Compression Garments for Medical Therapy and Sports

Abstract

:1. Introduction

2. Functional Compression Garments

2.1. Chronic Venous Disease and Edema Management

2.1.1. Action Principle

2.1.2. Application of Compression Stockings

2.1.3. Application of Bandages

2.2. Scar Management

2.3. Orthopedic Supports

2.4. Sportswear

2.5. Body Shaping

2.6. Smart Compression Garments

3. Fibers and Yarns

3.1. Types of Elastomeric Fibers and Yarns

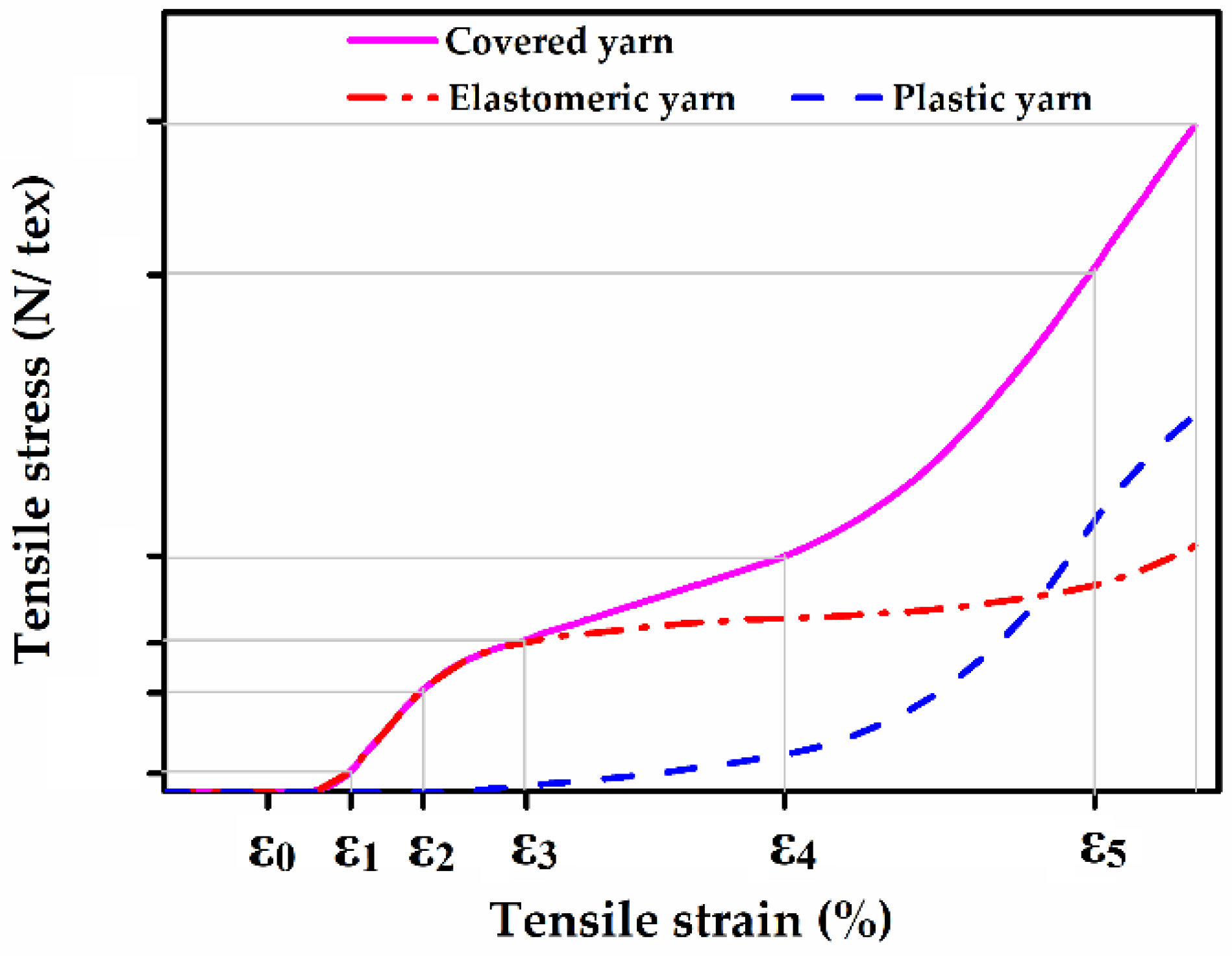

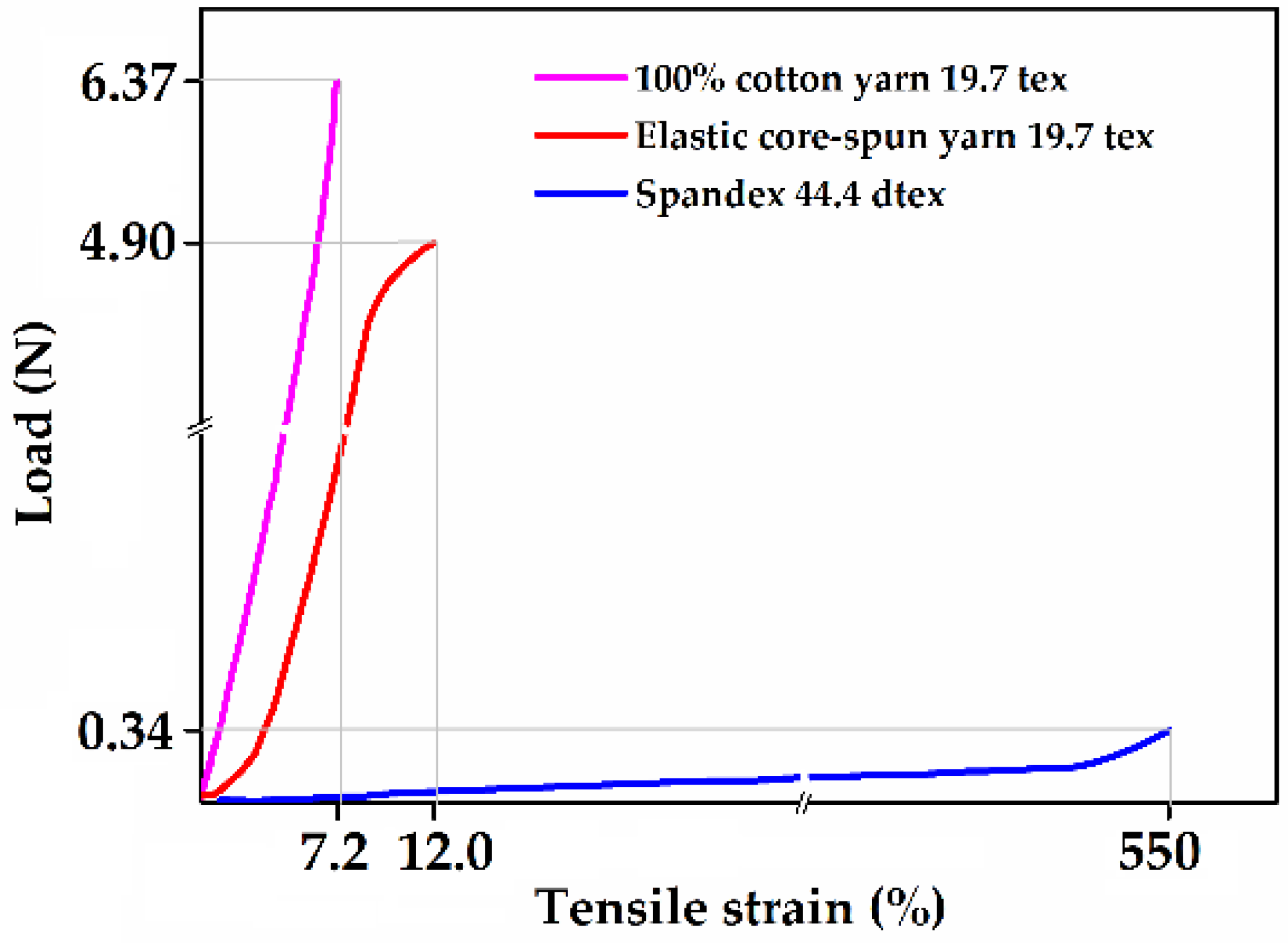

3.2. Characteristics of Elastomeric Yarns

4. Fabric Construction and Mechanical Properties

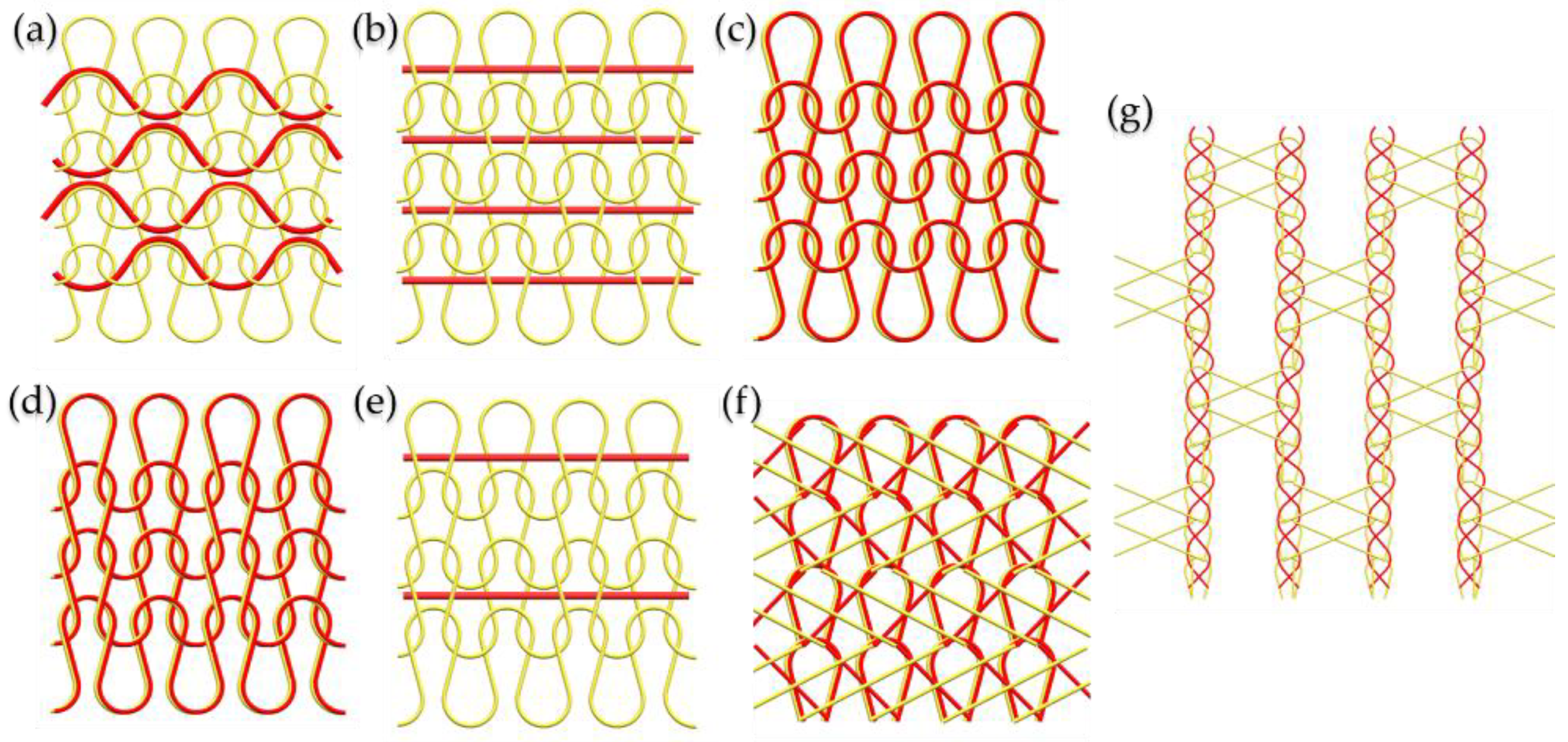

4.1. Knitting Construction and Fabrication

4.2. Fabric Mechanical Properties

5. Garment Design and Evaluation System

5.1. Garment Design

5.2. Design System

5.3. Evaluation for Compression Garments

6. Pressure Measurement and Modeling

6.1. Pressure Measurement

6.1.1. Pressure Sensors

6.1.2. Static Pressure Measurement

6.1.3. Dynamic Pressure Measurement

6.2. Pressure Modeling

7. Conclusions and Future Outlook

Funding

Acknowledgments

Conflicts of Interest

References

- MacRae, B.A.; Cotter, J.D.; Laing, R.M. Compression garments and exercise: Garment considerations, physiology and performance. Sports Med. 2011, 41, 815–843. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Felder, M.; Cai, J.Y. Study of properties of medical compression garment fabrics. J. Fiber Bioeng. Inform. 2011, 4, 15–22. [Google Scholar] [CrossRef]

- Felty, C.L.; Rooke, T.W. Compression therapy for chronic venous insufficiency. Semin. Vasc. Surg. 2005, 18, 36–40. [Google Scholar] [CrossRef] [PubMed]

- Martin, H.A. The india-rubber bandage for ulcers and other diseases of the legs. Br. Med. J. 1878, 2, 624. [Google Scholar] [CrossRef]

- Staley, M.J.; Richard, R.L. Use of pressure to treat hypertrophic burn scars. Adv. Wound Care 1997, 10, 44–46. [Google Scholar] [PubMed]

- Born, D.P.; Sperlich, B.; Holmberg, H.C. Bringing light into the dark: Effects of compression clothing on performance and recovery. Int. J. Sport Physiol. 2013, 8, 4–18. [Google Scholar] [CrossRef]

- Duffield, R.; Portus, M. Comparison of three types of full-body compression garments on throwing and repeat-sprint performance in cricket players. Br. J. Sport Med. 2007, 41, 409–414. [Google Scholar] [CrossRef] [PubMed]

- Fu, W.; Liu, Y.; Fang, Y. Research advancements in humanoid compression garments in sports. Int. J. Adv. Robot. Syst. 2013, 10, 66. [Google Scholar] [CrossRef]

- Gupta, D. Functional clothing—Definition and classification. Indian J. Fibre Text. Res. 2011, 36, 321–326. [Google Scholar]

- Denton, M. Fit, stretch and comfort. Textiles 1972, 3, 12–17. [Google Scholar]

- Tanaka, S.; Midorikawa, T.; Tokura, H. Effects of pressure exerted on the skin by elastic cord on the core temperature, body weight loss and salivary secretion rate at 35 °C. Eur. J. Appl. Physiol. 2006, 96, 471–476. [Google Scholar] [CrossRef] [PubMed]

- Eberhardt, R.T.; Raffetto, J.D. Chronic venous insufficiency. Circulation 2014, 130, 333–346. [Google Scholar] [CrossRef] [PubMed]

- Robertson, L.; Evans, C.; Fowkes, F. Epidemiology of chronic venous disease. Phlebology 2008, 23, 103–111. [Google Scholar] [CrossRef] [PubMed]

- Meissner, M.H.; Gloviczki, P.; Bergan, J.; Kistner, R.L.; Morrison, N.; Pannier, F.; Pappas, P.J.; Rabe, E.; Raju, S.; Villavicencio, J.L. Primary chronic venous disorders. J. Vasc. Surg. 2007, 46, S54–S67. [Google Scholar] [CrossRef] [PubMed]

- Jawien, A. The influence of environmental factors in chronic venous insufficiency. Angiology 2003, 54, S19–S31. [Google Scholar] [CrossRef] [PubMed]

- Nicolaides, A.; Allegra, C.; Bergan, J.; Bradbury, A.; Cairols, M.; Carpentier, P.; Comerota, A.; Delis, C.; Eklof, B.; Fassiadis, N. Management of chronic venous disorders of the lower limbs guidelines according to scientific evidence. Int. Angiol. 2008, 27, 1–59. [Google Scholar] [PubMed]

- Fletcher, J.; Moffatt, C.; Partsch, H.; Vowden, K.; Vowden, P. Principles of Compression in Venous Disease. A Practitioner’s Guide to Treatment and Prevention of Venous Leg Ulcers; Wounds International: London, UK, 2013; Available online: http://www.woundsinternational.com/media/issues/672/files/content_10802.pdf (accessed on 1 May 2018).

- Fan, C.-M. Venous pathophysiology. Semin. Interven. Radiol. 2005, 22, 157–161. [Google Scholar] [CrossRef] [PubMed]

- Bachelor, E.P. Varicose veins and telangiectasias: Diagnosis and treatment. Plast. Reconstr. Surg. 2001, 108, 572–573. [Google Scholar] [CrossRef]

- Schuren, J.; Mohr, K. Pascal’s law and the dynamics of compression therapy: A study on healthy volunteers. Int. Angiol. 2010, 29, 431–435. [Google Scholar] [PubMed]

- Li, Y.; Dai, D.X. Biomechanical engineering of compression stockings. In Biomechanical Engineering of Textiles and Clothing; Woodhead Publishing: Cambridge, UK, 2006; pp. 332–344. [Google Scholar]

- Sugisawa, R.; Unno, N.; Saito, T.; Yamamoto, N.; Inuzuka, K.; Tanaka, H.; Sano, M.; Katahashi, K.; Uranaka, H.; Marumo, T. Effects of compression stockings on elevation of leg lymph pumping pressure and improvement of quality of life in healthy female volunteers: A randomized controlled trial. Lymphat. Res. Biol. 2016, 14, 95–103. [Google Scholar] [CrossRef] [PubMed]

- Wollina, U.; Abdel-Naser, M.B.; Mani, R. A review of the microcirculation in skin in patients with chronic venous insufficiency: The problem and the evidence available for therapeutic options. Int. J. Low. Exterm. Wounds 2006, 5, 169–180. [Google Scholar] [CrossRef] [PubMed]

- Hill, J.; Howatson, G.; van Someren, K.; Davidson, S.; Pedlar, C. Pressures exerted by commercially available lower limb compression garments. Br. J. Sports Med. 2014, 48, 608. [Google Scholar] [CrossRef]

- Amsler, F.; Blättler, W. Compression therapy for occupational leg symptoms and chronic venous disorders—A meta-analysis of randomised controlled trials. Eur. J. Vasc. Endovasc. 2008, 35, 366–372. [Google Scholar] [CrossRef] [PubMed]

- Partsch, H.; Winiger, J.; Lun, B. Compression stockings reduce occupational leg swelling. Dermatol. Surg. 2004, 30, 737–743. [Google Scholar] [PubMed]

- Partsch, H.; Clark, M.; Mosti, G.; Steinlechner, E.; Schuren, J.; Abel, M.; Benigni, J.P.; Coleridge-Smith, P.; Cornu-Thénard, A.; Flour, M. Classification of compression bandages: Practical aspects. Dermatol. Surg. 2008, 34, 600–609. [Google Scholar] [CrossRef] [PubMed]

- Weingarten, M.S. State-of-the-art treatment of chronic venous disease. Clin. Infect. Dis. 2001, 32, 949–954. [Google Scholar] [PubMed]

- Partsch, H.; Damstra, R.; Mosti, G. Dose finding for an optimal compression pressure to reduce chronic edema of the extremities. Int. Angiol. 2011, 30, 527–533. [Google Scholar] [PubMed]

- Partsch, B.; Partsch, H. Calf compression pressure required to achieve venous closure from supine to standing positions. J. Vasc. Surg. 2005, 42, 734–738. [Google Scholar] [CrossRef] [PubMed]

- Partsch, H. Compression therapy: Clinical and experimental evidence. Ann. Vasc. Dis. 2012, 5, 416–422. [Google Scholar] [CrossRef] [PubMed]

- Widgerow, A.D.; Chait, L.A. Scar management practice and science: A comprehensive approach to controlling scar tissue and avoiding hypertrophic scarring. Adv. Skin Wound Care 2011, 24, 555–561. [Google Scholar] [CrossRef] [PubMed]

- Gauglitz, G.G.; Korting, H.C.; Pavicic, T.; Ruzicka, T.; Jeschke, M.G. Hypertrophic scarring and keloids: Pathomechanisms and current and emerging treatment strategies. Mol. Med. 2011, 17, 113–125. [Google Scholar] [CrossRef] [PubMed]

- Reno, F.; Sabbatini, M.; Lombardi, F.; Stella, M.; Pezzuto, C.; Magliacani, G.; Cannas, M. In vitro mechanical compression induces apoptosis and regulates cytokines release in hypertrophic scars. Wound Repair Regen. 2003, 11, 331–336. [Google Scholar] [CrossRef] [PubMed]

- Partsch, H.; Mortimer, P. Compression for leg wounds. Br. J. Dermatol. 2015, 173, 359–369. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Van den Kerckhove, E.; Stappaerts, K.; Fieuws, S.; Laperre, J.; Massage, P.; Flour, M.; Boeckx, W. The assessment of erythema and thickness on burn related scars during pressure garment therapy as a preventive measure for hypertrophic scarring. Burns 2005, 31, 696–702. [Google Scholar] [CrossRef] [PubMed]

- Zurada, J.M.; Kriegel, D.; Davis, I.C. Topical treatments for hypertrophic scars. J. Am. Acad. Dermatol. 2006, 55, 1024–1031. [Google Scholar] [CrossRef] [PubMed]

- Sharp, P.A.; Pan, B.; Yakuboff, K.P.; Rothchild, D. Development of a best evidence statement for the use of pressure therapy for management of hypertrophic scarring. J. Burn Care Res. 2016, 37, 255–264. [Google Scholar] [CrossRef] [PubMed]

- Johnson, J.; Greenspan, B.; Gorga, D.; Nagler, W.; Goodwin, C. Compliance with pressure garment use in burn rehabilitation. J. Burn Care Rehabil. 1994, 15, 181–188. [Google Scholar] [CrossRef]

- Parry, I.; Hanley, C.; Niszczak, J.; Sen, S.; Palmieri, T.; Greenhalgh, D. Harnessing the transparent face orthosis for facial scar management: A comparison of methods. Burns 2013, 39, 950–956. [Google Scholar] [CrossRef] [PubMed]

- Rogers, B.; Chapman, T.; Rettele, J.; Gatica, J.; Darm, T.; Beebe, M.; Dilworth, D.; Walsh, N. Computerized manufacturing of transparent face masks for the treatment of facial scarring. J. Burn Care Rehabil. 2003, 24, 91–96. [Google Scholar] [CrossRef] [PubMed]

- Van den Kerckhove, E.; Stappaerts, K.; Boeckx, W.; Van den Hof, B.; Monstrey, S.; Van der Kelen, A.; De Cubber, J. Silicones in the rehabilitation of burns: A review and overview. Burns 2001, 27, 205–214. [Google Scholar] [CrossRef]

- Yip, C.; Mehmood, Z.; Shah, M. Lego® as a customisable pressure garment insert. Burns 2008, 34, 430–431. [Google Scholar] [CrossRef] [PubMed]

- LáZáR, K. Application of knitted fabrics in technical and medical textiles. In Proceedings of the 45th International Congress (IFKT), Ljubljana, Slovenia, 27–29 May 2010; pp. 27–29. [Google Scholar]

- Ališauskienė, D.; Mikučioniené, D.; Milašiute, L. Influence of inlay-yarn properties and insertion density on the compression properties of knitted orthopaedic supports. Fibres Text. East. Eur. 2013, 6, 74–78. [Google Scholar]

- Mikučionienė, D.; Milašiūtė, L. Influence of knitted orthopaedic support construction on compression generated by the support. J. Ind. Text. 2017, 47, 551–566. [Google Scholar] [CrossRef]

- Doan, B.K.; Kwon, Y.H.; Newton, R.U.; Shim, J.; Popper, E.M.; Rogers, R.A.; Bolt, L.R.; Robertson, M.; Kraemer, W.J. Evaluation of a lower-body compression garment. J. Sport Sci. 2003, 21, 601–610. [Google Scholar] [CrossRef] [PubMed]

- Higgins, T.; Naughton, G.A.; Burgess, D. Effects of wearing compression garments on physiological and performance measures in a simulated game-specific circuit for netball. J. Sci. Med. Sport 2009, 12, 223–226. [Google Scholar] [CrossRef] [PubMed]

- Pearce, A.J.; Kidgell, D.J.; Grikepelis, L.A.; Carlson, J.S. Wearing a sports compression garment on the performance of visuomotor tracking following eccentric exercise: A pilot study. J. Sci. Med. Sport 2009, 12, 500–502. [Google Scholar] [CrossRef] [PubMed]

- Scanlan, A.T.; Dascombe, B.J.; Reaburn, P.R.; Osborne, M. The effects of wearing lower-body compression garments during endurance cycling. Int. J. Sport Physiol. 2008, 3, 424–438. [Google Scholar] [CrossRef]

- Kraemer, W.J.; Flanagan, S.D.; Comstock, B.A.; Fragala, M.S.; Earp, J.E.; Dunn-Lewis, C.; Ho, J.-Y.; Thomas, G.A.; Solomon-Hill, G.; Penwell, Z.R. Effects of a whole body compression garment on markers of recovery after a heavy resistance workout in men and women. J. Strength Cond. Res. 2010, 24, 804–814. [Google Scholar] [CrossRef] [PubMed]

- Kraemer, W.J.; Bush, J.A.; Wickham, R.B.; Denegar, C.R.; Gomez, A.L.; Gotshalk, L.A.; Duncan, N.D.; Volek, J.S.; Newton, R.U.; Putukian, M. Continuous compression as an effective therapeutic intervention in treating eccentric-exercise-induced muscle soreness. J. Sport Rehabil. 2001, 10, 11–23. [Google Scholar] [CrossRef]

- Sperlich, B.; Haegele, M.; Achtzehn, S.; Linville, J.; Holmberg, H.C.; Mester, J. Different types of compression clothing do not increase sub-maximal and maximal endurance performance in well-trained athletes. J. Sport Sci. 2010, 28, 609–614. [Google Scholar] [CrossRef] [PubMed]

- Morooka, H.; Nakahashi, M.; Morooka, H.; Kitamura, K. Effects of clothing pressure exerted on a trunk on heart rate, blood pressure, skin blood flow and respiratory function. J. Text. Mach. Soc. Jpn. 2001, 54, 57–62. [Google Scholar] [CrossRef]

- Xu, D.-F.; Liu, D.-Y.; Wu, Z.-M. Analysis of physiological response by pressure developed by female swimsuit. J. Beijing Inst. Cloth. Technol. 2012, 32, 1–8. [Google Scholar]

- Wang, C.C.; Tang, K. Pattern computation for compression garment by a physical/geometric approach. Comput. Aided Des. 2010, 42, 78–86. [Google Scholar] [CrossRef] [Green Version]

- Chan, A.; Fan, J. Effect of clothing pressure on the tightness sensation of girdles. Int. J. Cloth. Sci. Technol. 2002, 14, 100–110. [Google Scholar] [CrossRef]

- Makabe, H.; Momota, H.; Mitsuno, T.; Ueda, K. A study of clothing pressure developed by the girdle. J. Jpn. Res. Assoc. Text. End-Uses 1991, 32, 424–438. [Google Scholar]

- Belbasis, A.; Fuss, F.K.; Sidhu, J. Muscle activity analysis with a smart compression garment. Procedia Eng. 2015, 112, 163–168. [Google Scholar] [CrossRef]

- Belbasis, A.; Fuss, F.K. Development of next-generation compression apparel. Procedia Technol. 2015, 20, 85–90. [Google Scholar] [CrossRef]

- Belbasis, A.; Fuss, F.K.; Sidhu, J. Estimation of cruciate ligament forces via smart compression garments. Procedia Eng. 2015, 112, 169–174. [Google Scholar] [CrossRef]

- Chen, L.; Hoey, J.; Nugent, C.D.; Cook, D.J.; Yu, Z. Sensor-based activity recognition. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2012, 42, 790–808. [Google Scholar] [CrossRef]

- Hu, J.; Lu, J.; Zhu, Y. New developments in elastic fibers. Polym. Rev. 2008, 48, 275–301. [Google Scholar] [CrossRef]

- Senthilkumar, M.; Anbumani, N.; Hayavadana, J. Elastane fabrics—A tool for stretch applications in sports. Indian J. Fibre Text. Res. 2011, 36, 300–307. [Google Scholar]

- Brown, R.P. Polymers in Sport and Leisure; Rapra Review Reports 135; Rapra Technology Ltd.: Shawbury, UK, 2001; Volume 12. [Google Scholar]

- Hu, J.; Lu, J. Recent developments in elastic fibers and yarns for sportswear. In Textiles for Sportswear; Elsevier: New York, NY, USA, 2015; pp. 53–76. [Google Scholar]

- Bhat, G.; Chand, S.; Yakopson, S. Thermal properties of elastic fibers. Thermochim. Acta 2001, 367, 161–164. [Google Scholar] [CrossRef]

- Kumar, B.; Das, A.; Alagirusamy, R. Effect of material and structure of compression bandage on interface pressure variation over time. Phlebology 2014, 29, 376–385. [Google Scholar] [CrossRef] [PubMed]

- Bruniaux, P.; Crepin, D.; Lun, B. Modeling the mechanics of a medical compression stocking through its components behavior: Part 1—Modeling at the yarn scale. Text. Res. J. 2012, 82, 1833–1845. [Google Scholar] [CrossRef]

- Su, C.-I.; Maa, M.-C.; Yang, H.-Y. Structure and performance of elastic core-spun yarn. Text. Res. J. 2004, 74, 607–610. [Google Scholar] [CrossRef]

- Gazi Ortlek, H.; Ulku, S. Effects of spandex and yarn counts on the properties of elastic core-spun yarns produced on murata vortex spinner. Text. Res. J. 2007, 77, 432–436. [Google Scholar] [CrossRef]

- Krimmel, G. The construction and classification of compression garments. In Template for Practice: Compression Hosiery in Upper Body Lymphoedema; HeathComm: Aberdeen, UK, 2009; pp. 2–5. [Google Scholar]

- Ališaukienė, D.; Mikučionienė, D. Investigation on alteration of compression of knitted orthopaedic supports during exploitation. Mater. Sci. 2012, 18, 362–366. [Google Scholar]

- Senthilkumar, M.; Anbumani, N. Dynamics of elastic knitted fabrics for sports wear. J. Ind. Text. 2011, 41, 13–24. [Google Scholar] [CrossRef]

- Cooper, A., Jr.; Robinson, H.M.; Reeves, W.A.; Sloan, W.G. Mechanism for stretch and recovery properties of certain stretch fabrics1. Text. Res. J. 1965, 35, 452–458. [Google Scholar] [CrossRef]

- Van Der Wegen-franken, K.; Tank, B.; Neumann, M. Correlation between the static and dynamic stiffness indices of medical elastic compression stockings. Dermatol. Surg. 2008, 34, 1477–1485. [Google Scholar] [PubMed]

- Sau-fun Ng Yip, F. Medical clothing: The stress relaxation and shrinkage of pressure garments. Int. J. Cloth. Sci. Technol. 1994, 6, 17–27. [Google Scholar] [CrossRef]

- Šajn, D.; Geršak, J.; Flajs, R. Prediction of stress relaxation of fabrics with increased elasticity. Text. Res. J. 2006, 76, 742–750. [Google Scholar] [CrossRef]

- Hirai, M.; Koyama, A.; Miyazaki, K.; Iwata, H.; Kominami, Y. Interface pressure and stiffness in different combinations of compression material. Phlebology 2012, 27, 82–89. [Google Scholar] [CrossRef] [PubMed]

- Hirai, M.; Niimi, K.; Miyazaki, K.; Iwata, H.; Sugimoto, I.; Ishibashi, H.; Ota, T.; Kominami, Y. Development of a device to determine the stiffness of elastic garments and bandages. Phlebology 2011, 26, 285–291. [Google Scholar] [CrossRef] [PubMed]

- Ito, N.; Inoue, M.; Nakanishi, M.; Niwa, M. The relation among the biaxial extension properties of girdle cloths and wearing comfort and clothing pressure of girdles. J. Jpn. Res. Assoc. Text. End-Uses 1995, 36, 102–108. [Google Scholar]

- Hui, C.; Ng, S. Theoretical analysis of tension and pressure decay of a tubular elastic fabric. Text. Res. J. 2003, 73, 268–272. [Google Scholar] [CrossRef]

- Yamada, T.; Matsuo, M. Clothing pressure of knitted fabrics estimated in relation to tensile load under extension and recovery processes by simultaneous measurements. Text. Res. J. 2009, 79, 1021–1033. [Google Scholar] [CrossRef]

- Maleki, H.; Aghajani, M.; Sadeghi, A.; Jeddi, A.A.A. On the pressure behavior of tubular weft knitted fabrics constructed from textured polyester yarns. J. Eng. Fabr. Fibers 2011, 6, 30–39. [Google Scholar]

- Wang, Y.R.; Zhang, P.H.; Zhang, Y.P. Experimental investigation the dynamic pressure attenuation of elastic fabric for compression garment. Text. Res. J. 2014, 84, 572–582. [Google Scholar] [CrossRef]

- Macintyre, L.; Ferguson, R. Pressure garment design tool to monitor exerted pressures. Burns 2013, 39, 1073–1082. [Google Scholar] [CrossRef] [PubMed]

- Geršak, J.; Šajn, D.; Bukošek, V. A study of the relaxation phenomena in the fabrics containing elastane yarns. Int. J. Cloth. Sci. Technol. 2005, 17, 188–199. [Google Scholar] [CrossRef]

- Liu, R.; Kwok, Y.-L.; Li, Y.; Lao, T.-T. Fabric mechanical-surface properties of compression hosiery and their effects on skin pressure magnitudes when worn. Fibres Text. East. Eur. 2010, 18, 91–97. [Google Scholar]

- Mermelstein, S.; Hale, D. New developments in the manufacture of circular knitting machines for the production of medical textiles. In Medical Textiles; Elsevier: New York, NY, USA, 2001; pp. 3–11. [Google Scholar]

- Kanakaraj, P.; Ramachandran, R. Seamless garment: Needle selection techniques and applications. Pak. Text. J. 2010, 59, 44–46. [Google Scholar]

- Troynikov, O.; Watson, C. Knitting technology for seamless sportswear. In Textiles for Sportswear; Elsevier: New York, NY, USA, 2015; pp. 95–117. [Google Scholar]

- Salleh, M.N.B.; Acar, M.; Burns, N.D. Customised pressure garment development by using 3d scanned body image. Res. J. Text. Appar. 2011, 15, 9–18. [Google Scholar] [CrossRef]

- Macintyre, L.; Baird, M.; Weedall, P. The study of pressure delivery for hypertrophic scar treatment. Int. J. Cloth. Sci. Technol. 2004, 16, 173–183. [Google Scholar] [CrossRef]

- Maklewska, E.; Nawrocki, A.; Ledwoń, J.; Kowalski, K. Modelling and designing of knitted products used in compressive therapy. Fibres Text. East. Eur. 2006, 14, 111–113. [Google Scholar]

- Yıldız, N. A novel technique to determine pressure in pressure garments for hypertrophic burn scars and comfort properties. Burns 2007, 33, 59–64. [Google Scholar] [CrossRef] [PubMed]

- Salleh, M.N.B.; Lazim, H.B.M.; Othman, S.N.B.; Merican, A.F.M.B.A. Development of a flexible customised compression garment pattern design system. Int. J. Adv. Mech. Syst. 2013, 5, 202–208. [Google Scholar] [CrossRef]

- Gupta, D. Design and engineering of functional clothing. Indian J. Fibre Text. Res. 2011, 36, 327–335. [Google Scholar]

- Kirk, W., Jr.; Ibrahim, S. Fundamental relationship of fabric extensibility to anthropometric requirements and garment performance. Text. Res. J. 1966, 36, 37–47. [Google Scholar] [CrossRef]

- Choudhury, A.R.; Majumdar, P.; Datta, C. Factors affecting comfort: Human physiology and the role of clothing. In Improving Comfort in Clothing; Elsevier: New York, NY, USA, 2011; pp. 3–60. [Google Scholar]

- Pereira, S.; Anand, S.; Rajendran, S.; Wood, C. A study of the structure and properties of novel fabrics for knee braces. J. Ind. Text. 2007, 36, 279–300. [Google Scholar] [CrossRef]

- Partsch, H.; Partsch, B.; Braun, W. Interface pressure and stiffness of ready made compression stockings: Comparison of in vivo and in vitro measurements. J. Vasc. Surg. 2006, 44, 809–814. [Google Scholar] [CrossRef] [PubMed]

- Ferguson-Pell, M.; Hagisawa, S.; Bain, D. Evaluation of a sensor for low interface pressure applications. Med. Eng. Phys. 2000, 22, 657–663. [Google Scholar] [CrossRef]

- Partsch, H. The static stiffness index: A simple method to assess the elastic property of compression material in vivo. Dermatol. Surg. 2005, 31, 625–630. [Google Scholar] [CrossRef] [PubMed]

- Ferguson-Pell, M.; Cardi, M.D. Prototype development and comparative evaluation of wheelchair pressure mapping system. Assist Technol. 1993, 5, 78–91. [Google Scholar] [CrossRef] [PubMed]

- Maklewska, E.; Nawrocki, A.; Kowalski, K.; Andrzejewska, E.; Kuzański, W. New measuring device for estimating the pressure under compression garments. Int. J. Cloth. Sci. Technol. 2007, 19, 215–221. [Google Scholar] [CrossRef]

- Chavan, A.V.; Wise, K.D. Batch-processed vacuum-sealed capacitive pressure sensors. J. Microelectromech. Syst. 2001, 10, 580–588. [Google Scholar] [CrossRef]

- Hafner, J.; Lüthi, W.; Hänssle, H.; Kammerlander, G.; Burg, G. Instruction of compression therapy by means of interface pressure measurement. Dermatol. Surg. 2000, 26, 481–488. [Google Scholar] [CrossRef] [PubMed]

- Lai, C.H.; Li-Tsang, C.W. Validation of the pliance x system in measuring interface pressure generated by pressure garment. Burns 2009, 35, 845–851. [Google Scholar] [CrossRef] [PubMed]

- Swain, I. The measurement of interface pressure. In Pressure Ulcer Research; Springer: New York, NY, USA, 2005; pp. 51–71. [Google Scholar]

- Partsch, H.; Clark, M.; Bassez, S.; Benigni, J.P.; Becker, F.; Blazek, V.; Caprini, J.; Cornu-Thénard, A.; Hafner, J.; Flour, M. Measurement of lower leg compression in vivo: Recommendations for the performance of measurements of interface pressure and stiffness. Dermatol. Surg. 2006, 32, 224–233. [Google Scholar] [CrossRef] [PubMed]

- Stolk, R.; Wegen van der-Franken, C.; Neumann, H. A method for measuring the dynamic behavior of medical compression hosiery during walking. Dermatol. Surg. 2004, 30, 729–736. [Google Scholar] [PubMed]

- Partsch, H.; Mosti, G. Comparison of three portable instruments to measure compression pressure. Int. Angiol. 2010, 29, 426–430. [Google Scholar] [PubMed]

- Trenell, M.I.; Rooney, K.B.; Sue, C.M.; Thomspon, C.H. Compression garments and recovery from eccentric exercise: A 31P-MRS study. J. Sports Sci. Med. 2006, 5, 106–114. [Google Scholar] [PubMed]

- McLaren, J.; Helmer, R.; Horne, S.; Blanchonette, I. Preliminary development of a wearable device for dynamic pressure measurement in garments. Procedia Eng. 2010, 2, 3041–3046. [Google Scholar] [CrossRef]

- Shahidi, A.M.; Dias, T.; Nandasiri, G.K. The impact of direct and indirect pressure measuring systems on the pressure mapping for the medical compression garments. World Acad. Sci. Eng. Technol. Int. J. Fash. Text. Eng. 2018, 12, 120. [Google Scholar]

- Macintyre, L.; Baird, M. Pressure garments for use in the treatment of hypertrophic scars—A review of the problems associated with their use. Burns 2006, 32, 10–15. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Yeung, K.; Li, Y. Numerical simulation of 3d dynamic garment pressure. Text. Res. J. 2002, 72, 245–252. [Google Scholar] [CrossRef]

- Lin, Y.; Choi, K.-F.; Luximon, A.; Yao, L.; Hu, J.; Li, Y. Finite element modeling of male leg and sportswear: Contact pressure and clothing deformation. Text. Res. J. 2011, 81, 1470–1476. [Google Scholar]

- Liu, R.; Kwok, Y.-L.; Li, Y.; Lao, T.-T.; Dai, X.Q.; Zhang, X. Numerical simulation of internal stress profiles and three-dimensional deformations of lower extremity beneath medical graduated compression stocking (GCS). Fiber Polym. 2007, 8, 302–308. [Google Scholar] [CrossRef]

- Liu, R.; Kwok, Y.-L.; Li, Y.; Lao, T.-T.; Zhang, X.; Dai, X.Q. A three-dimensional biomechanical model for numerical simulation of dynamic pressure functional performances of graduated compression stocking (GCS). Fiber Polym. 2006, 7, 389–397. [Google Scholar] [CrossRef]

- Wang, J.-M.; Luo, X.-N.; Li, Y.; Dai, X.-Q.; You, F. The application of the volumetric subdivision scheme in the simulation of elastic human body deformation and garment pressure. Text. Res. J. 2005, 75, 591–597. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, Y.; Zhang, P.; Feng, X.; Shen, J.; Xiong, Q. A smart mannequin system for the pressure performance evaluation of compression garments. Text. Res. J. 2011, 81, 1113–1123. [Google Scholar] [CrossRef]

| Knitting Method | Knitting Machine | Knitting Construction | Isotropy in Deformation | Applications |

|---|---|---|---|---|

| Weft knitting | Single jersey | Elastic yarns are knitted or inlaid or plating to knit jersey or double jersey, fleece, pique | Elastic deformation in the wale and course direction | Sportswear; Medical compression garments |

| Double jersey | ||||

| Interlock | Bare or Covered elastic yarns are inlaid or plating | Elastic deformation in the wale direction | ||

| Rib | ||||

| Flat knitting | 1. covered elastic yarns are knitted or inlaid or plating 2. space fabric | Elastic deformation in the wale and course direction | ||

| Warp knitting | Tricot | Elastic yarns are knitted on the back bar with 1–0/1–2// tricot stitch to knit fabrics with plain jersey and mesh | Elastic deformation in the wale and course direction | Swimwear; tight-fitting garments |

| Raschel | Elastic yarns are as laid-in stitch to produce power-net construction | Elastic deformation in the course direction | Swimwear; tight-fitting garments; support garments | |

| Double-needle-bar Raschel | 1. Elastic yarns are in the surface bar to knit space fabric 2. Circular elastic fabric | Elastic deformation mainly in the course direction |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, Y.; Tao, X. Compression Garments for Medical Therapy and Sports. Polymers 2018, 10, 663. https://doi.org/10.3390/polym10060663

Xiong Y, Tao X. Compression Garments for Medical Therapy and Sports. Polymers. 2018; 10(6):663. https://doi.org/10.3390/polym10060663

Chicago/Turabian StyleXiong, Ying, and Xiaoming Tao. 2018. "Compression Garments for Medical Therapy and Sports" Polymers 10, no. 6: 663. https://doi.org/10.3390/polym10060663