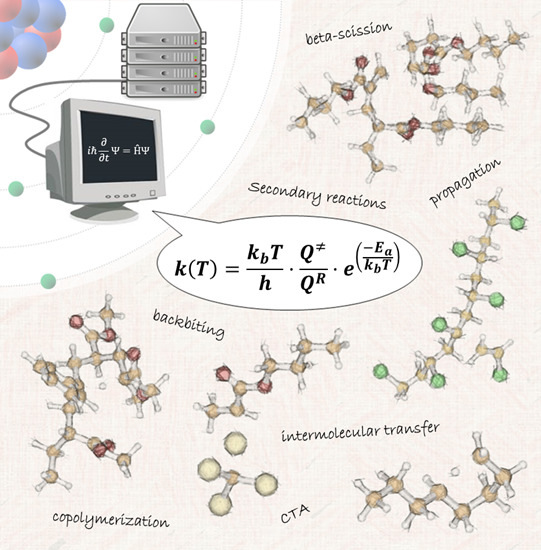

On the Use of Quantum Chemistry for the Determination of Propagation, Copolymerization, and Secondary Reaction Kinetics in Free Radical Polymerization

Abstract

:1. Introduction

| Monomer | Year | Ea (kJ/mol) | lg(A) (A, L/mol/s) | k (50 °C, L/mol/s) | Temperature range | Reference |

|---|---|---|---|---|---|---|

| MA | 2013 | 17.3 | 7.15 | 2.25 × 104 | −28 to 60 °C | [18] |

| BA | 2008 | 18.1 | 7.36 | 2.71 × 104 | 10 to 70 °C | [7] |

| EHA | 2010 | 15.8 | 6.96 | 2.54 × 104 | 10 to 82 °C | [23] |

| HEA | 2012 | 16.8 | 7.24 | 3.33 × 104 | 20 to 60 °C | [24] |

| MMA | 1997 | 22.4 | 6.43 | 6.42 × 102 | −1 to 90 °C | [21] |

| EMA | 2000 | 23.4 | 6.61 | 6.69 × 102 | 6 to 90 °C | [22] |

| BMA | 2000 | 22.9 | 6.58 | 7.53 × 102 | −20 to 90 °C | [22] |

| DMA | 2000 | 21.0 | 6.40 | 1.01 × 103 | 9 to 90 °C | [22] |

| HEMA | 1998 | 21.9 | 6.95 | 2.56 × 103 | −4 to 70 °C | [25] |

| iBMA | 1997 | 22.5 | 6.50 | 7.26 × 102 | 10 to 90 °C | [26] |

| iDMA | 1997 | 20.8 | 6.34 | 9.47 × 102 | 10 to 90 °C | [26] |

| EHMA | 1997 | 20.4 | 6.27 | 9.35 × 102 | 10 to 90 °C | [26] |

| EEMA | 2010 | 24.1 | 6.73 | 6.80 × 102 | 4 to 61 °C | [27] |

| PEGEEMA | 2010 | 24.4 | 6.97 | 1.06 × 103 | 4 to 61 °C | [27] |

| CHMA | 2003 | 23.0 | 6.80 | 1.20 × 103 | 10 to 91 °C | [28] |

| GMA | 2003 | 22.9 | 6.79 | 1.22 × 103 | 20 to 90 °C | [28] |

| BzMA | 2003 | 22.9 | 6.83 | 1.34 × 103 | 6 to 90 °C | [28] |

| iBoMA | 2003 | 23.1 | 6.79 | 1.13 × 103 | 0 to 90 °C | [28] |

| AA (10% w/w, H2O) | 2003 | 15.4 | 7.82 | 2.14 × 105 | 2 to 20 °C | [29] |

| NVP (40% w/w, H2O) | 2014 | 18.4 | 6.97 | 9.87 × 103 | −5 to 80 °C | [30,31] |

| NVF (40% w/w, H2O) | 2010 | 20.2 | 6.79 | 3.34 × 103 | 5 to 60 °C | [32] |

| AAm | 2005 | 13.4 | 7.20 | 1.08 × 105 | 6 to 50 °C | [33] |

| TRIS | 2000 | 19.9 | 6.16 | 8.74 × 102 | 15 to 50 °C | [34] |

| NVC | 2003 | 25.3 | 8.00 | 8.10 × 103 | 0 to 50 °C | [35] |

| VneoD | 1997 | 22.2 | 7.31 | 5.25 × 103 | −21 to 21 °C | [36] |

| VAc | 1995 | 20.7 | 7.17 | 6.64 × 103 | 10 to 60 °C | [37] |

| 1,3-butadiene | 1989 | 35.7 | 7.90 | 1.34 × 102 | 30 to 60 °C | [38] |

| MAN | 1995 | 29.7 | 6.43 | 4.23 × 101 | 10 to 60 °C | [39] |

| MAA | 1997 | 17.7 | 5.78 | 8.27 × 102 | 20 to 60 °C | [40] |

| AN | 2010 | 15.4 | 6.25 | 5.75 × 103 | 2 to 76 °C | [41] |

| St | 1995 | 32.5 | 7.63 | 2.37 × 102 | −12 to 93 °C | [42] |

| 4-MeO-St | 1999 | 34.9 | 7.80 | 1.43 × 102 | 20 to 40 °C | [43] |

| 4-Me-St | 1999 | 32.4 | 7.45 | 1.62 × 102 | 20 to 40 °C | [43] |

| 4-F-St | 1999 | 32.0 | 7.54 | 2.32 × 102 | 20 to 40 °C | [43] |

| 4-Cl-St | 1999 | 32.1 | 7.65 | 2.88 × 102 | 20 to 40 °C | [43] |

| 4-Br-St | 1999 | 33.9 | 7.98 | 3.14 × 102 | 20 to 40 °C | [43] |

| Chloroprene | 1993 | 26.6 | 7.29 | 9.73 × 102 | 10 to 55 °C | [44] |

2. Quantum Chemistry

3. From Initiation to Propagation

| Monomer | Method | Year | Ea (kJ/mol) | lg(A)(A, L/mol/s) | k (50 °C, L/mol/s) | Reference |

|---|---|---|---|---|---|---|

| St | B3LYP/6-31G(d,p) | 2011 | 34.7 | 8.42 | 6.43 × 102 | [96] |

| BP86/cc-PVTZ (corrected with CCSD) | 2009 | 41.5 | 6.57 | 7.22 × 10−1 | [97] | |

| B3LYP/6-311+G(d,p)//B3LYP/6-31G(d,p) | 2009 | 34.6 | 8.25 | 4.51 × 102 | [98] | |

| MA | B3LYP/6-31G(d,p) | 2011 | 27.4 | 8.55 | 1.31 × 104 | [96] |

| G3(MP2)-RAD// B3LYP/6-31G(d) | 2010 | 21.8 | 7.50 | 9.43 × 103 | [99] | |

| BP86/cc-PVTZ (corrected with CCSD) | 2009 | 23.8 | 6.14 | 1.95 × 102 | [97] | |

| MPWB1K/6-311+G(3df,2p)//B3LYP//6-31+G(d) | 2009 | 24.3 | 6.52 | 3.89 × 102 | [91] | |

| MPWB1K/6-31G(d,p)//B3LYP//6-31G(d) | 2008 | 21.5 | 7.78 | 2.01 × 104 | [89] | |

| ΒΑ | B3LYP/6-31G(d,p) | 2011 | 26.1 | 8.36 | 1.38 × 104 | [96] |

| EA | B3LYP/6-31G(d,p) | 2011 | 27.0 | 8.44 | 1.18 × 104 | [96] |

| HEA | B3LYP/6-31G(d,p) | 2012 | 22.5 | 7.66 | 1.05 × 104 | [24] |

| MMA | MPWB1K/6-31G(d,p)//B3LYP//6-31G(d,p) | 2015 | 11.1 | 4.38 | 3.84 × 102 | [100] |

| B3LYP/6-31G(d,p) | 2011 | 33.1 | 8.01 | 4.54 × 102 | [96] | |

| BP86/cc-PVTZ (corrected with CCSD) | 2009 | 26.0 | 6.06 | 7.16 × 10 | [97] | |

| B3LYP/6-311+G(d,p)//B3LYP/6-31G(d,p) | 2009 | 26.0 | 7.10 | 7.86 × 102 | [98] | |

| MPWB1K/6-31G(d,p)//B3LYP//6-31G(d) | 2008 | 22.7 | 6.19 | 3.30 × 102 | [89] | |

| BMA | B3LYP/6-311+G(d,p)// B3LYP/6-31G(d,p) | 2009 | 26.5 | 7.57 | 1.92 × 103 | [98] |

| GMA | B3LYP/6-311+G(d,p)//B3LYP/6-31G(d,p) | 2009 | 27.5 | 7.45 | 1.01 × 103 | [98] |

| HEMA | B3LYP/6-311+G(d,p)//B3LYP/6-31G(d,p) | 2009 | 26.8 | 7.10 | 5.83 × 102 | [98] |

| VAc | B3LYP/6-311+G(d,p) | 2010 | 29.7 | 7.33 | 3.36 × 102 | [101] |

| G3(MP2)-RAD//B3LYP/6-31G(d) | 2010 | 17.6 | 6.10 | 1.79 × 103 | [99] | |

| BP86/cc-PVTZ (corrected with CCSD) | 2009 | 23.9 | 6.61 | 5.56 × 102 | [97] | |

| VDF | MPWB1K/6-31G(d,p)//B3LYP/6-31G(d,p) | 2014 | 20.5 | 6.62 | 2.02 × 103 | [102] |

| HFP | MPWB1K/6-31G(d,p)//B3LYP/6-31G(d,p) | 2014 | 12.6 | 3.85 | 6.49 × 10 | [102] |

| TFE | MPWB1K/6-31G(d,p)//B3LYP/6-31G(d,p) | 2014 | 10.6 | 6.14 | 2.67 × 104 | [102] |

| BCA | MPWB1K/6-31G(d,p)//B3LYP//6-31G(d,p) | 2015 | 17.5 | 3.95 | 1.32 × 10 | [100] |

| AA | BP86/cc-PVTZ (corrected with CCSD) | 2009 | 24.2 | 6.29 | 2.38 × 102 | [97] |

| B3LYP/6-31+G(d) | 2004 | 23.3 | 7.57 | 6.34 × 103 | [103] | |

| MAA | BP86/cc-PVTZ (corrected with CCSD) | 2009 | 29.0 | 6.17 | 3.02 × 10 | [97] |

| NVP | BP86/cc-PVTZ (corrected with CCSD) | 2009 | 33.2 | 6.74 | 2.35 × 10 | [97] |

| AN | B3LYP/6-31G(d,p) | 2011 | 31.4 | 8.74 | 4.59 × 103 | [96] |

| G3(MP2)-RAD//B3LYP/6-31G(d) | 2006 | 22.4 | 6.40 | 5.99 × 102 | [86] | |

| EHMA | MPWB1K/6-311+G(3df,2p)//B3LYP/6-31+G(d) | 2012 | 24.4 | 5.26 | 2.06 × 10 | [93] |

| VC | MPWB1K/6-31G(d,p)//B3LYP/6-31G(d,p) | 2012 | 23.5 | 7.95 | 1.41 × 104 | [104] |

| B3LYP/6-31G(d,p) | 2011 | 23.7 | 9.03 | 1.57 × 105 | [105] | |

| BMK/6-311+G(3df,2p)//B3LYP/6-31G(d) | 2007 | 32.7 | 3.90 | 4.09 × 10−2 | [106] | |

| G3(MP2)-RAD//B3LYP/6-31G(d) | 2006 | 17.2 | 6.59 | 6.43 × 103 | [86] |

4. Copolymerization

| Copolymer System | Computational | Experimental | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Method | Copolymerization Model | T (°C) | Year | Reactivity Ratios/Propagation Rate Coefficients (L/mol/s) | Reference | T (°C) | Year | Reactivity Ratios/Propagation Rate Coefficients (L/mol/s) | Reference | |

| ST/MMA | B3LYP/6-31G(d,p) | TM, IPUE | 40 | 2011 | r1 = 0.53; r2 = 0.68; s1 = 0.23; s2 = 0.99 | [96] | 40 | 1985 | r1 = 0.52; r2 = 0.46; s1 = 0.30; s2 = 0.53 | [110] |

| TM | 100 | 2009 | kp,cop = 5.05 × 103 | [98] | 20 | 1997 | r1 = 0.39; r2 = 0.51 | [116] | ||

| ST/HEMA | B3LYP/6-31G(d,p) | TM | 100 | 2012 | r1 = 0.20; r2 = 0.51 | [114] | 50 | 2009 | r1 = 0.27; r2 = 0.49; s1 = 0.38; s2 = 1.34 | [98] |

| M06-2X/6-31G(d,p) | TM | 25 | 2014 | r1 = 0.05; r2 = 0.65 | [117] | |||||

| B3LYP/6-31G(d,p) | TM | 100 | 2009 | kp,cop = 12.37 × 103 | [98] | 70 | 1998 | kp,cop = 4.11 × 103 | [25] | |

| ST/GMA | B3LYP/6-31G(d,p) | TM | 100 | 2012 | r1 = 0.34; r2 = 0.56 | [114] | 50–160 | 2008 | r1 = 0.31; r2 = 0.51; s1 = 0.28; s2 = 1.05; | [118] |

| TM | 100 | 2009 | kp,cop = 7.37 × 103 | [98] | 70 | 2008 | kp,cop = 1.64 × 103 | [118] | ||

| ST/BMA | B3LYP/6-31G(d,p) | TM | 100 | 2012 | r1 = 0.46; r2 = 0.60 | [114] | 50–150 | 2006 | r1 = 0.61; r2 = 0.42; s1 = 0.44; s2 = 0.62 | [119] |

| TM | 100 | 2009 | kp,cop = 5.39 × 103 | [98] | 70–140 | 2006 | kp,cop = 1.23 × 103 | [119] | ||

| ST/HEA | B3LYP/6-31G(d,p) | TM | 50 | 2011 | r1= 0.31; r2= 0.14 | [120] | 60 | 1998 | r1 = 0.46; r2 = 0.20 | [121] |

| EPUE | 50 | 2012 | r11 = 0.72; r21 = 0.57; r12 = 0.38; r22 = 0.62; s1 = 0.72; s2 = 3.01 | [24] | 50 | 2012 | r1 = 0.44; r2 = 0.18; s1 = 3.00; r1 = 0.91 | [24] | ||

| ST/MA | B3LYP/6-31G(d,p) | TM | 25 | 2011 | r1 = 0.22; r2= 0.11 | [82] | 25 | 1991 | r1 = 0.73; r2 = 0.19 | [122] |

| MMA/MA | MPWB1K/6-31G(d,p) | TM, IPUE | 23 | 2008 | r1 = 2.99; r2 = 0.38; s1 = 1.71; r1 = 0.39 | [115] | 50 | 1971 | r1 = 2.23; r2 = 0.36 | [123] |

| EPUE | 23 | 2008 | r11 = 2.81; r21 = 3.17; r12 = 0.38; r22 = 0.37; s1 = 1.71; s2 = 0.39 | [115] | ||||||

| B3LYP/6-31G(d) | TM | 25 | 2006 | r1 = 0.83; r2 = 0.49 | [113] | |||||

| B3P86/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 0.97; r2 = 0.41 | [113] | |||||

| B971/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 1.06; r2 = 0.37 | [113] | |||||

| BA/BMA | B3LYP/6-31G(d) | TM | 25 | 2006 | r1 = 0.44; r2 = 0.84 | [113] | – | – | – | – |

| B3P86/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 0.40; r2 = 0.94 | [113] | |||||

| B971/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 0.36; r2 = 1.06 | [113] | |||||

| MA/BA | B3LYP/6-31G(d) | TM | 25 | 2006 | r1 = 1.09; r2 = 0.89 | [113] | – | – | – | – |

| B3P86/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 1.04; r2 = 0.97 | [113] | |||||

| B971/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 1.04; r2 = 0.97 | [113] | |||||

| MMA/BMA | B3LYP/6-31G(d) | TM | 25 | 2006 | r1 = 0.99; r2 = 1.01 | [113] | 20 | 1988 | r1 = 0.44; r2 = 0.26 | [124] |

| B3P86/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 1.02; r2 = 0.99 | [113] | |||||

| B971/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 1.02; r2 = 0.99 | [113] | |||||

| MA/MEA | B3LYP/6-31G(d) | TM | 25 | 2006 | r1 = 0.55; r2 = 0.38 | [113] | – | – | – | – |

| B3P86/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 0.52; r2 = 0.42 | [113] | |||||

| B971/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 0.53; r2 = 0.42 | [113] | |||||

| MMA/MEA | B3LYP/6-31G(d) | TM | 25 | 2006 | r1 = 1.85; r2 = 0.40 | [113] | – | – | – | – |

| B3P86/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 2.10; r2 = 0.37 | [113] | |||||

| B971/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 1.96; r2 = 0.43 | [113] | |||||

| MA/VAc | B3LYP/6-31G(d) | TM | 25 | 2006 | r1 = 6.76; r2 = 0.10 | [113] | 60 | 1994 | r1 = 7.28; r2 = 0.04 | [125] |

| B3P86/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 6.77; r2 = 0.10 | [113] | |||||

| B971/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 6.62; r2 = 0.10 | [113] | |||||

| MMA/VAc | B3LYP/6-31G(d) | TM | 25 | 2006 | r1 = 9.76; r2 = 0.22 | [113] | 40 | 1993 | r1 = 27.8; r2 = 0.014; s1 = 0.4; s2 = 0.4 | [126] |

| B3P86/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 11.9; r2 = 0.16 | [113] | |||||

| B971/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 13.14; r2 = 0.16 | [113] | |||||

| B3LYP/6-311G(d,p) | TM/IPUE | 50 | 2010 | r1 = 27.9; r2 = 0.001 s1 = 0.544; s2 = 0.173 | [101] | |||||

| B3LYP/6-311G(d,p) | TM/IPUE | 40 | 2010 | r1 = 31.0; r2 = 0.001 s1 = 0.538; s2 = 0.176 | [101] | |||||

| Et/VAc | B3LYP/6-31G(d) | TM | 25 | 2006 | r1 = 0.36; r2 = 1.86 | [113] | 60 | 1971 | r1 = 0.16; r2 = 1.12 | [127] |

| B3P86/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 0.31; r2 = 1.85 | [113] | |||||

| B971/6-311G(2d,2p) | TM | 25 | 2006 | r1 = 0.29; r2 = 2.19 | [113] | |||||

| B3LYP/6-31G(d) | TM | 60 | 2002 | r1 = 0.23; r2 = 0.83 r1 = 0.36; r2 = 0.70 | [107] | |||||

| BCA/MMA | MPWB1K/6-31G(d,p) | TM | 50 | 2015 | r1 = 0.272; r2 = 0.057 | [100] | 50 | 2015 | r1 = 0.236; r2 = 0.057 | [100] |

| VDF/HFP | MPWB1K/6-31G(d,p) | TM | 60 | 2014 | r1 = 0.06; r2 = 5 × 10−5 | [102] | 120 | 2005 | r1 = 2.9; r2 = 0.12 | [128] |

| VDF/TFE | MPWB1K/6-31G(d,p) | TM | 60 | 2014 | r1 = 0.04; r2 = 1.40 | [102] | 80 | 1984 | r1 = 3.73; r2 = 0.23 | [129] |

| HFP/TFE | MPWB1K/6-31G(d,p) | TM | 60 | 2014 | r1 = 6.4 × 10−5; r2 = 18.4 | [102] | 100 | 1989 | r1 ≅ 0; r2 = 10 | [130] |

5. Secondary Reactions

| Polymer/Monomer | Computational | Experimental | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Method | T (C°) | Year | Ea (kJ/mol) | lg(A)(A, L/mol/s or 1/s) | k (L/mol/s or 1/s) | Reaction | QT | Reference | T (°C) | Ea(kJ/mol) | lg(A)(A, L/mol/s or 1/s) | k (L/mol/s or 1/s) | Reference | |

| PEA | UHF/6-31G(d) | 160 | 2001 | 132.8 | 11.40 | 3.00 × 10−7 | Short-chain branching | – | [63] | – | – | – | – | – |

| PMA | UB3LYP/6-31G(d)//MPWB1K/6-31G(d,p) | 100 | 2012 | 57.3 | 12.17 | 1.41 × 104 | Backbiting | No | [145] | – | – | – | – | – |

| B3LYP/6-31G(d,p)//MPWB1K/6-31G(d,p) | 100 | 2013 | 50.7 | 10.66 | 4.12 × 103 | Backbiting | Yes | [70] | – | – | – | – | – | |

| B3LYP/6-31G(d,p)//MPWB1K/6-31G(d,p) | 100 | 2013 | 115.6 | 14.01 | 2.09 × 10−5 | β-Scission | – | [70] | – | – | – | – | – | |

| B3LYP/6-31G(d,p) | 25 | 2014 | 57.3 | 11.36 | 6.60 × 102 | Backbiting | Yes | [143] | – | – | – | – | – | |

| B3LYP/6-31G(d) | 25 | 2014 | 100.0 | 13.02 | 3.84 × 10−5 | β-Scission | – | [143] | – | – | – | – | – | |

| MA | M06-2X/6-31G(d,p) | 25 | 2013 | 56.0 | 5.11 | 1.70 × 10−5 | Chain transfer to monomer | Yes | [140] | – | – | – | – | – |

| PBA | UB3LYP/6-31G(d)//MPWB1K/6-31G(d,p) | 100 | 2012 | 73.2 | 13.65 | 2.57 × 103 | Backbiting | No | [145] | 50 | 33.3 | 7.97 | 3.83 × 102 | [12,17] |

| B3LYP/6-31G(d,p)//MPWB1K/6-31G(d,p) | 25 | 2013 | 55.0 | 11.46 | 1.64 × 103 | Backbiting | Yes | [144] | ||||||

| B3LYP/6-31G(d,p)//MPWB1K/6-31G(d,p) | 25 | 2013 | 116.9 | 12.46 | 9.22 × 10−9 | β-Scission | – | [144] | – | – | – | – | – | |

| B3LYP/6-31G(d,p)//MPWB1K/6-31G(d,p) | 25 | 2014 | 47.1 | 2.72 | 1.09 × 10−4 | Chain transfer to polymer | Yes | [150] | – | – | – | – | – | |

| BA | B3LYP/6-31G(d,p)//MPWB1K/6-31G(d,p) | 25 | 2014 | 57.4 | 5.24 | 4.03 × 10−4 | Chain transfer to monomer | Yes | [150] | 50 | 32.6 | 5.46 | 1.55 | [157] |

| M06-2X/6-31G(d,p) | 25 | 2013 | 31.0 | 5.17 | 5.00 × 10−1 | Chain transfer to monomer | Yes | [140] | ||||||

| EA | M06-2X/6-31G(d,p) | 25 | 2013 | 41.0 | 5.10 | 9.90 × 10−3 | Chain transfer to monomer | Yes | [140] | – | – | – | – | – |

| PVC | B3LYP/6-31G(d,p)//MPWB1K/6-31G(d,p) | 57 | 2012 | 74.9 | 14.13 | 1.90 × 102 | Backbiting | Yes | [104] | – | – | – | – | – |

| B3LYP/6-31G(d,p)//MPWB1K/6-31G(d,p) | 57 | 2012 | 98.1 | 12.81 | 1.96 × 10−3 | β-Scission | – | [104] | – | – | – | – | – | |

| B3LYP/6-31+G(d)//BMK/6-311+G(3fd,2p) | 57 | 2007 | 72.8 | 11.43 | 8.09 × 10−1 | Backbiting | No | [106] | – | – | – | – | – | |

6. Conclusions

Conflicts of Interest

References

- Cunningham, M.F.; Hutchinson, R.A. Industrial applications and processes. In Handbook of Radical Polymerization; John Wiley & Sons: Hoboken, NJ, USA, 2003; pp. 333–360. [Google Scholar]

- Braun, D. Origins and development of initiation of free radical polymerization processes. Int. J. Polym. Sci. 2009. [Google Scholar] [CrossRef]

- Coote, M.L.; Davis, T.P. Copolymerization kinetics. In Handbook of Radical Polymerization; John Wiley & Sons: Hoboken, NJ, USA, 2003; pp. 263–300. [Google Scholar]

- Olaj, O.F.; Bitai, I.; Hinkelmann, F. The laser-flash-initiated polymerization as a tool of evaluating (individual) kinetic constants of free-radical polymerization, 2. The direct determination of the rate-constant of chain propagation. Die Makromol. Chem. 1987, 188, 1689–1702. [Google Scholar] [CrossRef]

- Buback, M. Propagation kinetics in radical polymerization studied via pulsed laser techniques. Macromol. Symp. 2009, 275, 90–101. [Google Scholar] [CrossRef]

- Barth, J.; Buback, M.; Hesse, P.; Sergeeva, T. Termination and transfer kinetics of butyl acrylate radical polymerization studied via SP-PLP-EPR. Macromolecules 2010, 43, 4023–4031. [Google Scholar] [CrossRef]

- Barner-Kowollik, C.; Gunzler, F.; Junkers, T. Pushing the limit: Pulsed laser polymerization of N-butyl acrylate at 500 Hz. Macromolecules 2008, 41, 8971–8973. [Google Scholar] [CrossRef]

- Beuermann, S.; Buback, M. Rate coefficients of free-radical polymerization deduced from pulsed laser experiments. Prog. Polym. Sci. 2002, 27, 191–254. [Google Scholar] [CrossRef]

- Asua, J.M.; Beuermann, S.; Buback, M.; Castignolles, P.; Charleux, B.; Gilbert, R.G.; Hutchinson, R.A.; Leiza, J.R.; Nikitin, A.N.; Vairon, J.P.; et al. Critically evaluated rate coefficients for free-radical polymerization, 5. Macromol. Chem. Phys. 2004, 205, 2151–2160. [Google Scholar]

- Arzamendi, G.; Plessis, C.; Leiza, J.R.; Asua, J.M. Effect of the intramolecular chain transfer to polymer on PLP/SEC experiments of alkyl acrylates. Macromol. Theory Simul. 2003, 12, 315–324. [Google Scholar] [CrossRef]

- Reyes, Y.; Arzamendi, G.; Asua, J.M.; Leiza, J.R. Branching at high frequency pulsed laser polymerizations of acrylate monomers. Macromolecules 2011, 44, 3674–3679. [Google Scholar] [CrossRef]

- Nikitin, A.N.; Hutchinson, R.A.; Buback, M.; Hesse, P. Determination of intramolecular chain transfer and midchain radical propagation rate coefficients for butyl acrylate by pulsed laser polymerization. Macromolecules 2007, 40, 8631–8641. [Google Scholar] [CrossRef]

- Plessis, C.; Arzamendi, G.; Alberdi, J.M.; van Herk, A.M.; Leiza, J.R.; Asua, J.M. Evidence of branching in poly(butyl acrylate) produced in pulsed-laser polymerization experiments. Macromol. Rapid Commun. 2003, 24, 173–177. [Google Scholar] [CrossRef]

- Barth, J.; Buback, M.; Hesse, P.; Sergeeva, T. EPR Analysis of N-butyl acrylate radical polymerization. Macromol. Rapid Commun. 2009, 30, 1969–1974. [Google Scholar] [CrossRef] [PubMed]

- Barth, J.; Buback, M.; Barner-Kowollik, C.; Junkers, T.; Russell, G.T. Single-pulse pulsed laser polymerization–electron paramagnetic resonance investigations into the termination kinetics of N-butyl acrylate macromonomers. J. Polym. Sci. Part A 2012, 50, 4740–4748. [Google Scholar] [CrossRef]

- Barth, J.; Siegmann, R.; Beuermann, S.; Russell, G.T.; Buback, M. Investigations into chain-length-dependent termination in bulk radical polymerization of 1H, 1H, 2H, 2H-tridecafluorooctyl methacrylate. Macromol. Chem. Phys. 2012, 213, 19–28. [Google Scholar] [CrossRef]

- Barth, J.; Buback, M. SP-PLP-EPR—A novel method for detailed studies into the termination kinetics of radical polymerization. Macromol. React. Eng. 2010, 4, 288–301. [Google Scholar] [CrossRef]

- Barner-Kowollik, C.; Beuermann, S.; Buback, M.; Castignolles, P.; Charleux, B.; Coote, M.L.; Hutchinson, R.A.; Junkers, T.; Lacik, I.; Russell, G.T.; et al. Critically evaluated rate coefficients in radical polymerization—7. Secondary-radical propagation rate coefficients for methyl acrylate in the bulk. Polym. Chem. 2014, 5, 204–212. [Google Scholar] [CrossRef]

- Beuermann, S.; Buback, M.; Hesse, P.; Kuchta, F.-D.; Lacik, I.; van Herk, A.M. Critically evaluated rate coefficients for free-radical polymerization, 6. Propagation rate coefficient of methacrylic acid in aqueous solution. Pure Appl. Chem. 2007, 79, 1463–1469. [Google Scholar] [CrossRef]

- Buback, M.; Gilbert, R.G.; Russell, G.T.; Hill, D.J.T.; Moad, G.; Odriscoll, K.F.; Shen, J.; Winnik, M.A. Consistent values of rate parameters in free radical polymerization systems. II. Outstanding dilemmas and recommendations. J. Polym. Sci. Part A 1992, 30, 851–863. [Google Scholar] [CrossRef]

- Beuermann, S.; Buback, M.; Davis, T.P.; Gilbert, R.G.; Hutchinson, R.A.; Olaj, O.F.; Russell, G.T.; Schweer, J.; van Herk, A.M. Critically evaluated rate coefficients for free-radical polymerization, 2. Propagation rate coefficients for methyl methacrylate. Macromol. Chem. Phys. 1997, 198, 1545–1560. [Google Scholar] [CrossRef]

- Beuermann, S.; Buback, M.; Davis, T.P.; Gilbert, R.G.; Hutchinson, R.A.; Kajiwara, A.; Klumperman, B.; Russell, G.T. Critically evaluated rate coefficients for free-radical polymerization, 3. Propagation rate coefficients for alkyl methacrylates. Macromol. Chem. Phys. 2000, 201, 1355–1364. [Google Scholar] [CrossRef]

- Junkers, T.; Schneider-Baumann, M.; Koo, S.S.P.; Castignolles, P.; Barner-Kowollik, C. Determination of propagation rate coefficients for methyl and 2-ethylhexyl acrylate via high frequency PLP−SEC under consideration of the impact of chain branching. Macromolecules 2010, 43, 10427–10434. [Google Scholar] [CrossRef]

- Mavroudakis, E.; Liang, K.; Moscatelli, D.; Hutchinson, R.A. A combined computational and experimental study on the free-radical copolymerization of styrene and hydroxyethyl acrylate. Macromol. Chem. Phys. 2012, 213, 1706–1716. [Google Scholar] [CrossRef]

- Buback, M.; Kurz, C.H. Free-Radical propagation rate coefficients for cyclohexyl methacrylate, glycidyl methacrylate and 2-hydroxyethyl methacrylate homopolymerizations. Macromol. Chem. Phys. 1998, 199, 2301–2310. [Google Scholar] [CrossRef]

- Hutchinson, R.A.; Beuermann, S.; Paquet, D.A.; McMinn, J.H. Determination of free-radical propagation rate coefficients for alkyl methacrylates by pulsed-laser polymerization. Macromolecules 1997, 30, 3490–3493. [Google Scholar] [CrossRef]

- Siegmann, R.; Jelicic, A.; Beuermann, S. Propagation and termination kinetics of pegylated methacrylate radical polymerizations. Macromol. Chem. Phys. 2010, 211, 546–562. [Google Scholar] [CrossRef]

- Beuermann, S.; Buback, M.; Davis, T.P.; García, N.; Gilbert, R.G.; Hutchinson, R.A.; Kajiwara, A.; Kamachi, M.; Lacík, I.; Russell, G.T. Critically evaluated rate coefficients for free-radical polymerization, 4. Macromol. Chem. Phys. 2003, 204, 1338–1350. [Google Scholar] [CrossRef]

- Lacík, I.; Beuermann, S.; Buback, M. PLP−SEC study into free-radical propagation rate of nonionized acrylic acid in aqueous solution. Macromolecules 2003, 36, 9355–9363. [Google Scholar] [CrossRef]

- Uhelska, L.; Chorvat, D.; Hutchinson, R.A.; Santanakrishnan, S.; Buback, M.; Lacik, I. Radical propagation kinetics of N-vinylpyrrolidone in organic solvents studied by pulsed-laser polymerization-size-exclusion chromatography (PLP-SEC). Macromol. Chem. Phys. 2014, 215, 2327–2336. [Google Scholar] [CrossRef]

- Stach, M.; Lacik, I.; Chorvat, D.; Buback, M.; Hesse, P.; Hutchinson, R.A.; Tang, L. Propagation rate coefficient for radical polymerization of N-vinyl pyrrolidone in aqueous solution obtained by PLP-SEC. Macromolecules 2008, 41, 5174–5185. [Google Scholar] [CrossRef]

- Stach, M.; Lacik, I.; Kasak, P.; Chorvat, D.; Saunders, A.J.; Santanakrishnan, S.; Hutchinson, R.A. Free-radical propagation kinetics of N-vinyl formamide in aqueous solution studied by PLP-SEC. Macromol. Chem. Phys. 2010, 211, 580–593. [Google Scholar] [CrossRef]

- Seabrook, S.A.; Tonge, M.P.; Gilbert, R.G. Pulsed laser polymerization study of the propagation kinetics of acrylamide in water. J. Polym. Sci. Part A 2005, 43, 1357–1368. [Google Scholar] [CrossRef]

- Muratore, L.M.; Coote, M.L.; Davis, T.P. Determination of the propagation rate coefficient for 3-(tris(trimethylsilyloxy)silyl) propyl methacrylate by pulsed-laser polymerization. Polymer 2000, 41, 1441–1447. [Google Scholar] [CrossRef]

- Yin, M.; Davis, T.P.; Heuts, J.P.A.; Barner-Kowollik, C. Propagation and termination rate coefficients in N-vinylcarbazole free radical polymerization obtained via 440 nm pulsed laser and online 1H NMR kinetic experiments. Macromol. Rapid Commun. 2003, 24, 408–412. [Google Scholar] [CrossRef]

- Balic, R.; Gilbert, R.G.; Zammit, M.D.; Davis, T.P.; Miller, C.M. Propagation rate coefficient of vinyl neo-decanoate by pulsed laser polymerization. Macromolecules 1997, 30, 3775–3780. [Google Scholar] [CrossRef]

- Hutchinson, R.A.; Paquet, D.A.; McMinn, J.H.; Beuermann, S.; Fuller, R.E.; Jackson, C. The application of pulsed-laser methods for the determination of free-radical polymerization rate coefficients. In 5th International Workshop on Polymer Reaction Engineering; Reichert, K.H., Moritz, H.U., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 1995; Volume 131, pp. 467–492. [Google Scholar]

- Olaj, O.F.; Schnollbitai, I. Laser-flash-initiated polymerization as a tool for evaluating (individual) kinetic constants of free-radical polymerization—5. Complete analysis by means of a single experiment. Eur. Poly. J. 1989, 25, 635–641. [Google Scholar] [CrossRef]

- Shipp, D.A.; Smith, T.A.; Solomon, D.H.; Moad, G. Evaluation of propagation rate constants for the free radical polymerization of methacrylonitrile by pulsed laser photolysis. Macromol. Rapid Commun. 1995, 16, 837–844. [Google Scholar] [CrossRef]

- Beuermann, S.; Paquet, D.A.; McMinn, J.H.; Hutchinson, R.A. Propagation kinetics of methacrylic acid studied by pulsed-laser polymerization. Macromolecules 1997, 30, 194–197. [Google Scholar] [CrossRef]

- Junkers, T.; Koo, S.P.S.; Barner-Kowollik, C. Determination of the propagation rate coefficient of acrylonitrile. Polym. Chem. 2010, 1, 438–441. [Google Scholar] [CrossRef]

- Buback, M.; Gilbert, R.G.; Hutchinson, R.A.; Klumperman, B.; Kuchta, F.-D.; Manders, B.G.; O’Driscoll, K.F.; Russell, G.T.; Schweer, J. Critically evaluated rate coefficients for free-radical polymerization, 1. Propagation rate coefficient for styrene. Macromol. Chem. Phys. 1995, 196, 3267–3280. [Google Scholar] [CrossRef]

- Coote, M.L.; Davis, T.P. Propagation kinetics of para-substituted styrenes: A test of the applicability of the hammett relationship to free-radical polymerization. Macromolecules 1999, 32, 4290–4298. [Google Scholar] [CrossRef]

- Hutchinson, R.A.; Aronson, M.T.; Richards, J.R. Analysis of pulsed-laser-generated molecular-weight distributions for the determination of propagation rate coefficients. Macromolecules 1993, 26, 6410–6415. [Google Scholar] [CrossRef]

- Coote, M.L.; Lin, C.Y. Computational methods for modeling free-radical polymerization. In Computational Methods for Large Systems: Electronic Structure Approaches for Biotechnology and Nanotechnology; Reimers, J.R., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011; pp. 435–474. [Google Scholar]

- Te Velde, G.; Bickelhaupt, F.M.; Baerends, E.J.; Guerra, C.F.; van Gisbergen, S.J.A.; Snijders, J.G.; Ziegler, T. Chemistry with ADF. J. Comput. Chem. 2001, 22, 931–967. [Google Scholar] [CrossRef]

- Gordon, M.S.; Schmidt, M.W. Advances in electronic structure theory: Gamess a decade later. In Theory and Applications of Computational Chemistry: The First Forty Years; Dykstra, C.E., Frenking, G., Kim, K.S., Scuseria, G.E., Eds.; Elsevier: Amsterdam, The Netherlands, 2005; pp. 1167–1189. [Google Scholar]

- Frisch, M.J.; Trucks, G.W.; Schlegel, H.B.; Scuseria, G.E.; Robb, M.A.; Cheeseman, J.R.; Scalmani, G.; Barone, V.; Mennucci, B.; Petersson, G.A.; et al. Gaussian 09; Gaussian Inc.: Wallingford, CT, USA, 2009. [Google Scholar]

- Bochevarov, A.D.; Harder, E.; Hughes, T.F.; Greenwood, J.R.; Braden, D.A.; Philipp, D.M.; Rinaldo, D.; Halls, M.D.; Zhang, J.; Friesner, R.A. Jaguar: A high-performance quantum chemistry software program with strengths in life and materials sciences. Int. J. Quantum Chem. 2013, 113, 2110–2142. [Google Scholar] [CrossRef]

- Aquilante, F.; de Vico, L.; Ferre, N.; Ghigo, G.; Malmqvist, P.-A.; Neogrady, P.; Pedersen, T.B.; Pitonak, M.; Reiher, M.; Roos, B.O.; et al. Software news and update molcas 7: The next generation. J. Comput. Chem. 2010, 31, 224–247. [Google Scholar] [CrossRef] [PubMed]

- Werner, H.-J.; Knowles, P.J.; Knizia, G.; Manby, F.R.; Schuetz, M. Molpro: A general-purpose quantum chemistry program package. Wiley Interdiscip. Rev. Comput. Mol. Sci. 2012, 2, 242–253. [Google Scholar] [CrossRef]

- Shao, Y.; Gan, Z.; Epifanovsky, E.; Gilbert, A.T.B.; Wormit, M.; Kussmann, J.; Lange, A.W.; Behn, A.; Deng, J.; Feng, X.; et al. Advances in molecular quantum chemistry contained in the Q-Chem 4 program package. Mol. Phys. 2015, 113, 184–215. [Google Scholar] [CrossRef]

- Agarwal, M.; Frank, M.I. SPARTAN: A software tool for parallelization bottleneck analysis. In Proceedings of the 2009 ICSE Workshop on Multicore Software Engineering, Vancouver, BC, Canada, 18 May 2009; pp. 56–63.

- Furche, F.; Ahlrichs, R.; Haettig, C.; Klopper, W.; Sierka, M.; Weigend, F. Turbomole. Wiley Interdiscip. Rev. Comput. Mol. Sci. 2014, 4, 91–100. [Google Scholar] [CrossRef]

- Deumens, E.; Lotrich, V.F.; Perera, A.; Ponton, M.J.; Sanders, B.A.; Bartlett, R.J. Software design of aces III with the super instruction architecture. Wiley Interdiscip. Rev.Comput. Mol. Sci. 2011, 1, 895–901. [Google Scholar] [CrossRef]

- Mohr, S.; Ratcliff, L.E.; Boulanger, P.; Genovese, L.; Caliste, D.; Deutsch, T.; Goedecker, S. Daubechies wavelets for linear scaling density functional theory. J. Chem. Phys. 2014, 140, 204110. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Genovese, L.; Neelov, A.; Goedecker, S.; Deutsch, T.; Ghasemi, S.A.; Willand, A.; Caliste, D.; Zilberberg, O.; Rayson, M.; Bergman, A.; et al. Daubechies wavelets as a basis set for density functional pseudopotential calculations. J. Chem. Phys. 2008, 129, 014109. [Google Scholar] [CrossRef] [PubMed]

- Hutter, J.; Iannuzzi, M.; Schiffmann, F.; VandeVondele, J. CP2K: Atomistic simulations of condensed matter systems. Wiley Interdiscip. Rev. Comput. Mol. Sci. 2014, 4, 15–25. [Google Scholar] [CrossRef]

- Matsen, F.A. Spin-free quantum-chemistry. XXIV. Fermion Many-Body Theory. Int. J. Quantum Chem. 1987, 32, 87–104. [Google Scholar] [CrossRef]

- Fock, V. Approximation method for the solution of the quantum mechanical multibody problems. Z. Fur Phys. 1930, 61, 126–148. [Google Scholar] [CrossRef]

- Hohenberg, P.; Kohn, W. Inhomogeneous electron gas. Phys. Rev. B 1964, 136, B864. [Google Scholar] [CrossRef]

- Fischer, H.; Radom, L. Factors controlling the addition of carbon-centered radicals to alkenes—An experimental and theoretical perspective. Angew. Chem. Int. Edit. 2001, 40, 1340–1371. [Google Scholar] [CrossRef]

- Toh, J.S.S.; Huang, D.M.; Lovell, P.A.; Gilbert, R.G. Ab initio calculation of the rate coefficient for short-chain branching in free-radical polymerizations. Polymer 2001, 42, 1915–1920. [Google Scholar] [CrossRef]

- Gomez-Balderas, R.; Coote, M.L.; Henry, D.J.; Radom, L. Reliable theoretical procedures for calculating the rate of methyl radical addition to carbon-carbon double and triple bonds. J. Phys. Chem. A 2004, 108, 2874–2883. [Google Scholar] [CrossRef]

- Heuts, J.P.A.; Gilbert, R.G.; Radom, L. Determination of arrhenius parameters for propagation in free-radical polymerizations: An assessment of ab initio procedures. J. Phys. Chem. 1996, 100, 18997–19006. [Google Scholar] [CrossRef]

- Dossi, M.; Storti, G.; Moscatelli, D. Initiation kinetics in free-radical polymerization: Prediction of thermodynamic and kinetic parameters based on ab initio calculations. Macromol. Theory Simul. 2010, 19, 170–178. [Google Scholar] [CrossRef]

- Fascella, S.; Cavallotti, C.; Rota, R.; Carra, S. Quantum chemistry investigation of key reactions involved in the formation of naphthalene and indene. J. Phys. Chem. A 2004, 108, 3829–3843. [Google Scholar] [CrossRef]

- Van Speybroeck, V.; van Neck, D.; Waroquier, M.; Wauters, S.; Saeys, M.; Marin, G.B. Ab initio study of radical addition reactions: Addition of a primary ethylbenzene radical to ethene (I). J. Phys. Chem. A 2000, 104, 10939–10950. [Google Scholar] [CrossRef]

- Peng, C.Y.; Ayala, P.Y.; Schlegel, H.B.; Frisch, M.J. Using redundant internal coordinates to optimize equilibrium geometries and transition states. J. Comput. Chem. 1996, 17, 49–56. [Google Scholar] [CrossRef]

- Cuccato, D.; Mavroudakis, E.; Moscatelli, D. Quantum chemistry investigation of secondary reaction kinetics in acrylate-based copolymers. J. Phys. Chem. A 2013, 117, 4358–4366. [Google Scholar] [CrossRef] [PubMed]

- Coote, M.L. Quantum-chemical modeling of free-radical polymerization. Macromol. Theory Simul. 2009, 18, 388–400. [Google Scholar] [CrossRef]

- Noble, B.B.; Coote, M.L. First principles modelling of free-radical polymerisation kinetics. Int. Rev. Phys. Chem. 2013, 32, 467–513. [Google Scholar] [CrossRef]

- Fueno, T.; Kamachi, M. Ab initio SCF study of addition of the methyl radical to vinyl compounds. Macromolecules 1988, 21, 908–912. [Google Scholar] [CrossRef]

- Gonzalez, C.; Sosa, C.; Schlegel, H.B. Ab initio Study of the addition-reaction of the methyl radical to the ethylene and formaldehyde. J. Phys. Chem. 1989, 93, 2435–2440. [Google Scholar] [CrossRef]

- Arnaud, R.; Subra, R.; Barone, V.; Lelj, F.; Olivella, S.; Sole, A.; Russo, N. Ab-initio mechanistic studies of radical reactions. Directive effects in the addition of methyl radical to unsymmetrical fluoroathenes. J. Chem. Soc. Perkin Trans. 2 1986. [Google Scholar] [CrossRef]

- Wong, M.W.; Pross, A.; Radom, L. Comparison of the addition of CH3.bul., CH2OH.bul., and CH2CN.bul. Radicals to substituted alkenes: A theoretical study of the reaction mechanism. J. Am. Chem. Soc. 1994, 116, 6284–6292. [Google Scholar] [CrossRef]

- Heuts, J.P.A.; Gilbert, R.G.; Radom, L. A Priori prediction of propagation rate coefficients in free-radical polymerizations: Propagation of ethylene. Macromolecules 1995, 28, 8771–8781. [Google Scholar] [CrossRef]

- Wong, M.W.; Radom, L. Radical addition to alkenes: Further assessment of theoretical procedures. J. Phys. Chem. A 1998, 102, 2237–2245. [Google Scholar] [CrossRef]

- Coote, M.L.; Davis, T.P.; Radom, L. Conformational dependence of the penultimate unit effect in free-radical copolymerization. Macromolecules 1999, 32, 5270–5276. [Google Scholar] [CrossRef]

- Coote, M.L.; Davis, T.P.; Radom, L. Effect of the penultimate unit on radical stability and reactivity in free-radical polymerization. Macromolecules 1999, 32, 2935–2940. [Google Scholar] [CrossRef]

- Coote, M.L.; Davis, T.P.; Radom, L. The Effect of remote substituents in free radical addition reactions: New evidence for the penultimate unit effect. J. Mol. Struct. 1999, 461, 91–96. [Google Scholar] [CrossRef]

- Moscatelli, D.; Dossi, M.; Cavallotti, C.; Storti, G. Density functional theory study of addition reactions of carbon-centered radicals to alkenes. J. Phys. Chem. A 2011, 115, 52–62. [Google Scholar] [CrossRef] [PubMed]

- Hirunsit, P.; Balbuena, P.B. Addition reactions of alkyl and carboxyl radicals to vinylidene fluoride. J. Phys. Chem. A 2008, 112, 4483–4489. [Google Scholar] [CrossRef] [PubMed]

- Van Speybroeck, V.; van Cauter, K.; Coussens, B.; Waroquier, M. Ab initio study of free-radical polymerizations: Cost-effective methods to determine the reaction rates. ChemPhysChem 2005, 6, 180–189. [Google Scholar] [CrossRef] [PubMed]

- Van Cauter, K.; van Speybroeck, V.; Vansteenkiste, P.; Reyniers, M.F.; Waroquier, M. Ab initio study of free-radical polymerization: Polyethylene propagation kinetics. ChemPhysChem 2006, 7, 131–140. [Google Scholar] [CrossRef] [PubMed]

- Izgorodina, E.I.; Coote, M.L. Accurate ab initio prediction of propagation rate coefficients in free-radical polymerization: Acrylonitrile and vinyl chloride. Chem. Phys. 2006, 324, 96–110. [Google Scholar] [CrossRef]

- Van Cauter, K.; van Speybroeck, V.; Waroquier, M. Ab initio study of poly(vinyl chloride) propagation kinetics: Head-to-head versus head-to-tail additions. ChemPhysChem 2007, 8, 541–552. [Google Scholar] [CrossRef] [PubMed]

- Huang, D.M.; Monteiro, M.J.; Gilbert, R.G. A theoretical study of propagation rate coefficients for methacrylonitrile and acrylonitrile. Macromolecules 1998, 31, 5175–5187. [Google Scholar] [CrossRef]

- Yu, X.R.; Pfaendtner, J.; Broadbelt, L.J. Ab initio study of acrylate polymerization reactions: Methyl methacrylate and methyl acrylate propagation. J. Phys. Chem. A 2008, 112, 6772–6782. [Google Scholar] [CrossRef] [PubMed]

- Gunaydin, H.; Salman, S.; Tuzun, N.S.; Avci, D.; Aviyente, V. Modeling the free radical polymerization of acrylates. Int. J. Quantum Chem. 2005, 103, 176–189. [Google Scholar] [CrossRef]

- Degirmenci, I.; Aviyente, V.; van Speybroeck, V.; Waroquier, M. DFT study on the propagation kinetics of free-radical polymerization of α-substituted acrylates. Macromolecules 2009, 42, 3033–3041. [Google Scholar] [CrossRef]

- Isik, M.; Karahan, O.; Avci, D.; Aviyente, V. A computational approach to the free radical polymerization kinetics of alkyl α-hydroxymethacrylate monomers: A structure-reacti vity relationship. J. Polym. Sci. Part A 2013, 51, 2375–2384. [Google Scholar] [CrossRef]

- Dogan, B.; Catak, S.; van Speybroeck, V.; Waroquier, M.; Aviyente, V. Free radical polymerization of ethyl methacrylate and ethyl α-hydroxy methacrylate: A computational approach to the propagation kinetics. Polymer 2012, 53, 3211–3219. [Google Scholar] [CrossRef]

- Karahan, O.; Avci, D.; Aviyente, V. Structure-reactivity relationships of alkyl α-hydroxymethacrylate derivatives. J. Polym. Sci. Part A 2011, 49, 3058–3068. [Google Scholar] [CrossRef]

- Moscatelli, D.; Dossi, M.; Cavallotti, C.; Storti, G. Ab initio calculation of the propagation kinetics in free radical polymerization: Chain length and penultimate effects. Macromol. Symp. 2007, 259, 337–347. [Google Scholar] [CrossRef]

- Dossi, M.; Storti, G.; Moscatelli, D. Quantum chemistry: A powerful tool in polymer reaction engineering. Macromol. Symp. 2011, 302, 16–25. [Google Scholar] [CrossRef]

- Deglmann, P.; Muller, I.; Becker, F.; Schafer, A.; Hungenberg, K.D.; Weiss, H. Prediction of propagation rate coefficients in free radical solution polymerization based on accurate quantum chemical methods: Vinylic and related monomers, including acrylates and acrylic acid. Macromol. React. Eng. 2009, 3, 496–515. [Google Scholar] [CrossRef]

- Liang, K.; Dossi, M.; Moscatelli, D.; Hutchinson, R.A. An investigation of free-radical copolymerization propagation kinetics of styrene and 2-hydroxyethyl methacrylate. Macromolecules 2009, 42, 7736–7744. [Google Scholar] [CrossRef]

- Lin, C.Y.; Izgorodina, E.I.; Coote, M.L. First principles prediction of the propagation rate coefficients of acrylic and vinyl esters: Are we there yet? Macromolecules 2010, 43, 553–560. [Google Scholar] [CrossRef]

- Rooney, T.R.; Mavroudakis, E.; Lacik, I.; Hutchinson, R.A.; Moscatelli, D. Pulsed-laser and quantum mechanics study of N-butyl cyanoacrylate and methyl methacrylate free-radical copolymerization. Polym. Chem. 2015, 6, 1594–1603. [Google Scholar] [CrossRef]

- Dossi, M.; Liang, K.; Hutchinson, R.A.; Moscatelli, D. Investigation of free-radical copolymerization propagation kinetics of vinyl acetate and methyl methacrylate. J. Phys. Chem. B 2010, 114, 4213–4222. [Google Scholar] [CrossRef] [PubMed]

- Mavroudakis, E.; Cuccato, D.; Dossi, M.; Comino, G.; Moscatelli, D. Quantum chemistry investigation of fluorinated polymer systems of industrial interest. J. Phys. Chem. A 2014, 118, 238–247. [Google Scholar] [CrossRef] [PubMed]

- Thickett, S.C.; Gilbert, R.G. Propagation rate coefficient of acrylic acid: Theoretical investigation of the solvent effect. Polymer 2004, 45, 6993–6999. [Google Scholar] [CrossRef]

- Cuccato, D.; Dossi, M.; Moscatelli, D.; Storti, G. Quantum chemical investigation of secondary reactions in poly(vinyl chloride) free-radical polymerization. Macromol. React. Eng. 2012, 6, 330–345. [Google Scholar] [CrossRef]

- Cuccato, D.; Dossi, M.; Moscatelli, D.; Storti, G. A density functional theory study of poly(vinyl chloride) (PVC) free radical polymerization. Macromol. Symp. 2011, 302, 100–109. [Google Scholar] [CrossRef]

- Van Cauter, K.; van den Bossche, B.J.; van Speybroeck, V.; Waroquier, M. Ab initio study of free-radical polymerization: Defect structures in poly(vinyl chloride). Macromolecules 2007, 40, 1321–1331. [Google Scholar] [CrossRef]

- Filley, J.; McKinnon, J.T.; Wu, D.T.; Ko, G.H. Theoretical study of ethylene-vinyl acetate free-radical copolymerization: reactivity ratios, penultimate effects, and relative rates of chain transfer to polymer. Macromolecules 2002, 35, 3731–3738. [Google Scholar] [CrossRef]

- Mayo, F.R.; Lewis, F.M. Copolymerization. I. A basis for comparing the behavior of monomers in copolymerization; the copolymerization of styrene and methyl methacrylate. J. Am. Chem. Soc. 1944, 66, 1594–1601. [Google Scholar] [CrossRef]

- Merz, E.; Alfrey, T.; Goldfinger, G. Intramolecular reactions in vinyl polymers as a means of investigation of the propagation step. J. Polym. Sci. 1946, 1, 75–82. [Google Scholar] [CrossRef]

- Fukuda, T.; Ma, Y.D.; Inagaki, H. Free-radical copolymerization. 3. Determination of rate constants of propagation and termination for styrene/methyl methacrylate system. A critical test of terminal-model kinetics. Macromolecules 1985, 18, 17–26. [Google Scholar] [CrossRef]

- Mitoraj, M.; Michalak, A. DFT studies on isomerization reactions in the copolymerization of ethylene and methyl acrylate catalyzed by Ni-diimine and Pd-diimine complexes. J. Mol. Model. 2005, 11, 341–350. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Tanaka, T.; Tsubota, M.; Fujiki, M.; Yamanaka, S.; Nomura, K. Effect of cyclopentadienyl fragment in copolymerization of ethylene with cyclic olefins catalyzed by non-bridged (aryloxo)(cyclopentadienyl)titanium(IV) complexes. Adv. Synth. Catal. 2005, 347, 433–446. [Google Scholar] [CrossRef]

- Bebe, S.; Yu, X.R.; Hutchinson, R.A.; Broadbelt, L.J. Estimation of free radical polymerization rate coefficients using computational chemistry. Macromol. Symp. 2006, 243, 179–189. [Google Scholar] [CrossRef]

- Dossi, M.; Moscatelli, D. A QM approach to the calculation of reactivity ratios in free-radical copolymerization. Macromol. React. Eng. 2012, 6, 74–84. [Google Scholar] [CrossRef]

- Yu, X.; Levine, S.E.; Broadbelt, L.J. Kinetic study of the copolymerization of methyl methacrylate and methyl acrylate using quantum chemistry. Macromolecules 2008, 41, 8242–8251. [Google Scholar] [CrossRef]

- Coote, M.L.; Johnston, L.P.M.; Davis, T.P. Copolymerization propagation kinetics of styrene and methyl methacrylate-revisited. 2. Kinetic analysis. Macromolecules 1997, 30, 8191–8204. [Google Scholar] [CrossRef]

- Furuncuoglu Ozaltin, T.; Dereli, B.; Karahan, O.; Salman, S.; Aviyente, V. Solvent effects on free-radical copolymerization of styrene and 2-hydroxyethyl methacrylate: A DFT study. New J. Chem. 2014, 38, 170–178. [Google Scholar] [CrossRef]

- Wang, W.; Hutchinson, R.A. PLP/SEC/NMR study of free radical copolymerization of styrene and glycidyl methacrylate. Macromolecules 2008, 41, 9011–9018. [Google Scholar] [CrossRef]

- Li, D.; Li, N.; Hutchinson, R.A. High-temperature free radical copolymerization of styrene and butyl methacrylate with depropagation and penultimate kinetic effects. Macromolecules 2006, 39, 4366–4373. [Google Scholar] [CrossRef]

- Dossi, M.; Storti, G.; Moscatelli, D. A quantum chemistry study of the free-radical copolymerization propagation kinetics of styrene and 2-hydroxyethyl acrylate. Polym. Eng. Sci. 2011, 51, 2109–2114. [Google Scholar] [CrossRef]

- McManus, N.T.; Kim, J.D.; Penlidis, A. Observations on styrene-hydroxyethyl acrylate and styrene-hydroxyethyl acrylate-ethyl acrylate polymerizations. Polym. Bull. 1998, 41, 661–668. [Google Scholar] [CrossRef]

- Davis, T.P.; O'Driscoll, K.F.; Piton, M.C.; Winnik, M.A. Copolymerization propagation kinetics of styrene with alkyl acrylates. Polym. Int. 1991, 24, 65–70. [Google Scholar] [CrossRef]

- Zubov, V.P.; Valuev, L.I.; Kabanov, V.A.; Kargin, V.A. Effects of complexing agents in radical copolymerization. J. Polym. Sci. Part A 1971, 9, 833–854. [Google Scholar] [CrossRef]

- Jenkins, A.D.; Tsartolia, E.; Walton, D.R.M.; Stejskal, J.; Kratochvil, P. Statistical group-transfer copolymerization. 1. Monomer reactivity ratios for normal-butyl methacrylate and methyl-methacrylate. Polym. Bull. 1988, 20, 97–100. [Google Scholar]

- Brar, A.S.; Charan, S. Sequence determination of vinyl-acetate methyl acrylate copolymers by NMR-spectroscopy. J. Appl. Polym. Sci. 1994, 53, 1813–1822. [Google Scholar] [CrossRef]

- Ma, Y.D.; Won, Y.C.; Kubo, K.; Fukuda, T. Propagation and termination processes in the free-radical copolymerization of methyl methacrylate and vinyl acetate. Macromolecules 1993, 26, 6766–6770. [Google Scholar] [CrossRef]

- Rätzsch, M.; Schneider, W.; Musche, D. Reactivity of ethylene in the radically initiated copolymerization of ethylene with vinylacetate. J. Polym. Sci. Part A 1971, 9, 785–790. [Google Scholar] [CrossRef]

- Gelin, M.P.; Ameduri, B. Radical solution copolymerisation of vinylidene fluoride with hexafluoropropene. J. Fluor. Chem. 2005, 126, 577–585. [Google Scholar] [CrossRef]

- Moggi, G.; Bonardelli, P.; Bart, J.C.J. Copolymers of 1,1-difluoroethene with tetrafluoroethene, chlorotrifluoroethene, and bromotrifluoroethene. J. Polym. Sci. Part B 1984, 22, 357–365. [Google Scholar] [CrossRef]

- Logothetis, A.L. Chemistry of fluorocarbon elastomers. Prog. Polym. Sci. 1989, 14, 251–296. [Google Scholar] [CrossRef]

- De Sterck, B.; Vaneerdeweg, R.; Du Prez, F.; Waroquier, M.; van Speybroeck, V. Solvent effects on free radical polymerization reactions: The influence of water on the propagation rate of acrylamide and methacrylamide. Macromolecules 2010, 43, 827–836. [Google Scholar] [CrossRef]

- Degirmenci, I.; Ozaltin, T.F.; Karahan, O.; van Speybroeck, V.; Waroquier, M.; Aviyente, V. Origins of the solvent effect on the propagation kinetics of acrylic acid and methacrylic Acid. J. Polym. Sci. Part A 2013, 51, 2024–2034. [Google Scholar] [CrossRef]

- Degirmenci, I.; Eren, S.; Aviyente, V.; de Sterck, B.; Hemelsoet, K.; van Speybroeck, V.; Waroquier, M. Modeling the solvent effect on the tacticity in the free radical polymerization of methyl methacrylate. Macromolecules 2010, 43, 5602–5610. [Google Scholar] [CrossRef]

- Klamt, A.; Schuurmann, G. Cosmo: A new approach to dielectric screening in solvents with explicit expressions for the screening energy and its gradient. J. Chem. Soc. Perkin Trans. 2 1993. [Google Scholar] [CrossRef]

- Miertuš, S.; Scrocco, E.; Tomasi, J. Electrostatic interaction of a solute with a continuum. A direct utilizaion of ab initio molecular potentials for the prevision of solvent effects. Chem. Phys. 1981, 55, 117–129. [Google Scholar] [CrossRef]

- Ensing, B.; de Vivo, M.; Liu, Z.; Moore, P.; Klein, M.L. Metadynamics as a tool for exploring free energy landscapes of chemical reactions. Acc. Chem. Res. 2006, 39, 73–81. [Google Scholar] [CrossRef] [PubMed]

- Degirmenci, I.; Avci, D.; Aviyente, V.; van Cauter, K.; van Speybroeck, V.; Waroquier, M. Density functional theory study of free-radical polymerization of acrylates and methacrylates: Structure-reactivity relationship. Macromolecules 2007, 40, 9590–9602. [Google Scholar] [CrossRef]

- Hemelsoet, K.; Moran, D.; van Speybroeck, V.; Waroquier, M.; Radom, L. An assessment of theoretical procedures for predicting the thermochemistry and kinetics of hydrogen abstraction by methyl radical from benzene. J. Phys. Chem. A 2006, 110, 8942–8951. [Google Scholar] [CrossRef] [PubMed]

- Saeys, M.; Reyniers, M.F.; van Speybroeck, V.; Waroquier, M.; Marin, G.B. Ab initio group contribution method for activation energies of hydrogen abstraction reactions. ChemPhysChem 2006, 7, 188–199. [Google Scholar] [CrossRef] [PubMed]

- Moghadam, N.; Liu, S.; Srinivasan, S.; Grady, M.C.; Soroush, M.; Rappe, A.M. Computational study of chain transfer to monomer reactions in high-temperature polymerization of alkyl acrylates. J. Phys. Chem. A 2013, 117, 2605–2618. [Google Scholar] [CrossRef] [PubMed]

- Purmova, J.; Pauwels, K.F.D.; Agostini, M.; Bruinsma, M.; Vorenkamp, E.J.; Schouten, A.J.; Coote, M.L. Experimental and theoretical evaluation of the reactions leading to formation of internal double bonds in suspension PVC. Macromolecules 2008, 41, 5527–5539. [Google Scholar] [CrossRef]

- Pfaendtner, J.; Yu, X.R.; Broadbelt, L.J. Quantum chemical investigation of low-temperature intramolecular hydrogen transfer reactions of hydrocarbons. J. Phys. Chem. A 2006, 110, 10863–10871. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Srinivasan, S.; Grady, M.C.; Soroush, M.; Rappe, A.M. Backbiting and β-scission reactions in free-radical polymerization of methyl acrylate. Int. J. Quantum Chem. 2014, 114, 345–360. [Google Scholar] [CrossRef]

- Cuccato, D.; Mavroudakis, E.; Dossi, M.; Moscatelli, D. A density functional theory study of secondary reactions in N-butyl acrylate free radical polymerization. Macromol. Theory Simul. 2013, 22, 127–135. [Google Scholar] [CrossRef]

- Yu, X.R.; Broadbelt, L.J. Kinetic study of 1,5-hydrogen transfer reactions of methyl acrylate and butyl acrylate using quantum chemistry. Macromol. Theory Simul. 2012, 21, 461–469. [Google Scholar] [CrossRef]

- Karahan, O.; Isik, M.; Cifci, G.; Ugur, I.; Avci, D.; Aviyente, V. Cyclization tendencies in the free radical polymerization of allyl acrylate derivatives: A computational study. J. Polym. Sci. Part A 2011, 49, 2474–2483. [Google Scholar] [CrossRef]

- Moghadam, N.; Srinivasan, S.; Grady, M.C.; Rappe, A.M.; Soroush, M. Theoretical study of chain transfer to solvent reactions of alkyl acrylates. J. Phys. Chem. A 2014, 118, 5474–5487. [Google Scholar] [CrossRef] [PubMed]

- Furuncuoglu, T.; Ugur, I.; Degirmenci, I.; Aviyente, V. Role of chain transfer agents in free radical polymerization kinetics. Macromolecules 2010, 43, 1823–1835. [Google Scholar] [CrossRef]

- Mavroudakis, E.; Cuccato, D.; Moscatelli, D. Theoretical study of chain transfer to agent kinetics in butyl acrylate polymerization. Ind. Eng. Chem. Res. 2014, 53, 9058–9066. [Google Scholar] [CrossRef]

- Mavroudakis, E.; Cuccato, D.; Moscatelli, D. Quantum mechanical investigation on bimolecular hydrogen abstractions in butyl acrylate-based free radical polymerization processes. J. Phys. Chem. A 2014, 118, 1799–1806. [Google Scholar] [CrossRef] [PubMed]

- Moscatelli, D.; Cavallotti, C.; Morbidelli, M. Prediction of molecular weight distributions based on ab initio calculations: Application to the high temperature styrene polymerization. Macromolecules 2006, 39, 9641–9653. [Google Scholar] [CrossRef]

- Dossi, M.; Storti, G.; Moscatelli, D. Relevance of backbiting and β-scission reactions in the free radical polymerization of acrylonitrile. Macromol. Symp. 2010, 289, 119–123. [Google Scholar] [CrossRef]

- Liu, S.; Srinivasan, S.; Grady, M.C.; Soroush, M.; Rappe, A.M. Computational study of cyclohexanone–monomer co-initiation mechanism in thermal homo-polymerization of methyl acrylate and methyl methacrylate. J. Phys. Chem. A 2012, 116, 5337–5348. [Google Scholar] [CrossRef] [PubMed]

- Srinivasan, S.; Lee, M.W.; Grady, M.C.; Soroush, M.; Rappe, A.M. Computational evidence for self-initiation in spontaneous high-temperature polymerization of methyl methacrylate. J. Phys. Chem. A 2011, 115, 1125–1132. [Google Scholar] [CrossRef] [PubMed]

- Cuccato, D.; Dossi, M.; Polino, D.; Cavallotti, C.; Moscatelli, D. Is quantum tunneling relevant in free-radical polymerization? Macromol. React. Eng. 2012, 6, 496–506. [Google Scholar] [CrossRef]

- Eckart, C. The penetration of a potential barrier by electrons. Phys. Rev. 1930, 35, 1303–1309. [Google Scholar] [CrossRef]

- Maeder, S.; Gilbert, R.G. Measurement of transfer constant for butyl acrylate free-radical polymerization. Macromolecules 1998, 31, 4410–4418. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mavroudakis, E.; Cuccato, D.; Moscatelli, D. On the Use of Quantum Chemistry for the Determination of Propagation, Copolymerization, and Secondary Reaction Kinetics in Free Radical Polymerization. Polymers 2015, 7, 1789-1819. https://doi.org/10.3390/polym7091483

Mavroudakis E, Cuccato D, Moscatelli D. On the Use of Quantum Chemistry for the Determination of Propagation, Copolymerization, and Secondary Reaction Kinetics in Free Radical Polymerization. Polymers. 2015; 7(9):1789-1819. https://doi.org/10.3390/polym7091483

Chicago/Turabian StyleMavroudakis, Evangelos, Danilo Cuccato, and Davide Moscatelli. 2015. "On the Use of Quantum Chemistry for the Determination of Propagation, Copolymerization, and Secondary Reaction Kinetics in Free Radical Polymerization" Polymers 7, no. 9: 1789-1819. https://doi.org/10.3390/polym7091483