Thixotropic Supramolecular Pectin-Poly(Ethylene Glycol) Methacrylate (PEGMA) Hydrogels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of Pectin-PEGMA Copolymer, P-10K

2.2. Polymer Characterisation

2.3. Thermal Analysis

2.4. Preparation of Pectin-PEGMA/α-CD Hydrogels

2.5. Rheology Studies

3. Results

3.1. Synthesis and Characterization of Pectin-PEGMA Copolymer, P-10K

3.2. Thermal Analysis

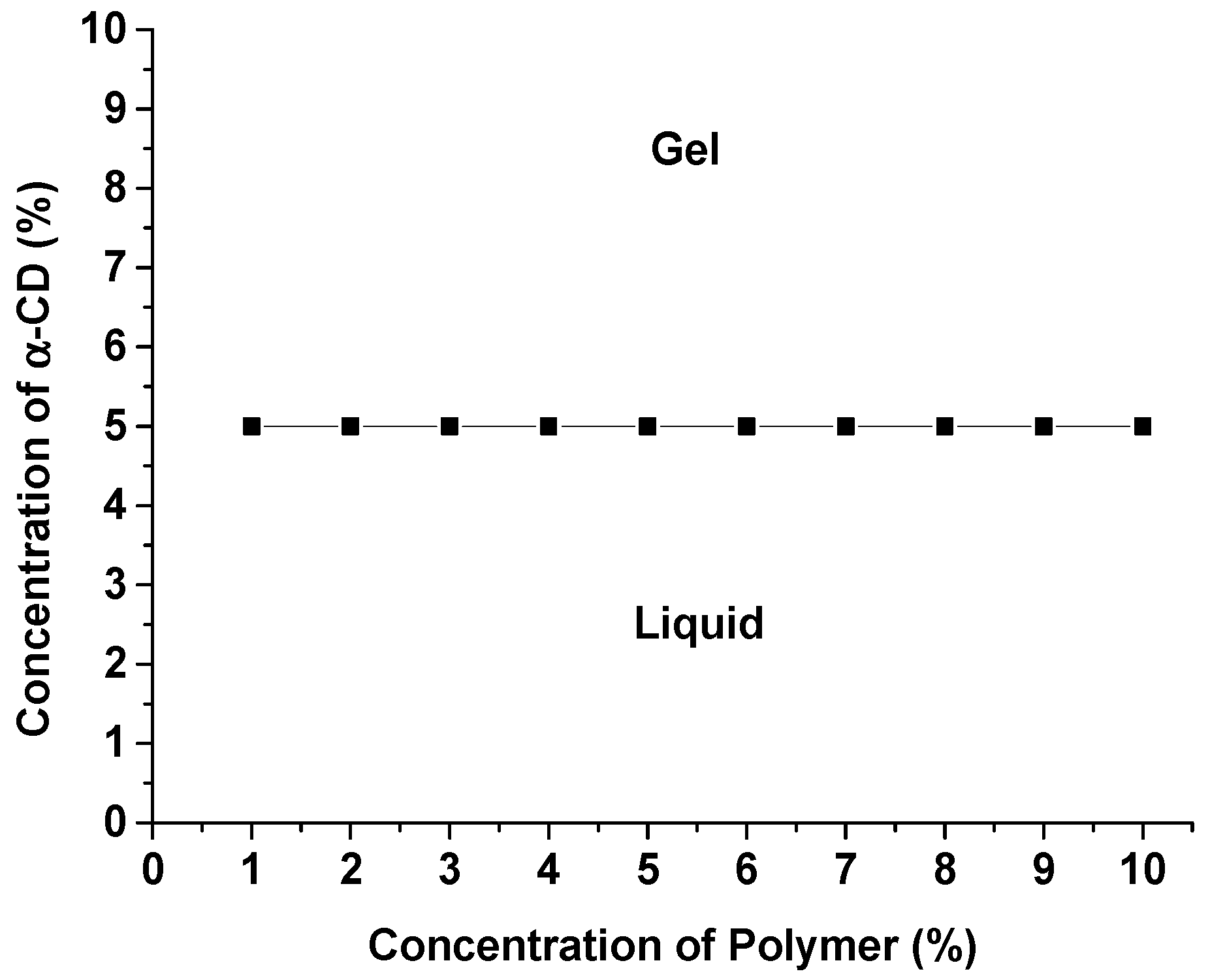

3.3. Critical Gelation Concentration Determination

3.4. Rheology of Pectin-PEGMA/α-CD Hydrogel

3.5. Thixotropic Properties of Pectin-PEGMA/α-CD Hydrogels

3.6. The Effect of Temperature on Pectin-PEGMA/α-CD Hydrogels

4. Discussion

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Braconnot, H. Recherches sur un nouvel acide universellement répandu dans tous les végétaux. Annales de Chimie et de Physique 1825, 28, 173–178. [Google Scholar]

- Chan, S.-Y.; Choo, W.-S. Effect of extraction conditions on the yield and chemical properties of pectin from cocoa husks. Food Chem. 2013, 141, 3752–3758. [Google Scholar] [CrossRef] [PubMed]

- Staunstrup, J. Citrus pectin production and world market. In Proceedings of the International Citrus & Beverage Conference, Clearwater, FL, USA, 15–18 September 2009.

- Ciriminna, R.; Chavarría-Hernández, N.; Inés Rodríguez Hernández, A.; Pagliaro, M. Pectin: A new perspective from the biorefinery standpoint. Biofuels Bioprod. Biorefin. 2015, 9, 368–377. [Google Scholar] [CrossRef]

- Sharma, R.; Ahuja, M. Thiolated pectin: Synthesis, characterization and evaluation as a mucoadhesive polymer. Carbohydr. Polym. 2011, 85, 658–663. [Google Scholar] [CrossRef]

- Sriamornsak, P.; Thirawong, N.; Nunthanid, J.; Puttipipatkhachorn, S.; Thongborisute, J.; Takeuchi, H. Atomic force microscopy imaging of novel self-assembling pectin–liposome nanocomplexes. Carbohydr. Polym. 2008, 71, 324–329. [Google Scholar] [CrossRef]

- Günter, E.A.; Popeyko, O.V. Calcium pectinate gel beads obtained from callus cultures pectins as promising systems for colon-targeted drug delivery. Carbohydr. Polym. 2016, 147, 490–499. [Google Scholar] [CrossRef] [PubMed]

- Lupi, F.R.; Gabriele, D.; Seta, L.; Baldino, N.; de Cindio, B.; Marino, R. Rheological investigation of pectin-based emulsion gels for pharmaceutical and cosmetic uses. Rheol. Acta 2014, 54, 41–52. [Google Scholar] [CrossRef]

- Da Costa, M.P.M.; de Mello Ferreira, I.L.; de Macedo Cruz, M.T. New polyelectrolyte complex from pectin/chitosan and montmorillonite clay. Carbohydr. Polym. 2016, 146, 123–130. [Google Scholar] [CrossRef] [PubMed]

- Codex Alimentarius. General standards for food additives, codex stan 192–1995. In Pectin; Food and Agriculture Organization of the United Nations: Rome, Italy, 2015. [Google Scholar]

- Müller-Maatsch, J.; Caligiani, A.; Tedeschi, T.; Elst, K.; Sforza, S. Simple and validated quantitative 1H NMR method for the determination of methylation, acetylation, and feruloylation degree of pectin. J. Agric. Food Chem. 2014, 62, 9081–9087. [Google Scholar] [CrossRef] [PubMed]

- Oakenfull, D.; Scott, A. Hydrophobic interaction in the gelation of high methoxyl pectins. J. Food Sci. 1984, 49, 1093–1098. [Google Scholar] [CrossRef]

- Gidley, M.J.; Morris, E.R.; Murray, E.J.; Powell, D.A.; Rees, D.A. Evidence for two mechanisms of interchain association in calcium pectate gels. Int. J. Biol. Macromol. 1980, 2, 332–334. [Google Scholar] [CrossRef]

- Harada, A.; Li, J.; Kamachi, M. The molecular necklace: A rotaxane containing many threaded α-cyclodextrins. Nature 1992, 356, 325–327. [Google Scholar] [CrossRef]

- Ren, L.; He, L.; Sun, T.; Dong, X.; Chen, Y.; Huang, J.; Wang, C. Dual-responsive supramolecular hydrogels from water-soluble PEG-grafted copolymers and cyclodextrin. Macromol. Biosci. 2009, 9, 902–910. [Google Scholar] [CrossRef] [PubMed]

- Wenz, G.; Han, B.-H.; Müller, A. Cyclodextrin rotaxanes and polyrotaxanes. Chem. Rev. 2006, 106, 782–817. [Google Scholar] [CrossRef] [PubMed]

- Harada, A.; Li, J.; Kamachi, M. Preparation and characterization of a polyrotaxane consisting of monodisperse poly(ethylene glycol) and α-cyclodextrins. J. Am. Chem. Soc. 1994, 116, 3192–3196. [Google Scholar] [CrossRef]

- Tonelli, A.E. Soluble PEG-α-CD-rotaxanes: Where on the PEG chains are the permanently threaded α-CDs located and are they mobile? Macromolecules 2008, 41, 4058–4060. [Google Scholar] [CrossRef]

- Abdul Karim, A.; Loh, X.J. Design of a micellized α-cyclodextrin based supramolecular hydrogel system. Soft Matter 2015, 11, 5425–5434. [Google Scholar] [CrossRef] [PubMed]

- Chatjigakis, A.K.; Pappas, C.; Proxenia, N.; Kalantzi, O.; Rodis, P.; Polissiou, M. Ft-ir spectroscopic determination of the degree of esterification of cell wall pectins from stored peaches and correlation to textural changes. Carbohydr. Polym. 1998, 37, 395–408. [Google Scholar] [CrossRef]

- Stewart, D.; Morrison, I.M. Ft-ir spectroscopy as a tool for the study of biological and chemical treatments of barley straw. J. Sci. Food Agric. 1992, 60, 431–436. [Google Scholar] [CrossRef]

- Wang, H.; Feng, Y.; An, B.; Zhang, W.; Sun, M.; Fang, Z.; Yuan, W.; Khan, M. Fabrication of PU/PEGMA crosslinked hybrid scaffolds by in situ UV photopolymerization favoring human endothelial cells growth for vascular tissue engineering. J. Mater. Sci. 2012, 23, 1499–1510. [Google Scholar] [CrossRef] [PubMed]

- Bagheri, M.; Bigdeli, E.; Pourmoazzen, Z. Self-assembled micellar nanoparticles of a novel amphiphilic cholesteryl-poly(l-lactic acid)-b-poly(poly(ethylene glycol)methacrylate) block-brush copolymer. Iran. Polym. J. 2013, 22, 293–302. [Google Scholar] [CrossRef]

- Ye, H.; Owh, C.; Jiang, S.; Ng, C.; Wirawan, D.; Loh, X. A thixotropic polyglycerol sebacate-based supramolecular hydrogel as an injectable drug delivery matrix. Polymers 2016, 8, 130. [Google Scholar] [CrossRef]

- Sun, Y.; Kaplan, J.A.; Shieh, A.; Sun, H.-L.; Croce, C.M.; Grinstaff, M.W.; Parquette, J.R. Self-assembly of a 5-fluorouracil-dipeptide hydrogel. Chem. Commun. 2016, 52, 5254–5257. [Google Scholar] [CrossRef] [PubMed]

- Raghavan, S.R.; Hou, J.; Baker, G.L.; Khan, S.A. Colloidal interactions between particles with tethered nonpolar chains dispersed in polar media: Direct correlation between dynamic rheology and interaction parameters. Langmuir 2000, 16, 1066–1077. [Google Scholar] [CrossRef]

- Yu, X.; Chen, X.; Chai, Q.; Ayres, N. Synthesis of polymer organogelators using hydrogen bonding as physical cross-links. Colloid Polym. Sci. 2016, 294, 59–68. [Google Scholar] [CrossRef]

- Li, J.; Harada, A.; Kamachi, M. Sol-gel transition during inclusion complex formation between α-cyclodextrin and high molecular weight poly(ethylene glycol)s in aqueous solution. Polym. J. 1994, 26, 1019–1026. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Ni, X.; Wang, X.; Li, H.; Leong, K.W. Self-assembled supramolecular hydrogels formed by biodegradable PEO–PHB–PEO triblock copolymers and α-cyclodextrin for controlled drug delivery. Biomaterials 2006, 27, 4132–4140. [Google Scholar] [CrossRef] [PubMed]

- Li, J. Self-assembled supramolecular hydrogels based on polymer–cyclodextrin inclusion complexes for drug delivery. NPG Asia Mater. 2010, 2, 112–118. [Google Scholar] [CrossRef]

- Ye, H.; Owh, C.; Loh, X.J. A thixotropic polyglycerol sebacate-based supramolecular hydrogel showing ucst behavior. RSC Adv. 2015, 5, 48720–48728. [Google Scholar] [CrossRef]

- Lucey, J.A.; Tamehana, M.; Singh, H.; Munro, P.A. Stability of model acid milk beverage: Effect of pectin concentration, storage temperature and milk heat treatment. J. Texture Stud. 1999, 30, 305–318. [Google Scholar] [CrossRef]

- Huh, K.M.; Ooya, T.; Lee, W.K.; Sasaki, S.; Kwon, I.C.; Jeong, S.Y.; Yui, N. Supramolecular-structured hydrogels showing a reversible phase transition by inclusion complexation between poly(ethylene glycol) grafted dextran and α-cyclodextrin. Macromolecules 2001, 34, 8657–8662. [Google Scholar] [CrossRef]

- Huh, K.M.; Cho, Y.W.; Chung, H.; Kwon, I.C.; Jeong, S.Y.; Ooya, T.; Lee, W.K.; Sasaki, S.; Yui, N. Supramolecular hydrogel formation based on inclusion complexation between poly(ethylene glycol)-modified chitosan and α-cyclodextrin. Macromol. Biosci. 2004, 4, 92–99. [Google Scholar] [CrossRef] [PubMed]

- Chee, P.L.; Prasad, A.; Fang, X.; Owh, C.; Yeo, V.J.J.; Loh, X.J. Supramolecular cyclodextrin pseudorotaxane hydrogels: A candidate for sustained release? Mater. Sci. Eng. 2014, 39, 6–12. [Google Scholar] [CrossRef] [PubMed]

- Kai, D.; Chua, Y.K.; Jiang, L.; Owh, C.; Chan, S.Y.; Loh, X.J. Dual functional anti-oxidant and SPF enhancing lignin-based copolymers as additives for personal and healthcare products. RSC Adv. 2016, 6, 86420–86427. [Google Scholar] [CrossRef]

| Sample | Td (°C) | Weight change (%) |

|---|---|---|

| Pectin | 86.33 | 8.95 |

| 253.33 | 80.82 | |

| 10KPEGMA | 418.07 | 99.02 |

| P-10K | 85.89 | 5.74 |

| 240.29 | 16.70 | |

| 421.19 | 62.91 |

| Sample | Gel |

|---|---|

| 10KPEGMA | ✗ |

| P-10K | ✓ |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chan, S.Y.; Choo, W.S.; Young, D.J.; Loh, X.J. Thixotropic Supramolecular Pectin-Poly(Ethylene Glycol) Methacrylate (PEGMA) Hydrogels. Polymers 2016, 8, 404. https://doi.org/10.3390/polym8110404

Chan SY, Choo WS, Young DJ, Loh XJ. Thixotropic Supramolecular Pectin-Poly(Ethylene Glycol) Methacrylate (PEGMA) Hydrogels. Polymers. 2016; 8(11):404. https://doi.org/10.3390/polym8110404

Chicago/Turabian StyleChan, Siew Yin, Wee Sim Choo, David James Young, and Xian Jun Loh. 2016. "Thixotropic Supramolecular Pectin-Poly(Ethylene Glycol) Methacrylate (PEGMA) Hydrogels" Polymers 8, no. 11: 404. https://doi.org/10.3390/polym8110404