Google Scholar] [CrossRef]

- Dasari, A.; Zhang, Q.X.; Yu, Z.Z.; Mai, Y.W. Toughening polypropylene and its nanocomposites with submicrometer voids. Macromolecules 2010, 43, 5734–5739. [Google Scholar] [CrossRef]

- Zhu, Y.D.; Allen, G.C.; Jones, P.G.; Adams, J.M.; Gittins, D.I.; Heard, P.J.; Skuse, D.R. Dispersion characterisation of CaCO3 particles in PP/CaCO3 composites. Compos. A 2014, 60, 38–43. [Google Scholar] [CrossRef]

- Pérez, E.; Bernal, C.; Piacquadio, M. Multifractal analysis of tensile toughness and filler dispersion for polypropylene-CaCO3 composites. Appl. Surf. Sci. 2012, 258, 8940–8945. [Google Scholar] [CrossRef]

- Liang, J.Z. Evaluation of dispersion of nano-CaCO3 particles in polypropylene matrix based on fractal method. Compos. A 2007, 38, 1502–1506. [Google Scholar] [CrossRef]

- Li, L.X.; Wang, T.J. A unified approach to predict overall properties of composite materials. Mater. Charact. 2005, 54, 49–62. [Google Scholar] [CrossRef]

- Akbarzadeh, A.H.; Abedini, A.; Chen, Z.T. Effect of micromechanical models on structural responses of functionally graded plates. Compos. Struct. 2015, 119, 598–609. [Google Scholar] [CrossRef]

- Bonfoh, N.; Hounkpati, V.; Sabar, H. New micromechanical approach of the coated inclusion problem: Exact solution and applications. Comp. Mater. Sci. 2012, 62, 175–183. [Google Scholar] [CrossRef]

- Norris, A.N. A differential scheme for the effective moduli of composites. Mech. Mater. 1985, 4, 1–16. [Google Scholar] [CrossRef]

- Rao, W.; Zhang, J.; Jiang, H.; Kang, G. Meso-mechanical constitutive model of bulk metallic glass matrix composites. Mech. Mater. 2016, 103, 68–77. [Google Scholar] [CrossRef]

- Wang, K.; Bahlouli, N.; Addiego, F.; Ahzi, S. Elastic and yield behaviors of recycled polypropylene-based composites: Experimental and modeling study. Compos. Part B Eng. 2016, 99, 132–153. [Google Scholar] [CrossRef]

- Buck, F.; Brylka, B.; Müller, V.; Müller, T.; Weidenmann, K.A.; Hrymak, A.N.; Henning, F.; Böhlke, T. Two-scale structural mechanical modeling of long fiber reinforced thermoplastics. Compos. Sci. Technol. 2015, 117, 159–167. [Google Scholar] [CrossRef]

- Pan, J.; Bian, L.; Zhao, H.; Zhao, Y. A new micromechanics model and effective elastic modulus of nanotube reinforced composites. Comp. Mater. Sci. 2016, 113, 21–26. [Google Scholar] [CrossRef]

- Hoang-Duc, H.; Bonnet, G.; Meftah, F. Generalized self-consistent scheme for the effective behavior of viscoelastic heterogeneous media: A simple approximate solution. Eur. J. Mech. A 2013, 39, 35–49. [Google Scholar] [CrossRef]

- Xu, W.; Ma, H.; Ji, S.; Chen, H. Analytical effective elastic properties of particulate composites with soft interfaces around anisotropic particles. Compos. Sci. Technol. 2016, 129, 10–18. [Google Scholar] [CrossRef]

- Seidel, G.; Lagoudas, D. A micromechanics model for the electrical conductivity of nanotube-polymer nanocomposites. J. Compos. Mater. 2009, 43, 917–941. [Google Scholar] [CrossRef]

- Feng, C.; Wang, Y.; Kitipornchai, S.; Yang, J. Effects of reorientation of graphene platelets (GPLs) on young’s modulus of polymer nanocomposites under uni-axial stretching. Polymers 2017, 9, 532. [Google Scholar] [CrossRef]

- Feng, C.; Jiang, L.Y. Investigation of uniaxial stretching effects on the electrical conductivity of CNT-polymer nanocomposites. J. Phys. D 2014, 47, 405103. [Google Scholar] [CrossRef]

- Ji, X.Y.; Cao, Y.P.; Feng, X.Q. Micromechanics prediction of the effective elastic moduli of graphene sheet-reinforced polymer nanocomposites. Model. Simul. Mater. Sci. Eng. 2010, 18, 045005. [Google Scholar] [CrossRef]

- Kube, C.M.; Arguelles, A.P. Bounds and self-consistent estimates of the elastic constants of polycrystals. Comput. Geosci. 2016, 95, 118–122. [Google Scholar] [CrossRef]

- Nakamura, T.; Wang, T.; Sampath, S. Determination of properties of graded materials by inverse analysis and instrumented indentation. Acta Mater. 2000, 48, 4293–4306. [Google Scholar] [CrossRef]

- Brown, J.M. Determination of hashin-shtrikman bounds on the isotropic effective elastic moduli of polycrystals of any symmetry. Comput. Geosci. 2015, 80, 95–99. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. Development of Hashin-Shtrikman model to determine the roles and properties of interphases in clay/CaCO3/PP ternary nanocomposite. Appl. Clay Sci. 2017, 137, 176–182. [Google Scholar] [CrossRef]

- Tan, J.F.; Jia, Y.J.; Li, L.X. A series-parallel mixture model to predict the overall property of particle reinforced composites. Compos. Struct. 2016, 150, 219–225. [Google Scholar] [CrossRef]

- Kretsis, G. A review of the tensile, compressive, flexural and shear properties of hybrid fibre-reinforced plastics. Composites 1987, 18, 13–23. [Google Scholar] [CrossRef]

- Swolfs, Y.; Verpoest, I.; Gorbatikh, L. Maximising the hybrid effect in unidirectional hybrid composites. Mater. Des. 2015, 93, 39–45. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Tandon, G.P.; Weng, G.J. Elastic moduli for a class of porous materials. Acta Mech. 1989, 76, 105–131. [Google Scholar] [CrossRef]

- Xiong, Z.; Li, Y.; Pan, L.; Yu, J.; Lu, S. An analytical study of mechanical behavior of polypropylene/calcium carbonate composites under uniaxial tension and three-point bending. Compos. Struct. 2017, 171, 370–381. [Google Scholar] [CrossRef]

- Alian, A.R.; El-Borgi, S.; Meguid, S.A. Multiscale modeling of the effect of waviness and agglomeration of cnts on the elastic properties of nanocomposites. Comput. Mater. Sci. 2016, 117, 195–204. [Google Scholar] [CrossRef]

| Parameters | Approximate Model | Accurate Model | |||

|---|---|---|---|---|---|

| Adj. R2 | Adj. R2 | ||||

| Tension | 0.0057 | 0.9768 | 0.0069 | 0.0073 | 0.9886 |

| Bending | 0.0149 | 0.9815 | 0.1408 | 0.0170 | 0.9748 |

| Parameters | (MPa) | Adj. R2 |

|---|---|---|

| Tension | 24.7957 | 0.9881 |

| Bending | 31.4176 | 0.9787 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, Z.; Lu, S.; Liu, J.; Lv, G.; Li, Y.; Yu, J. A Combined Self-Consistent Method to Estimate the Effective Properties of Polypropylene/Calcium Carbonate Composites. Polymers 2018, 10, 101. https://doi.org/10.3390/polym10010101

Xiong Z, Lu S, Liu J, Lv G, Li Y, Yu J. A Combined Self-Consistent Method to Estimate the Effective Properties of Polypropylene/Calcium Carbonate Composites. Polymers. 2018; 10(1):101. https://doi.org/10.3390/polym10010101

Chicago/Turabian StyleXiong, Zhongqiang, Shaorong Lu, Junkun Liu, Guangsheng Lv, Yuqi Li, and Jinhong Yu. 2018. "A Combined Self-Consistent Method to Estimate the Effective Properties of Polypropylene/Calcium Carbonate Composites" Polymers 10, no. 1: 101. https://doi.org/10.3390/polym10010101