Synthesis, Characterization, and Applications of Magnetic Nanoparticles Featuring Polyzwitterionic Coatings

Abstract

:1. Introduction and Scope

2. The Core: Materials for Magnetic Nanoparticles

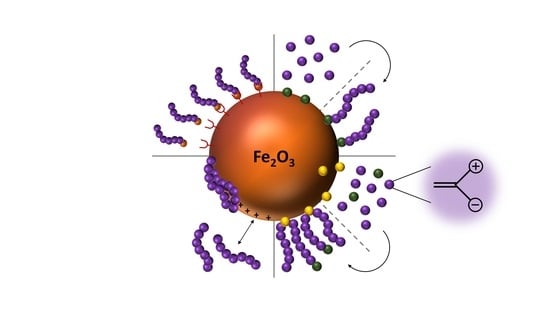

2.1. Magnetic Properties of Magnetic Nanoparticles

2.2. Preparation of Magnetic Nanoparticles

- (i)

- biomineralization

- (ii)

- physical methods

- (iii)

- chemical methods

- (i)

- By means of biomineralization some living organisms prepare magnetic particles for use for their sense of direction [50]. For example, magnetotactic bacteria are capable of preparing magnetosomes (protein coated nanosized crystals of magnetic iron oxide). The bacteria use the particles as a compass to find their preferred habitat in anaerobic areas at the bottom of the sea [51]. Under anaerobic synthesis conditions in the lab, which are similar to the conditions of their habitat, uniform particles of 20 to 45 nm core diameter may be produced [52,53,54]. Despite the fact that magnetosomes show excellent magnetic properties for medical application (especially hyperthermia) [55,56], they have found no application in medicine until now due to their bacterial protein coating. Current recent research on magnetosomes focuses on elucidation and optimization of the biomineralization process [57,58] with the aim to develop wet chemical preparation routines which emulate the biologic process, thus providing MNP with similar magnetic behavior.

- (ii)

- The physical methods can be divided into “top down” and “bottom up” procedures. Top down methods are based on the size reduction of macroscopic magnetic materials to the nanometer range, e.g., by means of milling. A major drawback of these methods is the difficulty of adjusting the desired particle size and shape [59]. Furthermore, the milling procedure leads to lattice defects that cause deviations in the magnetic properties compared to regular particles of the same size [60]. Bottom up methods use the condensation of nanoparticles from either a liquid or gaseous phase. A promising bottom up method for the synthesis of MNP powders is laser evaporation. Starting materials are coarse metal oxide powders of a few µm sized particles, which are evaporated by means of a laser. As a result of the steep temperature gradient outside of the evaporation zone, a very fast condensation and nucleation takes place from the gas phase and nanoparticles are formed [61,62].The resulting mean particle sizes (20 to 50 nm) and magnetic phase are tuned by laser power and composition of the atmosphere in the evaporation chamber [63].

- (iii)

- The chemical methods provide a multitude of different bottom up synthesis routes for the preparation of MNP, from which the most prominent will be described shortly.

2.3. Recent Developments in the Synthesis of Magnetic Nanoparticles

3. The Shell: Polyzwitterions

4. Coating of Magnetic Nanoparticles

5. Characterization Methods

6. Synthesis of Polyzwitterionic Shell Materials

6.1. Covalent Surface Functionalization

6.2. Electrostatic Adsorption

6.3. Other Methods

7. A Short Note on Application Fields

8. Conclusions and Outlook

Acknowledgments

Conflicts of Interest

References

- Veiseh, O.; Gunn, J.W.; Zhang, M. Design and fabrication of magnetic nanoparticles for targeted drug delivery and imaging. Adv. Drug Deliv. Rev. 2010, 62, 284–304. [Google Scholar] [CrossRef] [PubMed]

- Cao, B.; Tang, Q.; Cheng, G. Recent advances of zwitterionic carboxybetaine materials and their derivatives. J. Biomater. Sci. 2014, 25, 1502–1513. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Wu, Z.; Yu, T.; Jiang, C.; Kim, W.-S. Recent progress on magnetic iron oxide nanoparticles: Synthesis, surface functional strategies and biomedical applications. Sci. Technol. Adv. Mater. 2015, 16. [Google Scholar] [CrossRef] [PubMed]

- García, K.P.; Zarschler, K.; Barbaro, L.; Barreto, J.A.; O’Malley, W.; Spiccia, L.; Stephan, H.; Graham, B. Zwitterionic-Coated “Stealth” Nanoparticles for Biomedical Applications: Recent Advances in Countering Biomolecular Corona Formation and Uptake by the Mononuclear Phagocyte System. Small 2014, 10, 2516–2529. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.-Y.; Hu, S.-H.; Liu, D.-M.; Chen, S.-Y.; Chen, I.W. Biomedical nanoparticle carriers with combined thermal and magnetic responses. Nano Today 2009, 4, 52–65. [Google Scholar] [CrossRef]

- Ai, H. Layer-by-layer capsules for magnetic resonance imaging and drug delivery. Adv. Drug Deliv. Rev. 2011, 63, 772–788. [Google Scholar] [CrossRef] [PubMed]

- Xing, R.; Liu, G.; Zhu, J.; Hou, Y.; Chen, X. Functional Magnetic Nanoparticles for Non-Viral Gene Delivery and MR Imaging. Pharm. Res. 2014, 31, 1377–1389. [Google Scholar] [CrossRef] [PubMed]

- Bodker, F.; Morup, S.; Linderoth, S. Surface effects in metallic iron nanoparticles. Phys. Rev. Lett. 1994, 72, 282–285. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hacliipanayis, C.G.; Bonder, M.J.; Balakrishanan, S.; Wang, X.; Mao, H.; Hadjipanayis, G.C. Metallic Iron Nanoparticles for MRI Contrast Enhancement and Local Hyperthermia. Small 2008, 4, 1925–1929. [Google Scholar]

- Li, Y.F.; Hu, Y.J.; Huang, G.J.; Li, C.Z. Metallic iron nanoparticles: Flame synthesis, characterization and magnetic properties. Particuology 2013, 11, 460–467. [Google Scholar] [CrossRef]

- Yamamuro, S.; Ando, T.; Sumiyama, K.; Uchida, T.; Kojima, I. Monodisperse Metallic Iron Nanoparticles Synthesized from Noncarbonyl Complex. Jpn. J. Appl. Phys. Part 1 2004, 43, 4458–4459. [Google Scholar] [CrossRef]

- Seong, G.; Takami, S.; Arita, T.; Minami, K.; Hojo, D.; Yavari, A.R.; Adschiri, T. Supercritical hydrothermal synthesis of metallic cobalt nanoparticles and its thermodynamic analysis. J. Supercrit. Fluids 2011, 60, 113–120. [Google Scholar] [CrossRef]

- Zeisberger, M.; Dutz, S.; Müller, R.; Hergt, R.; Matoussevitch, N.; Bönnemann, H. Metallic cobalt nanoparticles for heating applications. J. Magn Magn. Mater. 2007, 311, 224–227. [Google Scholar] [CrossRef]

- Tran, N.; Webster, T.J. Magnetic nanoparticles: Biomedical applications and challenges. J. Mater. Chem. 2010, 20, 8760–8767. [Google Scholar] [CrossRef]

- Lee, J.G.; Li, P.; Dong, X.L.; Choi, C.J. Fabrication of Ferromagnetic Mn-Al Alloy Nanoparticles Using a Plasma Arc-discharge Process. Korean J. Met. Mater. 2010, 48, 357–362. [Google Scholar] [CrossRef]

- Wang, C.H.; Meyer, J.; Teichert, N.; Auge, A.; Rausch, E.; Balke, B.; Hutten, A.; Fecher, G.H.; Felser, C. Heusler Nanoparticles for Spintronics and Ferromagnetic Shape Memory Alloys. J. Vac. Sci. Technol. B 2014, 32. [Google Scholar] [CrossRef]

- White, C.W.; Withrow, S.P.; Sorge, K.D.; Meldrum, A.; Budai, J.D.; Thompson, J.R.; Boatner, L.A. Oriented Ferromagnetic Fe-Pt Alloy Nanoparticles Produced in Al2O3 by Ion-Beam Synthesis. J. Appl. Phys. 2003, 93, 5656–5669. [Google Scholar] [CrossRef]

- Lasheras, X.; Insausti, M.; de Muro, I.G.; Garaio, E.; Plazaola, F.; Moros, M.; De Matteis, L.; de la Fuente, J.M.; Lezama, L. Chemical Synthesis and Magnetic Properties of Monodisperse Nickel Ferrite Nanoparticles for Biomedical Applications. J. Phys. Chem. C 2016, 120, 3492–3500. [Google Scholar] [CrossRef]

- Rodrigues, A.R.O.; Gomes, I.T.; Almeida, B.G.; Araujo, J.P.; Castanheira, E.M.S.; Coutinho, P.J.G. Magnetic liposomes based on nickel ferrite nanoparticles for biomedical applications. Phys. Chem. Chem. Phys. 2015, 17, 18011–18021. [Google Scholar] [CrossRef] [PubMed]

- Ruthradevi, T.; Akbar, J.; Kumar, G.S.; Thamizhavel, A.; Kumar, G.A.; Vatsa, R.K.; Dannangoda, G.C.; Martirosyan, K.S.; Girija, E.K. Investigations on nickel ferrite embedded calcium phosphate nanoparticles for biomedical applications. J. Alloy. Compd. 2017, 695, 3211–3219. [Google Scholar] [CrossRef]

- Tomitaka, A.; Jeun, M.; Bae, S.; Takemura, Y. Evaluation of Magnetic and Thermal Properties of Ferrite Nanoparticles for Biomedical Applications. J. Magn. 2011, 16, 164–168. [Google Scholar] [CrossRef]

- Peeples, B.; Goornavar, V.; Peeples, C.; Spence, D.; Parker, V.; Bell, C.; Biswal, D.; Ramesh, G.T.; Pradhan, A.K. Structural, Stability, Magnetic, and Toxicity Studies of Nanocrystalline Iron Oxide and Cobalt Ferrites for Biomedical Applications. J. Nanopart. Res. 2014, 16, 2290. [Google Scholar] [CrossRef]

- Salunkhe, A.B.; Khot, V.M.; Thorat, N.D.; Phadatare, M.R.; Sathish, C.I.; Dhawale, D.S.; Pawar, S.H. Polyvinyl alcohol functionalized cobalt ferrite nanoparticles for biomedical applications. Appl. Surf. Sci. 2013, 264, 598–604. [Google Scholar] [CrossRef]

- Sanpo, N.; Berndt, C.C.; Wen, C.; Wang, J. Transition metal-substituted cobalt ferrite nanoparticles for biomedical applications. Acta Biomater. 2013, 9, 5830–5837. [Google Scholar] [CrossRef] [PubMed]

- Cornell, R.M.; Schwertmann, U. The Iron Oxides: Structure, Properties, Reactions, Occurences and Uses; Wiley-VCH: Weinheim, Germany, 2003. [Google Scholar]

- Khalafalla, S.E.; Reimers, G.W. Preparation of Dilution-Stable Aqueous Magnetic Fluids. IEEE Trans. Magn. 1980, 16, 178–183. [Google Scholar] [CrossRef]

- Massart, R. Preparation of aqueous ferrofluids without using surfactant—Behavior as a function of the pH and the counterions. C. R. Seances Acad. Sci. Ser. C 1980, 291, 1–3. [Google Scholar]

- Krishnan, K.M. Biomedical Nanomagnetics: A Spin through Possibilities in Imaging, Diagnostics, and Therapy. IEEE Trans. Magn. 2010, 46, 2523–2558. [Google Scholar] [CrossRef] [PubMed]

- Pankhurst, Q.A.; Thanh, N.T.K.; Jones, S.K.; Dobson, J. Progress in Applications of Magnetic Nanoparticles in Biomedicine. J. Phys. D 2009, 42. [Google Scholar] [CrossRef]

- Bloch, F. Zur Theorie des Austauschproblems und der Remanenzerscheinung der Ferromagnetika. Z. Phys. 1932, 74, 295–335. [Google Scholar] [CrossRef]

- Weiss, P. L’hypothese du Champ Moleculaire et la Propriete Ferromagnetique. J. Phys. Radium 1907, 6, 661–690. [Google Scholar] [CrossRef]

- Landau, L.D.; Lifshitz, E.M. On the Theory of the Dispersion of Magnetic Permeability in Ferromagnetic Bodies. Phys. Z. Sowjetunion 1935, 8, 153–167. [Google Scholar]

- Kittel, C. Theory of the Structure of Ferromagnetic Domains in Films and Small Particles. Phys. Rev. 1946, 70, 965–971. [Google Scholar] [CrossRef]

- Butler, R.F.; Banerjee, S.K. Theoretical Single-Domain Grain Size Range in Magnetite and Titanomagnetite. J. Geophys. Res. 1975, 80, 4049–4058. [Google Scholar] [CrossRef]

- Fabian, K.; Kirchner, A.; Williams, W.; Heider, F.; Leibl, T.; Hubert, A. Three-dimensional micromagnetic calculations for magnetite using FFT. Geophys. J. Int. 1996, 124, 89–104. [Google Scholar] [CrossRef]

- Dutz, S. Nanopartikel in der Medizin; Verlag Dr. Kovac: Hamburg, Germany, 2008. [Google Scholar]

- Néel, L. Influence des fluctuations thermiques a l’aimantation des particules ferromagnetiques. C. R. Acad. Sci. 1949, 228, 664–668. [Google Scholar]

- Dutz, S. Are Magnetic Multicore Nanoparticles Promising Candidates for Biomedical Applications? IEEE Trans. Magn. 2016, 52. [Google Scholar] [CrossRef]

- Dutz, S.; Andrä, W.; Hergt, R.; Müller, R.; Oestreich, C.; Schmidt, C.; Töpfer, J.; Zeisberger, M.; Bellemann, M.E. Influence of Dextran Coating on the Magnetic Behaviour of Iron Oxide Nanoparticles. J. Magn. Magn. Mater. 2007, 311, 51–54. [Google Scholar] [CrossRef]

- Suzdalev, I.P.; Maksimov, Y.V.; Buravtsev, V.N.; Imshennik, V.K.; Kazakevich, A.G.; Novichikhin, S.V. The formation and properties of a system of iron oxide nanoclusters. Colloid J. 2000, 62, 224–233. [Google Scholar]

- Blanco-Andujar, C.; Ortega, D.; Southern, P.; Pankhurst, Q.A.; Thanh, N.T.K. High Performance Multi-core Iron Oxide Nanoparticles for Magnetic Hyperthermia: Microwave Synthesis, and the Role of Core-to-Core Interactions. Nanoscale 2015, 7, 1768–1775. [Google Scholar] [CrossRef] [PubMed]

- Dutz, S.; Kettering, M.; Hilger, I.; Müller, R.; Zeisberger, M. Magnetic multicore nanoparticles for hyperthermia-influence of particle immobilization in tumour tissue on magnetic properties. Nanotechnology 2011, 22. [Google Scholar] [CrossRef] [PubMed]

- Lartigue, L.; Hugounenq, P.; Alloyeau, D.; Clarke, S.P.; Levy, M.; Bacri, J.-C.; Bazzi, R.; Brougham, D.F.; Wilhelm, C.; Gazeau, F. Cooperative Organization in Iron Oxide Multi-Core Nanoparticles Potentiates Their Efficiency as Heating Mediators and MRI Contrast Agents. ACS Nano 2012, 6, 10935–10949. [Google Scholar] [CrossRef] [PubMed]

- Hergt, R.; Dutz, S.; Roder, M. Effects of size distribution on hysteresis losses of magnetic nanoparticles for hyperthermia. J. Phys. Condens. Matter 2008, 20. [Google Scholar] [CrossRef] [PubMed]

- Müller, R.; Dutz, S.; Neeb, A.; Cato, A.C.B.; Zeisberger, M. Magnetic heating effect of nanoparticles with different sizes and size distributions. J. Magn. Magn. Mater. 2013, 328, 80–85. [Google Scholar] [CrossRef]

- Barry, S.E. Challenges in the Development of Magnetic Particles for Therapeutic Applications. Int. J. Hyperth. 2008, 24, 451–466. [Google Scholar] [CrossRef] [PubMed]

- Laurent, S.; Forge, D.; Port, M.; Roch, A.; Robic, C.; Elst, L.V.; Müller, R.N. Magnetic Iron Oxide Nanoparticles: Synthesis, Stabilization, Vectorization, Physicochemical Characterizations, and Biological Applications. Chem. Rev. 2008, 108, 2064–2110. [Google Scholar] [CrossRef] [PubMed]

- Lu, A.H.; Salabas, E.L.; Schüth, F. Magnetic Nanoparticles: Synthesis, Protection, Functionalization, and Application. Angew. Chem. Int. Ed. 2007, 46, 1222–1244. [Google Scholar] [CrossRef] [PubMed]

- Reddy, L.H.; Arias, J.L.; Nicolas, J.; Couvreur, P. Magnetic Nanoparticles: Design and Characterization, Toxicity and Biocompatibility, Pharmaceutical and Biomedical Applications. Chem. Rev. 2012, 112, 5818–5878. [Google Scholar] [CrossRef] [PubMed]

- Krishnan, K.M. Fundamentals and Applications of Magnetic Materials; Oxford University Press: Oxford, UK, 2016. [Google Scholar]

- Bazylinski, D.A.; Garrattreed, A.J.; Frankel, R.B. Electron microscopic studies of magnetosomes in magnetotactic bacteria. Microsc. Res. Tech. 1994, 27, 389–401. [Google Scholar] [CrossRef] [PubMed]

- Faivre, D.; Schuler, D. Magnetotactic Bacteria and Magnetosomes. Chem. Rev. 2008, 108, 4875–4898. [Google Scholar] [CrossRef] [PubMed]

- Schüler, D.; Frankel, R.B. Bacterial magnetosomes: Microbiology, biomineralization and biotechnological applications. Appl. Microbiol. Biotechnol. 1999, 52, 464–473. [Google Scholar] [CrossRef] [PubMed]

- Timko, M.; Molcan, M.; Hashim, A.; Skumiel, A.; Müller, M.; Gojzewski, H.; Jozefczak, A.; Kovac, J.; Rajnak, M.; Makowski, M.; et al. Hyperthermic Effect in Suspension of Magnetosomes Prepared by Various Methods. IEEE Trans. Magn. 2013, 49, 250–254. [Google Scholar] [CrossRef]

- Hergt, R.; Hiergeist, R.; Zeisberger, M.; Schuler, D.; Heyen, U.; Hilger, I.; Kaiser, W.A. Magnetic Properties of Bacterial Magnetosomes as Potential Diagnostic and Therapeutic Tools. J. Magn. Magn. Mater. 2005, 293, 80–86. [Google Scholar] [CrossRef]

- Molcan, M.; Gojzewski, H.; Skumiel, A.; Dutz, S.; Kovac, J.; Kubovcikova, M.; Kopcansky, P.; Vekas, L.; Timko, M. Energy Losses in Mechanically Modified Bacterial Magnetosomes. J. Phys. D 2016, 49. [Google Scholar] [CrossRef]

- Baumgartner, J.; Carillo, M.A.; Eckes, K.M.; Werner, P.; Faivre, D. Biomimetic Magnetite Formation: From Biocombinatorial Approaches to Mineralization Effects. Langmuir 2014, 30, 2129–2136. [Google Scholar] [CrossRef] [PubMed]

- Scheffel, A.; Gruska, M.; Faivre, D.; Linaroudis, A.; Plitzko, J.M.; Schüler, D. An acidic protein aligns magnetosomes along a filamentous structure in magnetotactic bacteria. Nature 2006, 440, 110–114. [Google Scholar] [CrossRef] [PubMed]

- DeCastro, C.L.; Mitchell, B.S. Nanoparticles from Mechanical Attrition. In Synthesis, Functionalization, and Surface Treatment of Nanoparticles; Baraton, M.-I., Ed.; American Scientific Publishers: Valencia, CA, USA, 2002. [Google Scholar]

- Dutz, S.; Hergt, R.; Mürbe, J.; Müller, R.; Zeisberger, M.; Andrä, W.; Töpfer, J.; Bellemann, M.E. Hysteresis Losses of Magnetic Nanoparticle Powders in the Single Domain Size Range. J. Magn. Magn. Mater. 2007, 308, 305–312. [Google Scholar] [CrossRef]

- Kurland, H.-D.; Grabow, J.; Staupendahl, G.; Andrä, W.; Dutz, S.; Bellemann, M.E. Magnetic Iron Oxide Nanopowders Produced by CO2 Laser Evaporation. J. Magn. Magn. Mater. 2007, 311, 73–77. [Google Scholar] [CrossRef]

- Kurland, H.-D.; Grabow, J.; Staupendahl, G.; Müller, F.A.; Müller, E.; Dutz, S.; Bellemann, M.E. Magnetic iron oxide nanopowders produced by CO2 laser evaporation—‘In situ’ coating and particle embedding in a ceramic matrix. J. Magn. Magn. Mater. 2009, 321, 1381–1385. [Google Scholar] [CrossRef]

- Stötzel, C.; Kurland, H.-D.; Grabow, J.; Dutz, S.; Müller, E.; Sierka, M.; Müller, F.A. Control of the Crystal Phase Composition of FexOy Nanopowders Prepared by CO2 Laser Vaporization. Cryst. Growth Des. 2013, 13, 4868–4876. [Google Scholar] [CrossRef]

- Grüttner, C.; Müller, K.; Teller, J.; Westphal, F.; Foreman, A.; Ivkov, R. Synthesis and Antibody Conjugation of Magnetic Nanoparticles with Improved Specific Power Absorption Rates for Alternating Magnetic Field Cancer Therapy. J. Magn. Magn. Mater. 2007, 311, 181–186. [Google Scholar] [CrossRef]

- Dutz, S.; Clement, J.H.; Eberbeck, D.; Gelbrich, T.; Hergt, R.; Müller, R.; Wotschadlo, J.; Zeisberger, M. Ferrofluids of magnetic multicore nanoparticles for biomedical applications. J. Magn. Magn. Mater. 2009, 321, 1501–1504. [Google Scholar] [CrossRef]

- Sun, S.; Zeng, H. Size-Controlled Synthesis of Magnetite Nanoparticles. J. Am. Chem. Soc. 2002, 124, 8204–8205. [Google Scholar] [CrossRef] [PubMed]

- Kuckelhaus, S.; Garcia, V.A.P.; Lacava, L.M.; Azevedo, R.B.; Lacava, Z.G.M.; Lima, E.C.D.; Figueiredo, F.; Tedesco, A.C.; Morais, P.C. Biological investigation of a citrate-coated cobalt-ferrite-based magnetic fluid. J. Appl. Phys. 2003, 93, 6707–6708. [Google Scholar] [CrossRef]

- Hyeon, T.; Lee, S.S.; Park, J.; Chung, Y.; Bin Na, H. Synthesis of highly crystalline and monodisperse maghemite nanocrystallites without a size-selection process. J. Am. Chem. Soc. 2001, 123, 12798–12801. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Lee, E.; Hwang, N.M.; Kang, M.S.; Kim, S.C.; Hwang, Y.; Park, J.G.; Noh, H.J.; Kini, J.Y.; Park, J.H.; et al. One-nanometer-scale size-controlled synthesis of monodisperse magnetic iron oxide nanoparticles. Angew. Chem. Int. Ed. 2005, 44, 2872–2877. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.H.; Wang, J.; Liu, X.; Chan, H.S.O. Synthesis of Fe3O4 nanoparticles from emulsions. J. Mater. Chem. 2001, 11, 1704–1709. [Google Scholar] [CrossRef]

- Okoli, C.; Sanchez-Dominguez, M.; Boutonnet, M.; Jaras, S.; Civera, C.; Solans, C.; Kuttuva, G.R. Comparison and Functionalization Study of Microemulsion-Prepared Magnetic Iron Oxide Nanoparticles. Langmuir 2012, 28, 8479–8485. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Q.; Baker, I.; Loudis, J.A.; Liao, Y.; Hoopes, P.J.; Weaver, J.B. Fe/Fe oxide nanocomposite particles with large specific absorption rate for hyperthermia. Appl. Phys. Lett. 2007, 90. [Google Scholar] [CrossRef]

- Hao, Y.L.; Teja, A.S. Continuous hydrothermal crystallization of α-Fe2O3 and Co3O4 nanoparticles. J. Mater. Res. 2003, 18, 415–422. [Google Scholar] [CrossRef]

- Lv, Y.D.; Wang, H.; Wang, X.F.; Bai, J.B. Synthesis, characterization and growing mechanism of monodisperse Fe3O4 microspheres. J. Cryst. Growth 2009, 311, 3445–3450. [Google Scholar] [CrossRef]

- Chen, D.; Xu, R. Hydrothermal synthesis and characterization of nanocrystalline Fe3O4 powders. Mater. Res. Bull. 1998, 33, 1015–1021. [Google Scholar] [CrossRef]

- Xu, C.; Teja, A.S. Continuous hydrothermal synthesis of iron oxide and PVA-protected iron oxide nanoparticles. J. Supercrit. Fluids 2008, 44, 85–91. [Google Scholar] [CrossRef]

- Hugounenq, P.; Levy, M.; Alloyeau, D.; Lartigue, L.; Dubois, E.; Cabuil, V.; Ricolleau, C.; Roux, S.; Wilhelm, C.; Gazeau, F.; et al. Iron Oxide Monocrystalline Nanoflowers for Highly Efficient Magnetic Hyperthermia. J. Phys. Chem. C 2012, 116, 15702–15712. [Google Scholar] [CrossRef]

- Müller, R.; Hergt, R.; Dutz, S.; Zeisberger, M.; Gawalek, W. Nanocrystalline Iron Oxide and Ba Ferrite Particles in the Superparamagnetism-Ferromagnetism Transition Range with Ferrofluid Applications. J. Phys. Condens. Matter 2006, 18, S2527–S2542. [Google Scholar] [CrossRef]

- Faraji, M.; Yamini, Y.; Rezaee, M. Magnetic Nanoparticles: Synthesis, Stabilization, Functionalization, Characterization, and Applications. J. Iran. Chem. Soc. 2010, 7, 1–37. [Google Scholar] [CrossRef]

- Xu, J.; Yang, H.B.; Fu, W.Y.; Du, K.; Sui, Y.M.; Chen, J.J.; Zeng, Y.; Li, M.H.; Zou, G. Preparation and Magnetic Properties of Magnetite Nanoparticles by Sol-Gel Method. J. Magn. Magn. Mater. 2007, 309, 307–311. [Google Scholar] [CrossRef]

- Alexiou, C.; Arnold, W.; Klein, R.J.; Parak, F.G.; Hulin, P.; Bergemann, C.; Erhardt, W.; Wagenpfeil, S.; Lubbe, A.S. Locoregional Cancer Treatment with Magnetic Drug Targeting. Cancer Res. 2000, 60, 6641–6648. [Google Scholar] [PubMed]

- Lubbe, A.S.; Bergemann, C.; Riess, H.; Schriever, F.; Reichardt, P.; Possinger, K.; Matthias, M.; Dorken, B.; Herrmann, F.; Gurtler, R.; et al. Clinical Experiences with Magnetic Drag Targeting: A Phase I Study With 4′-Epidoxorubicin in 14 Patients with Advanced Solid Tumors. Cancer Res. 1996, 56, 4686–4693. [Google Scholar] [PubMed]

- Gleich, B.; Weizenecker, R. Tomographic Imaging Using the Nonlinear Response of Magnetic Particles. Nature 2005, 435, 1214–1217. [Google Scholar] [CrossRef] [PubMed]

- Dutz, S.; Hergt, R. Magnetic Particle Hyperthermia—A Promising Tumour Therapy? Nanotechnology 2014, 25. [Google Scholar] [CrossRef] [PubMed]

- Dutz, S.; Hergt, R.; Mürbe, J.; Töpfer, J.; Muller, R.; Zeisberger, M.; Andrä, W.; Bellemann, M.E. Magnetic Nanoparticles for Biomedical Heating Applications. Z. Phys. Chem. 2006, 220, 145–151. [Google Scholar] [CrossRef]

- Bordelon, D.E.; Cornejo, C.; Gruttner, C.; Westphal, F.; DeWeese, T.L.; Ivkov, R. Magnetic Nanoparticle Heating Efficiency Reveals Magneto-Structural Differences when Characterized with Wide Ranging and High Amplitude Alternating Magnetic Fields. J. Appl. Phys. 2011, 109. [Google Scholar] [CrossRef]

- Meng, L.; Gan, N.; Li, T.; Cao, Y.; Hu, F.; Zheng, L. A Three-Dimensional, Magnetic and Electroactive Nanoprobe for Amperometric Determination of Tumor Biomarkers. Int. J. Mol. Sci. 2011, 12, 362–375. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez-Fernandez, M.A.; Torres, T.E.; Andres-Verges, M.; Costo, R.; de la Presa, P.; Serna, C.J.; Morales, M.R.; Marquina, C.; Ibarra, M.R.; Goya, G.F. Magnetic nanoparticles for power absorption: Optimizing size, shape and magnetic properties. J. Solid State Chem. 2009, 182, 2779–2784. [Google Scholar] [CrossRef]

- Bae, K.H.; Park, M.; Do, M.J.; Lee, N.; Ryu, J.H.; Kim, G.W.; Kim, C.; Park, T.G.; Hyeon, T. Chitosan Oligosaccharide-Stabilized Ferrimagnetic Iron Oxide Nanocubes for Magnetically Modulated Cancer Hyperthermia. Acs Nano 2012, 6, 5266–5273. [Google Scholar] [CrossRef] [PubMed]

- Nishio, K.; Ikeda, M.; Gokon, N.; Tsubouchi, S.; Narimatsu, H.; Mochizuki, Y.; Sakamoto, S.; Sandhu, A.; Abe, M.; Handa, H. Preparation of size-controlled (30–100 nm) magnetite nanoparticles for biomedical applications. J. Magn. Magn. Mater. 2007, 310, 2408–2410. [Google Scholar] [CrossRef]

- Verges, M.A.; Costo, R.; Roca, A.G.; Marco, J.F.; Goya, G.F.; Serna, C.J.; Morales, M.P. Uniform and Water Stable Magnetite Nanoparticles with Diameters Around the Monodomain-Multidomain Limit. J. Phys. D 2008, 41. [Google Scholar] [CrossRef]

- Ristic, M.; Krehula, S.; Reissner, M.; Jean, M.; Hannoyer, B.; Music, S. Synthesis and properties of precipitated cobalt ferrite nanoparticles. J. Mol. Struct. 2017, 1140, 32–38. [Google Scholar] [CrossRef]

- Khandhar, A.P.; Keselman, P.; Kemp, S.J.; Ferguson, R.M.; Goodwill, P.W.; Conolly, S.M.; Krishnan, K.M. Evaluation of PEG-coated iron oxide nanoparticles as blood pool tracers for preclinical magnetic particle imaging. Nanoscale 2017, 9, 1299–1306. [Google Scholar] [CrossRef] [PubMed]

- Ludwig, R.; Stapf, M.; Dutz, S.; Müller, R.; Teichgräber, U.; Hilger, I. Structural Properties of Magnetic Nanoparticles Determine Their Heating Behavior—An Estimation of the In Vivo Heating Potential. Nanoscale Res. Lett. 2014, 9, 602. [Google Scholar] [CrossRef] [PubMed]

- Hergt, R.; Dutz, S.; Müller, R.; Zeisberger, M. Magnetic Particle Hyperthermia: Nanoparticle Magnetism and Materials Development for Cancer Therapy. J. Phys. Condens. Matter 2006, 18, S2919–S2934. [Google Scholar] [CrossRef]

- Lee, J.-H.; Jang, J.-T.; Choi, J.-S.; Moon, S.H.; Noh, S.-H.; Kim, J.-W.; Kim, J.-G.; Kim, I.-S.; Park, K.I.; Cheon, J. Exchange-Coupled Magnetic Nanoparticles for Efficient Heat Induction. Nat. Nanotechnol. 2011, 6, 418–422. [Google Scholar] [CrossRef] [PubMed]

- Lottini, E.; Lopez-Ortega, A.; Bertoni, G.; Turner, S.; Meledina, M.; Van Tendeloo, G.; Fernandez, C.D.J.; Sangregorio, C. Strongly Exchange Coupled CorelShell Nanoparticles with High Magnetic Anisotropy: A Strategy toward Rare-Earth-Free Permanent Magnets. Chem. Mater. 2016, 28, 4214–4222. [Google Scholar] [CrossRef]

- Phadatare, M.R.; Meshram, J.V.; Gurav, K.V.; Kim, J.H.; Pawar, S.H. Enhancement of Specific Absorption Rate by Exchange Coupling of the Core-Shell Structure of Magnetic Nanoparticles for Magnetic Hyperthermia. J. Phys. D 2016, 49. [Google Scholar] [CrossRef]

- Zhang, Q.; Castellanos-Rubio, I.; Munshi, R.; Orue, I.; Pelaz, B.; Gries, K.I.; Parak, W.J.; del Pino, P.; Pralle, A. Model Driven Optimization of Magnetic Anisotropy of Exchange-Coupled Core-Shell Ferrite Nanoparticles for Maximal Hysteretic Loss. Chem. Mater. 2015, 27, 7380–7387. [Google Scholar] [CrossRef]

- Barón, M.; Hellwich, K.H.; Hess, M.; Horie, K.; Jenkins, A.D.; Jones, R.G.; Kahovec, J.; Kratochvíl, P.; Metanomski, W.V.; Mormann, W.; et al. Glossary of Class Names of Polymers Based on Chemical Structure and Molecular Architecture (Iupac Recommendations 2009). Pure Appl. Chem. 2009, 81, 1131–1186. [Google Scholar] [CrossRef]

- Laschewsky, A. Structures and Synthesis of Zwitterionic Polymers. Polymers 2014, 6, 1544–1601. [Google Scholar] [CrossRef]

- Branch, D.W.; Wheeler, B.C.; Brewer, G.J.; Leckband, D.E. Long-term stability of grafted polyethylene glycol surfaces for use with microstamped substrates in neuronal cell culture. Biomaterials 2001, 22, 1035–1047. [Google Scholar] [CrossRef]

- Sharma, S.; Johnson, R.W.; Desai, T.A. Evaluation of the Stability of Nonfouling Ultrathin Poly(ethylene glycol) Films for Silicon-Based Microdevices. Langmuir 2004, 20, 348–356. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Xue, H.; Li, W.; Zhang, J.; Jiang, S. Pursuing “Zero” Protein Adsorption of Poly(carboxybetaine) from Undiluted Blood Serum and Plasma. Langmuir 2009, 25, 11911–11916. [Google Scholar] [CrossRef] [PubMed]

- Lalani, R.; Liu, L. Electrospun Zwitterionic Poly(Sulfobetaine Methacrylate) for Nonadherent, Superabsorbent, and Antimicrobial Wound Dressing Applications. Biomacromolecules 2012, 13, 1853–1863. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Chen, S.; Jiang, S. Dual-Functional Biomimetic Materials: Nonfouling Poly(carboxybetaine) with Active Functional Groups for Protein Immobilization. Biomacromolecules 2006, 7, 3311–3315. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Cao, Z. Ultralow-Fouling, Functionalizable, and Hydrolyzable Zwitterionic Materials and Their Derivatives for Biological Applications. Adv. Mater. 2010, 22, 920–932. [Google Scholar] [CrossRef] [PubMed]

- Alexis, F.; Pridgen, E.; Molnar, L.K.; Farokhzad, O.C. Factors Affecting the Clearance and Biodistribution of Polymeric Nanoparticles. Mol. Pharm. 2008, 5, 505–515. [Google Scholar] [CrossRef] [PubMed]

- Jang, S.H.; Wientjes, M.G.; Lu, D.; Au, J.L.-S. Drug Delivery and Transport to Solid Tumors. Pharm. Res. 2003, 20, 1337–1350. [Google Scholar] [CrossRef] [PubMed]

- Ma, H.; Hyun, J.; Stiller, P.; Chilkoti, A. “Non-Fouling” Oligo(ethylene glycol)-Functionalized Polymer Brushes Synthesized by Surface-Initiated Atom Transfer Radical Polymerization. Adv. Mater. 2004, 16, 338–341. [Google Scholar] [CrossRef]

- Li, L.; Chen, S.; Zheng, J.; Ratner, B.D.; Jiang, S. Protein Adsorption on Oligo(ethylene glycol)-Terminated Alkanethiolate Self-Assembled Monolayers: The Molecular Basis for Nonfouling Behavior. J. Phys. Chem. B 2005, 109, 2934–2941. [Google Scholar] [CrossRef] [PubMed]

- Knop, K.; Hoogenboom, R.; Fischer, D.; Schubert, U.S. Poly(ethylene glycol) in Drug Delivery: Pros and Cons as Well as Potential Alternatives. Angew. Chem. Int. Ed. 2010, 49, 6288–6308. [Google Scholar] [CrossRef] [PubMed]

- Singer, S.J.; Nicolson, G.L. The Fluid Mosaic Model of the Structure of Cell Membranes. Science 1972, 175, 720–731. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Wang, L.; Chi, X.; Bao, J.; Yang, L.; Zhao, W.; Chen, Z.; Wang, X.; Chen, X.; Gao, J. Engineered Iron-Oxide-Based Nanoparticles as Enhanced T1 Contrast Agents for Efficient Tumor Imaging. ACS Nano 2013, 7, 3287–3296. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yuan, S.; Zhang, Y.; Wu, W.; Hu, Y.; Jiang, X. The effects of poly(zwitterions)s versus poly(ethylene glycol) surface coatings on the biodistribution of protein nanoparticles. Biomater. Sci. 2016, 4, 1351–1360. [Google Scholar] [CrossRef] [PubMed]

- Muro, E.; Fragola, A.; Pons, T.; Lequeux, N.; Ioannou, A.; Skourides, P.; Dubertret, B. Comparing Intracellular Stability and Targeting of Sulfobetaine Quantum Dots with Other Surface Chemistries in Live Cells. Small 2012, 8, 1029–1037. [Google Scholar] [CrossRef] [PubMed]

- Mayhew, E.; Harlos, J.P.; Juliano, R.L. The effect of polycations on cell membrane stability and transport processes. J. Membr. Biol. 1973, 14, 213–228. [Google Scholar] [CrossRef] [PubMed]

- Lowe, A.B.; McCormick, C.L. Synthesis and Solution Properties of Zwitterionic Polymers. Chem. Rev. 2002, 102, 4177–4190. [Google Scholar] [CrossRef] [PubMed]

- Kudaibergenov, S.; Jäger, W.; Laschewsky, A. Polymeric Betaines: Synthesis, Characterization, and Application. Adv. Polym. Sci. 2006, 201, 157–224. [Google Scholar]

- Singh, P.K.; Singh, V.K.; Singh, M. Zwitterionic Polyelectrolytes: A Review. e-Polymers 2007, 7, 335–368. [Google Scholar] [CrossRef]

- Tarannum, N.; Singh, M. Advances in synthesis of Sulfo and Carbo Analogues of Polybetaines: A Review. Rev. Adv. Sci. Eng. 2013, 2, 90–111. [Google Scholar] [CrossRef]

- Ostermayer, B.; Albrecht, O.; Vogt, W. Polymerizable Lipid Analogs of Diacetylenic Phosphonic-Acids—Synthesis, Spreading Behavior and Polymerization at the Gas-Water Interface. Chem. Phys. Lipids 1986, 41, 265–291. [Google Scholar] [CrossRef]

- Hamaide, T.; Germanaud, L.; Leperchec, P. New Polymeric Phosphonatobetaine, Phosphinatobetaine and Carboxybetaine. 1. Syntheses and Characterization by Ir Spectroscopy. Makromol. Chem. 1986, 187, 1097–1107. [Google Scholar] [CrossRef]

- Al-Hamouz, O.C.S.; Ali, S.A. pH-responsive polyphosphonates using butler’s cyclopolymerization. J. Polym. Sci. Polym. Chem. 2012, 50, 3580–3591. [Google Scholar] [CrossRef]

- Xue, C.H.; Cai, F.F.; Liu, H.Y. Ultrasensitive fluorescent responses of water-soluble, zwitterionic, boronic acid-bearing, regioregular head-to-tail polythiophene to biological species. Chem. Eur. J. 2008, 14, 1648–1653. [Google Scholar] [CrossRef] [PubMed]

- Yoshizawa, M.; Hirao, M.; Ito-Akita, K.; Ohno, H. Ion conduction in zwitterionic-type molten salts and their polymers. J. Mater. Chem. 2001, 11, 1057–1062. [Google Scholar] [CrossRef]

- Stöber, W.; Fink, A.; Bohn, E. Controlled growth of monodisperse silica spheres in the micron size range. J. Colloid Interface Sci. 1968, 26, 62–69. [Google Scholar] [CrossRef]

- Urena-Benavides, E.E.; Lin, E.L.; Foster, E.L.; Xue, Z.; Ortiz, M.R.; Fei, Y.; Larsen, E.S.; Kmetz, A.A., II; Lyon, B.A.; Moaseri, E.; et al. Low Adsorption of Magnetite Nanoparticles with Uniform Polyelectrolyte Coatings in Concentrated Brine on Model Silica and Sandstone. Ind. Eng. Chem. Res. 2016, 55, 1522–1532. [Google Scholar] [CrossRef]

- Bach, L.G.; Islam, M.R.; Kim, J.T.; Seo, S.; Lim, K.T. Encapsulation of Fe3O4 magnetic nanoparticles with poly(methyl methacrylate) via surface functionalized thiol-lactam initiated radical polymerization. Appl. Surf. Sci. 2012, 258, 2959–2966. [Google Scholar] [CrossRef]

- Zhang, X.A.; Lin, W.; Chen, S.; Xu, H.; Gu, H. Development of a Stable Dual Functional Coating with Low Non-specific Protein Adsorption and High Sensitivity for New Superparamagnetic Nanospheres. Langmuir 2011, 27, 13669–13674. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Xiong, Z.; Zhang, L.; Zhao, J.; Zhang, Q.; Peng, L.; Zhang, W.; Ye, M.; Zou, H. Facile synthesis of zwitterionic polymer-coated core-shell magnetic nanoparticles for highly specific capture of N-linked glycopeptides. Nanoscale 2015, 7, 3100–3108. [Google Scholar] [CrossRef] [PubMed]

- Von der Lühe, M.; Günther, U.; Weidner, A.; Grafe, C.; Clement, J.H.; Dutz, S.; Schacher, F.H. SPION@polydehydroalanine hybrid particles. RSC Adv. 2015, 5, 31920–31929. [Google Scholar] [CrossRef]

- Pombo-Garcia, K.; Weiss, S.; Zarschler, K.; Ang, C.-S.; Hübler, R.; Pufe, J.; Meister, S.; Seidel, J.; Pietzsch, J.; Spiccia, L.; et al. Zwitterionic Polymer-Coated Ultrasmall SuperparamagneticIron Oxide Nanoparticles with low Protein Interaction and High Biocompatibility. ChemNanoMat 2016, 2, 959–971. [Google Scholar] [CrossRef]

- Mincheva, R.; Stoilova, O.; Penchev, H.; Ruskov, T.; Spirov, I.; Manolova, N.; Rashkov, I. Synthesis of Polymer-Stabilized Magnetic Nanoparticles and Fabrication of Nanocomposite Fibers Thereof Using Electrospinning. Eur. Polym. J. 2008, 44, 615–627. [Google Scholar] [CrossRef]

- Zhang, L.; Xue, H.; Gao, C.; Carr, L.; Wang, J.; Chu, B.; Jiang, S. Imaging and Cell Targeting Characteristics of Magnetic Nanoparticles Modified by a Functionalizable Zwitterionic Polymer with Adhesive 3,4-Dihydroxyphenyl-l-Alanine Linkages. Biomaterials 2010, 31, 6582–6588. [Google Scholar] [CrossRef] [PubMed]

- Monteil, C.; Bar, N.; Bee, A.; Villemin, D. An Efficient Recyclable Magnetic Material for the Selective Removal of Organic Pollutants. Beilstein J. Nanotechnol. 2016, 7, 1447–1453. [Google Scholar] [CrossRef] [PubMed]

- Korpany, K.V.; Majewski, D.D.; Chiu, C.T.; Cross, S.N.; Blum, A.S. Iron Oxide Surface Chemistry: Effect of Chemical Structure on Binding in Benzoic Acid and Catechol Derivatives. Langmuir 2017, 33, 3000–3013. [Google Scholar] [CrossRef] [PubMed]

- Yabu, H.; Koike, R.; Hirai, D.Y. Preparation of Poly(Vinyl Catechol-block-Styrene) (PVCa-b-PSt) Stabilized Iron Oxide Nanoparticles by Ligand Exchange and Janus Particle Formation. J. Nanosci. Nanotechnol. 2017, 17, 9251–9256. [Google Scholar] [CrossRef]

- Li, P.; Xiao, W.; Chevallier, P.; Biswas, D.; Ottenwaelder, X.; Fortin, M.-A.; Oh, J.K. Extremely Small Iron Oxide Nanoparticles Stabilized with Catechol-Functionalized Multidentate Block Copolymer for Enhanced MRI. ChemistrySelect 2016, 1, 4087–4091. [Google Scholar] [CrossRef]

- Amstad, E.; Gehring, A.U.; Fischer, H.; Nagaiyanallur, V.V.; Hähner, G.; Textor, M.; Reimhult, E. Influence of Electronegative Substituents on the Binding Affinity of Catechol-Derived Anchors to Fe3O4 Nanoparticles. J. Phys. Chem. C 2011, 115, 683–691. [Google Scholar] [CrossRef]

- Miles, W.C.; Huffstetler, P.P.; Goff, J.D.; Chen, A.Y.; Riffle, J.S.; Davis, R.M. Design of stable polyether-magnetite complexes in aqueous media: Effects of the anchor group, molecular weight, and chain density. Langmuir 2011, 27, 5456–5463. [Google Scholar] [CrossRef] [PubMed]

- Goff, J.D.; Huffstetler, P.P.; Miles, W.C.; Pothayee, N.; Reinholz, C.M.; Ball, S.; Davis, R.M.; Riffle, J.S. Novel Phosphonate-Functional Poly(ethylene oxide)-Magnetite Nanoparticles Form Stable Colloidal Dispersions in Phosphate-Buffered Saline. Chem. Mater. 2009, 21, 4784–4795. [Google Scholar] [CrossRef]

- Maliakal, A.; Katz, H.; Cotts, P.M.; Subramoney, S.; Mirau, P. Inorganic Oxide Core, Polymer Shell Nanocomposite as a High K Gate Dielectric for Flexible Electronics Applications. J. Am. Chem. Soc. 2005, 127, 14655–14662. [Google Scholar] [CrossRef] [PubMed]

- Caruso, F. Nanoengineering of Particle Surfaces. Adv. Mater. 2001, 13, 11–22. [Google Scholar] [CrossRef]

- Babu, K.; Dhamodharan, R. Synthesis of Polymer Grafted Magnetite Nanoparticle with the Highest Grafting Density via Controlled Radical Polymerization. Nanoscale Res. Lett. 2009, 4, 1090–1102. [Google Scholar] [CrossRef] [PubMed]

- Hassan, P.A.; Rana, S.; Verma, G. Making Sense of Brownian Motion: Colloid Characterization by Dynamic Light Scattering. Langmuir 2015, 31, 3–12. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.-Y.; Wu, D.-C.; Li, Z.-J.; Chen, G.-Q. Polymer Nanoparticles. Prog. Mol. Biol. Transl. Sci. 2011, 104, 299–323. [Google Scholar] [PubMed]

- Lim, J.; Yeap, S.P.; Che, H.X.; Low, S.C. Characterization of magnetic nanoparticle by dynamic light scattering. Nanoscale Res. Lett. 2013, 8, 381. [Google Scholar] [CrossRef] [PubMed]

- Mestrom, L.; Lenders, J.J.M.; de Groot, R.; Hooghoudt, T.; Sommerdijk, N.A.J.M.; Artigas, M.V. Stable ferrofluids of magnetite nanoparticles in hydrophobic ionic liquids. Nanotechnology 2015, 26, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Zhang, X.; Liu, Y.; Lin, Z.Y.; Liu, B.; Liu, J. Profiling Metal Oxides with Lipids: Magnetic Liposomal Nanoparticles Displaying DNA and Proteins. Angew. Chem. Int. Ed. 2016, 55, 12063–12067. [Google Scholar] [CrossRef] [PubMed]

- Bonnaud, C.; Monnier, C.A.; Demurtas, D.; Jud, C.; Vanhecke, D.; Montet, X.; Hovius, R.; Lattuada, M.; Rothen-Rutishauser, B.; Petri-Fink, A. Insertion of Nanoparticle Clusters into Vesicle Bilayers. ACS Nano 2014, 8, 3451–3460. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, D.; Tenzer, S.; Bannwarth, M.B.; Messerschmidt, C.; Glaser, S.-F.; Schild, H.; Landfester, K.; Mailaender, V. Mass Spectrometry and Imaging Analysis of Nanoparticle-Containing Vesicles Provide a Mechanistic Insight into Cellular Trafficking. ACS Nano 2014, 8, 10077–10088. [Google Scholar] [CrossRef] [PubMed]

- Clogston, J.D.; Patri, A.K. Zeta Potential Measurement. In Characterization of Nanoparticles Intended for Drug Delivery; McNeil, S.E., Ed.; Humana Press: Totowa, NJ, USA, 2011; pp. 63–70. [Google Scholar]

- Monopoli, M.P.; Aberg, C.; Salvati, A.; Dawson, K.A. Biomolecular Coronas Provide the Biological Identity of Nanosized Materials. Nat. Nanotechnol. 2012, 7, 779–786. [Google Scholar] [CrossRef] [PubMed]

- López, J.; González, F.; Bonilla, F.; Zambrano, G.; Gomez, M. Synthesis and characterization of Fe3O4 magnetic nanofluid. Rev. LatinAm. Metal. Mat. 2010, 30, 60–66. [Google Scholar]

- Mansfield, E.; Tyner, K.M.; Poling, C.M.; Blacklock, J.L. Determination of Nanoparticle Surface Coatings and Nanoparticle Purity Using Microscale Thermogravimetric Analysis. Anal. Chem. 2014, 86, 1478–1484. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Han, Y.; Qiao, R.; Zeng, J.; Jia, Q.; Wang, Y.; Gao, M. Investigations on the Interactions between Plasma Proteins and Magnetic Iron Oxide Nanoparticles with Different Surface Modifications. J. Phys. Chem. C 2010, 114, 21270–21276. [Google Scholar] [CrossRef]

- Qin, L.; Xu, Y.; Han, H.; Liu, M.; Chen, K.; Wang, S.; Wang, J.; Xu, J.; Li, L.; Guo, X. β-Lactoglobulin (BLG) binding to highly charged cationic polymer-grafted magnetic nanoparticles: Effect of ionic strength. J. Colloid Interface Sci. 2015, 460, 221–229. [Google Scholar] [CrossRef] [PubMed]

- Zhao, T.; Chen, K.; Gu, H. Investigations on the Interactions of Proteins with Polyampholyte-Coated Magnetite Nanoparticles. J. Phys. Chem. B 2013, 117, 14129–14135. [Google Scholar] [CrossRef] [PubMed]

- Joseph, D.; Sachar, S.; Kishore, N.; Chandra, S. Mechanistic insights into the interactions of magnetic nanoparticles with bovine serum albumin in presence of surfactants. Colloids Surf. B Biointerfaces 2015, 135, 596–603. [Google Scholar] [CrossRef] [PubMed]

- Alfrey, T.; Fuoss, R.M.; Morawetz, H.; Pinner, H. Amphoteric Polyelectrolytes. II. Copolymers of Methacrylic Acid and Diethylaminoethyl Methacrylate1. J. Am. Chem. Soc. 1952, 74, 438–441. [Google Scholar] [CrossRef]

- Alfrey, T.; Morawetz, H.; Fitzgerald, E.B.; Fuoss, R.M. Synthetic electrical analog of Proteins1. J. Am. Chem. Soc. 1950, 72, 1864. [Google Scholar] [CrossRef]

- Ladenheim, H.; Morawetz, H. A new type of polyampholyte: Poly(4-vinyl pyridine betaine). J. Polym. Sci. 1957, 26, 251–254. [Google Scholar] [CrossRef]

- Billing, M.; Gräfe, C.; Saal, A.; Biehl, P.; Clement, J.H.; Dutz, S.; Weidner, S.; Schacher, F.H. Zwitterionic Iron Oxide (γ-Fe2O3) Nanoparticles Based on P(2VP-grad-AA) Copolymers. Macromol. Rapid Commun. 2017, 38. [Google Scholar] [CrossRef] [PubMed]

- Billing, M.; Schacher, F.H. ATRP of tert-Butoxycarbonylaminomethyl acrylate (tBAMA): Well-Defined Precursors for Polyelectrolytes of Tunable Charge. Macromolecules 2016, 49, 3696–3705. [Google Scholar] [CrossRef]

- Yuan, J.J.; Armes, S.P.; Takabayashi, Y.; Prassides, K.; Leite, C.A.P.; Galembeck, F.; Lewis, A.L. Synthesis of Biocompatible Poly[2-(methacryloyloxy)ethyl phosphorylcholine]-Coated Magnetite Nanoparticles. Langmuir 2006, 22, 10989–10993. [Google Scholar] [CrossRef] [PubMed]

- Hildebrand, V.; Heydenreich, M.; Laschewsky, A.; Möller, H.M.; Müller-Buschbaum, P.; Papadakis, C.M.; Schanzenbach, D.; Wischerhoff, E. “Schizophrenic” self-assembly of dual thermoresponsive block copolymers bearing a zwitterionic and a non-ionic hydrophilic block. Polymer 2017, 122, 347–357. [Google Scholar] [CrossRef]

- Zhu, A.; Yuan, L.; Dai, S. Preparation of Well-Dispersed Superparamagnetic Iron Oxide Nanoparticles in Aqueous Solution with Biocompatible N-Succinyl-O-carboxymethylchitosan. J. Phys. Chem. C 2008, 112, 5432–5438. [Google Scholar] [CrossRef]

- Demillo, V.G.; Zhu, X. Zwitterionic Amphiphile Coated Magnetofluorescent Nanoparticles—Synthesis, Characterization and Tumor Cell Targeting. J. Mater. Chem. B 2015, 3, 8328–8336. [Google Scholar] [CrossRef] [PubMed]

- Xiao, W.; Lin, J.; Li, M.; Ma, Y.; Chen, Y.; Zhang, C.; Li, D.; Gu, H. Prolonged in vivo circulation time by zwitterionic modification of magnetite nanoparticles for blood pool contrast agents. Contrast Media Mol. Imaging 2012, 7, 320–327. [Google Scholar] [CrossRef] [PubMed]

- Von der Lühe, M.; Weidner, A.; Dutz, S.; Schacher, F.H. Reversible Electrostatic Adsorption of Polyelectrolytes and Bovine Serum Albumin onto Polyzwitterion-Coated Magnetic Multicore Nanoparticles: Implications for Sensing and Drug Delivery. Appl. Nano Mater. 2017. in Revision. [Google Scholar] [CrossRef]

- Yeh, C.-H.; Chen, S.-H.; Li, D.-T.; Lin, H.-P.; Huang, H.-J.; Chang, C.-I.; Shih, W.-L.; Chern, C.-L.; Shi, F.-K.; Hsu, J.-L. Magnetic Bead-Based Hydrophilic Interaction Liquid Chromatography for Glycopeptide Enrichments. J. Chromatogr. A 2012, 1224, 70–78. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Wang, L.; Yang, W. Preparation and Characterization of Functional Inorganic/Organic Composite Microspheres via Electrostatic Interaction. J. Colloid Interface Sci. 2009, 333, 749–756. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Chen, Y.; Xiong, Z.; Sun, X.; Zhang, Q.; Gan, Y.; Zhang, L.; Zhang, W. Synthesis of Magnetic Zwitterionic-Hydrophilic Material for the Selective Enrichment of N-Linked Glycopeptides. J. Chromatogr. A 2017, 1482, 23–31. [Google Scholar] [CrossRef] [PubMed]

- Fidale, L.C.; Nikolajski, M.; Rudolph, T.; Dutz, S.; Schacher, F.H.; Heinze, T. Hybrid Fe3O4@amino Cellulose Nanoparticles in Organic Media—Heterogeneous Ligands for Atom Transfer Radical Polymerizations. J. Colloid Interface Sci. 2013, 390, 25–33. [Google Scholar] [CrossRef] [PubMed]

| Nr. | Polyzwitterionic Unit Structure/Name | Binding Method | Application | Type of Polyelectrolyte +/− |

|---|---|---|---|---|

| 1 |  P(AMPS-co-AA) [128] | covalent attachment via grafting-to to amino-silylated particles | weak/strong | |

| 2 |  PCBMA [130] | grafting-from | Sensing | Strong/weak |

| 3 |  PMSA [131] | grafting-through using γ-MPS (silylation) | Isolation of glycoptides from biological samples (bioseparation) | strong/strong |

| Nr. | Polyzwitterionic Unit Structure/Name | Binding Method | Application | Type of Polyelectrolyte +/− |

|---|---|---|---|---|

| 4 |  P(AA-stat-PDEAPA) [170] | carboxyl group anchoring, grafting-to | weak/weak | |

| 5 |  P(2VP-grad-AA) [164] | carboxyl group anchoring, grafting-to | antifouling | weak/weak |

| 6 |  PDha[132] | carboxyl group anchoring, grafting-to | antifouling | weak/weak |

| 7 |  NSOCMS [168] | carboxyl group anchoring, grafting-to | weak/weak | |

| 8 |  PCBMA[135] | Catechol anchoring, grafting-to | strong/weak | |

| 9 |  PMPC-b-PGMA [166] | adsorption via bishydroxides of the PGMA block, grafting-to | strong/weak |

| Nr. | Polyzwitterionic Unit Structure/Name | Binding Method | Application | Type of Polyelectrolyte +/− |

|---|---|---|---|---|

| 10 |  P4VP-SB [172] | electrostatic interactions PAA@MNP | isolation of glycopeptides from biological samples (bio-separation) | strong/strong |

| 11 |  PMAO-CB-SB [169] | hydrophilic hydrophobic interactions | cancer diagnosis | strong/weak |

| 12 |  PAsp [173] | polyelectrolyte complexes between chitosan (CS) and poly(aspartic acid) (PAsp) with encapsulated MNP | weak/weak | |

| 13 |  PMAL [133] | hydrophilic hydrophobic interactions | anti-fouling | weak/weak |

| 14 |  CeCh [134] | adsorption via carboxylates | electro spinning | weak/weak |

| 15 |  PAMPS [134] | sulfonate anchoring | electro spinning | weak/strong |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biehl, P.; Von der Lühe, M.; Dutz, S.; Schacher, F.H. Synthesis, Characterization, and Applications of Magnetic Nanoparticles Featuring Polyzwitterionic Coatings. Polymers 2018, 10, 91. https://doi.org/10.3390/polym10010091

Biehl P, Von der Lühe M, Dutz S, Schacher FH. Synthesis, Characterization, and Applications of Magnetic Nanoparticles Featuring Polyzwitterionic Coatings. Polymers. 2018; 10(1):91. https://doi.org/10.3390/polym10010091

Chicago/Turabian StyleBiehl, Philip, Moritz Von der Lühe, Silvio Dutz, and Felix H. Schacher. 2018. "Synthesis, Characterization, and Applications of Magnetic Nanoparticles Featuring Polyzwitterionic Coatings" Polymers 10, no. 1: 91. https://doi.org/10.3390/polym10010091