Spectroscopic, Physical and Topography of Photochemical Process of PVC Films in the Presence of Schiff Base Metal Complexes

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Film Preparation

2.3. Accelerated Testing Technique

2.4. Photodegradation Measuring Methods

2.4.1. Measurement of Polymer Films Photodegradation Rate Using IR Spectrophotometry

2.4.2. Measuring the Photodegradation by Morphology Study

2.4.3. Determination of Average Molecular Weight Using Viscometry Method

3. Results and Discussion

3.1. FTIR Spectroscopy for PVC Films

3.2. Variation of PVC Molecular Weight during Photolysis

3.3. Surface Analysis

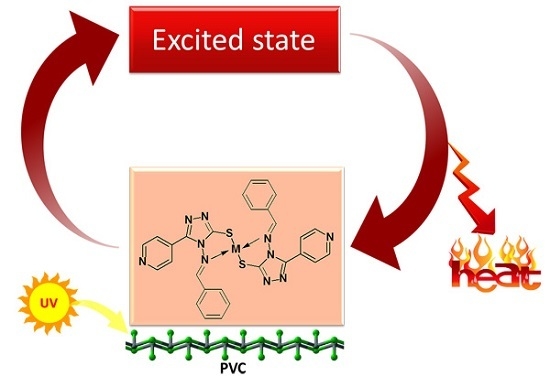

3.4. Suggested Mechanisms of PVC Photostabilization in the Presence of Additives

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Saeki, Y.; Emura, T. Technical progresses for PVC production. Prog. Polym. Sci. 2002, 27, 2055–2131. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, T.; Pi, H.; Guo, S. Mechanochemical preparation of a novel polymeric photostabilizer for poly(vinyl chloride). J. Appl. Polym. Sci. 2010, 116, 3079–3086. [Google Scholar] [CrossRef]

- Real, L.E.P.; Ferraria, A.M.; Botelho de Rego, A.M. Comparison of different photo-oxidation conditions of poly(vinyl chloride) for outdoor applications. Polym. Test. 2008, 27, 743–751. [Google Scholar] [CrossRef]

- Nicholson, J.W. The Chemistry of Polymers, 3rd ed.; RSC Pub.: Cambridge, UK, 2012. [Google Scholar]

- Decker, C. Degradation and Stabilisation of PVC; Owen, E.D., Ed.; Springer: Dordrecht, The Netherlands, 1984. [Google Scholar]

- Gewert, B.; Plassmann, M.M.; MacLeod, M. Pathways for degradation of plastic polymers floating in the marine environment. Environ. Sci. Process. Impact. 2015, 17, 1513–1521. [Google Scholar] [CrossRef] [PubMed]

- Blanchet, T. Handbook of Thermoplastics; Olabisi, O., Ed.; Marcel Dekker: New York, NY, USA, 1997. [Google Scholar]

- Yoshioka, T.; Kameda, T.; Ieshige, M.; Okuwaki, A. Dechlorination behaviour of flexible poly(vinyl chloride) in NaOH/EG solution. Polym. Degrad. Stab. 2008, 93, 1822–1825. [Google Scholar] [CrossRef]

- Shih, H.-K.; Chen, Y.H.; Chu, Y.L.; Cheng, C.-C.; Chang, F.-C.; Zhu, C.-Y.; Kuo, S.-W. Photo-crosslinking of pendent uracil units provides supramolecular hole injection/transport conducting polymers for highly efficient light-emitting diodes. Polymers 2015, 7, 804–818. [Google Scholar] [CrossRef]

- Griffini, G.; Bella, F.; Nisic, F.; Dragonetti, C.; Roberto, D.; Levi, M.; Bongiovanni, R.; Turri, S. Multifunctional luminescent down shifting fluoropolymer coatings: A straightforward strategy to improve the UV-Light harvesting ability and long term outdoor stability of organic dye sensitized solar cells. Adv. Energy Mater. 2015. [Google Scholar] [CrossRef]

- Bella, F.; Griffini, G.; Gerosa, M.; Turri, S.; Bongiovanni, R. Performance and stability improvements for dye-Sensitized solar cells in the presence of luminescent coatings. J. Power Sour. 2015, 283, 195–203. [Google Scholar] [CrossRef]

- Fouassier, J.P.; Lalevée, J. Photochemical production of interpenetrating polymer networks; simultaneous initiation of radical and cationic polymerization reactions. Polymers 2014, 6, 2588–2610. [Google Scholar] [CrossRef]

- Mosnáček, J.; Kundys, A.; Andicsová, A. Reversible-deactivation radical polymerization of methyl methacrylate induced by photochemical reduction of various copper catalysts. Polymers 2014, 6, 2862–2874. [Google Scholar] [CrossRef]

- Yousif, E.; Haddad, R. Photodegradation and photostabilization of polymers, especially polystyrene: Review. SpringerPlus 2013, 2, 398–460. [Google Scholar] [CrossRef] [PubMed]

- Buruaga, L.; Pomposo, J.A. Metal-Free polymethyl methacrylate (PMMA) nanoparticles by enamine “click” chemistry at room temperature. Polymers 2011, 3, 1673–1683. [Google Scholar] [CrossRef] [Green Version]

- Ratnam, C.T. Irradiation crosslinking of PVC-ENR blend effect of efficient radical scavenger. Plast. Rubber Compos. 2001, 30, 416–420. [Google Scholar] [CrossRef]

- Wypych, G. PVC Degradation and Stabilization; Chem Tec Publishing: Toronto, ON, Canada, 2008. [Google Scholar]

- Andrady, A.L.; Hamid, S.H.; Hu, X.; Torikai, A. Effects of increased solar ultraviolet radiation on materials. J. Photochem. Photobiol. B 1998, 46, 96–103. [Google Scholar] [CrossRef]

- Chmela, Š.; Lajoie, P.; Hrdlovič, P.; Lacoste, J. Combined oligomeric light and heat stabilizers. Polym. Degrad. Stab. 2000, 71, 171–177. [Google Scholar] [CrossRef]

- Smith, K.; El-Hiti, G.A.; Al-Zuhairi, A.J. The synthesis of polymeric sulfides by reaction of dihaloalkanes with sodium sulphide. J. Sulfur Chem. 2011, 32, 521–531. [Google Scholar] [CrossRef]

- Smith, K.; Balakit, A.A.; Pardasani, R.T.; El-Hiti, G.A. New polymeric sulfide–borane complexes: Convenient hydroborating and reducing reagents. J. Sulfur Chem. 2011, 32, 287–295. [Google Scholar] [CrossRef]

- Smith, K.; Balakit, A.A.; El-Hiti, G.A. Poly(propylene sulfide)-borane: Convenient and versatile reagent for organic synthesis. Tetrahedron 2012, 68, 7834–7839. [Google Scholar] [CrossRef]

- Smith, K.; Al-Zuhairi, A.J.; El-Hiti, G.A.; Alshammari, M.B. Comparison of cyclic and polymeric disulfides as catalysts for the regioselective chlorination of phenols. J. Sulfur Chem. 2015, 36, 74–85. [Google Scholar] [CrossRef]

- Yousif, E.; El-Hiti, G.A.; Hussain, Z.; Altaie, A. Viscoelastic, spectroscopic and microscopic study of the photo irradiation effect on the stability of PVC in the presence of sulfamethoxazole Schiff’s bases. Polymers 2015, 7, 2190–2204. [Google Scholar] [CrossRef]

- Balakit, A.A.; Ahmed, A.; El-Hiti, G.A.; Smith, K.; Yousif, E. Synthesis of new thiophene derivatives and their use as photostabilizers for rigid poly(vinyl chloride). Int. J. Polym. Sci. 2015. [Google Scholar] [CrossRef]

- Yousif, E.; El-Hiti, G.A.; Haddad, R.; Balakit, A.A. Photochemical stability and photostabilizing efficiency of poly(methyl methacrylate) based on 2-(6-methoxynaphthalen-2-yl)propanoate metal ion complexes. Polymers 2015, 7, 1005–1019. [Google Scholar] [CrossRef]

- Yousif, E.; Haddad, R.; Ameer, A.B.; Win, Y.-F. Ultra-violet spectra studies of photodegradation of PVC films in presence of Fe(III) chelate complex. Eur. J. Chem. 2014, 5, 607–611. [Google Scholar] [CrossRef]

- Yousif, E.; Abdallh, M.; Hashim, H.; Salih, N.; Salimon, J.; Abdullah, B.M.; Win, Y.-F. Optical properties of pure and modified poly(vinyl chloride). Int. J. Ind. Chem. 2013. [Google Scholar] [CrossRef]

- Koparir, M.; Koparir, P.; Cansiz, A.; Temuz, M.M. Synthesis of some 5-substituted-1,2,4-triazole-3-thiones, containing thiourea, arylidenamino and morpholin-4-yl methyl fragments. Asian J. Chem. 2010, 22, 6059–6066. [Google Scholar]

- Hasan, A.; Ameer, A.; Ahmed, A.; Yousif, E. Synthesis and characterization of some transition metal (II) complexes with 1,2,4-triazole Schiff base. J. Chem. Pharm. Res. 2015, 7, 531–535. [Google Scholar]

- Kwiatkowski, E.; Kwiatkowski, M. Unsymmetrical Schiff base complexes of nickel(II) and palladium(II). Inorg. Chim. Acta 1980, 42, 197–202. [Google Scholar] [CrossRef]

- Joseyphus, R.S.; Nair, M.S. Synthesis, characterization and biological studies of some Co(II), Ni(II) and Cu(II) complexes derived from indole-3-carboxaldehyde and glycylglycine as Schiff base ligand. Arab. J. Chem. 2010, 3, 195–204. [Google Scholar] [CrossRef]

- Akila, E.; Usharani, M.; Ramachandran, S.; Jayaseelan, P.; Velraj, G.; Rajavel, R. Tetradentate-arm Schiff base derived from the condensation reaction of 3,30-dihydroxybenzidine, glyoxal/diacetyl and 2-aminophenol: Designing, structural elucidation and properties of their binuclear metal(II) complexes. Arab. J. Chem. 2013. [Google Scholar] [CrossRef]

- Osowole, A.A. Synthesis, characterization, and magnetic and thermal studies on some metal(II) thiophenyl Schiff base complexes. Int. J. Inorg. Chem. 2011. [Google Scholar] [CrossRef]

- Shneshil, M.K.; Redayan, M.A. Photostabilization of PVC films by using some novel tetra Schiff’s bases derived from1,2,4,5-tetra-[5-amino-1,3,4-thiadiazole-2-yl]benzene. Diyala J. Pure Sci. 2011, 7, 34–47. [Google Scholar]

- Yousif, E.A.; Hameed, A.S.; Bakir, E.T. Synthesis and photochemical study of poly(vinyl chloride)-1,3,4-oxadiazole and 1,3,4-thiadiazole. J. Al-Nahrain Univ. 2007, 10, 7–12. [Google Scholar]

- Rabek, J.; Ranby, B. Photodegradation, Photooxidation and Photostabilization of Polymers; John Wiley: New York, NY, USA, 1975. [Google Scholar]

- Mark, J. Physical Properties of Polymers Handbook; Springer: New York, NY, USA, 2007. [Google Scholar]

- Geuskens, G. Photodegradation of polymers. In Comprehensive Chemical Kinetics; Compton, R.G., Bamford, C.H., Tipper, C.F.H., Eds.; Elsevier: Amsterdam, The Netherlands, 1975; Volume 14, pp. 333–424. [Google Scholar]

- Mori, F.; Koyama, M.; Oki, Y. Studies on photodegradation of poly(vinyl chloride (part I). Die Angew. Makromol. Chem. 1977, 64, 89–99. [Google Scholar] [CrossRef]

- Scott, G. Polymers and Ecological Problems; Plennm Press: New York, NY, USA, 1973; Volume 3, pp. 27–35. [Google Scholar]

- Gugumus, F. Mechanism of Polymer Degradation and Stabilization; Elsevier: Amsterdam, The Netherlands, 1990. [Google Scholar]

- Shyichuk, A.V.; White, J.R. Analysis of chain-scission and crosslinking rates on the photooxidation of polystyrene. J. Appl. Polym. Sci. 2000, 77, 3015–3023. [Google Scholar] [CrossRef]

- Yousif, E.A.; Aliwi, S.M.; Ameer, A.A.; Ukal, J.R. Improved photostability of PVC films in the presence of 2-thioacetic acid-5-phenyl-1,3,4-oxadiazole complexes. Turk. J. Chem. 2009, 33, 399–410. [Google Scholar]

- Kara, F.; Aksoy, E.; Yuksekdagd, Z.; Hasirci, N.; Aksoy, S. Synthesis and surface modification of polyurethanes with chitosan forantibacterial properties. Carbohydr. Polym. 2014, 112, 39–47. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.-G.; Tang, L.-H.; Zhang, N.; Gao, Q.-H.; Zhang, C.-F.; Zhu, Z.-B. Dehydrochlorination of PVC materials at high temperature. Energ. Fuels 2003, 17, 896–900. [Google Scholar] [CrossRef]

- Starnes, W.H.; Du, B.; Kim, S.; Zaikov, V.G.; Ge, X.; Culyba, E.K. Thermal stabilization and plasticization of poly(vinyl chloride) by ester thiols: Update and current status. Thermochim. Acta 2006, 442, 78–80. [Google Scholar] [CrossRef]

- Folarin, O.M.; Sadiku, E.R. Thermal stabilizers for poly(vinyl chloride): A review. Int. J. Phys. Sci. 2011, 6, 4323–4330. [Google Scholar]

- Yousif, E.; Bakir, E.; Salimon, J.; Salih, N. Evaluation of Schiff bases of 2,5-dimercapto-1,3,4-thiadiazole as photostabilizer for poly(methyl methacrylate). J. Saudi Chem. Soc. 2012, 16, 279–285. [Google Scholar] [CrossRef]

- Pospíšil, J.; Klemchuk, P.P. Oxidation Inhibition in Organic Materials; CRC Press: Boca Raton, FL, USA, 1989; Volume 1, pp. 48–49. [Google Scholar]

| PVC Film (0.5 wt %) | Quantum Yield of Main Chain Scission (Φcs) |

|---|---|

| PVC | 4.65 × 10−6 |

| PVC + CuL2 | 2.19 × 10−6 |

| PVC + CdL2 | 8.69 × 10−7 |

| PVC + ZnL2 | 4.19 × 10−7 |

| PVC + SnL2 | 1.93 × 10−7 |

| PVC + NiL2 | 1.15 × 10−7 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yousif, E.; Hasan, A.; El-Hiti, G.A. Spectroscopic, Physical and Topography of Photochemical Process of PVC Films in the Presence of Schiff Base Metal Complexes. Polymers 2016, 8, 204. https://doi.org/10.3390/polym8060204

Yousif E, Hasan A, El-Hiti GA. Spectroscopic, Physical and Topography of Photochemical Process of PVC Films in the Presence of Schiff Base Metal Complexes. Polymers. 2016; 8(6):204. https://doi.org/10.3390/polym8060204

Chicago/Turabian StyleYousif, Emad, Ali Hasan, and Gamal A. El-Hiti. 2016. "Spectroscopic, Physical and Topography of Photochemical Process of PVC Films in the Presence of Schiff Base Metal Complexes" Polymers 8, no. 6: 204. https://doi.org/10.3390/polym8060204