Antimicrobial Polymers in Solution and on Surfaces: Overview and Functional Principles

Abstract

:1. Introduction

2. Antimicrobial Polymers

2.1. Polymeric Biocides

2.2. Biocidal Polymers

2.3. Biocide-Releasing Polymers

3. Antimicrobial Surfaces via Attachment of Antimicrobial Polymers

3.1. Techniques towards Surface Attached Polymers

| Method | Polymer | Ref. | |

|---|---|---|---|

| Grafting from | Immobilized initiator | QPAM | [75] |

| PEtOx | [87] | ||

| Grafting to | Immobilized comonomer | QP4VP | [16] |

| End-on | AMP | [88,89] | |

| Side-on | QPEI | [90] | |

| NB | [91] | ||

| Parallel grafting to and modification | QP4VP | [17] | |

| In situ end-on | PMOx | [78] | |

| In situ side-on | QPU | [76] | |

| Coating | Layer-by-layer | Polylysine | [79] |

| PAA | [92] | ||

| PHGH | [93] | ||

| Chitosan | [94] | ||

| Particles with grafted polymer | Magnetide with QPEI | [95] | |

| PA-particles with QP4VP | [81] | ||

| Hyperbranched Polymers | QPEI | [80,96] | |

| Plasma Polymerization | PDAA | [97] | |

| Polyterpenol | [98] | ||

| Surface induced Hydrogelation | Vancomycin | [82] | |

| AMP | [86] |

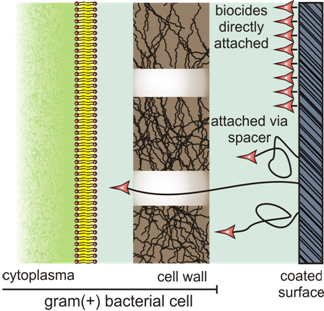

3.2. Functional Principles of Contact-Active Antimicrobial Polymers

4. Multifunctional Antimicrobial Surfaces

4.1. Repelling and Releasing

4.2. Contact-Killing and Repelling

4.3. Releasing and Contact-Killing

5. Conclusions

References

- Nicolas, P.; Mor, A. Peptides as Weapons against Microorganisms in the Chemical Defense System of Vertebrates. Annu. Rev. Microbiol. 1995, 49, 277–304. [Google Scholar] [CrossRef]

- Lode, H.M. Clinical Impact of Antibiotic-Resistant Gram-Positive Pathogens. Clin. Microbiol. Infect. 2009, 15, 212–217. [Google Scholar] [CrossRef]

- Gonzales, F.P.; Maisch, T. XF Drugs: A New Family of Antibacterials. Drug News Perspect. 2010, 23, 167–174. [Google Scholar] [CrossRef]

- Milovic, N.M.; Wang, J.; Lewis, K.; Klibanov, A.M. Immobilized N-Alkylated Polyethylenimine Avidly Kills Bacteria by Rupturing Cell Membranes with No Resistance Developed. Biotechnol. Bioeng. 2005, 90, 715–722. [Google Scholar] [CrossRef]

- Mah, T.-F.; Pitts, B.; Pellock, B.; Walker, G.C.; Stewart, P.S.; O’Toole, G.A. A genetic Basis for Pseudomonas Aeruginosa Biofilm Antibiotic Resistance. Nature 2003, 426, 306–310. [Google Scholar] [CrossRef]

- Gabriel, G.J.; Som, A.; Madkour, A.E.; Eren, T.; Tew, G.N. Infectious Disease: Connecting Innate Immunity to Biocidal Polymers. Mater. Sci. Eng. R 2007, R57, 28–64. [Google Scholar]

- Klein, E.; Smith, D.L.; Laxminarayan, R. Hospitalizations and Deaths Caused by Methicillin-Resistant Staphylococcus aureus, United States, 1999–2005. Emerg. Infect. Dis 2007, 13, 1840–1846. [Google Scholar] [CrossRef]

- Viazis, S.; Diez-Gonzalez, F. Enterohemorrhagic Escherichia coli: The Twentieth Century’s Emerging Foodborne Pathogen: A Review. In Advances in Agronomy; Sparks, D.L., Ed.; Elsevier Academic Press Inc.: San Diego, CA, USA, 2011; Volume 111, pp. 1–50. [Google Scholar]

- Macedo, M.F.; Miller, A.Z.; Dionisio, A.; Saiz-Jimenez, C. Biodiversity of Cyanobacteria and Green Algae on Monuments in the Mediterranean Basin: An Overview. Microbiology 2009, 155, 3476–3490. [Google Scholar]

- Andresen, J.A.; Muir, D.; Ueno, D.; Darling, C.; Theobald, N.; Bester, K. Emerging Pollutants in the North Sea in Comparison to Lake Ontario, Canada, Data. Environ. Toxicol. Chem. 2007, 26, 1081–1089. [Google Scholar]

- Romao, C.; Miranda, C.A.; Silva, J.; Clementino, M.M.; de Filippis, I.; Asensi, M. Presence of qacE Delta 1 Gene and Susceptibility to a Hospital Biocide in Clinical Isolates of Pseudomonas aeruginosa Resistant to Antibiotics. Curr. Microbiol. 2011, 63, 16–21. [Google Scholar]

- Buffet-Bataillon, S.; Branger, B.; Cormier, M.; Bonnaure-Mallet, M.; Jolivet-Gougeon, A. Effect of Higher Minimum Inhibitory Concentrations of Quaternary Ammonium Compounds in Clinical E. coli Isolates on Antibiotic Susceptibilities and Clinical Outcomes. J. Hosp. Infect. 2011, 79, 141–146. [Google Scholar] [CrossRef]

- Klevens, R.M.; Morrison, M.A.; Nadle, J.; Petit, S.; Gershman, K.; Ray, S.; Harrison, L.H.; Lynfield, R.; Dumyati, G.; Townes, J.M.; et al. Invasive Methicillin-Resistant Staphylococcus aureus Infections in the United States. J. Am. Med. Assoc. 2007, 298, 1763–1771. [Google Scholar]

- Tiller, J.C. Coatings for Prevention or Deactivation of Biological Contamination. In Developments in Surface Contamination and Cleaning; Kohli, R., Mittal, K.L., Eds.; William Andrew: Norwich, NY, USA, 2008; pp. 1013–1065. [Google Scholar]

- Tiller, J.C. Antimicrobial Surfaces. In Bioactive Surfaces; Borner, H.G., Lutz, J.F., Eds.; Springer-Verlag Berlin: Berlin, Germany, 2011; Volume 240, pp. 193–217. [Google Scholar]

- Tiller, J.C.; Liao, C.-J.; Lewis, K.; Klibanov, A.M. Designing Surfaces That Kill Bacteria on Contact. Proc. Natl. Acad. Sci. USA 2001, 98, 5981–5985. [Google Scholar]

- Tiller, J.C.; Lee, S.B.; Lewis, K.; Klibanov, A.M. Polymer Surfaces Derivatized with Poly(vinyl-N-hexylpyridinium) Kill Airborne and Waterborne Bacteria. Biotechnol. Bioeng. 2002, 79, 465–471. [Google Scholar] [CrossRef]

- Cornell, R.J.; Donaruma, L.G. 2-Methacryloxytroponones. Intermediates for Synthesis of Biologically Active Polymers. J. Med. Chem. 1965, 8, 388–390. [Google Scholar] [CrossRef]

- Vogl, O.; Tirrell, D. Functional Polymers with Biologically-Active Groups. J. Macromol. Sci.-Chem. 1979, A13, 415–439. [Google Scholar]

- Panarin, E.F.; Solovski, M.; Ekzemply, O. Synthesis and Antimicrobial Properties of Polymers Containing Quaternary Ammonium Groups. Khim.-Farm. Zh. 1971, 5, 24–28. [Google Scholar]

- Tew, G.N.; Scott, R.W.; Klein, M.L.; De Grado, W.F. De Novo Design of Antimicrobial Polymers, Foldamers, and Small Molecules: From Discovery to Practical Applications. Account. Chem. Res. 2010, 43, 30–39. [Google Scholar] [CrossRef]

- Kenawy, E.-R.; Worley, S.D.; Broughton, R. The Chemistry and Applications of Antimicrobial Polymers: A State-of-the-Art Review. Biomacromolecules 2007, 8, 1359–1384. [Google Scholar] [CrossRef]

- Timofeeva, L.; Kleshcheva, N. Antimicrobial Polymers: Mechanism of Action, Factors of Activity, and Applications. Appl. Microbiol. Biotechnol. 2011, 89, 475–492. [Google Scholar] [CrossRef]

- Banerjee, I.; Pangule, R.C.; Kane, R.S. Antifouling Coatings: Recent Developments in the Design of Surfaces That Prevent Fouling by Proteins, Bacteria, and Marine Organisms. Adv. Mater. 2011, 23, 690–718. [Google Scholar] [CrossRef]

- Kawabata, N. Capture of Microorganisms and Viruses by Pyridinium-Type Polymers and Application to Biotechnology and Water-Purification. Prog. Polym. Sci. 1992, 17, 1–34. [Google Scholar] [CrossRef]

- Nathan, A.; Zalipsky, S.; Ertel, S.I.; Agathos, S.N.; Yarmush, M.L.; Kohn, J. Copolymers of Lysine and Polyethylene Glycol: A New Family of Functionalized Drug Carriers. Bioconjug. Chem. 1993, 4, 54–62. [Google Scholar] [CrossRef]

- Dizman, B.; Elasri, M.O.; Mathias, L.J. Synthesis, Characterization, and Antibacterial Activities of Novel Methacrylate Polymers Containing Norfloxacin. Biomacromolecules 2005, 6, 514–520. [Google Scholar] [CrossRef]

- Lawson, M.C.; Shoemaker, R.; Hoth, K.B.; Bowman, C.N.; Anseth, K.S. Polymerizable Vancomycin Derivatives for Bactericidal Biomaterial Surface Modification: Structure-Function Evaluation. Biomacromolecules 2009, 10, 2221–2234. [Google Scholar] [CrossRef]

- Waschinski, C.J.; Tiller, J.C. Poly(oxazoline)s with Telechelic Antimicrobial Functions. Biomacromolecules 2005, 6, 235–243. [Google Scholar] [CrossRef]

- Turos, E.; Shim, J.Y.; Wang, Y.; Greenhalgh, K.; Reddy, G.S.K.; Dickey, S.; Lim, D.V. Antibiotic-Conjugated Polyacrylate Nanoparticles: New Opportunities for Development of Anti-MRSA Agents. Bioorg. Med. Chem. Lett. 2007, 17, 53–56. [Google Scholar]

- Tashiro, T. Antibacterial and Bacterium Adsorbing Macromolecules. Macromol. Mater. Eng. 2001, 286, 63–87. [Google Scholar] [CrossRef]

- Kawabata, N.; Nishiguchi, M. Antibacterial Activity of Soluble Pyridinium-Type Polymers. Appl. Environ. Microbiol. 1988, 54, 2532–2535. [Google Scholar]

- Kanazawa, A.; Ikeda, T.; Endo, T. Polymeric Phosphonium Salts as a Novel Class of Cationic Biocides. IV. Synthesis and Antibacterial Activity of Polymers with Phosphonium Salts in the Main Chain. J. Polym. Sci. Part A: Polym. Chem. 1993, 31, 3031–3038. [Google Scholar] [CrossRef]

- Kanazawa, A.; Ikeda, T.; Endo, T. Novel Polycationic Biocides: Synthesis and Antibacterial Activity of Polymeric Phosphonium Salts. J. Polym. Sci. Part A: Polym. Chem. 1993, 31, 335–343. [Google Scholar]

- Kanazawa, A.; Ikeda, T.; Endo, T. Antibacterial Activity of Polymeric Sulfonium Salts. J. Polym. Sci. Part A: Polym. Chem. 1993, 31, 2873–2876. [Google Scholar] [CrossRef]

- Ikeda, T.; Ledwith, A.; Bamford, C.H.; Hann, R.A. Interaction of a Polymeric Biguanide Biocide with Phospholipid Membranes. Biochim. Biophys. Acta Biomembr. 1984, 769, 57–66. [Google Scholar] [CrossRef]

- Ikeda, T.; Hirayama, H.; Yamaguchi, H.; Tazuke, S.; Watanabe, M. Polycationic Biocides with Pendant Active Groups: Molecular Weight Dependence of Antibacterial Activity. Antimicrob. Agents Chemother. 1986, 30, 132–136. [Google Scholar]

- Tew, G.N.; Liu, D.; Chen, B.; Doerksen, R.J.; Kaplan, J.; Carroll, P.J.; Klein, M.L.; DeGrado, W.F. De Novo Design of Biomimetic Antimicrobial Polymers. Proc. Natl. Acad. Sci. USA 2002, 99, 5110–5114. [Google Scholar]

- Ilker, M.F.; Nuesslein, K.; Tew, G.N.; Coughlin, E.B. Tuning the Hemolytic and Antibacterial Activities of Amphiphilic Polynorbornene Derivatives. J. Am. Chem. Soc. 2004, 126, 15870–15875. [Google Scholar]

- Gabriel, G.J.; Madkour, A.E.; Dabkowski, J.M.; Nelson, C.F.; Nusslein, K.; Tew, G.N. Synthetic Mimic of Antimicrobial Peptide with Nonmembrane-Disrupting Antibacterial Properties. Biomacromolecules 2008, 9, 2980–2983. [Google Scholar]

- Lienkamp, K.; Madkour, A.E.; Musante, A.; Nelson, C.F.; Nusslein, K.; Tew, G.N. Antimicrobial Polymers Prepared by ROMP with Unprecedented Selectivity: A Molecular Construction Kit Approach. J. Am. Chem. Soc. 2008, 130, 9836–9843. [Google Scholar]

- Zasloff, M. Antimicrobial Peptides of Multicellular Organisms. Nature 2002, 415, 389–395. [Google Scholar] [CrossRef]

- Shai, Y. Mechanism of the Binding, Insertion and Destabilization of Phospholipid Bilayer Membranes by Alpha-Helical Antimicrobial and Cell Non-Selective membrane-Lytic Peptides. Biochim. Biophys. Acta-Biomembr. 1999, 1462, 55–70. [Google Scholar] [CrossRef]

- Mowery, B.P.; Lee, S.E.; Kissounko, D.A.; Epand, R.F.; Epand, R.M.; Weisblum, B.; Stahl, S.S.; Gellman, S.H. Mimicry of Antimicrobial Host-Defense Peptides by Random Copolymers. J. Am. Chem. Soc. 2007, 129, 15474–15476. [Google Scholar]

- Gelman, M.A.; Weisblum, B.; Lynn, D.M.; Gellman, S.H. Biocidal Activity of Polystyrenes That Are Cationic by Virtue of Protonation. Org. Lett. 2004, 6, 557–560. [Google Scholar]

- Palermo, E.F.; Kuroda, K. Chemical Structure of Cationic Groups in Amphiphilic Polymethacrylates Modulates the Antimicrobial and Hemolytic Activities. Biomacromolecules 2009, 10, 1416–1428. [Google Scholar] [CrossRef]

- Palermo, E.F.; Sovadinova, I.; Kuroda, K. Structural Determinants of Antimicrobial Activity and Biocompatibility in Membrane-Disrupting Methacrylamide Random Copolymers. Biomacromolecules 2009, 10, 3098–3107. [Google Scholar] [CrossRef]

- Timofeeva, L.M.; Kleshcheva, N.A.; Moroz, A.F.; Didenko, L.V. Secondary and Tertiary Polydiallylammonium Salts: Novel Polymers with High Antimicrobial Activity. Biomacromolecules 2009, 10, 2976–2986. [Google Scholar] [CrossRef]

- Pasquier, N.; Keul, H.; Heine, E.; Moeller, M.; Angelov, B.; Linser, S.; Willumeit, R. Amphiphilic Branched Polymers as Antimicrobial Agents. Macromol. Biosci. 2008, 8, 903–915. [Google Scholar] [CrossRef]

- Debnath, S.; Shome, A.; Das, D.; Das, P.K. Hydrogelation through Self-Assembly of Fmoc-Peptide Functionalized Cationic Amphiphiles: Potent Antibacterial Agent. J. Phys. Chem. B 2010, 114, 4407–4415. [Google Scholar]

- Roy, S.; Das, P.K. Antibacterial Hydrogels of Amino Acid-Based Cationic Amphiphiles. Biotechnol. Bioeng. 2008, 100, 756–764. [Google Scholar] [CrossRef]

- Waschinski, C.J.; Herdes, V.; Schueler, F.; Tiller, J.C. Influence of Satellite Groups on Telechelic Antimicrobial Functions of Polyoxazolines. Macromol. Biosci. 2005, 5, 149–156. [Google Scholar] [CrossRef]

- Waschinski, C.J.; Barnert, S.; Theobald, A.; Schubert, R.; Kleinschmidt, F.; Hoffmann, A.; Saalwaechter, K.; Tiller, J.C. Insights in the Antibacterial Action of Poly(methyloxazoline)s with a Biocidal End Group and Varying Satellite Groups. Biomacromolecules 2008, 9, 1764–1771. [Google Scholar]

- Mowery, B.P.; Lindner, A.H.; Weisblum, B.; Stahl, S.S.; Gellman, S.H. Structure-activity Relationships among Random Nylon-3 Copolymers That Mimic Antibacterial Host-Defense Peptides. J. Am. Chem. Soc. 2009, 131, 9735–9745. [Google Scholar]

- Bortnowska-Barela, B.; Polowinska, A.; Polowiski, S.; Vaskova, V.; Barton, J. Bioactive Emulsions of o-Carboxyphenyl Methacrylate Copolymers. Acta Polym. 1987, 38, 652–654. [Google Scholar] [CrossRef]

- Rosenberg, L.E.; Carbone, A.L.; Roemling, U.; Uhrich, K.E.; Chikindas, M.L. Salicylic Acid-Based Poly(anhydride esters) for Control of Biofilm Formation in Salmonella Enterica Serovar Typhimurium. Lett. Appl. Microbiol. 2008, 46, 593–599. [Google Scholar] [CrossRef]

- Huttinger, K.J.; Muller, H.; Bomar, M.T. Synthesis and Effect of Carrier-Bound Disinfectants. J. Colloid Interface Sci. 1982, 88, 274–285. [Google Scholar] [CrossRef]

- Sun, G.; Wheatley, W.B.; Worley, S.D. A New Cyclic N-Halamine Biocidal Polymer. Ind. Eng. Chem. Res. 1994, 33, 168–170. [Google Scholar] [CrossRef]

- Eknoian, M.W.; Worley, S.D.; Harris, J.M. New Biocidal N-Halamine-PEG Polymers. J. Bioact. Compat. Polym. 1998, 13, 136–145. [Google Scholar]

- Liang, J.; Barnes, K.; Akdag, A.; Worley, S.D.; Lee, J.; Broughton, R.M.; Huang, T.-S. Improved Antimicrobial Siloxane. Ind. Eng. Chem. Res. 2007, 46, 1861–1866. [Google Scholar]

- Coneski, P.N.; Rao, K.S.; Schoenfisch, M.H. Degradable Nitric Oxide-Releasing Biomaterials via Post-Polymerization Functionalization of Cross-Linked Polyesters. Biomacromolecules 2010, 11, 3208–3215. [Google Scholar] [CrossRef]

- Stasko, N.A.; Schoenfisch, M.H. Dendrimers as a Scaffold for Nitric Oxide Release. J. Am. Chem. Soc. 2006, 128, 8265–8271. [Google Scholar]

- Charville, G.W.; Hetrick, E.M.; Geer, C.B.; Schoenfisch, M.H. Reduced Bacterial Adhesion to Fibrinogen-Coated Substrates via Nitric Oxide Release. Biomaterials 2008, 29, 4039–4044. [Google Scholar]

- Ferrazzano, G.F.; Roberto, L.; Amato, I.; Cantile, T.; Sangianantoni, G.; Ingenito, A. Antimicrobial Properties of Green Tea Extract against Cariogenic Microflora: An in vivo Study. J. Med. Food 2011, 14, 907–911. [Google Scholar]

- Kenawy, E.-R.; El-Shanshoury, A.E.-R.R.; Omar Shaker, N.; El-Sadek, B.M.; Khattab, A.H.B.; Badr, B.I. Biocidal Polymers: Synthesis, Antimicrobial Activity, and Possible Toxicity of Poly (hydroxystyrene-co-methylmethacrylate) Derivatives. J. Appl. Polym. Sci. 2011, 120, 2734–2742. [Google Scholar]

- Chemburu, S.; Corbitt, T.S.; Ista, L.K.; Ji, E.; Fulghum, J.; Lopez, G.P.; Ogawa, K.; Schanze, K.S.; Whitten, D.G. Light-Induced Biocidal Action of Conjugated Polyelectrolytes Supported on Colloids. Langmuir 2008, 24, 11053–11062. [Google Scholar]

- Ji, E.-K.; Corbitt, T.S.; Parthasarathy, A.; Schanze, K.S.; Whitten, D.G. Light and Dark-Activated Biocidal Activity of Conjugated Polyelectrolytes. ACS Appl. Mater. Interfaces 2011, 3, 2820–2829. [Google Scholar]

- Wang, Y.; Canady, T.D.; Zhou, Z.J.; Tang, Y.L.; Price, D.N.; Bear, D.G.; Chi, E.Y.; Schanze, K.S.; Whitten, D.G. Cationic Phenylene Ethynylene Polymers and Oligomers Exhibit Efficient Antiviral Activity. ACS Appl. Mater. Interfaces 2011, 3, 2209–2214. [Google Scholar]

- Advincula, R. Polymer Brushes by Anionic and Cationic Surface-Initiated Polymerization (SIP). Adv. Polym. Sci. 2006, 197, 107–136. [Google Scholar] [CrossRef]

- Edmondson, S.; Osborne, V.L.; Huck, W.T.S. Polymer Brushes via Surface-Initiated Polymerizations. Chem. Soc. Rev. 2004, 33, 14–22. [Google Scholar]

- Hammond, P.T. Engineering Materials Layer-by-Layer: Challenges and Opportunities in Multilayer Assembly. AIChE J. 2011, 57, 2928–2940. [Google Scholar] [CrossRef]

- Lyklema, J.; Deschenes, L. The First Step in Layer-by-Layer Deposition: Electrostatics and/or Non-Electrostatics? Adv. Colloid Interface Sci. 2011, 168, 135–148. [Google Scholar] [CrossRef]

- Friedrich, J. Mechanisms of Plasma Polymerization—Reviewed from a Chemical Point of View. Plasma Processes Polym. 2011, 8, 783–802. [Google Scholar] [CrossRef]

- Lin, J.; Qiu, S.Y.; Lewis, K.; Klibanov, A.M. Bactericidal Properties of Flat Surfaces and Nanoparticles Derivatized with Alkylated Polyethylenimines. Biotechnol. Prog. 2002, 18, 1082–1086. [Google Scholar] [CrossRef]

- Lee, S.B.; Koepsel, R.R.; Morley, S.W.; Matyjaszewski, K.; Sun, Y.J.; Russell, A.J. Permanent, Nonleaching Antibacterial Surfaces. 1. Synthesis by Atom Transfer Radical Polymerization. Biomacromolecules 2004, 5, 877–882. [Google Scholar] [CrossRef]

- Kurt, P.; Wood, L.; Ohman, D.E.; Wynne, K.J. Highly Effective Contact Antimicrobial Surfaces via Polymer Surface Modifiers. Langmuir 2007, 23, 4719–4723. [Google Scholar]

- Wynne, J.H.; Fulmer, P.A.; McCluskey, D.M.; Mackey, N.M.; Buchanan, J.P. Synthesis and Development of a Multifunctional Self-Decontaminating Polyurethane Coating. ACS Appl. Mater. Interfaces 2011, 3, 2005–2011. [Google Scholar] [CrossRef]

- Waschinski, C.J.; Zimmermann, J.; Salz, U.; Hutzler, R.; Sadowski, G.; Tiller, J.C. Design of Contact-Active Antimicrobial Acrylate-Based Materials Using Biocidal Macromers. Adv. Mater. 2008, 20, 104–108. [Google Scholar]

- Guyomard, A.; De, E.; Jouenne, T.; Malandain, J.J.; Muller, G.; Glinel, K. Incorporation of a Hydrophobic Antibacterial Peptide into Amphiphilic Polyelectrolyte Multilayers: A Bioinspired Approach to Prepare Biocidal Thin Coatings. Advanced Functional Materials 2008, 18, 758–765. [Google Scholar] [CrossRef]

- Park, D.; Wang, J.; Klibanov, A.M. One-Step, Painting-Like Coating Procedures to Make Surfaces Highly and Permanently Bactericidal. Biotechnol. Prog. 2006, 22, 584–589. [Google Scholar] [CrossRef]

- Fuchs, A.D.; Tiller, J.C. Contact-Active Antimicrobial Coatings Derived from Aqueous Suspensions. Angew. Chem. Int. Ed. 2006, 45, 6759–6762. [Google Scholar]

- Xing, B.G.; Yu, C.W.; Chow, K.H.; Ho, P.L.; Fu, D.G.; Xu, B. Hydrophobic Interaction and Hydrogen Bonding Cooperatively Confer a Vancomycin Hydrogel: A Potential Candidate for Biomaterials. J. Am. Chem. Soc. 2002, 124, 14846–14847. [Google Scholar]

- Tiller, J.C. Increasing the Local Concentration of Drugs by Hydrogel Formation. Angew. Chem. Int. Ed. 2003, 42, 3072–3075. [Google Scholar] [CrossRef]

- Bieser, A.M.; Tiller, J.C. Surface-Induced Hydrogelation. Chem. Commun. 2005. [Google Scholar] [CrossRef]

- Bieser, A.M.; Tiller, J.C. Supramolecular Self-organization of Potential Hydrogelators on Attracting Surfaces. Supramol. Chem. 2008, 20, 363–367. [Google Scholar]

- Salick, D.A.; Kretsinger, J.K.; Pochan, D.J.; Schneider, J.P. Inherent Antibacterial Activity of a Peptide-Based Beta-Hairpin Hydrogel. J. Am. Chem. Soc. 2007, 129, 14793–14799. [Google Scholar]

- Bieser, A.M.; Thomann, Y.; Tiller, J.C. Contact-Active Antimicrobial and Potentially Self-Polishing Coatings Based on Cellulose. Macromol. Biosci. 2011, 11, 111–121. [Google Scholar] [CrossRef]

- Bagheri, M.; Beyermann, M.; Dathe, M. Immobilization Reduces the Activity of Surface-Bound Cationic Antimicrobial Peptides with No Influence upon the Activity Spectrum. Antimicrob. Agents Chemother. 2009, 53, 1132–1141. [Google Scholar] [CrossRef]

- Costa, F.; Carvalho, I.F.; Montelaro, R.C.; Gomes, P.; Martins, M.C.L. Covalent Immobilization of Antimicrobial Peptides (AMPs) onto Biomaterial Surfaces. Acta Biomater. 2011, 7, 1431–1440. [Google Scholar] [CrossRef]

- Haldar, J.; An, D.Q.; de Cienfuegos, L.A.; Chen, J.Z.; Klibanov, A.M. Polymeric Coatings That Inactivate Both Influenza Virus and Pathogenic Bacteria. Proc. Nal. Acad. Sci. USA 2006, 103, 17667–17671. [Google Scholar]

- Madkour, A.E.; Dabkowski, J.M.; Nusslein, K.; Tew, G.N. Fast Disinfecting Antimicrobial Surfaces. Langmuir 2009, 25, 1060–1067. [Google Scholar]

- Lichter, J.A.; Rubner, M.F. Polyelectrolyte Multilayers with Intrinsic Antimicrobial Functionality: The Importance of Mobile Polycations. Langmuir 2009, 25, 7686–7694. [Google Scholar] [CrossRef]

- Pan, Y.; Xiao, H. Rendering Rayon Fibres Antimicrobial and Thermal-Responsive via Layer-by-Layer Self-Assembly of Functional Polymers. Adv. Mater. Res. 2011, 236-238, 1103–1106. [Google Scholar]

- Cecius, M.; Jerome, C. A fully Aqueous Sustainable Process for Strongly Adhering Antimicrobial Coatings on Stainless Steel. Prog. Org. Coat. 2011, 70, 220–223. [Google Scholar]

- Lin, J.; Qiu, S.; Lewis, K.; Klibanov, A.M. Bactericidal Properties of Flat Surfaces and Nanoparticles Derivatized with Alkylated Polyethylenimines. Biotechnol. Prog. 2002, 18, 1082–1086. [Google Scholar] [CrossRef]

- Pasquier, N.; Keul, H.; Heine, E.; Moeller, M. From Multifunctionalized Poly(ethylene imine)s toward Antimicrobial Coatings. Biomacromolecules 2007, 8, 2874–2882. [Google Scholar] [CrossRef]

- Thome, J.; Hollander, A.; Jaeger, W.; Trick, I.; Oehr, C. Ultrathin Antibacterial Polyammonium Coatings on Polymer Surfaces. Surf. Coat. Technol. 2003, 174-175, 584–587. [Google Scholar] [CrossRef]

- Bazaka, K.; Jacob, M.V.; Truong, V.K.; Crawford, R.J.; Ivanova, E.P. The Effect of Polyterpenol Thin Film Surfaces on Bacterial Viability and Adhesion. Polymers 2011, 3, 388–404. [Google Scholar] [CrossRef]

- Lin, J.; Tiller, J.C.; Lee, S.B.; Lewis, K.; Klibanov, A.M. Insights into Bactericidal Action of Surface-Attached Poly(vinyl-N-hexylpyridinium) Chains. Biotechnol. Lett. 2002, 24, 801–805. [Google Scholar] [CrossRef]

- Kang, S.; Pinault, M.; Pfefferle, L.D.; Elimelech, M. Single-Walled Carbon Nanotubes Exhibit Strong Antimicrobial Activity. Langmuir 2007, 23, 8670–8673. [Google Scholar]

- Glinel, K.; Jonas, A.M.; Jouenne, T.; Leprince, J.; Galas, L.; Huck, W.T.S. Antibacterial and Antifouling Polymer Brushes Incorporating Antimicrobial Peptide. Bioconjug. Chem. 2009, 20, 71–77. [Google Scholar] [CrossRef]

- Humblot, V.; Yala, J.F.; Thebault, P.; Boukerma, K.; Hequet, A.; Berjeaud, J.M.; Pradier, C.M. The Antibacterial Activity of Magainin I Immobilized onto Mixed Thiols Self-Assembled Monolayers. Biomaterials 2009, 30, 3503–3512. [Google Scholar] [CrossRef]

- Bieser, A.M.; Tiller, J.C. Mechanistic Considerations on Contact-Active Antimicrobial Surfaces with Controlled Functional Group Densities. Macromol. Biosci. 2011, 11, 526–534. [Google Scholar] [CrossRef]

- Isquith, A.J.; Abbott, E.A.; Walters, P.A. Surface-Bonded Antimicrobial Activity of an Organosilicon Quaternary Ammonium Chloride. Appl. Microbiol. 1972, 24, 859–863. [Google Scholar]

- Gottenbos, B.; van der Mei, H.C.; Klatter, F.; Nieuwenhuis, P.; Busscher, H.J. In vitro and in vivo Antimicrobial Activity of Covalently Coupled Quaternary Ammonium Silane Coatings on Silicone Rubber. Biomaterials 2002, 23, 1417–1423. [Google Scholar] [CrossRef]

- Bouloussa, O.; Rondelez, F.; Semetey, V. A New, Simple Approach to Confer Permanent Antimicrobial Properties to Hydroxylated Surfaces by Surface Functionalization. Chem. Commun. 2008. [Google Scholar] [CrossRef]

- Kugler, R.; Bouloussa, O.; Rondelez, F. Evidence of a Charge-Density Threshold for Optimum Efficiency of Biocidal Cationic Surfaces. Microbiology-(UK) 2005, 151, 1341–1348. [Google Scholar] [CrossRef]

- Murata, H.; Koepsel, R.R.; Matyjaszewski, K.; Russell, A.J. Permanent, Non-Leaching Antibacterial Surfaces—2: How High Density Cationic Surfaces Kill Bacterial Cells. Biomaterials 2007, 28, 4870–4879. [Google Scholar] [CrossRef]

- Huang, J.Y.; Koepsel, R.R.; Murata, H.; Wu, W.; Lee, S.B.; Kowalewski, T.; Russell, A.J.; Matyjaszewski, K. Nonleaching Antibacterial Glass Surfaces via “Grafting Onto”: The Effect of the Number of Quaternary Ammonium Groups on Biocidal Activity. Langmuir 2008, 24, 6785–6795. [Google Scholar]

- Page, K.; Wilson, M.; Parkin, I.P. Antimicrobial Surfaces and Their Potential in Reducing the Role of the Inanimate Environment in the Incidence of Hospital-Acquired Infections. J. Mater. Chem. 2009, 19, 3819–3831. [Google Scholar] [CrossRef]

- Fleming, A. Containing Papers of a Biological Character. Proc. Roy. Soc. London Ser. B 1922, 93, 306–317. [Google Scholar] [CrossRef]

- Edwards, J.V.; Sethumadhavan, K.; Ullah, A.H.J. Conjugation and Modeled Structure/Function Analysis of Lysozyme on Glycine Esterified Cotton Cellulose-Fibers. Bioconjug. Chem. 2000, 11, 469–473. [Google Scholar] [CrossRef]

- Luckarift, H.R.; Dickerson, M.B.; Sandhage, K.H.; Spain, J.C. Rapid, Room-Temperature Synthesis of Antibacterial Bionanocomposites of Lysozyme with Amorphous Silica or Titania. Small 2006, 2, 640–643. [Google Scholar] [CrossRef]

- Wang, Q.; Fan, X.R.; Hu, Y.J.; Yuan, J.G.; Cui, L.; Wang, P. Antibacterial Functionalization of Wool Fabric via Immobilizing Lysozymes. Bioprocess. Biosyst. Eng. 2009, 32, 633–639. [Google Scholar] [CrossRef]

- Watanabe, S.; Kato, H.; Shimizu, Y.; Teramatsu, T.; Hino, T. Antibacterial Biomaterials by Immobilization of Hen Egg-White Lysozyme onto Collagen—Synthetic Polymer Composites—Histological Findings of Immobilized Lysozyme in the Tissue of a Different Species. Artif. Organs 1981, 5, 309–309. [Google Scholar]

- Caro, A.; Humblot, V.; Methivier, C.; Minier, M.; Salmain, M.; Pradier, C.M. Grafting of Lysozyme and/or Poly(ethylene glycol) to Prevent Biofilm Growth on Stainless Steel Surfaces. J. Phys. Chem. B 2009, 113, 2101–2109. [Google Scholar]

- Schindler, C.A.; Schuhardt, V.T. Lysostaphin—New Bacteriolytic Agent for Staphylococcus. Proc. Natl. Acad. Sci. USA 1964, 51, 414–421. [Google Scholar] [CrossRef]

- Navarre, W.W.; Ton-That, H.; Faull, K.F.; Schneewind, O. Multiple Enzymatic Activities of the Murein Hydrolase from Staphylococcal Phage phi 11—Identification of a D-alanyl-glycine Endopeptidase Activity. J. Biol. Chem. 1999, 274, 15847–15856. [Google Scholar]

- Schuch, R.; Nelson, D.; Fischetti, V.A. A Bacteriolytic Agent that Detects and Kills Bacillus anthracis. Nature 2002, 418, 884–889. [Google Scholar] [CrossRef]

- Loeffler, J.M.; Nelson, D.; Fischetti, V.A. Rapid Killing of Streptococcus Pneumoniae with a Bacteriophage Cell Wall Hydrolase. Science 2001, 294, 2170–2172. [Google Scholar] [CrossRef]

- Pangule, R.C.; Brooks, S.J.; Dinu, C.Z.; Bale, S.S.; Salmon, S.L.; Zhu, G.; Metzger, D.W.; Kane, R.S.; Dordick, J.S. Antistaphylococcal Nanocomposite Films Based on Enzyme-Nanotube Conjugates. ACS Nano 2010, 4, 3993–4000. [Google Scholar]

- Kuo, P.L.; Chuang, T.F.; Wang, H.L. Surface-Fragmenting, Self-Polishing, Tin-Free Antifouling Coatings. J. Coat. Technol. 1999, 71, 77–83. [Google Scholar] [CrossRef]

- Ibbitson, D.; Johnson, A.F.; Morley, N.J.; Penman, A.K. Structure-Property Relationships in Tin-Based Antifouling Paints. Acs Symp. Ser. 1986, 322, 326–340. [Google Scholar]

- Qian, P.Y.; Xu, Y.; Fusetani, N. Natural Products as Antifouling Compounds: Recent Progress and Future Perspectives. Biofouling 2010, 26, 223–234. [Google Scholar] [CrossRef]

- Ho, C.H.; Tobis, J.; Sprich, C.; Thomann, R.; Tiller, J.C. Nanoseparated Polymeric Networks with Multiple Antimicrobial Properties. Adv. Mater. 2004, 16, 957–961. [Google Scholar] [CrossRef]

- Cheng, G.; Xue, H.; Zhang, Z.; Chen, S.; Jiang, S. A Switchable Biocompatible Polymer Surface with Self-Sterilizing and Nonfouling Capabilities. Angew. Chem. Int. Ed. 2008, 47, 8831–8834. [Google Scholar]

- Laloyaux, X.; Fautre, E.; Blin, T.; Purohit, V.; Leprince, J.; Jouenne, T.; Jonas, A.M.; Glinel, K. Temperature-Responsive Polymer Brushes Switching from Bactericidal to Cell-Repellent. Adv. Mater. 2010, 22, 5024–5028. [Google Scholar]

- Kocer, H.B.; Cerkez, I.; Worley, S.D.; Broughton, R.M.; Huang, T.S. Polymeric Antimicrobial N-Halamine Epoxides. ACS Appl. Mater. Interfaces 2011, 3, 2845–2850. [Google Scholar] [CrossRef]

- Liang, J.; Chen, Y.; Barnes, K.; Wu, R.; Worley, S.D.; Huang, T.S. N-Halamine/Quat Siloxane Copolymers for Use in Biocidal Coatings. Biomaterials 2006, 27, 2495–2501. [Google Scholar] [CrossRef]

- Li, Z.; Lee, D.; Sheng, X.X.; Cohen, R.E.; Rubner, M.F. Two-Level Antibacterial Coating with both Release-Killing and Contact-Killing Capabilities. Langmuir 2006, 22, 9820–9823. [Google Scholar] [CrossRef]

- Sambhy, V.; MacBride, M.M.; Peterson, B.R.; Sen, A. Silver Bromide Nanoparticle/Polymer Composites: Dual Action Tunable Antimicrobial Materials. J. Am. Chem. Soc. 2006, 128, 9798–9808. [Google Scholar]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Siedenbiedel, F.; Tiller, J.C. Antimicrobial Polymers in Solution and on Surfaces: Overview and Functional Principles. Polymers 2012, 4, 46-71. https://doi.org/10.3390/polym4010046

Siedenbiedel F, Tiller JC. Antimicrobial Polymers in Solution and on Surfaces: Overview and Functional Principles. Polymers. 2012; 4(1):46-71. https://doi.org/10.3390/polym4010046

Chicago/Turabian StyleSiedenbiedel, Felix, and Joerg C. Tiller. 2012. "Antimicrobial Polymers in Solution and on Surfaces: Overview and Functional Principles" Polymers 4, no. 1: 46-71. https://doi.org/10.3390/polym4010046