Effect of Moisture on Mechanical Properties and Thermal Stability of Meta-Aramid Fiber Used in Insulating Paper

Abstract

:1. Introduction

2. Model Calculation and Parameter Analysis

2.1. Modeling

2.2. Molecular Dynamics Analog Calculation

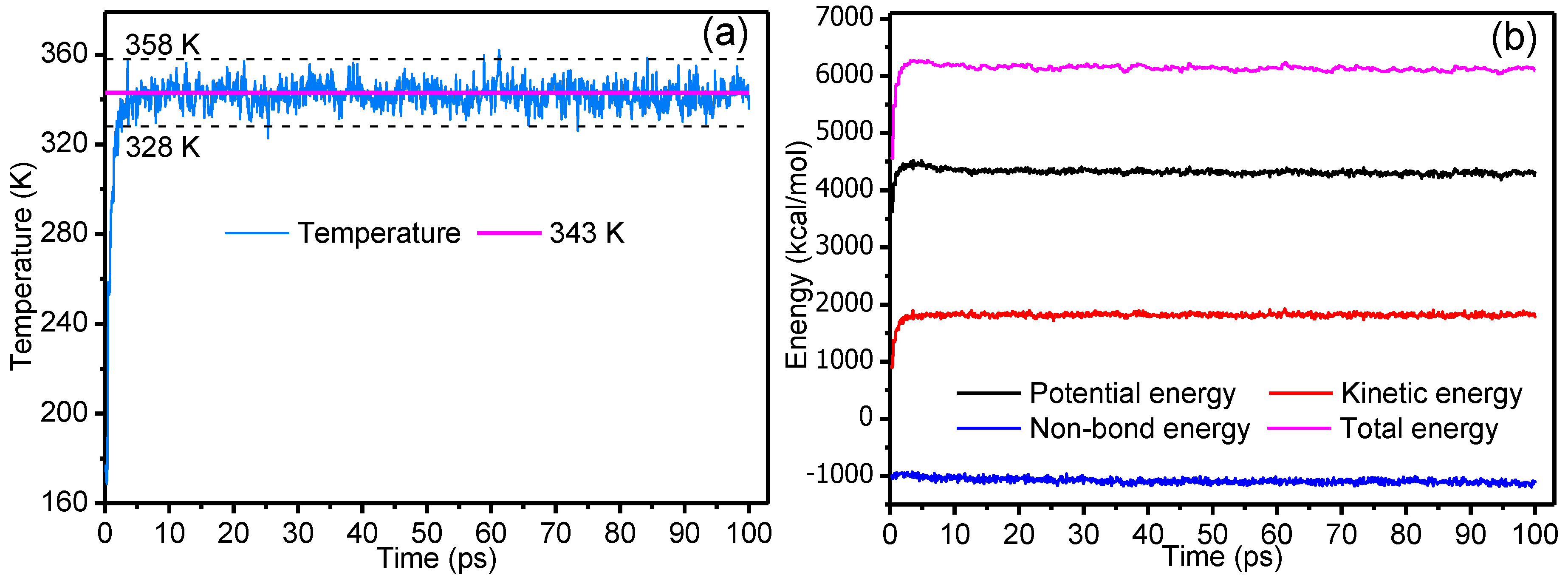

2.3. Rationality of Parameter Settings

3. Results and Discussion

3.1. Effect of Temperature

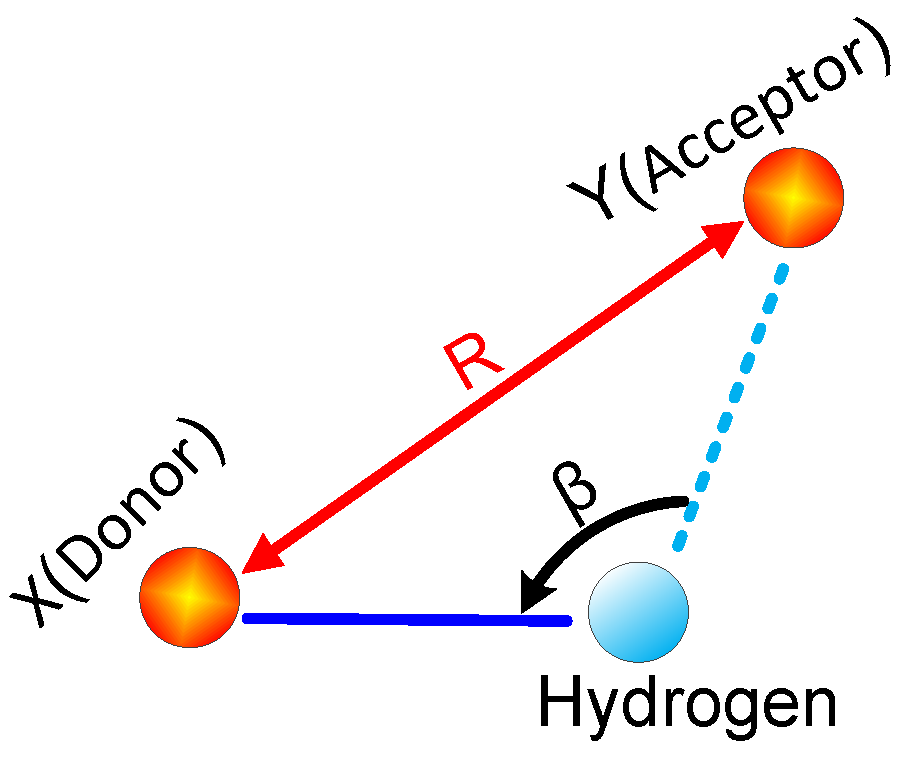

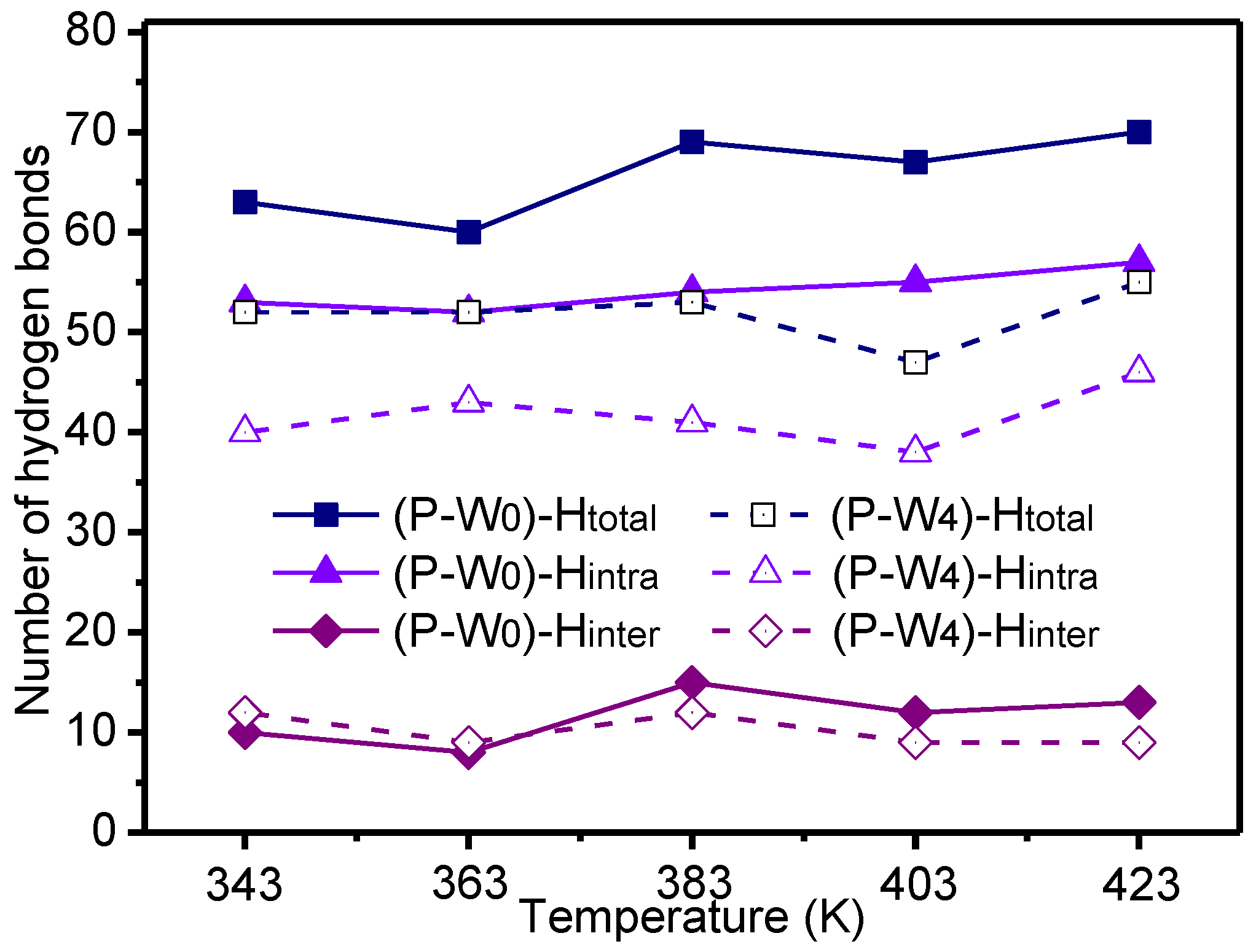

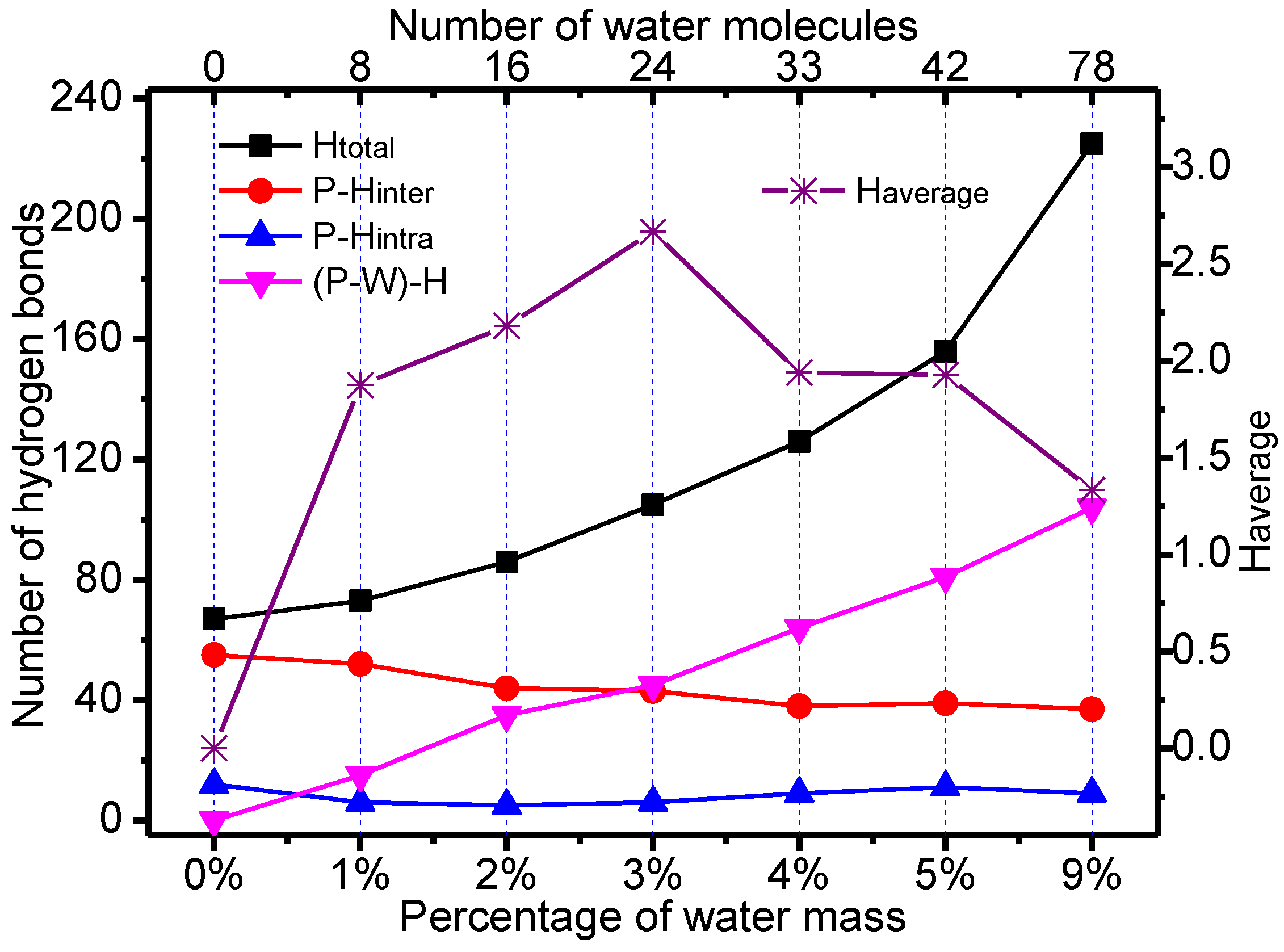

3.2. Analysis of Hydrogen Bonds

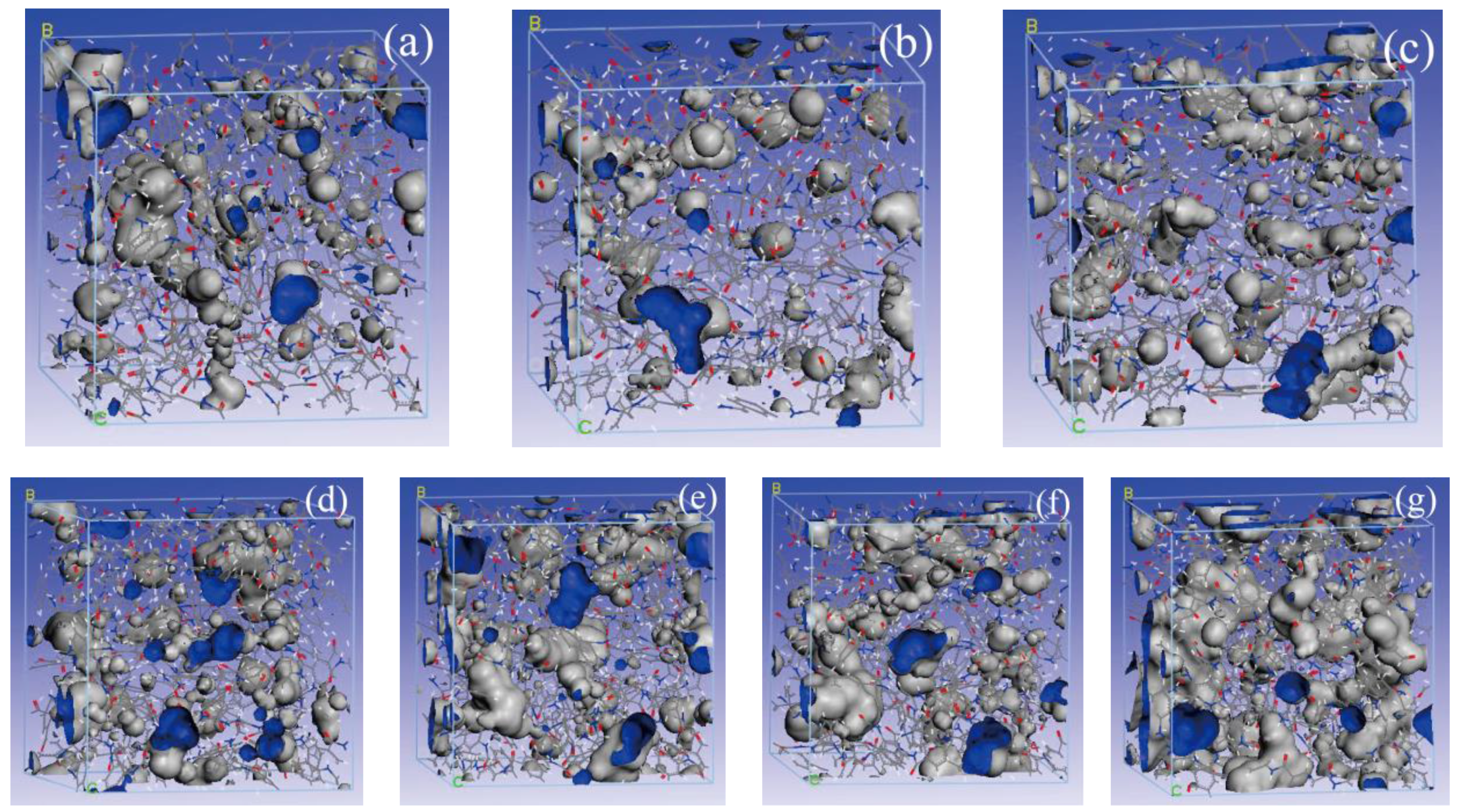

3.3. Free Volume

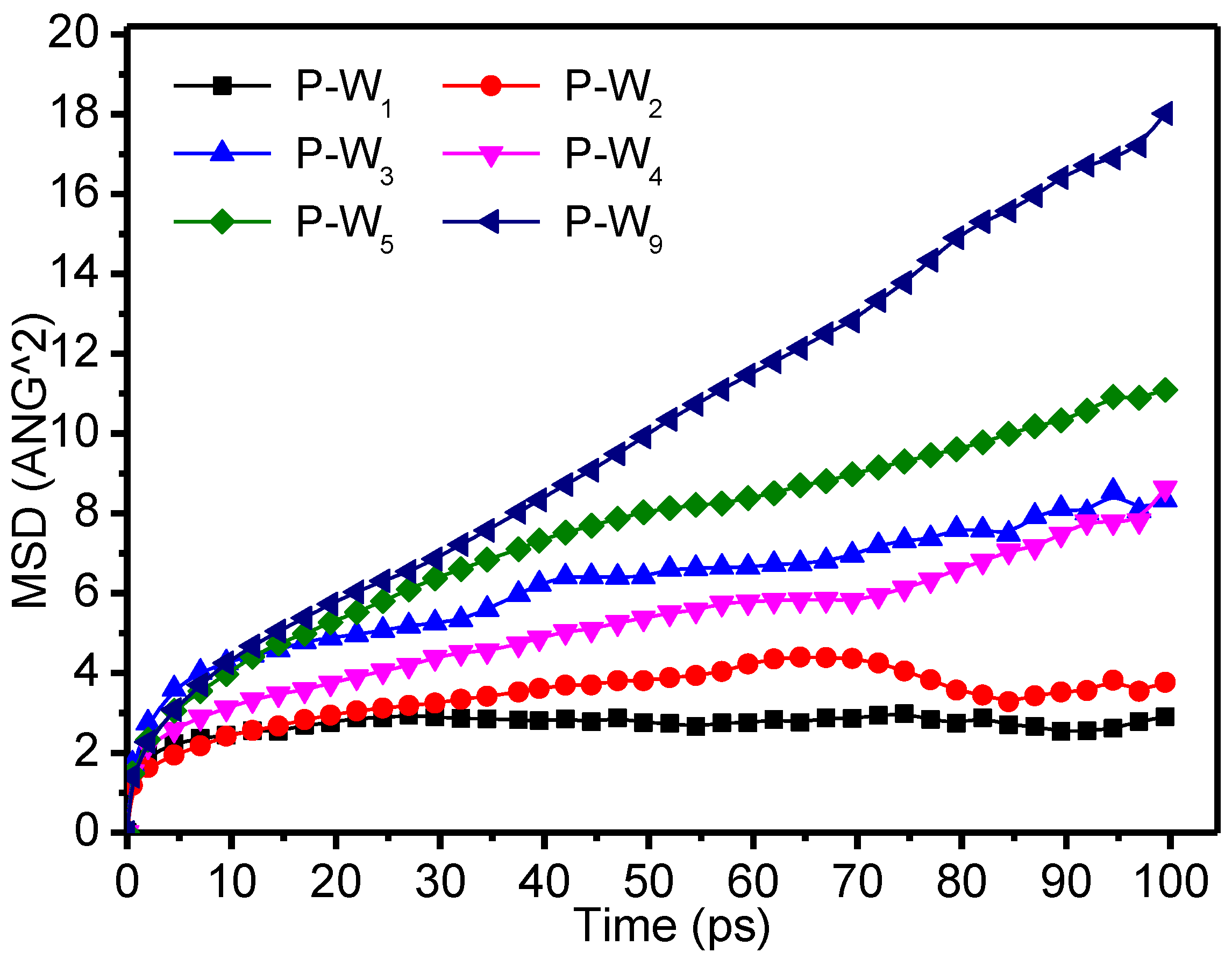

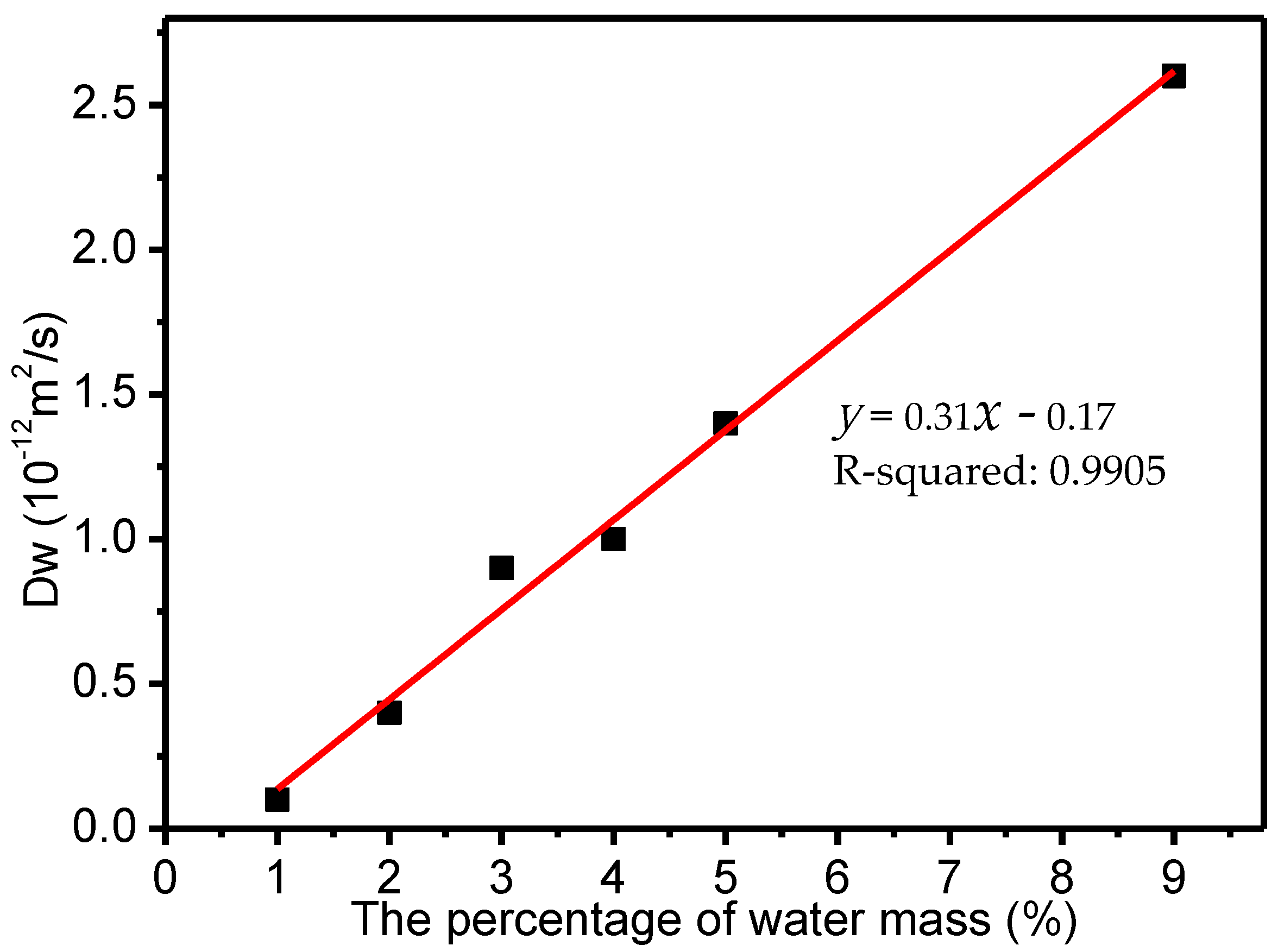

3.4. Thermal Stability of Meta-Aramid Fibers and Water Molecule Diffusion

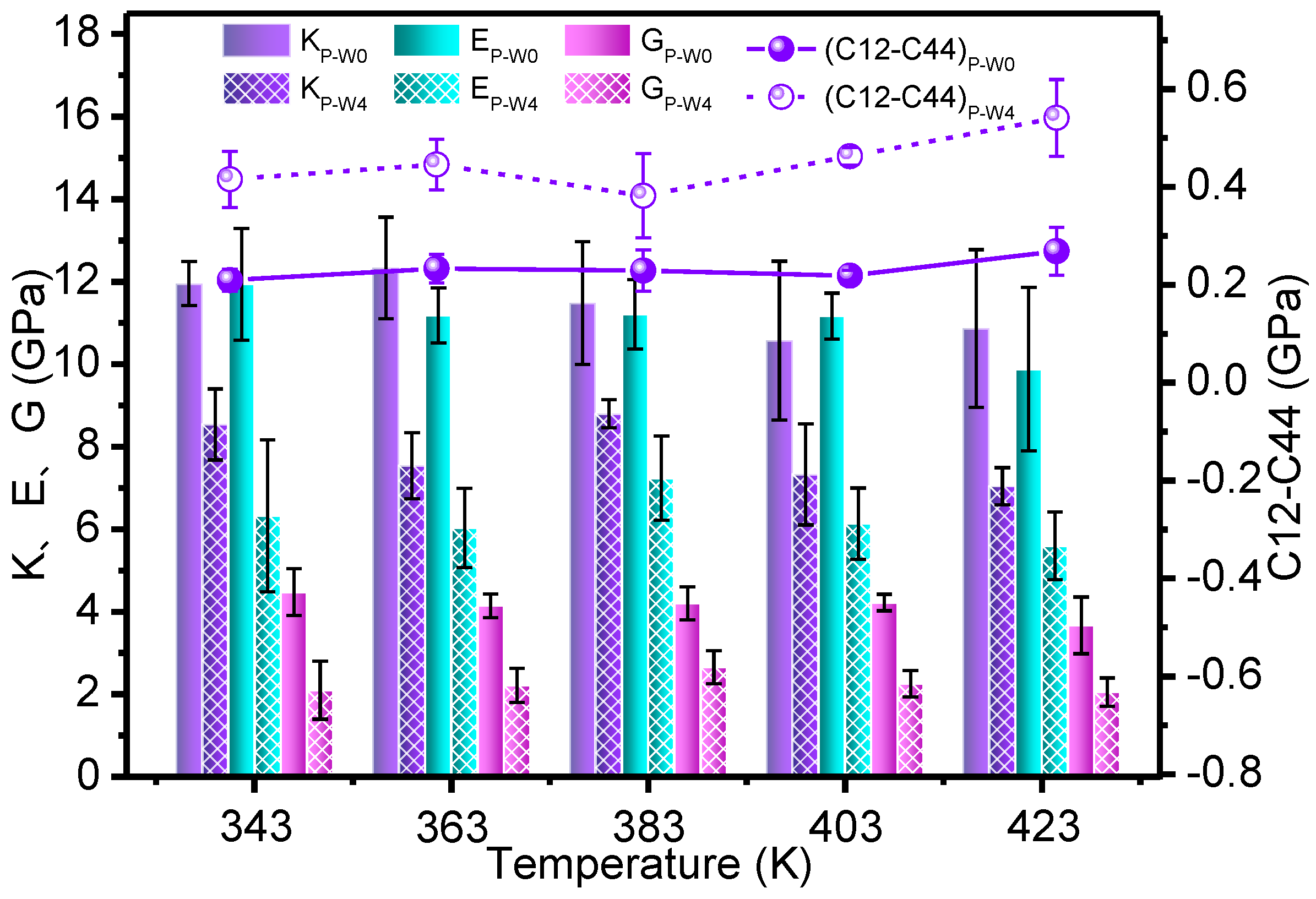

3.5. Analysis of Mechanical Properties

4. Conclusions

- Through the analysis of the hydrogen-bond networks of the composite models, it was found that the hydrogen bonds between the molecular chains of the meta-aramid fibers were first affected by moisture. Damage to this network resulted in a decrease in mechanical properties. With increasing moisture content, a large number of hydrogen bonds formed between the water molecules and meta-aramid fibers, which damaged the hydrogen bonds in both the intra- and intermolecular chains of the fibers. Therefore, protection of the intermolecular hydrogen-bond network of meta-aramid fibers from water molecules is a feasible method for improving their mechanical properties under certain water contents.

- The thermal stability of meta-aramid fibers was decreased by the presence of moisture. The free volume of the meta-aramid fibers increased with increasing moisture content, the interactions between the fiber chains weakened, and this led to an increase in chain motion; in contrast, the linear relationship between the water molecule diffusion coefficients and moisture content, characterized by a slope of 0.31, showed that the rate of damage to the original hydrogen-bond network of the fibers increased, their chain movement increased further, and their thermal stability decreased.

- In general, the mechanical properties of meta-aramid fibers decreased with an increase in moisture content. Compared with the water-free model, the tensile and bulk moduli of the model with a moisture content of 9% decreased by 59.47% and 52.19%, respectively. Damage to the hydrogen-bond network is an important factor leading to reduction in mechanical properties.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Liao, R.J.; Liu, J.F.; Lü, Y.D.; Yang, L.J.; Gao, J. Frequency domain dielectric characteristic parameters for quantitative assessment of moisture content of oil-Paper insulation in power transformers. Trans. China Electrotech. Soc. 2015, 30, 204–211. [Google Scholar]

- Tang, C.; Huang, B.; Hao, M.; Xu, J.; Chen, G. Progress of space charge research on oil-paper insulation using pulsed electroacoustic techniques. Energies 2016, 9, 53. [Google Scholar] [CrossRef]

- Liao, R.J.; Hu, J.; Yang, L.J.; Zhu, M.Z.; Tang, C. Molecular simulation for thermal degradative micromechanism of power transformer insulation paper. High Volt. Eng. 2009, 35, 1565–1570. [Google Scholar] [CrossRef]

- Liao, R.J.; Wang, K.; Yin, J.G.; Yang, L.J.; Sun, H.G.; Deng, X.P. Influence of initial moisture on thermal aging characteristics of oil-paper insulation. High Volt. Eng. 2012, 38, 1172–1178. [Google Scholar] [CrossRef]

- Lundgaard, L.E.; Hansen, W.; Linhjell, D.; Painter, T.J. Aging of Oil-impregnated paper in power transformers. IEEE Trans. Power Deliv. 2014, 19, 230–239. [Google Scholar] [CrossRef]

- Liao, R.J.; Yang, L.J.; Zheng, H.B.; Wang, K.; Ma, Z.Q. Reviews on oil-paper insulation thermal aging in power transformers. Trans. China Electrotech. Soc. 2012, 27, 1–12. [Google Scholar]

- Du, Y.; Zahn, M.; Lesieutre, B.C.; Mamishev, A.V.; Lindgren, S.R. Moisture equilibrium in transformer paper-oil systems. IEEE Electr. Insul. Mag. 1999, 15, 11–20. [Google Scholar] [CrossRef]

- Zhou, L.J.; Li, X.L.; Duan, Z.C.; Wang, X.J.; Gao, B.; Wu, G.G. Influence of cellulose aging on characteristics of moisture diffusion in oil-paper insulation. Proc. CSEE 2014, 34, 3541–3547. [Google Scholar]

- Liao, R.J.; Lin, Y.D.; Yang, L.J.; Zhao, X.T. Effects and correction of temperature, moisture and aging on furfural content in insulating oil and aging assessment of insulation paper. Proc. CSEE 2017, 37, 3037–3044. [Google Scholar]

- Żukowski, P.; Kołtunowicz, T.N.; Kierczyński, K.; Subocz, J.; Szrot, M. Formation of water nanodrops in cellulose impregnated with insulating oil. Cellulose 2015, 22, 861–866. [Google Scholar] [CrossRef]

- Gao, B.S.; Chen, L.; Zhu, L.L.; Hu, Z.M.; Yu, J.R.; Zhu, J. Thermal properties of heterocyclic aramid. J. Donghua Univ. 2011, 37, 272–277. [Google Scholar]

- Zhao, H.F.; Zhang, M.Y.; Lu, J.B. Configuration of PMIA-pulp and its effect on aramid paper. China Pulp Pap. 2010, 29, 1–5. [Google Scholar]

- Jain, A.; Vijayan, K. Thermally induced structural changes in nomex fibres. Bull. Mater. Sci. 2002, 25, 341–346. [Google Scholar] [CrossRef]

- Villar-Rodil, S.; Martı́Nez-Alonso, A.; Tascón, J. Studies on pyrolysis of nomex polyaramid fibers. J. Anal. Appl. Pyrolysis 2001, 58–59, 105–115. [Google Scholar] [CrossRef]

- Zha, J.W.; Dang, Z.M.; Zhou, T.; Song, H.T.; Chen, G. Electrical properties of TiO2-filled polyimide nanocomposite films prepared via an in situ polymerization process. Synth. Met. 2010, 160, 2670–2674. [Google Scholar] [CrossRef]

- Larsen, J.W.; Freund, M.; Kim, K.Y.; Sidovar, M.; Stuart, J.L. Mechanism of the carbon catalyzed reduction of nitrobenzene by hydrazine. Carbon 2000, 38, 655–661. [Google Scholar] [CrossRef]

- Zhu, J.; Cao, W.; Yue, M.; Hou, Y.; Han, J.; Yang, M. Strong and stiff aramid nanofiber/carbon nanotube nanocomposites. ACS Nano 2015, 9, 2489–2501. [Google Scholar] [CrossRef] [PubMed]

- Tang, C.; Zhang, S.; Zhang, F.H.; Li, X.; Zhou, Q. Simulation and experimental about the thermal aging performance improvement of cellulose insulation paper. Trans. China Electrotech. Soc. 2016, 31, 68–76. [Google Scholar]

- Zha, J.W.; Li, W.K.; Zhu, Y.H.; Dang, Z.M.; Chen, G. Effect of micro-Si3N4-nano-Al2O3 cofilled particles on thermal conductivity, dielectric and mechanical properties of sillicone rubber composites. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1989–1996. [Google Scholar] [CrossRef]

- Zhao, L.H.; Wang, S.Y.; Wang, P.; Zhou, C.; Mou, S.A. Long-life oil-immersed transformers based on hybrid insulation systems of nomex. High Volt. Eng. 2016, 42, 1754–1759. [Google Scholar] [CrossRef]

- Chen, L.; Xie, X.Y.; Gu, X.F.; Hu, Z.M.; Liu, Z.F. Synthesis of modified meta-aramid and study on it’s heat-resistant properties. J. East China Univ. Sci. Technol. 2006, 32, 55–59. [Google Scholar] [CrossRef]

- Bai, G.; Liao, R.J.; Liu, N.; Liu, H.B.; Yang, L.J.; Shakeel, A. Influence of nano-AlN modification on the dielectric properties of meta-aramid paper. High Volt. Eng. 2015, 41, 461–467. [Google Scholar] [CrossRef]

- Wang, H.H.; Mei, Q.L.; Xia, X.; Wang, C. Improved properties for polyphenylene oxide/nylon 6 alloy reinforced by aramid fiber. Fiber Reinf. Plast. Compos. 2017, 6, 75–79. [Google Scholar]

- Tang, C.; Zhang, S.; Xie, J.; Lv, C. Molecular simulation and experimental analysis of Al2O3-nanoparticle-modified insulation paper cellulose. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1018–1026. [Google Scholar] [CrossRef]

- Tang, C.; Zhang, S.; Li, X.; Xiong, B.F.; Xie, J.Y. Experimental analyses and molecular simulation of the thermal aging of transformer insulation paper. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 3608–3616. [Google Scholar] [CrossRef]

- Zheng, Z.J.; Liu, H.J.; Shen, J.X.; Liu, J.; Wu, Y.P.; Zhang, L.Q. Tailoring the static and dynamic mechanical properties of tri-block copolymers through molecular dynamics simulation. Polymers 2016, 8, 335. [Google Scholar] [CrossRef]

- Inagaki, T.; Siesler, H.W.; Mitsui, K.; Tsuchikawa, S. Difference of the crystal structure of cellulose in wood after hydrothermal and aging degradation: A NIR spectroscopy and XRD study. Biomacromolecules 2010, 11, 2300–2305. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Tang, C.; Xie, J.; Zhou, Q. Improvement of thermal stability of insulation paper cellulose by modified polysiloxane grafting. Appl. Phys. Lett. 2016, 109, 1565. [Google Scholar] [CrossRef]

- Papadopoulos, G.D.; Tsalikis, D.G.; Mavrantzas, V.G. Microscopic dynamics and topology of polymer rings immersed in a host matrix of longer linear polymers: Results from a detailed molecular dynamics simulation study and comparison with experimental data. Polymers 2016, 8, 283. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Tian, M.; Luo, M.W.; Yang, T.; Yuan, W. Molecular modeling study for impact of moisture on the microscope properties of insulating paper. High Volt. Eng. 2013, 39, 2615–2622. [Google Scholar]

- Zhao, H.F. Study on Relationships between Structure of Aramid Fibers and Aramid Pulp and Properties of Aramid Paper. Ph.D. Thesis, Shaanxi University of Science & Technology, Xi’an, China, 2012. [Google Scholar]

- Sun, H. COMPASS: An ab initio force-field optimized for condensed-phase applications over view with details on alkane and benzene compounds. J. Phys. Chem. B 1998, 102, 7338–7364. [Google Scholar] [CrossRef]

- Zhu, M.Z.; Chen, Y.F.; Gu, C.; Liao, R.J.; Zhu, W.B.; Du, X.M. Simulation on thermodynamic properties of amorphous cellulose based on molecular dynamics. High Volt. Eng. 2015, 41, 432–439. [Google Scholar] [CrossRef]

- Zhang, X.M.; Cao, J.; Qiu, X.C.; Tschopp, M.A.; Horstemeyer, M.; Shi, S. Modeling of mechanical properties for amorphous nanocellulose of wood. J. Northeast For. Univ. 2012, 40, 93–98. [Google Scholar] [CrossRef]

- Yin, K.L.; Zou, D.H.; Yang, B.; Zhang, X.H.; Xia, Q.; Xu, D.J. Investigation of H-bonding for the related force fields in materials studio software. Comput. Appl. Chem. 2006, 23, 169–174. [Google Scholar] [CrossRef]

- Kumar, R.; Schmidt, J.R.; Skinner, J.L. Hydrogen bonding definitions and dynamics in liquid water. J. Chem. Phys. 2007, 126, 204107. [Google Scholar] [CrossRef] [PubMed]

- And, J.C.; Bandyopadhyay, S. Hydrogen bond lifetime dynamics at the interface of a surfactant monolayer. J. Phys. Chem. B 2006, 110, 23443–23449. [Google Scholar] [CrossRef]

- Li, X.; Tang, C.; Wang, Q.; Li, X.P.; Hao, J. Molecular simulation research on the micro effect mechanism of interfacial properties of nano SiO2/meta-aramid fiber. Int. J. Heat Technol. 2017, 35, 123–129. [Google Scholar] [CrossRef]

- Wu, B.; Zhao, Y.; Wu, H.M.; Wang, M.; Chen, J.F.; Ding, Y. Using molecular simulation to predict the mechanical properties of linear aromatic polyamides. J. Univ. South China 2014, 4, 86–90. [Google Scholar]

- Qi, D.P.; Hu, J.Q.; Peng, S.N.; Zhu, Z.F. Study on PPTA micro thermodynamic property. Cotton Text. Technol. 2012, 40, 4–7. [Google Scholar]

- Luo, W.B.; Yang, T.Q.; Wang, X.Y. Effects of temperature and stress level on the free volume in high polymers. Polym. Mater. Sci. Eng. 2005, 21, 11–15. [Google Scholar] [CrossRef]

- Liu, L.F.; Liu, J.X.; Zhang, J.; You, L.; Yu, L.J.; Qiao, G.M. Molecular dynamics simulation of the corrosive medium diffusion behavior inhibited by the corrosion inhibitor membranes. Chem. J. Chin. Univ. 2010, 31, 537–541. [Google Scholar] [CrossRef]

| Volume | P_W0 | P_W1 | P_W2 | P_W3 | P_W4 | P_W5 | P_W9 |

|---|---|---|---|---|---|---|---|

| VF | 848.56 | 675.14 | 1058.37 | 1086.89 | 1482.10 | 1517.35 | 2607.84 |

| VO | 16329.32 | 16364.57 | 16565.28 | 16740.05 | 16666.25 | 1671.07 | 16502.19 |

| FFV (%) | 4.49 | 3.86 | 6.00 | 6.09 | 8.17 | 8.29 | 13.64 |

| R and DW | P_W0 | P_W1 | P_W2 | P_W3 | P_W4 | P_W5 | P_W9 |

|---|---|---|---|---|---|---|---|

| R | 65.91 | 66.67 | 66.83 | 67.01 | 66.60 | 67.48 | 67.80 |

| DW | - | 0.1 | 0.4 | 0.9 | 1 | 1.4 | 2.6 |

| Mechanical Parameters | P_W0 | P_W1 | P_W2 | P_W3 | P_W4 | P_W5 | P_W9 |

|---|---|---|---|---|---|---|---|

| K | 11.88 | 11.76 | 9.22 | 10.37 | 7.17 | 7.02 | 5.68 |

| E | 11.72 | 8.22 | 6.90 | 5.24 | 6.46 | 4.27 | 4.75 |

| C12–C44 | 0.21 | 0.37 | 0.40 | 0.54 | 0.48 | 0.75 | 0.63 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, F.; Tang, C.; Li, X.; Wang, X. Effect of Moisture on Mechanical Properties and Thermal Stability of Meta-Aramid Fiber Used in Insulating Paper. Polymers 2017, 9, 537. https://doi.org/10.3390/polym9100537

Yin F, Tang C, Li X, Wang X. Effect of Moisture on Mechanical Properties and Thermal Stability of Meta-Aramid Fiber Used in Insulating Paper. Polymers. 2017; 9(10):537. https://doi.org/10.3390/polym9100537

Chicago/Turabian StyleYin, Fei, Chao Tang, Xu Li, and Xiaobo Wang. 2017. "Effect of Moisture on Mechanical Properties and Thermal Stability of Meta-Aramid Fiber Used in Insulating Paper" Polymers 9, no. 10: 537. https://doi.org/10.3390/polym9100537