Biocompatible Silk/Polymer Energy Harvesters Using Stretched Poly (vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP) Nanofibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Polymer Materials

2.1.1. Preparation of PVDF-HFP Solvents and PDMS

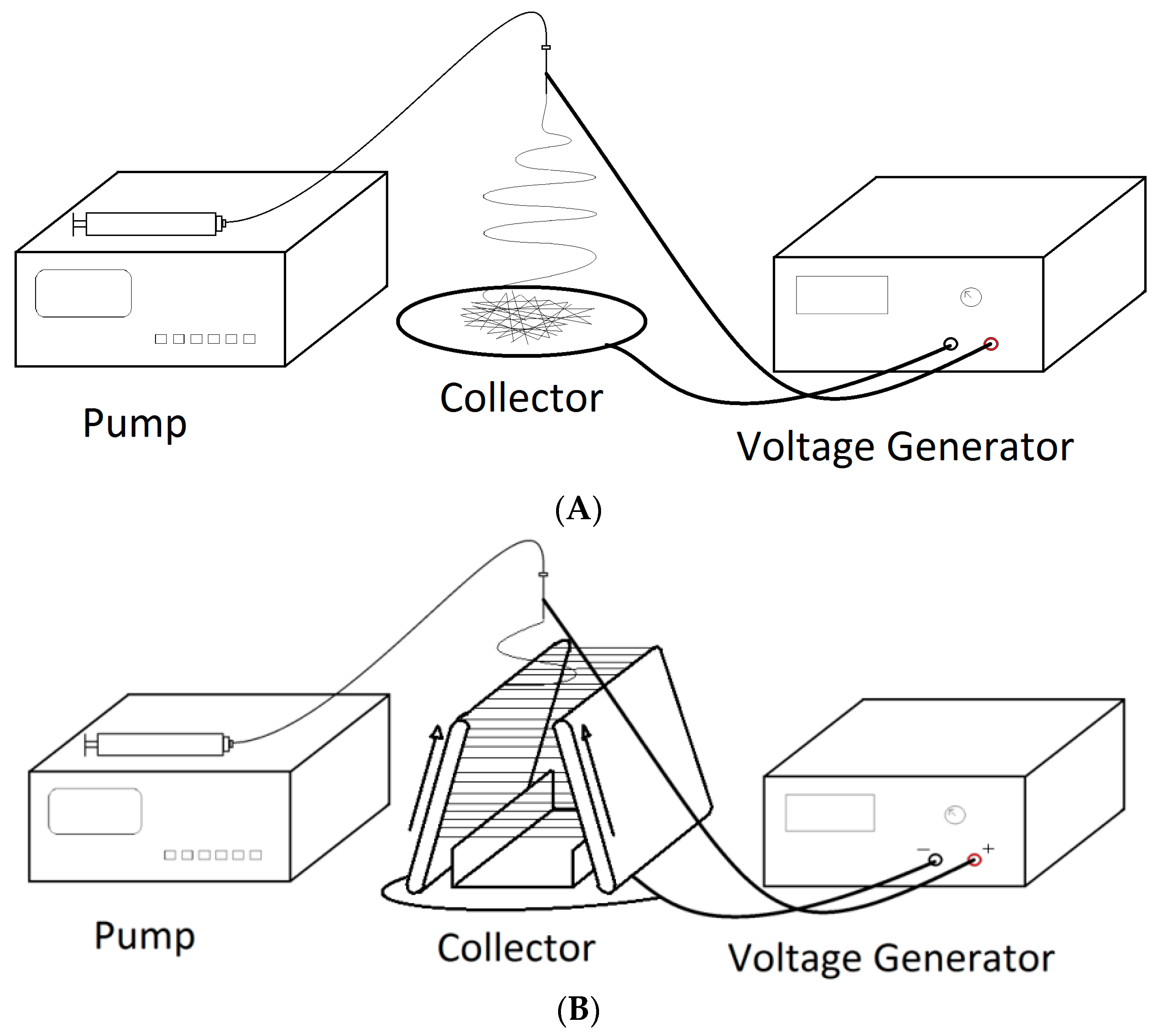

2.1.2. Electrospinning and Stretching of PVDF-HFP Nanofibers

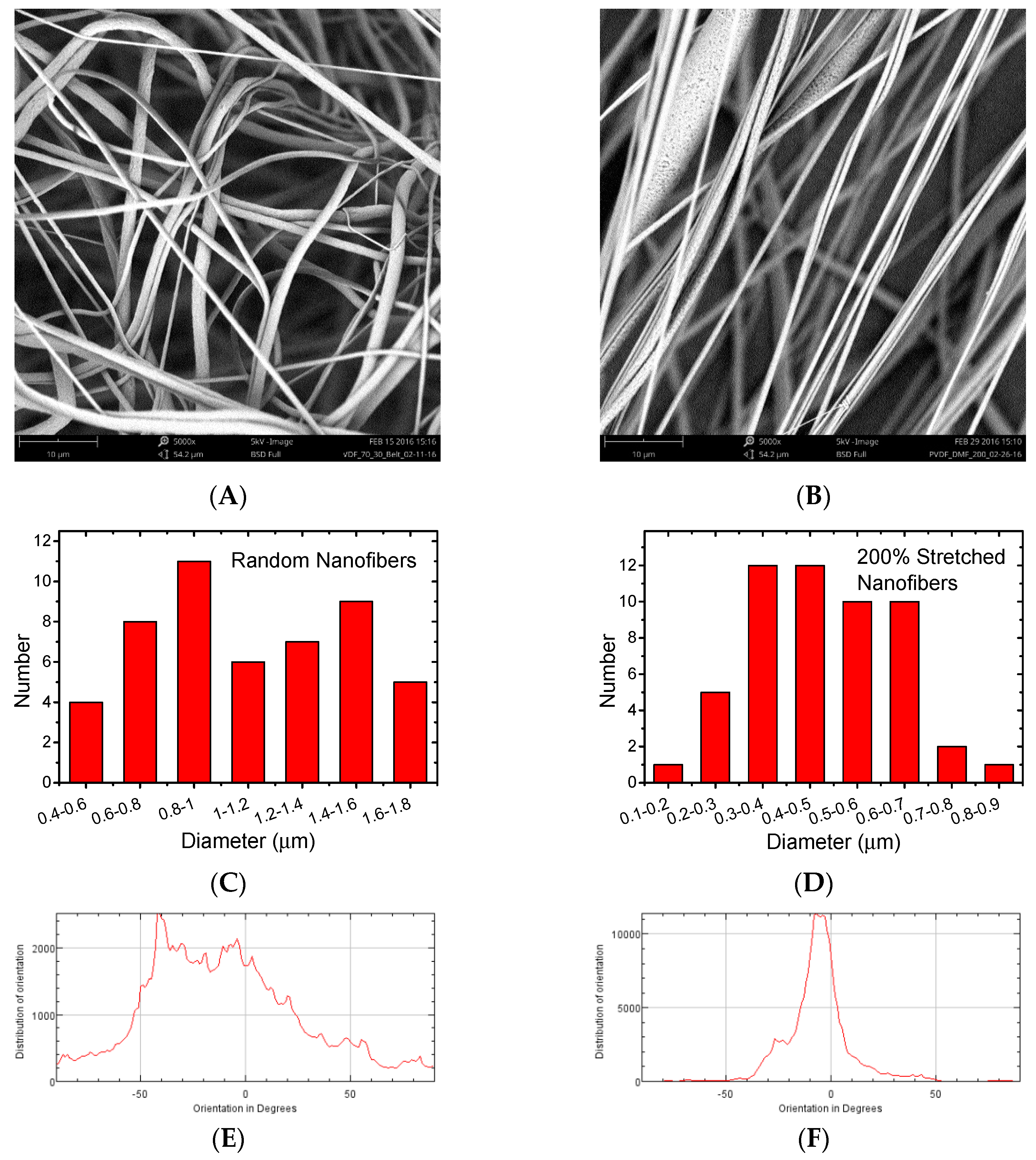

2.1.3. Scanning Electron Microscopy (SEM) Inspection and Quantitative Analysis of Nanofibers

2.2. Silk Materials

2.2.1. Preparation of Silk and Silk-Glycerol Solutions

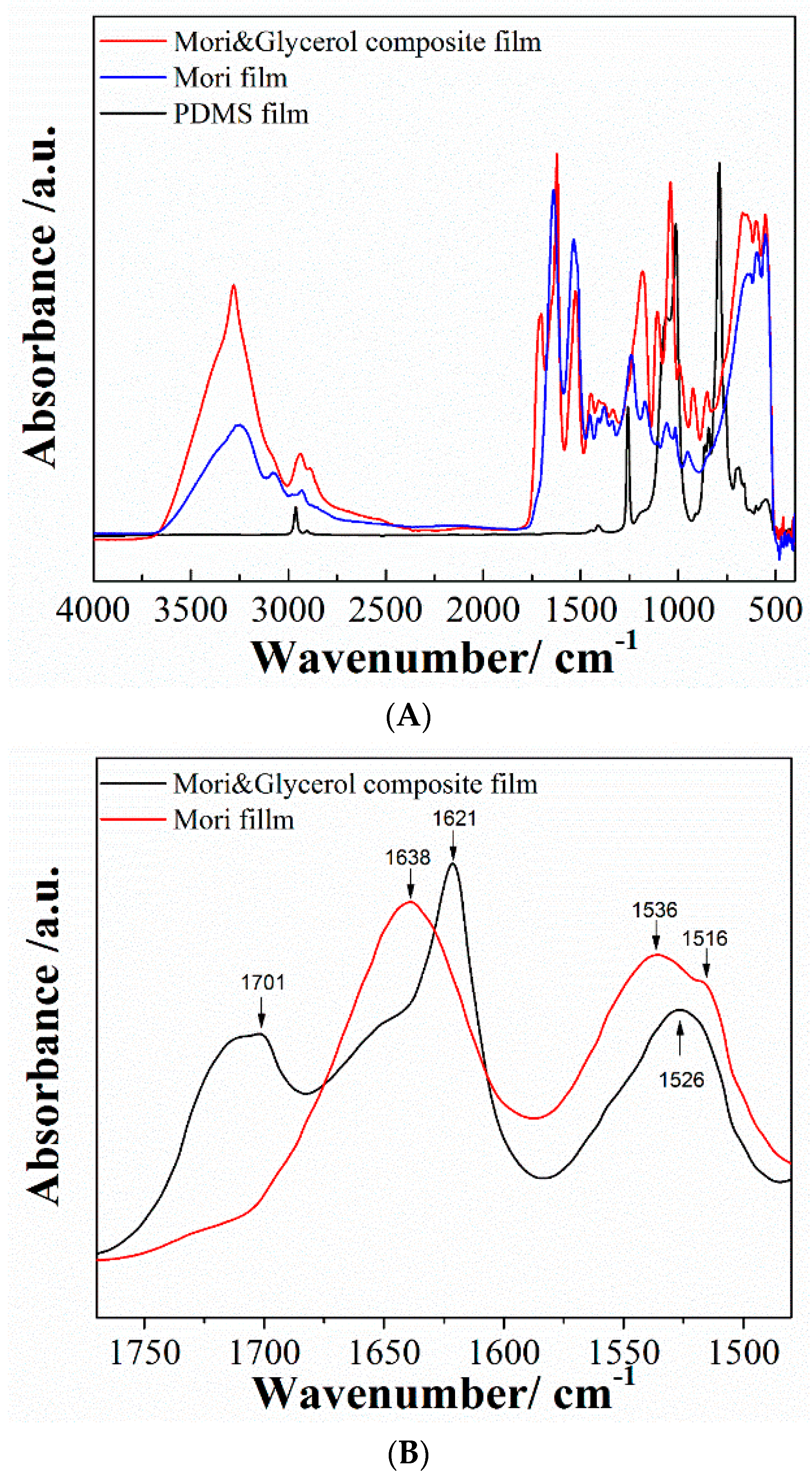

2.2.2. Fourier Transform Infrared Spectroscopy (FTIR) Analysis

2.2.3. Differential Scanning Calorimetry (DSC) Analysis

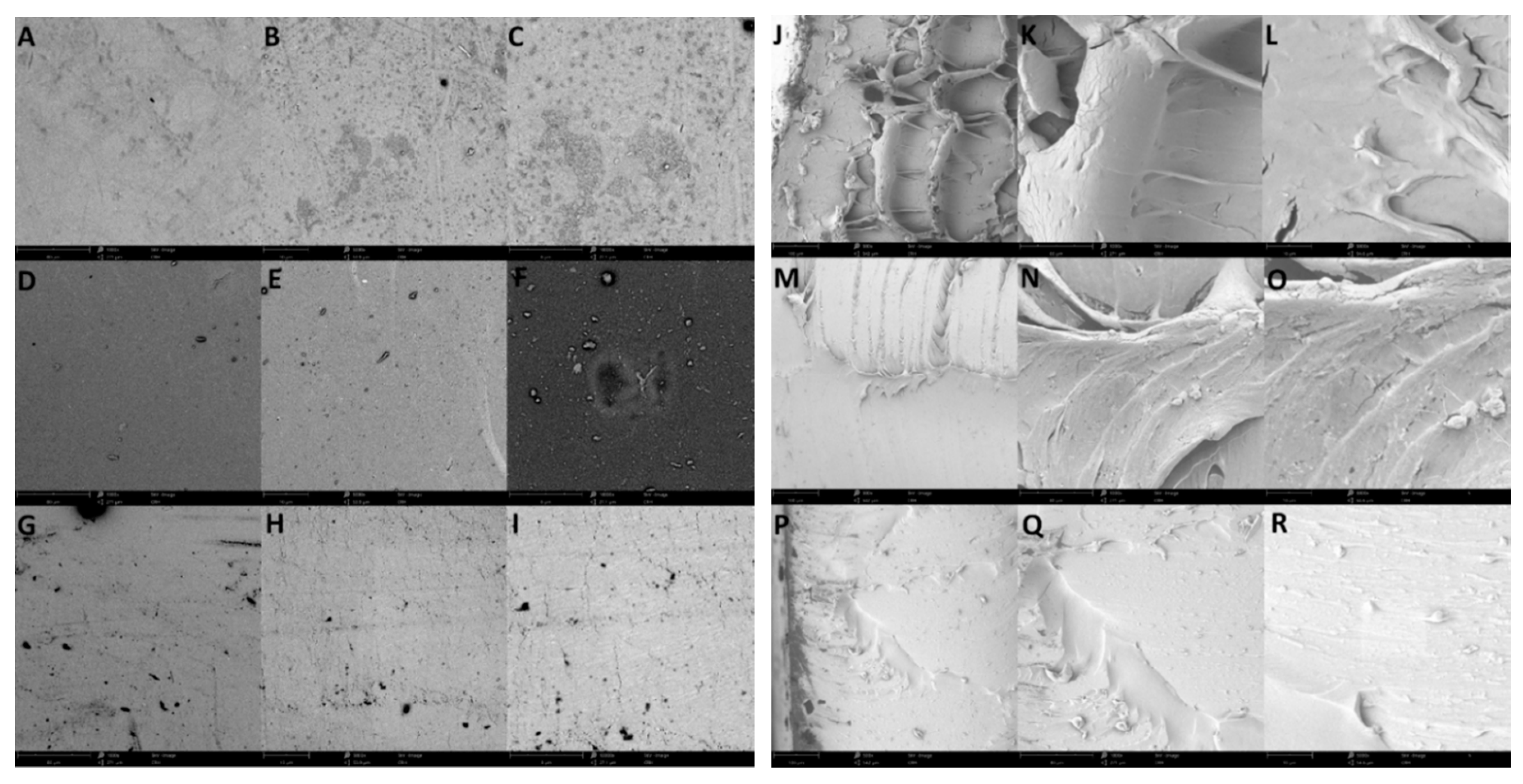

2.2.4. SEM Imaging

2.3. Mechanical Property Characterization

2.4. Energy Harvester Design and Assembly

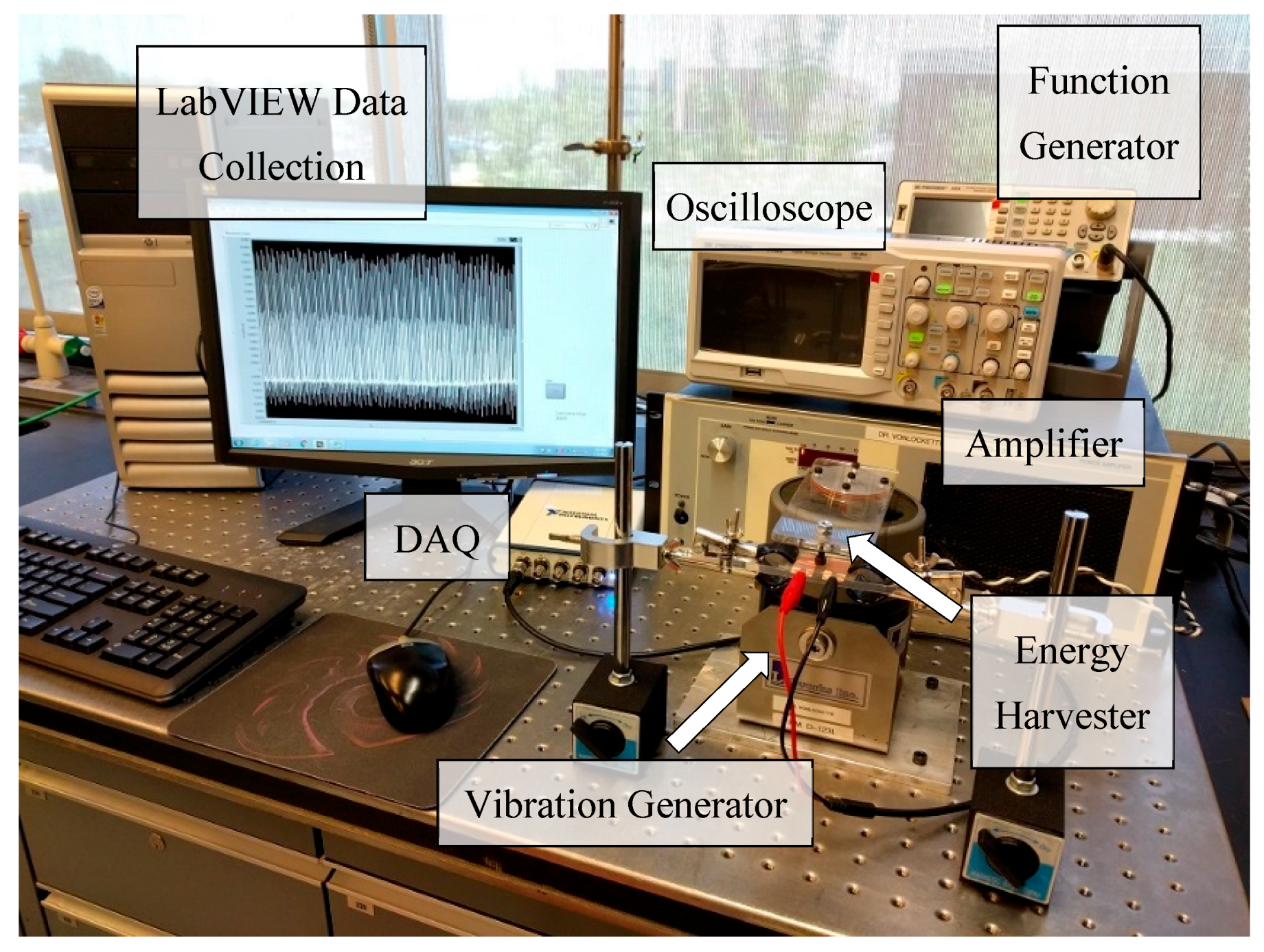

2.5. Mechanical-Electrical Experimental System Setup

3. Results and Discussion

3.1. Material Characterization

3.1.1. SEM Imaging

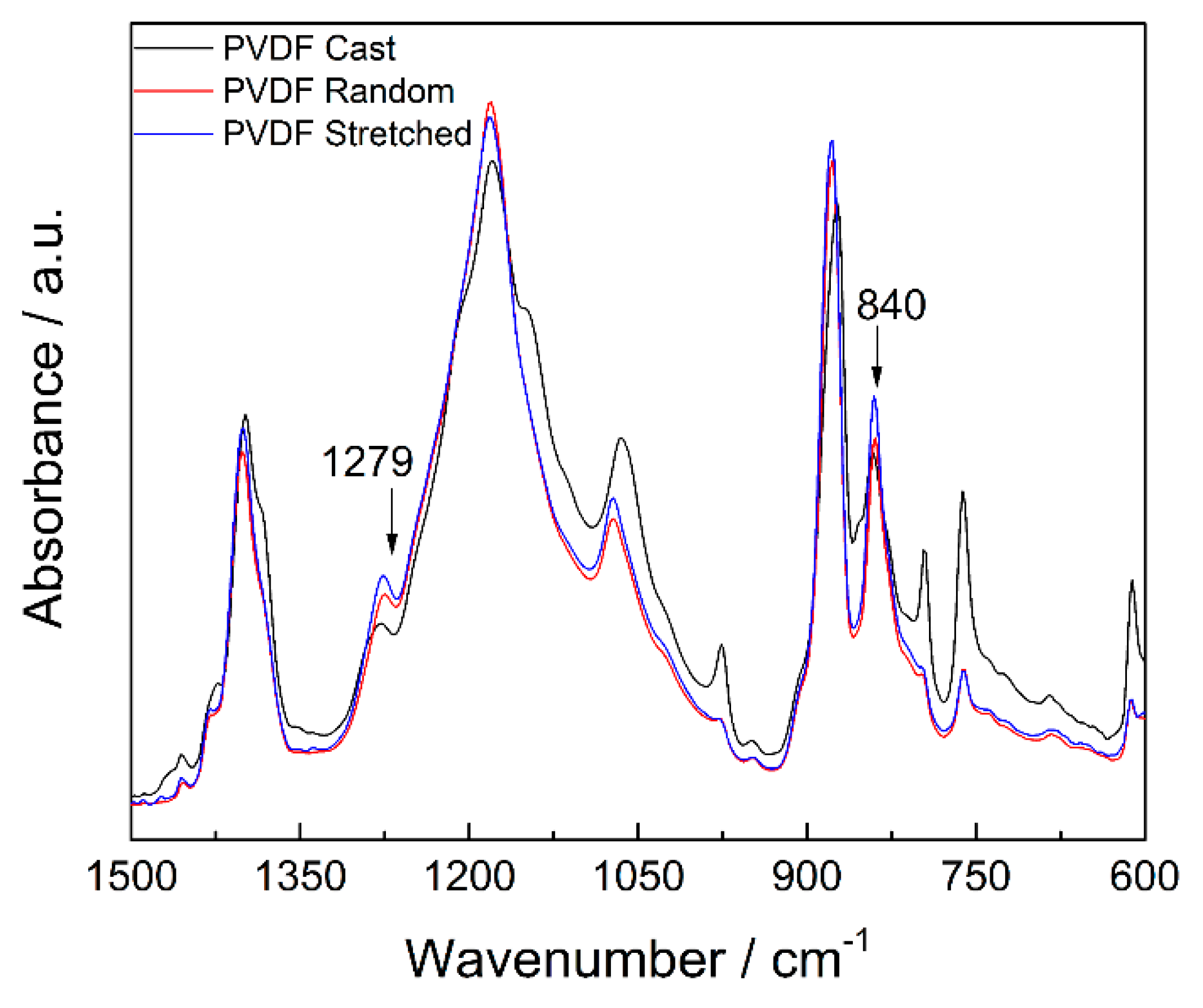

3.1.2. FTIR Analysis

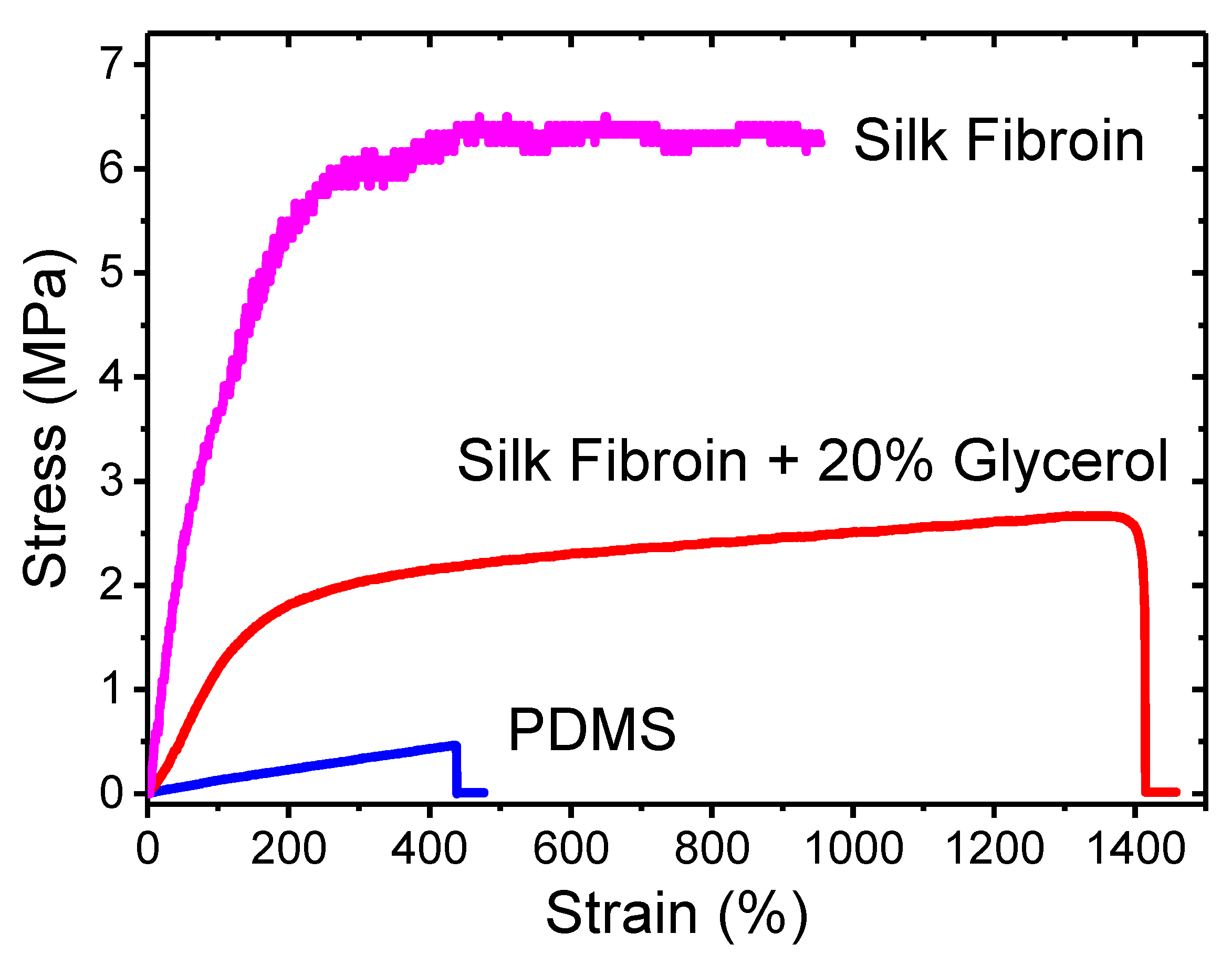

3.1.3. Mechanical Property Characterization

3.2. PVDF-HFP Nanofibers

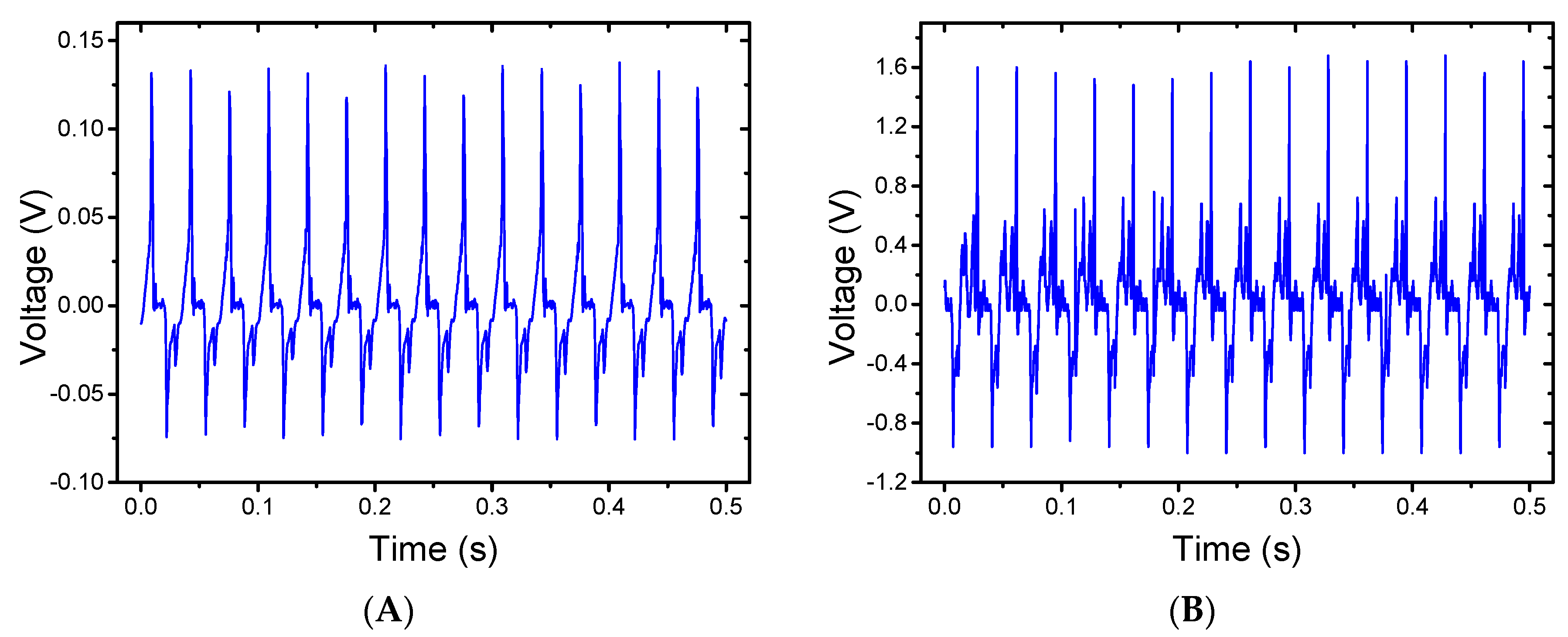

3.3. Energy Harvesting Measurement

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Steven, R.A.; Henry, A.S. A review of power harvesting using piezoelectric materials (2003–2006). Smart Mater. Struct. 2007, 16, R1. [Google Scholar]

- Qi, Y.; McAlpine, M.C. Nanotechnology-enabled flexible and biocompatible energy harvesting. Energy Environ. Sci. 2010, 3, 1275–1285. [Google Scholar] [CrossRef]

- Chang, J.; Dommer, M.; Chang, C.; Lin, L. Piezoelectric nanofibers for energy scavenging applications. Nano Energy 2012, 1, 356–371. [Google Scholar] [CrossRef]

- Shu, Y.; Lien, I. Analysis of power output for piezoelectric energy harvesting systems. Smart Mater. Struct. 2006, 15, 1499. [Google Scholar] [CrossRef]

- Fukada, E. History and recent progress in piezoelectric polymers. IEEE Tran. Ultrason. Ferroelectr. Freq. Control 2000, 47, 1277–1290. [Google Scholar] [CrossRef] [PubMed]

- Tressler, J.F. Piezoelectric sensors and sensor materials. J. Electroceram. 1998, 2, 257–272. [Google Scholar] [CrossRef]

- Cook-Chennault, K.A.; Thambi, N.; Sastry, A.M. Powering mems portable devices—A review of non-regenerative and regenerative power supply systems with special emphasis on piezoelectric energy harvesting systems. Smart Mater. Struct. 2008, 17, 043001. [Google Scholar] [CrossRef]

- Beeby, S.P.; Tudor, M.J.; White, N.M. Energy harvesting vibration sources for microsystems applications. Meas. Sci. Technol. 2006, 17, R175. [Google Scholar] [CrossRef]

- Panda, P.K. Review: Environmental friendly lead-free piezoelectric materials. J. Mater. Sci. 2009, 44, 5049–5062. [Google Scholar] [CrossRef]

- Shrout, T.R.; Zhang, S.J. Lead-free piezoelectric ceramics: Alternatives for pzt? J. Electroceram. 2007, 19, 113–126. [Google Scholar] [CrossRef]

- Kolb, E.D.; Laudise, R.A. Properties of lithium-doped hydrothermally grown single crystals of zinc oxide. J. Am. Ceram. Soc. 1965, 48, 342–345. [Google Scholar] [CrossRef]

- Huan, Y.; Liu, Y.; Yang, Y. Simultaneous stretching and static electric field poling of poly (vinylidene fluoride-hexafluoropropylene) copolymer films. Polym. Eng. Sci. 2007, 47, 1630–1633. [Google Scholar] [CrossRef]

- Wu, L.; Huang, G.; Hu, N.; Fu, S.; Qiu, J.; Wang, Z.; Ying, J.; Chen, Z.; Li, W.; Tang, S. Improvement of the piezoelectric properties of pvdf-hfp using agnws. RSC Adv. 2014, 4, 35896–35903. [Google Scholar] [CrossRef]

- Moggi, G.; Bonardelli, P.; Bart, J.C.J. Synthesis and properties of some hexafluoropropene-1,1-difluoroethene copolymers. Polym. Bull. 1982, 7, 115–122. [Google Scholar]

- Dodds, J.S.; Meyers, F.N.; Loh, K.J. Piezoelectric characterization of pvdf-trfe thin films enhanced with zno nanoparticles. IEEE Sens. J. 2012, 12, 1889–1890. [Google Scholar] [CrossRef]

- Lallart, M.; Cottinet, P.J.; Lebrun, L.; Guiffard, B.; Guyomar, D. Evaluation of energy harvesting performance of electrostrictive polymer and carbon-filled terpolymer composites. J. Appl. Phys. 2010, 108, 034901. [Google Scholar] [CrossRef]

- Bhavanasi, V.; Kumar, V.; Parida, K.; Wang, J.; Lee, P.S. Enhanced piezoelectric energy harvesting performance of flexible pvdf-trfe bilayer films with graphene oxide. ACS Appl. Mater. Interfaces 2016, 8, 521–529. [Google Scholar] [CrossRef] [PubMed]

- Martins, P.; Lopes, A.; Lanceros-Mendez, S. Electroactive phases of poly (vinylidene fluoride): Determination, processing and applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- Braga, F.J.C.; Rogero, S.O.; Couto, A.A.; Marques, R.F.C.; Ribeiro, A.A.; Campos, J.S.D.C. Characterization of pvdf/hap composites for medical applications. Mater. Res. 2007, 10, 247–251. [Google Scholar] [CrossRef]

- Fang, J.; Wang, X.; Lin, T. Electrical power generator from randomly oriented electrospun poly (vinylidene fluoride) nanofibre membranes. J. Mater. Chem. 2011, 21, 11088–11091. [Google Scholar] [CrossRef]

- Huang, Z.-M.; Zhang, Y.Z.; Kotaki, M.; Ramakrishna, S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar] [CrossRef]

- Baker, J.; Roundy, S.; Wright, P. Alternative geometries for increasing power density in vibration energy scavenging for wireless sensor networks. In Proceedings of the 3rd International Energy Conversion Engineering Conference, San Francisco, CA, USA, 15–18 August 2005; pp. 959–970. [Google Scholar]

- Starner, T. Human-powered wearable computing. IBM Syst. J. 1996, 35, 618–629. [Google Scholar] [CrossRef]

- Ishida, K.; Huang, T.-C.; Honda, K.; Shinozuka, Y.; Fuketa, H.; Yokota, T.; Zschieschang, U.; Klauk, H.; Tortissier, G.; Sekitani, T. Insole pedometer with piezoelectric energy harvester and 2 v organic circuits. IEEE J. Solid State Circuits 2013, 48, 255–264. [Google Scholar] [CrossRef]

- Jonathan, G.; Joel, F.; Henry, A.S.; Kevin, F. Energy harvesting from a backpack instrumented with piezoelectric shoulder straps. Smart Mater. Struct. 2007, 16, 1810. [Google Scholar]

- Kundu, B.; Kurland, N.E.; Yadavalli, V.K.; Kundu, S.C. Isolation and processing of silk proteins for biomedical applications. Int. J. Biol. Macromol. 2014, 70, 70–77. [Google Scholar] [CrossRef] [PubMed]

- Kundu, B.; Kurland, N.E.; Bano, S.; Patra, C.; Engel, F.B.; Yadavalli, V.K.; Kundu, S.C. Silk proteins for biomedical applications: Bioengineering perspectives. Prog. Polym. Sci. 2014, 39, 251–267. [Google Scholar] [CrossRef]

- Koh, L.-D.; Cheng, Y.; Teng, C.-P.; Khin, Y.-W.; Loh, X.-J.; Tee, S.-Y.; Low, M.; Ye, E.; Yu, H.-D.; Zhang, Y.-W.; et al. Structures, mechanical properties and applications of silk fibroin materials. Prog. Polym. Sci. 2015, 46, 86–110. [Google Scholar] [CrossRef]

- Minoura, N.; Tsukada, M.; Nagura, M. Physico-chemical properties of silk fibroin membrane as a biomaterial. Biomaterials 1990, 11, 430–434. [Google Scholar] [CrossRef]

- Lu, S.; Wang, X.; Lu, Q.; Zhang, X.; Kluge, J.A.; Uppal, N.; Omenetto, F.; Kaplan, D.L. Insoluble and flexible silk films containing glycerol. Biomacromolecules 2010, 11, 143–150. [Google Scholar] [CrossRef]

- Beachley, V.; Wen, X. Effect of electrospinning parameters on the nanofiber diameter and length. Mater. Sci. Eng. A 2009, 29, 663. [Google Scholar] [CrossRef]

- Beachley, V.; Wen, X. Polymer nanofibrous structures: Fabrication, biofunctionalization, and cell interactions. Prog. Polym. Sci. 2010, 35, 868–892. [Google Scholar] [CrossRef] [PubMed]

- Beachley, V.; Wen, X. Fabrication of nanofiber reinforced protein structures for tissue engineering. Mater. Sci. Eng. C 2009, 29, 2448–2453. [Google Scholar] [CrossRef] [PubMed]

- Brennan, D.A.; Jao, D.; Siracusa, M.C.; Wilkinson, A.R.; Hu, X.; Beachley, V.Z. Concurrent collection and post-drawing of individual electrospun polymer nanofibers to enhance macromolecular alignment and mechanical properties. Polymer 2016, 103, 243–250. [Google Scholar] [CrossRef]

- Chang, C.; Tran, V.H.; Wang, J.; Fuh, Y.-K.; Lin, L. Direct-write piezoelectric polymeric nanogenerator with high energy conversion efficiency. Nano Lett. 2010, 10, 726–731. [Google Scholar] [CrossRef] [PubMed]

- Pu, J.; Yan, X.; Jiang, Y.; Chang, C.; Lin, L. Piezoelectric actuation of direct-write electrospun fibers. Sens. Actuators A 2010, 164, 131–136. [Google Scholar] [CrossRef]

- Liu, Z.H.; Pan, C.T.; Lin, L.W.; Huang, J.C.; Ou, Z.Y. Direct-write pvdf nonwoven fiber fabric energy harvesters via the hollow cylindrical near-field electrospinning process. Smart Mater. Struct. 2014, 23, 025003. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Najjar, R.; Luo, Y.; Jao, D.; Brennan, D.; Xue, Y.; Beachley, V.; Hu, X.; Xue, W. Biocompatible Silk/Polymer Energy Harvesters Using Stretched Poly (vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP) Nanofibers. Polymers 2017, 9, 479. https://doi.org/10.3390/polym9100479

Najjar R, Luo Y, Jao D, Brennan D, Xue Y, Beachley V, Hu X, Xue W. Biocompatible Silk/Polymer Energy Harvesters Using Stretched Poly (vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP) Nanofibers. Polymers. 2017; 9(10):479. https://doi.org/10.3390/polym9100479

Chicago/Turabian StyleNajjar, Raghid, Yi Luo, Dave Jao, David Brennan, Ye Xue, Vince Beachley, Xiao Hu, and Wei Xue. 2017. "Biocompatible Silk/Polymer Energy Harvesters Using Stretched Poly (vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP) Nanofibers" Polymers 9, no. 10: 479. https://doi.org/10.3390/polym9100479