Effect of (Cd:Zn)S Particle Concentration and Photoexcitation on the Electrical and Ferroelectric Properties of (Cd:Zn)S/P(VDF-TrFE) Composite Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Characterization

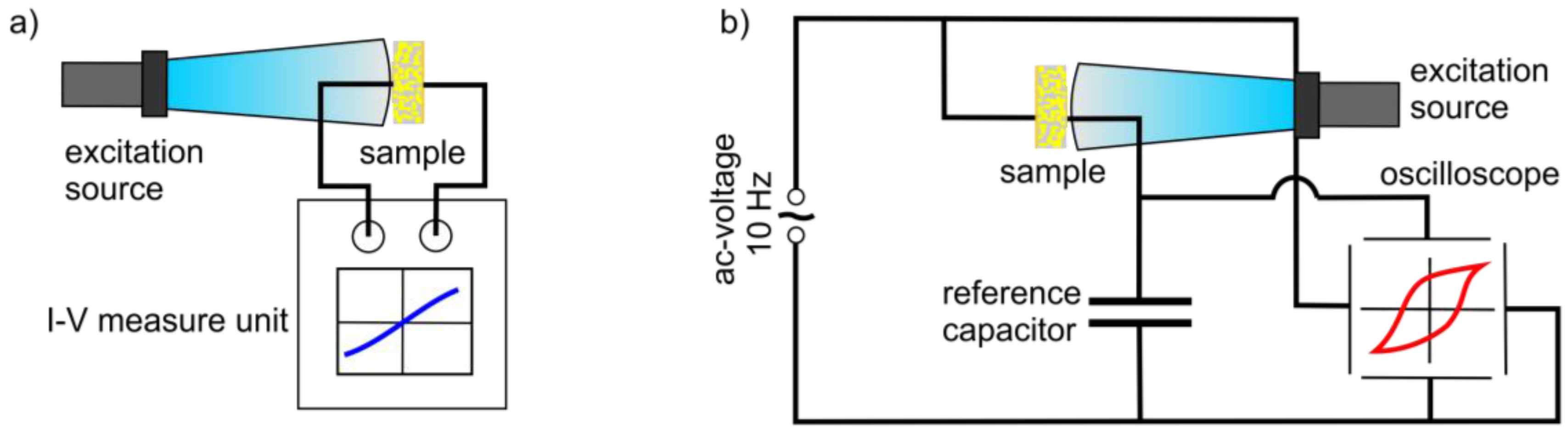

2.3. Electrical, Ferroelectric and Pyroelectric Properties

3. Results

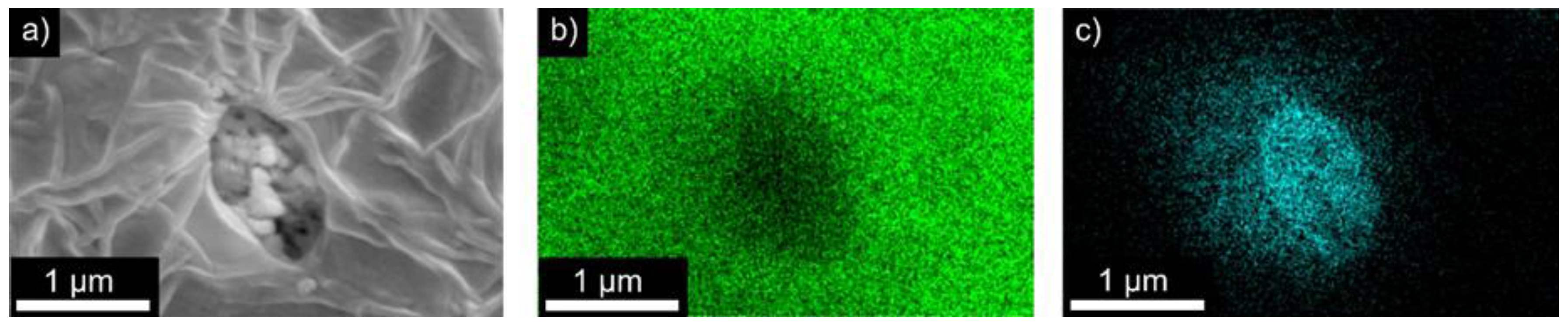

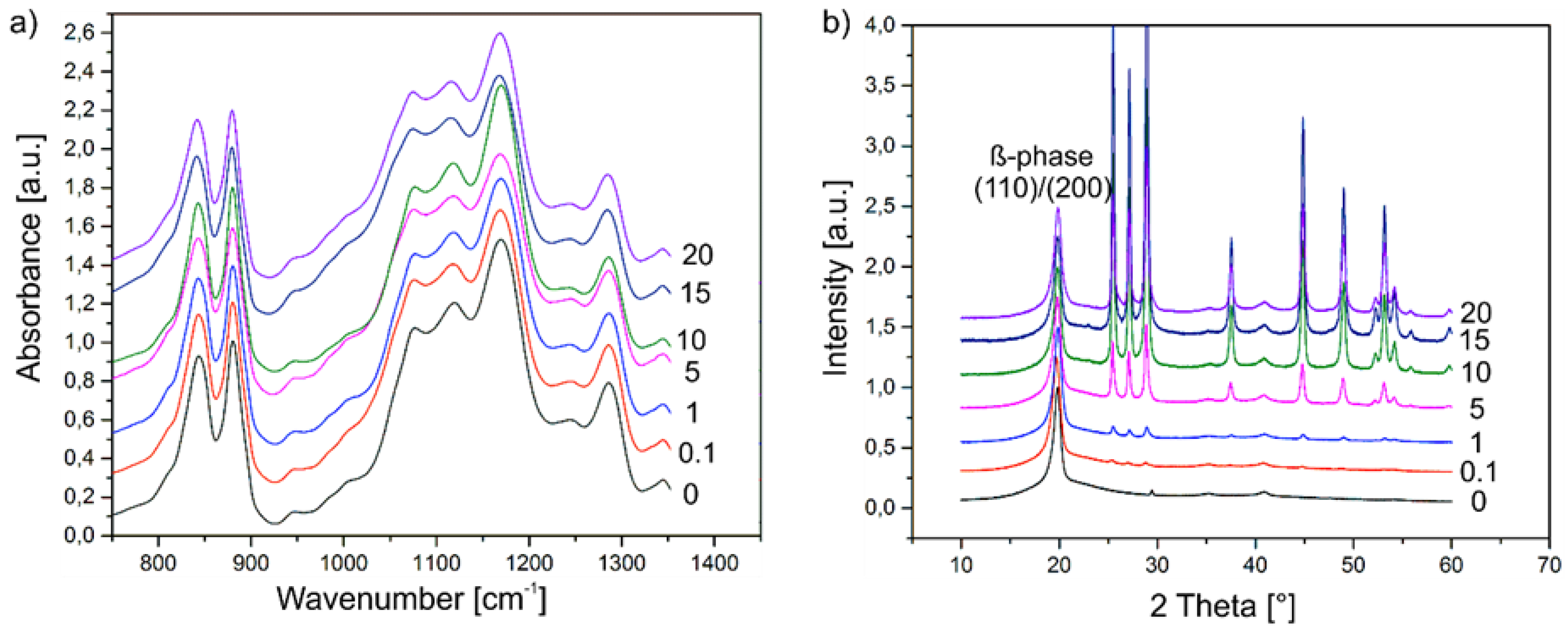

3.1. Microstructure and Optical Properties

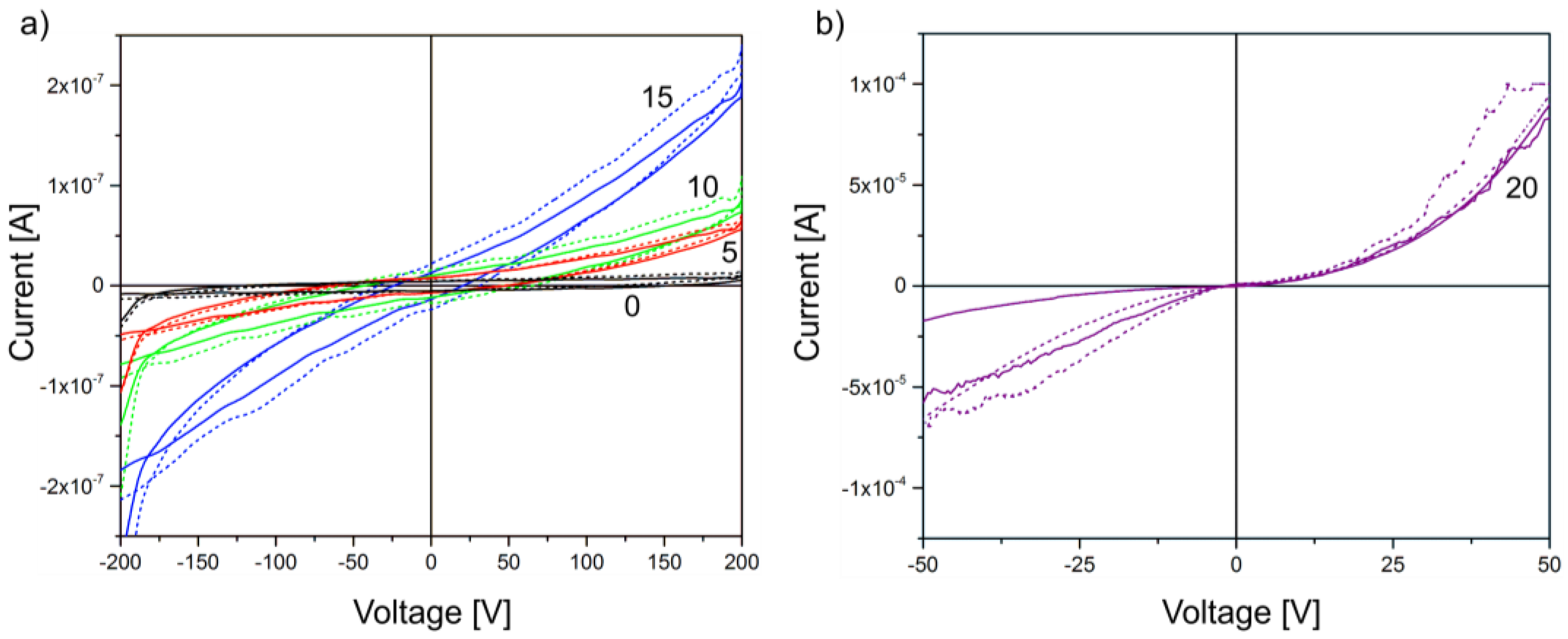

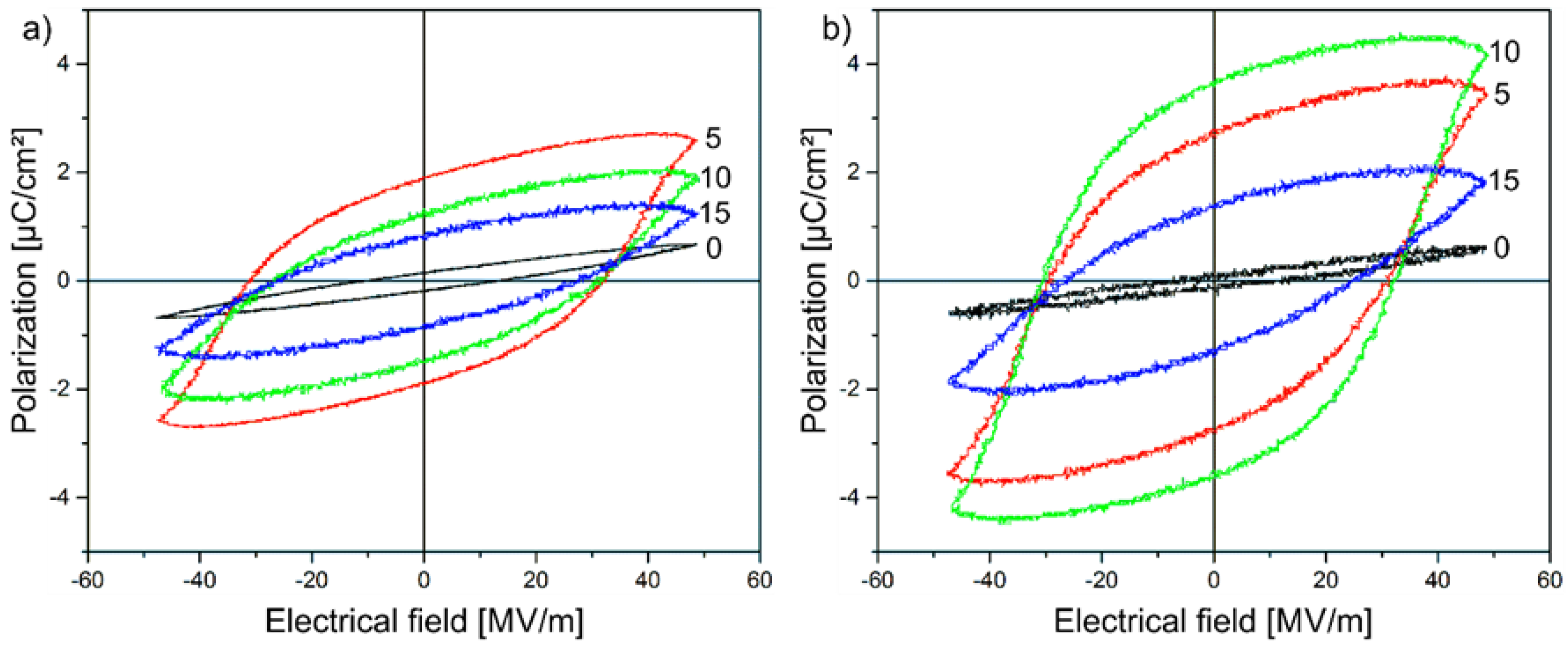

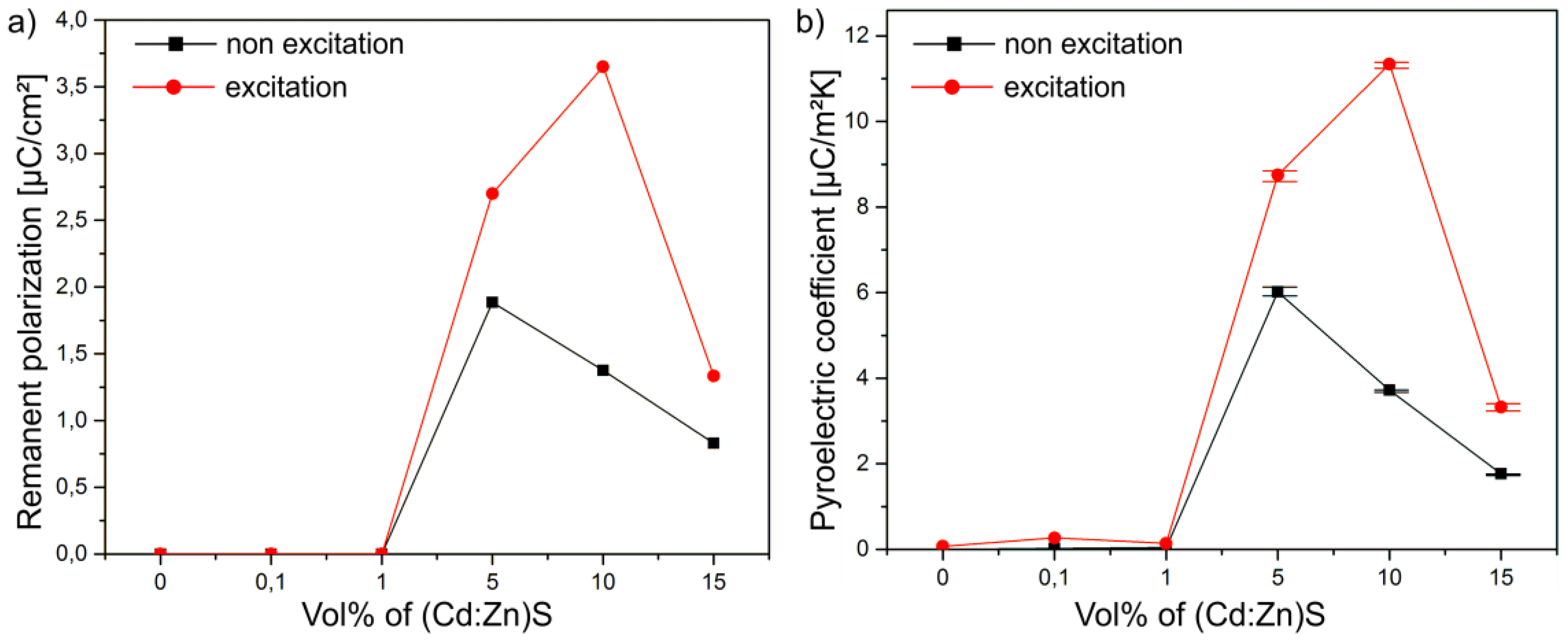

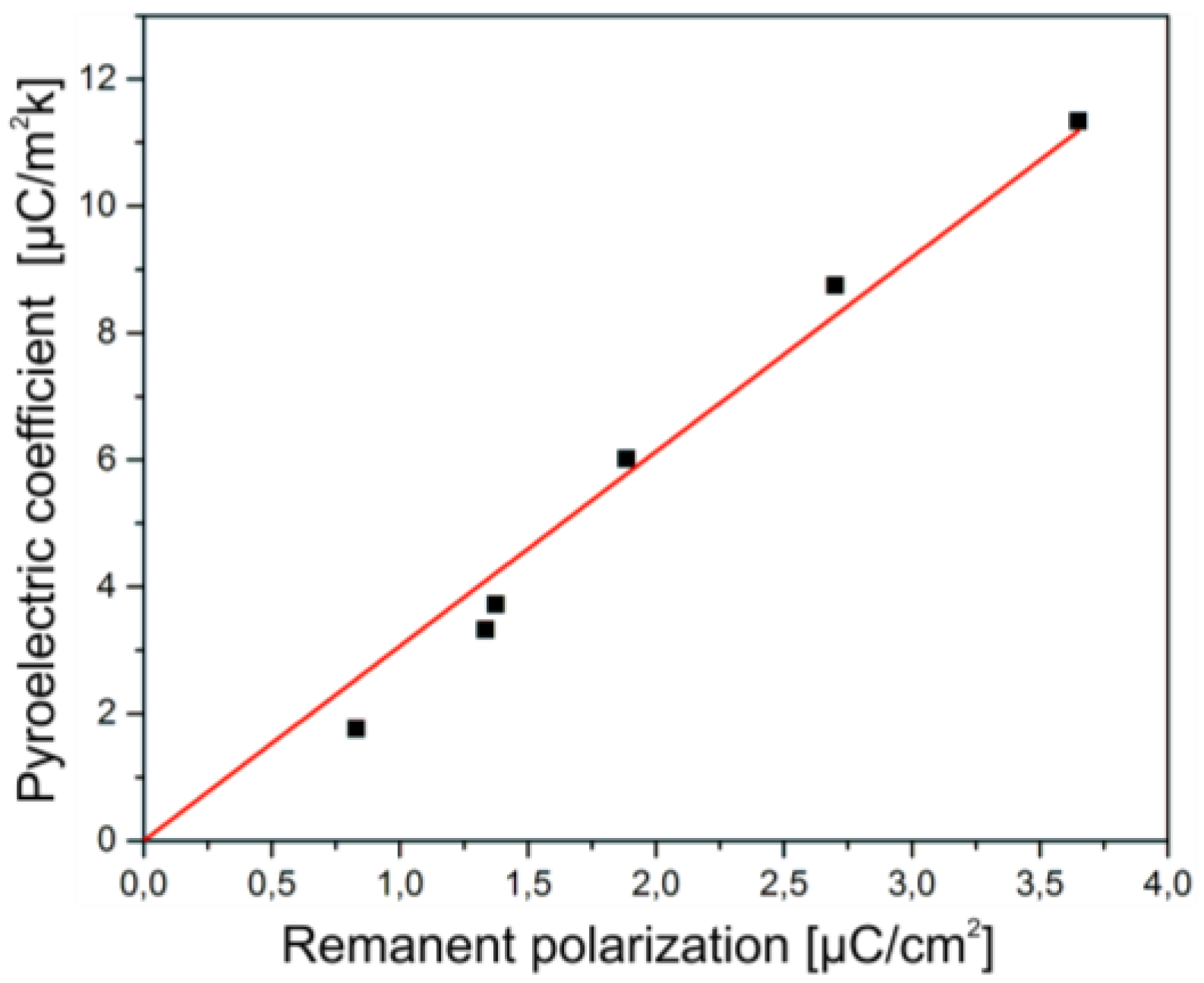

3.2. Electrical and Ferroelectric Properties

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, B.; Xu, C.; Zhang, F.; Zheng, J.; Xu, C. Self-polarized piezoelectric thin films: Preparation, formation mechanism and application. J. Mater. Chem. C 2015, 3, 8926–8931. [Google Scholar] [CrossRef]

- Li, M.; Katsouras, I.; Piliego, C.; Glasser, G.; Lieberwirth, I.; Blom, P.W.; de Leeuw, D.M. Controlling the microstructure of poly(vinylidene-fluoride)(PVDF) thin films for microelectronics. J. Mater. Chem. C 2013, 1, 7695–7702. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Q. Ferroelectric polymers and their energy-related applications. Macromol. Chem. Phys. 2016, 217, 1228–1244. [Google Scholar] [CrossRef]

- Shirinov, A.; Schomburg, W. Pressure sensor from a PVDF film. Sens. Actuators A Phys. 2008, 142, 48–55. [Google Scholar] [CrossRef]

- Yuan, Y.; Reece, T.J.; Sharma, P.; Poddar, S.; Ducharme, S.; Gruverman, A.; Yang, Y.; Huang, J. Efficiency enhancement in organic solar cells with ferroelectric polymers. Nat. Mater. 2011, 10, 296–302. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L. Exploring strategies for high dielectric constant and low loss polymer dielectrics. J. Phys. Chem. Lett. 2014, 5, 3677–3687. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Yang, B.; Liu, J.; Zhu, Y.; Yang, C.; He, Q. A flexible triboelectric-piezoelectric hybrid nanogenerator based on P(VDF-TRFE) nanofibers and PDMS/MWCNT for wearable devices. Sci. Rep. 2016, 6, 36409. [Google Scholar] [CrossRef] [PubMed]

- Von Münch, W.; Nägele, M.; Rinner, M.; Wöhl, G.; Ploss, B.; Ruppel, W. P(VDF/TRFE) copolymer films for the fabrication of pyroelectric arrays. Sens. Actuators A Phys. 1993, 37, 365–369. [Google Scholar] [CrossRef]

- Ploss, B.; Lehmann, P.; Schopf, H.; Lessle, T.; Bauer, S.; Thiemann, U. Integrated pyroelectric detector arrays with the sensor material PVDF. Ferroelectrics 1990, 109, 223–228. [Google Scholar] [CrossRef]

- Lovinger, A.J. Ferroelectric polymers. Science 1983, 220, 1115–1121. [Google Scholar] [CrossRef] [PubMed]

- Matsushige, K.; Nagata, K.; Imada, S.; Takemura, T. The II-I crystal transformation of poly (vinylidene fluoride) under tensile and compressional stresses. Polymer 1980, 21, 1391–1397. [Google Scholar] [CrossRef]

- Lovinger, A.J.; Furukawa, T.; Davis, G.T.; Broadhurst, M.G. Crystallographic changes characterizing the Curie transition in three ferroelectric copolymers of vinylidene fluoride and trifluoroethylene: 1. As-crystallized samples. Polymer 1983, 24, 1225–1232. [Google Scholar] [CrossRef]

- Bargain, F.; Panine, P.; Dos Santos, F.D.; Tence-Girault, S. From solvent-cast to annealed and poled poly (VDF-co-TRFE) films: New insights on the defective ferroelectric phase. Polymer 2016, 105, 144–156. [Google Scholar] [CrossRef]

- Furukawa, T. Structure and functional properties of ferroelectric polymers. Adv. Colloid Interface Sci. 1997, 71, 183–208. [Google Scholar] [CrossRef]

- Dahiya, R.S.; Metta, G.; Valle, M.; Adami, A.; Lorenzelli, L. Piezoelectric oxide semiconductor field effect transistor touch sensing devices. Appl. Phys. Lett. 2009, 95, 034105. [Google Scholar] [CrossRef]

- Oh, S.R.; Wong, T.C.; Tan, C.Y.; Yao, K.; Tay, F.E.-H. Fabrication of piezoelectric polymer multilayers on flexible substrates for energy harvesting. Smart Mater. Struct. 2013, 23, 015013. [Google Scholar] [CrossRef]

- Rendl, C.; Kim, D.; Fanello, S.; Parzer, P.; Rhemann, C.; Taylor, J.; Zirkl, M.; Scheipl, G.; Rothl, T.; Michael, H.; et al. Flexsense: A transparent self-sensing deformable surface. In Proceedings of the 27th Annual ACM Symposium on User Interface Software and Technology, Honolulu, HI, USA, 5–8 October 2014; pp. 129–138. [Google Scholar]

- Graz, I.; Krause, M.; Bauer-Gogonea, S.; Bauer, S.; Lacour, S.P.; Ploss, B.; Zirkl, M.; Stadlober, B.; Wagner, S. Flexible active-matrix cells with selectively poled bifunctional polymer-ceramic nanocomposite for pressure and temperature sensing skin. J. Appl. Phys. 2009, 106, 034503. [Google Scholar] [CrossRef]

- Ploss, B.; Ploss, B.; Shin, F.G.; Chan, H.L.; Choy, C. Pyroelectric activity of ferroelectric PT/PVDF-TrFE. IEEE Trans. Dielectr. Electr. Insul. 2000, 7, 517–522. [Google Scholar] [CrossRef]

- Martins, P.; Lasheras, A.; Gutierrez, J.; Barandiaran, J.; Orue, I.; Lanceros-Mendez, S. Optimizing piezoelectric and magnetoelectric responses on CoFe2O4/P(VDF-TrFE) nanocomposites. J. Phys. D Appl. Phys. 2011, 44, 495303. [Google Scholar] [CrossRef]

- Paik, H.; Choi, Y.-Y.; Hong, S.; No, K. Effect of Ag nanoparticle concentration on the electrical and ferroelectric properties of Ag/P(VDF-TrFE) composite films. Sci. Rep. 2015, 5. [Google Scholar] [CrossRef] [PubMed]

- Tsutsumi, N.; Kosugi, R.; Kinashi, K.; Sakai, W. Nature of the enhancement in ferroelectric properties by gold nanoparticles in vinylidene fluoride and trifluoroethylene copolymer. ACS Appl. Mater. Interfaces 2016, 8, 16816–16822. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.X.; Dai, J.Y.; So, L.C.; Sun, C.L.; Lo, C.Y.; Or, S.W.; Chan, H.L.W. The effect of magnetic nanoparticles on the morphology, ferroelectric, and magnetoelectric behaviors of CFO/P(VDF-TrFE) 0–3 nanocomposites. J. Appl. Phys. 2009, 105, 054102. [Google Scholar] [CrossRef]

- Zhu, H.; Liu, Z.; Wang, F.; Yan, K. Influence of shell thickness on the dielectric properties of composites filled with Ag@SiO2 nanoparticles. RSC Adv. 2016, 6, 64634–64639. [Google Scholar] [CrossRef]

- Zou, Y.; Han, L.; Yuan, G.; Liu, B.; Zhao, X.; Tian, B.; Wang, J.; Sun, S.; Sun, J.; Meng, X. Enhanced ferroelectric and dielectric properties of the P(VDF-TrFE)/Ag nanoparticles composite thin films. J. Mater. Sci. Mater. Electron. 2014, 25, 3461–3465. [Google Scholar] [CrossRef]

- Ploss, B.; Shin, F. A general formula for the effective pyroelectric coefficient of composites. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 1170–1176. [Google Scholar] [CrossRef]

- Ploss, B. Improving the pyroelectric coefficient of ceramic/polymer composite by doping the polymer matrix. Ferroelectrics 2006, 338, 145–151. [Google Scholar] [CrossRef]

- Ploss, B.; Krause, M. Optimized pyroelectric 0–3 composites of PZT particles in doped polyurethane. In Proceedings of the Sixteenth IEEE International Symposium on Applications of Ferroelectrics ISAF, Nara, Japan, 27–31 May 2007; pp. 818–820. [Google Scholar]

- Almeida, N.A.; Martins, P.M.; Teixeira, S.; da Silva, J.A.L.; Sencadas, V.; Kühn, K.; Cuniberti, G.; Lanceros-Mendez, S.; Marques, P.A. TiO2/graphene oxide immobilized in P(VDF-TrFE) electrospun membranes with enhanced visible-light-induced photocatalytic performance. J. Mater. Sci. 2016, 51, 6974–6986. [Google Scholar] [CrossRef]

- Martins, P.; Gomez, V.; Lopes, A.; Tavares, C.; Botelho, G.; Irusta, S.; Lanceros-Mendez, S. Improving photocatalytic performance and recyclability by development of er-doped and er/pr-codoped TiO2/Poly (vinylidene difluoride)–trifluoroethylene composite membranes. J. Phys. Chem. C 2014, 118, 27944–27953. [Google Scholar] [CrossRef]

- Meng, N.; Zhu, X.; Mao, R.; Reece, M.J.; Bilotti, E. Nanoscale interfacial electroactivity in PVDF/PVDF-TrFE blended films with enhanced dielectric and ferroelectric properties. J. Mater. Chem. C 2017, 5, 3296–3305. [Google Scholar] [CrossRef]

- Jiang, Z.-Y.; Zheng, G.-P.; Zheng, X.-C.; Wang, H. Exceptionally high negative electro-caloric effects of poly (VDF–co–TrFE) based nanocomposites tuned by the geometries of barium titanate nanofillers. Polymers 2017, 9, 315. [Google Scholar] [CrossRef]

- Lutkenhaus, J.L.; McEnnis, K.; Serghei, A.; Russell, T.P. Confinement effects on crystallization and curie transitions of poly(vinylidene fluoride-co-trifluoroethylene). Macromolecules 2010, 43, 3844–3850. [Google Scholar] [CrossRef]

- Li, M.; Jiang, J.; Guo, L. Synthesis, characterization, and photoelectrochemical study of Cd1−xZnxS solid solution thin films deposited by spray pyrolysis for water splitting. Int. J. Hydrogen Energy 2010, 35, 7036–7042. [Google Scholar] [CrossRef]

- Wang, L.; Wang, W.; Shang, M.; Yin, W.; Sun, S.; Zhang, L. Enhanced photocatalytic hydrogen evolution under visible light over Cd1−xZnxS solid solution with cubic zinc blend phase. Int. J. Hydrogen Energy 2010, 35, 19–25. [Google Scholar] [CrossRef]

- Furukawa, T. Piezoelectricity and pyroelectricity in polymers. IEEE Trans. Electr. Insul. 1989, 24, 375–394. [Google Scholar] [CrossRef]

- Ploss, B.; Domig, A. Static and dynamic pyroelectric properties of PVDF. Ferroelectrics 1994, 159, 263–268. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Engel, S.; Smykalla, D.; Ploss, B.; Gräf, S.; Müller, F.A. Effect of (Cd:Zn)S Particle Concentration and Photoexcitation on the Electrical and Ferroelectric Properties of (Cd:Zn)S/P(VDF-TrFE) Composite Films. Polymers 2017, 9, 650. https://doi.org/10.3390/polym9120650

Engel S, Smykalla D, Ploss B, Gräf S, Müller FA. Effect of (Cd:Zn)S Particle Concentration and Photoexcitation on the Electrical and Ferroelectric Properties of (Cd:Zn)S/P(VDF-TrFE) Composite Films. Polymers. 2017; 9(12):650. https://doi.org/10.3390/polym9120650

Chicago/Turabian StyleEngel, Sebastian, David Smykalla, Bernd Ploss, Stephan Gräf, and Frank A. Müller. 2017. "Effect of (Cd:Zn)S Particle Concentration and Photoexcitation on the Electrical and Ferroelectric Properties of (Cd:Zn)S/P(VDF-TrFE) Composite Films" Polymers 9, no. 12: 650. https://doi.org/10.3390/polym9120650