Green Strategies for Molecularly Imprinted Polymer Development

Abstract

:1. Introduction

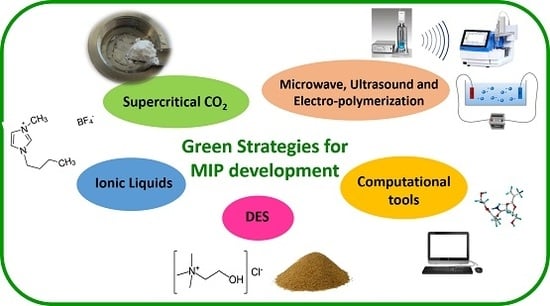

2. Green Strategies in MIP Development

2.1. Supercritical Fluid Technology

2.1.2. MIP-Supported Materials Preparation in scCO2

2.2. Ionic Liquids (ILs) and Deep Eutectic Solvents (DES)

2.2.1. ILs as Solvents (Porogenic Solvents)

2.2.2. ILs as Monomers

2.2.3. ILs as Crosslinkers

2.2.4. ILs as Templates

2.2.5. Deep Eutectic Solvents (DESs)

2.3. Ultrasound-Assisted MIP Synthesis

2.4. Microwave-Assisted MIP Synthesis

2.5. Solvent-Free and Solvent-Less MIP Preparation

2.6. Electropolymerization-Assisted MIPs

2.7. Computational Tools on Rational Design of MIPs

3. Conclusions

Acknowledgments

Conflicts of Interest

Abbreviations

| AAm | Acrylamide |

| AAP | Acetaminophen |

| ACET | Acetamide |

| ACN | Acetonitrile |

| AIBN | 2,2′-Azobis(2-methylpropionitrile) |

| AME | Ametryn |

| API | Active Pharmaceutical Ingredient |

| AS | Aspirin |

| ATR | Atrazine |

| AuNPs | Gold nanoparticles |

| BAI | Baicalein |

| BENZ | Benzamide |

| BHb | Bovine hemoglobin |

| [Bmim][BF4] | 1-butyl-3-methylimidazolium tetrafluoroborate |

| [Bmim][PF6] | 1-butyl-3-methylimidazolium hexafluorophosphate |

| BPA | Bisphenol A |

| BPADM | Bisphenol dimethacrylate |

| BPO | Benzoyl peroxide |

| BSA | Bovine serum albumin |

| [Bvim]Br | 1-Butyl-3-vinylimidazolium bromide |

| BZE | Benzoylecgonine |

| CAP | Chloramphenicol |

| CCl4 | Carbon tetrachloride |

| CE | Cocaethylene |

| CFME | Carbon fiber microelectrode |

| CHO | Cholesterol |

| CMZ | Carbamazepine |

| COC | Cocaine |

| CPFX | Ciprofloxacin |

| CV | Cyclic voltammetry |

| 2,4 D | 2,4-Dichlorophenoxyacetic acid |

| DBTSO2 | Dibenzothiophene sulfone |

| DEGDMA | Diethylene glycol dimethacrylate |

| DES | Deep Eutetic Solvents |

| DMAEMA | 2-(Dimethylamino)ethylmethacrylate |

| DMF | Dimethylformamide |

| DMPA | 2,2′-Dimethoxy-2-phenylacetophenone |

| DMSO | Dimethylsulfoxide |

| DNOC | 4,6-Dinitro- o-cresol |

| DPA | Bisphenol acid |

| EA | Albumin egg |

| EGDMA | Ethylene glycol dimethacrylate |

| EIS | Electrochemical impedance spectroscopy |

| EME | Ecgonine methyl ester |

| ENRH | Enrofloxacin hydrochloride |

| E2 | Estradiol |

| E3 | Estriol |

| FA | Flufenamic acid |

| FF | Florfenicol |

| FMMA | Ferrocenylmethyl methacrylate |

| FO | Folic acid |

| GA | Gallic acid |

| GTFX | Gatifloxacin |

| HEMA | 2-Hydroxyethyl methacrylate |

| HEX | Hexestrol |

| [Hmim][PF6] | 1-Hexyl-3-methylimidazolium hexafluorophosphate |

| HPLC | High Performance Liquid Chromatography |

| HAS | Human Albumin Serum |

| HVA | Homovanillic Acid |

| i-NAM | Isonicotinamide |

| IAA | Indole-3-acetic acid |

| IBU | Ibuprofen |

| IF | Imprinting factor |

| ITA | Itaconic acid |

| ITO | Indium tin oxide |

| IVMA | Isovanillic acid |

| LA | Labdanolic acid |

| Lyz | Lysozyme |

| LOFX | Levofloxacin |

| MAA | Methacrylic acid |

| MBAAM | N,N-Methylene bisacrylamide |

| 2-MBI | 2-Macaptobenzimidazole |

| MDMA | 3,4-Methylenedioxymethamphetamine |

| MHPE | 4-Hydroxy-3-methoxyphenylethanol |

| MMA | Methyl methacrylate |

| MAM | Methacrylamide |

| 1-MA-3MI-Br | 1-(α-Methyl acrylate)-3-methylimidazolium bromide |

| MET | Metribuzin |

| MPS | 3-(Trimethoxysilyl) propyl methacrylate |

| n-Bu4OH | Tetrabutylammonium hydroxide |

| NAM | Nicotinamide |

| 4-NAP | 2-Amino-4-nitrophenol |

| NIPAAm | N-Isopropylacrylamide |

| NMP | N-Methyl-2-pyrrolidone |

| NOFX | Norfloxacin |

| 2-NP | 2-Nitrophenol |

| 4-NP | 4-Nitrophenol |

| OA | Oleanolic acid |

| [Omim][PF6] | 1-Methyl-3-octylimidazolium hexafluorophosphate |

| o-PD | o-Phenylenediamine dihydrochloride |

| OTA | Ochratoxin A |

| PA6 | Polyamide-6 |

| PAM | Picolinamide |

| p-BA | p-Hydroxybenzoic acid |

| pc | Critical pressure |

| PEDOT | Poly(3,4-ethylenedioxythiophene) |

| PGE | Pencil graphite electrode |

| p-HBA | p-Hydroxylphenylacetic acid |

| PHDFDMA | Poly(heptadecafluorodecyl methacrylate) |

| p-HPPA | p-Hydroxyphenylpropionic acid |

| PIV | Pivalamide |

| p-NA | Nitrophenyl acetate |

| Poly(DEGDMA) | Poly(diethylene glycol dimethacrylate) |

| PPy | Polypyrrole |

| PSMA | Poly(styrene- co-maleic acid) |

| PZFX | Pazufloxacin |

| QDs | Quantum Dots |

| Qu | Quercetin |

| RES | Resveratrol |

| RhB | Rhodamine B |

| scCO2 | Supercritical carbon dioxide |

| SEM | Scanning electron microscopy |

| SPE | Solid phase extraction |

| SPME | Solid phase microextraction |

| St | Styrene |

| TBAH | Tetrabutylammonium hexafluorophosphate |

| TBAP | Tetrabutylammonium perchlorate |

| Tc | Critical temperature |

| TC | Tetracycline |

| TER | Terbutylazine |

| TFMAA | 2-(trifluoromethyl)acrylic acid |

| Tg | Glass transition temperature |

| THF | Tetrahydrofuran |

| THO | Theophylline |

| Tm | Melting temperature |

| TMPTA | Trimethylolpropane acrylate |

| TRI | (2-Amino-4-methoxy-6-methyl-1,3,5)-triazine |

| TRIM | Trimethylpropane Trimethacrylate |

| Tyr | Tyrosine |

| URA | Uracil |

| VMA | Vanillylmandelic acid |

| 2-Vpy | 2-Vinylpyridine |

| 4-Vpy | 4-Vinylpyridine |

References

- Anastas, P.T.; Warner, J.C. Green Chemistry: Theory and Practice; Oxford University Press: New York, NY, USA, 1998. [Google Scholar]

- EPA US Environmental Protection Agency. Available online: https://www.epa.gov/greenchemistry (accessed on 2 January 2018).

- El-Sharif, H.F.; Hawkins, D.M.; Stevenson, D.; Reddy, S.M. Determination of protein binding affinities within hydrogel-based molecularly imprinted polymers. Phys. Chem. Chem. Phys. 2014, 16, 15483–15489. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Boyère, C.; Jérôme, C.; Debuigne, A. Input of supercritical carbon dioxide to polymer synthesis: An overview. Eur. Polym. J. 2014, 61, 45–63. [Google Scholar] [CrossRef]

- Luckow, P.; Stanton, E.A.; Fields, S.; Biewald, B.; Jackson, S.; Fisher, J.; Wilson, R. Carbon Dioxide Price Forecast. Available online: http://www.synapse-energy.com/sites/default/files/2015CarbonDioxidePrice Report.pdf (accessed on 11 January 2018).

- Wimmer, Z.; Zarevúcka, M. A review on the effects of supercritical carbon dioxide on enzyme activity. Int. J. Mol. Sci. 2010, 11, 233–253. [Google Scholar] [CrossRef] [PubMed]

- Desimone, M.J.; Zihibin, G.; Elsbernd, C.S. Synthesis of Fluoropolymers in Supercritical Carbon Dioxide. Science 1992, 257, 945–947. [Google Scholar] [CrossRef] [PubMed]

- Hoefling, T.A.; Newman, D.A.; Enick, R.M.; Beckman, E.J. Effect of structure on the cloud-point curves of silicone-based amphiphiles in supercritical carbon dioxide. J. Supercrit. Fluids 1993, 6, 165–171. [Google Scholar] [CrossRef]

- Patel, D.; Kellici, S.; Saha, B. Green Process Engineering as the Key to Future Processes. Processes 2014, 2, 311–332. [Google Scholar] [CrossRef]

- Bonavoglia, B.; Storti, G.; Morbidelli, M.; Rajendran, A.; Mazzotti, M. Sorption and Swelling of Semicrystalline Polymers in Supercritical CO2. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 1531–1546. [Google Scholar] [CrossRef]

- Kazarian, S.G. Polymer Processing with Supercritical Fluids. Polym. Sci. Ser. C 2000, 42, 78–101. [Google Scholar] [CrossRef]

- Walker, T.A.; Frankowski, D.J.; Spontak, R.J. Thermodynamics and kinetic processes of polymer blends and block copolymers in the presence of pressurized carbon dioxide. Adv. Mater. 2008, 20, 879–898. [Google Scholar] [CrossRef]

- Restani, R.B.; Morgado, P.I.; Ribeiro, M.P.; Correia, I.J.; Aguiar-Ricardo, A.; Bonifácio, V.D.B. Biocompatible polyurea dendrimers with pH-dependent fluorescence. Angew. Chem. Int. Ed. 2012, 51, 5162–5165. [Google Scholar] [CrossRef] [PubMed]

- Araújo, M.; Viveiros, R.; Correia, T.R.; Correia, I.J.; Bonifácio, V.D.B.; Casimiro, T.; Aguiar-Ricardo, A. Natural melanin: A potential pH-responsive drug release device. Int. J. Pharm. 2014, 469, 140–145. [Google Scholar] [CrossRef] [PubMed]

- Barroso, T.; Viveiros, R.; Temtem, M.; Casimiro, T.; Botelho Do Rego, A.M.; Aguiar-Ricardo, A. A combined strategy to surface-graft stimuli-responsive hydrogels using plasma activation and supercritical carbon dioxide. ACS Macro Lett. 2012, 1, 356–360. [Google Scholar] [CrossRef]

- Barroso, T.; Viveiros, R.; Coelho, M.; Casimiro, T.; Botelho do Rego, A.M.; Aguiar-Ricardo, A. Influence of poly (N-isopropylacrylamide) and poly (N,N′-diethyl acrylamide) coatings on membranes for protein separation. Polym. Adv. Technol. 2012, 23, 381–1393. [Google Scholar] [CrossRef]

- Restani, R.B.; Silva, A.S.; Pires, R.F.; Cabral, R.P.; Correia, I.J.; Casimiro, T.; Bonifácio, V.D.B.; Aguiar-Ricardo, A. Nano-in-Micro POxylated Polyurea Dendrimers and Chitosan Dry Powder Formulations for Pulmonary Delivery. Part. Part. Syst. Charact. 2016, 33, 851–858. [Google Scholar] [CrossRef]

- Soares da Silva, M.; Viveiros, R.; Aguiar-Ricardo, A.; Bonifácio, V.D.B.; Casimiro, T. Supercritical fluid technology as a new strategy for the development of semi-covalent molecularly imprinted materials. RSC Adv. 2012, 2, 5075–5079. [Google Scholar] [CrossRef]

- Soares da Silva, M.; Viveiros, R.; Coelho, M.B.; Aguiar-Ricardo, A.; Casimiro, T. Supercritical CO2-assisted preparation of a PMMA composite membrane for bisphenol A recognition in aqueous environment. Chem. Eng. Sci. 2012, 68, 94–100. [Google Scholar] [CrossRef]

- Baggiani, C.; Baravalle, P.; Anfossi, L.; Tozzi, C. Comparison of pyrimethanil-imprinted beads and bulk polymer as stationary phase by non-linear chromatography. Anal. Chim. Acta 2005, 542, 125–134. [Google Scholar] [CrossRef]

- Cooper, A.I.; Hems, W.P.; Holmes, A.B. Synthesis of highly cross-linked polymers in supercritical carbon dioxide by heterogeneous polymerization. Macromolecules 1999, 32, 2156–2166. [Google Scholar] [CrossRef]

- Duarte, A.R.C.; Casimiro, T.; Aguiar-Ricardo, A.; Simplício, A.L.; Duarte, C.M.M. Supercritical fluid polymerisation and impregnation of molecularly imprinted polymers for drug delivery. J. Supercrit. Fluids 2006, 39, 102–106. [Google Scholar] [CrossRef]

- Ye, L.; Yoshimatsu, K.; Kolodziej, D.; Da Cruz Francisco, J.; Dey, E.S. Preparation of molecularly imprinted polymers in supercritical carbon dioxide. J. Appl. Polym. Sci. 2006, 102, 2863–2867. [Google Scholar] [CrossRef]

- Soares da Silva, M.; Vão, E.R.; Temtem, M.; Mafra, L.; Caldeira, J.; Aguiar-Ricardo, A.; Casimiro, T. Clean synthesis of molecular recognition polymeric materials with chiral sensing capability using supercritical fluid technology. Application as HPLC stationary phases. Biosens. Bioelectron. 2010, 25, 1742–1747. [Google Scholar] [CrossRef] [PubMed]

- Soares da Silva, M.; Nobrega, F.L.; Aguiar-Ricardo, A.; Cabrita, E.J.; Casimiro, T. Development of molecularly imprinted co-polymeric devices for controlled delivery of flufenamic acid using supercritical fluid technology. J. Supercrit. Fluids 2011, 58, 150–157. [Google Scholar] [CrossRef]

- Soares da Silva, M.; Viveiros, R.; Morgado, P.I.; Aguiar-Ricardo, A.; Correia, I.J.; Casimiro, T. Development of 2-(dimethylamino)ethyl methacrylate-based molecular recognition devices for controlled drug delivery using supercritical fluid technology. Int. J. Pharm. 2011, 416, 61–68. [Google Scholar] [CrossRef] [PubMed]

- Geens, T.; Aerts, D.; Berthot, C.; Bourguignon, J.P.; Goeyens, L.; Lecomte, P.; Maghuin-Rogister, G.; Pironnet, A.M.; Pussemier, L.; Scippo, M.L.; Van Loco, J.; Covaci, A. A review of dietary and non-dietary exposure to bisphenol-A. Food Chem. Toxicol. 2012, 50, 3725–3740. [Google Scholar] [CrossRef] [PubMed]

- Dairkee, S.H.; Seok, J.; Champion, S.; Sayeed, A.; Mindrinos, M.; Xiao, W.; Davis, R.W.; Goodson, W.H. Bisphenol A induces a profile of tumor aggressiveness in high-risk cells from breast cancer patients. Cancer Res. 2008, 68, 2076–2080. [Google Scholar] [CrossRef] [PubMed]

- Lang, I.A.; Galloway, T.S.; Scarlett, A.; Henley, W.E.; Depledge, M.; Wallace, R.B.; Melzer, D. Association of Urinary Bisphenol A Concentration With Medical Disorders and Laboratory Abnormalities in Adults. JAMA 2008, 300, 1303–1310. [Google Scholar] [CrossRef] [PubMed]

- Yoon, S.-D.; Byun, H.-S. Molecularly imprinted polymers for selective separation of acetaminophen and aspirin by using supercritical fluid technology. Chem. Eng. J. 2013, 226, 171–180. [Google Scholar] [CrossRef]

- Nikolaou, A.; Meric, S.; Fatta, D. Occurrence patterns of pharmaceuticals in water and wastewater environments. Anal. Bioanal. Chem. 2007, 387, 1225–1234. [Google Scholar] [CrossRef] [PubMed]

- Patrono, C.; Rocca, B. Aspirin: Promise and resistance in the new millennium. Arterioscler. Thromb. Vasc. Biol. 2008, 28, 25–33. [Google Scholar] [CrossRef] [PubMed]

- Byun, H.-S.; Youn, Y.-N.; Yun, Y.-H.; Yoon, S.-D. Selective separation of aspirin using molecularly imprinted polymers. Sep. Purif. Technol. 2010, 74, 144–153. [Google Scholar] [CrossRef]

- Byun, H.-S.; Yang, D.-S.; Cho, S.-H. Synthesis and characterization of high selective molecularly imprinted polymers for bisphenol A and 2,4-dichlorophenoxyacetic acid by using supercritical fluid technology. Polymer 2013, 54, 589–595. [Google Scholar] [CrossRef]

- Lee, J.C.; Kim, C.R.; Byun, H.S. Synthesis and adsorption properties of carbamazepine imprinted polymer by dispersion polymerization in supercritical carbon dioxide. Korean J. Chem. Eng. 2014, 31, 2266–2273. [Google Scholar] [CrossRef]

- Nair, R.; Gonen, S.; Hoag, S.W. Influence of polyethylene glycol and povidone on the polymorphic transformation and solubility of carbamazepine. Int. J. Pharm. 2002, 240, 11–22. [Google Scholar] [CrossRef]

- Bernus, I.; Dickinson, R.G.; Hooper, W.D.; Eadie, M.J. Dose-dependent metabolism of carbamazepine in humans. Epilepsy Res. 1996, 24, 163–172. [Google Scholar] [CrossRef]

- Martins, A.N.C.; Simeonov, S.P.; Frija, L.M.T.; Viveiros, R.; Lourenço, A.; Soares da Silva, M.; Casimiro, T.; Afonso, C.A.M. Isolation, analytical quantification and seasonal variation of labdanolic acid from the Portuguese-grown Cistus ladaniferus. Ind. Crops Prod. 2014, 60, 226–232. [Google Scholar] [CrossRef]

- Frija, L.M.T.; Frade, R.F.M.; Afonso, C.A.M. Isolation, chemical, and biotransformation routes of labdane-type diterpenes. Chem. Rev. 2011, 111, 4418–4452. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, J.P.; Viveiros, R.; Lourenço, A.; Soares da Silva, M.; Rosatella, A.; Casimiro, T.; Afonso, C.A.M. Integrated desulfurization of diesel by combination of metal-free oxidation and product removal by molecularly imprinted polymers. RSC Adv. 2014, 4, 54948–54952. [Google Scholar] [CrossRef]

- Byun, H.-S.; Chun, D. Adsorption and separation properties of gallic acid imprinted polymers prepared using supercritical fluid technology. J. Supercrit. Fluids 2017, 120, 249–257. [Google Scholar] [CrossRef]

- Locatelli, C.; Filippin-Monteiro, F.B.; Creczynski-Pasa, T.B. Alkyl esters of gallic acid as anticancer agents: A review. Eur. J. Med. Chem. 2013, 60, 233–239. [Google Scholar] [CrossRef] [PubMed]

- Viveiros, R.; Lopes, M.I.; Heggie, W.; Casimiro, T. Green approach on the development of lock-and-key polymers for API purification. Chem. Eng. J. 2017, 308, 229–239. [Google Scholar] [CrossRef]

- Bolt, H.M.; Foth, H.; Hengstler, J.G.; Degen, G.H. Carcinogenicity categorization of chemicals-new aspects to be considered in a European perspective. Toxicol. Lett. 2004, 151, 29–41. [Google Scholar] [CrossRef] [PubMed]

- Cunningham, A.R.; Rosenkranz, H.S.; Zhang, Y.P.; Klopman, G. Identification of “genotoxic” and “non-genotoxic” alerts for cancer in mice: The carcinogenic potency database. Mutat. Res. 1998, 398, 1–17. [Google Scholar] [CrossRef]

- Rebocho, S.; Cordas, C.M.; Viveiros, R.; Casimiro, T. Development of a ferrocenyl-based MIP in supercritical carbon dioxide: Towards an electrochemical sensor for bisphenol A. J. Supercrit. Fluids 2018, 98–104. [Google Scholar] [CrossRef]

- Viveiros, R.; Karim, K.; Piletsky, S.A.; Heggie, W.; Casimiro, T. Development of a molecularly imprinted polymer for a pharmaceutical impurity in supercritical CO2 : Rational design using computational approach. J. Clean. Prod. 2017, 168, 1025–1031. [Google Scholar] [CrossRef]

- Kobayashi, T.; Leong, S.S.; Zhang, Q. Using Polystyrene-co-maleic Acid for Molecularly Imprinted Membranes Prepared in Supercritical Carbon Dioxide. J. Appl. Polym. Sci. 2008, 108, 757–768. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, X.; Zhang, W.; Pan, J.; Liu, L.; Zhang, H.; Zhao, D.; Li, Z. Preparation and adsorption properties of PA6/PSMA-OA molecularly imprinted composite membranes in supercritical CO2. Bull. Korean Chem. Soc. 2011, 32, 3348–3354. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, H.; Zhang, Q.; Cui, Y.; Wu, Z.; Zheng, R.; Liu, L. Molecularly imprinted polymers prepared by precipitation polymerization and used for inducing crystallization of oleanolic acid in supercritical CO2. Sep. Purif. Technol. 2011, 81, 411–417. [Google Scholar] [CrossRef]

- Lourenço, A.; Viveiros, R.; Mouro, A.; Lima, J.C.; Bonifácio, V.D.B.; Casimiro, T. Supercritical CO2-assisted synthesis of an ultrasensitive amphibious quantum dot-molecularly imprinted sensor. RSC Adv. 2014, 4, 63338–63341. [Google Scholar] [CrossRef]

- Viveiros, R.; Dias, F.M.; Maia, L.B.; Heggie, W.; Casimiro, T. Green strategy to produce large core–shell affinity beads for gravity-driven API purification processes. J. Ind. Eng. Chem. 2017, 54, 341–349. [Google Scholar] [CrossRef]

- Sudhakar, G.K.; Bhaskar, K.V.; Verma, R. Ionic liquids-useful reaction green solvents for the future. J. Biomed. Pharm. Res. 2012, 1, 7–12. [Google Scholar]

- Greaves, T.L.; Drummond, C.J. Ionic liquids as amphiphile self-assembly media. Chem. Soc. Rev. 2008, 37, 1709–1726. [Google Scholar] [CrossRef] [PubMed]

- Wilkes, J.S. A short history of ionic liquids—From molten salts to neoteric solvents. Green Chem. 2002, 4, 73–80. [Google Scholar] [CrossRef]

- Frade, R.F.; Afonso, C.A. Impact of ionic liquids in environment and humans: an overview. Hum. Exp. Toxicol. 2010, 29, 1038–1054. [Google Scholar] [CrossRef] [PubMed]

- Pham, T.P.T.; Cho, C.-W.W.; Yun, Y.-S.S.; Thuy Pham, T.P. Environmental fate and toxicity of ionic liquids: a review. Water Res. 2010, 44, 352–372. [Google Scholar] [CrossRef] [PubMed]

- Sebastiao, E.; Cook, C.; Hu, A.; Murugesu, M. Recent developments in the field of energetic ionic liquids. J. Mater. Chem. A 2014, 2, 8153. [Google Scholar] [CrossRef]

- Booker, K.; Bowyer, M.C.; Holdsworth, C.I.; McCluskey, A. Efficient preparation and improved sensitivity of molecularly imprinted polymers using room temperature ionic liquids. Chem. Commun. 2006, 1730–1732. [Google Scholar] [CrossRef] [PubMed]

- Zhong, D.D.; Huang, Y.P.; Xin, X.L.; Liu, Z.S.; Aisa, H.A. Preparation of metallic pivot-based imprinted monolith for polar template. J. Chromatogr. B 2013, 934, 109–116. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Long, Y.; Pan, J.; Li, K.; Liu, F. Molecularly imprinted silica prepared with immiscible ionic liquid as solvent and porogen for selective recognition of testosterone. Talanta 2008, 74, 1126–1131. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Chen, X.X.; Huang, Y.P.; Liu, Z.S. Preparation of polyhedral oligomeric silsesquioxane based imprinted monolith. J. Chromatogr. A 2015, 1425, 180–188. [Google Scholar] [CrossRef] [PubMed]

- Booker, K.; Holdsworth, C.I.; Doherty, C.M.; Hill, A.J.; Bowyer, M.C.; McCluskey, A. Ionic liquids as porogens for molecularly imprinted polymers: propranolol, a model study. Org. Biomol. Chem. 2014, 12, 7201–7210. [Google Scholar] [CrossRef] [PubMed]

- Li, X.-J.; Chen, X.-X.; Sun, G.-Y.; Zhao, Y.X.; Liu, Z.-S.; Aisa, H.A. Green synthesis and evaluation of isoquercitrin imprinted polymers for class-selective separation and purification of flavonol glycosides. Anal. Methods 2015, 7, 4717–4724. [Google Scholar] [CrossRef]

- Booker, K.; Bowyer, M.C.; Lennard, C.J.; Holdsworth, C.I.; McCluskey, A. Molecularly imprinted polymers and room temperature ionic liquids: Impact of template on polymer morphology. Aust. J. Chem. 2007, 60, 51–56. [Google Scholar] [CrossRef]

- Li, J.; Hu, X.; Guan, P.; Song, D.; Qian, L.; Du, C.; Song, R.; Wang, C. Preparation of “dummy” l-phenylalanine molecularly imprinted microspheres by using ionic liquid as a template and functional monomer. J. Sep. Sci. 2015, 38, 3279–3287. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.F.; Hu, X.L.; Guan, P.; Li, J.; Wu, D.F.; Gao, B. Molecularly imprinted polymers for the selective recognition of l-phenylalanine based on 1-buty-3-methylimidazolium ionic liquid. J. Appl. Polym. Sci. 2015, 132, 1–9. [Google Scholar] [CrossRef]

- Li, J.; Hu, X.; Guan, P.; Song, R.; Zhang, X.; Tang, Y.; Wang, C.; Qian, L. Preparation of core-shell structural surface molecular imprinting microspheres and recognition of l-Asparagine based on [N1111]Asn ionic liquid as template. React. Funct. Polym. 2015, 88, 8–15. [Google Scholar] [CrossRef]

- Li, J.; Hu, X.; Guan, P.; Zhang, X.; Qian, L.; Song, R.; Du, C.; Wang, C. Preparation of molecularly imprinted polymers using ion-pair dummy template imprinting and polymerizable ionic liquids. RSC Adv. 2015, 5, 62697–62705. [Google Scholar] [CrossRef]

- Yuan, S.; Deng, Q.; Fang, G.; Wu, J.; Li, W.; Wang, S. Protein imprinted ionic liquid polymer on the surface of multiwall carbon nanotubes with high binding capacity for lysozyme. J. Chromatogr. B 2014, 960, 239–246. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Dong, R.; Luo, S.; Zhan, Y.; Tu, X.; Yang, L. Preparation of water-compatible molecularly imprinted polymers for caffeine with a novel ionic liquid as a functional monomer. J. Appl. Polym. Sci. 2013, 127, 2884–2890. [Google Scholar] [CrossRef]

- Ding, H.; Chen, R.; Liu, M.; Huang, R.; Du, Y.; Huang, C.; Yu, X.; Feng, X.; Liu, F. Preparation and characterization of biocompatible molecularly imprinted poly(ionic liquid) films on the surface of multi-walled carbon nanotubes. RSC Adv. 2016, 6, 43526–43538. [Google Scholar] [CrossRef]

- Hamdan, S.; Moore, L.; Lejeune, J.; Hasan, F.; Carlisle, T.K.; Bara, J.E.; Gin, D.L.; LaFrate, A.L.; Noble, R.D.; Spivak, D.A.; et al. Ionic liquid crosslinkers for chiral imprinted nanoGUMBOS. J. Colloid Interface Sci. 2016, 463, 29–36. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Wang, X.; Lu, W.; Wu, X.; Li, J. Molecular imprinting: Perspectives and applications. Chem. Soc. Rev. 2016, 45, 2137–2211. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Fang, G.; Wang, S. Molecularly imprinted solid phase extraction coupled to high-performance liquid chromatography for determination of trace dichlorvos residues in vegetables. Food Chem. 2010, 119, 845–850. [Google Scholar] [CrossRef]

- Alonso, D.A.; Baeza, A.; Chinchilla, R.; Guillena, G.; Pastor, I.M.; Ramón, D.J. Deep Eutectic Solvents: The Organic Reaction Medium of the Century. Eur. J. Org. Chem. 2016, 4, 612–632. [Google Scholar] [CrossRef]

- Li, X.; Row, K.H. Development of deep eutectic solvents applied in extraction and separation. J. Sep. Sci. 2016, 39, 3505–3520. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Wang, W.; Wang, Q.; Zhu, T. Deep Eutectic Solvents Modified Molecular Imprinted Polymers for Optimized Purification of Chlorogenic Acid from Honeysuckle. J. Chromatogr. Sci. 2016, 54, 271–279. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, Y.; Dai, Q.; Zhou, Y. Magnetic deep eutectic solvents molecularly imprinted polymers for the selective recognition and separation of protein. Anal. Chim. Acta 2016, 936, 168–178. [Google Scholar] [CrossRef] [PubMed]

- Price, G. Ultrasonically enhanced polymer synthesis. Ultrason. Sonochem. 1996, 3, S229–S238. [Google Scholar] [CrossRef]

- Suslick, K.S. The Chemical Effects of Ultrasound. Sci. Am. 1989, 260, 80–86. [Google Scholar] [CrossRef]

- Svenson, J. Ultrasound-assisted preparation of molecularly imprinted polymers: Effects on polymer morphology, binding, and chromatographic behavior. Anal. Lett. 2006, 39, 2749–2760. [Google Scholar] [CrossRef]

- Gogate, P.R. Cavitational reactors for process intensification of chemical processing applications: A critical review. Chem. Eng. Process. Process Intensif. 2008, 47, 515–527. [Google Scholar] [CrossRef]

- Dmitrienko, S.G.; Popov, S.A.; Chumichkina, Y.A.; Zolotov, Y.A. The sorption properties of polymers with molecular imprints of 2,4-dichlorophenoxyacetic acid synthesized by various methods. Russ. J. Phys. Chem. A 2011, 85, 472–477. [Google Scholar] [CrossRef]

- Jenkins, A.L.; Uy, O.M.; Murray, G.M. Polymer-based lanthanide luminescent sensor for detection of the hydrolysis product of the nerve agent soman in water. Anal. Chem. 1999, 71, 373–378. [Google Scholar] [CrossRef] [PubMed]

- Weinberger, M.; Hendeles, L. Theophylline in Asthma. N. Engl. J. Med. 1996, 334, 1380–1388. [Google Scholar] [CrossRef] [PubMed]

- Xia, X.; Lai, E.P.C.; Ormeci, B. Ultrasonication-Assisted Synthesis of Molecularly Imprinted Polymer-Encapsulated Magnetic Nanoparticles for Rapid and Selective Removal of 17 β-Estradiol from Aqueous Environment. Polym. Eng. Sci. 2012, 47, 1–9. [Google Scholar] [CrossRef]

- Phutthawong, N.; Pattarawarapan, M. Facile synthesis of magnetic molecularly imprinted polymers for caffeine via ultrasound-assisted precipitation polymerization. Polym. Bull. 2013, 70, 691–705. [Google Scholar] [CrossRef]

- Phutthawong, N.; Pattarawarapan, M. Synthesis of highly selective spherical caffeine imprinted polymers via ultrasound-assisted precipitation polymerization. J. Appl. Polym. Sci. 2013, 128, 3893–3899. [Google Scholar] [CrossRef]

- Chantada-Vázquez, M.P.; Sánchez-González, J.; Peña-Vázquez, E.; Tabernero, M.J.; Bermejo, A.M.; Bermejo-Barrera, P.; Moreda-Piñeiro, A. Synthesis and characterization of novel molecularly imprinted polymer-coated Mn-doped ZnS quantum dots for specific fluorescent recognition of cocaine. Biosens. Bioelectron. 2016, 75, 213–221. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-González, J.; Jesús Tabernero, M.; María Bermejo, A.; Bermejo-Barrera, P.; Moreda-Piñeiro, A. Development of magnetic molecularly imprinted polymers for solid phase extraction of cocaine and metabolites in urine before high performance liquid chromatography-tandem mass spectrometry. Talanta 2016, 147, 641–649. [Google Scholar] [CrossRef] [PubMed]

- Asfaram, A.; Ghaedi, M.; Dashtian, K. Ultrasound assisted combined molecularly imprinted polymer for selective extraction of nicotinamide in human urine and milk samples: Spectrophotometric determination and optimization study. Ultrason. Sonochem. 2017, 34, 640–650. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Liu, R.; Hu, Y.; Li, G. Microwave Heating in Preparation of Magnetic Molecularly Imprinted Polymer Beads for Trace Triazines Analysis in Complicated Samples Microwave Heating in Preparation of Magnetic Molecularly Imprinted Polymer Beads for Trace Triazines Analysis in Complicat. Anal. Chem. 2009, 81, 967–976. [Google Scholar] [CrossRef] [PubMed]

- Hoogenboom, R.; Wiesbrock, F.; Leenen, M.A.M.; Meier, M.A.R.; Schubert, U.S. Accelerating the living polymerization of 2-nonyl-2-oxazoline by implementing a microwave synthesizer into a high-throughput experimentation workflow. J. Comb. Chem. 2005, 7, 10–13. [Google Scholar] [CrossRef] [PubMed]

- Chia, H.L.; Jacob, J.; Boey, F.Y.C. The microwave radiation effect on the polymerization of styrene. J. Polym. Sci. Part A Polym. Chem. 1996, 34, 2087–2094. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Hu, Y.; Li, G.; Chen, Y. Preparation of magnetic indole-3-acetic acid imprinted polymer beads with 4-vinylpyridine and β-cyclodextrin as binary monomer via microwave heating initiated polymerization and their application to trace analysis of auxins in plant tissues. J. Chromatogr. A 2010, 1217, 7337–7344. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Liu, R.; Zhang, Y.; Li, G. Improvement of extraction capability of magnetic molecularly imprinted polymer beads in aqueous media via dual-phase solvent system. Talanta 2009, 79, 576–582. [Google Scholar] [CrossRef] [PubMed]

- Turner, N.W.; Holdsworth, C.I.; Donne, S.W.; McCluskey, A.; Bowyer, M.C. Microwave induced MIP synthesis: comparative analysis of thermal and microwave induced polymerisation of caffeine imprinted polymers. New J. Chem. 2010, 34, 686–692. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, Y.; Yuan, Y.; Zeng, H. Development and characterization of molecularly imprinted polymer microspheres for the selective detection of kaempferol in traditional Chinese medicines. Anal. Methods 2011, 3, 348–355. [Google Scholar] [CrossRef]

- Hu, Y.; Li, Y.; Liu, R.; Tan, W.; Li, G. Magnetic molecularly imprinted polymer beads prepared by microwave heating for selective enrichment of β-agonists in pork and pig liver samples. Talanta 2011, 84, 462–470. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Mao, H.; Huang, W.; Guan, W.; Zou, X.; Pan, J.; Yan, Y. Preparation of magnetic imprinted polymer particles via microwave heating initiated polymerization for selective enrichment of 2-amino-4-nitrophenol from aqueous solution. Chem. Eng. J. 2011, 178, 85–92. [Google Scholar] [CrossRef]

- Zhang, Z.; Tan, W.; Hu, Y.; Li, G.; Zan, S. Microwave synthesis of gibberellin acid 3 magnetic molecularly imprinted polymer beads for the trace analysis of gibberellin acids in plant samples by liquid chromatography-mass spectrometry detection. Analyst 2012, 137, 968–977. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Lv, P.; Yao, G.; Ma, C.; Huo, P.; Yan, Y. Microwave-assisted synthesis of selective degradation photocatalyst by surface molecular imprinting method for the degradation of tetracycline onto ClTiO2. Chem. Eng. J. 2013, 217, 398–406. [Google Scholar] [CrossRef]

- Hou, J.; Li, H.; Wang, L.; Zhang, P.; Zhou, T.; Ding, H.; Ding, L. Rapid microwave-assisted synthesis of molecularly imprinted polymers on carbon quantum dots for fluorescent sensing of tetracycline in milk. Talanta 2016, 146, 34–40. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Zhang, X.; Sun, Y.; Yu, D. Microwave-assisted preparation of monolithic molecularly imprinted polymeric fibers for solid phase microextraction. Analyst 2013, 138, 2982–2987. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Bai, L.; Tian, M.; Zhou, X.; Zhang, Y. Hollow-fiber membrane tube embedded with a molecularly imprinted monolithic bar for the microextraction of triazine pesticides. Anal. Methods 2014, 6, 602–608. [Google Scholar] [CrossRef]

- Lu, Z.; Chen, F.; He, M.; Song, M.; Ma, Z.; Shi, W.; Yan, Y.; Lan, J.; Li, F.; Xiao, P. Microwave synthesis of a novel magnetic imprinted TiO2 photocatalyst with excellent transparency for selective photodegradation of enrofloxacin hydrochloride residues solution. Chem. Eng. J. 2014, 249, 15–26. [Google Scholar] [CrossRef]

- Seifi, M.; Hassanpour Moghadam, M.; Hadizadeh, F.; Ali-Asgari, S.; Aboli, J.; Mohajeri, S.A. Preparation and study of tramadol imprinted micro-and nanoparticles by precipitation polymerization: Microwave irradiation and conventional heating method. Int. J. Pharm. 2014, 471, 37–44. [Google Scholar] [CrossRef] [PubMed]

- Zayas, H.; Holdsworth, C.I.; Bowyer, M.C.; McCluskey, A. Evaluation of 4-substituted styrenes as functional monomers for the synthesis of theophylline-specific molecularly imprinted polymers. Org. Biomol. Chem. 2014, 12, 6994–7003. [Google Scholar] [CrossRef] [PubMed]

- Schwarz, L.J.; Potdar, M.K.; Danylec, B.; Boysen, R.I.; Hearn, M.T.W. Microwave-assisted synthesis of resveratrol imprinted polymers with enhanced selectivity. Anal. Methods 2015, 7, 150–154. [Google Scholar] [CrossRef]

- Wang, S.; Wang, B.; Si, H.; Shan, J.; Yang, X. Preparation of magnetic molecularly imprinted polymer beads and their recognition for baicalein. RSC Adv. 2015, 5, 8028–8036. [Google Scholar] [CrossRef]

- Chen, H.; Son, S.; Zhang, F.; Yan, J.; Li, Y.; Ding, H.; Ding, L. Rapid preparation of molecularly imprinted polymers by microwave-assisted emulsion polymerization for the extraction of florfenicol in milk. J. Chromatogr. B 2015, 983, 32–38. [Google Scholar] [CrossRef] [PubMed]

- Zhong, D.D.; Liu, X.; Pang, Q.Q.; Huang, Y.P.; Liu, Z.S. Rapid preparation of molecularly imprinted polymer by frontal polymerization. Anal. Bioanal. Chem. 2013, 405, 3205–3214. [Google Scholar] [CrossRef] [PubMed]

- Davis, R.; Bryson, H.M. Levofloxacin: A Review of its Antibacterial Activity, Pharmacokinetics and Therapeutic Efficacy. Drugs 1994, 47, 677–700. [Google Scholar] [CrossRef] [PubMed]

- Lange, U.; Roznyatovskaya, N.V.; Mirsky, V.M. Conducting polymers in chemical sensors and arrays. Anal. Chim. Acta 2008, 614, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Malitesta, C.; Losito, I.; Zambonin, P.G. Molecularly imprinted electrosynthesized polymers: New materials for biomimetic sensors. Anal. Chem. 1999, 71, 1366–1370. [Google Scholar] [CrossRef] [PubMed]

- Panasyuk, T.L.; Mirsky, V.M.; Piletsky, S.A.; Wolfbeis, O.S. Electropolymerized molecularly imprinted polymers as receptor layers in capacitive chemical sensors. Anal. Chem. 1999, 71, 4609–4613. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, E.; Yang, X. Capacitive detection of glucose using molecularly imprinted polymers. Biosens. Bioelectron. 2001, 16, 179–185. [Google Scholar] [CrossRef]

- Gong, J.-L.; Gong, F.-C.; Zeng, G.-M.; Shen, G.-L.; Yu, R.-Q. A novel electrosynthesized polymer applied to molecular imprinting technology. Talanta 2003, 61, 447–453. [Google Scholar] [CrossRef]

- Aghaei, A.; Milani Hosseini, M.R.; Najafi, M. A novel capacitive biosensor for cholesterol assay that uses an electropolymerized molecularly imprinted polymer. Electrochim. Acta 2010, 55, 1503–1508. [Google Scholar] [CrossRef]

- Weetall, H.H.; Rogers, K.R. Preparation and characterization of molecularly imprinted electropolymerized carbon electrodes. Talanta 2004, 62, 329–335. [Google Scholar] [CrossRef] [PubMed]

- Gong, J.L.; Gong, F.C.; Kuang, Y.; Zeng, G.M.; Shen, G.L.; Yu, R.Q. Capacitive chemical sensor for fenvalerate assay based on electropolymerized molecularly imprinted polymer as the sensitive layer. Anal. Bioanal. Chem. 2004, 379, 302–307. [Google Scholar] [CrossRef] [PubMed]

- Ebarvia, B.S.; Cabanilla, S.; Sevilla, F. Biomimetic properties and surface studies of a piezoelectric caffeine sensor based on electrosynthesized polypyrrole. Talanta 2005, 66, 145–152. [Google Scholar] [CrossRef] [PubMed]

- Yeh, W.M.; Ho, K.C. Amperometric morphine sensing using a molecularly imprinted polymer-modified electrode. Anal. Chim. Acta 2005, 542, 76–82. [Google Scholar] [CrossRef]

- Özcan, L.; Şahin, Y. Determination of paracetamol based on electropolymerized-molecularly imprinted polypyrrole modified pencil graphite electrode. Sens. Actuators B Chem. 2007, 127, 362–369. [Google Scholar] [CrossRef]

- Gómez-Caballero, A.; Unceta, N.; Aranzazu Goicolea, M.; Barrio, R.J. Evaluation of the selective detection of 4,6-dinitro-o-cresol by a molecularly imprinted polymer based microsensor electrosynthesized in a semiorganic media. Sens. Actuators B Chem. 2008, 130, 713–722. [Google Scholar] [CrossRef]

- Özcan, L.; Sahin, M.; Sahin, Y. Electrochemical Preparation of a Molecularly Imprinted Polypyrrole-modified Pencil Graphite Electrode for Determination of Ascorbic Acid. Sensors 2008, 8, 5792–5805. [Google Scholar] [CrossRef] [PubMed]

- Özkorucuklu, S.P.; Şahin, Y.; Alsancak, G. Voltammetric behaviour of sulfamethoxazole on electropolymerized-molecularly imprinted overoxidized polypyrrole. Sensors 2008, 8, 8463–8478. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Song, Q.J.; Wang, L. Development and characterization of an amperometric sensor for triclosan detection based on electropolymerized molecularly imprinted polymer. Microchem. J. 2009, 91, 222–226. [Google Scholar] [CrossRef]

- Apodaca, D.C.; Pernites, R.B.; Ponnapati, R.R.; Del Mundo, F.R.; Advincula, R.C. Electropolymerized molecularly imprinted polymer films of a bis-terthiophene dendron: Folic acid quartz crystal microbalance sensing. ACS Appl. Mater. Interfaces 2011, 3, 191–203. [Google Scholar] [CrossRef] [PubMed]

- Apodaca, D.C.; Pernites, R.B.; Ponnapati, R.; Del Mundo, F.R.; Advincula, R.C. Electropolymerized molecularly imprinted polymer film: EIS sensing of bisphenol A. Macromolecules 2011, 44, 6669–6682. [Google Scholar] [CrossRef]

- Pernites, R.; Ponnapati, R.; Felipe, M.J.; Advincula, R. Electropolymerization molecularly imprinted polymer (E-MIP) SPR sensing of drug molecules: Pre-polymerization complexed terthiophene and carbazole electroactive monomers. Biosens. Bioelectron. 2011, 26, 2766–2771. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Wang, Z.; Wu, B.; Liu, X.; Xue, Z.; Lu, X. Rapid and sensitive detection of methyl-parathion pesticide with an electropolymerized, molecularly imprinted polymer capacitive sensor. Electrochim. Acta 2012, 62, 319–326. [Google Scholar] [CrossRef]

- Kan, X.; Xing, Z.; Zhu, A.; Zhao, Z.; Xu, G.; Li, C.; Zhou, H. Molecularly imprinted polymers based electrochemical sensor for bovine hemoglobin recognition. Sens. Actuators B Chem. 2012, 168, 395–401. [Google Scholar] [CrossRef]

- Zhang, X.; Peng, Y.; Bai, J.; Ning, B.; Sun, S.; Hong, X.; Liu, Y.; Liu, Y.; Gao, Z. A novel electrochemical sensor based on electropolymerized molecularly imprinted polymer and gold nanomaterials amplification for estradiol detection. Sens. Actuators B Chem. 2014, 200, 69–75. [Google Scholar] [CrossRef]

- Cai, D.; Ren, L.; Zhao, H.; Xu, C.; Zhang, L.; Yu, Y.; Wang, H.; Lan, Y.; Roberts, M.F.; Chuang, J.H.; et al. A molecular-imprint nanosensor for ultrasensitive detection of proteins. Nat. Nanotechnol. 2010, 5, 597–601. [Google Scholar] [CrossRef] [PubMed]

- Takeuchi, T.; Fukuma, D.; Matsui, J. Combinatorial molecular imprinting: An approach to synthetic polymer receptors. Anal. Chem. 1999, 71, 285–290. [Google Scholar] [CrossRef]

- Chen, B.; Day, R.M.; Subrahmanyam, S.; Piletsky, S.A.; Piletska, O.V.; Turner, A.P.F. Molecularly Imprinted Polymer. U.S. Patent US8086415B2, 25 January 2000. [Google Scholar]

- Subrahmanyam, S.; Karim, K.; Piletsky, S.A. Computational Approaches in the Design of Synthetic Receptors. In Designing Receptors for the Next Generation of Biosensors; Springer Science & Business Media: New York, NY, USA, 2013; ISBN 978-3-540-27757-6. [Google Scholar]

- Piletsky, S.A.; Karim, K.; Piletska, E.V.; Turner, A.P.F.; Day, C.J.; Freebairn, K.W.; Legge, C. Recognition of ephedrine enantiomers by molecularly imprinted polymers designed using a computational approach. Analyst 2001, 126, 1826–1830. [Google Scholar] [CrossRef]

- Böhm, H.J. The computer program LUDI: A new method for the de novo design of enzyme inhibitors. J. Comput. Aided Mol. Des. 1992, 6, 61–78. [Google Scholar] [CrossRef] [PubMed]

- Subrahmanyam, S.; Piletsky, S.A.; Piletska, E.V.; Chen, B.; Karim, K.; Turner, A.P.F. “Bite-and-Switch” approach using computationally designed molecularly imprinted polymers for sensing of creatinine. Biosens. Bioelectron. 2001, 16, 631–637. [Google Scholar] [CrossRef]

- Chianella, I.; Lotierzo, M.; Piletsky, S.A.; Tothill, I.E.; Chen, B.; Karim, K.; Turner, A.P.F. Rational design of a polymer specific for microcystin-LR using a computational approach. Anal. Chem. 2002, 74, 1288–1293. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Sun, B.; Li, Y.; Chang, W. Study properties of molecular imprinting polymer using a computational approach. Analyst 2003, 128, 944–949. [Google Scholar] [CrossRef]

- Meng, Z.; Yamazaki, T.; Sode, K. A molecularly imprinted catalyst designed by a computational approach in catalysing a transesterification process. Biosens. Bioelectron. 2004, 20, 1068–1075. [Google Scholar] [CrossRef] [PubMed]

- Turner, N.W.; Piletska, E.V.; Karim, K.; Whitcombe, M.; Malecha, M.; Magan, N.; Baggiani, C.; Piletsky, S.A. Effect of the solvent on recognition properties of molecularly imprinted polymer specific for ochratoxin A. Biosens. Bioelectron. 2004, 20, 1060–1067. [Google Scholar] [CrossRef] [PubMed]

- Dong, W.; Yan, M.; Zhang, M.; Liu, Z.; Li, Y. A computational and experimental investigation of the interaction between the template molecule and the functional monomer used in the molecularly imprinted polymer. Anal. Chim. Acta 2005, 542, 186–192. [Google Scholar] [CrossRef]

- Wu, L.; Li, Y. Study on the recognition of templates and their analogues on molecularly imprinted polymer using computational and conformational analysis approaches. J. Mol. Recognit. 2004, 17, 567–574. [Google Scholar] [CrossRef] [PubMed]

- Pavel, D.; Lagowski, J. Computationally designed monomers and polymers for molecular imprinting of theophylline—Part I. Polymer 2005, 46, 7528–7542. [Google Scholar] [CrossRef]

- Pavel, D.; Lagowski, J. Computationally designed monomers and polymers for molecular imprinting of theophylline—Part II. Polymer 2005, 46, 7543–7556. [Google Scholar] [CrossRef]

- Piletska, E.V.; Turner, N.W.; Turner, A.P.F.; Piletsky, S.A. Controlled release of the herbicide simazine from computationally designed molecularly imprinted polymers. J. Control. Release 2005, 108, 132–139. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Diñeiro, Y.; Menéndez, M.I.; Blanco-López, M.C.; Lobo-Castanon, M.J.; Miranda-Ordieres, A.J.; Tunon-Blanco, P. Computational Approach to the Rational Design of Molecularly Imprinted Polymers for Voltammetric Sensing of Homovanillic Acid. Anal. Chem. 2005, 77, 6741–6746. [Google Scholar] [CrossRef] [PubMed]

- Diñeiro, Y.; Menéndez, M.I.; Blanco-López, M.C.; Lobo-Castañón, M.J.; Miranda-Ordieres, A.J.; Tuñón-Blanco, P. Computational predictions and experimental affinity distributions for a homovanillic acid molecularly imprinted polymer. Biosens. Bioelectron. 2006, 22, 364–371. [Google Scholar] [CrossRef] [PubMed]

- Monti, S.; Cappelli, C.; Bronco, S.; Giusti, P.; Ciardelli, G. Towards the design of highly selective recognition sites into molecular imprinting polymers: A computational approach. Biosens. Bioelectron. 2006, 22, 153–163. [Google Scholar] [CrossRef] [PubMed]

- Dong, W.; Yan, M.; Liu, Z.; Wu, G.; Li, Y. Effects of solvents on the adsorption selectivity of molecularly imprinted polymers: Molecular simulation and experimental validation. Sep. Purif. Technol. 2007, 53, 183–188. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, F.; Tan, T.; Lei, M. Study of the properties of molecularly imprinted polymers by computational and conformational analysis. Anal. Chim. Acta 2007, 581, 137–146. [Google Scholar] [CrossRef] [PubMed]

- Nantasenamat, C.; Isarankura-Na-Ayudhya, C.; Naenna, T.; Prachayasittikul, V. Quantitative structure-imprinting factor relationship of molecularly imprinted polymers. Biosens. Bioelectron. 2007, 22, 3309–3317. [Google Scholar] [CrossRef] [PubMed]

- Yao, J.; Li, X.; Qin, W. Computational design and synthesis of molecular imprinted polymers with high selectivity for removal of aniline from contaminated water. Anal. Chim. Acta 2008, 610, 282–288. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Li, X.; Li, Y.; Jin, P.; Qin, W.; Qi, J. Effective removal of rhodamine B from contaminated water using non-covalent imprinted microspheres designed by computational approach. Biosens. Bioelectron. 2009, 25, 629–634. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Li, X.; Li, Y.; Dong, C.; Jin, P.; Qi, J. Selective recognition of veterinary drugs residues by artificial antibodies designed using a computational approach. Biomaterials 2009, 30, 3205–3211. [Google Scholar] [CrossRef] [PubMed]

- Dong, C.; Li, X.; Guo, Z.; Qi, J. Development of a model for the rational design of molecular imprinted polymer: Computational approach for combined molecular dynamics/quantum mechanics calculations. Anal. Chim. Acta 2009, 647, 117–124. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi, F.; Ahmadi, J.; Rahimi-Nasrabadi, M. Computational approaches to design a molecular imprinted polymer for high selective extraction of 3,4-methylenedioxymethamphetamine from plasma. J. Chromatogr. A 2011, 1218, 7739–7747. [Google Scholar] [CrossRef] [PubMed]

- Nicholls, I.A.; Andersson, H.S.; Charlton, C.; Henschel, H.; Karlsson, B.C.G.; Karlsson, J.G.; O’Mahony, J.; Rosengren, A.M.; Rosengren, K.J.; Wikman, S. Theoretical and computational strategies for rational molecularly imprinted polymer design. Biosens. Bioelectron. 2009, 25, 543–552. [Google Scholar] [CrossRef] [PubMed]

- Nicholls, I.A.; Andersson, H.S.; Golker, K.; Henschel, H.; Karlsson, B.C.G.; Olsson, G.D.; Rosengren, A.M.; Shoravi, S.; Suriyanarayanan, S.; Wiklander, J.G.; et al. Rational design of biomimetic molecularly imprinted materials: Theoretical and computational strategies for guiding nanoscale structured polymer development. Anal. Bioanal. Chem. 2011, 400, 1771–1786. [Google Scholar] [CrossRef] [PubMed]

| Template | Strategy | Monomer | Crosslinker | Particle Size Diameter | Year | Ref. |

|---|---|---|---|---|---|---|

| Salicylic acid and acetylsalicylic acid | Non-covalent | DEGDMA | - | 1.7 μm | 2006 | [22] |

| Propranolol | Non-covalent | MAA | DVB | 100 nm | 2006 | [23] |

| Boc-l-tryptophan | Non-covalent | NIPAAm | EGDMA | micron-sized | 2010 | [24] |

| Flufenamic acid | Non-covalent | MAA NIPAAm | EGDMA | micron-sized | 2011 | [25] |

| Ibuprofen | Non-covalent | DMAEMA | EGDMA | ~1 μm | 2011 | [26] |

| Bisphenol A | Non-covalent | MAA, FMMA | EGDMA | micron-sized | 2012, 2018 | [18,46] |

| Bisphenol A | Semi-covalent | BPADM | EGDMA | micron-sized | 2012 | [18] |

| Aspirin and Acetaminophen | Non-covalent | MAA 4-Vpy MMA | EGDMA | 250–300 nm | 2013 | [30] |

| Bisphenol A and 2,4-dichlorophenoxyacetic acid | Non-covalent | MAA | EGDMA | 300 nm | 2013 | [34] |

| Carbamazepine | Non-covalent | MAA | EGDMA | 200 nm | 2013 | [35] |

| Labdanolic acid | Non-covalent | DMAEMA | EGDMA | micron-sized | 2014 | [38] |

| DBTSO2 | Non-covalent | MAA | EGDMA | micron-sized | 2014 | [40] |

| Gallic acid | Non-covalent | MAA MMA | EGDMA | 150–200 nm | 2016 | [41] |

| Acetamide | Non-covalent | MAA and MAM, ITA and HEMA | EGDMA | 3.4–5.3 μm | 2017 | [43,47] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Viveiros, R.; Rebocho, S.; Casimiro, T. Green Strategies for Molecularly Imprinted Polymer Development. Polymers 2018, 10, 306. https://doi.org/10.3390/polym10030306

Viveiros R, Rebocho S, Casimiro T. Green Strategies for Molecularly Imprinted Polymer Development. Polymers. 2018; 10(3):306. https://doi.org/10.3390/polym10030306

Chicago/Turabian StyleViveiros, Raquel, Sílvia Rebocho, and Teresa Casimiro. 2018. "Green Strategies for Molecularly Imprinted Polymer Development" Polymers 10, no. 3: 306. https://doi.org/10.3390/polym10030306