Flexible Ultrahigh-Temperature Polymer-Based Dielectrics with High Permittivity for Film Capacitor Applications

Abstract

:1. Introduction

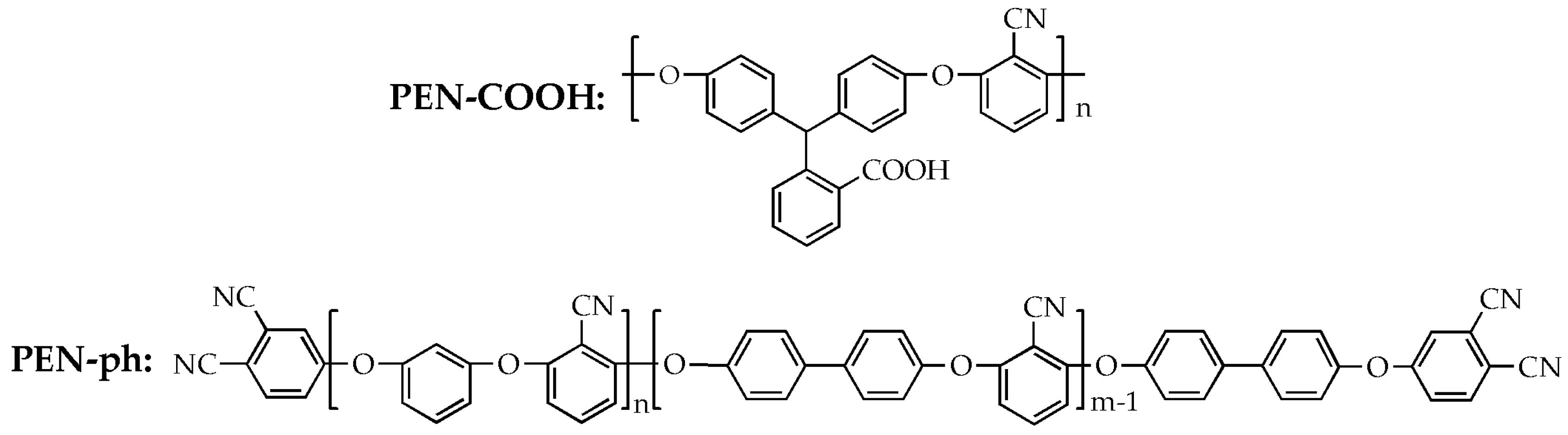

2. Experimental Section

2.1. Materials

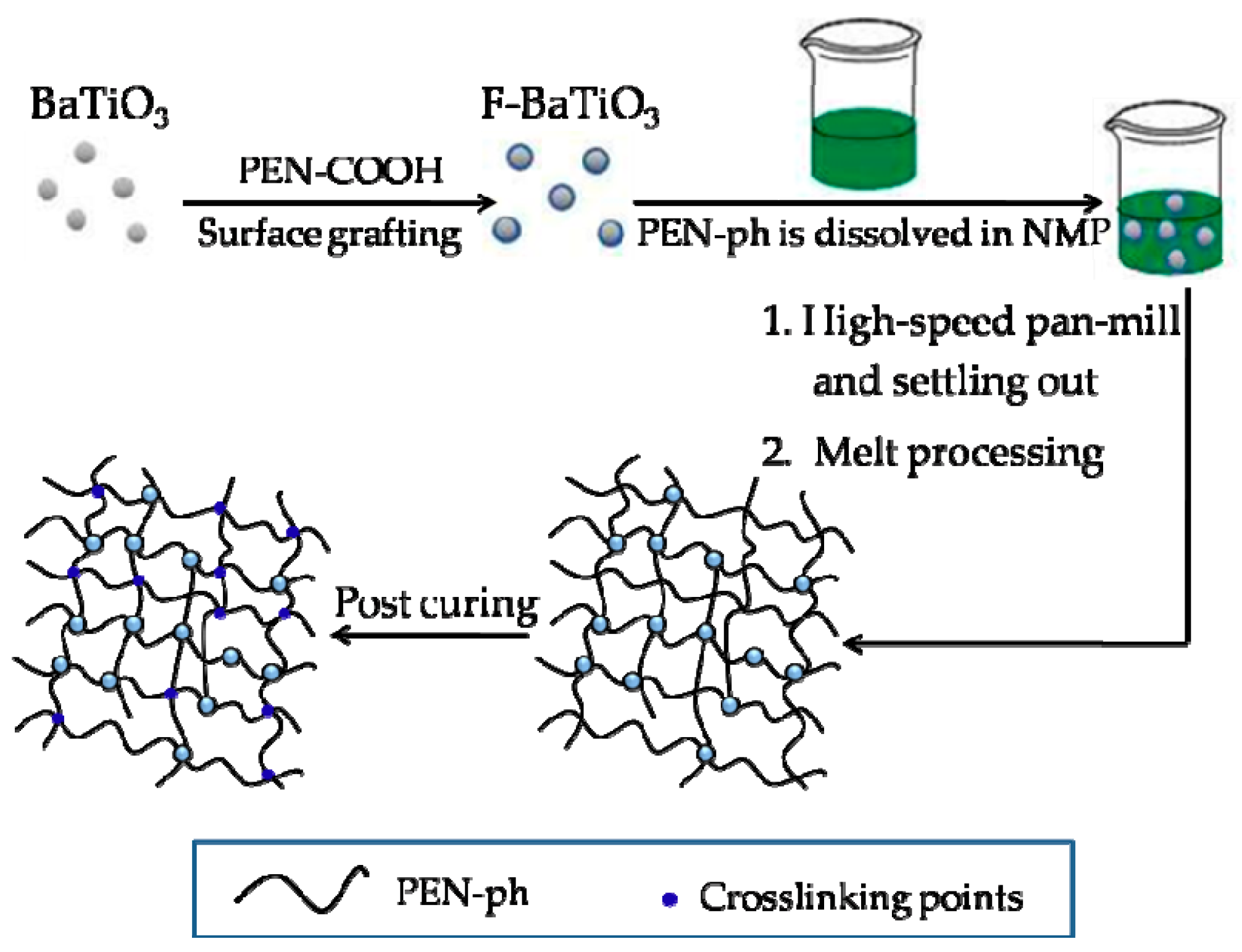

2.2. Preparation of F-BaTiO3 Particles

2.3. Preparation of the CPEN/F-BaTiO3 Composites Films

2.4. Characterization

3. Results and Discussion

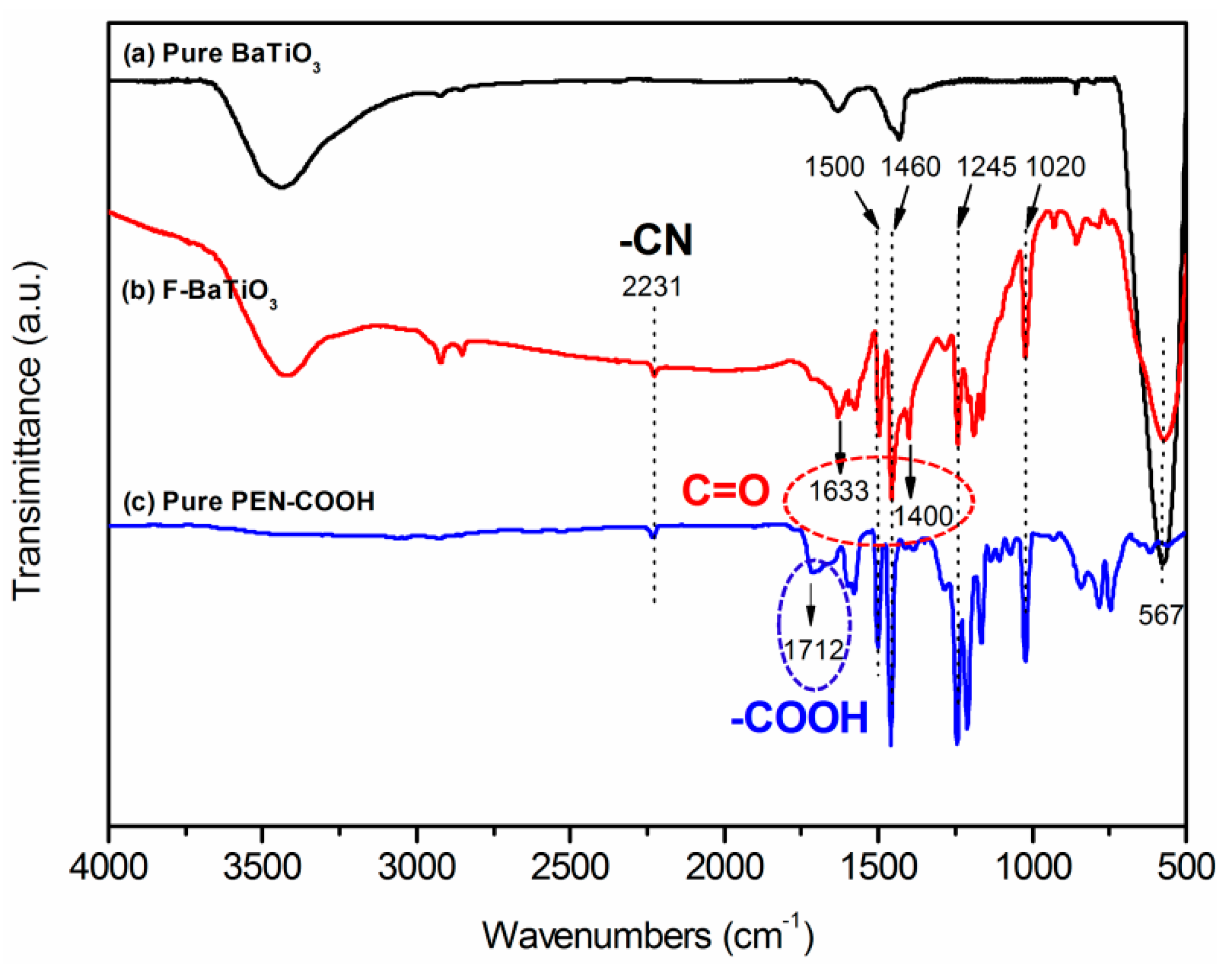

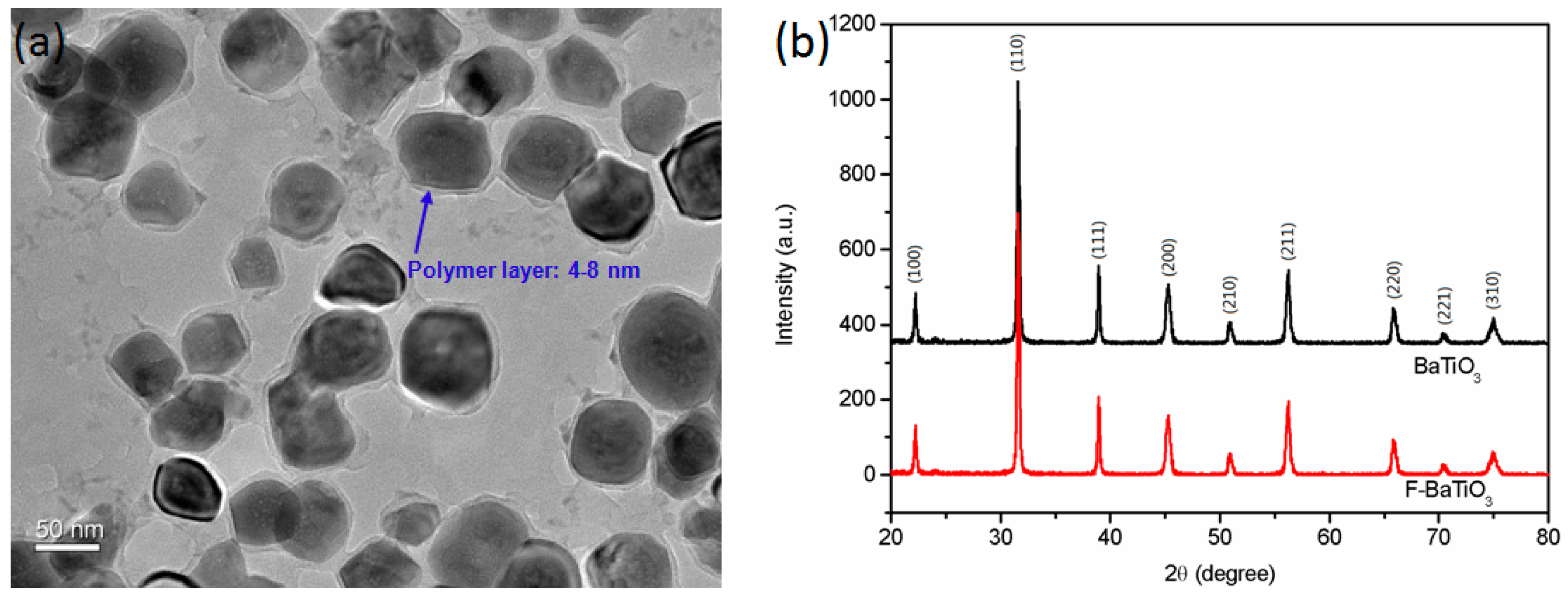

3.1. Characterizations of F-BaTiO3 Particles

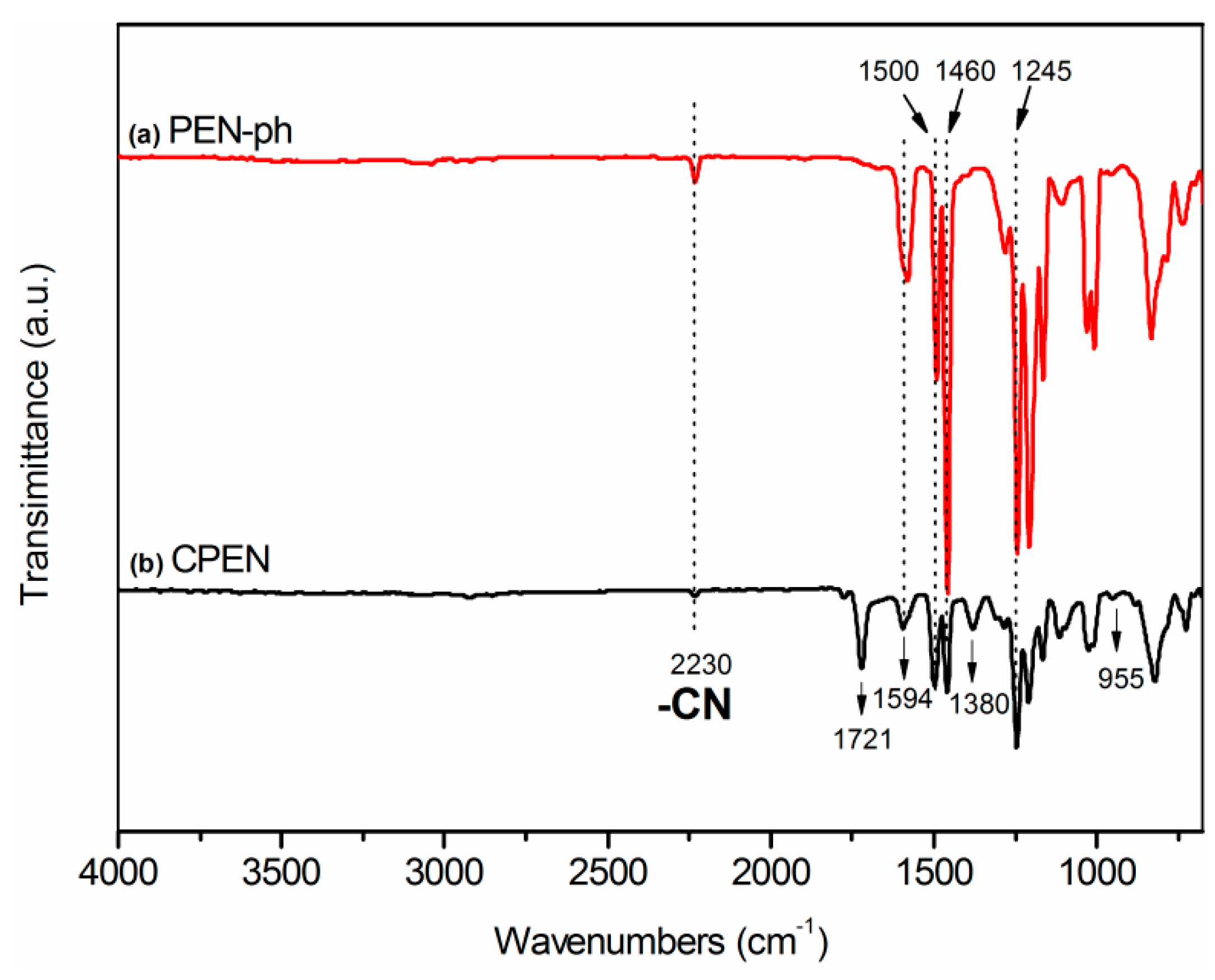

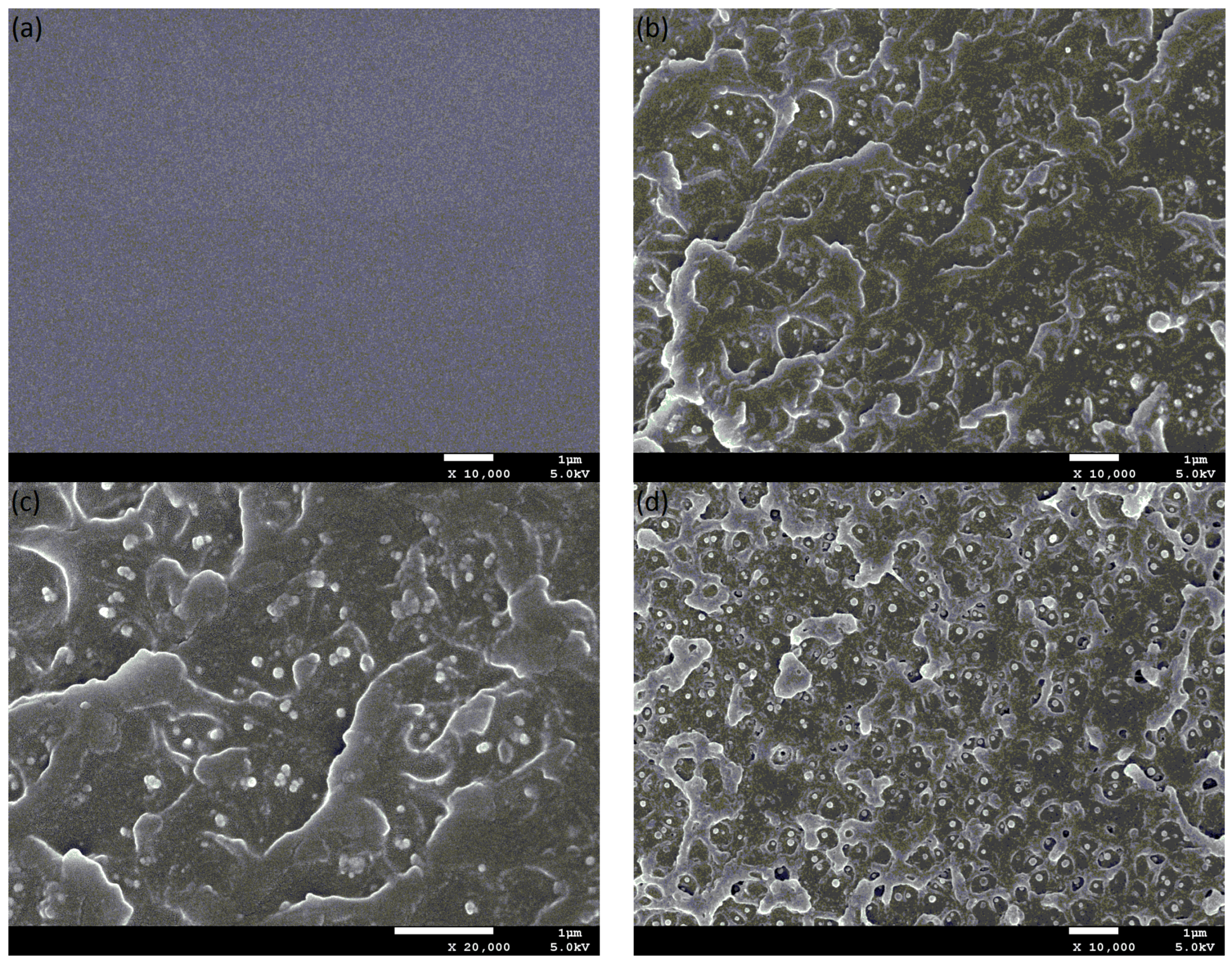

3.2. Chemical Structure and Morphology of CPEN Composite Films

3.3. Mechanical Properties of CPEN Composite Films

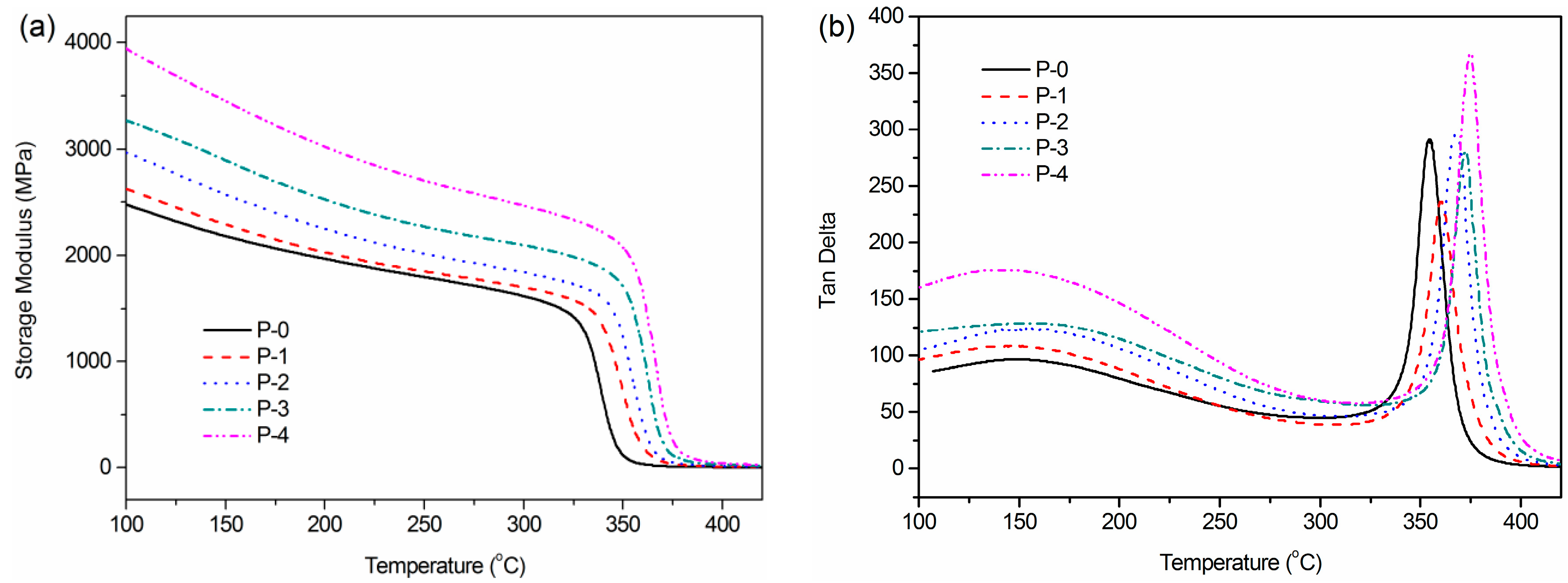

3.4. Dynamic Mechanical Properties of CPEN Composite Films

3.5. Dielectric Properties of CPEN Composite Films

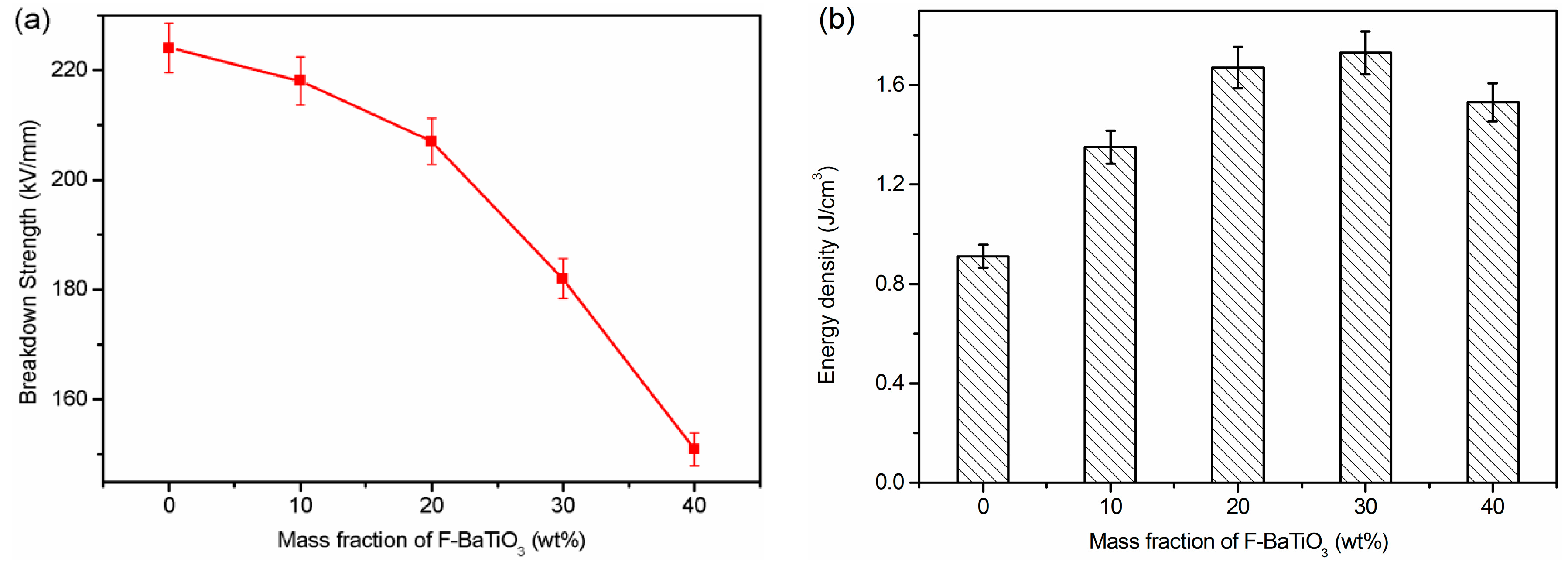

3.6. Electric Breakdown and Energy Storage Capacity of CPEN Composite Films

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, C.; Tang, A.B.; Zou, Y.K.; Liu, X.B. Preparation and dielectric properties of polyarylene ether nitriles/TiO2 nanocomposite film. Mater. Lett. 2005, 59, 59–63. [Google Scholar] [CrossRef]

- Zhan, Y.Q.; Wan, X.Y.; He, J.S.; Yang, Q.B.; He, Y. Design of durable and efficient poly(arylene ether nitrile)/bioinspired polydopamine coated graphene oxide nanofibrous composite membrane for anionic dyes separation. Chem. Eng. J. 2018, 333, 132–145. [Google Scholar] [CrossRef]

- You, Y.; Du, X.; Mao, H.; Tang, X.H.; Wei, R.B.; Liu, X.B. Synergistic enhancement of mechanical, crystalline and dielectric properties of polyarylene ether nitrile-based nanocomposites by unidirectional hot stretching–quenching. Polym. Int. 2017, 66, 1151–1158. [Google Scholar] [CrossRef]

- Huang, X.; Pu, Z.J.; Feng, M.N.; Tong, L.F.; Liu, X.B. BaTiO3@ MWCNTs core/shell nanotubes embedded PEN nanocomposite films with high thermal stability and high permittivity. Mater. Lett. 2013, 96, 139–142. [Google Scholar] [CrossRef]

- Tang, H.L.; Huang, X.; Yang, X.L.; Yang, J.; Zhao, R.; Liu, X.B. An effective approach to enhance temperature independence of dielectric properties for polyarylene ether nitrile films. Mater. Lett. 2012, 75, 218–220. [Google Scholar] [CrossRef]

- Wei, R.B.; Li, K.; Ma, J.Y.; Zhang, H.X.; Liu, X.B. Improving dielectric properties of polyarylene ether nitrile with conducting polyaniline. J. Mater. Sci. Mater. Electron. 2016, 27, 9565–9571. [Google Scholar] [CrossRef]

- Pu, Z.J.; Tong, L.F.; Feng, M.N.; Jia, K.; Liu, X.B. Influence of hyperbranched copper phthalocyanine grafted carbon nanotubes on the dielectric and rheological properties of polyarylene ether nitriles. RSC Adv. 2015, 5, 72028–72036. [Google Scholar] [CrossRef]

- Zhan, Y.Q.; Yang, X.L.; Guo, H.; Yang, J.; Meng, F.B.; Liu, X.B. Cross-linkable nitrile functionalized graphene oxide/poly (arylene ether nitrile) nanocomposite films with high mechanical strength and thermal stability. J. Mater. Chem. 2012, 22, 5602–5608. [Google Scholar] [CrossRef]

- Huang, X.; Wang, K.; Jia, K.; Liu, X.B. Polymer-based composites with improved energy density and dielectric constants by monoaxial hot-stretching for organic film capacitor applications. RSC Adv. 2015, 5, 51975–51982. [Google Scholar] [CrossRef]

- Tang, H.L.; Wang, P.; Zheng, P.L.; Liu, X.B. Core-shell structured BaTiO3@polymer hybrid nanofiller for poly(arylene ether nitrile) nanocomposites with enhanced dielectric properties and high thermal stability. Compos. Sci. Technol. 2016, 123, 134–142. [Google Scholar] [CrossRef]

- Xie, Y.C.; Yu, Y.Y.; Feng, Y.F.; Jiang, W.R.; Zhang, Z.C. Fabrication of stretchable nanocomposites with high energy density and low loss from cross-linked PVDF filled with poly (dopamine) encapsulated BaTiO3. ACS Appl. Mater. Interface 2017, 9, 2995–3005. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.Q.; Wei, R.B.; Li, K.; Tong, L.F.; Jia, K.; Liu, X.B. Crosslinked polyarylene ether nitrile film as flexible dielectric materials with ultrahigh thermal stability. Sci. Rep. 2016, 6, 36434. [Google Scholar] [CrossRef] [PubMed]

- Xie, L.Y.; Huang, X.Y.; Wu, C.; Jiang, P.K. Core-shell structured poly(methyl methacrylate)/BaTiO3 nanocomposites prepared by in situ atom transfer radical polymerization: A route to high dielectric constant materials with the inherent low loss of the base polymer. J. Mater. Chem. 2011, 21, 5897–5906. [Google Scholar] [CrossRef]

- Yang, K.; Huang, X.Y.; Huang, Y.H.; Xie, L.Y.; Jiang, P.K. Fluoro-polymer@BaTiO3 hybrid nanoparticles prepared via RAFT polymerization: Toward ferroelectric polymer nanocomposites with high dielectric constant and low dielectric loss for energy storage application. Chem. Mater. 2013, 25, 2327–2338. [Google Scholar] [CrossRef]

- Li, Y.H.; Yuan, J.J.; Xue, J.; Cai, F.Y.; Chen, F.; Fu, Q. Towards suppressing loss tangent: Effect of polydopamine coating layers on dielectric properties of core-shell barium titanate filled polyvinylidene fluoride composites. Compos. Sci. Technol. 2015, 118, 198–206. [Google Scholar] [CrossRef]

- Zhang, G.Q.; Brannum, D.; Dong, D.X.; Tang, L.X.; Allahyarov, E.; Tang, S.; Kodweis, K.; Lee, J.K.; Zhu, L. Interfacial polarization-induced loss mechanisms in polypropylene/BaTiO3 nanocomposite dielectrics. Chem. Mater. 2016, 28, 4646–4660. [Google Scholar] [CrossRef]

- Wan, Y.J.; Zhu, P.L.; Yu, S.H.; Yang, W.H.; Sun, R.; Wong, C.P.; Liao, W.H. Barium titanate coated and thermally reduced graphene oxide towards high dielectric constant and low loss of polymeric composites. Compos. Sci. Technol. 2017, 141, 48–55. [Google Scholar] [CrossRef]

- Tang, H.L.; Tong, L.F.; Wei, J.J.; Guo, H.Y.; Liu, X.B. An effective and controllable approach to derive polymer corona on oxide nanoparticles to enhance their compatibility in polymeric nanocomposites. Mater. Lett. 2013, 93, 285–288. [Google Scholar] [CrossRef]

- Zou, Y.K.; Yang, J.; Zhan, Y.Q.; Yang, X.L.; Zhong, J.C.; Zhao, R.; Liu, X.B. Effect of curing behaviors on the properties of poly (arylene ether nitrile) end-capped with phthalonitrile. J. Appl. Polym. Sci. 2012, 125, 3829–3835. [Google Scholar] [CrossRef]

- Tang, H.L.; Pu, Z.J.; Huang, X.; Wei, J.J.; Liu, X.B.; Lin, Z.Q. Novel blue-emitting carboxyl functionalized poly(arylene ether nitrile)s with excellent thermal and mechanical properties. Polym. Chem. 2014, 11, 3673–3679. [Google Scholar] [CrossRef]

- Yang, R.Q.; Li, K.; Tong, L.F.; Jia, K.; Liu, X.B. The relationship between processing and performances of polyarylene ether nitriles terminated with phthalonitrile/trifunctional phthalonitrile composites. J. Polym. Res. 2015, 22, 1–9. [Google Scholar] [CrossRef]

- Snow, A.W.; Griffith, J.R.; Marullo, N.P. Syntheses and characterization of heteroatom-bridged metal-free phthalocyanine network polymers and model compounds. Macromolecules 1984, 17, 1614–1624. [Google Scholar] [CrossRef]

- Tong, L.F.; Pu, Z.J.; Huang, X.; Chen, Z.R.; Yang, X.L.; Liu, X.B. Crosslinking behavior of polyarylene ether nitrile terminated with phthalonitrile (PEN-t-Ph)/1,3,5-Tri-(3,4-dicyanophenoxy) benzene (TPh) system and its enhanced thermal stability. J. Appl. Polym. Sci. 2013, 130, 1363–1368. [Google Scholar] [CrossRef]

- Shi, X.; Zhu, G.S.; Wang, X.H.; Li, G.H.; Fang, Q.R.; Zhao, X.J.; Wu, G.; Tian, G.; Xue, M.; Wang, R.W.; et al. Polymeric frameworks constructed from a metal-organic coordination compound, in 1-D and 2-D systems: synthesis, crystal structures, and fluorescent properties. Cryst. Growth Des. 2015, 5, 341–346. [Google Scholar] [CrossRef]

- Suchanicz, J.; Swierczek, K.; Nogas-Cwikiel, E.; Konieczny, K.; Sitko, D. PbMg1/3Nb2/3O3-doping effects on structural, thermal, Raman, dielectric and ferroelectric properties of BaTiO3 ceramics. J. Eur. Ceram. Soc. 2015, 35, 1777–1783. [Google Scholar] [CrossRef]

- Cui, Y.F.; Briscoe, J.; Dunn, S. An investigation into the effect of ferroelectricity of BaTiO3 on the photocatalytic activity in dye decolourisation. Adv. Sci. Technol. 2014, 93, 190–195. [Google Scholar] [CrossRef]

- Tong, L.F.; Jia, K.; Liu, X.B. Phthalonitrile end-capped polyarylene ether nitrile: Crystals embedded in matrix through crosslinking reaction. Polym. Int. 2015, 64, 1361–1365. [Google Scholar] [CrossRef]

- Tong, L.F.; Jia, K.; Liu, X.B. Novel phthalonitrile-terminated polyarylene ether nitrile with high glass transition temperature and enhanced thermal stability. Mater. Lett. 2014, 128, 267–270. [Google Scholar] [CrossRef]

- Tong, L.F.; Zheng, P.L.; Tang, H.L.; Jia, K.; Liu, X.B. Novel high-temperature- resistant single-polymer composites based on self-reinforced phthalonitrile end-capped polyarylene ether nitrile. Mater. Lett. 2015, 159, 337–340. [Google Scholar] [CrossRef]

- Yang, R.Q.; Xiao, Q.; You, Y.; Wei, R.B.; Liu, X.B. In situ catalyzed and reinforced high-temperature flexible crosslinked ZnO nano-whisker/polyarylene ether nitriles composite dielectric films. Polym. Compos. 2016. [Google Scholar] [CrossRef]

- Wei, R.B.; Wang, J.L.; Zhang, H.X.; Han, W.H.; Liu, X.B. Crosslinked polyarylene ether nitrile interpenetrating with zinc ion bridged graphene sheet and carbon nanotube network. Polymers 2017, 9, 342. [Google Scholar] [CrossRef]

- Pu, Z.J.; Tang, H.L.; Huang, X.; Yang, J.; Zhan, Y.Q.; Zhao, R.; Liu, X.B. Effect of surface functionalization of SiO2 particles on the interfacial and mechanical properties of PEN composite films. Colloid Surf. A 2012, 415, 125–133. [Google Scholar] [CrossRef]

- Huang, X.Y.; Jiang, P.K. Core-shell structured high-k polymer nanocomposites for energy storage and dielectric applications. Adv. Mater. 2015, 27, 546–554. [Google Scholar] [CrossRef] [PubMed]

- Yoon, D.H.; Zhang, J.; Lee, B.I. Dielectric constant and mixing model of BaTiO3 composite thick films. Mater. Res. Bull. 2003, 38, 765–772. [Google Scholar] [CrossRef]

- Deligöz, H.; Yalcinyuvaa, T.; Özgümüsa, S.; Yildirimb, S. Preparation, characterization and dielectric properties of 4, 4-diphenylmethane diisocyanate (MDI) based cross-linked polyimide films. Eur. Polym. J. 2006, 42, 1370–1377. [Google Scholar] [CrossRef]

- Wang, Y.F.; Cui, J.; Yuan, Q.B.; Niu, Y.J.; Bai, Y.Y.; Wang, H. Significantly enhanced breakdown strength and energy density in sandwich-structured barium titanate/poly(vinylidene fluoride) nanocomposites. Adv. Mater. 2015, 27, 6658–6663. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pu, Z.; Zheng, X.; Tian, Y.; Hu, L.; Zhong, J. Flexible Ultrahigh-Temperature Polymer-Based Dielectrics with High Permittivity for Film Capacitor Applications. Polymers 2017, 9, 596. https://doi.org/10.3390/polym9110596

Pu Z, Zheng X, Tian Y, Hu L, Zhong J. Flexible Ultrahigh-Temperature Polymer-Based Dielectrics with High Permittivity for Film Capacitor Applications. Polymers. 2017; 9(11):596. https://doi.org/10.3390/polym9110596

Chicago/Turabian StylePu, Zejun, Xiaoyi Zheng, Yuhan Tian, Linqing Hu, and Jiachun Zhong. 2017. "Flexible Ultrahigh-Temperature Polymer-Based Dielectrics with High Permittivity for Film Capacitor Applications" Polymers 9, no. 11: 596. https://doi.org/10.3390/polym9110596