Swelling Behaviour of Superabsorbent Polymers for Soil Amendment under Different Loads

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

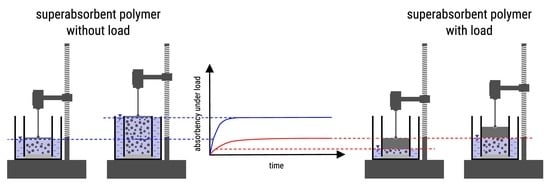

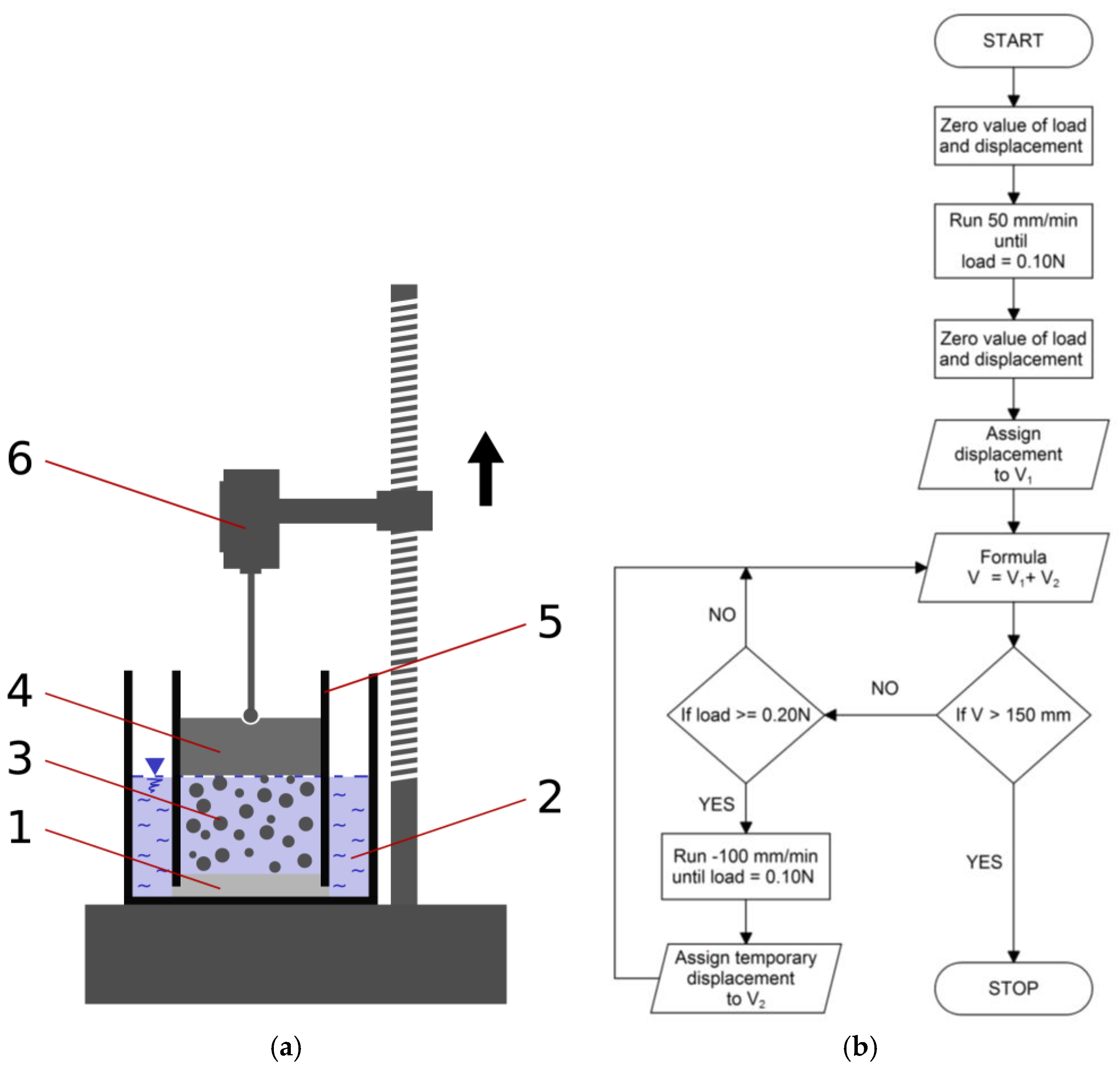

2.2. Measurment of AUL and Swelling Kinetics

3. Results

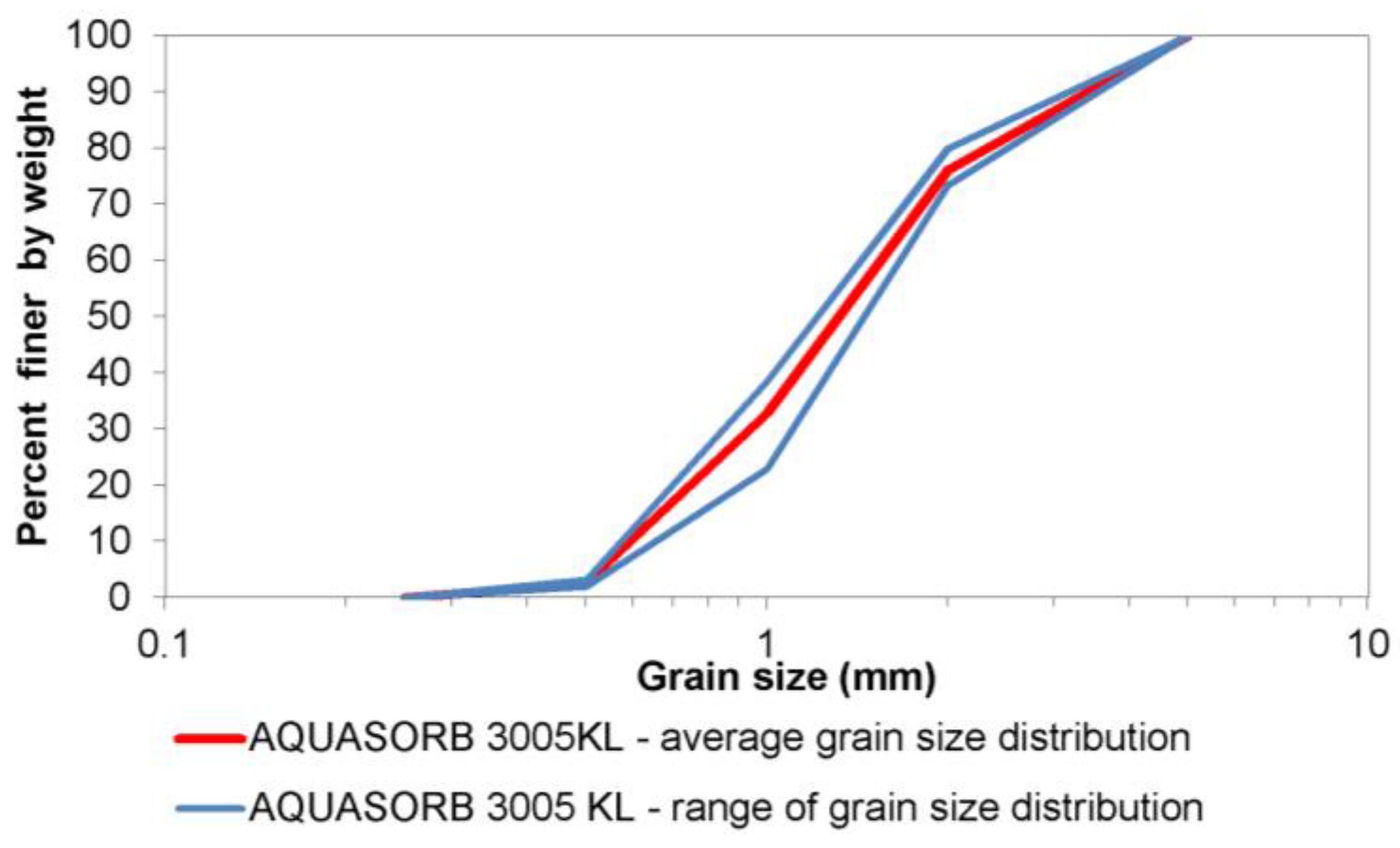

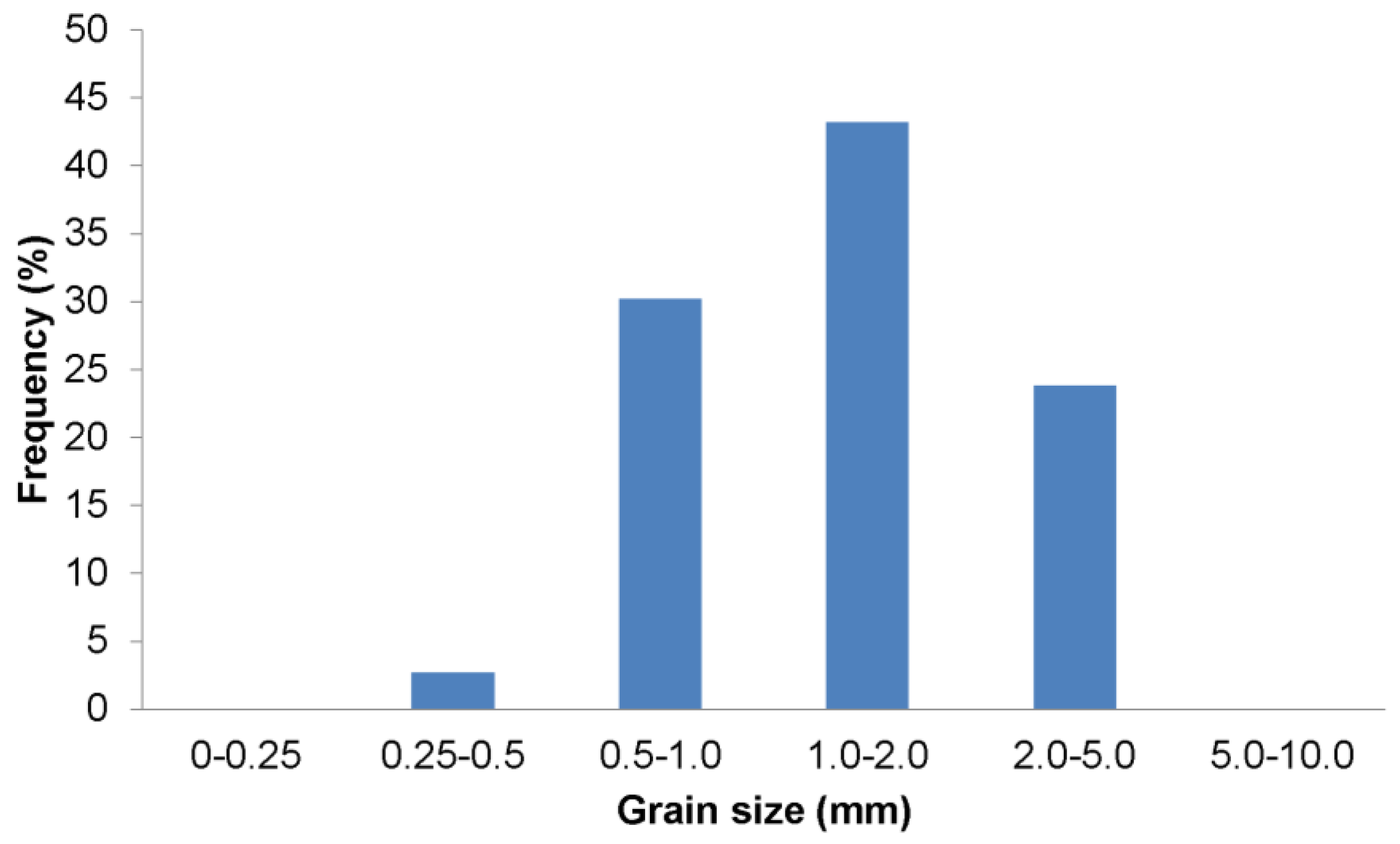

3.1. Grain Size Distribution of the Tested Superabsorbent Polymer

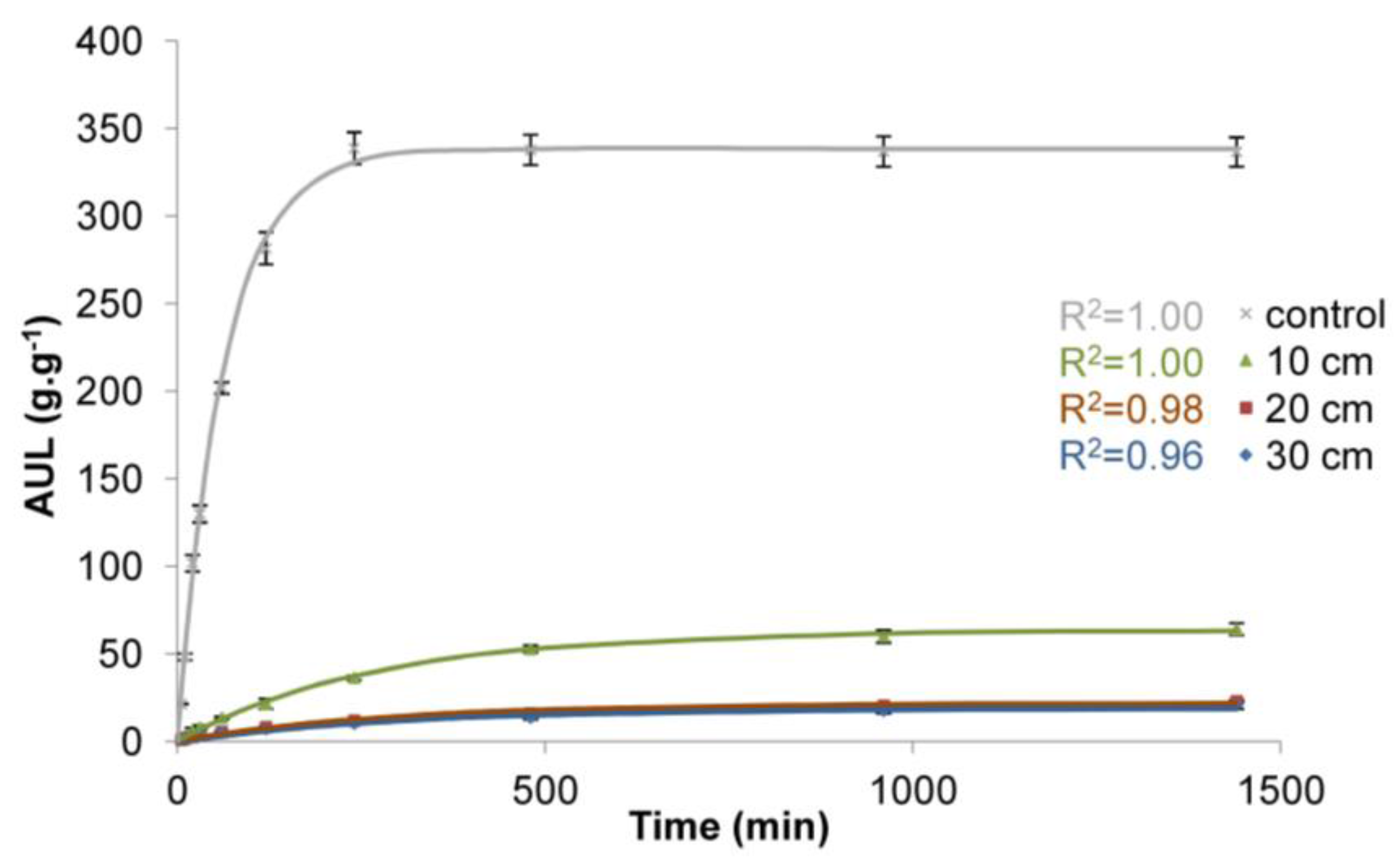

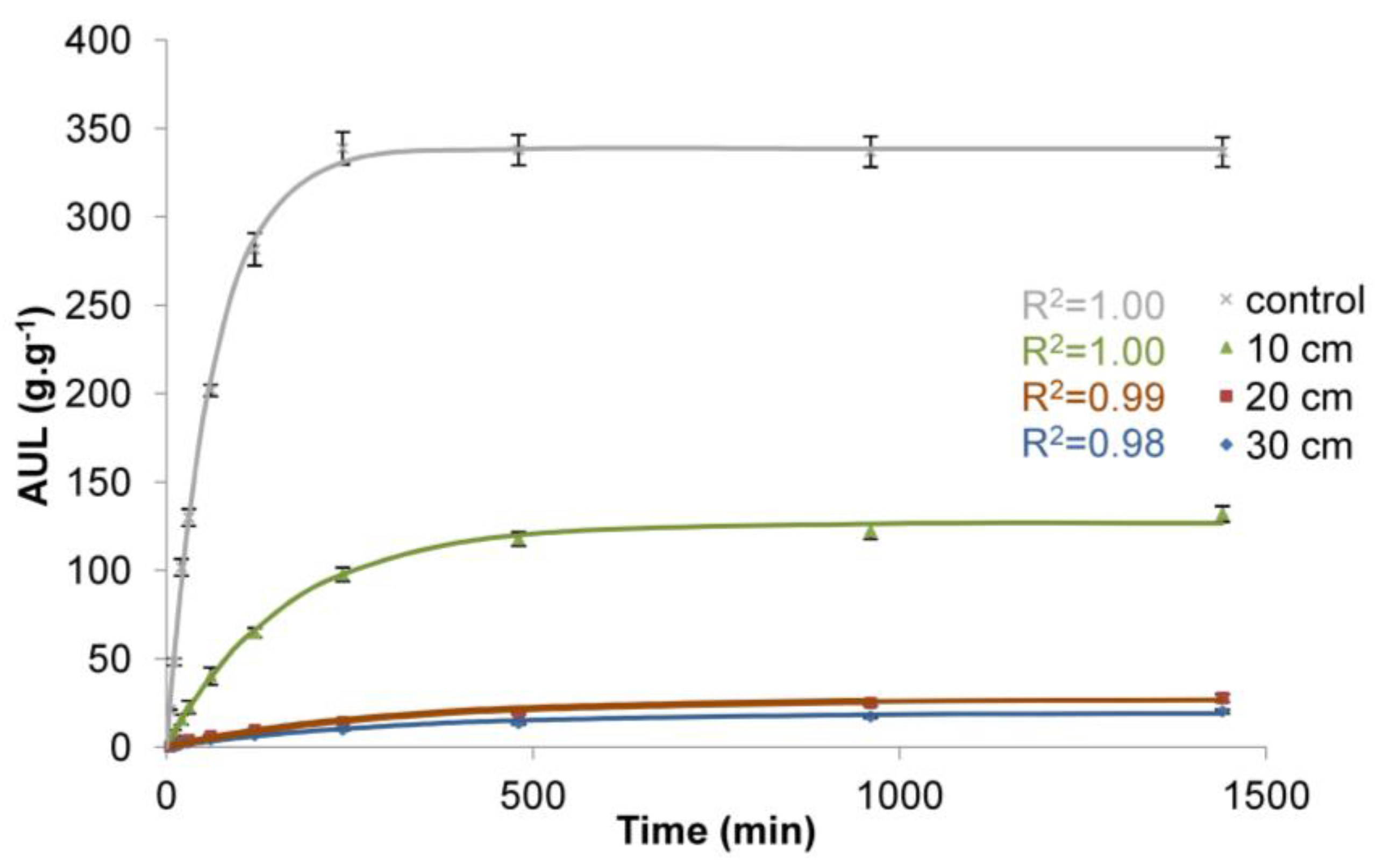

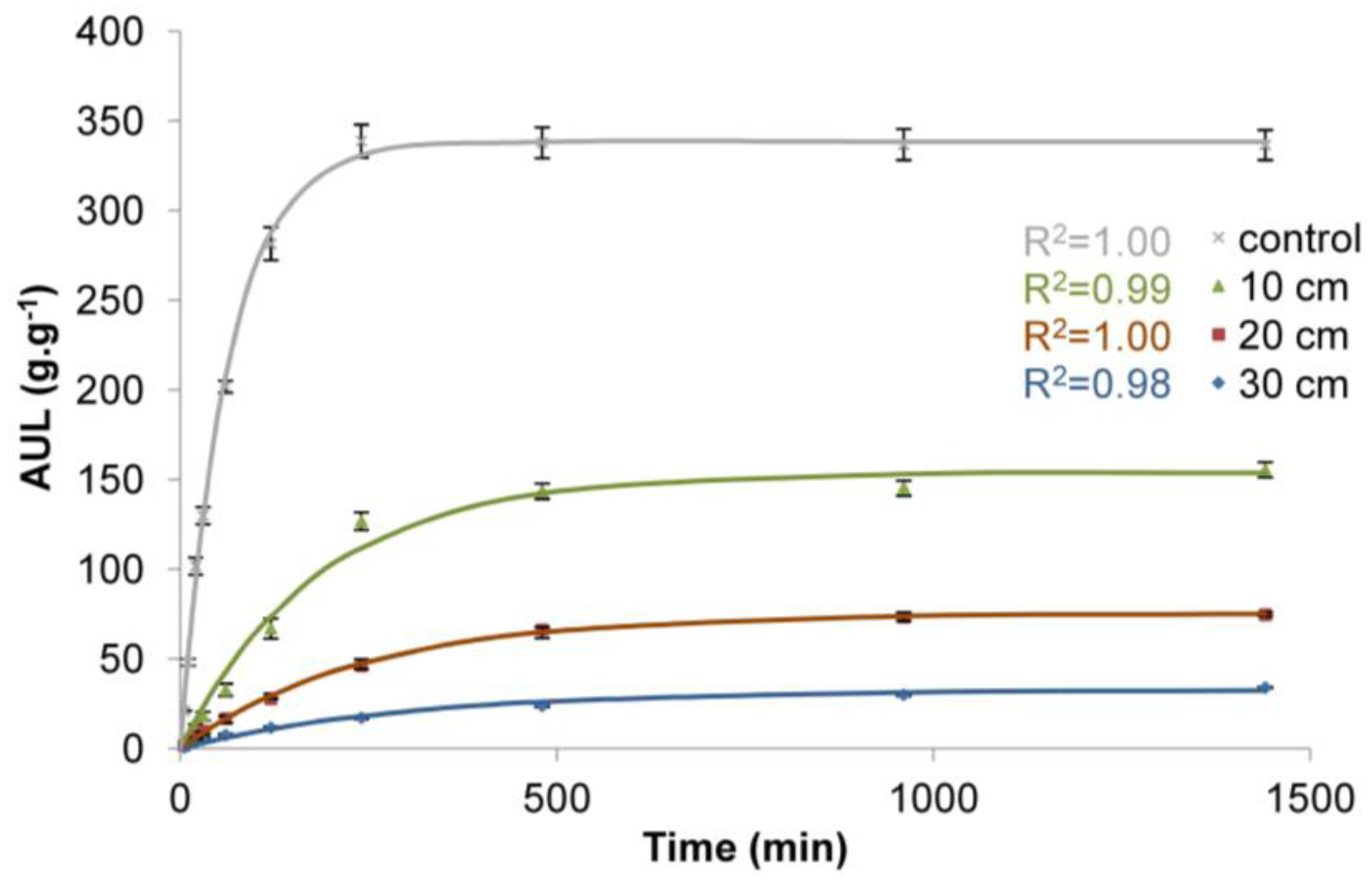

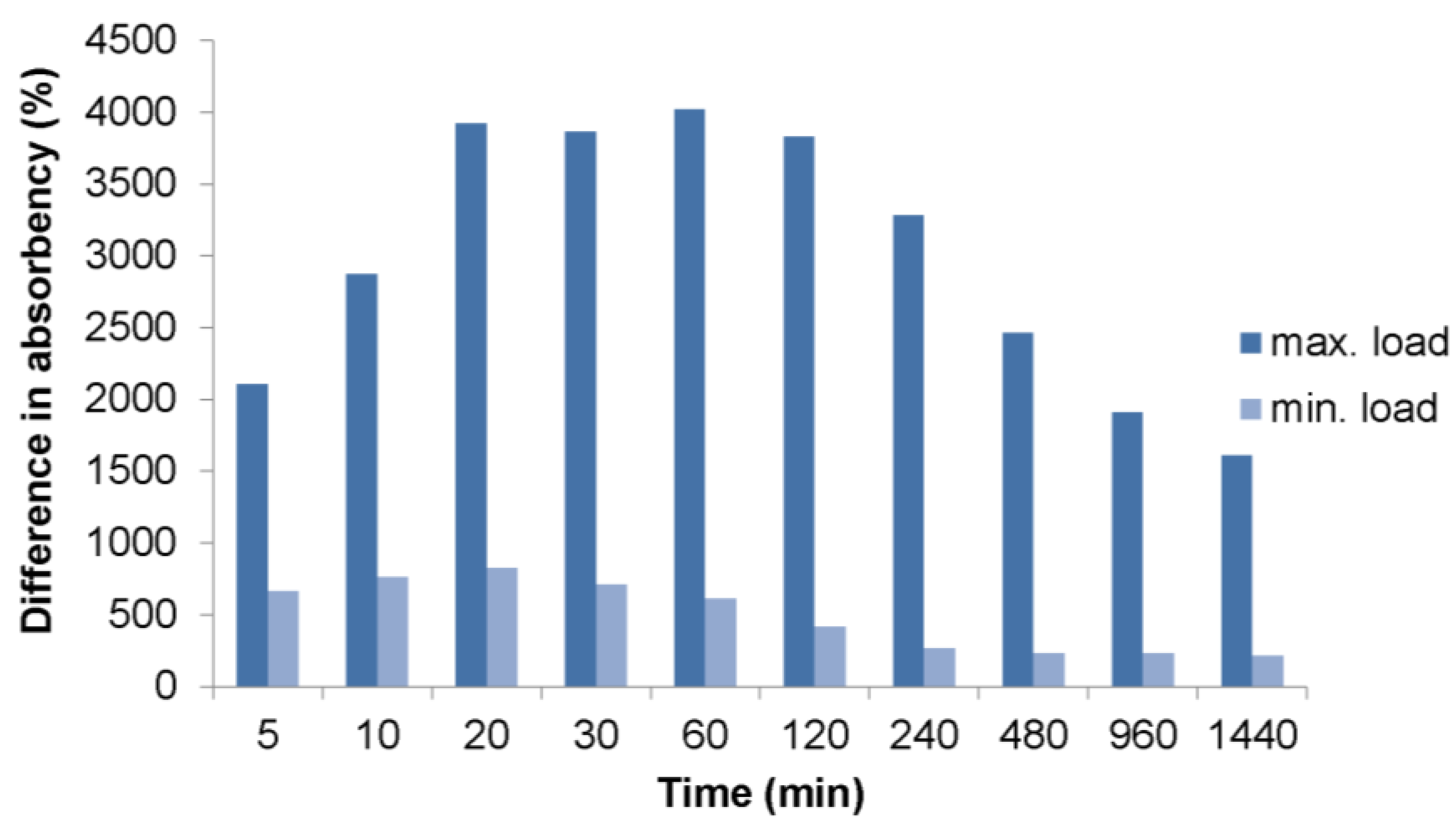

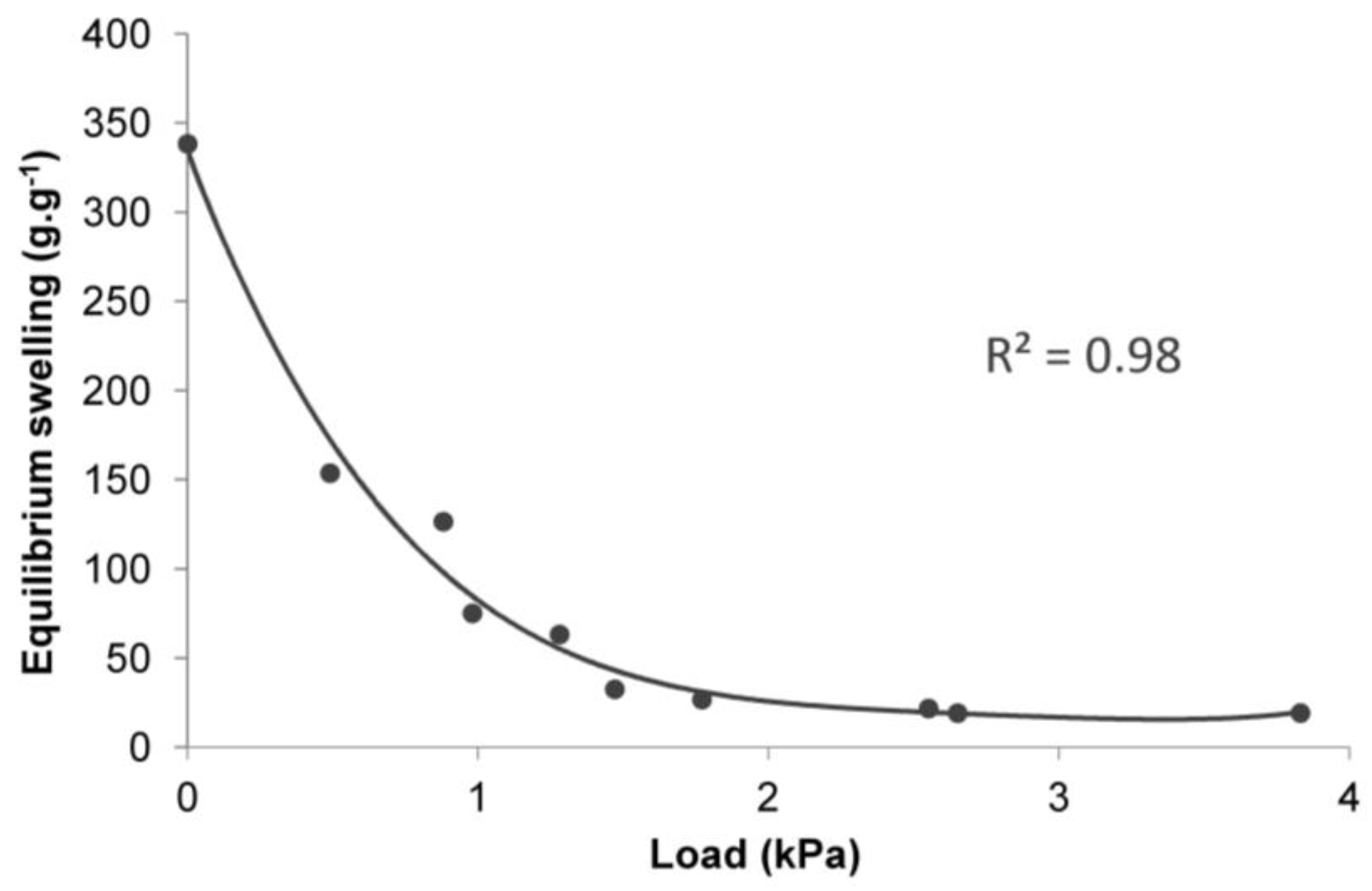

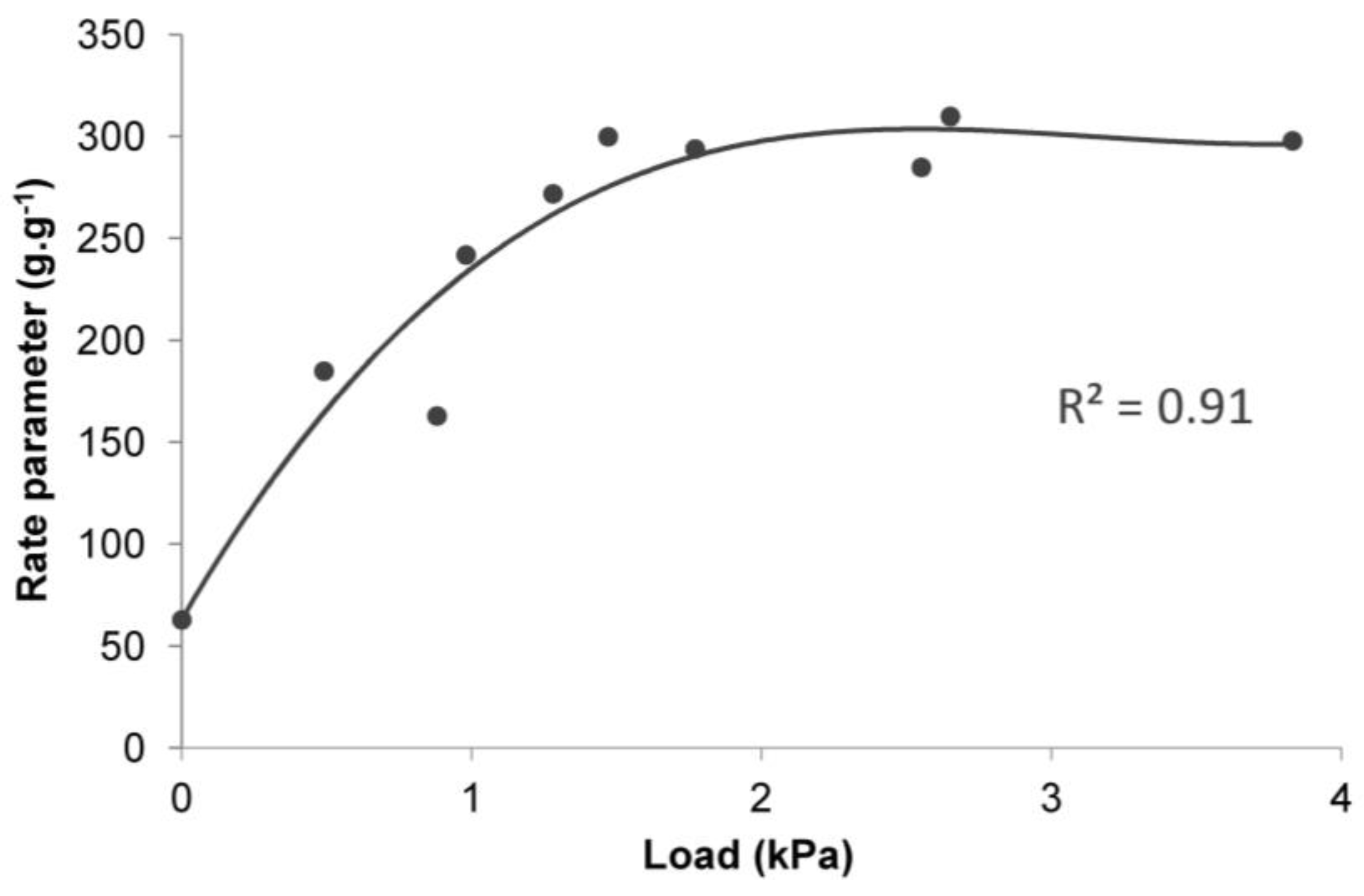

3.2. AUL and Swelling Kinetics

4. Discussion

5. Conclusions

6. Patents

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, X.; He, J.Z.; Hughes, J.M.; Liu, Y.R.; Zheng, Y.M. Effects of super-absorbent polymers on a soil-wheat (Triticum aestivum L.) system in the field. Appl. Soil Ecol. 2014, 73, 58–63. [Google Scholar] [CrossRef]

- Laftah, W.A.; Hashim, S.; Ibrahim, A.N. Polymer hydrogels: A review. Polym. Plast. Technol. Eng. 2011, 50, 1475–1486. [Google Scholar] [CrossRef]

- Cheng, W.M.; Hu, X.M.; Wang, D.M.; Liu, G.H. Preparation and characteristics of corn straw-co-amps-co-aa superabsorbent hydrogel. Polymers 2015, 7, 2431–2445. [Google Scholar] [CrossRef]

- Calo, E.; Khutoryanskiy, V.V. Biomedical applications of hydrogels: A review of patents and commercial products. Eur. Polym. J. 2015, 65, 252–267. [Google Scholar] [CrossRef]

- Zohuriaan-Mehr, M.J.; Omidian, H.; Doroudiani, S.; Kabiri, K. Advances in non-hygienic applications of superabsorbent hydrogel materials. J. Mater. Sci. 2010, 45, 5711–5735. [Google Scholar] [CrossRef]

- Justs, J.; Wyrzykowski, M.; Winnefeld, F.; Bajare, D.; Lura, P. Influence of superabsorbent polymers on hydration of cement pastes with low water-to-binder ratio. J. Therm. Anal. Calorim. 2014, 115, 425–432. [Google Scholar] [CrossRef]

- Yang, L.X.; Yang, Y.; Chen, Z.; Guo, C.X.; Li, S.C. Influence of super absorbent polymer on soil water retention, seed germination and plant survivals for rocky slopes eco-engineering. Ecol. Eng. 2014, 62, 27–32. [Google Scholar] [CrossRef]

- Bakass, M.; Mokhlisse, A.; Lallemant, M. Absorption and desorption of liquid water by a superabsorbent polymer: Effect of polymer in the drying of the soil and the quality of certain plants. J. Appl. Polym. Sci. 2002, 83, 234–243. [Google Scholar] [CrossRef]

- Xu, S.T.; Zhang, L.; McLaughlin, N.B.; Mi, J.Z.; Chen, Q.; Liu, J.H. Effect of synthetic and natural water absorbing soil amendment soil physical properties under potato production in a semi-arid region. Soil Tillage Res. 2015, 148, 31–39. [Google Scholar] [CrossRef]

- Palacios-Romero, A.; Rodriguez-Laguna, R.; Razo-Zarate, R.; Meza-Rangel, J.; Prieto-Garcia, F.; Hernandez-Flores, M.D. Survival of plants of pinus leiophylla schiede ex schltdl. & charm., by adding water reservoirs at transplanting in a greenhouse. Rev. Chapingo Ser. Cienc. For. Am. 2017, 23, 35–45. [Google Scholar]

- Lejcus, K.; Dabrowska, J.; Grzybowska-Pietras, J.; Garlikowski, D.; Lejcus, I.; Pawlowski, A.; Spitalniak, M. Optimisation of operational parameters for nonwoven sheaths of water absorbing geocomposites in unsaturated soil conditions. Fibres Text. East. Eur. 2016, 24, 110–116. [Google Scholar] [CrossRef]

- Song, X.; Zhu, C.; Fan, D.; Mi, Y.; Li, X.; Fu, R.; Duan, Z.; Wang, Y.; Feng, R. A novel human-like collagen hydrogel scaffold with porous structure and sponge-like properties. Polymers 2017, 9, 638. [Google Scholar] [CrossRef]

- Dang, J.; Zhao, J.; Du, Z. Effect of superabsorbent polymer on the properties of concrete. Polymers 2017, 9, 672. [Google Scholar] [CrossRef]

- Yun, K.K.; Kim, K.K.; Choi, W.; Yeon, J.H. Hygral behavior of superabsorbent polymers with various particle sizes and cross-linking densities. Polymers 2017, 9, 600. [Google Scholar] [CrossRef]

- Huttermann, A.; Orikiriza, L.J.B.; Agaba, H. Application of superabsorbent polymers for improving the ecological chemistry of degraded or polluted lands. Clean-Soil Air Water 2009, 37, 517–526. [Google Scholar] [CrossRef]

- Akelah, A. Functionalized Polymeric Materials in Agriculture and the Food Industry; Springer US: New York, NY, USA, 2013. [Google Scholar]

- Sivapalan, S. Benefits of treating a sandy soil with a crosslinked-type polyacrylamide. Aust. J. Exp. Agric. 2006, 46, 579–584. [Google Scholar] [CrossRef]

- Liang, R.; Liu, M.Z.; Wu, L. Controlled release npk compound fertilizer with the function of water retention. React. Funct. Polym. 2007, 67, 769–779. [Google Scholar] [CrossRef]

- Rudzinski, W.E.; Dave, A.M.; Vaishanav, U.H.; Kumbar, S.G.; Kulkarni, A.R.; Aminabhavi, T.M. Hydrogels as controlled release devices in agriculture. Des. Monomers Polym. 2002, 5, 39–65. [Google Scholar] [CrossRef]

- Wei, Y.; Durian, D.J. Effect of hydrogel particle additives on water-accessible pore structure of sandy soils: A custom pressure plate apparatus and capillary bundle model. Phys. Rev. E 2013, 87, 10. [Google Scholar] [CrossRef] [PubMed]

- Jakubiak-Marcinkowska, A.; Ronka, S.; Pilśniak-Rabiega, M.; Butewicz, A.; Czulak, J.; Trochimczuk, A.W. Changes of the ion content in soil contacted hydrogels. In Separation Science Theory and Practice 2011; Jakubiak-Marcinkowska, A., Trochimczuk, A.W., Eds.; Oficyna Wydawnicza Politechniki Wrocławskiej: Kudowa Zdrój, Poland, 2011. [Google Scholar]

- Dabrowska, J.; Lejcus, K. Characteristics of selected properties of superabsorbents. Infrastruct. Ecol. Rural Areas 2012, 3, 59–68. [Google Scholar]

- Banedjschafie, S.; Durner, W. Water retention properties of a sandy soil with superabsorbent polymers as affected by aging and water quality. J. Plant Nutr. Soil Sci. 2015, 178, 798–806. [Google Scholar] [CrossRef]

- Zohuriaan-Mehr, M.J.; Kabiri, K. Superabsorbent polymer materials: A review. Iran. Polym. J. 2008, 17, 451–477. [Google Scholar]

- Oksinska, M.P.; Magnucka, E.G.; Lejcus, K.; Pietr, S.J. Biodegradation of the cross-linked copolymer of acrylamide and potassium acrylate by soil bacteria. Environ. Sci. Pollut. Res. 2016, 23, 5969–5977. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.T.; Xu, S.M.; Shi, X.M.; Feng, S.; Wang, J.D. Synthesis and properties of a novel double network nanocomposite hydrogel. Polym. Adv. Technol. 2009, 20, 645–649. [Google Scholar] [CrossRef]

- Li, A.; Wang, A.Q. Synthesis and properties of clay-based superabsorbent composite. Eur. Polym. J. 2005, 41, 1630–1637. [Google Scholar] [CrossRef]

- Santiago, F.; Mucientes, A.E.; Osorio, M.; Rivera, C. Preparation of composites and nanocomposites based on bentonite and poly(sodium acrylate). Effect of amount of bentonite on the swelling behaviour. Eur. Polym. J. 2007, 43, 1–9. [Google Scholar] [CrossRef]

- Hejduk, S.; Baker, S.W.; Spring, C.A. Evaluation of the effects of incorporation rate and depth of water-retentive amendment materials in sports turf constructions. Acta Agric. Scand. Sect. B-Soil Plant Sci. 2012, 62, 155–164. [Google Scholar]

- Sojka, R.E.; Lentz, R.D.; Westermann, D.T. Water and erosion management with multiple applications of polyacrylamide in furrow irrigation. Soil Sci. Soc. Am. J. 1998, 62, 1672–1680. [Google Scholar] [CrossRef]

- Frantz, J.M.; Locke, J.C.; Pitchay, D.S.; Krause, C.R. Actual performance versus theoretical advantages of polyacrylamide hydrogel throughout bedding plant production. Hortscience 2005, 40, 2040–2046. [Google Scholar]

- Islam, M.R.; Hu, Y.G.; Mao, S.S.; Mao, J.Z.; Eneji, A.E.; Xue, X.Z. Effectiveness of a water-saving super-absorbent polymer in soil water conservation for corn (Zea mays L.) based on eco-physiological parameters. J. Sci. Food Agric. 2011, 91, 1998–2005. [Google Scholar] [CrossRef] [PubMed]

- Syvertsen, J.P.; Dunlop, J.M. Hydrophilic gel amendments to sand soil can increase growth and nitrogen uptake efficiency of citrus seedlings. Hortscience 2004, 39, 267–271. [Google Scholar]

- Wroblewska, K.; Debicz, R.; Babelewski, P. The influence of water sorbing geocomposite and pine bark mulching on growth and flowering of some perennial species. Acta Sci. Pol. Hortorum Cultus 2012, 11, 203–216. [Google Scholar]

- Omidian, H.; Hashemi, S.A.; Sammes, P.G.; Meldrum, I. A model for the swelling of superabsorbent polymers. Polymer 1998, 39, 6697–6704. [Google Scholar] [CrossRef]

- Buchholz, F.L.; Graham, A.T. Modern Superabsorbent Polymer Technology; Wiley-VCH: New York, NY, USA, 1997; p. 304. [Google Scholar]

- Ramazani-Harandi, M.J.; Zohuriaan-Mehr, M.J.; Yousefi, A.A.; Ershad-Langroudi, A.; Kabiri, K. Effects of structural variables on aul and rheological behavior of sap gels. J. Appl. Polym. Sci. 2009, 113, 3676–3686. [Google Scholar] [CrossRef]

- Ramazani-Harandi, M.J.; Zohuriaan-Mehr, M.J.; Yousefi, A.A.; Ershad-Langroudi, A.; Kabiri, K. Rheological determination of the swollen gel strength of superabsorbent polymer hydrogels. Polym. Test. 2006, 25, 470–474. [Google Scholar] [CrossRef]

- Osunbitan, J.A.; Oyedele, D.J.; Adekalu, K.O. Tillage effects on bulk density, hydraulic conductivity and strength of a loamy sand soil in southwestern nigeria. Soil Tillage Res. 2005, 82, 57–64. [Google Scholar] [CrossRef]

- Collins, G.; Stibbe, E.; Kroesbergen, B. Influence of soil moisture stress and soil bulk density on the imbibition of corn seeds in a sandy soil. Soil Tillage Res. 1984, 4, 361–370. [Google Scholar] [CrossRef]

- Sonneveld, C.; Voogt, W. Plant Nutrition of Greenhouse Crops; Springer: Amsterdam, The Netherlands, 2009; p. 431. [Google Scholar]

- Sutton, R. Green Roof Ecosystems; Springer International Publishing: Basel, Switzerland, 2015; Volume 223, p. 447. [Google Scholar]

- Craig, R.F. Soil Mechanics, 6th ed.; CRC Press: London, UK, 1997; p. 496. [Google Scholar]

- Pourjavadi, A.; Jahromi, P.E.; Seidi, F.; Salimi, H. Synthesis and swelling behavior of acrylatedstarch-g-poly (acrylic acid) and acrylated starch-g-poly (acrylamide) hydrogels. Carbohydr. Polym. 2010, 79, 933–940. [Google Scholar] [CrossRef]

- Sadeghi, M.; Hosseinzadeh, H. Synthesis and swelling behavior of starch-poly(sodium acrylate-co-acrylamide) superabsorbent hydrogel. Turk. J. Chem. 2008, 32, 375–388. [Google Scholar]

- Rosa, F.; Bordado, J.; Casquilho, M. Kinetics of water absorbency in aa/amps copolymers: Applications of a diffusion-relaxation model. Polymer 2002, 43, 63–70. [Google Scholar] [CrossRef]

- Ahmed, E.M. Hydrogel: Preparation, characterization, and applications: A review. J. Adv. Res. 2015, 6, 105–121. [Google Scholar] [CrossRef] [PubMed]

- Stephenson, D.J. Stormwater Hydrology and Drainage; Elsevier Science: Amsterdam, The Netherlands, 1981; Volume 14. [Google Scholar]

- Young, M.H.; Wierenga, P.J.; Warrick, A.W.; Hofmann, L.L.; Musil, S.A. Variability of wetting front velocities during a field-scale infiltration experiment. Water Resour. Res. 1999, 35, 3079–3087. [Google Scholar] [CrossRef]

- Knödel, K.; Lange, G.; Voigt, H.-J. Environmental Geology—Handbook of Field Methods and Case Studies; Springer: Berlin, Germany, 2007; p. 1358. [Google Scholar]

- Lejcus, K.; Dabrowska, J.; Garlikowski, D.; Spitalniak, M. The application of water-absorbing geocomposites to support plant growth on slopes. Geosynth. Int. 2015, 22, 452–456. [Google Scholar] [CrossRef]

- Leciejewski, P. The effect of hydrogel additives on the water retention curve of sandy soil from forest nursery in julinek. J. Water Land Dev. 2009, 13, 239–247. [Google Scholar] [CrossRef]

- Akhter, J.; Mahmood, K.; Malik, K.A.; Mardan, A.; Ahmad, M.; Iqbal, M.M. Effects of hydrogel amendment on water storage of sandy loam and loam soils and seedling growth of barley, wheat and chickpea. Plant Soil Environ. 2004, 50, 463–469. [Google Scholar] [CrossRef]

- Shahid, S.A.; Qidwai, A.A.; Anwar, F.; Ullah, I.; Rashid, U. Improvement in the water retention characteristics of sandy loam soil using a newly synthesized poly(acrylamide-co-acrylic acid)/alznfe2o4 superabsorbent hydrogel nanocomposite material. Molecules 2012, 17, 9397–9412. [Google Scholar] [CrossRef] [PubMed]

- Montesano, F.F.; Parente, A.; Santamaria, P.; Sannino, A.; Serio, F. Biodegradable superabsorbent hydrogel increases water retention properties of growing media and plant growth. Eff. Irriga. Manag. Effects Urban Rural Landsc. 2015, 4, 451–458. [Google Scholar]

- Bai, W.; Zhang, H.; Liu, B.; Wu, Y.; Song, J. Effects of super-absorbent polymers on the physical and chemical properties of soil following different wetting and drying cycles. Soil Use Manag. 2010, 26, 253–260. [Google Scholar] [CrossRef]

- Narjary, B.; Aggarwal, P.; Singh, A.; Chakraborty, D.; Singh, R. Water availability in different soils in relation to hydrogel application. Geoderma 2012, 187, 94–101. [Google Scholar] [CrossRef]

- Baran, A.; Zaleski, T.; Kulikowski, E.; Wieczorek, J. Hydrophysical and biological properties of sandy substrata enriched with hydrogel. Pol. J. Environ. Stud. 2015, 24, 2355–2362. [Google Scholar] [CrossRef]

| Load (Simulated Soil Layer Depth and Bulk Density) | τ (min) | Se (g∙g−1) | Standard Error of the Regression (g∙g−1) | Coefficient of Determination R2 (-) | Load (kPa) |

|---|---|---|---|---|---|

| 30 cm, ρ = 1.3 g∙cm−3 | 298 | 19.3 | 1.4 | 0.96 | 3.83 |

| 30 cm, ρ = 0.9 g∙cm−3 | 310 | 19.3 | 1.1 | 0.98 | 2.65 |

| 30 cm, ρ = 0.5 g∙cm−3 | 300 | 32.7 | 1.6 | 0.98 | 1.47 |

| 20 cm, ρ = 1.3 g∙cm−3 | 285 | 21.9 | 1.3 | 0.98 | 2.55 |

| 20 cm, ρ = 0.9 g∙cm−3 | 294 | 26.9 | 1.3 | 0.99 | 1.77 |

| 20 cm, ρ = 0.5 g∙cm−3 | 242 | 75.3 | 1.1 | 1.00 | 0.98 |

| 10 cm, ρ = 1.3 g∙cm−3 | 272 | 63.4 | 1.3 | 1.00 | 1.28 |

| 10 cm, ρ = 0.9 g∙cm−3 | 163 | 126.6 | 2.7 | 1.00 | 0.88 |

| 10 cm, ρ = 0.5 g∙cm−3 | 185 | 153.8 | 7.6 | 0.99 | 0.49 |

| Control without load | 63 | 338.5 | 5.7 | 1.00 | 0.00 |

| Test Group Versus Control | p-Value | Statistically Significant |

|---|---|---|

| 30 cm, ρ = 1.3 g∙cm−3 | 0.00003 | yes |

| 30 cm, ρ = 0.9 g∙cm−3 | 0.00003 | yes |

| 30 cm, ρ = 0.5 g∙cm−3 | 0.00005 | yes |

| 20 cm, ρ = 1.3 g∙cm−3 | 0.00004 | yes |

| 20 cm, ρ = 0.9 g∙cm−3 | 0.00004 | yes |

| 20 cm, ρ = 0.5 g∙cm−3 | 0.00036 | yes |

| 10 cm, ρ = 1.3 g∙cm−3 | 0.00019 | yes |

| 10 cm, ρ = 0.9 g∙cm−3 | 0.00685 | yes |

| 10 cm, ρ = 0.5 g∙cm−3 | 0.01790 | yes |

| Authors | Applied Superabsorbent Polymer Additions (% w/w) | Type of Superabsorbent Polymer | Type of Soil | Bulk Density (g∙cm−3) | Volume Moisture (% v/v) | Mass Moisture (% w/w) |

|---|---|---|---|---|---|---|

| Shahid et al. [54] | 0 | poly(Acrylamide-co-acrylic acid)/AlZnFe2O4 | sandy loam | 1.46 | 25 | |

| 0.1 | 34 | |||||

| 0.2 | 36 | |||||

| 0.3 | 45 | |||||

| 0.4 | 55 | |||||

| Leciejewski [52] | 0 | Super Absorbent Plus | loamy sand | 1.67 | 26 | |

| 0.2 | 30 | |||||

| 0.3 | 32 | |||||

| Baran et al. [58] | 0 | Agroaquagel | loamy sand | 1.29 | 32 | |

| 0.2 | 41 | |||||

| 0.6 | 45 | |||||

| 1 | 55 | |||||

| Hutterman et al. [15] | 0 | N/a | sandy soil | N/a | 22 | |

| 0.4 | 33 | |||||

| Narjary et al. [57] | 0 | cellulose based grafted and crosslinked anionic polyacrylate | sandy soil | 1.6 | 24 | |

| 0.5 | 32 | |||||

| 0.7 | 38 | |||||

| Akhter et al. [53] | 0 | Polymerisation of acrylamide (N,N-methylbis-acrylamide) and mixed Na and K salts of acrylic acid | sandy loam | N/a | 28 | |

| 0.1 | 34 | |||||

| 0.2 | 36 | |||||

| 0.3 | 42 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lejcuś, K.; Śpitalniak, M.; Dąbrowska, J. Swelling Behaviour of Superabsorbent Polymers for Soil Amendment under Different Loads. Polymers 2018, 10, 271. https://doi.org/10.3390/polym10030271

Lejcuś K, Śpitalniak M, Dąbrowska J. Swelling Behaviour of Superabsorbent Polymers for Soil Amendment under Different Loads. Polymers. 2018; 10(3):271. https://doi.org/10.3390/polym10030271

Chicago/Turabian StyleLejcuś, Krzysztof, Michał Śpitalniak, and Jolanta Dąbrowska. 2018. "Swelling Behaviour of Superabsorbent Polymers for Soil Amendment under Different Loads" Polymers 10, no. 3: 271. https://doi.org/10.3390/polym10030271