Ultra-Broadband THz Antireflective Coating with Polymer Composites

Abstract

:1. Introduction

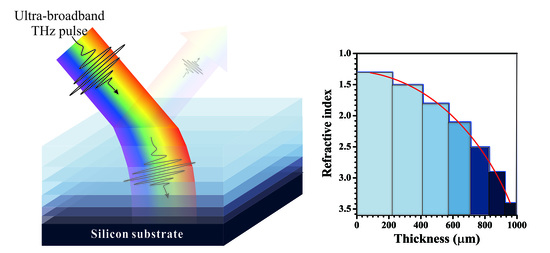

2. Surface-Relief Graded-Index AR Structure

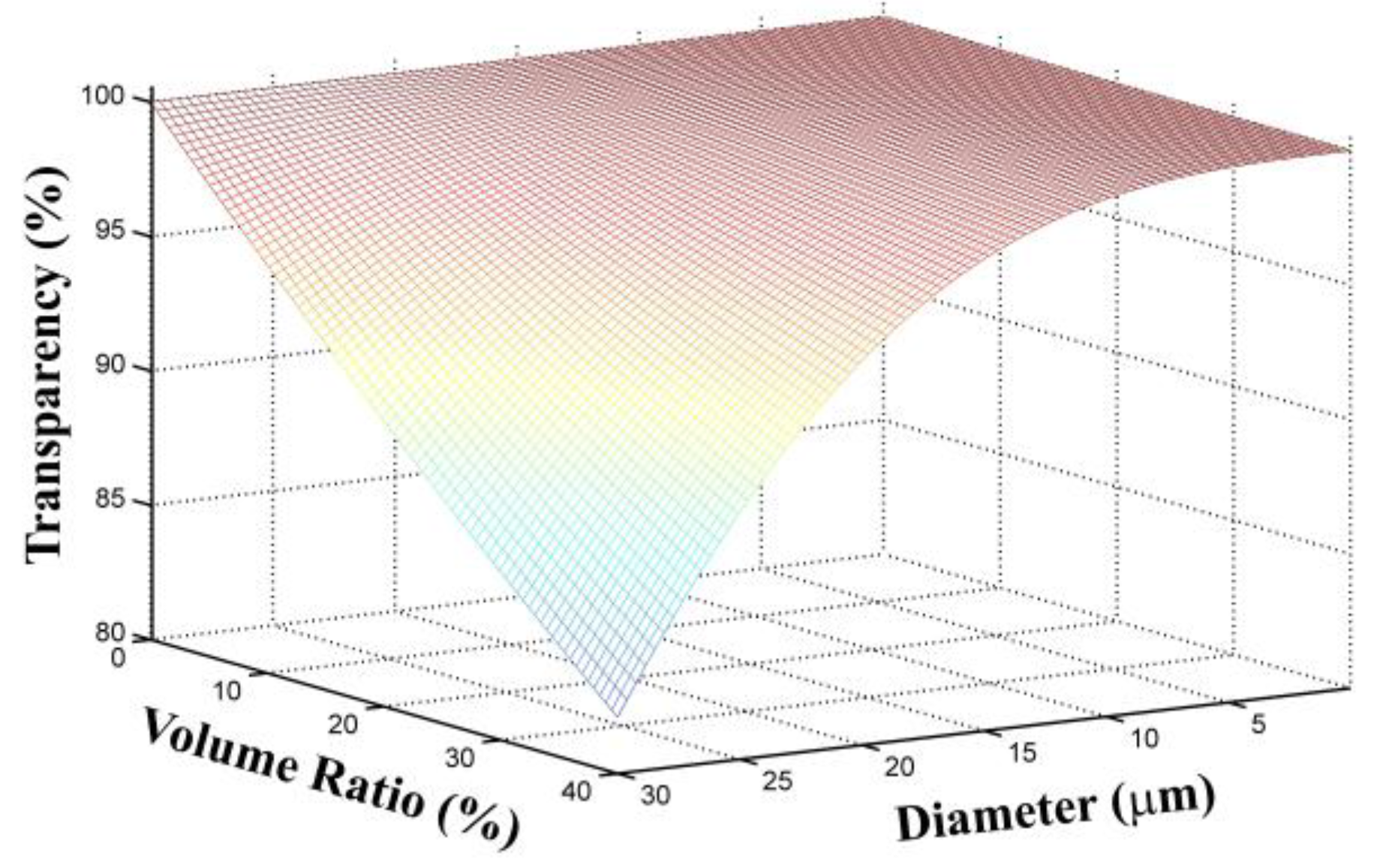

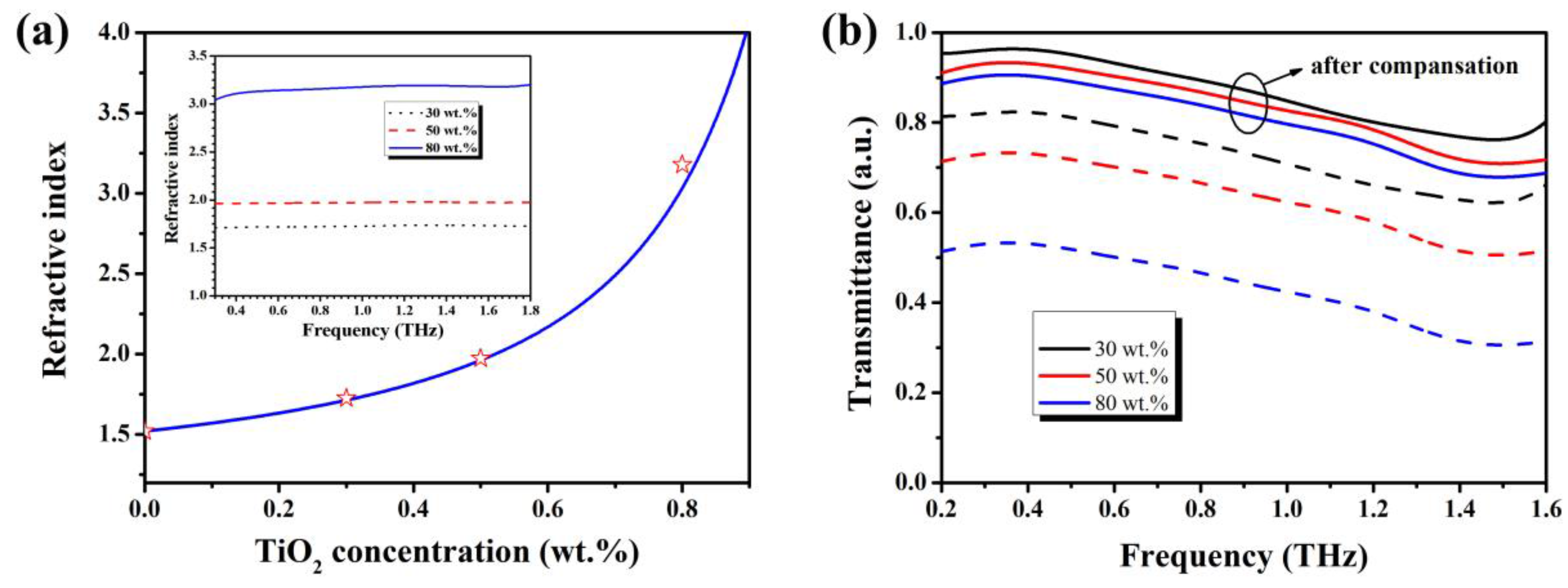

2.1. Polymer Composite Preparation

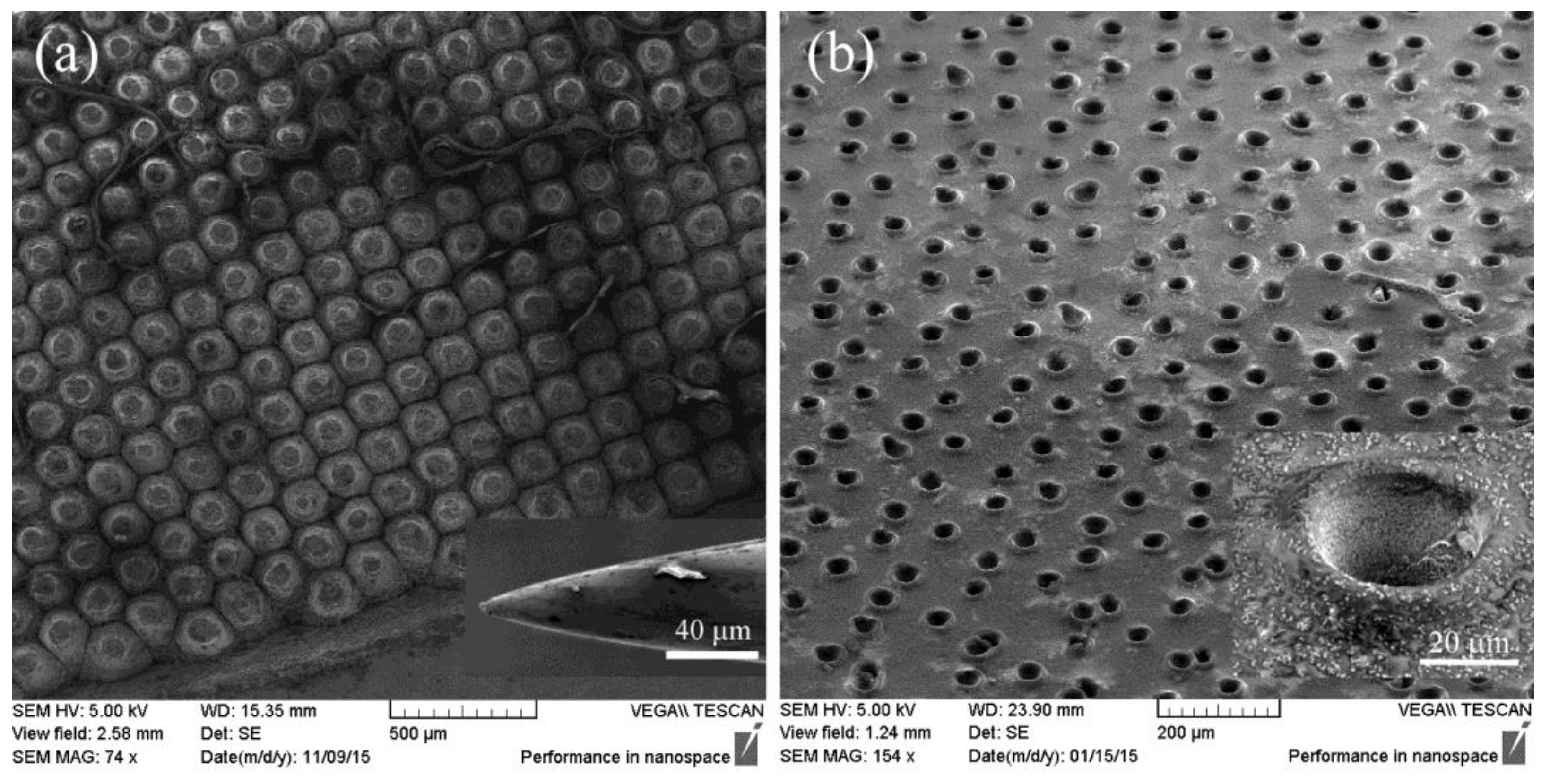

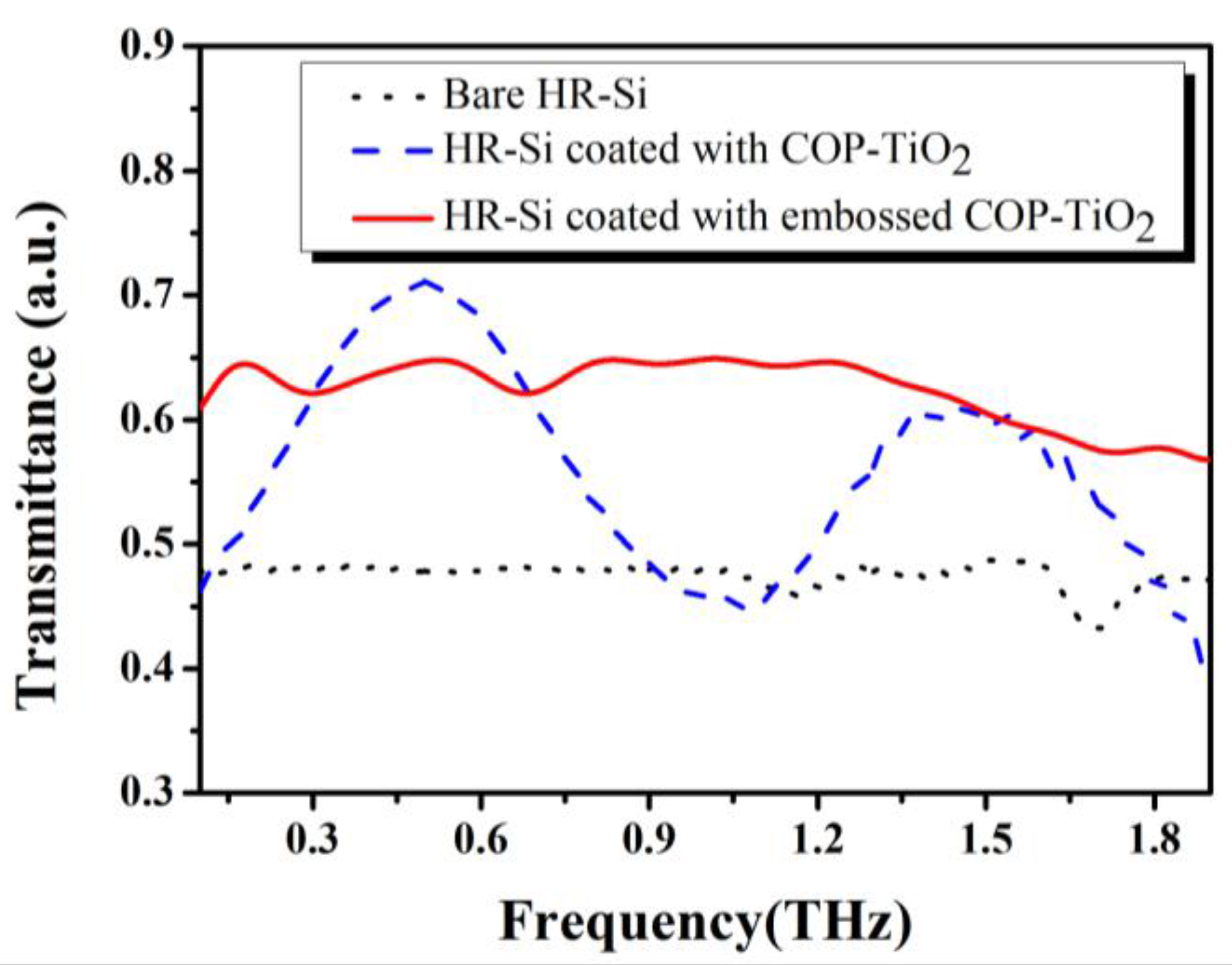

2.2. Surface-Relief AR Structure Fabircation and Its AR Effect

3. Surface Flat Graded-Index AR Structure

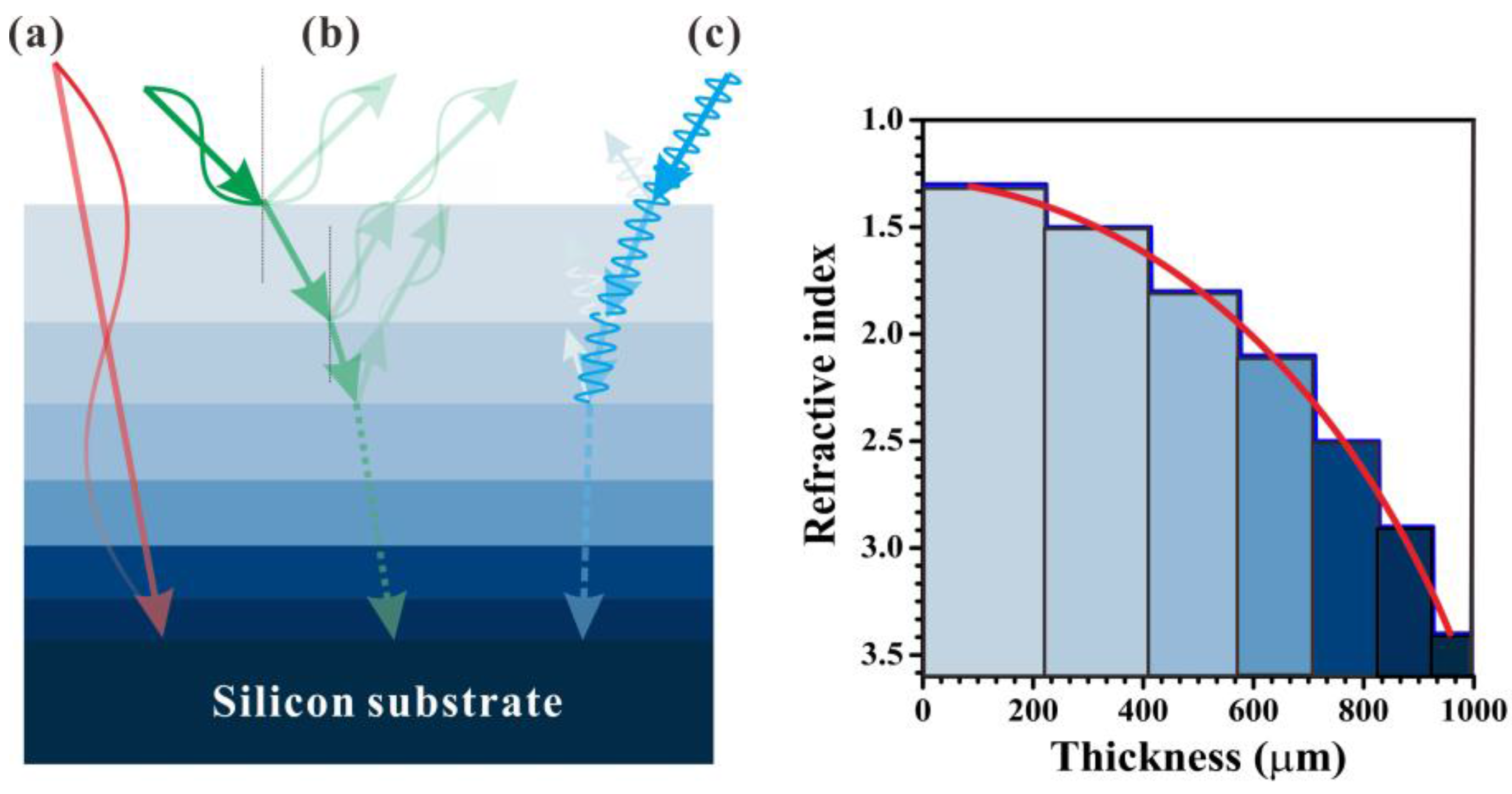

3.1. Structure Design and Fabrication

3.2. Materials and Device Fabircation

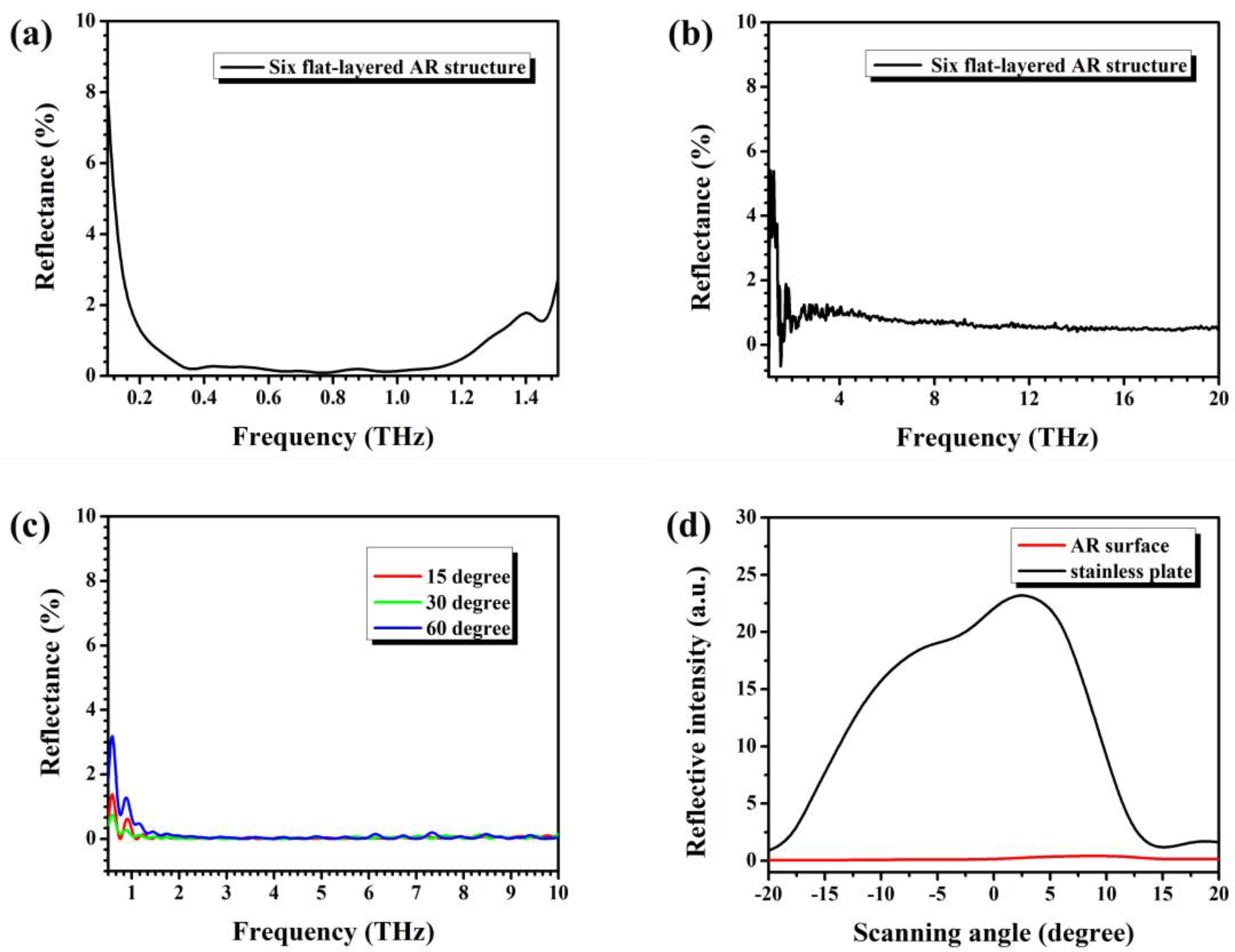

3.3. AR Effect of the Flat Six-Layer Structure

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ferguson, B.; Zhang, X.C. Materials for terahertz science and technology. Nat. Mater. 2002, 1, 26–33. [Google Scholar] [CrossRef] [PubMed]

- Fischer, B.M.; Hoffmann, M.; Helm, H. Terahertz time-domain spectroscopy and imaging of artificial RNA. Opt. Express 2005, 13, 5205–5215. [Google Scholar] [CrossRef] [PubMed]

- Tonouchi, M. Cutting-edge terahertz technology. Nat. Photonics 2007, 1, 97–105. [Google Scholar] [CrossRef]

- Woodward, R.M.; Cole, B.E.; Wallace, V.P.; Pye, R.J.; Arnone, D.D.; Linfield, E.H.; Pepper, M. Terahertz pulse imaging in reflection geometry of human skin cancer and skin tissue. Phys. Med. Biol. 2002, 47, 3853–3863. [Google Scholar] [CrossRef] [PubMed]

- Matsui, T.; Agrawal, A.; Nahata, A.; Vardeny, Z.V.; Matsui, T.; Agrawal, A.; Nahata, A.; Vardeny, Z.V. Transmission resonances through aperiodic arrays of subwavelength apertures. Nature 2007, 446, 517–527. [Google Scholar] [CrossRef] [PubMed]

- George, P.A.; Manolatou, C.; Rana, F.; Bingham, A.L.; Grischkowsky, D. Integrated waveguide-coupled terahertz microcavity resonators. Appl. Phys. Lett. 2007, 90, 091105. [Google Scholar] [CrossRef]

- Skorobogatiy, M.; Dupuis, A. Ferroelectric all-polymer hollow Bragg fibers for terahertz guidance. Appl. Phys. Lett. 2007, 90, 113514. [Google Scholar] [CrossRef]

- Kim, K.Y.; Taylor, A.J.; Glownia, J.H.; Rodriguez, G. Coherent control of terahertz supercontinuum generation in ultrafast laser-gas interactions. Nat. Photonics 2008, 2, 605–609. [Google Scholar] [CrossRef]

- Somma, C.; Folpini, G.; Gupta, J.; Reimann, K.; Woerner, M.; Elsaesser, T. Ultra-broadband terahertz pulses generated in the organic crystal DSTMS. Opt. Lett. 2015, 40, 3404–3407. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Zhu, J.; Xu, J.; He, J.; Sun, J.; Wang, Y.; Zhao, Z. Ultra-broadband photodetector for the visible to terahertz range by self-assembling reduced graphene oxide-silicon nanowire array heterojunctions. Small 2014, 10, 2345–2351. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.-T.; Zhou, J.; O’Hara, J.F.; Chen, F.; Azad, A.K.; Taylor, A.J. Antireflection coating using metamaterials and identification of its mechanism. Phy. Rev. Lett. 2010, 105, 073901. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.F.; Chattopadhyay, S.; Jen, Y.J.; Peng, C.Y.; Liu, T.A.; Hsu, Y.K.; Pan, C.L.; Lo, H.C.; Hsu, C.H.; Chang, Y.H.; et al. Improved broadband and quasi-omnidirectional anti-reflection properties with biomimetic silicon nanostructures. Nat. Nano Technol. 2007, 2, 770–774. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.W.; Han, P.Y.; Zhang, X.-C. Tunable broadband antireflection structures for silicon at terahertz frequency. Appl. Phys. Lett. 2009, 94, 041106. [Google Scholar] [CrossRef]

- Kim, D.-S.; Kim, D.-J.; Kim, D.-H.; Hwang, S.; Jang, J.-H. Simple fabrication of an antireflective hemispherical surface structure using a self-assembly method for the terahertz frequency range. Opt. Lett. 2012, 37, 2742–2744. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, K.; Rasmussen, H.K.; Adam, A.J.L.; Planken, P.C.M.; Bang, O.; Jepsen, P.U. Bendable, low-loss Topas fibers for the terahertz frequency range. Opt. Express 2009, 17, 8592–8601. [Google Scholar] [CrossRef] [PubMed]

- Bolivar, P.H.; Brucherseifer, M.; Rivas, J.G.; Gonzalo, R.; Ederra, I.; Reynolds, A.L.; Holker, M.; De Maagt, P. Measurement of dielectric constant and loss tangent of high dielectric constant materials at terahertz frequencies. IEEE Trans. Microw. Theory Tech. 2003, 51, 1062–1066. [Google Scholar] [CrossRef]

- Cai, B.; Sugihara, O.; Elim, H.I.; Adschiri, T.; Kaino, T. A Novel Preparation of high-refractive-index and highly transparent polymer nanohybrid composites. Appl. Phys. Express 2011, 4, 092601. [Google Scholar] [CrossRef]

- Cai, B.; Kaino, T.; Sugihara, O. Sulfonyl-containing polymer and its alumina nanocomposite with high Abbe number and high refractive index. Opt. Mater. Exp. 2015, 5, 1210–1216. [Google Scholar] [CrossRef]

- Scheller, M.; Wietzke, S.; Jansen, C.; Koch, M. Modelling heterogeneous dielectric mixtures in the terahertz regime: A quasi-static effective medium theory. J. Phys. D Appl. Phys. 2009, 42, 065415. [Google Scholar] [CrossRef]

- Li, Y.-Z.; Cai, B.; Zhu, Y.-M. Fabrication of anti-reflective micro-structure at terahertz frequency by using Chinese acupuncture needles. Opt. Lett. 2015, 40, 2917–2920. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.-C.; Li, Y.-Z.; Cai, B.; Zhu, Y.-M. High refractive index composite for broadband antireflection in terahertz frequency range. Appl. Phys. Lett. 2015, 106, 231107. [Google Scholar] [CrossRef]

- Xu, G.-J.; Zhang, J.; Zang, X.-F.; Sugihara, O.; Zhao, H.-W.; Cai, B. 0.1–20 THz ultra-broadband perfect absorber via a flat multi-layer structure. Opt. Express 2016, 24, 23177–23185. [Google Scholar] [CrossRef] [PubMed]

| Layer | 1st | 2nd | 3rd | 4th | 5th | 6th |

|---|---|---|---|---|---|---|

| Refractive index | 1.3 | 1.5 | 1.8 | 2.1 | 2.5 | 2.9 |

| Theoretical thickness (μm) | 224 | 190 | 161 | 136 | 116 | 98 |

| Real thickness (μm) | 238 | 194 | 158 | 134 | 116 | 114 |

| Thickness deviation | 6.3% | 2.1% | 1.9% | 1.5% | 0 | 16% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, B.; Chen, H.; Xu, G.; Zhao, H.; Sugihara, O. Ultra-Broadband THz Antireflective Coating with Polymer Composites. Polymers 2017, 9, 574. https://doi.org/10.3390/polym9110574

Cai B, Chen H, Xu G, Zhao H, Sugihara O. Ultra-Broadband THz Antireflective Coating with Polymer Composites. Polymers. 2017; 9(11):574. https://doi.org/10.3390/polym9110574

Chicago/Turabian StyleCai, Bin, Haitao Chen, Gongjie Xu, Hongwei Zhao, and Okihiro Sugihara. 2017. "Ultra-Broadband THz Antireflective Coating with Polymer Composites" Polymers 9, no. 11: 574. https://doi.org/10.3390/polym9110574