Transparent Low Electrostatic Charge Films Based on Carbon Nanotubes and Polypropylene. Homopolymer Cast Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.3. Characterization Techniques

2.4. Electrical Surface Resistivity

2.5. Electrostatic Charge

2.6. Optical Properties

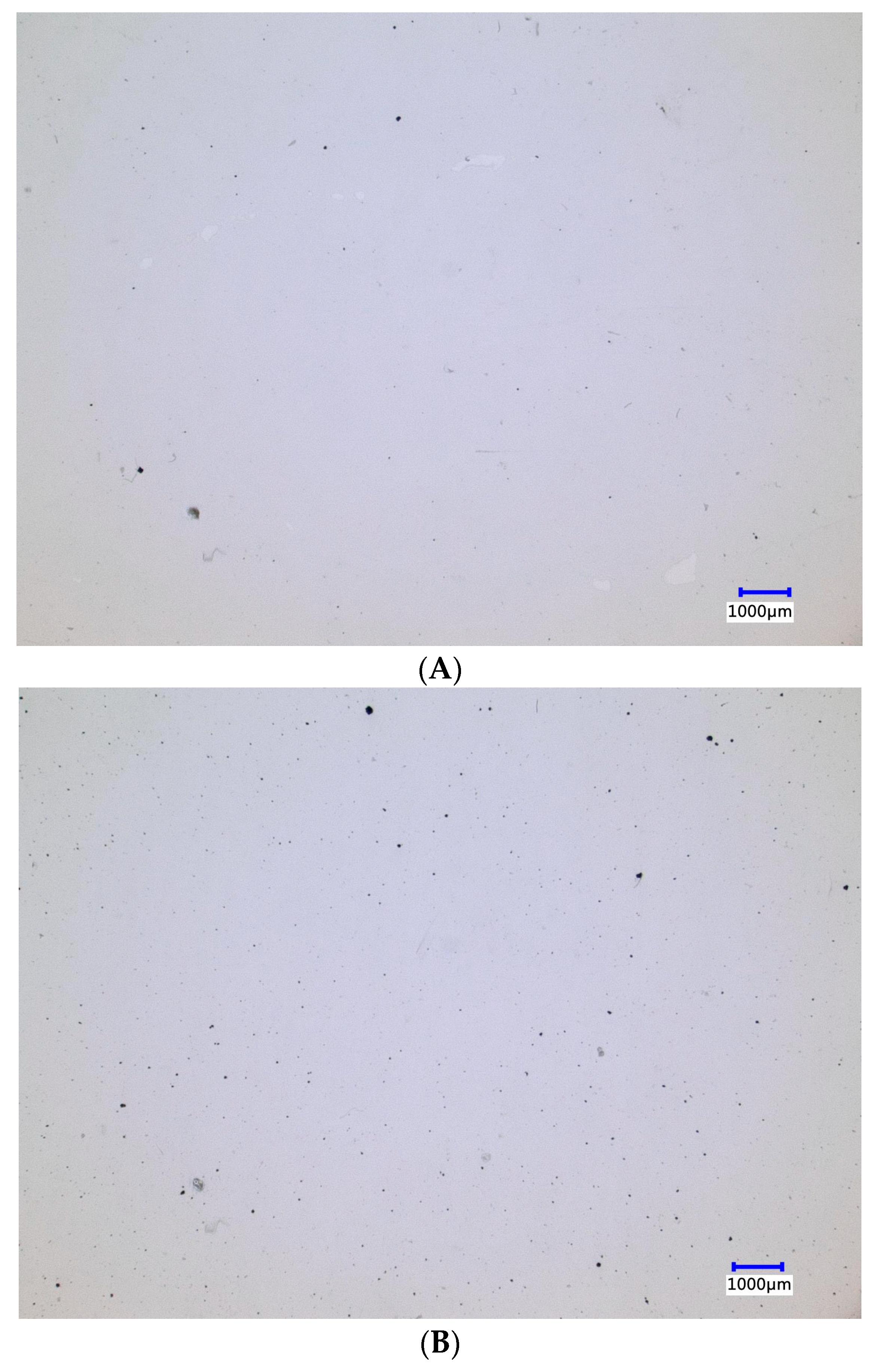

2.7. Optical Microscopy (OM)

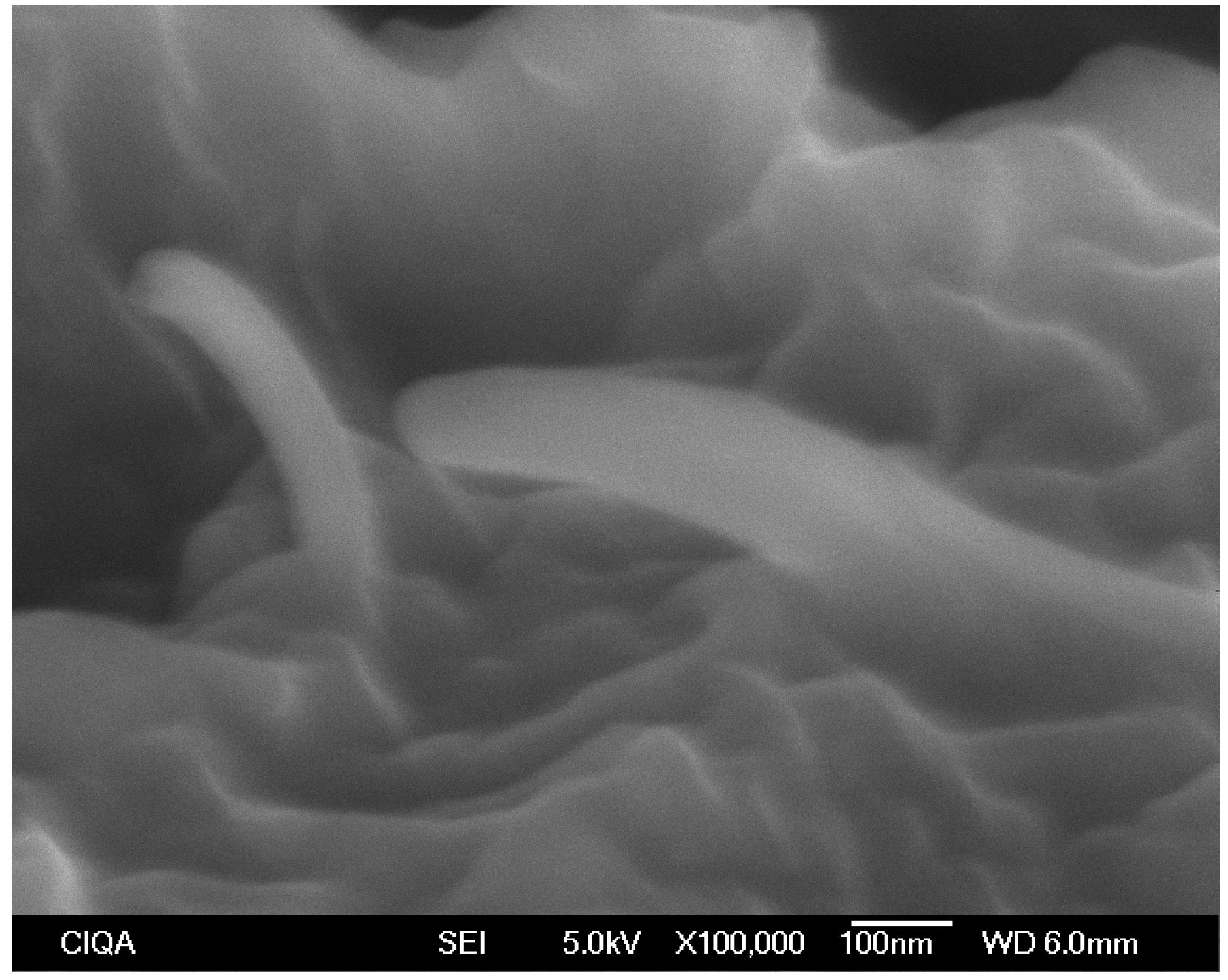

2.8. Transmission Electron Microscopy (TEM)

2.9. Scanning Electron Microscopy (SEM)

3. Results

3.1. Electrical Properties

3.1.1. Surface Resistivity

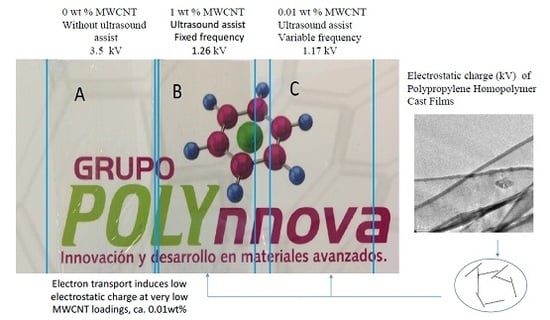

3.1.2. Electrostatic Charge

3.2. Optical Properties

3.2.1. Color Coordinates L*, a*, b*

3.2.2. Haze and Gloss

4. Discussion

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Swogger, K.W.; Poon, B.; Stephens, C.H.; Ansems, P.; Chum, S.; Hiltner, A.; Baer, E. Material classification and applications of new propylene-ethylene copolymers. In Proceedings of the ANTEC 2003: Annual Technical Conference, Nashville, TN, USA, 4–8 May 2003; pp. 1768–1774. [Google Scholar]

- Chow, W.S.; Tham, W.L. Effects of antistatic agent on the mechanical, morphological and antistatic properties of polypropylene/organo-montmorillonite nanocomposites. Express Polym. Lett. 2009, 3, 116–125. [Google Scholar] [CrossRef]

- Li, C.; Liang, T.; Lu, W.; Tang, C.; Hu, X.; Cao, M.; Liang, J. Improving the antistatic ability of polypropylene fibers by inner antistatic agent filled with carbon nanotubes. Compos. Sci. Technol. 2004, 64, 2089–2096. [Google Scholar] [CrossRef]

- Valdez-Garza, J.; Avila-Orta, C.; Cruz-Delgado, V.; Gonzalez-Morones, P.; Hurtado-Lopez, G.; Waldo-Mendoza, M.; Quinones-Jurado, Z.; Perez-Medina, J. Antistatic films based on polymer nanocomposites. Boletín del Grupo Español del Carbón 2017, 44, 8–9. [Google Scholar]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Dürkop, T.; Getty, S.A.; Cobas, E.; Fuhrer, M.S. Extraordinary mobility in semiconducting carbon nanotubes. Nano Lett. 2004, 4, 35–39. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Seo, M.K.; Park, S.J. Electrical resistivity and rheological behaviors of carbon nanotubes-filled polypropylene composites. Chem. Phys. Lett. 2004, 395, 44–48. [Google Scholar] [CrossRef]

- McLachlan, D.S.; Chiteme, C.; Park, C.; Wise, K.E.; Lowther, S.E.; Lillehei, P.T.; Siochi, E.J.; Harrison, J.S. Ac and dc percolative conductivity of single wall carbon nanotube polymer composites. J. Polym. Sci. B 2005, 43, 3273–3287. [Google Scholar] [CrossRef]

- Bauhofer, W.; Kovacs, J.Z. A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos. Sci. Technol. 2009, 69, 1486–1498. [Google Scholar] [CrossRef]

- Shen, J.B.; Champagne, M.F.; Yang, Z.; Yu, Q.; Gendron, R.; Guo, S.Y. The development of a conductive carbon nanotube (CNT) network in CNT/polypropylene composite films during biaxial stretching. Compos. A Appl. Sci. Manuf. 2012, 43, 1448–1453. [Google Scholar] [CrossRef]

- You, F.; Li, X.; Zhang, L.; Wang, D.; Shi, C.; Dang, Z. Polypropylene/poly(methyl methacrylate)/graphene composites with high electrical resistivity anisotropy via sequential biaxial stretching. RSC Adv. 2017, 7, 6170–6178. [Google Scholar] [CrossRef]

- Shen, J.B.; Champagne, M.F.; Gendron, R.; Guo, S.Y. The development of conductive carbon nanotube network in polypropylene-based composites during simultaneous biaxial stretching. Eur. Polym. J. 2012, 48, 930–939. [Google Scholar] [CrossRef]

- Ávila-Orta, C.A.; Quiñones-Jurado, Z.V.; Waldo-Mendoza, M.A.; Rivera-Paz, E.A.; Cruz-Delgado, V.C.J.; Mata-Padilla, J.M.; González-Morones, P.; Ziolo, R.F. Ultrasound-assist extrusion methods for the fabrication of polymer nanocomposites based on polypropylene/multi-wall carbon nanotubes. Materials 2015, 8, 7900–7912. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Medina, J.C.; Waldo-Mendoza, M.A.; Cruz-Delgado, V.J.; Quiñones-Jurado, Z.V.; González-Morones, P.; Ziolo, R.F.; Martínez-Colunga, J.G.; Soriano-Corral, F.; Avila-Orta, C.A. Metamaterial behavior of polymer nanocomposites based on polypropylene/multi-walled carbon nanotubes fabricated by means of ultrasound-assisted extrusion. Materials 2016, 9, 923. [Google Scholar] [CrossRef] [PubMed]

- Mc Laren, K. The Colour Science of Dyes and Pigments; Adam Hilger Ltd.: Bristol, UK, 1986. [Google Scholar]

- Judd, D.B.; Wyszecki, G. Colour in Bussines, Science and Industry; John Wiley & Sons: New York, NY, USA, 1975. [Google Scholar]

- Gong, S.; Zhu, Z.H.; Li, Z. Electron tunnelling and hopping effects on the temperature coefficient of resistance of carbon nanotube/polymer nanocomposites. Phys. Chem. Chem. Phys. 2017, 19, 5113–5120. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Azumi, R. Carbon nanotube based transparent conductive films: Progress, challenges, and perspectives. Sci. Technol. Adv. Mater. 2016, 17, 493–516. [Google Scholar] [CrossRef] [PubMed]

- Ventura, I.A.; Zhou, J.; Lubineau, G. Investigating the inter-tube conduction mechanism in polycarbonate nanocomposites prepared with conductive polymer-coated carbon nanotubes. Nanoscale Res. Lett. 2015, 10, 485. [Google Scholar] [CrossRef] [PubMed]

- Wąsik, M.; Judek, J.; Zdrojek, M. Polarization-dependent optical reflection from vertically aligned multiwalled carbon nanotube arrays. Carbon 2013, 64, 550–552. [Google Scholar] [CrossRef]

- Valentini, L.; Biagiotti, J.; Kenny, J.M.; Santucci, S. Morphological characterization of single-walled carbon nanotubes-pp composites. Compos. Sci. Technol. 2003, 63, 1149–1153. [Google Scholar] [CrossRef]

| Code | MFI (g/10 min) | Provider | Grade |

|---|---|---|---|

| iPPMFI=2.5 | 2.5 | Exxon (Houston, TX, USA) | PP4712 |

| iPPMFI=34 | 34 | Indelpro (Altamira, Mexico) | PL835N |

| iPPMFI=1200 | 1200 | Indelpro (Altamira, Mexico) | Profax PL 505 |

| wt % MWCNT in A-Layers | iPPMFI=2.5 | iPPMFI=34 | iPPMFI=1200 |

|---|---|---|---|

| W-U | |||

| 0.01 | 4.2 × 1014 | 8.6 × 1014 | 2.5 × 1015 |

| 0.10 | 1.1 × 1015 | 1.0 × 1015 | 4.0 × 1016 |

| 1.00 | 8.3 × 1013 | 2.6 × 1012 | 3.6 × 1016 |

| F-U | |||

| 0.01 | 3.0 × 1015 | 2.8 × 1014 | 1.6 × 1013 |

| 0.10 | 1.2 × 1016 | 6.0 × 1015 | 8.0 × 1013 |

| 1.00 | 1.2 × 1013 | 1.2 × 1014 | 1.3 × 1016 |

| V-U | |||

| 0.01 | 9.4 × 1014 | 2.2 × 1015 | 4.0 × 1014 |

| 0.10 | 5.1 × 1015 | 2.0 × 1014 | 1.4 × 1014 |

| 1.00 | 6.0 × 1014 | 5.3 × 1012 | 1.8 × 1014 |

| wt % MWCNT in A-Layers | iPPMFI=2.5 | iPPMFI=34 | iPPMFI=1200 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| F1 | F2 | F3 | F1 | F2 | F3 | F1 | F2 | F3 | |

| W-U | |||||||||

| 0.01 | 0.87 | −1.60 | 0.73 | −0.16 | −0.46 | 0.27 | −1.19 | −1.24 | 0.48 |

| 0.10 | 0.94 | −1.61 | 0.73 | 0.62 | −0.89 | −0.01 | 2.40 | −0.27 | −1.80 |

| 1.00 | 0.50 | −1.40 | −2.50 | 0.53 | −0.34 | 0.01 | 1.90 | −1.80 | 0.97 |

| F-U | |||||||||

| 0.01 | 0.22 | 0.07 | 1.60 | 0.45 | 0.77 | −1.20 | −2.40 | 0.92 | −0.69 |

| 0.10 | −0.92 | −1.50 | 0.21 | 1.38 | −2.10 | 2.60 | −0.08 | −0.51 | −3.60 |

| 1.00 | 0.92 | −4.60 | 1.22 | −0.77 | 1.26 | −0.35 | −2.30 | 0.41 | 1.25 |

| V-U | |||||||||

| 0.01 | 0.03 | −0.87 | 0.19 | 0.37 | −0.34 | 1.17 | −0.19 | −0.79 | 0.38 |

| 0.10 | −4.20 | −3.60 | 0.67 | −0.50 | −0.06 | −0.37 | −0.78 | −0.32 | 0.40 |

| 1.00 | 0.50 | −3.70 | 1.28 | −0.20 | −0.16 | 0.07 | −3.70 | 3.80 | −1.50 |

| wt % MWCNT in A-Layers | iPPMFI=2.5 | iPPMFI=34 | iPPMFI=1200 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | L* | a* | b* | |

| W-U | |||||||||

| 0.01 | 98.68 | −0.16 | −0.38 | 98.64 | −0.16 | −0.38 | 98.64 | −0.16 | −0.39 |

| 0.10 | 98.26 | −0.15 | −0.30 | 98.22 | −0.14 | −0.29 | 98.18 | −0.15 | −0.27 |

| 1.00 | 94.71 | −0.07 | 0.25 | 94.00 | −0.05 | 0.41 | 94.14 | −0.05 | 0.37 |

| F-U | |||||||||

| 0.01 | 98.68 | −0.17 | −0.38 | 98.72 | −0.17 | −0.40 | 98.68 | −0.16 | −0.41 |

| 0.10 | 98.34 | −0.16 | −0.32 | 98.13 | −0.14 | −0.27 | 98.28 | −0.14 | −0.30 |

| 1.00 | 94.34 | −0.04 | 0.29 | 93.89 | −0.04 | 0.42 | 94.45 | −0.05 | 0.34 |

| V-U | |||||||||

| 0.01 | 98.62 | −0.16 | −0.38 | 98.64 | −0.15 | −0.40 | 98.69 | −0.15 | −0.41 |

| 0.10 | 98.22 | −0.14 | −0.32 | 98.10 | −0.13 | −0.28 | 98.30 | −0.14 | −0.33 |

| 1.00 | 96.39 | −0.03 | 0.01 | 95.19 | −0.05 | 0.21 | 95.56 | −0.06 | 0.17 |

| wt % MWCNT in A-Layers | iPPMFI=2.5 | iPPMFI=34 | iPPMFI=1200 | |||

|---|---|---|---|---|---|---|

| Haze (%) | Gloss | Haze | Gloss | Haze | Gloss | |

| W-U | ||||||

| 0.01 | 2.9 | 66.2 | 3.6 | 70.2 | 3.9 | 76.3 |

| 0.10 | 3.9 | 89.1 | 3.9 | 80.9 | 4.7 | 81.6 |

| 1.00 | 5.6 | 75.7 | 7.0 | 78.4 | 8.3 | 80.3 |

| F-U | ||||||

| 0.01 | 4.9 | 78.4 | 3.9 | 76.5 | 3.8 | 77.5 |

| 0.10 | 4.9 | 77.6 | 4.8 | 73.8 | 5.1 | 73.7 |

| 1.00 | 8.6 | 94.1 | 8.7 | 83.1 | 7.6 | 80.8 |

| V-U | ||||||

| 0.01 | 5.5 | 77.5 | 4.4 | 78.6 | 4.9 | 75.8 |

| 0.10 | 4.8 | 82.8 | 4.8 | 75.4 | 4.7 | 74.7 |

| 1.00 | 4.7 | 78.1 | 6.5 | 79.2 | 5.6 | 84.3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quiñones-Jurado, Z.V.; Waldo-Mendoza, M.Á.; Mata-Padilla, J.M.; González-Morones, P.; Martínez-Colunga, J.G.; Soriano-Corral, F.; Cruz-Delgado, V.J.; Ziolo, R.F.; Avila-Orta, C.A. Transparent Low Electrostatic Charge Films Based on Carbon Nanotubes and Polypropylene. Homopolymer Cast Films. Polymers 2018, 10, 55. https://doi.org/10.3390/polym10010055

Quiñones-Jurado ZV, Waldo-Mendoza MÁ, Mata-Padilla JM, González-Morones P, Martínez-Colunga JG, Soriano-Corral F, Cruz-Delgado VJ, Ziolo RF, Avila-Orta CA. Transparent Low Electrostatic Charge Films Based on Carbon Nanotubes and Polypropylene. Homopolymer Cast Films. Polymers. 2018; 10(1):55. https://doi.org/10.3390/polym10010055

Chicago/Turabian StyleQuiñones-Jurado, Zoe Vineth, Miguel Ángel Waldo-Mendoza, José Manuel Mata-Padilla, Pablo González-Morones, Juan Guillermo Martínez-Colunga, Florentino Soriano-Corral, Víctor Javier Cruz-Delgado, Ronald Francis Ziolo, and Carlos Alberto Avila-Orta. 2018. "Transparent Low Electrostatic Charge Films Based on Carbon Nanotubes and Polypropylene. Homopolymer Cast Films" Polymers 10, no. 1: 55. https://doi.org/10.3390/polym10010055