3.1. Electrochemical Polymerization

The polarization curves of neat TTPA, DIT, and BDTA monomers, and the mixture of two monomers (TTPA + DIT and TTPA + BDTA) in 0.1 M LiClO

4/ACN are shown in

Figure 1. PTTPA showed

Eonset and oxidation peak at 0.79 and 1.16 V, respectively (

Figure 1a). On the other hand, the

Eonset of PDIT and PBDTA films were 0.68 and 0.73 V, respectively, and the oxidation peaks of PDIT and PBDTA films were 0.90 and 0.97 V, respectively (

Figure 1b,c). When the CVs were scanned in 0.1 M LiClO

4/ACN solution containing two monomers (2 mM TTPA + 2 mM DIT and 2 mM TTPA + 2 mM BDTA), the CVs’ shape and redox peaks observed in

Figure 1d,e are different to those of PTTPA, PDIT, and PBDTA homopolymer films, demonstrating the formation of copolymers. The electrosynthetic routes of P(TTPA-

co-DIT) and P(TTPA-

co-BDTA) are shown in

Figure 2.

Copolymer films P(TTPA-

co-DIT) and P(TTPA-

co-BDTA) prepared by constant potential deposition at 1.0 V were scanned at different rates in the range from 25 to 200 mV·s

−1 in 0.1 M LiClO

4/ACN solution. As can be seen in

Figure 3a and

Figure 4a, the P(TTPA-

co-DIT) and P(TTPA-

co-BDTA) presented two well-defined redox peaks, the current density response increased with the increasing of the scan rate, indicating that the copolymer films had good electrochemical activity and were adhered well to the electrode. With the increasing scan rate, the anodic and cathodic peak current densities showed a linear dependence on the scan rate as illustrated in

Figure 3b and

Figure 4b, demonstrating that the redox process of the copolymers were not limited by diffusion control [

33].

3.2. Electrochromic Properties of the Copolymer Films

Spectroelectrochemistry combines electrochemical and spectroscopic methods for investigating the changes in the absorption spectra upon applying of an external electrical potential. Spectroelectrochemistry of P(TTPA-

co-DIT) and P(TTPA-

co-BDTA) copolymer films coated on ITO electrode was studied in an ionic liquid solution.

Figure 5 displayed the spectroelectrochemical spectra of P(TTPA-

co-DIT) film at various potentials in EPIDIL solution. The copolymer films were prepared potentiostatically at 1.0 V, 1.1 V, and 1.2 V (see

Figure 5a–c, respectively). As shown in

Figure 5a and

Table 1, the peak of P(TTPA-

co-DIT) film in the neutral state was found at 388 nm, which corresponded to the π–π * transition of P(TTPA-

co-DIT) in EPIDIL solution. Upon applying more than 0.8 V, the absorbance of π–π * transition peak of P(TTPA-

co-DIT) decreased gradually and charge carrier bands appeared in higher wavelength region, which corresponded to the development of polaron and bipolaron bands [

34]. When the P(TTPA-

co-DIT) film was prepared potentiostatically at 1.1 V and 1.2 V, the π–π * transition of P(TTPA-

co-DIT) film did not shift significantly. However, the position of polaron peak with maximal absorbance changes shifted conspicuously upon applying various potentials, this can be ascribed to adherent polymer films undergo configuration changes during electrochemical overoxidation [

35]. The π–π * transition of P(TTPA-

co-BDTA) film in EPIDIL solution located at similar position with P(TTPA-

co-DIT) film, whereas the polaron peak positions of P(TTPA-

co-BDTA) film with maximal absorbance shifted bathochromically relative to those of P(TTPA-

co-DIT) film upon applying various potentials (

Figure 6), which could be attributed to an electron-withdrawing 1,2,5-thiadiazole unit in BDTA unit showed narrower band gap in EPIDIL solution than that of DIT unit.

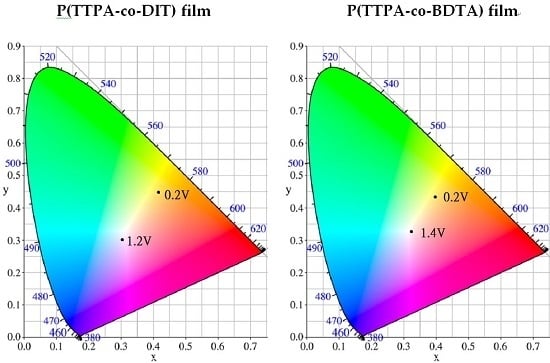

Table 2 shows the photographs and colorimetric values (L*, a*, b*) of the copolymer films at various potentials in EPIDIL solution. The P(TTPA-

co-DIT) film was yellow (0.2 V) in the neutral state, yellowish-green (0.8 V) and green (1.0 V) in the intermediate state, and blue (1.2 V) in highly oxidized state. The P(TTPA-

co-BDTA) film showed less color changes than those of P(TTPA-

co-DIT) film, P(TTPA-

co-BDTA) film was yellow (0.2 V) in the neutral state, bluish-green (1.0 V) in the intermediate state, and blue (1.2 V) in highly oxidized state, indicating the incorporation of DIT unit into copolymer backbone gives rise to more color changes than that of BDTA unit.

A square-wave potential step technology coupled with a UV-Visible spectrophotometer was used for analysis of switching kinetics and optical contrast of the copolymer films [

36]. The P(TTPA-

co-DIT) and P(TTPA-

co-BDTA) films were stepped by repeated potential between neutral state (0.2 V) and oxidized state (+1.2 V) with a time interval of 5 s in an ionic liquid solution. The

in situ transmittance–time profiles of P(TTPA-

co-DIT) and P(TTPA-

co-BDTA) films in EPIDIL solution are displayed in

Figure 7, and the optical contrast (∆

T) estimated at 1st, 50th, and 100th cycles are summarized in

Table 3. For P(TTPA-

co-DIT) film prepared potentiostatically at 1.0 V, 1.1 V, and 1.2 V, the ∆

T of P(TTPA-

co-DIT)-1.0 V, P(TTPA-

co-DIT)-1.1 V, and P(TTPA-

co-DIT)-1.2 V films at first cycle are 60.3, 55.6, and 49.4%, respectively, and P(TTPA-

co-DIT) film prepared potentiostatically at 1.0 V shows the highest ∆

T. For the Δ

T of copolymer films at different switching cycles, the Δ

T of P(TTPA-

co-DIT)-1.0 V film from the bleaching state to the coloration state in EPIDIL solution was 60.3, 58.8 and 57.1%, respectively, at 1st, 50th, and 100th cycle. However, the Δ

T of P(TTPA-

co-DIT)-1.2 V film from the bleaching state to the coloration state in EPIDIL solution was 49.4, 43.2 and 42.6%, respectively, at 1st, 50th, and 100th cycle. The stability of P(TTPA-

co-DIT)-1.0 V and P(TTPA-

co-DIT)-1.2 V films at the 100th cycle was 94.7 and 86.2%, respectively, and the P(TTPA-

co-DIT)-1.0 V film shows higher stability than that of P(TTPA-

co-DIT)-1.2 V film at high switching cycles, which can be attributed to an overoxidation of the copolymer takes place when electropolymerization at high potential (

i.e., in highly oxidized state). The Δ

T of P(TTPA-

co-DIT)-1.0 V and P(TTPA-

co-BDTA)-1.0 V films from the bleaching state to the coloration state in EPIDIL solution were 60.3 and 47.1%, respectively, at the first cycle, implying P(TTPA-

co-DIT) film shows higher Δ

T than that of P(TTPA-

co-BDTA) film. The stability of P(TTPA-

co-DIT)-1.0 V and P(TTPA-

co-BDTA)-1.0 V films at the 100

th cycle was 94.7 and 85.6%, respectively, revealing the P(TTPA-

co-DIT) film shows higher stability than that of P(TTPA-

co-BDTA) film at high switching cycles.

The coloration switching time (τ

c) and the bleaching switching time (τ

b) of copolymer films estimated at 1st, 50th, and 100th cycles are also summarized in

Table 3. The switching time was estimated at 90% of the full-transmittance variation. P(TTPA-

co-BDTA) film shows shorter τ

c and τ

b than those of P(TTPA-

co-DIT) film, revealing that P(TTPA-

co-BDTA) film exhibits fast switching speeds from the dedoped to the doped state and from the doped to the dedoped state when we employ EPIDIL as a supporting electrolyte. The Δ

Tmax of P(TTPA-

co-DIT)-1.0 V and P(TTPA-

co-BDTA)-1.0 V films are higher than that reported for PTTPA derivative (P(TTPA-

co-EDOT)) [

37], and higher than those reported for PSNS derivatives (PTEPA [

38], PSNS-1-NAPH [

39], and P(SNS-Fc-

co-EDOT) [

40]). This could be ascribed to the fact that Δ

Tmax of P(TTPA-

co-DIT)-1.0 V and P(TTPA-

co-BDTA)-1.0 V films were estimated in long wavelength region (1042–1096 nm) when we employed EPIDIL as a supporting electrolyte.

ΔOD is the discrepancy of optical density, which can be estimated using the transmittance of the oxidation state (

Tox) and neutral state (

Tneu) using the following equation:

The ΔODmax of P(TTPA-co-DIT)-1.0 V film at 1042 nm and P(TTPA-co-BDTA)-1.0 V film at 1096 nm in EPIDIL solution are 80 and 49%, respectively. Similar to ΔTmax, P(TTPA-co-DIT)-1.0 V film showed higher ΔODmax than that of P(TTPA-co-BDTA)-1.0 V film.

The coloration efficiency (η) at a specific wavelength can be defined as the ΔOD for the charge (

q) consumed per unit electrode area (

A):

As shown in

Table 4, the η

max of P(TTPA-

co-DIT)-1.0 V film at 1042 nm and P(TTPA-

co-BDTA)-1.0 V film at 1096 nm in EPIDIL solution are 181.9 and 217.8 cm·C

−1, respectively, which were higher than those reported for PTEPA [

38] at 448 nm and PSNS-1-NAPH [

39] at 423 nm.

3.3. Spectroelectrochemistry of ECDs

Dual type ECDs consisting of electrochemically deposited P(TTPA-

co-DIT)-1.0 V/PProDOT-Et

2 and P(TTPA-

co-BDTA)-1.0 V/PProDOT-Et

2 were constructed and their spectroelectrochemical behaviors were studied by recording the optical absorbance spectra at various potentials. ECDs showed a reversible response in a potential range of −0.4 V and 1.2 V, as depicted in

Figure 8. At −0.4 V, P(TTPA-

co-DIT)-1.0 V/PProDOT-Et

2 and P(TTPA-

co-BDTA)-1.0 V/PProDOT-Et

2 ECDs revealed well defined transitions at

ca. 382 and 424 nm, respectively, which are in accordance with the spectral behaviors of P(TTPA-

co-DIT)-1.0 V and P(TTPA-

co-BDTA)-1.0 V films in reduced state. However, in this situation, the complementary PProDOT-Et

2 layer is expected to be in oxidized state and it does not show significant transition in UV spectrum. Upon increasing the potential gradually, P(TTPA-

co-DIT)-1.0 V and P(TTPA-

co-BDTA)-1.0 V films begin to oxidize and a new absorption band at 588 nm appeared due to neutralization of the PProDOT-Et

2 layer, and the ECDs were blue in the potential range of +0.8 and 1.2 V for P(TTPA-

co-DIT)-1.0 V/PProDOT-Et

2 ECD and in the potential range of +1.0 and 1.4 V for P(TTPA-

co-BDTA)-1.0 V/PProDOT-Et

2 ECD (

Table 5).

The transmittance–time profiles of P(TTPA-

co-DIT)-1.0 V/PProDOT-Et

2 and P(TTPA-

co-BDTA)-1.0 V/PProDOT-Et

2 ECDs were shown in

Figure 9, which were stepped by repeated potential in the range of neutral (− 0.2 V) and oxidized states (+1.2 V) with a time interval of 5 s, and the Δ

T, τ

c, and τ

b estimated at different double-step potential cycles are summarized in

Table 6. The Δ

T of P(TTPA-

co-DIT)-1.0 V/PProDOT-Et

2 and P(TTPA-

co-BDTA)-1.0 V/PProDOT-Et

2 ECDs is 43.5 and 48.1% at the first cycle, respectively, implying P(TTPA-

co-BDTA) film is a promising electrochromic material to increase the Δ

T when we employ P(TTPA-

co-BDTA) film as anodic copolymer layer in ECDs. For P(TTPA-

co-BDTA) film was prepared potentiostatically at 1.0 V, 1.1 V, and 1.2 V, the ∆

T of P(TTPA-

co-BDTA)-1.0 V/PProDOT-Et

2, P(TTPA-

co-BDTA)-1.1 V/PProDOT-Et

2, and P(TTPA-

co-BDTA)-1.2 V/PProDOT-Et

2 ECDs at first cycle are 48.1, 35.6, and 30.1%, respectively, and P(TTPA-

co-BDTA) film prepared potentiostatically at 1.0 V shows the highest ∆

T. The stability of P(TTPA-

co-DIT)-1.0 V/PProDOT-Et

2 and P(TTPA-

co-DIT)-1.2 V/PProDOT-Et

2 ECDs at the 100th cycle was 96.3 and 90.8%, respectively, indicating the P(TTPA-

co-DIT)-1.0 V/PProDOT-Et

2 ECD shows higher stability than that of P(TTPA-

co-DIT)-1.2 V/PProDOT-Et

2 ECD at high switching cycles. Moreover, the stability of P(TTPA-

co-BDTA)-1.0 V/PProDOT-Et

2 ECD is higher than P(TTPA-

co-DIT)-1.0 V/PProDOT-Et

2 ECD, and the stabilities of ECDs are high than those of copolymer films in an ionic liquid solution. For the optical switching time of P(TTPA-

co-DIT)/PProDOT-Et

2 and P(TTPA-

co-BDTA)/PProDOT-Et

2 ECDs, the

τc and

τb of the ECDs were shorter than those of copolymer films in EPIDIL solution, displaying the ECDs changed color faster upon applying potentials than the copolymer films in EPIDIL solution.

Table 7 shows the Δ

Tmax, ΔOD

max, and

ηmax of P(TTPA-

co-DIT)/PProDOT-Et

2 and P(TTPA-

co-BDTA)/PProDOT-Et

2 ECDs and reported dual-type ECDs, P(TTPA-

co-DIT)/PProDOT-Et

2 and P(TTPA-

co-BDTA)/PProDOT-Et

2 ECDs show higher Δ

Tmax than those reported for P(SNS-HE)/PEDOT [

41], PTEPA/PEDOT [

38], P(TTPA-

co-BT)/PEDOT [

42], P(TTPA-

co-EDOT)/PEDOT [

37], and P(Cz4-

co-CIn1)/PProDOT-Me

2 [

43] ECDs. In another aspect, P(TTPA-

co-BDTA)/PProDOT-Et

2 ECD shows higher

η than that of P(TTPA-

co-DIT)/PProDOT-Et

2 ECD. P(TTPA-

co-BDTA)/PProDOT-Et

2 ECD shows higher

η than those reported for PTEPA/PEDOT [

38], P(TTPA-

co-EDOT)/PEDOT [

37], and P(Cz4-

co-CIn1)/PProDOT-Me

2 ECDs [

43], whereas P(TTPA-

co-BDTA)/PProDOT-Et

2 ECD shows lower η than that reported for P(SNS-HE)/PEDOT [

41] ECD.