1. Introduction

Polyoxymethylene (POM) is an excellent engineering thermoplastic well known for its superior tribological properties and good balance of mechanical and thermal characteristics [

1,

2]. Attempt to improve one of these properties usually results in deterioration of another. Improvements in mechanical and tribological properties are typically carried out by blending with other polymers [

3,

4], fibers [

5,

6], and micro- or nano-sized particles. The fibers and particles used as modifiers can be organic or non-organic [

7,

8,

9].

On the contrary, POM has very poor compatibility with other materials. Compatibilizers are often used as additives to obtain the desired properties of its composites [

10]. Improving the compatibility of immiscible polymers results in improved morphology and properties of the composite [

11,

12,

13]. It is often challenging to disperse fillers effectively in the matrix polymer of a composite. Development of compatibilization technologies will be crucial for the polymer industry to reap the full benefits of such approaches to obtain materials with optimum performance and cost characteristics.

The addition of glass fibers (GF) to POM as reinforcement has been one approach to improve strength, stiffness, and hardness. The change of these properties is due to the strength of GF holding the POM matrix together and the bond of GF to the POM matrix. When impacted or loaded, the energy absorbed by the reinforcement makes the polymer not only tougher, but also stronger. This is evident when comparing the morphology of a fractured surface for filled versus reinforced after impact testing. Addition of GF to POM negatively affects the wear resistance and coefficient of friction (COF) [

14,

15].

POM have good self-lubricating characteristics with low coefficient of friction (COF) coupled with high wear resistance. However, pure POM may not be able to meet the requirement of an application by depending on its own inherent properties only. As such, the addition of particulates is necessary in applications where tribological and mechanical properties are of equal importance, Typically, tribology properties are enhanced by blending POM with solid lubricants such as molybdenum disulfide (MoS

2), alumina (Al

2O

3) and polytetrafluoroethylene (PTFE) in micro- or nano-sized particles and other polymeric materials such as polyethylene oxide (PEO), polylactic acid (PLA), etc. [

7,

8,

9,

10,

12,

13,

16,

17].

PTFE is a hydrophobic polymer often used for wear and COF reduction in thermoplastics. Its composites are typically processed using melt mixing process. Since the surface energy of PTFE is low, melt mixing process leads to poor distribution and non-homogenous dispersion. In composites where PTFE is added as second or third phase, mechanical properties can be compromised depending on the matrix material [

18,

19]. As such, surface modification of PTFE is required to enhance compatibility to the matrix. The methods commonly employed to alter the chemical structure of PTFE are chemical etching, electron beam irradiation, and plasma treatment [

20,

21].

Naturally, adhesion between POM and PTFE is poor due to incompatibility between these two polymers. PTFE has very low wettability and bond ability due to its low surface energy and non-stick properties [

11]. Its chemical stability and inertness makes the surface modification of PTFE very challenging. In order to impart polar functional groups to form hydrogen, oxygen, or other bonds with the backbone carbon chain, the surface needs to be etched chemically. One of the conventional techniques applied is treatment using an alkaline metal solution that de-fluorinates the surface [

22].

Suresha et al. [

16] reported that the addition of PTFE particles into neat POM deteriorated the tensile strength by 23%. Addition of glass fibers improved the strength of POM/GF/PTFE composite by 20%. Tribology characterization was not reported. Benabdallah reported that POM filled with 20% GF resulted in deterioration of COF and wear resistance. When POM was filled with 20% PTFE micro powder, COF and wear resistance improved significantly [

14]. Franklin et al. [

23] conducted a detailed study investigating the relationship between the characteristics of a transfer layer formed by POM filled with 20% PTFE and the counter face surface topography. Wear rate was influenced by the counter face surface topography and the characteristics of the transfer layer. Mechanical properties such as tensile strength, elasticity modulus, elongation at break, and impact strength can be improved as a result of better compatibility of POM and PTFE. This is evident in the work carried out by Chiang et al. [

11], where increasing PTFE particles composition up to 15% steadily improved tensile properties. Beyond 15% composition, the strength of POM/PTFE composite deteriorated. With surface modification of PTFE particles through chemical etching, superior mechanical properties were achieved. Huang et al. [

24] characterized the effects of interface modification between POM and PTFE in the form of fibers. The surface of PTFE fibers was treated first using argon plasma and then grafted with acrylic acid. The impact strength, coefficient of friction, and wear resistance of the composite by blending POM with surface modified and grafted PTFE fibers were double that of non-treated PTFE fibers.

It is known that toughening of polymer composites by addition of fillers in the form of particulates usually results in reduction of strength and stiffness. Addition of fibers can compensate for the loss of these mechanical properties. Where tribological properties are of equal importance, a suitable particulate filler can be added to the composite. To obtain a high-performance POM composite, the dependency of mechanical properties against the variation of fillers during sample fabrication is vital.

In this work, POM/GF is used as a matrix where GF acts as the reinforcement phase. The composition of GF is unchanged at 25% of weight ratio. Surface modified PTFE microparticles are melt-blended with the matrix. The POM/GF/PTFE composites’ strength, stiffness, toughness, and hardness are characterized with PTFE content and PTFE etch time as control variables. Response surface methodology (RSM) is employed to determine the dependency of these mechanical properties against PTFE content and PTFE etch time. The aim of this work is to identify a stable region where the mechanical properties for POM/GF/PTFE composites are optimal. Based on the literature search, there is no information available on any optimization work involving POM/GF/PTFE composites using the statistical modeling approach.

2. Materials and Methods

2.1. Materials

Polyoxymethylene (POM) with 25% GF reinforcement matrix material used in this work purchased from Du Pont (Starke, FL, USA), commercially known as POM525GR. It is a homopolymer with a density of 1.6 g/cm3 and a melting temperature of 178 °C. Polytetrafluoroethylene (PTFE) microparticles with an average particle size of 12 µm, density of 0.425 g/cm3, and specific surface area of 1.5–3.0 m2/g were also purchased from Du Pont. The PTFE etch solution was prepared in the lab using sodium naphthalene with a density of 0.45 g/cm3. Tetrahydrofuran, purchased from J.T. Bakker, (Phillipsburg, NJ, USA) was used as a solvent to dissolve the salt.

2.2. Preparation of PTFE Microparticles Etch Solution

The etch solution was prepared by stirring sodium naphthalene in tetrahydrofuran at 25 °C at a stirring speed of 350 rpm. The mixture was comprised of 5% of sodium naphthalene to 95% of tetrahydrofuran and was stirred for 5 min, resulting in a dark brown solution. Subsequently, 30 g of PTFE microparticles were added to the solution and stirred at 25 °C with a stirring speed of 525 rpm. The stirring time was varied to obtain different surface etch depths. Once the required etching time was achieved, the stirrer was shut off and the solution was left to settle through sedimentation for about 1 min. The solid sediment containing PTFE and sodium salt settled at the bottom, separated from the liquid. The upper liquid was then poured away carefully.

For each wash cycle, 200 cm3 of acetone was added to the PTFE and stirred for 5 min with 525 rpm. Upon completion of the first wash cycle, the solution was left to settle, followed by pouring away the upper liquid. Another two wash cycles were repeated. The process was then followed by rinsing of the solid using 200 cm3 of distilled water. Stirrer speed of 525 rpm was used for rinsing. After each rinse cycle, the solid was left to settle and the upper portion containing mainly dissolved sodium salt in distilled water was poured away prior to the next rinse cycle. A total of five rinse cycles were performed to completely separate the etched PTFE micro powder from the sodium salt. The residue containing only the etched PTFE micro powder in distilled water was then placed in a petri dish of 150 mm diameter. This formed a PTFE layer of approximately 1 mm thick. An incubator with a temperature of 40 °C was used to dry the solution for 48 h. The etched PTFE was then removed from the petri dish and placed in a lab container in a dark environment to prevent exposure to light.

2.3. Preparation of POM Composites

POM525GR and surface-etched PTFE with various mix ratios by weight were compounded by melt blending using a Brabender Mixer 50EHT 3Z (Brabender GmBH & Co KG, Kulturstraße, Duisburg, Germany). Processing parameters of the mixer were temperature 180 °C, blades rotational speed 60 rpm and 10 min mix time. It was then crushed to approximately 1–3 mm in length prior to an injection molding process using a BOY XS machine (BOY Machines, Inc., Exton, PA, USA). The molding was comprised of three main processes, i.e., filling, plasticizing, and holding. For the filling process, the injection pressure used was 14 MPa with an injection speed of 100 mm/s. For the plasticizing process, pressure, screw rotational speed, and barrel temperature were controlled to 1 MPa, 170 rpm, and 180 °C, respectively. A holding pressure of 12 MPa was applied during the melt injection into the mold.

2.4. Model Development Using Response Surface Methodology (RSM)

RSM is a combination of mathematical and statistical techniques. These techniques are useful for the modeling and analysis of problems where the response is influenced by several input variables [

25,

26,

27]. RSM is able to quantify the relationships of the response (

) to the input variables (

). If these input variables are determinable, randomized on the experiment, and with minimal error, the response (

) can be expressed as:

The input variables are transformed into coded values and are determined using the following equation:

where

is the coded value for the

i-th variable,

is the uncoded value of the

i-th variable, and

is the uncoded value of the

i-th variable at the center point. The regression analysis is performed to estimate the response function as a second-order polynomial;

where

is the predicted response,

is constant, and

,

, and

are the linear, quadratic, and interactions coefficients estimated from the regression design, respectively.

The central composite design (CCD) was used to study the effects of PTFE content and PTFE etch time on the mechanical properties of POM/GF/PTFE composites. Subsequently, the effects of these key process input variables (KPIVs) on their responses or key process output variables (KPOVs) were used in optimization studies. Samples were tested for tensile strength, elasticity modulus, toughness, and hardness. This method suitably fitted a polynomial and optimized the effective input variables to obtain the desired responses. The correlations between these parameters were analyzed as well.

The data collected were analyzed in a statistical manner to determine the relationship between the input variables and each of the responses. To model the response as a mathematical function where the independent input variables may include linear, interaction, quadratic, and cubic terms, a regression design was used. The goal was to obtain good model parameter estimates.

The CCD was built up from two level full factorial design with center points and axial points with one additional center point. These axial points or augmented points were chosen as ±√2 since two factors were of interest. Thus, the experiment comprised 13 runs consisting of four axial points, four high and low levels of factors, and five central points. The values of each input variables were defined at the low, mid, and high points.

Table 1 shows the selected KPIVs and their range.

2.5. Statistical Analysis and Model Fitting

Statistical analysis, comprising regression and graphical analysis, was performed using Design-Expert software (version 10.0.6, Stat-Ease, Inc., Minneapolis, MN, USA). Based on the regression equation, optimum values of input variables were obtained. Analysis of variance (ANOVA) was used to further justify the adequacy of the models. The procedure calculates F-ratio, the ratio between the regression mean square and the mean square error. The F-ratio, called the variance ratio, is the variance ratio due to the effect of a factor and variance due to the error term. This ratio measures the significance of the model with respect to the variance of all terms included in the error term. The desire is to obtain a model that is significant.

Testing for significance of individual model coefficients forms the basis for optimizing the model. This is achieved by adding or deleting coefficients through forward addition, backward elimination or stepwise elimination, addition, or exchange. p-value or probability of risk to falsely rejecting a given hypothesis is determined. Generally, a lowest-order polynomial is chosen to adequately describe the system.

Lack-of-fit is a special diagnostic test for the adequacy of a model. As replicate measurements are available, a test indicating the significance of the replicate error in comparison to the model dependent error can be performed. This test splits the residual or error sum of squares into two portions, one due to pure error based on the replicate measurements and the other due to lack-of-fit based on the model performance. The test statistic for lack-of-fit is the ratio between the lack-of-fit mean square and the pure error mean square. As stated previously, this F-test statistic can be used to determine whether the lack-of-fit error is significant. Insignificant lack-of-fit is desired as significant lack-of-fit indicates that there might be contributions in the input variables–response relationship that are not accounted for by the model.

In addition, verification is needed to determine whether the model actually describes the experimental data. The two basic components of a valid regression model are the deterministic portion and stochastic error. The deterministic portion is the predictor variables in the model. The expected value of response is a function of these predictor variables. Stochastic error is the difference between the actual and predicted values represented by residuals. The residuals must be unpredictable and centered on zero throughout the range of predicted values. Random errors produce residuals that are normally distributed. Therefore, the residuals are in symmetrical pattern and have a constant spread throughout the range. A normal probability plot of residuals tests the dataset in the model to see if it fits a normal distribution. Once residual analysis validates no biased results, statistical measures for goodness of fit between experimental and predicted is performed. The coefficient of determination, R2, signifies the level of fit of the polynomial model, with values between 0 and 1. R2 is one of the measures for variability reduction of a response in statistical modeling. As more terms are added, the value of R2 increases without consideration of the statistical significance of these additional terms. The goal is to obtain R2 values close to 1. Adjusted R2 (R2adj) takes into consideration only the terms that are statistically significant. A lower value of R2adj than R2 indicates no necessity of adding extra terms into the model.

Adequate precision is a measure of the signal to noise ratio. A precision of more than 4.0 is desired, proving the model is able to predict the response. Then, the model can be used to navigate the design space. The adequacy of the model is investigated by the examination of residuals. The residuals, which are the difference between the observed responses and the predicted responses, are examined using normal probability plots. For an adequate model, the points on the normal probability plots form a straight line. For a weak model, residuals versus the predicted response plots have no obvious patterns.

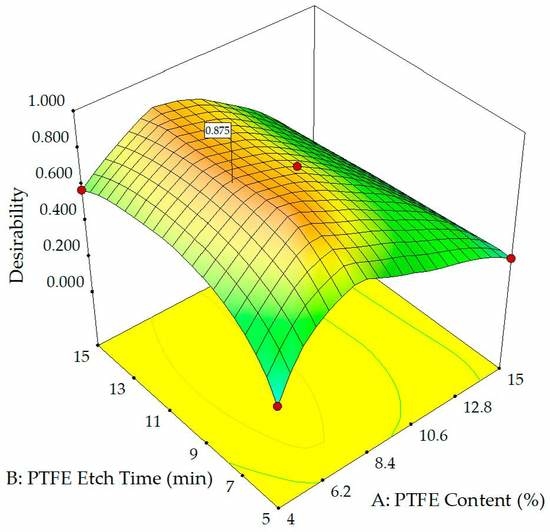

2.6. Optimization of Mechanical Properties Using the Desirability Method

Desirability method was used to determine the values of input variables, i.e., PTFE content and PTFE etch time for optimization of multiple responses, i.e., mechanical properties of POM/GF/PTFE composites simultaneously. The condition of each mechanical property (

) is selected based on its importance by selecting a maximum, minimum, or a target value of specification. Equation (4) is used to obtain the

D global index for the overall desirability based on the combination of responses processed through a geometric mean:

The responses (, , , ) are transformed such that . The value increases when the i-th response approaches the desired condition. Resulting from the geometric mean, D evaluates the levels of the combined responses with an index of . It is maximized when all responses approach the desirable specification. Responses can be assigned different importance. All responses with their own importance are included in one desirability index. Multiplication causes an outcome to be low if any one response is unable to achieve its desirability.

The Design-Expert software allows the input variables and responses to be changed to obtain the greatest overall desirability. These input variables are left within their experimental range and only responses are adjusted. This is where subject matter expertise and engineering knowledge become essential. The software also has an option to assign a weighting on a 1 to 10 scale and importance using a five-point scale. In this work, the same weighting was assigned to all mechanical properties. The stiffness and hardness of the POM/GF/PTFE composites were of higher importance than the strength and toughness.

2.7. Morphology Analysis Using Scanning Electron Microscopy (SEM)

SEM images provide information on the effects of etching to the surface of PTFE. The morphology of POM/GF/PTFE composites as a result of brittle fracture during tensile testing was also investigated. The central section of the dumbbells was selected for morphology analysis. The micrographs were taken using a Phenom ProX desktop SEM (Phenom-World B.V., Eindhoven, The Netherlands) operated at 10 kV accelerating voltage.

2.8. Mechanical Testing

Injection molded samples were tested for tensile strength, elasticity modulus, and toughness using an Instron 3369 universal tensile test machine (Instron, Norwood, MA, USA) according to ASTM D638. Type IV dumbbell-shaped specimens was prepared for tensile tests. Prior to testing, samples were conditioned in accordance with ASTM D618. The crosshead speed is fixed at 5 mm/min at room temperature with the distance between grips of 60 mm. The thickness and width of each sample were measured individually to obtain an accurate cross-sectional area. The average value of six samples for each POM composite type was used to determine its strength, stiffness, and toughness.

Hardness testing was performed using an Instron B2000 tester (Instron, Norwood, MA, USA) using the HRR scale. Rectangular injection-molded samples of approximately 63.5 mm (length) × 12.7 mm (width) × 3 mm (thick) were tested. A total of four fixed points along the length were taken. Similar to tensile testing, a hardness value was obtained by averaging six tested samples for each POM composite type.

4. Conclusions

The mechanical properties of POM/GF/PTFE composites were optimized by varying the PTFE content and PTFE etch time. As PTFE is known to weaken a polymer composite’s strength and stiffness due to its low surface energy, chemical etching was necessary to improve its compatibility with the POM/GF matrix prior to blending. Therefore, PTFE content and PTFE etch time were important factors in determining the mechanical properties of POM/GF/PTFE composites. The need to control these factors accurately was necessary. SEM analysis correlated the etch time to the defluorination layer on the surface of PTFE particles. Morphology study of fractured surfaces during tensile testing revealed the effects of PTFE content and PTFE etch time on the matrix and GF. The polymeric material adhesion to GF affected the interfacial bond. As a result, strength, stiffness, and hardness were compromised but the toughness improved. The altered GF surface can be an enabler for applications requiring polymer composites with superior strength and tribological properties. Response surface methodology in conjunction with central composite design was used to model the effects of these factors on the strength, stiffness, toughness, and hardness of POM/GF/PTFE composites. Using experimental data and ANOVA, a mathematical model was derived for each response. The normal probability test, significance test, and correlation coefficients determined the significance of fit between the model and experimental data. To optimize the mechanical properties simultaneously, each property was specified and a desirability function was derived. The overall desirability or D global index for the mechanical properties of the POM/GF/PTFE composite was 87.5% when the PTFE content and PTFE etch time were 6.5% and 10 min, respectively. The individual desirability index, d, for tensile strength was 89.6%, the elasticity modulus was 78.0%, the toughness was 82.7%, and the hardness was 100%. Finally, the contour plot for overall desirability showed a wide region of 80% when the PTFE content ranged from 5.0% to 8.0% and the PTFE etch time ranged from 8 min to 13 min.