Preparation and Application of Starch/Polyvinyl Alcohol/Citric Acid Ternary Blend Antimicrobial Functional Food Packaging Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Films

2.3. Surface Color and Transparency of Films

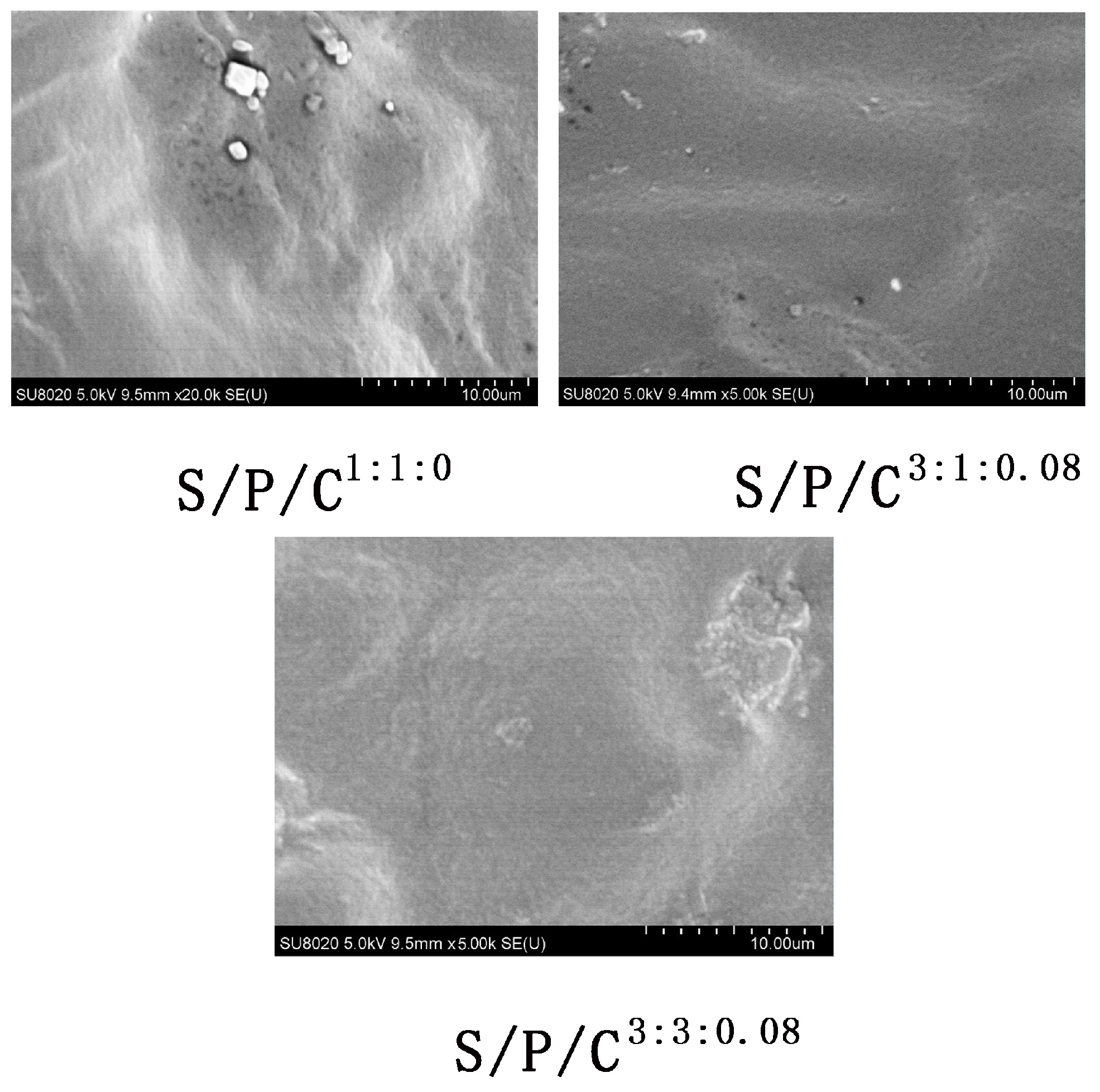

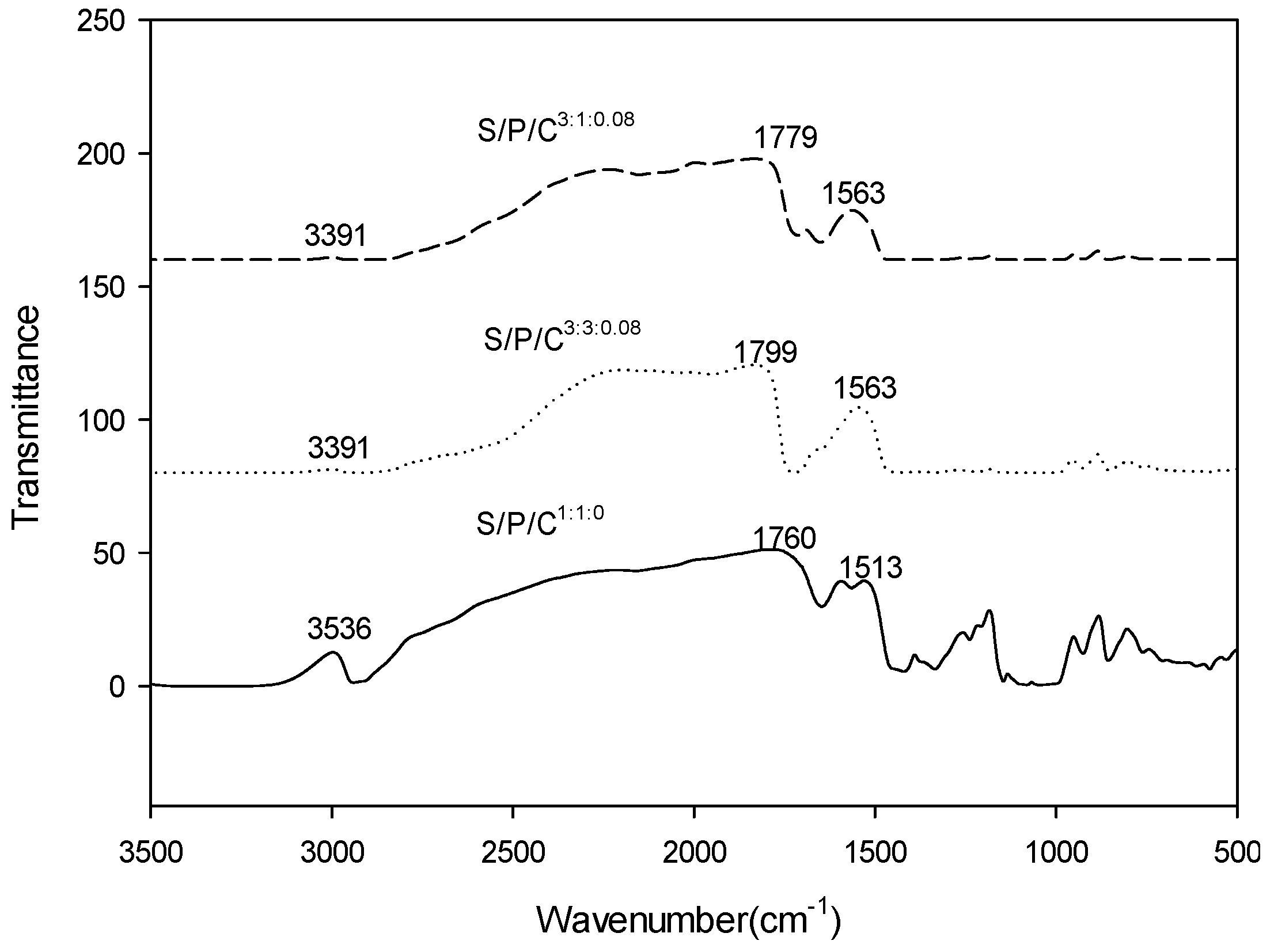

2.4. Surface Morphology and FTIR Analysis

2.5. Mechanical Properties

- Ts—Tensile strength, MPa;

- F—The maximum tensile force when the sample breaks, N;

- S—Cross-sectional area of specimen, m2.

2.6. Water Vapor Permeability (WVP)

- WVP—Water vapor transmission coefficient, ×10–9 g·m/(m2·Pa·s);

- WVTR—The amount of water vapor transmitted through the instrument was measured, g/(m·d);

- n—Film thickness, mm;

- Δp—The output pressure of the gas is 0.20 MPa.

2.7. Determination of Solubility of Cling Film References

- D—Dissolution rate, %;

- M0—Initial film weight, g.

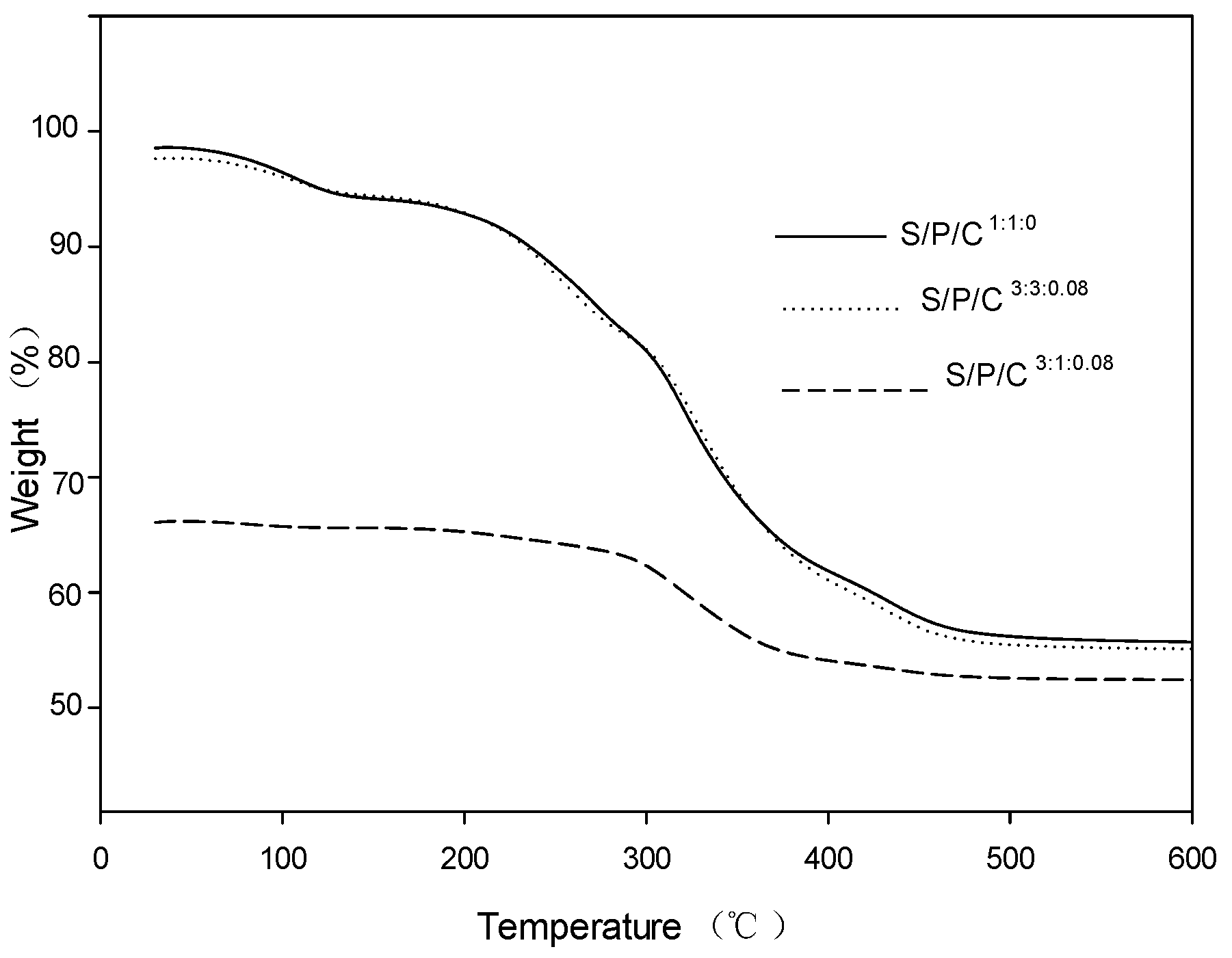

2.8. Thermal Stability

2.9. Antibacterial Activity

2.10. Packaging Test

2.10.1. Determination of Malondialdehyde (MDA) Content

- V—Volume of extract, mL;

- V1—Volume of reaction, mL;

- V2—Determined volume of extract, mL;

- M—Fresh weight of plant tissue, g.

2.10.2. Determination of Ascorbic Acid Content

- X—mg of ascorbic acid per 100 g of figs, mg/(100 g);

- H—Concentration of standard iodine, mg/mL;

- V1—Consumption of standard iodine titration volume, mL;

- V2—Consumption of standard iodine solution volume by blank titration, mL;

- M—Quality of the sample, g.

2.10.3. Determination of Reducing Sugar Content

- F-10 mL of basic copper tartrate solution corresponds to the mass of glucose, mg;

- C-Concentration of standard glucose solution, mg/mL;

- V-The volume of the standard glucose solution consumed during calibration, mL.

- X—mg of reducing sugar per 100 g of figs, mg/(100 g);

- M—Weight of sample, g; F-10 mL of basic copper tartrate solution corresponds to the mass of glucose, mg;

- V—The volume of the sample solution consumed in the assay, mL;

- 250—Total volume of sample solution, mL.

2.10.4. Determination of Titratable Acid Content

- X—Number of grams of acid per 100 g of figs, g/(100 g);

- C—Concentration of sodium hydroxide standard titration solution, mol/L;

- V1—The volume of the standard sodium hydroxide solution consumed, mL;

- V2—The volume of the standard sodium hydroxide solution consumed in the blank experiment, in mL;

- K—Conversion factor of acid, 0.067 in malic acid;

- M—Weight of sample, g.

2.10.5. Determination of Polyphenols

- P—Content of polyphenols, g/100 mL;

- A—Absorbance of sample solution;

- V1—Total sample solution, mL;

- V2—The amount of test solution taken, mL;

- M—Quality of sample, g.

2.10.6. Determination of the Activity of Catalase (CAT)

2.11. Statistical Analysis

3. Results and Discussion

3.1. Apparent Color and Optical Properties of Films

3.2. Microstructure and Fourier Transform Infrared (FTIR) Analysis

3.3. Mechanical Properties

3.4. Water Vapor Permeability (WVP)

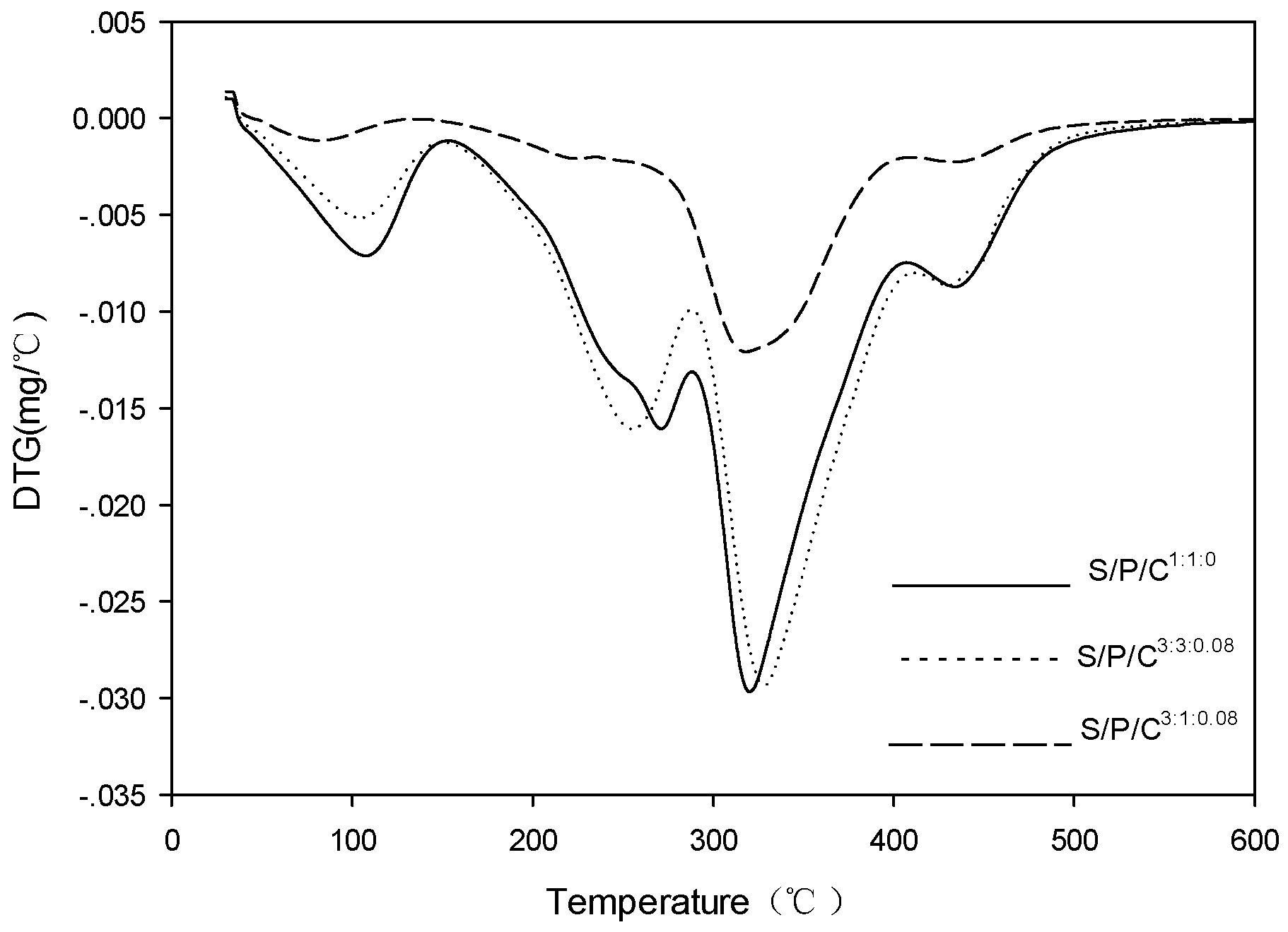

3.5. Thermal Stability

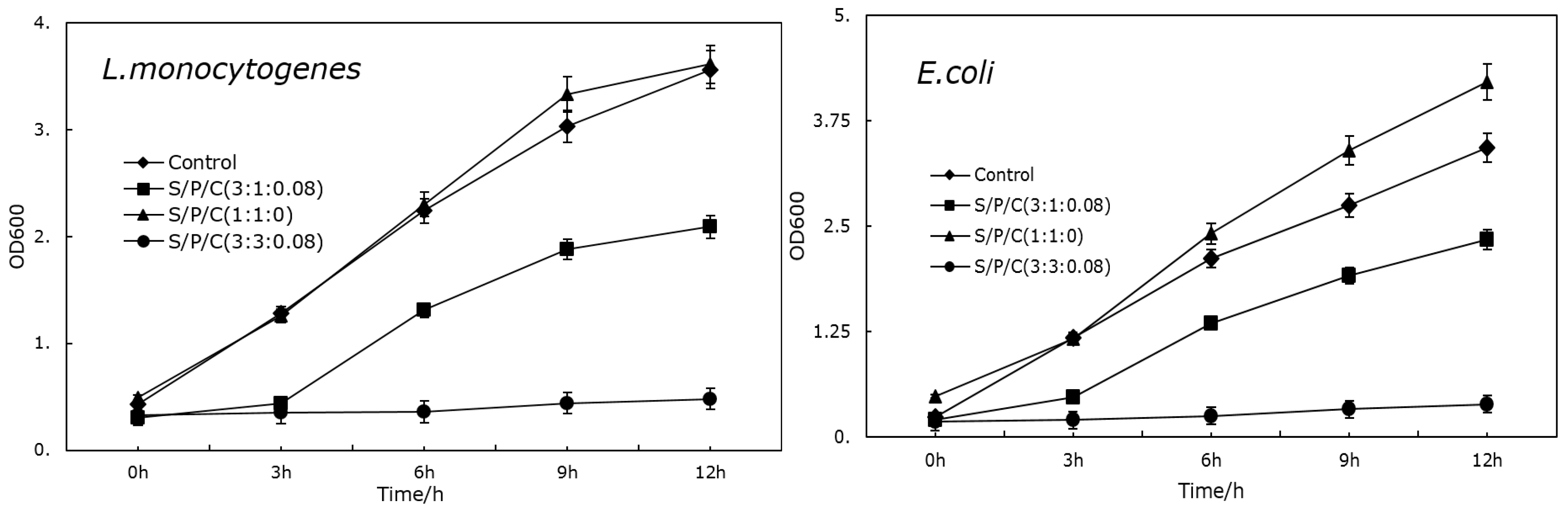

3.6. Antimicrobial Activity

3.7. Packaging Test

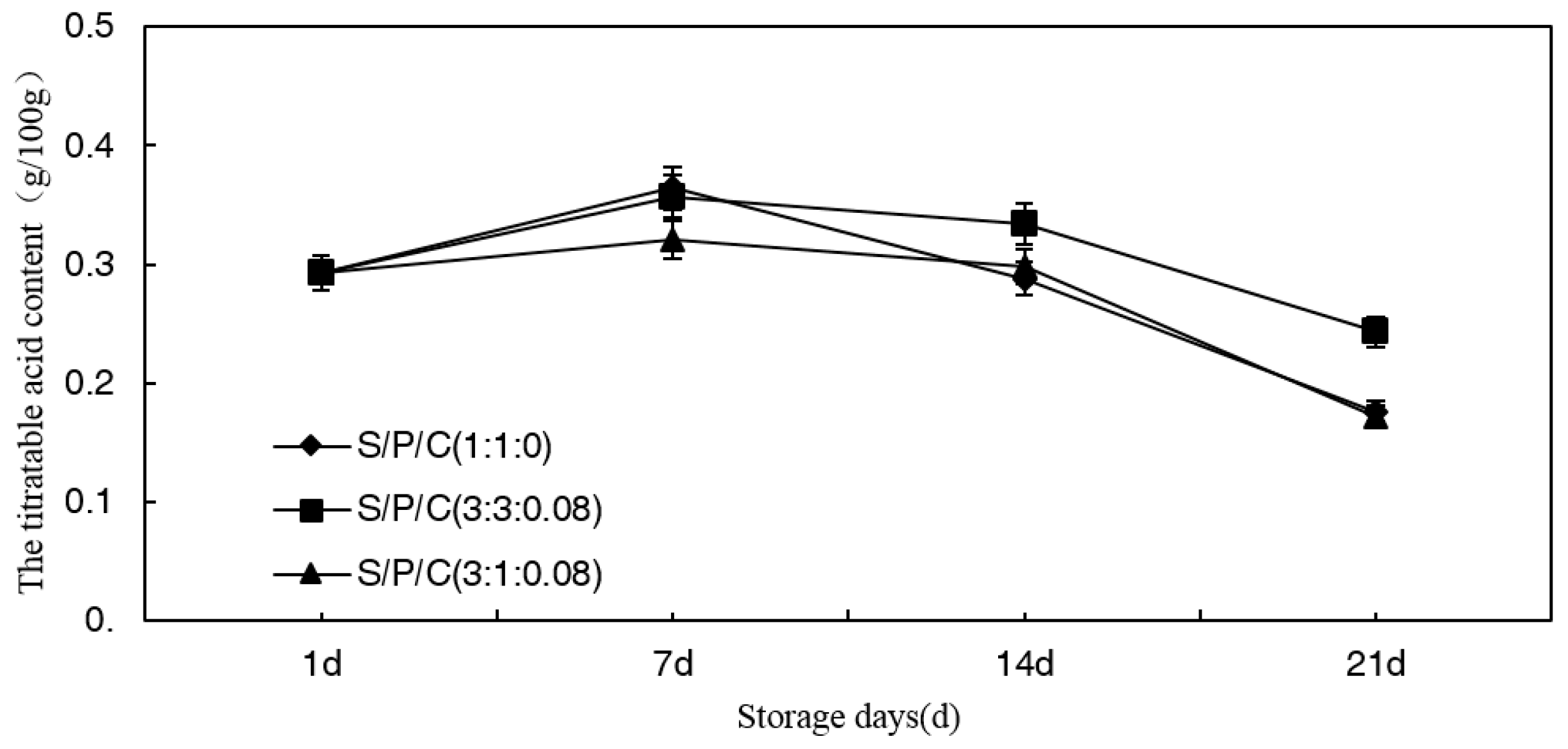

3.7.1. Effect of Degradable Antibacterial Films on Titratable Acid (TA) Content during Storage

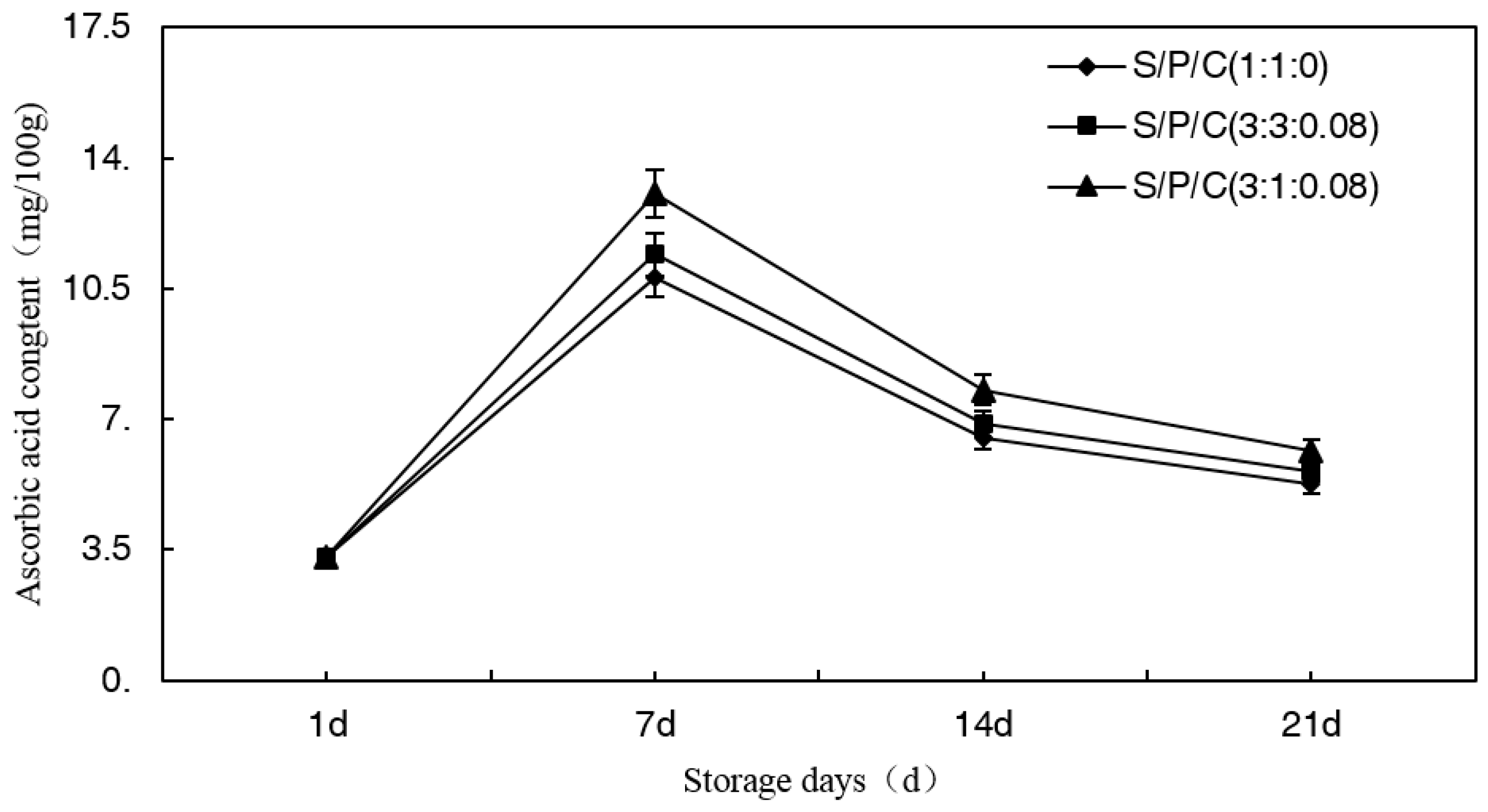

3.7.2. Effect of Degradable Antibacterial Films on Ascorbic Acid Content during Storage

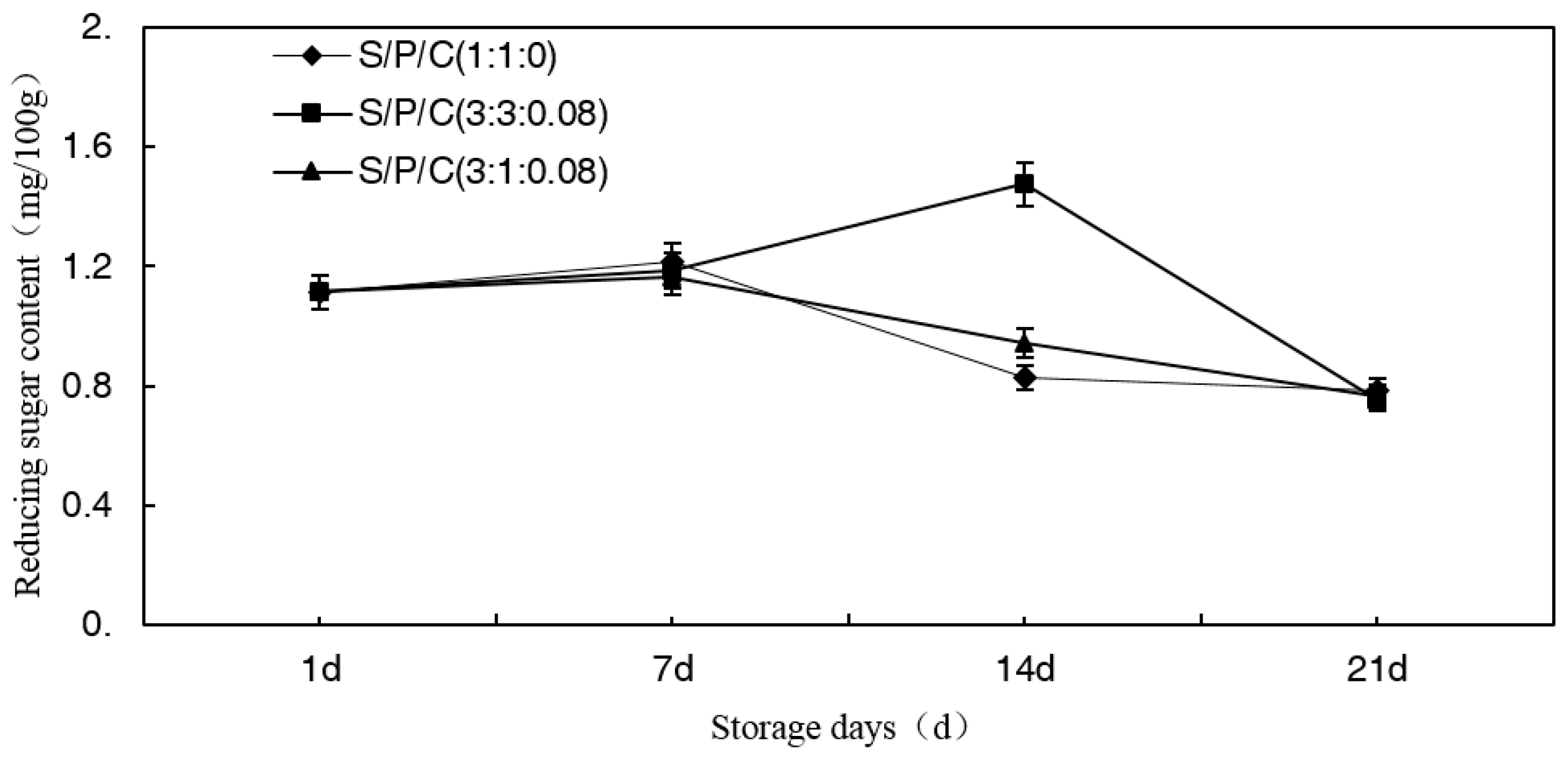

3.7.3. Effect of Degradable Antibacterial Films on Reducing Sugar Content during Storage

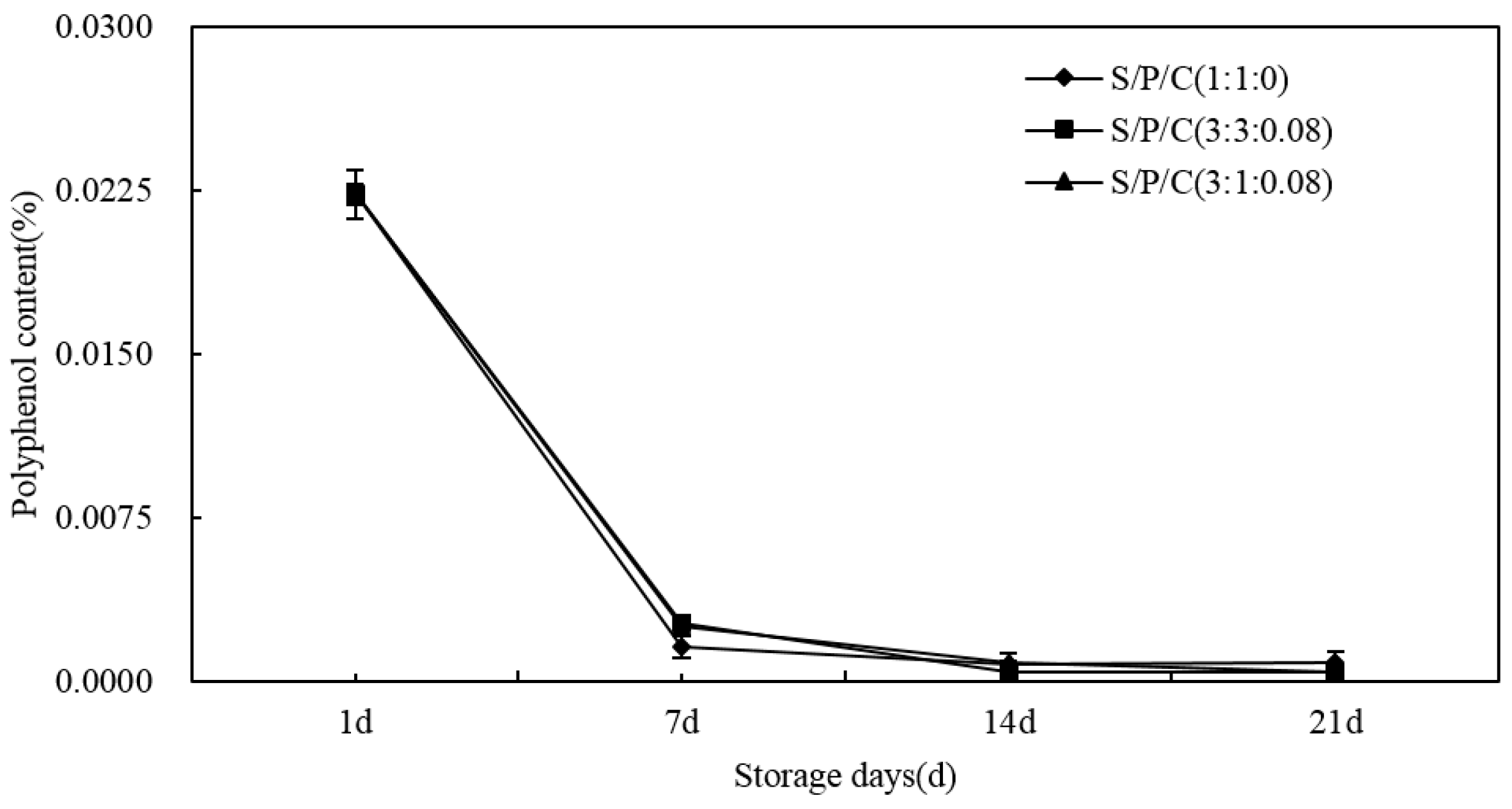

3.7.4. Effect of Degradable Antibacterial Films on Polyphenol Content during Storage

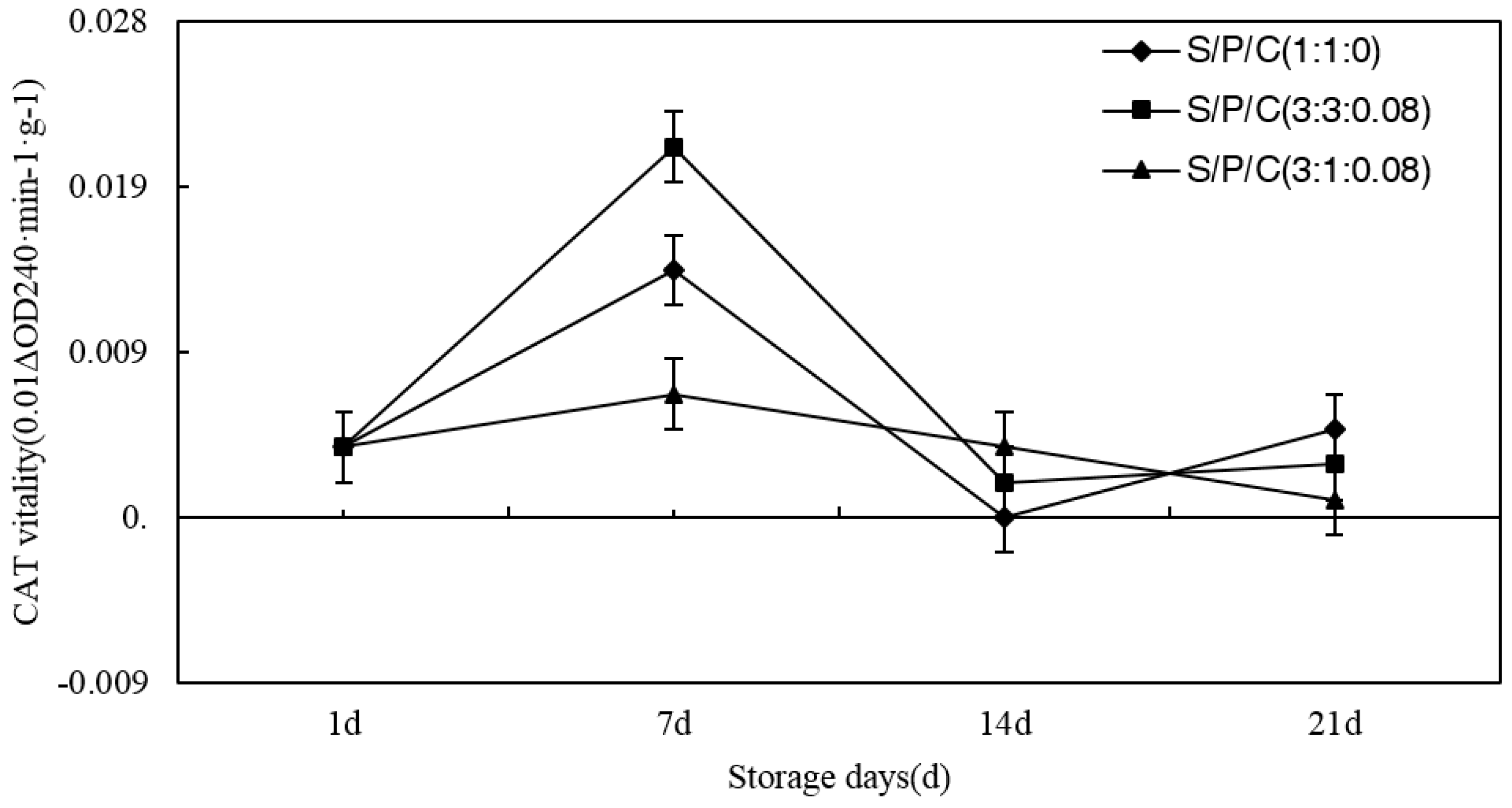

3.7.5. Effect of Degradable Antibacterial Films on CAT Content during Storage

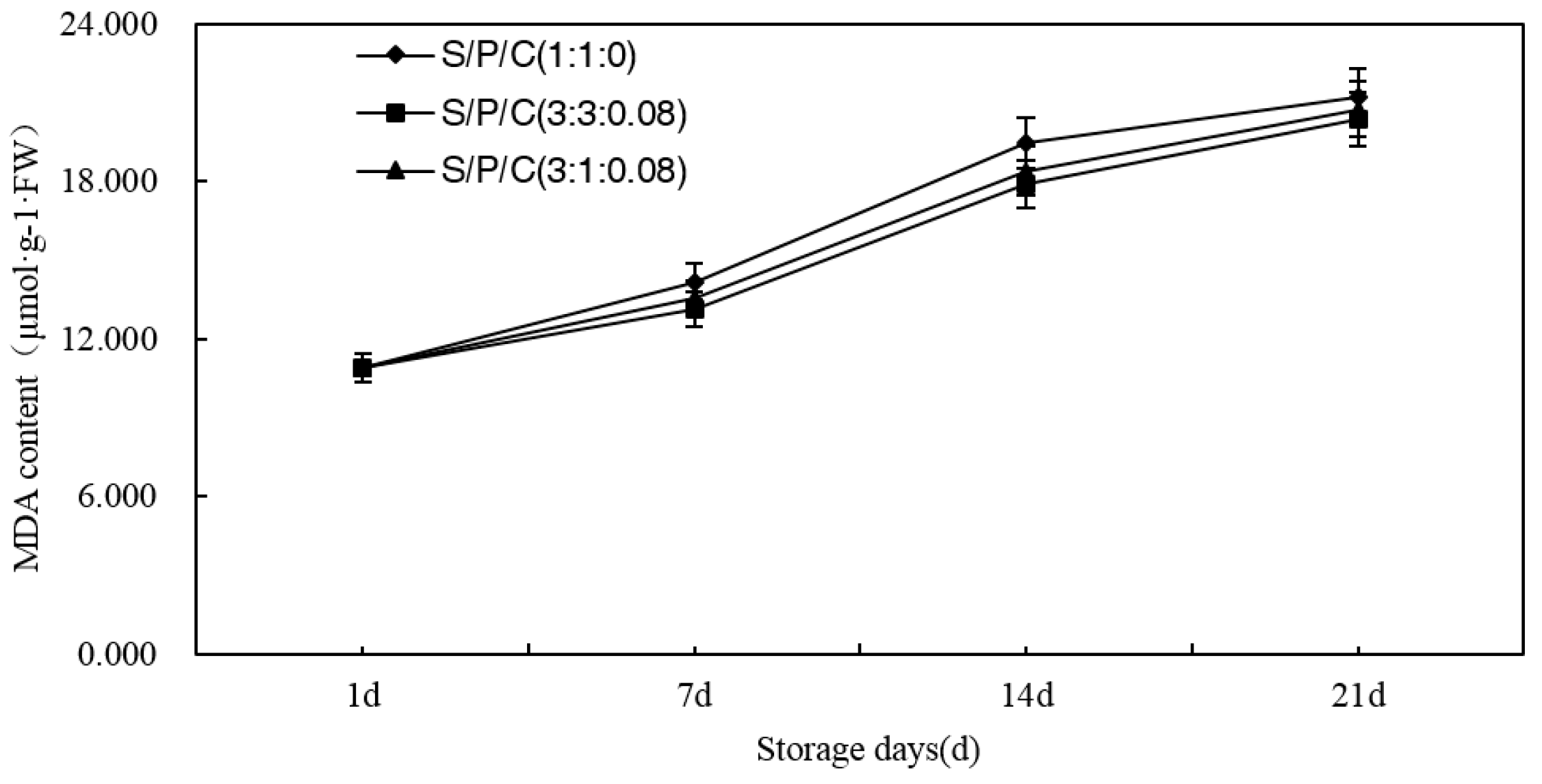

3.7.6. Effect of Degradable Antibacterial Films on MDA Content during Storage

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shankar, S.; Teng, X.N.; Li, G.B.; Rhim, J.W. Preparation, characterization, and antimicrobial activity of gelatin/ZnO nanocomposite films. Food Hydrocoll. 2015, 45, 264–271. [Google Scholar] [CrossRef]

- Sudesh, K.; Iwata, T. Sustainability of biobased and biodegradable plastics. Clean Soil Air Water 2008, 36, 433–442. [Google Scholar] [CrossRef]

- Follain, N.; Joly, C.; Dole, P.; Bliard, C. Properties of starch based blends. Part 2. Influence of poly vinyl alcohol addition and photocrosslinking on starch based materials mechanical properties. Carbohydr. Polym. 2005, 60, 185–192. [Google Scholar] [CrossRef]

- De Dicastillo, C.L.; Bustos, F.; Guarda, A.; Galotto, M.J. Cross-linked methyl cellulose films with murta fruit extract for antioxidant and antimicrobial active food packaging. Food Hydrocoll. 2016, 10, 335–344. [Google Scholar] [CrossRef]

- Qin, Y.; Liu, D.; Wu, Y.; Yuan, M.; Li, L.; Yang, J. Effect of PLA/PCL/cinnamaldehyde antimicrobial packaging on physicochemical and microbial quality of button mushroom (agaricusbisporus). Postharvest Biol. Technol. 2015, 99, 73–79. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Yang, F.; Yang, X. Excellent antimicrobial properties of mesoporous anatase TiO2 and Ag/TiO2 composite films. Microporous Mesoporous Mater. 2008, 114, 431–439. [Google Scholar] [CrossRef]

- Quintavalla, S.; Vicini, L. Antimicrobial food packaging in meat industry. Meat Sci. 2002, 62, 373–380. [Google Scholar] [CrossRef]

- Cano, A.; Cháfer, M.; Chiralt, A.; González-Martínez, C. Physical and antimicrobial properties of starch-pva blend films as affected by the incorporation of natural antimicrobial agents. Foods 2016, 5, 42–45. [Google Scholar] [CrossRef] [PubMed]

- Virtanen, S.; Vartianen, J.; Setälä, H.; Tammelin, T.; Vuoti, S. Modified nanofibrillated cellulose-polyvinyl alcohol films with improved mechanical performance. RSC Adv. 2014, 4, 11343–11350. [Google Scholar] [CrossRef]

- Appendini, P.; Hotchkiss, J.H. Review of antimicrobial food packaging. Innov. Food Sci. Emerg. 2002, 3, 113–126. [Google Scholar] [CrossRef]

- Lin, D.R.; Hu, L.J.; Xing, B.S.; You, H.; Loy, D.A. Mechanisms of competitive adsorption organic pollutants on hexylene-bridged polysilsesquioxane(BPS). Materials 2015, 8, 5806–5817. [Google Scholar] [CrossRef]

- Pranoto, Y.; Salokhe, V.M.; Rakshit, S.K. Physical and antibacterial properties of alginate-based edible film incorporated with garlic oil. Food Res. Int. 2005, 38, 267–272. [Google Scholar] [CrossRef]

- Xu, W.; Qu, W.; Huang, K.; Guo, F.; Yang, J.; Zhao, H.; Luo, Y. Antibacterial effect of grapefruit seed extract on food-borne pathogena and its application in the preservation of minimally processed vegetables. Postharvest Biol. Technol. 2007, 45, 126–133. [Google Scholar] [CrossRef]

- Tripathi, P.; Dubey, N.K.; Shukia, A.K. Use of essential oils as post-harvest botanical fungicides in the management of grey mould of grapes caused by Botrytis cinerea. World J. Microbiol. Biotechnol. 2008, 24, 39–46. [Google Scholar] [CrossRef]

- Lin, D.R.; Hu, L.J.; You, H.; Williams, R.J.J. Synthesis and characterization of a nanostructured photoluminescent silsesquioxane containing urea and dodecyl groups that can be patterned on carbon films. Eur. Polym. J. 2011, 47, 1526–1533. [Google Scholar] [CrossRef]

- Mehdizadeh, T.; Tajik, H.; Rohani, S.M.R.; Oromiehie, A.R. Antibacterial antioxidant and optical properties of edible starch-chitosan composite film containing thymus kotschyanus essential oil. Vet. Res. Forum 2012, 3, 167–173. [Google Scholar] [PubMed]

- Masril, K.I. Antibacterial and antioxidant of uwi (dioscoreaalata L) starch edible film incorporated with ginger essential oil. Int. J. Biosci. Biochem. Bioinform. 2013, 3, 354–356. [Google Scholar]

- Kusnadi, J.; Budyanto, P. Antibacterial active packaging edible film formulation with addition teak (tectonagrandis) leaf extract. Int. J. Life Sci. Biotechnol. Pharm. Res. 2015, 4, 79–84. [Google Scholar]

- Vovlas, N.; Larizza, A. Relationship of schistonchuscaprifici (aphelenchoididae) with fig inflorescences, the fig pollinator Blastophagapsenes, and its cleptoparasitePhilotrypesiscaricae. Fund. Appl. Nematol. 1996, 19, 443–448. [Google Scholar]

- Bucić-Kojić, A.; Planinić, M.; Tomas, S.; Jokić, S.; Mujić, I.; Bilić, M.; Velić, D. Effect of extraction conditions on the extractability of phenolic compounds from lyophilised fig fruits (ficuscarica L.). Pol. J. Food Nutr. Sci. 2011, 61, 195. [Google Scholar]

- Ozkaya, O.; ÇÖmlekÇioglu, S.; DemircioĞlu, H. Assessment of the potential of 1-methylcyclopropene treatments to maintain fruit quality of the common fig (ficuscarica L. cv. bursa siyahi) during refrigerated storage. Not. Bot. Horti Agrobot. 2014, 42, 516–522. [Google Scholar]

- Bernalte, G.M.; Hernandez, M.T.; Lozano, R.M. Effect of temperature on the shelf-life of fig fruit during refrigerated storage. Acta Hortic. 2003, 6, 229–232. [Google Scholar] [CrossRef]

- Gozlekci, S.; Erkan, M.; Karasahin, I.; Sahin, G. Effect of 1-methylcyclopropene (1-MCP) on fig (Ficuscarica cv. Bardakci) storage. Acta Hortic. 2008, 798, 325–330. [Google Scholar] [CrossRef]

- Weibin, J.; Kai, M.; Zhifeng, L.; Yelin, W. The production and research of fig (Ficuscarica L.) in China. Acta Hortic. 2003, 6, 191–196. [Google Scholar]

- Javed, A.; Iffat, K. Evaluation of antioxidant and antimicrobial activity of ficuscarica leaves: An in vitro approach. J. Plant Pathol. Microbiol. 2013, 4, 1–4. [Google Scholar]

- Soliva-Fortuny, R.C.; Martı́n-Belloso, O. New advances in extending the shelf-life of fresh-cut fruits: A review. Trends Food Sci. Technol. 2003, 14, 341–353. [Google Scholar] [CrossRef]

- Veronique, C. Bioactive packaging technologies for extended shelf life of meat-based products. Meat Sci. 2008, 78, 90–103. [Google Scholar]

- Wang, L.F.; Rhim, J.W. Preparation and application of agar/alginate/collagen ternary blend functional food packaging films. Int. J. Biol. Macromol. 2015, 80, 460–468. [Google Scholar] [CrossRef] [PubMed]

- Guerrero, P.; Etxabide, A.; Leceta, I.; Penalba, M.; DelaCaba, K. Extraction of agar from Gelidium sesquipedale (Rodhophyta) and surface characterization of agarbased films. Carbohydr. Polym. 2014, 99, 491–498. [Google Scholar] [CrossRef] [PubMed]

- Cristiaen, D.; Bodard, M. Spectroscopic infrarouge de films dagar de Gracilariaverrucosa (Huds.) papenfuss. Bot. Mar. 1983, 26, 425–427. [Google Scholar]

- Kanmani, P.; Rhim, J.W. Physical, mechanical and antimicrobial properties of gelatin based active nanocomposite films containing AgNPs and nanoclay. Food Hydrocoll. 2014, 35, 644–652. [Google Scholar] [CrossRef]

- Rhim, J.W. Physical-mechanical properties of ager/k-carrageenan blend film and derived clay nanocomposite film. J. Food Sci. 2012, 77, 66–73. [Google Scholar] [CrossRef] [PubMed]

- Tako, M.; Higa, M.; Medoruma, K.; Nakasone, Y. A highly methylated agar from red seaweed, gracilaria arcuata. Bot. Mar. 1999, 42, 513–517. [Google Scholar] [CrossRef]

- Armisen, R.; Galatas, F. Production, properties and uses of agar. In Production and Utilization of Products from Commercial Seaweeds, FAO Fisheries Technical Paper, 1st ed.; McHugh, D.J., Ed.; Food and Agriculture Organization of the United Nations: Rome, Italy, 1987; pp. 1–57. [Google Scholar]

- Gomez-Ordonez, E.; Ruperez, P. FTIR-ATR spectroscopy as a tool for polysaccharide identification in edible brown and red seaweeds. Food Hydrocoll. 2011, 25, 1514–1520. [Google Scholar] [CrossRef]

- Reddy, N.; Yang, Y.Q. Citric acid cross-linking of starch films. Food Chem. 2010, 118, 702–711. [Google Scholar] [CrossRef]

- Rhim, J.W.; Wang, L.F. Mechanical and water barrier properties of agar/carrageenan/konjacglucomannan ternary blend biohydrogel films. Carbohydr. Polym. 2013, 96, 71–81. [Google Scholar] [CrossRef] [PubMed]

- Selke, S.E.M.; Cutler, J.D.; Hernandez, R.J. Plastics Packaging: Properties, Processing, Applications and Regulations, 2nd ed.; Hanser: Munich, Germany, 2004; p. 203. [Google Scholar]

- Kanmani, P.; Rhim, J.W. Physicochemical properties of gelatin/silver nanoparticle antimicrobial composite films. Food Chem. 2014, 148, 162–169. [Google Scholar] [CrossRef] [PubMed]

- Rhim, J.W.; Wang, L.F.; Hong, S.I. Preparation and characterization of agar/AgNPs composite films with antimicrobial activity. Food Hydrocoll. 2013, 33, 327–335. [Google Scholar] [CrossRef]

- Restaino, L.; Komatsu, K.K.; Syracuse, M.J. Effects of acids on potassium sorbate inhibition of food-related microorganisms in culture media. J. Food Sci. 1982, 47, 134–138. [Google Scholar] [CrossRef]

- Perdones, Á.; Escriche, I.; Chiralt, A.; Vargas, M. Effect of chitosan-lemon essential oil coatings on volatile profile of strawberries during storage. Food Chem. 2016, 197, 979–986. [Google Scholar] [CrossRef] [PubMed]

- Ghafir, S.A.M.; Gadalla, S.O.; Murajei, B.N.; El-Nady, M. Physiological and anatomical comparison between four different apple cultivars under cold-storage conditions. Afr. J. Plant Sci. 2009, 3, 133–138. [Google Scholar]

- Jan, I.; Rab, A. Influence of storage duration on physico-chemical changes in fruit of apple cultivars. J. Anim. Plant Sci. 2012, 22, 708–714. [Google Scholar]

- Irfan, P.K.; Vanjakshi, V.; Prakash, M.N.K.; Ravi, R.; Kudachikar, V.B. Calcium chloride extends the keeping quality of fig fruit (Ficuscarica L.) during storage and shelf-life. Postharvest Biol. Technol. 2013, 82, 70–75. [Google Scholar] [CrossRef]

- Marpudi, L.S.; Ramachandran, P.; Srividya, N. Aloe vera gel coating for postharvest quality maintenance of fresh fig fruits. Res. J. Pharm. Biol. Chem. Sci. 2013, 4, 878–887. [Google Scholar]

- Wang, J.; Chao, Y. Effect of 60 Co irradiation on drying characteristics of apple. J. Food Eng. 2003, 56, 347–351. [Google Scholar] [CrossRef]

- Jiang, Y.; Fu, J. Inhibition of polyphenol oxidase and the browning control of litchi fruit by glutathione and citric acid. Food Chem. 1998, 62, 49–52. [Google Scholar] [CrossRef]

- Santerre, C.R.; Cash, J.N.; Vannorman, D.J. Ascorbic acid/citric acid combination in the processing of frozen apple slices. J. Food Sci. 1988, 53, 1713–1716. [Google Scholar] [CrossRef]

- Nath, A.; Deka, B.C.; Singh, A.; Patel, R.K.; Paul, D.; Misra, L.K.; Ojha, H. Extension of shelf life of pear fruits using different packaging materials. J. Food Sci. Technol. 2012, 49, 556–563. [Google Scholar] [CrossRef] [PubMed]

- Goncalves, E.D.; Antunes, P.L.; Brackmann, A. Controlled atmosphere storage of Asian pears CV. Nijisseiki. Rev. Bras. Frutic. 2000, 22, 226–231. [Google Scholar]

- Park, Y.M. Relationship between instrumental and sensory analysis of quality factors in apple and pear fruits. Korean J. Hortic. Sci. Technol. 2002, 20, 394–398. [Google Scholar]

- Carrillo-Lopez, A.; Cruz-Hernandez, A.; Guevara-Lara, F.; Paredes-Lopez, O. Physico-chemical changes during ripening in storage of two varieties of prickly pear stored at 18 °C. J. Food Sci. Technol. 2003, 40, 461–464. [Google Scholar]

- Feng, C.Y.; Wang, W.W.; Ye, J.F.; Li, S.S.; Wu, Q.; Yin, D.D.; Li, B.; Xu, Y.J.; Wang, L.S. Polyphenol profile and antioxidant activity of the fruit and leaf of vacciniumglaucoalbum from the Tibetan Himalayas. Food Chem. 2017, 219, 490–495. [Google Scholar] [CrossRef] [PubMed]

- Khatabi, O. Extraction and determination of polyphenols and betalain pigments in the Moroccan prickly pear fruits (Opuntiaficusindica). Arabian J. Chem. 2016, 9, 278–281. [Google Scholar] [CrossRef]

- Sheng, L.; Shen, D.; Luo, Y.; Sun, X.; Wang, J.; Luo, T.; Zeng, Y.; Xu, J.; Deng, X.; Cheng, Y. Exogenous γ-aminobutyric acid treatment affects citrate and amino acid accumulation to improve fruit quality and storage performance of postharvest citrus fruit. Food Chem. 2017, 216, 138–145. [Google Scholar] [CrossRef] [PubMed]

- Aguado, A.; Galán, M.; Zhenyukh, O.; Wiggers, G.A.; Roque, F.R.; Redondo, S.; Peçanha, F.; Martín, A.; Fortuño, A.; Cachofeiro, V. Mercury induces proliferation and reduces cell size in vascular smooth musclecells through MAPK, oxidative stress and cyclooxygenase-2 pathways. Toxicol. Appl. Pharm. 2013, 268, 188–200. [Google Scholar] [CrossRef] [PubMed]

- Mateos, R.; Lecumberri, E.; Ramos, S.; Goya, L.; Bravo, L. Determination of malondialdehyde (MDA) by high-performance liquid chromatography in serum and liver as a biomarker for oxidative stress: Application to a rat model for hypercholesterolemia and evaluation of the effect of diets rich in phenolic antioxidants from fruits. J. Chromatogr. B 2005, 827, 76–82. [Google Scholar]

| Film | Polyvinyl Alcohol (g) | Starch (g) | Glycerol (g) | Citric Acid (g) | Baking Time (min) |

|---|---|---|---|---|---|

| S/P/C1:1:0 | 2.81 | 2.81 | 1.87 | 0 | 120 |

| S/P/C3:3:0.08 | 2.81 | 2.81 | 2.11 | 1 | 120 |

| S/P/C3:1:0.08 | 3.75 | 1.25 | 2.5 | 1 | 120 |

| S/P/C1:1:0 | 2.81 | 2.81 | 1.87 | 0 | 270 |

| S/P/C3:3:0.08 | 2.81 | 2.81 | 2.11 | 1 | 270 |

| S/P/C3:1:0.08 | 3.75 | 1.25 | 2.5 | 1 | 270 |

| S/P/C1:1:0 | 2.81 | 2.81 | 1.87 | 0 | 300 |

| S/P/C3:3:0.08 | 2.81 | 2.81 | 2.11 | 1 | 300 |

| S/P/C3:1:0.08 | 3.75 | 1.25 | 2.5 | 1 | 300 |

| Film | ΔL(NBS) | Δa(NBS) | Δb(NBS) | ΔE(NBS) |

|---|---|---|---|---|

| Without cover | 39.690 ± 0.0035 | 5.603 ± 0.0008 | –17.503 ± 0.0002 | 43.740 ± 0.0028 |

| S/P/C1:1:0 | 62.490 ± 0.0010 | 5.613 ± 0.0028 | –17.943 ± 0.0002 | 65.260 ± 0.0009 |

| S/P/C3:3:0.08 | 71.200 ± 0.0012 | 5.860 ± 0.0062 | –18.453 ± 0.0047 | 73.790 ± 0.0012 |

| S/P/C3:1:0.08 | 54.707 ± 0.0006 | 5.680 ± 0.0012 | –17.273 ± 0.0010 | 57.653 ± 0.0004 |

| S/P/C1:1:0 | 66.053 ± 0.0032 | 6.020 ± 0.0044 | –17.890 ± 0.0011 | 68.687 ± 0.0031 |

| S/P/C3:3:0.08 | 67.617 ± 0.0014 | 5.627 ± 0.0052 | –17.963 ± 0.0002 | 70.190 ± 0.0013 |

| Film | Thickness (mm) | Tensile Strength (MPa) | Elastic Modulus (%) |

|---|---|---|---|

| S/P/C1:1:0 | 0.0606 ± 0.0277 | 33.84 ± 1.8 | 27 ± 2.5 |

| S/P/C3:3:0.08 | 0.0648 ± 0.0691 | 45.22 ± 2.4 | 66 ± 3.6 |

| S/P/C3:1:0.08 | 0.1150 ± 0.0139 | 19.58 ± 1.1 | 27 ± 5.1 |

| S/P/C1:1:0 | 0.0688 ± 0.0674 | 35.98 ± 2.5 | 29 ± 4.8 |

| S/P/C3:3:0.08 | 0.1220 ± 0.0250 | 45.54 ± 2.6 | 74 ± 2.4 |

| S/P/C3:1:0.08 | 0.1074 ± 0.0327 | 23.25 ± 1.5 | 31 ± 2.1 |

| S/P/C1:1:0 | 0.0538 ± 0.0416 | 34.51 ± 2.3 | 27 ± 2.0 |

| S/P/C3:3:0.08 | 0.0694 ± 0.0276 | 31.68 ± 2.0 | 36 ± 3.1 |

| S/P/C3:1:0.08 | 0.1166 ± 0.0402 | 20.00 ± 2.7 | 21 ± 2.4 |

| Film | WVP(×10−9 g·m/m2·Pa·s) | Water Solubility (%) |

|---|---|---|

| S/P/C1:1:0 | 1.15 ± 0.04 | 29.8 ± 0.5 |

| S/P/C3:3:0.08 | 1.21 ± 0.05 | 41.1 ± 0.2 |

| S/P/C3:1:0.08 | 0.36 ± 0.11 | 6.5 ± 0.12 |

| S/P/C1:1:0 | 1.56 ± 0.09 | 36.1 ± 0.04 |

| S/P/C3:3:0.08 | 1.95 ± 0.15 | 45.6 ± 0.3 |

| S/P/C3:1:0.08 | 0.42 ± 0.08 | 7.0 ± 0.7 |

| S/P/C1:1:0 | 1.64 ± 0.10 | 33.5 ± 0.2 |

| S/P/C3:3:0.08 | 1.76 ± 0.03 | 40.9 ± 0.14 |

| S/P/C3:1:0.08 | 0.21 ± 0.13 | 6.2 ± 0.6 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Wu, J.; Peng, T.; Li, Y.; Lin, D.; Xing, B.; Li, C.; Yang, Y.; Yang, L.; Zhang, L.; et al. Preparation and Application of Starch/Polyvinyl Alcohol/Citric Acid Ternary Blend Antimicrobial Functional Food Packaging Films. Polymers 2017, 9, 102. https://doi.org/10.3390/polym9030102

Wu Z, Wu J, Peng T, Li Y, Lin D, Xing B, Li C, Yang Y, Yang L, Zhang L, et al. Preparation and Application of Starch/Polyvinyl Alcohol/Citric Acid Ternary Blend Antimicrobial Functional Food Packaging Films. Polymers. 2017; 9(3):102. https://doi.org/10.3390/polym9030102

Chicago/Turabian StyleWu, Zhijun, Jingjing Wu, Tingting Peng, Yutong Li, Derong Lin, Baoshan Xing, Chunxiao Li, Yuqiu Yang, Li Yang, Lihua Zhang, and et al. 2017. "Preparation and Application of Starch/Polyvinyl Alcohol/Citric Acid Ternary Blend Antimicrobial Functional Food Packaging Films" Polymers 9, no. 3: 102. https://doi.org/10.3390/polym9030102