Ball-Milled Recycled Lead-Graphite Pencils as Highly Stretchable and Low-Cost Thermal-Interface Materials

Abstract

:1. Introduction

2. Materials and Methods

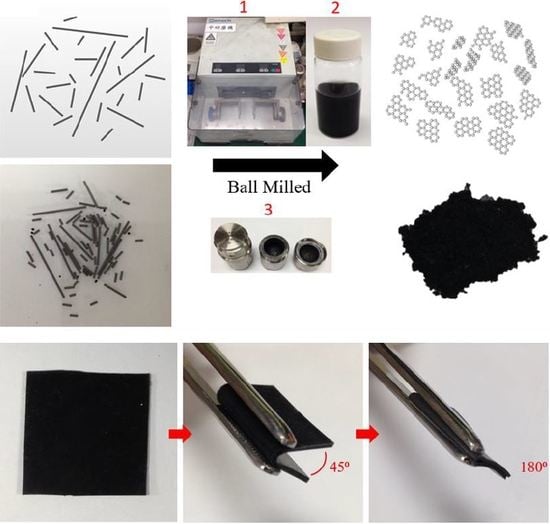

2.1. Materials and Preparation of Recycled 2B TIMs

2.2. Analysis Methods

3. Results and Discussions

3.1. Mechanical Properties

3.2. Scanning Electron Microscopy (SEM)

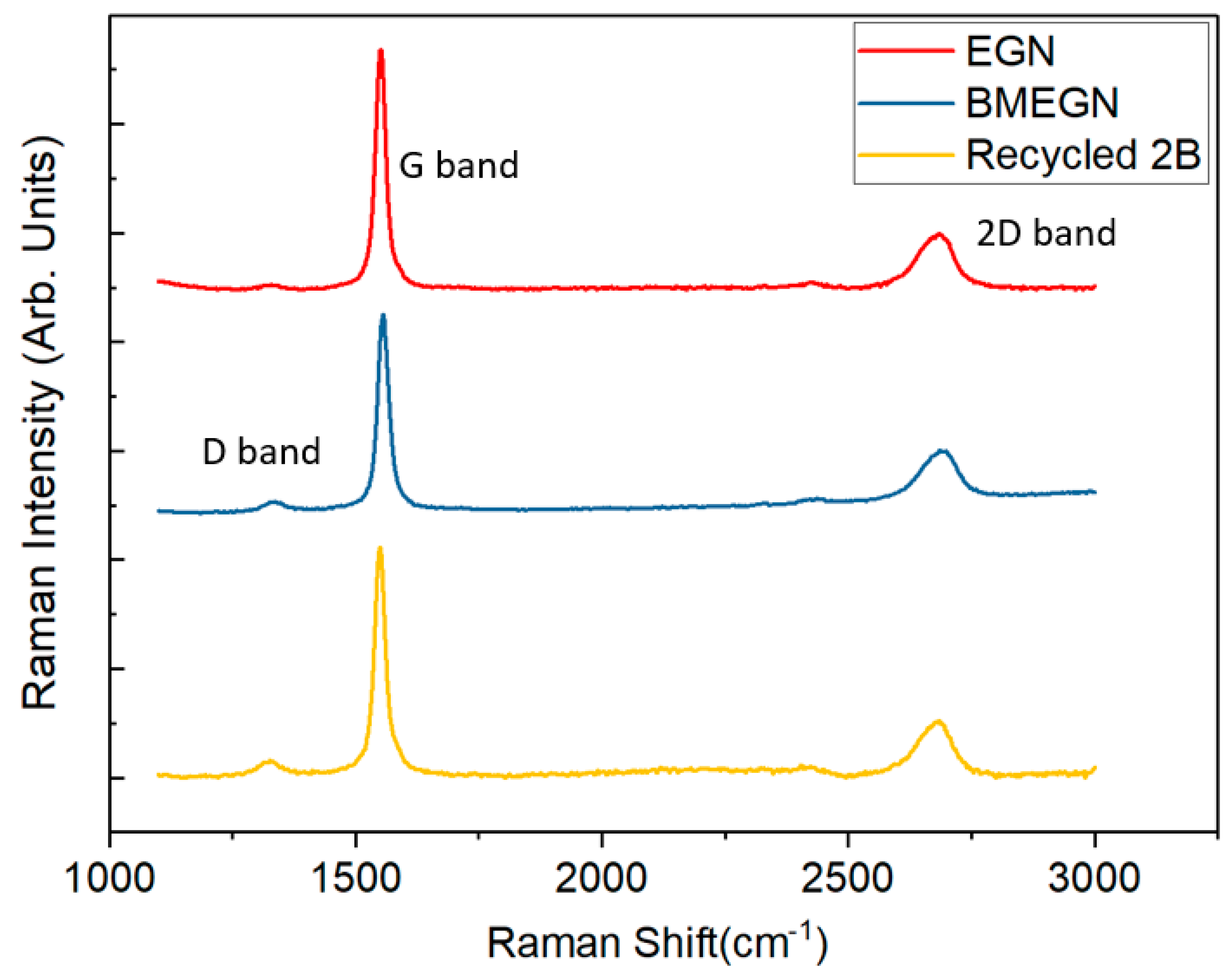

3.3. Raman Spectra

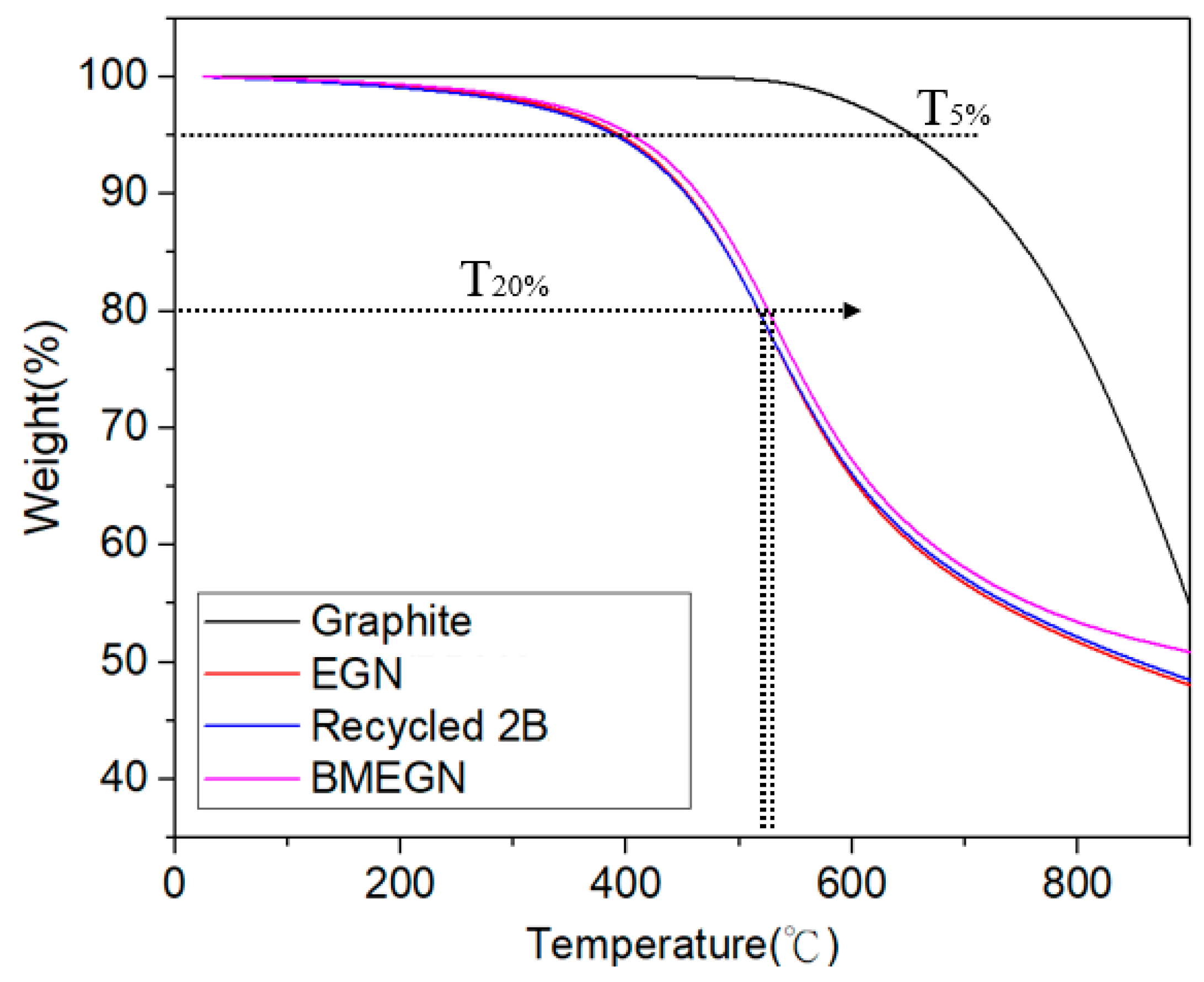

3.4. Thermogravimetric Analysis (TGA)

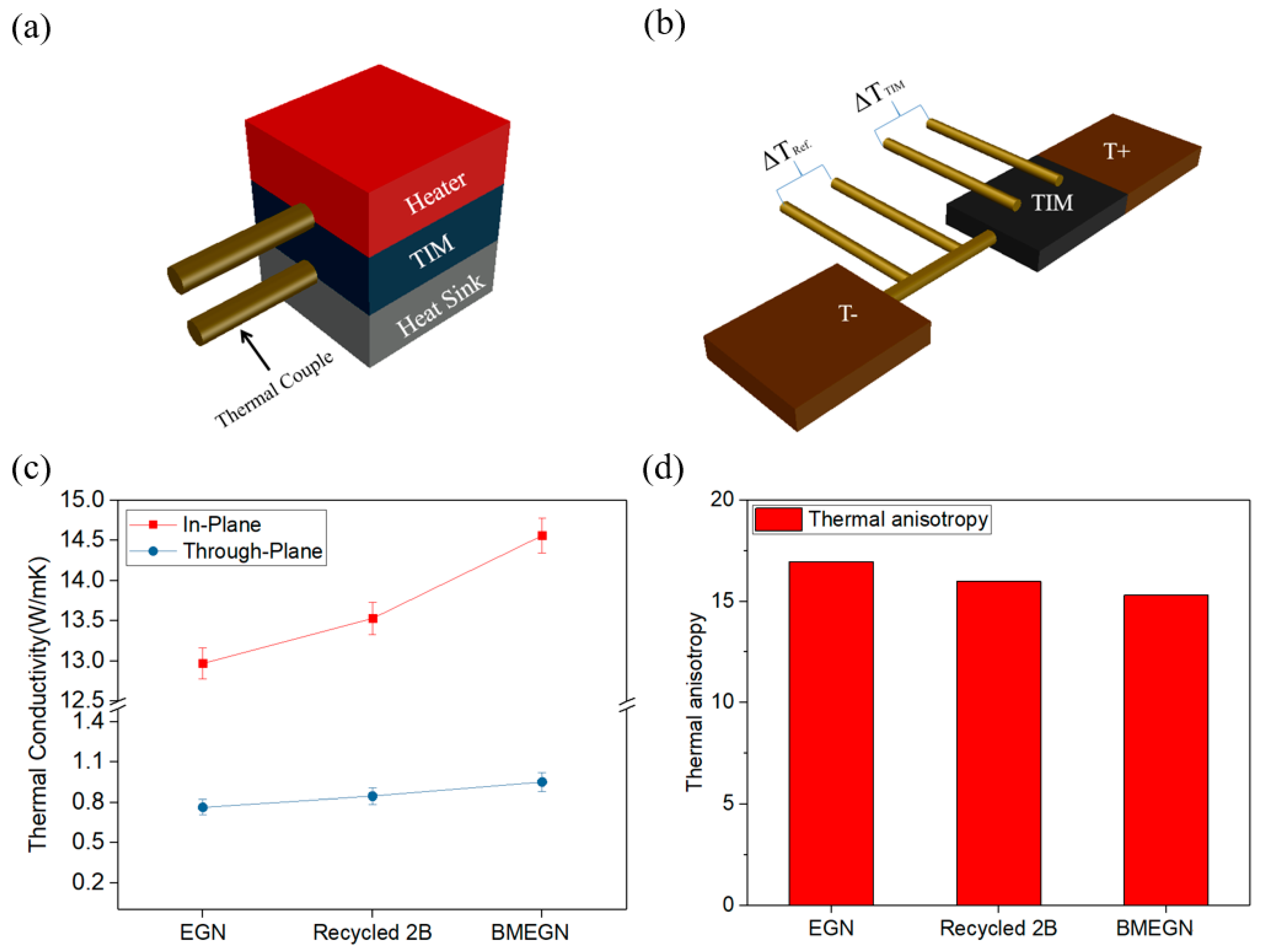

3.5. Thermal Conductivity (K) of BMEGN/PDMS Composite

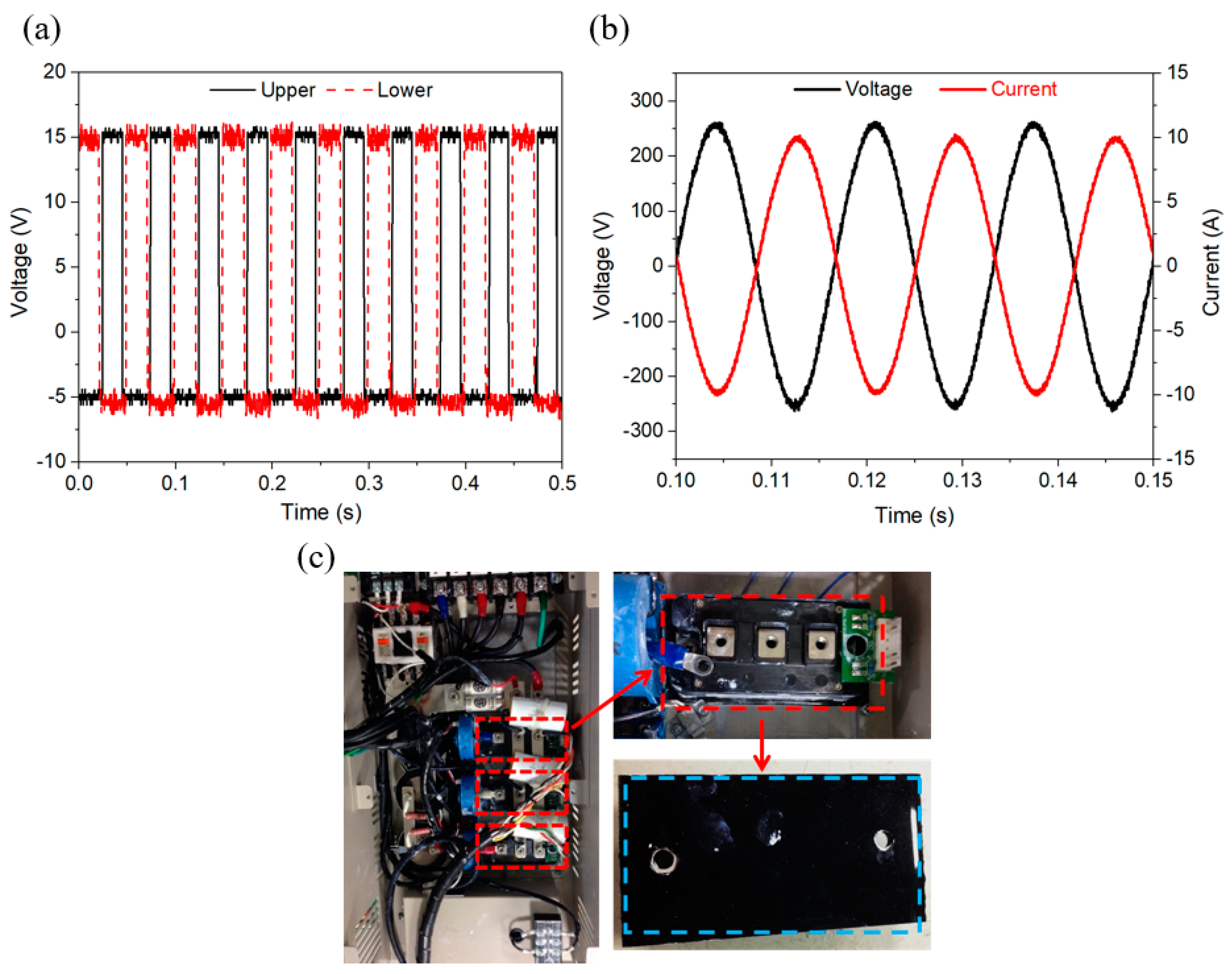

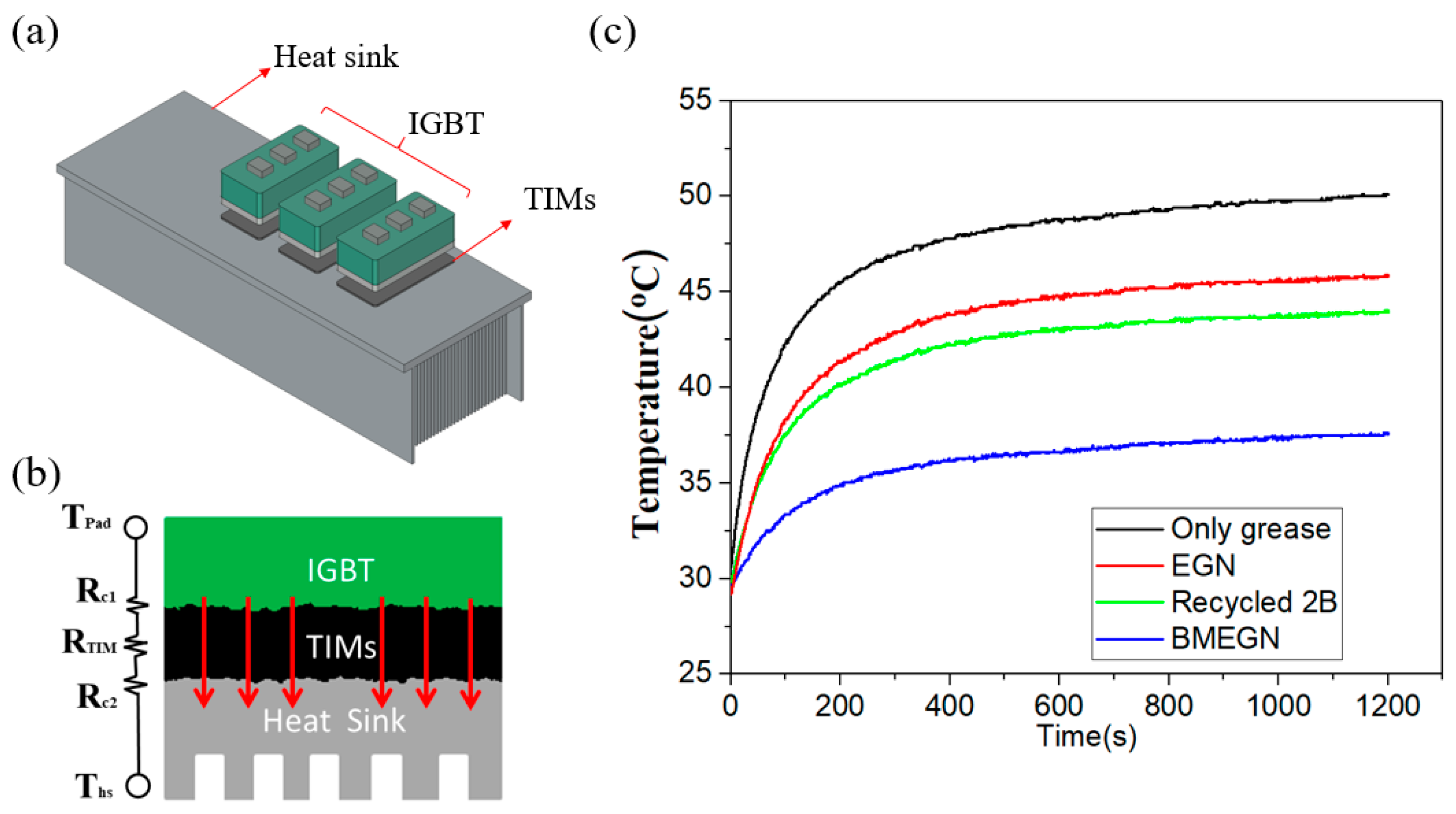

3.6. Heat Dissipation Tests for High-Power IGBT

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chang, T.C.; Lee, S.; Fuh, Y.K.; Peng, Y.C.; Lin, Z.H. PCM based heat sinks of Paraffin/nanoplatelet graphite composite for thermal management of IGBT. Appl. Therm. Eng. 2017, 112, 1129–1136. [Google Scholar] [CrossRef]

- Garimella, S.V.; Fleischer, A.S.; Murthy, J.Y.; Keshavarzi, A.; Prasher, R.; Patel, C.; Bhavnani, S.H.; Venkatasubramanian, R.; Mahajan, R.; Joshi, Y.; Sammakia, B.; et al. Thermal challenges in next-generation electronic systems. IEEE Trans. Compon. Pack. Thechnol. 2008, 31, 801–815. [Google Scholar] [CrossRef]

- Ahn, B.Y.; Duoss, E.B.; Motala, M.J.; Guo, X.; Park, S.I.; Xiong, Y.; Yoon, J.; Nuzzo, R.G.; Rogers, J.A.; Lewis, J.A. Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes. Science 2009, 323, 1590–1593. [Google Scholar] [CrossRef] [PubMed]

- Thostenson, E.T.; Ren, Z.; Chou, T.-W. Advances in the science and technology of carbon nanotubes and their composites: A review. Compos. Sci. Technol. 2001, 61, 1899–1912. [Google Scholar] [CrossRef]

- Ritts, A.C.; Yu, Q.; Li, H.; Lombardo, S.J.; Han, X.; Xia, Z.; Lian, J. Plasma treated multi-walled carbon nanotubes (MWCNTs) for epoxy nanocomposites. Polymers 2011, 3, 2142–2155. [Google Scholar] [CrossRef]

- Atif, R.; Shyha, I.; Inam, F. Mechanical, thermal, and electrical properties of graphene-epoxy nanocomposites-A review. Polymers 2016, 8, 281. [Google Scholar] [CrossRef]

- Prasher, R. Thermal interface materials: Historical perspective, status, and future directions. Proc. IEEE 2006, 94, 1571–1586. [Google Scholar] [CrossRef]

- Green, M.A. Ag requirements for silicon wafer-based solar cells. Prog. Photovoltaics Res. 2011, 19, 911–916. [Google Scholar] [CrossRef]

- Rane, S.B.; Khanna, P.K.; Seth, T.; Phatak, G.J.; Amalnerkar, D.P.; Das, B.K. Firing and processing effects on microstructure of fritted silver thick film electrode materials for solar cells. Mater. Chem. Phys. 2003, 82, 237–245. [Google Scholar] [CrossRef]

- Perelaer, J.; Smith, P.J.; Mager, D.; Soltman, D.; Volkman, S.K.; Subramanian, V.; Korvink, J.G. Printed electronics: The challenges involved in printing devices, interconnects, and contacts based on inorganic materials. J. Mater. Chem. 2010, 20, 8446–8453. [Google Scholar] [CrossRef]

- Veca, L.M.; Meziani, M.J.; Wang, W.; Wang, X.; Lu, F.; Zhang, P.; Fee, R.; Connell, J.W.; Sun, Y.P. Carbon nanosheets for polymeric nanocomposites with high thermal conductivity. Adv. Mater. 2009, 21, 2088–2092. [Google Scholar] [CrossRef]

- Khan, A.; Savi, P.; Quaranta, S.; Rovere, M.; Giorcelli, M.; Tagliaferro, A.; Rosso, C.; Jia, C. Low-cost carbon fillers to improve mechanical properties and conductivity of epoxy composites. Polymers 2017, 9, 642. [Google Scholar] [CrossRef]

- Janowska, I.; Vigneron, F.; Bégin, D.; Ersen, O.; Bernhardt, P.; Romero, T.; Ledoux, M.J.; Pham-Huu, C. Mechanical thinning to make few-layer graphene from pencil lead. Carbon 2012, 50, 3106–3110. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Wu, Z.K.; Bai, S.L. Study on thermal properties of graphene foam/graphene sheets filled polymer composites. Compos. Part A Appl. Sci. Manuf. 2015, 72, 200–206. [Google Scholar] [CrossRef]

- Renteria, J.D.; Nika, D.L.; Balandin, A.A. graphene thermal properties: Applications in thermal management and energy storage. Appl. Sci. 2014, 4, 525–547. [Google Scholar] [CrossRef]

- Shi, J.N.; Ger, M.D.; Liu, Y.M.; Fan, Y.C.; Wen, N.T.; Lin, C.K.; Pu, N.W. Improving the thermal conductivity and shape-stabilization of phase change materials using nanographite additives. Carbon 2013, 51, 365–372. [Google Scholar] [CrossRef]

- Kim, S.; Drzal, L.T. High latent heat storage and high thermal conductive phase change materials using exfoliated graphite nanoplatelets. Sol. Energy Mater. Sol. Cells 2009, 93, 136–142. [Google Scholar] [CrossRef]

- Xiang, J.; Drzal, L.T. Thermal conductivity of exfoliated graphite nanoplatelet paper. Carbon 2011, 49, 773–778. [Google Scholar] [CrossRef]

- Zhu, X.; Dai, H.; Hu, J.; Ding, L.; Jiang, L. Reduced graphene oxide-nickel oxide composite as high performance electrode materials for supercapacitors. J. Power Sources 2012, 203, 243–249. [Google Scholar] [CrossRef]

- Oh, I.; Kim, M.; Kim, J. Controlling hydrazine reduction to deposit iron oxides on oxidized activated carbon for supercapacitor application. Energy 2015, 86, 292–299. [Google Scholar] [CrossRef]

- Choi, B.G.; Yang, M.; Hong, W.H.; Choi, J.W.; Huh, Y.S. 3D macroporous graphene frameworks for supercapacitors with high energy and power densities. ACS Nano 2012, 6, 4020–4028. [Google Scholar] [CrossRef] [PubMed]

- Liao, Q.; Li, N.; Jin, S.; Yang, G.; Wang, C. All-solid-state symmetric supercapacitor based on Co3O4 nanoparticles on vertically aligned graphene. ACS Nano 2015, 9, 5310–5317. [Google Scholar] [CrossRef] [PubMed]

- Velhal, N.; Kulkarni, G.; Mahadik, D.; Chowdhury, P.; Barshilia, H.; Puri, V. Effect of Ba+2 ion on structural, magnetic and microwave properties of screen printed BaxSr1-XFe12O19 thick films. J. Alloy Compd. 2016, 682, 730–737. [Google Scholar] [CrossRef]

- Li, H.; Xu, X.; Li, Y.; Wu, S.; Tian, P.; Ying, T. Preparation and luminescent properties of the coating of phosphor in lead-free glass by multilayer screen-printing. J. Alloy Compd. 2016, 684, 372–378. [Google Scholar] [CrossRef]

- Mohamed, H.M. Screen-printed disposable electrodes: Pharmaceutical applications and recent developments. Trends Anal. Chem. 2016, 82, 1–11. [Google Scholar] [CrossRef]

- Chang, D.W.; Choi, H.J.; Jeon, I.Y.; Seo, J.M.; Dai, L.; Baek, J.B. Solvent-free mechanochemical reduction of graphene oxide. Carbon 2014, 77, 501–507. [Google Scholar] [CrossRef]

- Chang, T.C.; Fuh, Y.K.; Lin, Z.Y.; Liao, C.A. Highly stretchable thermal interface materials with uniformly dispersed network of exfoliated graphite nanoplatelets via ball milled processing route. Microsyst. Technol. 2018, 1–9. [Google Scholar] [CrossRef]

- Delogu, F.; Gorrasi, G.; Sorrentino, A. Fabrication of polymer nanocomposites via ball milling: Present status and future perspectives. Prog. Mater. Sci. 2017, 86, 75–126. [Google Scholar] [CrossRef]

- Cao, Y.; Feng, J.; Wu, P. Preparation of organically dispersible graphene nanosheet powders through a lyophilization method and their poly (lactic acid) composites. Carbon 2010, 48, 3834–3839. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Zhang, Y.F.; Bai, S.L. High thermal conductivity of flexible polymer composites due to synergistic effect of multilayer graphene flakes and graphene foam. Compos. Part A Appl. Sci. Manuf. 2016, 85, 148–155. [Google Scholar] [CrossRef]

- Bai, Q.Q.; Wei, X.; Yang, J.H.; Zhang, N.; Huang, T.; Wang, Y.; Zhou, Z.W. Dispersion and network formation of graphene platelets in polystyrene composites and the resultant conductive properties. Compos. Part A Appl. Sci. Manuf. 2017, 96, 89–98. [Google Scholar] [CrossRef]

- He, G.; Ding, J.; Zhang, J.; Hao, Q.; Chen, H. One-step ball-milling preparation of highly photocatalytic active CoFe2O4-reduced graphene oxide heterojunctions for organic dye removal. Ind. Eng. Chem. Res. 2015, 54, 2862–2867. [Google Scholar] [CrossRef]

- Yi, M.; Shen, Z. A review on mechanical exfoliation for the scalable production of graphene. J. Mater. Chem. A 2015, 3, 11700–11715. [Google Scholar] [CrossRef]

- Zhao, B.; Zheng, Y.; Ye, F.; Deng, X.; Xu, X.; Liu, M.; Shao, Z. Multifunctional iron oxide nanoflake/graphene composites derived from mechanochemical synthesis for enhanced lithium storage and electrocatalysis. ACS Appl. Mater. Interface 2015, 7, 14446–14455. [Google Scholar] [CrossRef] [PubMed]

- Rider, A.N.; An, Q.; Thostenson, E.T.; Brack, N. Ultrasonicated-ozone modification of exfoliated graphite for stable aqueous graphitic nanoplatelet dispersions. Nanotechnology 2014, 25, 495607. [Google Scholar] [CrossRef] [PubMed]

- Xuan, Y.; Li, Q. Heat transfer enhancement of nanofluids. Int. J. Heat Fluid Flow 2000, 21, 58–64. [Google Scholar] [CrossRef]

- Chang, T.C.; Fuh, Y.K.; Tu, S.X. Application of graphite nanoplatelet-based and nanoparticle composites to thermal interface materials. Micro Nano Lett. 2015, 10, 296–301. [Google Scholar] [CrossRef]

- Chang, T.C.; Fuh, Y.K.; Lin, Z.Y.; Liao, C.A. Ball milled dispersed network of graphene platelets as thermal interface materials for high-efficiency heat dissipation of electronic devices. J. Micro Nanolithogr. MEMS MOEMS 2018, 17, 024001. [Google Scholar] [CrossRef]

- Malard, L.M.; Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S. Raman spectroscopy in graphene. Phys. Rep. 2009, 473, 51–87. [Google Scholar] [CrossRef]

- Ferrari, A.C. Raman spectroscopy of graphene and graphite: Disorder, electron–phonon coupling, doping and nonadiabatic effects. Solid State Commun. 2007, 143, 47–57. [Google Scholar] [CrossRef]

- Bhowmik, R.N. Ferromagnetism in lead-graphite pencils and magnetic composite with CoFe2O4 particles. Compos. Part B Eng. 2012, 43, 503–509. [Google Scholar] [CrossRef]

- Yu, A.; Ramesh, P.; Itkis, M.E.; Bekyarova, E.; Haddon, R.C. Graphite nanoplatelet-epoxy composite thermal interface materials. J. Phys. Chem. C 2007, 111, 7565–7569. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, C.-A.; Kwan, Y.-K.; Chang, T.-C.; Fuh, Y.-K. Ball-Milled Recycled Lead-Graphite Pencils as Highly Stretchable and Low-Cost Thermal-Interface Materials. Polymers 2018, 10, 799. https://doi.org/10.3390/polym10070799

Liao C-A, Kwan Y-K, Chang T-C, Fuh Y-K. Ball-Milled Recycled Lead-Graphite Pencils as Highly Stretchable and Low-Cost Thermal-Interface Materials. Polymers. 2018; 10(7):799. https://doi.org/10.3390/polym10070799

Chicago/Turabian StyleLiao, Chun-An, Yee-Kwan Kwan, Tien-Chan Chang, and Yiin-Kuen Fuh. 2018. "Ball-Milled Recycled Lead-Graphite Pencils as Highly Stretchable and Low-Cost Thermal-Interface Materials" Polymers 10, no. 7: 799. https://doi.org/10.3390/polym10070799