Tissue Engineering Bionanocomposites Based on Poly(propylene fumarate)

Abstract

:1. Introduction

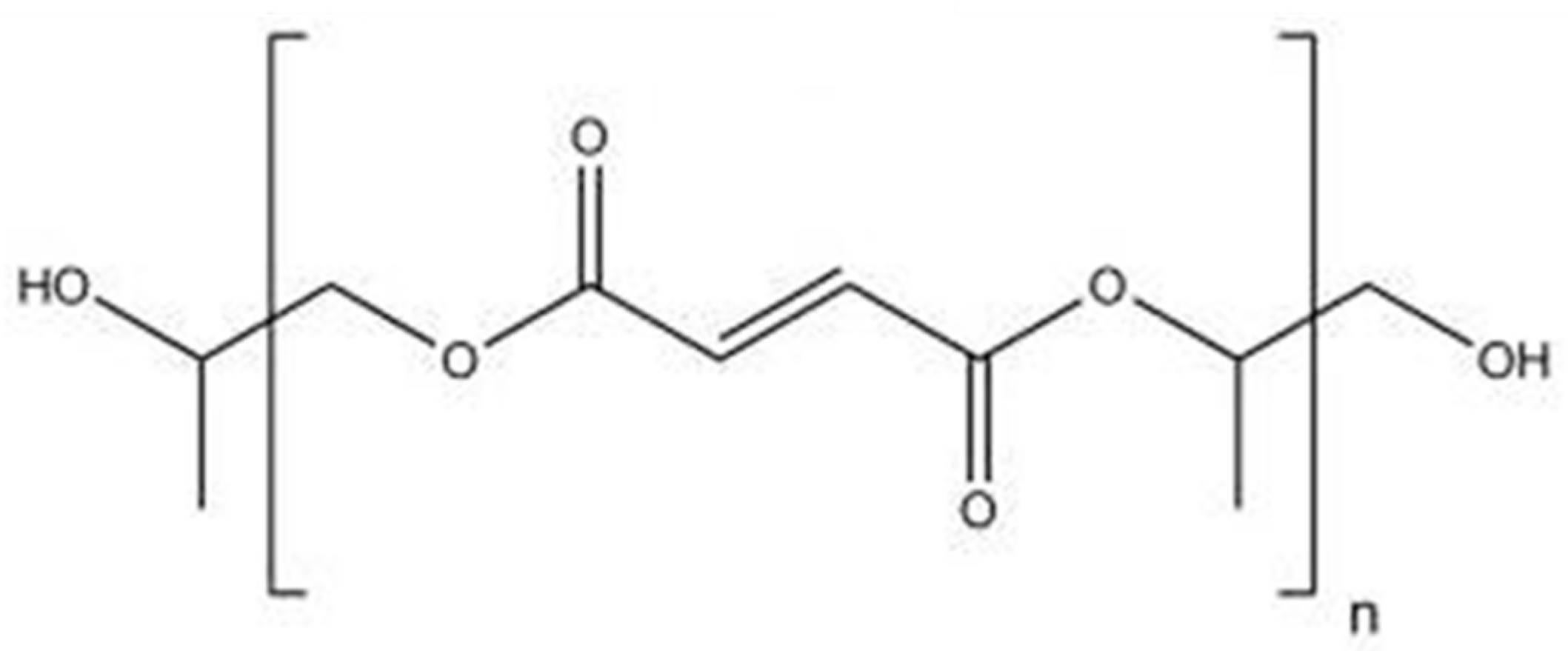

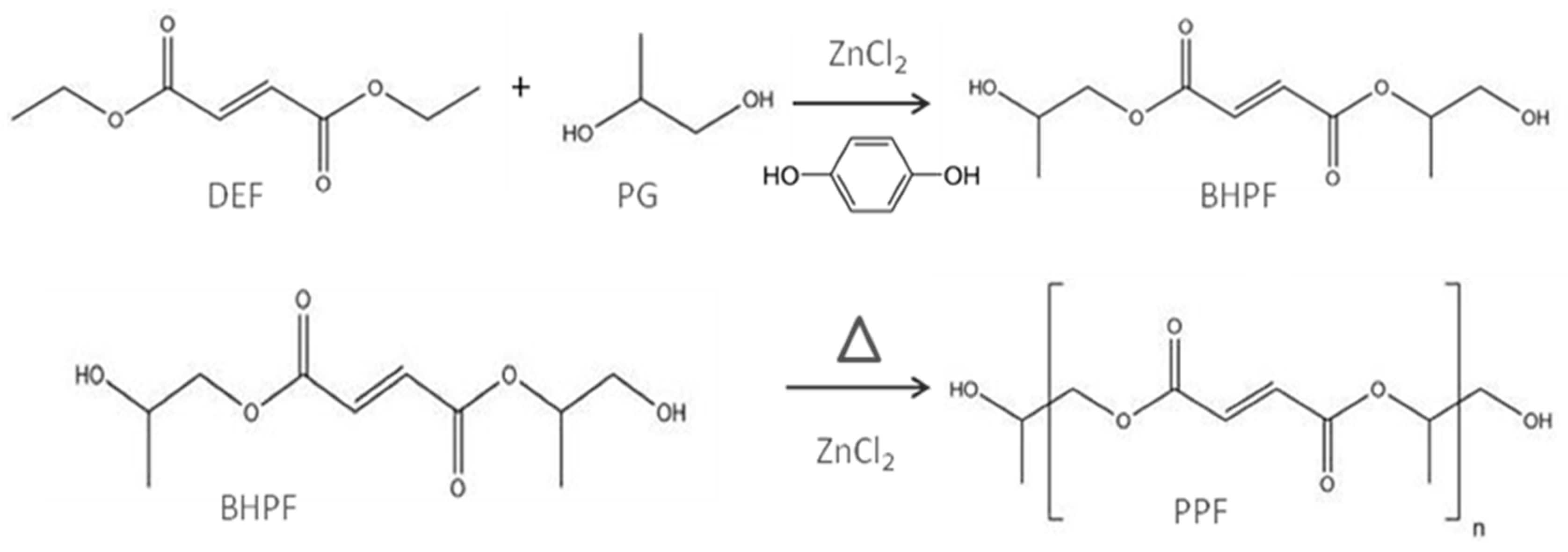

2. Poly(propylene fumarate): Synthesis, Properties and Applications

2.1. Synthesis

2.2. Properties

2.3. Applications

3. Preparation of Nanofiller-Reinforced PPF Biocomposites

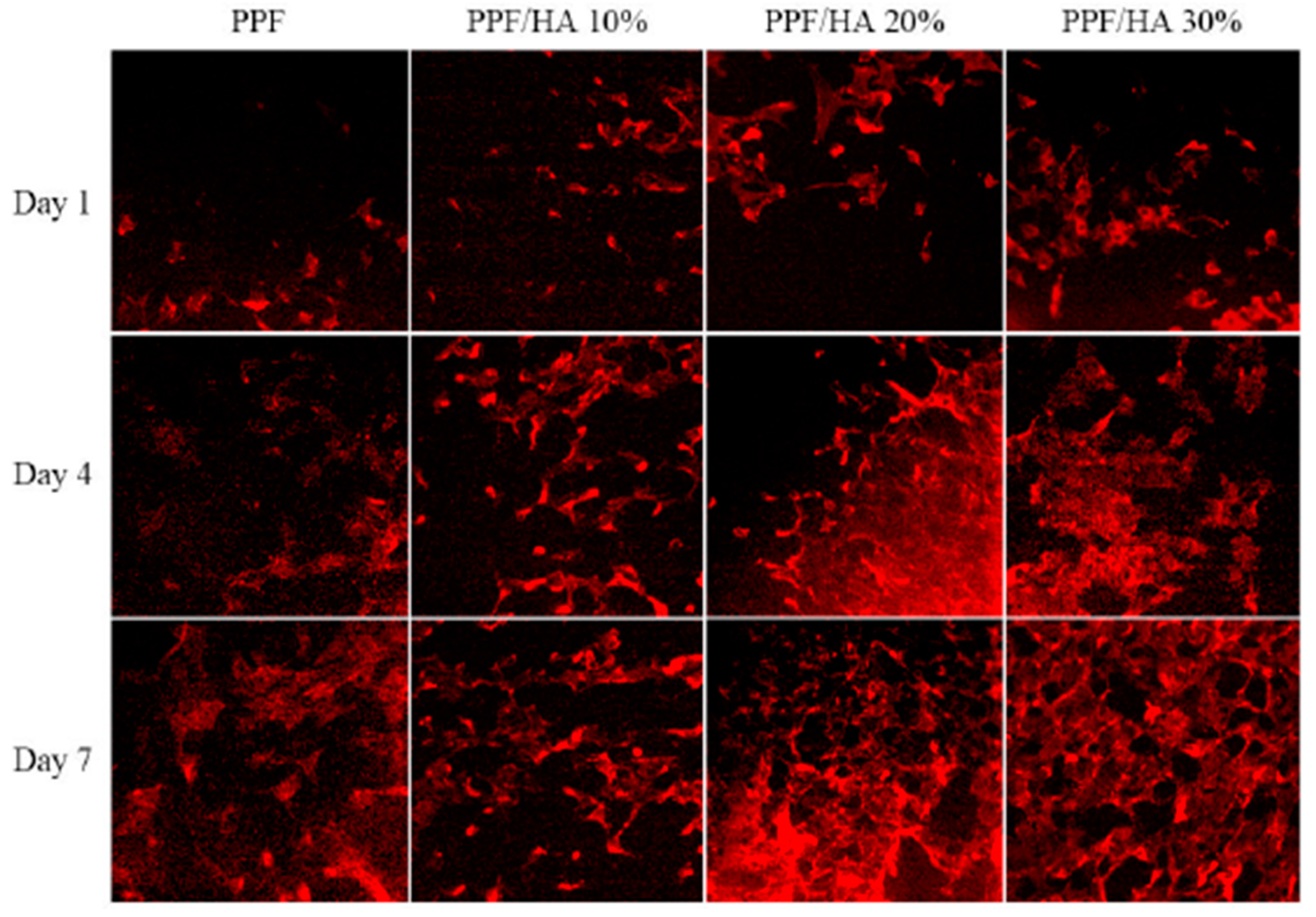

3.1. PPF/SWCNT and PPF/HA Nanocomposites

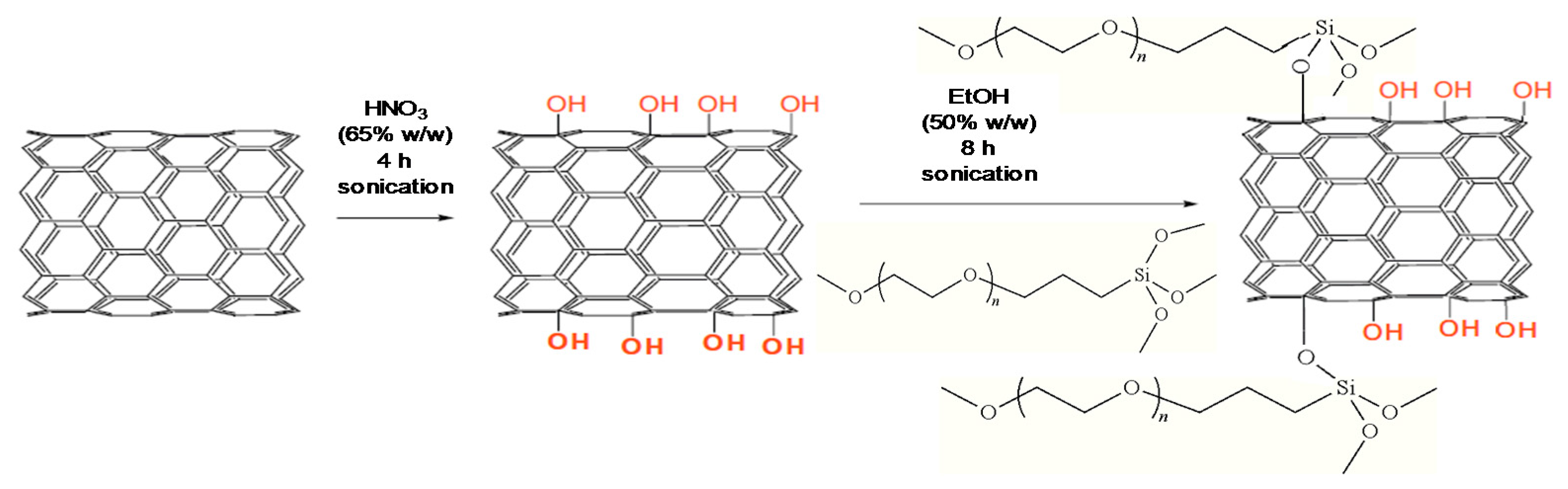

3.2. PPF/GO Nanocomposites

3.3. PPF/MWCNT, PPF/GONR, PPF/GONP and PPF/MSNPs Nanocomposites

3.4. PPF/PEG-g-BNNT Nanocomposites

4. Characterization of PPF-Based Nanocomposites

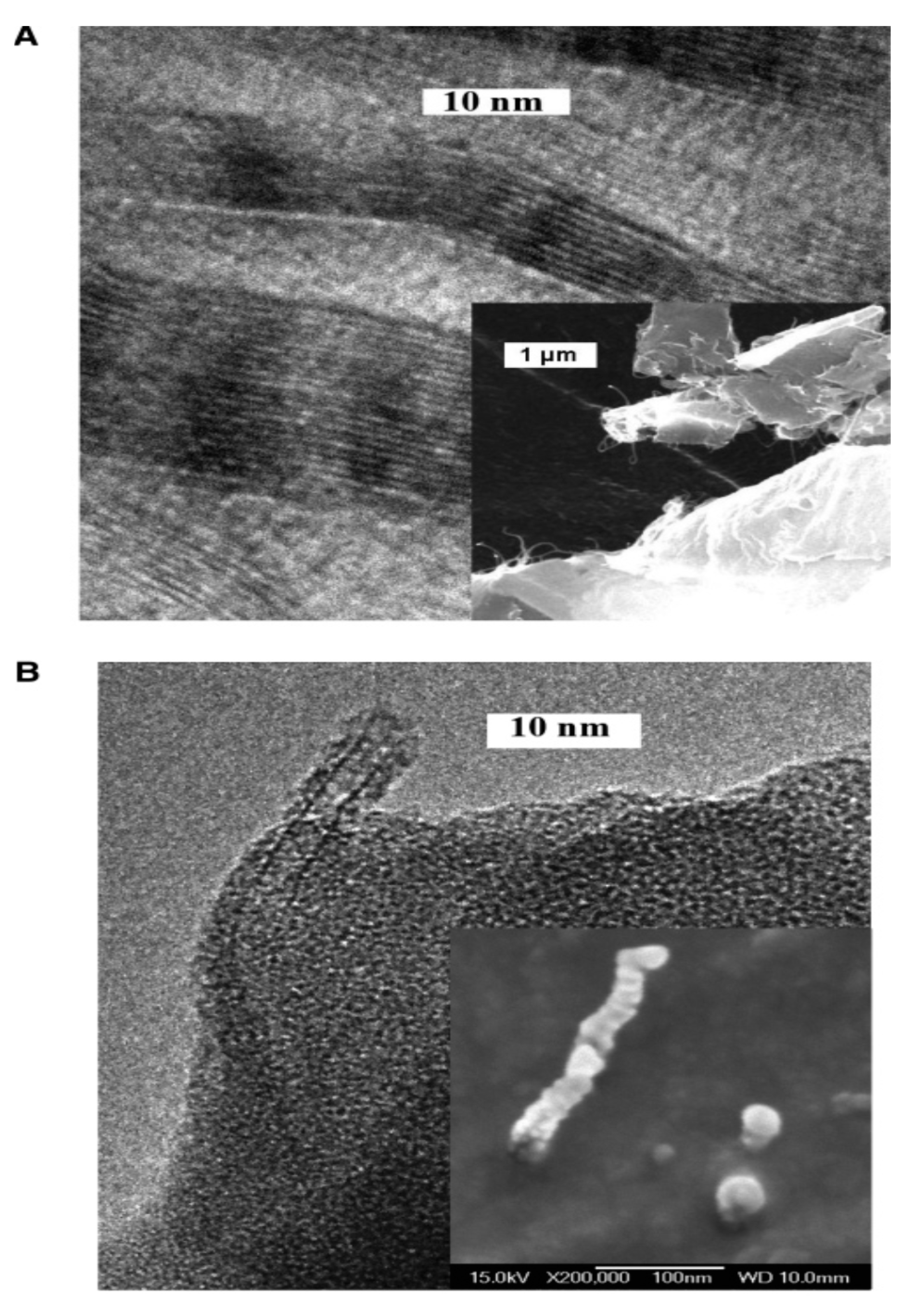

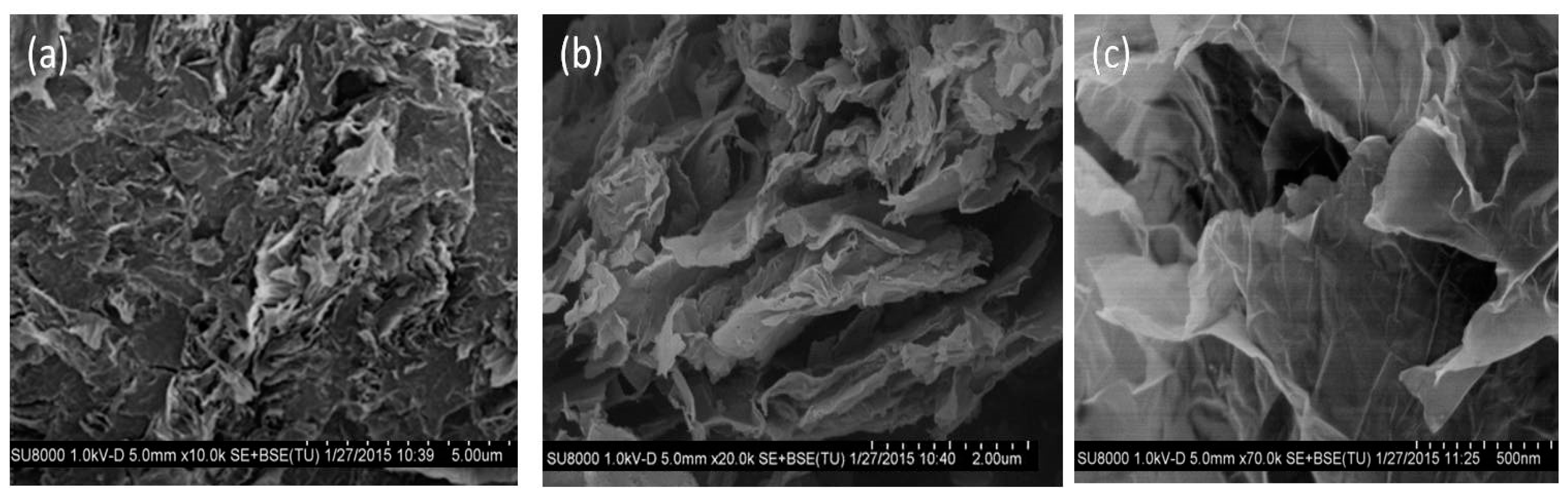

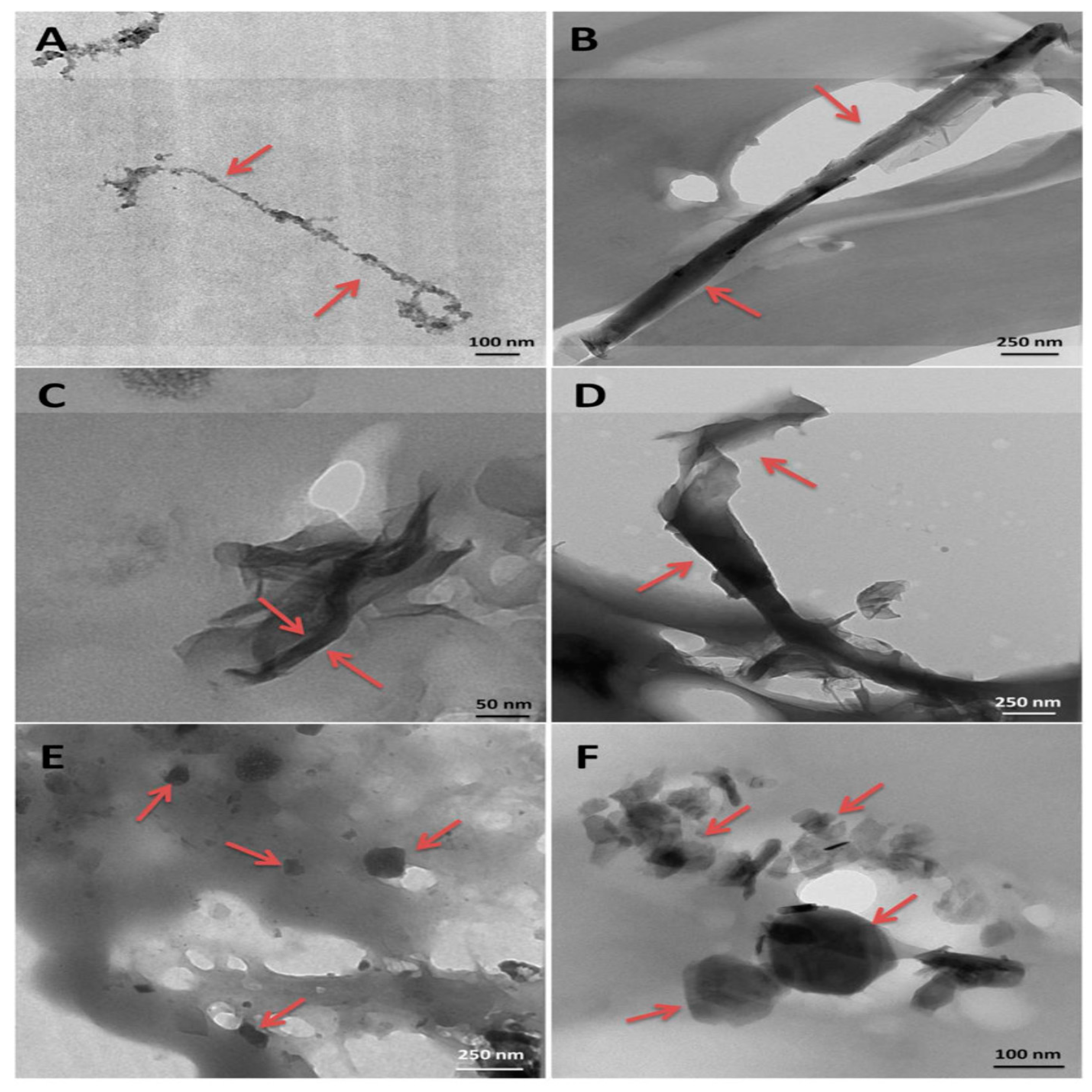

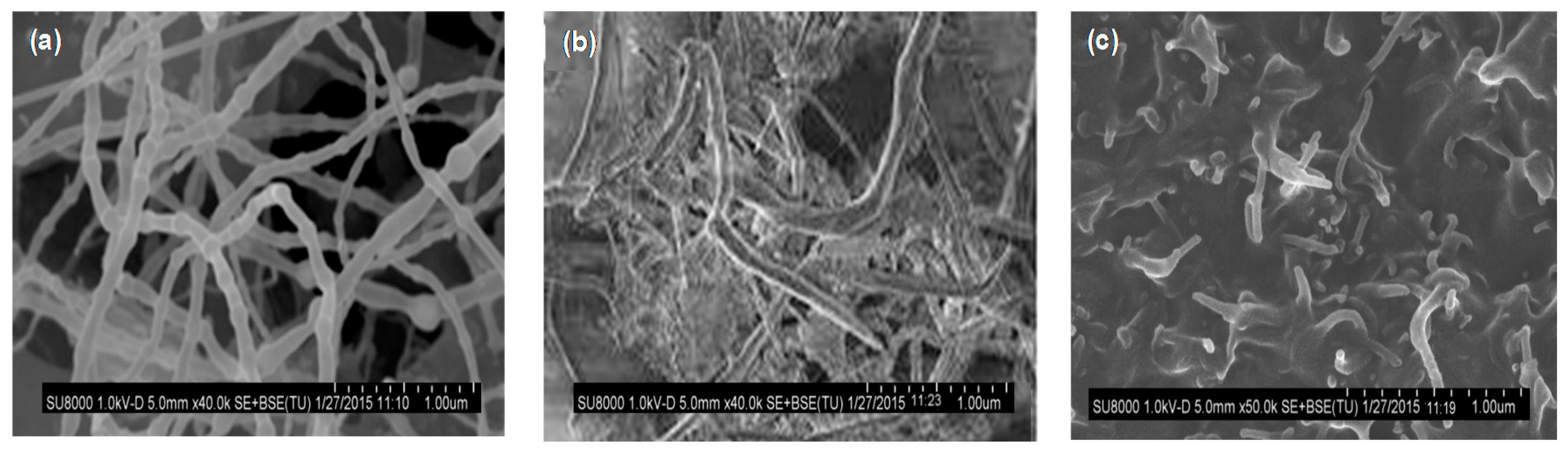

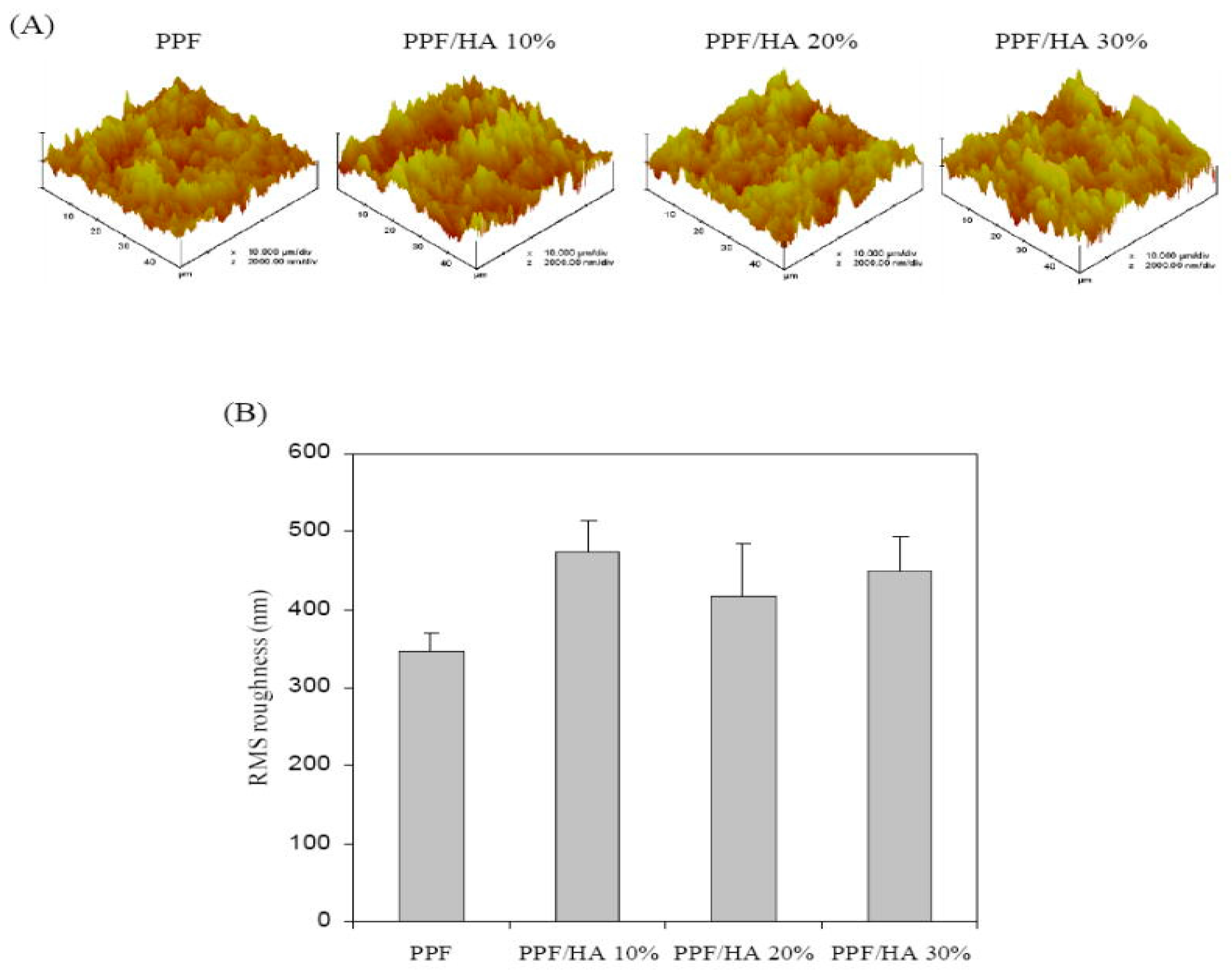

4.1. Morphology

4.2. Mechanical Properties

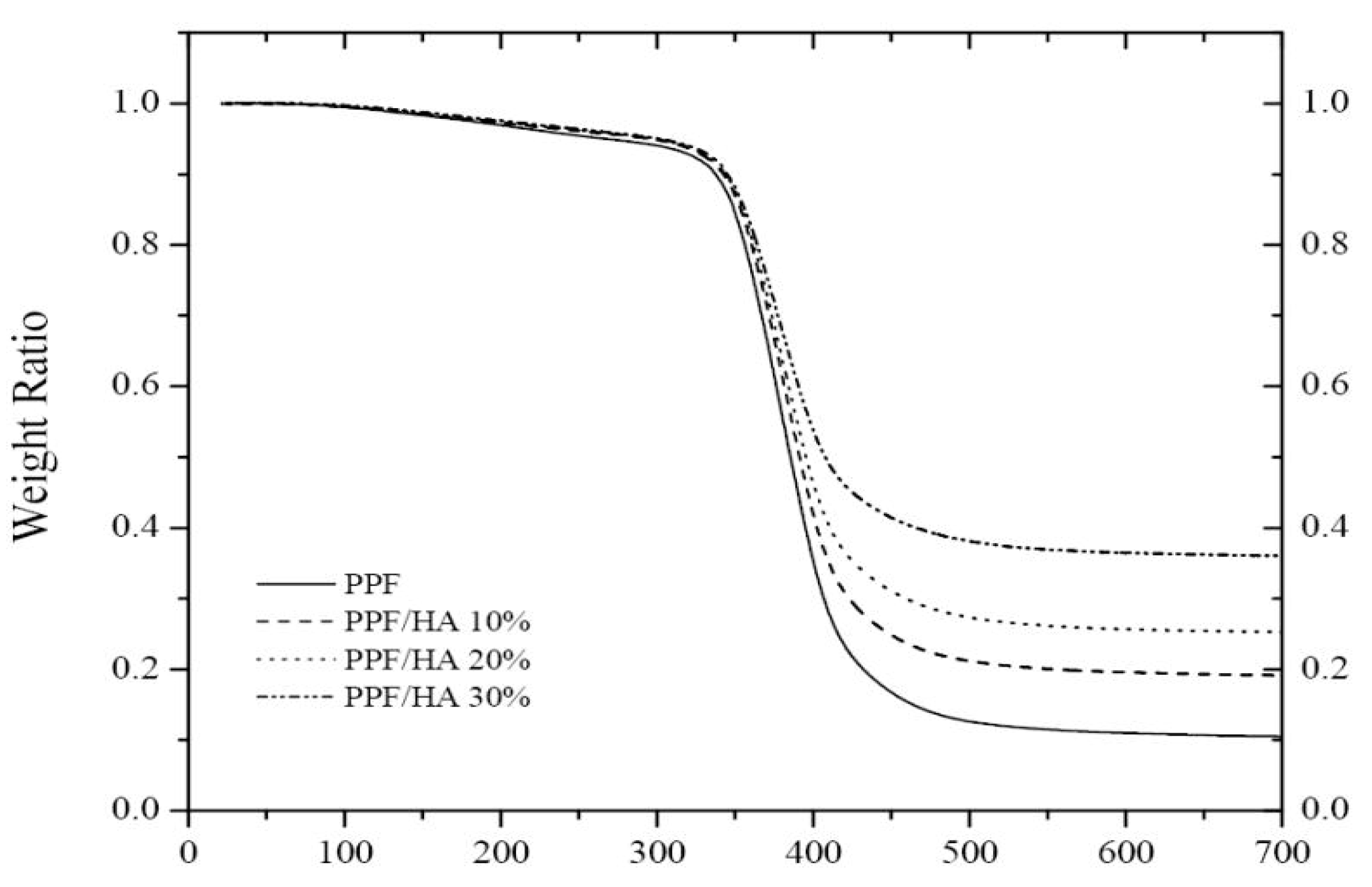

4.3. Thermal Properties

4.4. Rheological Properties

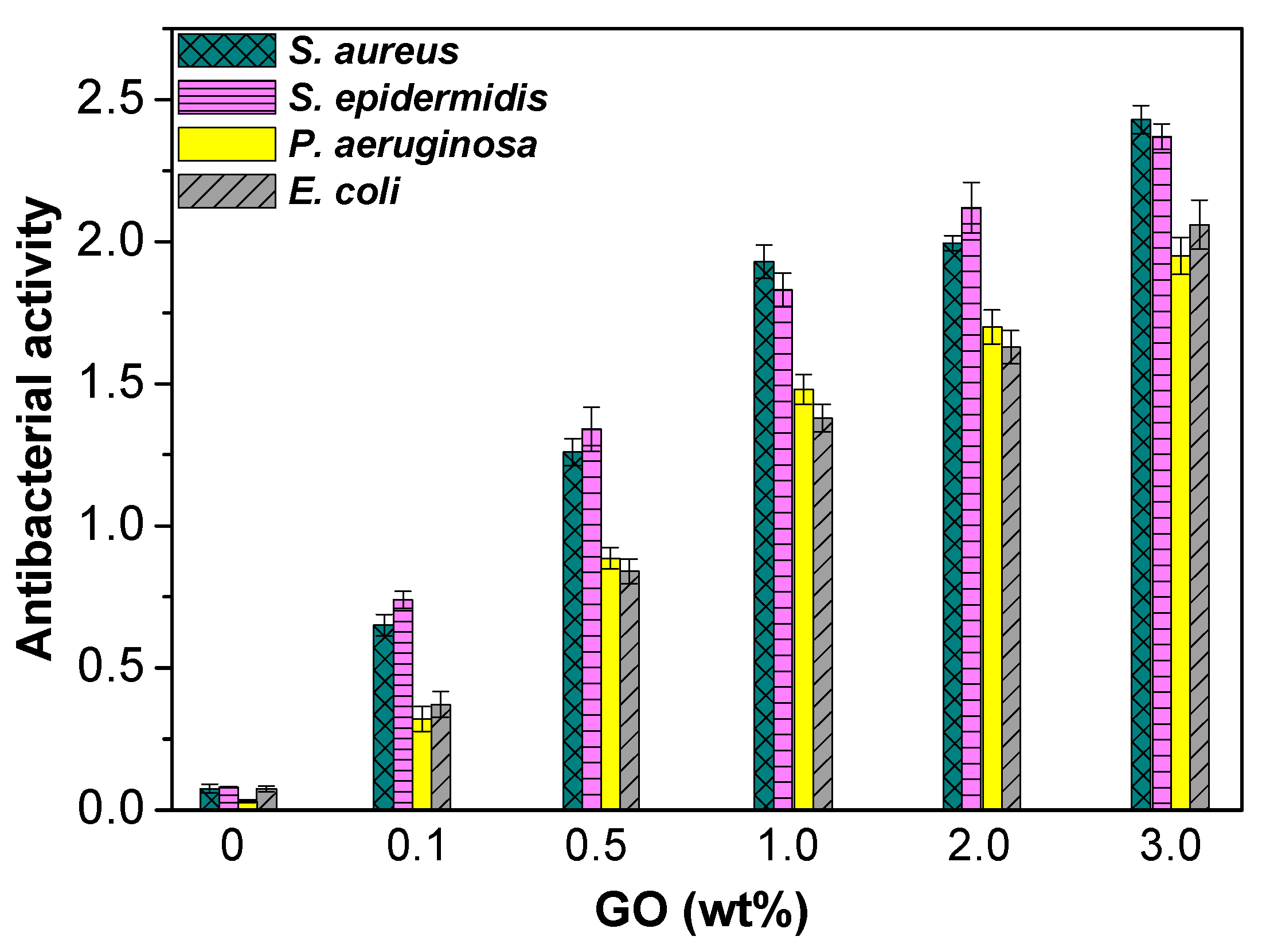

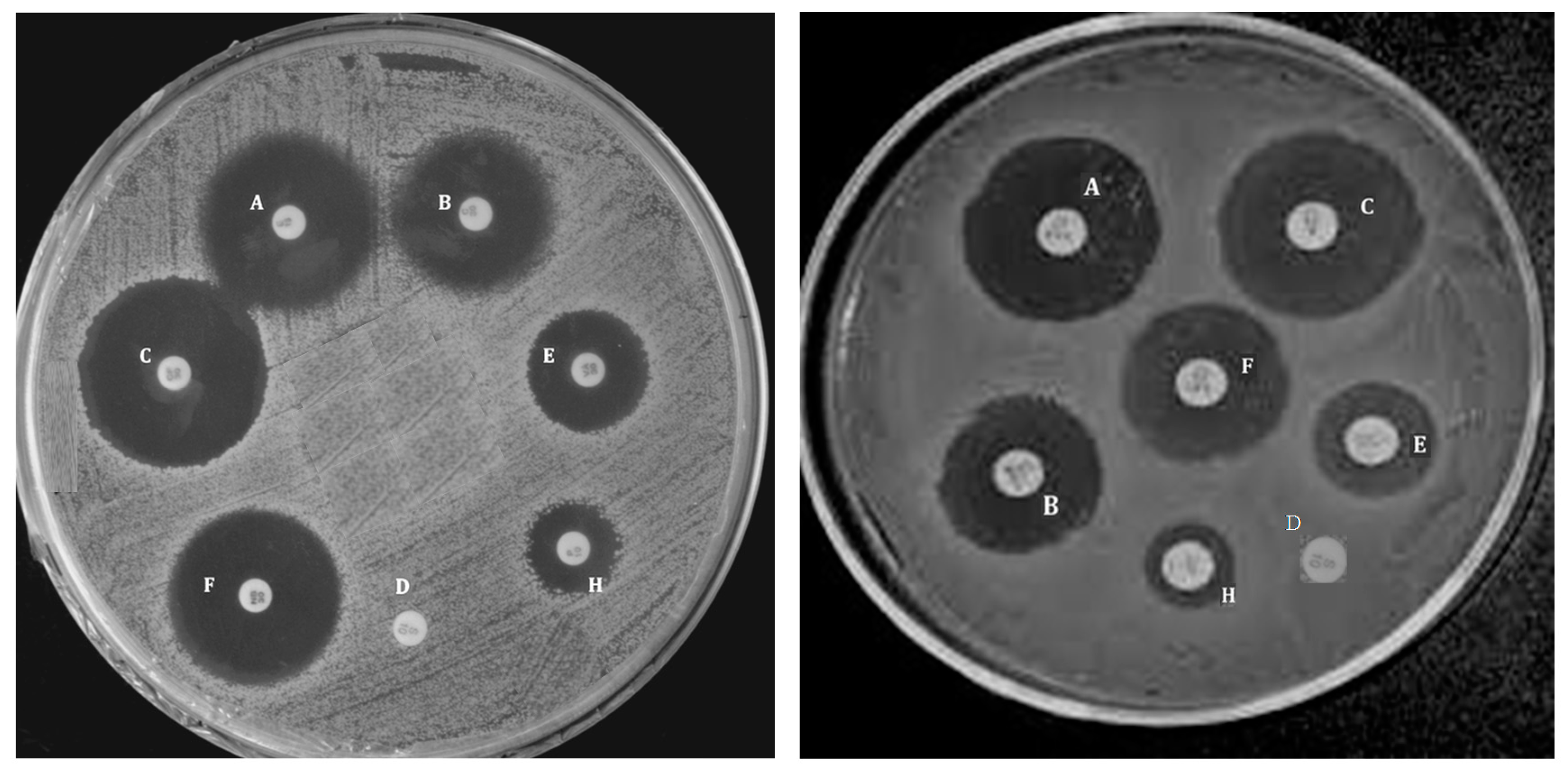

4.5. Antibacterial Properties

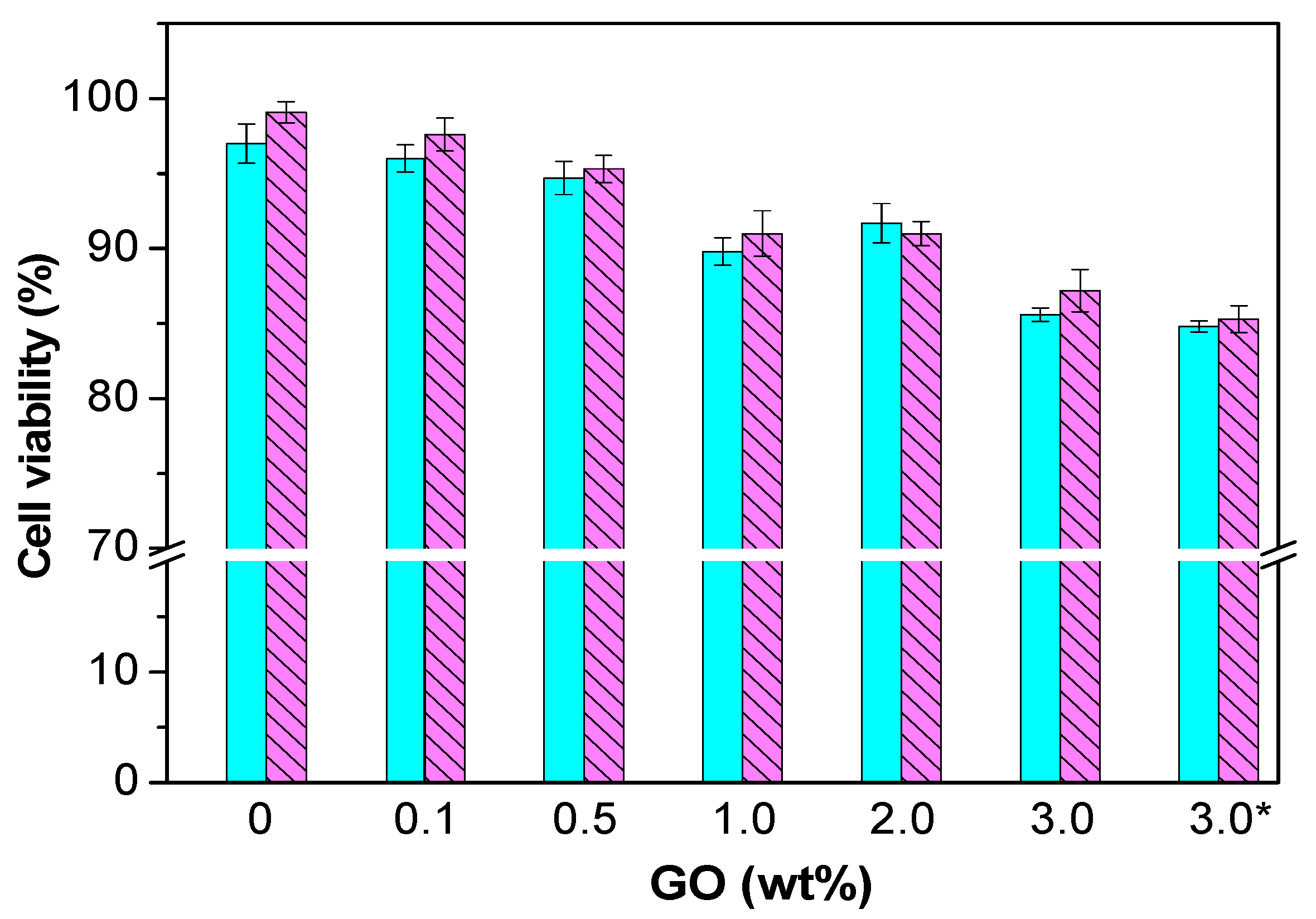

4.6. Cytotoxicity and Biodegradation

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- Okamoto, M.; John, B. Synthetic biopolymer nanocomposites for tissue engineering scaffolds. Prog. Polym. Sci. 2013, 38, 1487–1503. [Google Scholar] [CrossRef]

- Diez-Pascual, A.M.; Diez-Vicente, A.L. Electrospun fibers of chitosan-grafted polycaprolactone/poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) blends. J. Mater. Chem. B 2016, 4, 600–612. [Google Scholar] [CrossRef]

- Kasper, F.K.; Tanahashi, K.; Fisher, J.P.; Mikos, A.G. Synthesis of poly(propylene fumarate). Nat. Protoc. 2009, 4, 518–525. [Google Scholar] [CrossRef] [PubMed]

- Fisher, J.P.; Holland, T.A.; Dean, D.; Engel, P.S.; Mikos, A.G. Synthesis and properties of photocrosslinked poly(propylene fumarate) scaffolds. J. Biomater. Sci. Polym. Ed. 2001, 12, 673–687. [Google Scholar] [CrossRef] [PubMed]

- Gunatillake, P.A.; Adhikari, R. Biodegradable synthetic polymers for tissue engineering. Eur. Cells Mater. 2003, 5, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Lu, L.; Yaszemski, M.J. Bone tissue-engineering material poly(propylene fumarate): Correlation between molecular weight, chain dimensions, and physical properties. Biomacromolecules 2006, 7, 1976–1982. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.Y.; Yang, D.A.; Zhang, N.; Ji, C.G.; Zhu, L.; Zhang, T. Poly(propylene Fumarate)/(calcium sulphate/beta-tricalcium phosphate) composites: Preparation, characterization and in vitro degradation. Acta Biomater. 2009, 5, 628–635. [Google Scholar] [CrossRef] [PubMed]

- Mistry, A.S.; Pham, Q.P.; Schouten, C.; Yeh, T.; Christenson, E.M.; Mikos, A.G.; Jansen, J.A. In Vivo bone biocompatibility and degradation of porous fumarate-based polymer/alumoxanenanocomposites for bone tissue engineering. J. Biomed. Mater. Res. A 2010, 92, 451–462. [Google Scholar] [PubMed]

- Shi, X.; Hudson, J.L.; Spicer, P.P.; Tour, J.M.; Krishnamoorti, R.; Mikos, A.G. Injectable nanocomposites of single-walled carbon nanotubes and biodegradable polymers for tissue engineering. Biomacromolecules 2006, 7, 2237–2242. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.; Hudson, J.L.; Spicer, P.P.; Tour, J.M.; Krishnamoorti, R.; Mikos, A.G. Rheological behaviour and mechanical characterization of injectable poly(propylene fumarate)/single-walled carbon nanotube composites for bone tissue engineering. Nanotechnology 2005, 16, S531–S538. [Google Scholar] [CrossRef] [PubMed]

- Lalwani, G.; Henslee, A.M.; Farshid, B.; Pramar, B.; Lin, L.; Qin, Y.-X.; Kasper, F.K.; Mikos, A.G.; Sitharaman, B. Tungsten disulfide nanotubes reinforced biodegradable polymers for bone tissue engineering. Acta Biomater. 2013, 9, 8365–8373. [Google Scholar] [CrossRef] [PubMed]

- Lalwani, G.; Henslee, A.M.; Farshid, B.; Lin, L.; Kasper, F.K.; Qin, Y.-X.; Mikos, A.G.; Sitharaman, B. Two-dimensional nanostructure-reinforced biodegradable polymeric nanocomposites for bone tissue engineering. Biomacromolecules 2013, 14, 900–909. [Google Scholar] [CrossRef] [PubMed]

- Diez-Pascual, A.M.; Diez-Vicente, A.L. Poly(propylene fumarate)/polyethyleneglycol-modified graphene oxide nanocomposites for tissue engineering. ACS Appl. Mater. Interfaces 2016, 8, 17902–17914. [Google Scholar] [CrossRef] [PubMed]

- Diez-Pascual, A.M.; Diez-Vicente, A.L. PEGylated boron nitride nanotube-reinforced poly(propylene fumarate) nanocomposite biomaterials. RSC Adv. 2016, 6, 79507–79519. [Google Scholar] [CrossRef]

- Lee, K.-W.; Wang, S.; Yaszemski, M.J.; Lu, L. Physical properties and cellular responses to crosslinkable poly(propylene fumarate)/hydroxiapatite nanocomposites. Biomaterials 2008, 29, 2839–2848. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Cai, L.; Hao, F.; Xu, X.; Cui, M.; Wang, S. Distinct cell responses to substrates consisting of poly(ε-caprolactone) and poly(propylene fumarate) in the presence or absence of cross-links. Biomacromolecules 2010, 11, 2748–2759. [Google Scholar] [CrossRef] [PubMed]

- Diez-Pascual, A.M.; Diez-Vicente, A.L. Magnetic Fe3O4@poly(propylene fumarate-co-ethylene glycol) core-shell biomaterials. RSC Adv. 2017, 7, 10221–10234. [Google Scholar] [CrossRef]

- Diez-Pascual, A.M.; Diez-Vicente, A.L. Antibacterial SnO2 nanorods as efficient fillers of propylene fumarate-co-ethylene glycol) biomaterials. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 78, 806–816. [Google Scholar] [CrossRef] [PubMed]

- Diez-Pascual, A.M.; Gómez-Fatou, M.A.; Ania, F.; Flores, A. Nanoindentation in polymer nanocomposites. Prog. Mater. Sci. 2015, 67, 1–94. [Google Scholar] [CrossRef]

- Yang, K.; Wan, J.; Zhang, S.; Zhang, Y.; Lee, S.T.; Liu, Z. In vivo pharmacokinetics, long-term biodistribution, and toxicology of PEGylated graphene in mice. ACS Nano 2011, 5, 516–522. [Google Scholar] [CrossRef] [PubMed]

- Presolski, S.; Pumera, M. Covalent functionalization of MoS2. Mater. Today 2016, 19, 140–145. [Google Scholar] [CrossRef]

- Park, Y.-J.; Park, S.Y.; In, I. Preparation of water soluble graphene using polyethylene glycol: Comparison of covalent approach and noncovalent approach. J. Ind. Eng. Chem. 2011, 17, 298–303. [Google Scholar] [CrossRef]

- Frazier, D.D.; Lathi, V.K.; Gerhart, T.N.; Altobelli, D.E.; Hayes, W.C. In Vivo degradation of a poly(propylene fumarate) biodegradable particulate composite bone cement. Mater. Res. Soc. 1995, 394, 15–19. [Google Scholar] [CrossRef]

- Gresser, J.D.; Hsu, S.-H.; Nagaoka, H.; Lyons, C.M.; Nieratko, D.P.; Wise, D.L.; Barabino, G.A.; Trantolo, D.J. Analysis of a vinyl pyrrolidone/poly(propylene fumarate) resorbable bone cement. J. Biomed. Mater. Res. 1995, 29, 1241–1247. [Google Scholar] [CrossRef] [PubMed]

- Kharas, G.B.; Kamenetsky, M.; Simantirakis, J.; Beinlich, K.C.; Rizzo, A.-M.T.; Caywood, G.A.; Watson, K. Synthesis and characterization of fumarate-based polyesters for use in bioresorbable bone cement composites. J. Appl. Polym. Sci. 1997, 66, 1123–1137. [Google Scholar] [CrossRef]

- Shin, J.H.; Lee, J.W.; Jung, J.H.; Cho, D.W.; Lim, G. Evaluation of cell proliferation and differentiation on a poly(propylene fumarate) 3D scaffold treated with functional peptides. J. Mater. Sci. 2011, 46, 5282–5287. [Google Scholar] [CrossRef]

- Suggs, L.J.; West, J.L.; Mikos, A.G. Platelet adhesion on a bioresorbablepoly(propylene fumarate-co-ethylene glycol) copolymer. Biomaterials 1999, 20, 683–690. [Google Scholar] [CrossRef]

- Fang, Z.; Giambini, H.; Zeng, H.; Camp, J.J.; Dadsetan, M.; Robb, R.A.; An, K.-N.; Yaszemski, M.J.; Lu, L. Biomechanical evaluation of an injectable and biodegradable copolymer P(PF-co-CL) in a cadaveric vertebral body defect model. Tissue Eng. A 2014, 20, 1096–1102. [Google Scholar] [CrossRef] [PubMed]

- Henslee, A.M.; Gwak, D.-H.; Mikos, A.G.; Kasper, F.K. Development of a biodegradable bone cement for craniofacial applications. J. Biomed. Mater. Res. A 2012, 100, 2252–2259. [Google Scholar] [CrossRef] [PubMed]

- Behravesh, E.; Mikos, A.G. Three-dimensional culture of differentiating marrow stromal osteoblastsin biomimetic poly(propylene fumarate-co-ethylene glycol)-based macroporous hydrogels. J. Biomed. Mater. Res. A 2003, 66, 698–706. [Google Scholar] [CrossRef] [PubMed]

- Paratala, B.S.; Jacobson, B.D.; Kanakia, S.; Francis, L.D.; Sitharaman, B. Physicochemical characterization, and relaxometry studies of micro-graphite oxide, graphene nanoplatelets, and nanoribbons. PLoS ONE 2012, 7, e38185. [Google Scholar] [CrossRef] [PubMed]

- Castro-Guerrero, C.F.; Deepak, F.L.; Ponce, A.; Cruz-Reyes, J.; Valle-Granados, M.D.; Fuentes-Moyado, S.; Galvan, D.H.; Jose-Yacaman, M. Structure and catalytic properties of hexagonal molybdenum disulfide nanoplates. Catal. Sci. Technol. 2011, 1, 1024–1031. [Google Scholar] [CrossRef]

- Ferreira, T.H.; Ornelas da Silva, P.R.; Gouvêa dos Santos, R.; Barros de Sousa, E.M. A novel synthesis route to produce boron nitride nanotubes for bioapplications. J. Biomater. Nanobiotechnol. 2011, 2, 426–434. [Google Scholar] [CrossRef]

- Santosh, M.; Maiti, P.K.; Sood, A.K. Elastic properties of boron nitride nanotubes and their comparison with carbon nanotubes. J. Nanosci. Nanotechnol. 2009, 9, 5425–5430. [Google Scholar] [CrossRef] [PubMed]

- Suk, J.W.; Piner, R.D.; An, J.; Ruoff, R.S. Mechanical properties of monolayer graphene oxide. ACS Nano 2010, 4, 6557–6564. [Google Scholar] [CrossRef] [PubMed]

- Diez-Pascual, A.M.; Diez-Vicente, A.L. Epoxidized soybean oil/ZnObiocomposites for soft tissue applications: Preparation and characterization. ACS Appl. Mater. Interfaces 2014, 6, 17277–17288. [Google Scholar] [CrossRef] [PubMed]

- Diez-Pascual, A.M.; Diez-Vicente, A.L. Wound healing bionanocomposites based on castor oil polymeric films reinforced with chitosan-modified ZnO nanoparticles. Biomacromolecules 2015, 16, 2631–2644. [Google Scholar] [CrossRef] [PubMed]

- Diez-Pascual, A.M.; Diez-Vicente, A.L. ZnO-reinforced poly(hydroxybutyrate-co-valerate) bionanocomposites with antimicrobial function for food packaging. ACS Appl. Mater. Interfaces 2014, 6, 9822–9834. [Google Scholar] [CrossRef] [PubMed]

- Cabeen, M.T.; Jacobs-Wagner, C. Bacterial Cell Shape. Nat. Rev. Microbiol. 2005, 3, 601–610. [Google Scholar] [CrossRef] [PubMed]

- Szunerits, S.; Boukherrouba, R. Antibacterial activity of graphene-based materials. J. Mater. Chem. B 2016, 4, 6892–6912. [Google Scholar] [CrossRef]

- Akhavan, O.; Ghaderi, E. Toxicity of graphene and graphene oxide nanowalls against bacteria. ACS Nano 2010, 4, 5731–5736. [Google Scholar] [CrossRef] [PubMed]

- Krishnamoorthy, K.; Umasuthan, N.; Mohan, R.; Lee, J.; Kim, S.-J. Investigation of the antibacterial activity of graphene oxide nanosheets. Sci. Adv. Mater. 2012, 4, 1–7. [Google Scholar] [CrossRef]

- Horváth, L.; Magrez, A.; Golberg, D.; Zhi, C.; Bando, Y.; Smajda, R.; Horváth, E.; Forró, L.; Schwaller, B. In Vitro investigation of the cellular toxicity of boron nitride nanotubes. ACS Nano 2011, 5, 3800–3810. [Google Scholar] [CrossRef] [PubMed]

- Corredor, C.; Hou, W.-C.; Klein, S.A.; Moghadam, B.Y.; Goryll, M.; Doudrick, K.; Westerhoff, P.; Posner, J.D. Disruption of model cell membranes by carbon nanotubes. Carbon 2013, 60, 67–75. [Google Scholar] [CrossRef]

- Wang, K.; Ruan, J.; Song, H.; Zhang, J.; Wo, Y.; Guo, S.; Cui, D. Biocompatibility of graphene oxide. Nanoscale Res. Lett. 2011, 6, 8. [Google Scholar] [CrossRef] [PubMed]

- Lammel, T.; Boisseaux, P.; Fernández-Cruz, M.L.; Navas, J.M. Internalization and cytotoxicity of graphene oxide and carboxyl graphene nanoplatelets in the human hepatocellular carcinoma cell line Hep G2. Part. Fibre Toxicol. 2013, 10, 27. [Google Scholar] [CrossRef] [PubMed]

- Thomas, M.; Enciso, M.; Hilder, T.A. Insertion mechanism and stability of boron nitride nanotubes in lipid bilayers. J. Phys. Chem. B 2015, 119, 4929–4936. [Google Scholar] [CrossRef] [PubMed]

- Ciofani, G.; Genchi, G.G.; Liakos, I.; Athanassiou, A.; Dinucci, D.; Chiellini, F.; Mattoli, V. A simple approach to covalent functionalization of boron nitride nanotubes. J. Colloid Interface Sci. 2012, 374, 308–314. [Google Scholar] [CrossRef] [PubMed]

- Abagnale, G.; Steger, M.; Nguyen, V.H.; Hersch, N.; Sechi, A.; Joussen, S.; Denecke, B.; Merkel, R.; Hoffmann, B.; Dreser, A.; et al. Surface topography enhances differentiation of mesenchymal stem cells towards osteogenic and adipogenic lineages. Biomaterials 2015, 61, 316–326. [Google Scholar] [CrossRef] [PubMed]

| Nanofiller (wt %) | E (GPa) | σy (MPa) | Nanofiller (wt %) | EF (GPa) | σF (MPa) |

|---|---|---|---|---|---|

| 0.99 | 39.1 | - | 0.68 | 7.5 | |

| EG-GO (0.1) | 1.36 | 47.2 | SWCNT (0.1) | 0.78 | 14.5 |

| PEG-GO (0.5) | 1.72 | 59.4 | MWCNT (0.1) | 0.74 | 18.8 |

| EG-GO (1.0) | 2.33 | 70.3 | SWGONR (0.1) | 0.74 | 14.6 |

| EG-GO (2.0) | 2.51 | 74.9 | MWGONR (0.1) | 0.70 | 21.5 |

| PEG-GO (3.0) | 2.91 | 90.2 | GONP (0.1) | 0.84 | 26.5 |

| PEG-g-BNNTs (0.1) | 1.14 | 37.3 | MSNP (0.1) | 0.90 | 27.2 |

| PEG-g-BNNTs (0.5) | 1.29 | 45.2 | SWCNT (0.2) | 0.78 | 11.2 |

| PEG-g-BNNTs (1.0) | 1.72 | 56.3 | MWCNT (0.2) | 0.70 | 14.5 |

| PEG-g-BNNTs (2.0) | 1.98 | 59.5 | SWGONR (0.2) | 0.79 | 13.8 |

| PEG-g-BNNTs (4.0) | 2.34 | 67.2 | MWGONR (0.2) | 0.80 | 18.0 |

| GONP (0.2) | 0.90 | 27.2 | |||

| MSNP (0.2) | 0.95 | 24.8 |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diez-Pascual, A.M. Tissue Engineering Bionanocomposites Based on Poly(propylene fumarate). Polymers 2017, 9, 260. https://doi.org/10.3390/polym9070260

Diez-Pascual AM. Tissue Engineering Bionanocomposites Based on Poly(propylene fumarate). Polymers. 2017; 9(7):260. https://doi.org/10.3390/polym9070260

Chicago/Turabian StyleDiez-Pascual, Ana M. 2017. "Tissue Engineering Bionanocomposites Based on Poly(propylene fumarate)" Polymers 9, no. 7: 260. https://doi.org/10.3390/polym9070260