Modeling of Structure Effect for Ferroelectric Capacitor Based on Poly(vinylidene fluoride-trifluoroethylene) Ultrathin Films

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

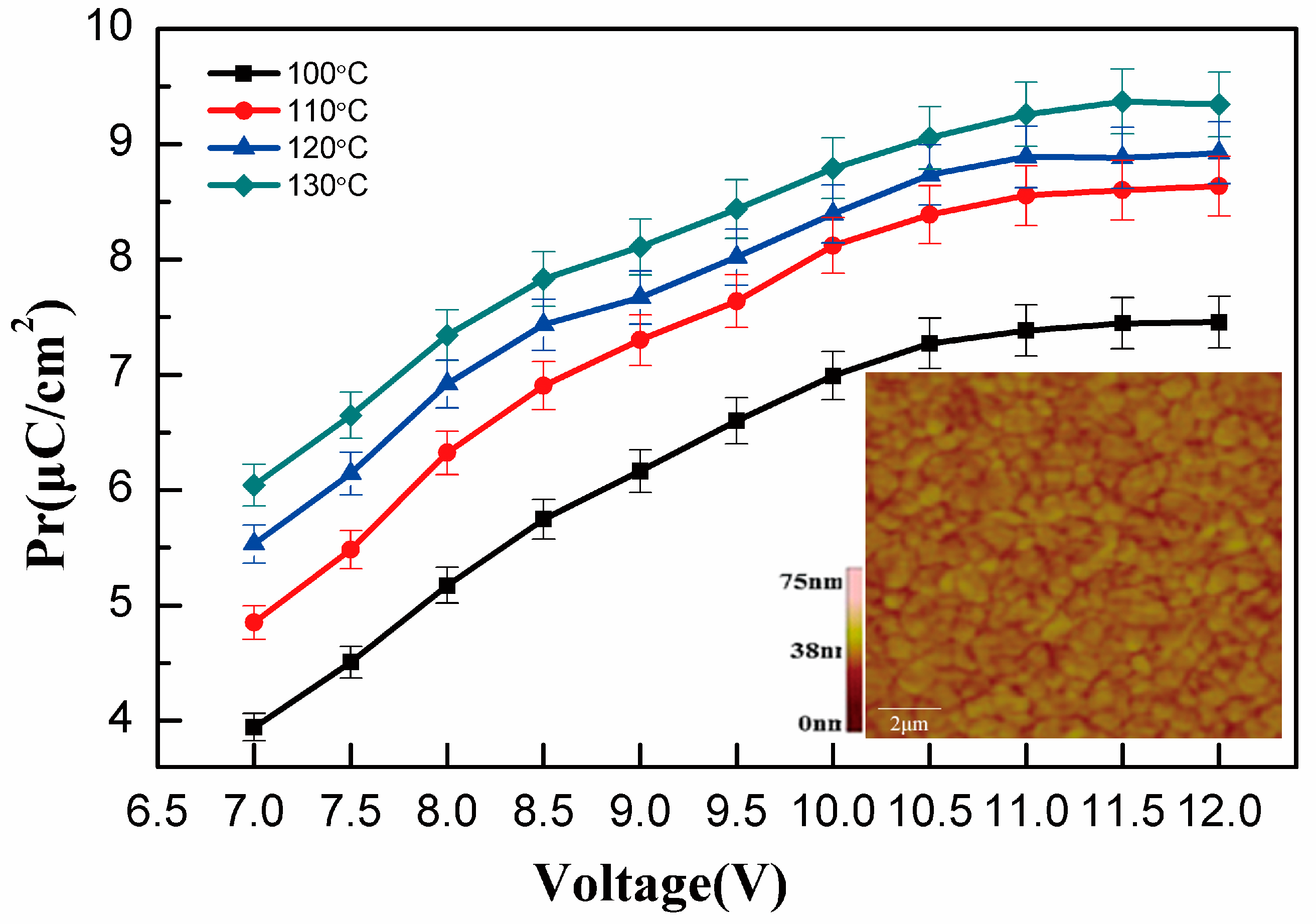

3.1. Polarization

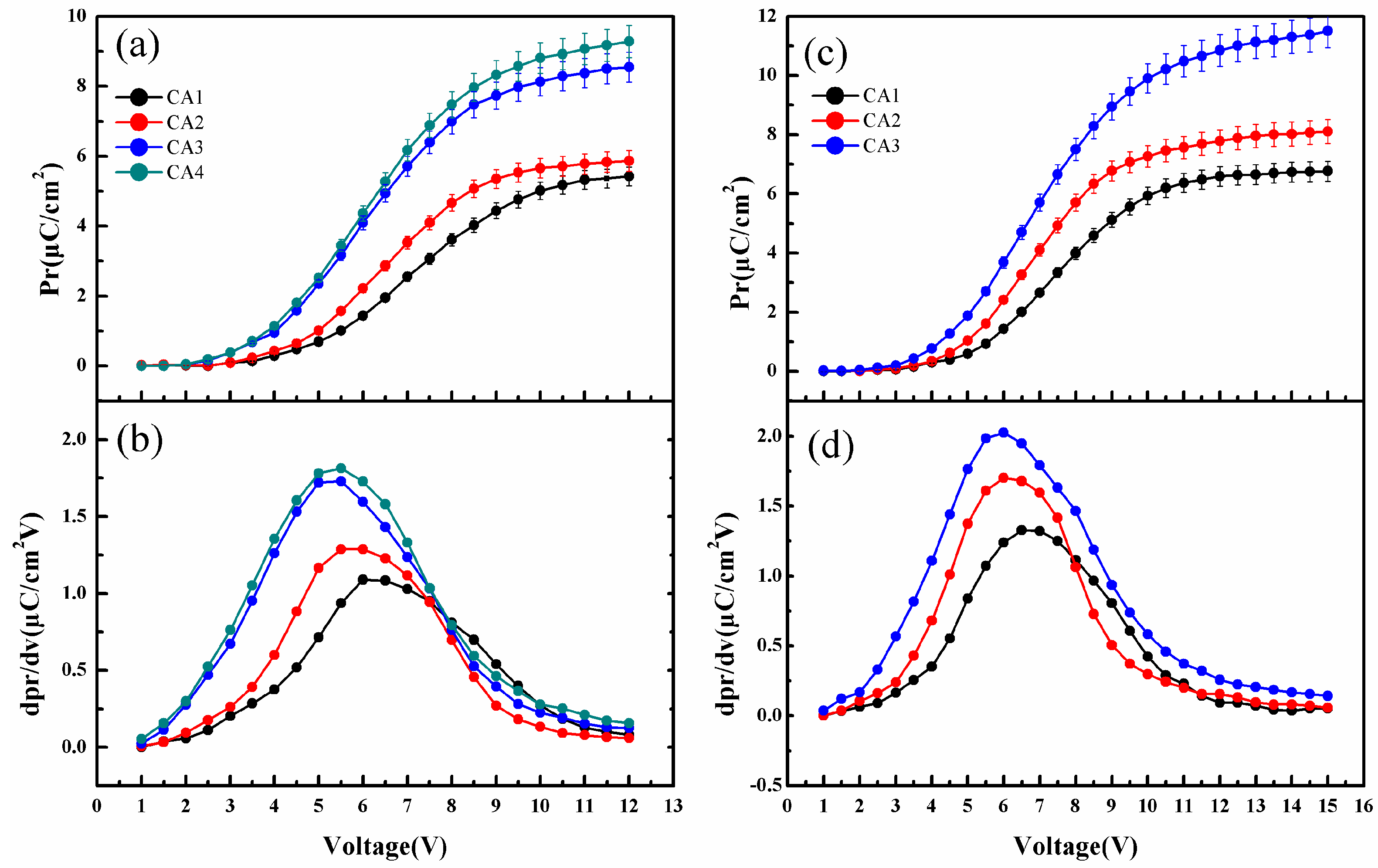

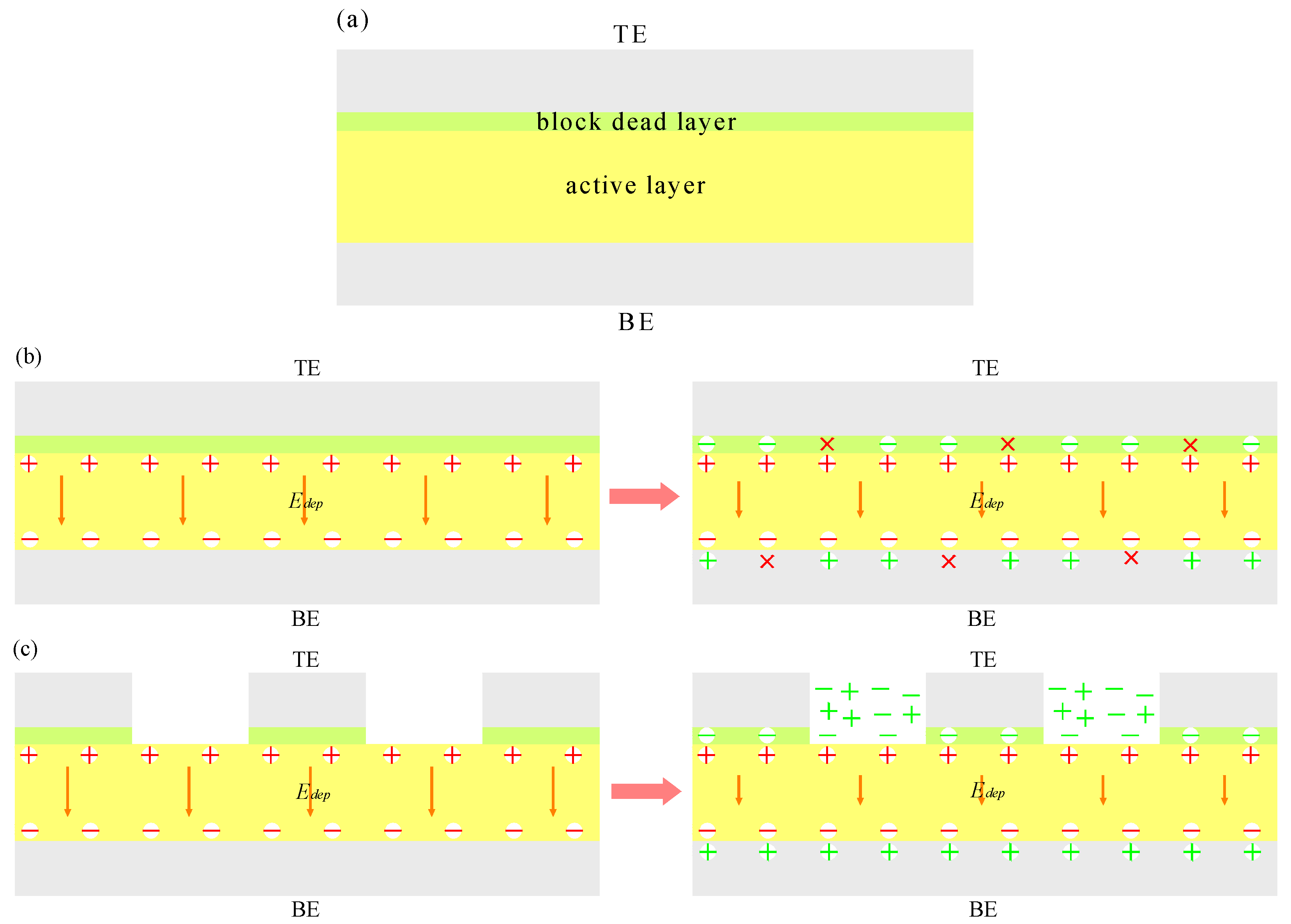

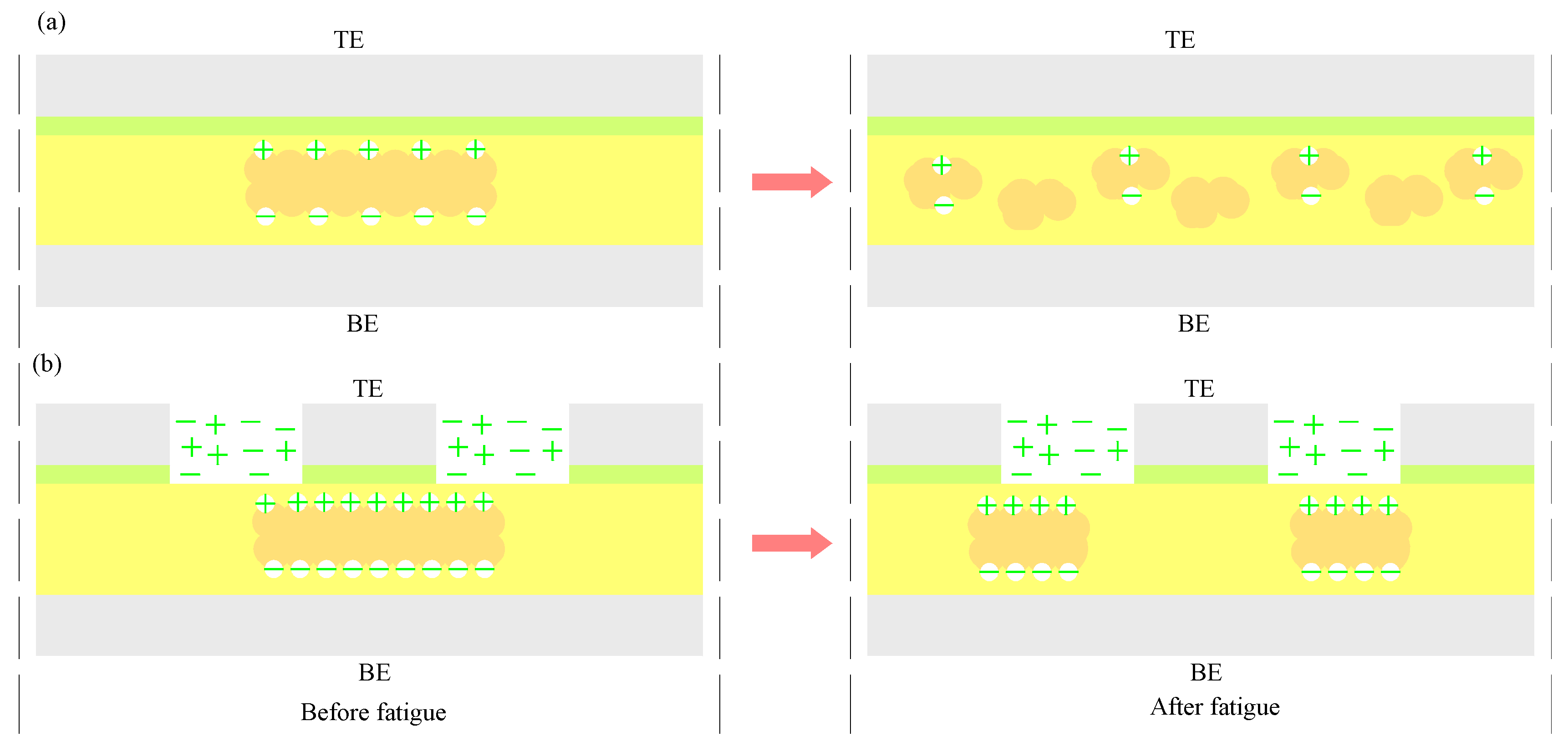

3.2. Effect of Electrode Structure on Fatigue

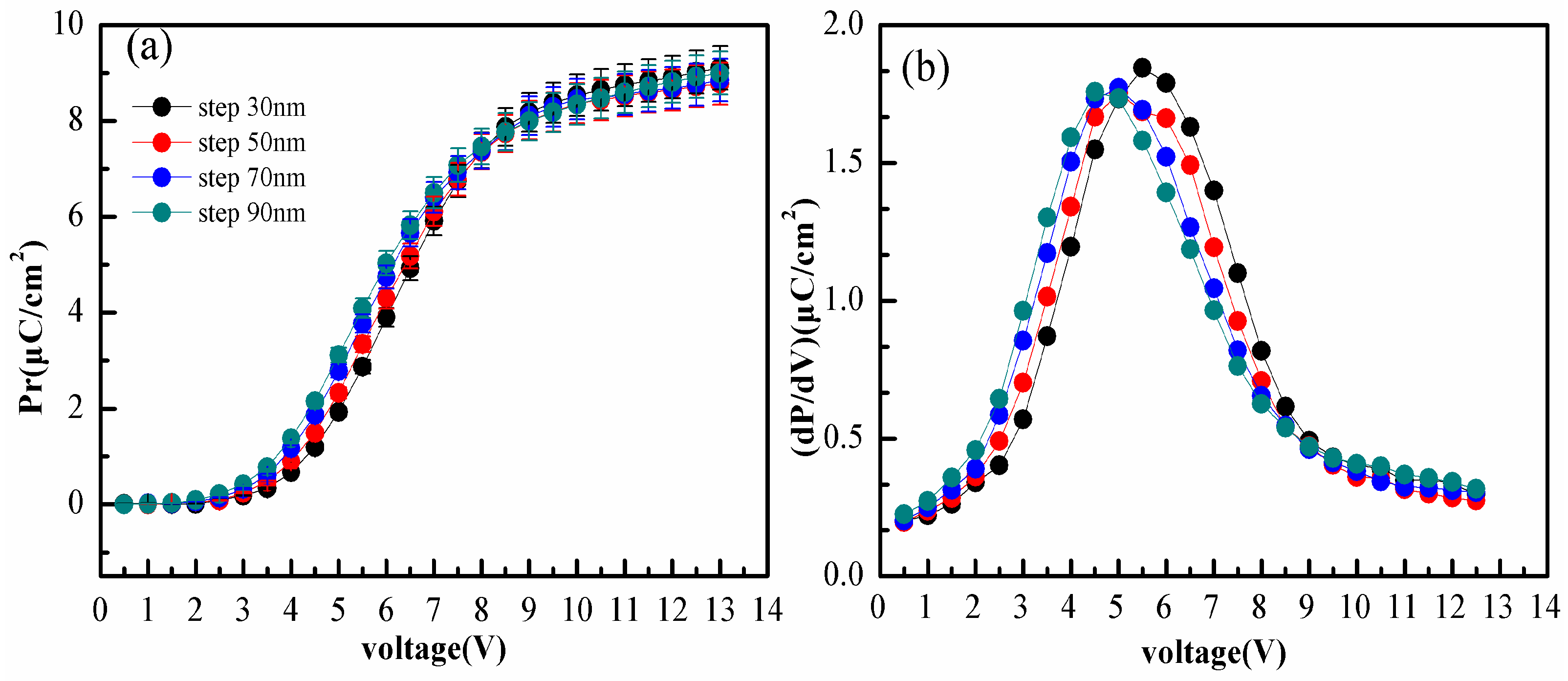

3.3. Effect of Electrode Structure on Driving Voltage

3.4. Polarization Independence of the Electrode Step Heights

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Xu, H.; Fang, X.; Liu, X.; Wu, S.; Gu, Y.; Meng, X.; Sun, J.; Chu, J. Fabrication and properties of solution processed all polymer thin-film ferroelectric device. J. Appl. Polym. Sci. 2011, 120, 1510–1513. [Google Scholar] [CrossRef]

- Zhang, X.; Du, X.; Liu, C.; Ji, X.; Xu, H. High temperature-dependent imprint and switching mechanism of poly(vinylidene fluoride-trifluoroethylene) copolymer ultrathin films with electroactive interlayers. Appl. Phys. Lett. 2015, 106, 022906. [Google Scholar] [CrossRef]

- Naber, R.C.G.; Blom, P.W.M.; Marsman, A.W.; de Leeuw, D.M. Low voltage switching of a spin cast ferroelectric polymer. Appl. Phys. Lett. 2004, 85, 2032–2034. [Google Scholar] [CrossRef]

- Fujisaki, S.; Ishiwara, H.; Fujisaki, Y. Low-voltage operation of ferroelectric poly(vinylidene fluoride-trifluoroethylene) copolymer capacitors and metal-ferroelectric-insulator-semiconductor diodes. Appl. Phys. Lett. 2007, 90, 162902. [Google Scholar] [CrossRef]

- Naber, R.C.G.; de Boer, B.; Blom, P.W.M.; de Leeuw, D.M. Low-voltage polymer field-effect transistors for nonvolatile memories. Appl. Phys. Lett. 2005, 87, 203509. [Google Scholar] [CrossRef]

- Bae, S.H.; Kahya, O.; Sharma, B.K.; Kwon, J.; Cho, H.J.; Özyilmaz, B.; Ahn, J.H. Graphene-P(VDF-TrFE) multilayer film for flexible applications. ACS Nano 2013, 7, 3130–3138. [Google Scholar] [CrossRef] [PubMed]

- Martins, P.; Lasheras, A.; Gutierrez, J.; Barandiaran, J.M.; Orue, I.; Lanceros-Mendez, S. Optimizing piezoelectric and magnetoelectric responses on CoFe2O4/P(VDF-TrFE) nanocomposites. J. Phys. D Appl. Phys. 2011, 44, 495303. [Google Scholar] [CrossRef]

- Zhang, X.; Dong, W.; Liu, Y.; Xu, G.; Xu, H. Structural and ferroelectric behaviours in blends of vinylidene fluoride oligomer and poly(vinylidene fluoride-trifluoroethylene) copolymer thin film. J. Phys. D Appl. Phys. 2011, 44, 435304. [Google Scholar] [CrossRef]

- Mai, M.; Ke, S.; Lin, P.; Zeng, X. Ferroelectric polymer thin films for organic electronics. J. Nanomater. 2015, 2015, 1–14. [Google Scholar] [CrossRef]

- Hu, W.J.; Juo, D.M.; You, L.; Wang, J.; Chen, Y.C.; Chu, Y.H.; Wu, T. Universal ferroelectric switching dynamics of vinylidene fluoride-trifluoroethylene copolymer films. Sci. Rep. 2014, 4, 4772. [Google Scholar] [CrossRef] [PubMed]

- Hou, Y.; Zhang, X.; Zhang, Y.; Xu, G.; Xu, H. High-temperature ferroelectric behaviors of poly(vinylidene fluoride-trifluoroethylene) copolymer ultrathin films with electroactive interlayers. J. Appl. Phys. 2012, 111, 064506. [Google Scholar] [CrossRef]

- Won, S.S.; Sheldon, M.; Mostovych, N.; Kwak, J.; Chang, B.-S.; Ahn, C.W.; Kingon, A.I.; Kim, I.W.; Kim, S.-H. Piezoelectric poly(vinylidene fluoride trifluoroethylene) thin film-based power generators using paper substrates for wearable device applications. Appl. Phys. Lett. 2015, 107, 202901. [Google Scholar] [CrossRef]

- Mathur, S.C.; Scheinbeim, J.I.; Newman, B.A. Piezoelectric properties and ferroelectric hysteresis effects in uniaxially stretched nylon-11 films. J. Appl. Phys. 1984, 56, 2419–2425. [Google Scholar] [CrossRef]

- Kawai, H. The piezoelectricity of poly(vinylidene fluoride). Jpn. J. Appl. Phys. 2014, 8, 975–976. [Google Scholar] [CrossRef]

- Pratap, A.; Joshi, N.J.; Rakshit, P.B.; Grewal, G.S.; Shrinet, V. Dielectric behavior of nano barium titanate filled polymeric composites. Int. J. Mod. Phys. Conf. Ser. 2013, 22, 1–10. [Google Scholar] [CrossRef]

- Xu, H. Dielectric properties and ferroelectric behavior of poly(vinylidene fluoride-trifluoroethylene) 50/50 copolymer ultrathin films. J. Appl. Polym. Sci. 2001, 80, 2259–2266. [Google Scholar] [CrossRef]

- Chen, S.; Yao, K.; Tay, F.E.H.; Chew, L.L.S. Comparative investigation of the structure and properties of ferroelectric poly(vinylidene fluoride) and poly(vinylidene fluoride-trifluoroethylene) thin films crystallized on substrates. J. Appl. Polym. Sci. 2010. [Google Scholar] [CrossRef]

- Yamada, T.; Kitayama, T. Ferroelectric properties of vinylidene fluoride-trifluoroethylene copolymers. J. Appl. Phys. 1981, 52, 6859–6863. [Google Scholar] [CrossRef]

- Mahdi, R.I.; Gan, W.C.; Abd Majid, W.H. Hot plate annealing at a low temperature of a thin ferroelectric P(VDF-TrFE) film with an improved crystalline structure for sensors and actuators. Sensors 2014, 14, 19115–19127. [Google Scholar] [CrossRef] [PubMed]

- Park, J.-M.; Kong, J.-W.; Kim, D.-S.; Yoon, D.-J. Nondestructive damage detection and interfacial evaluation of single-fibers/epoxy composites using PZT, PVDF and P(VDF-TrFE) copolymer sensors. Compos. Sci. Technol. 2005, 65, 241–256. [Google Scholar] [CrossRef]

- Mandal, D.; Yoon, S.; Kim, K.J. Origin of piezoelectricity in an electrospun poly(vinylidene fluoride-trifluoroethylene) nanofiber web-based nanogenerator and nano-pressure sensor. Macromol. Rapid Commun. 2011, 32, 831–837. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.M.; Li, H.; Poh, M.; Xia, F.; Cheng, Z.Y.; Xu, H.; Huang, C. An all-organic composite actuator material with a high dielectric constant. Nature 2002, 419, 284–287. [Google Scholar] [CrossRef] [PubMed]

- Asadi, K.; de Leeuw, D.M.; de Boer, B.; Blom, P.W. Organic non-volatile memories from ferroelectric phase-separated blends. Nat. Mater. 2008, 7, 547–550. [Google Scholar] [CrossRef] [PubMed]

- Naber, R.C.; Asadi, K.; Blom, P.W.; de Leeuw, D.M.; de Boer, B. Organic nonvolatile memory devices based on ferroelectricity. Adv. Mater. 2010, 22, 933–945. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Tian, M.; Nysten, B.; Jonas, A.M. Regular arrays of highly ordered ferroelectric polymer nanostructures for non-volatile low-voltage memories. Nat. Mater. 2009, 8, 62–67. [Google Scholar] [CrossRef] [PubMed]

- Mao, D.; Mejia, I.; Stiegler, H.; Gnade, B.E.; Quevedo-Lopez, M.A. Polarization behavior of poly(vinylidene fluoride-trifluoroethylene) copolymer ferroelectric thin film capacitors for nonvolatile memory application in flexible electronics. J. Appl. Phys. 2010, 108, 094102. [Google Scholar] [CrossRef]

- Xu, H.; Liu, X.; Fang, X.; Xie, H.; Li, G.; Meng, X.; Sun, J.; Chu, J. Domain stabilization effect of interlayer on ferroelectric poly(vinylidene fluoride-trifluoroethylene) copolymer ultrathin film. J. Appl. Phys. 2009, 105, 22. [Google Scholar] [CrossRef]

- Xia, F.; Xu, H.; Fang, F.; Razavi, B.; Cheng, Z.Y.; Lu, Y.; Xu, B.; Zhang, Q.M. Thickness dependence of ferroelectric polarization switching in poly(vinylidene fluoride–trifluoroethylene) spin cast films. Appl. Phys. Lett. 2001, 78, 1122–1124. [Google Scholar] [CrossRef]

- Du, X.; Zhao, M.; Chen, G.; Zhang, X. Thickness dependence of ferroelectric properties for ferroelectric random access memory based on poly(vinylidene fluoride-trifluoroethylene) ultrathin films. Ferroelectrics 2015, 488, 148–153. [Google Scholar] [CrossRef]

- Furukawa, T. Ferroelectric properties of vinylidene fluoride copolymers. Phase Transit. 1989, 18, 143–211. [Google Scholar] [CrossRef]

- Singh, D.; Deepak, A.G. Cooling rate controlled microstructure evolution and reduced coercivity in P(VDF-TrFE) devices for memory applications. Org. Electron. 2014, 15, 82–90. [Google Scholar] [CrossRef]

- Furukawa, T. Structure and functional properties of ferroelectric polymers. Key Eng. Mater. 1994, 92–93, 15–30. [Google Scholar] [CrossRef]

- Onishi, S.; Hamada, K.; Ishihara, K.; Ito, Y. A half-micron ferroelectric memory cell technology with stacked capacitor structure. In Proceedings of the 1994 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 11–14 December 1994; pp. 843–846. [Google Scholar]

- Subash, C.K.; Valiyaneerilakkal, U.; Singh, K.; Varghese, S. Device level optimization of poly(vinylidene fluoride-trifluoroethylene)-zinc oxide polymer nanocomposite thin films for ferroelectric applications. J. Appl. Phys. 2015, 118, 204102. [Google Scholar]

- Hou, Y.; Lü, Z.; Pu, T.; Zhang, Y.; Xu, G.; Xu, H. Fast switching protocol for ferroelectric random access memory based on poly(vinylidene fluoride-trifluoroethylene) copolymer ultrathin films. Appl. Phys. Lett. 2013, 102, 063507. [Google Scholar] [CrossRef]

- Zhang, X.; Hou, Y.; Zhang, Y.; Lv, Z.; Xu, G.; Xu, H. The effect of electroactive interlayer on the ferroelectric properties in poly(vinylidene fluoride-trifluoroethylene) copolymer ultrathin films. J. Appl. Phys. 2012, 112, 074111. [Google Scholar] [CrossRef]

- Genc, R.; Alas, M.O.; Harputlu, E.; Repp, S.; Kremer, N.; Castellano, M.; Colak, S.G.; Ocakoglu, K.; Erdem, E. High-capacitance hybrid supercapacitor based on multi-colored fluorescent carbon-dots. Sci. Rep. 2017, 7, 11222. [Google Scholar] [CrossRef] [PubMed]

- Larsen, P.K.; Dormans, G.J.M.; Taylor, D.J.; van Veldhoven, P.J. Ferroelectric properties and fatigue of PbZr051Ti0.49O3 thin films of varying thickness: Blocking layer model. J. Appl. Phys. 1994, 76, 2405–2413. [Google Scholar]

- Jiang, A.Q.; Lin, Y.Y.; Tang, T.A. Charge injection and polarization fatigue in ferroelectric thin films. J. Appl. Phys. 2007, 102, 074109. [Google Scholar] [CrossRef]

- Yang, Q.; Cao, J.; Zhou, Y.; Sun, L.; Lou, X. Dead layer effect and its elimination in ferroelectric thin film with oxide electrodes. Acta Mater. 2016, 112, 216–223. [Google Scholar] [CrossRef]

- Bratkovsky, A.M.; Levanyuk, A.P. Very large dielectric response of thin ferroelectric films with the dead layers. Phys. Rev. B 2001, 63. [Google Scholar] [CrossRef]

- Black, C.T.; Farrell, C.; Licata, T.J. Suppression of ferroelectric polarization by an adjustable depolarization field. Appl. Phys. Lett. 1997, 71, 2041–2043. [Google Scholar] [CrossRef]

- Wurfel, P.; Batra, I.P. Depolarization-field-induced instability in thin ferroelectric films—Experiment and theory. Phys. Rev. B 1973, 8, 5126–5133. [Google Scholar] [CrossRef]

- Zhu, G.; Gu, Y.; Yu, H.; Fu, S.; Jiang, Y. Polarization fatigue in ferroelectric vinylidene fluoride and trifluoroethylene copolymer thin films. J. Appl. Phys. 2011, 110, 024109. [Google Scholar] [CrossRef]

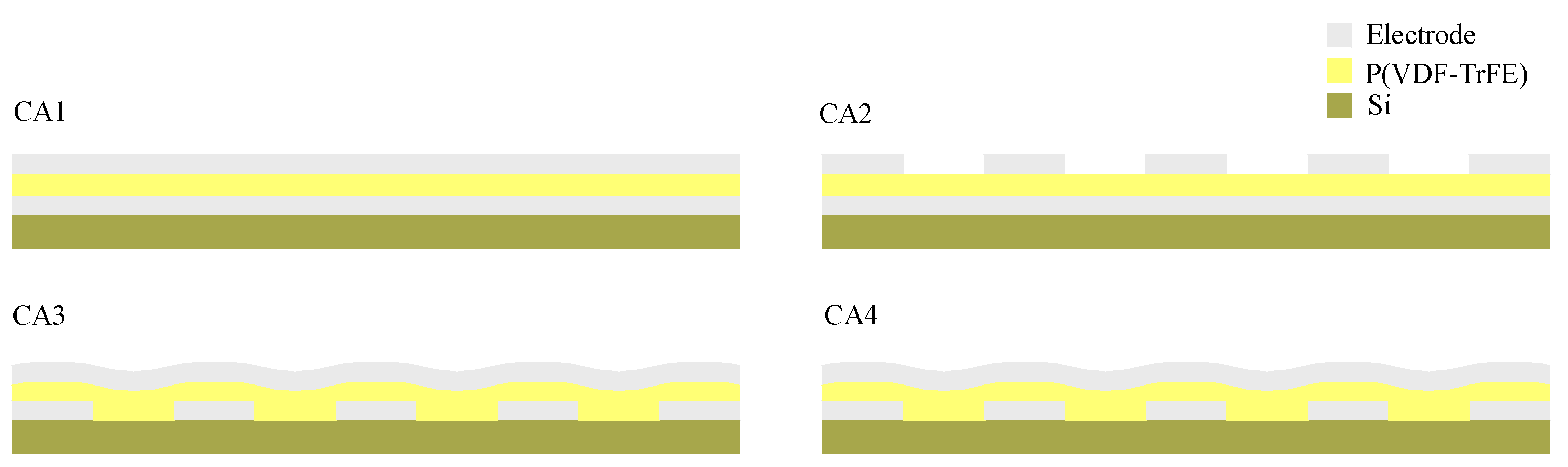

| Cell name | CA1 | CA2 | CA3 | CA4 |

|---|---|---|---|---|

| Top electrode | Flat | Line | Flat | Line |

| Bottom electrode | Flat | Flat | Line | Line |

| Pr(BF) (μC/cm2) | 4.65 | 5.02 | 6.93 | 6.90 |

| Pr(AF) (μC/cm2) | 2.98 | 3.40 | 3.80 | 5.43 |

| Ratio (AF/BF) | 0.44 | 0.67 | 0.56 | 0.79 |

| Cell name | CA1 | CA2 | CA3 | CA4 |

|---|---|---|---|---|

| Vd | 10.1 V | 9.8 V | 9.6 V | 9.3 V |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Zhang, X.; Chen, H.; Sun, X.; Yuan, H.; Xu, H. Modeling of Structure Effect for Ferroelectric Capacitor Based on Poly(vinylidene fluoride-trifluoroethylene) Ultrathin Films. Polymers 2018, 10, 6. https://doi.org/10.3390/polym10010006

Li L, Zhang X, Chen H, Sun X, Yuan H, Xu H. Modeling of Structure Effect for Ferroelectric Capacitor Based on Poly(vinylidene fluoride-trifluoroethylene) Ultrathin Films. Polymers. 2018; 10(1):6. https://doi.org/10.3390/polym10010006

Chicago/Turabian StyleLi, Long, Xiuli Zhang, Hongzhen Chen, Xiaohui Sun, Haidong Yuan, and Haisheng Xu. 2018. "Modeling of Structure Effect for Ferroelectric Capacitor Based on Poly(vinylidene fluoride-trifluoroethylene) Ultrathin Films" Polymers 10, no. 1: 6. https://doi.org/10.3390/polym10010006