Synthesis of Humin-Phenol-Formaldehyde Adhesive

Abstract

:1. Introduction

2. Methods

2.1. Alkaline Hydrothermal Treatment

2.2. Synthesis of Adhesive

2.3. Characterization and Analysis

3. Results and Discussion

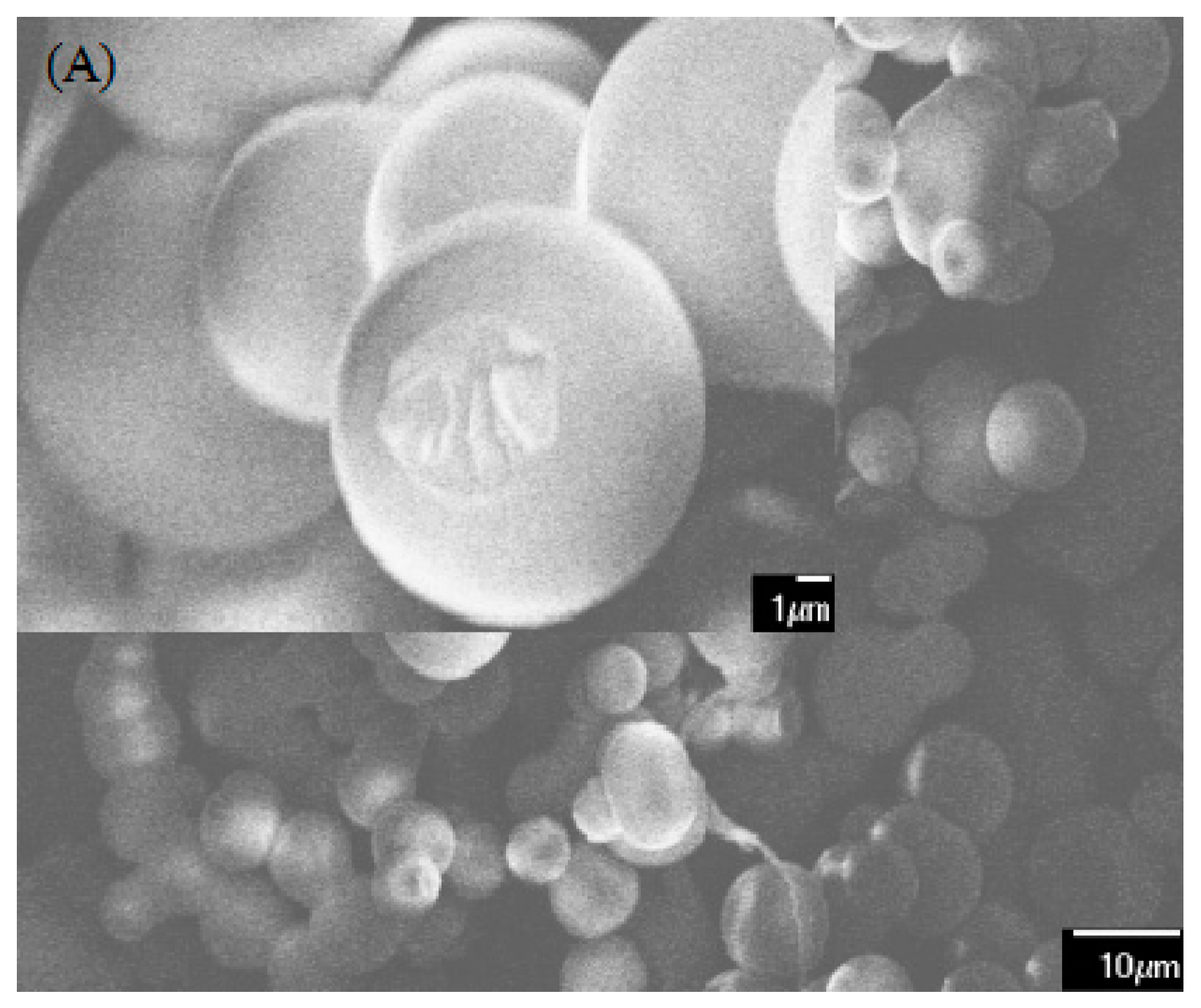

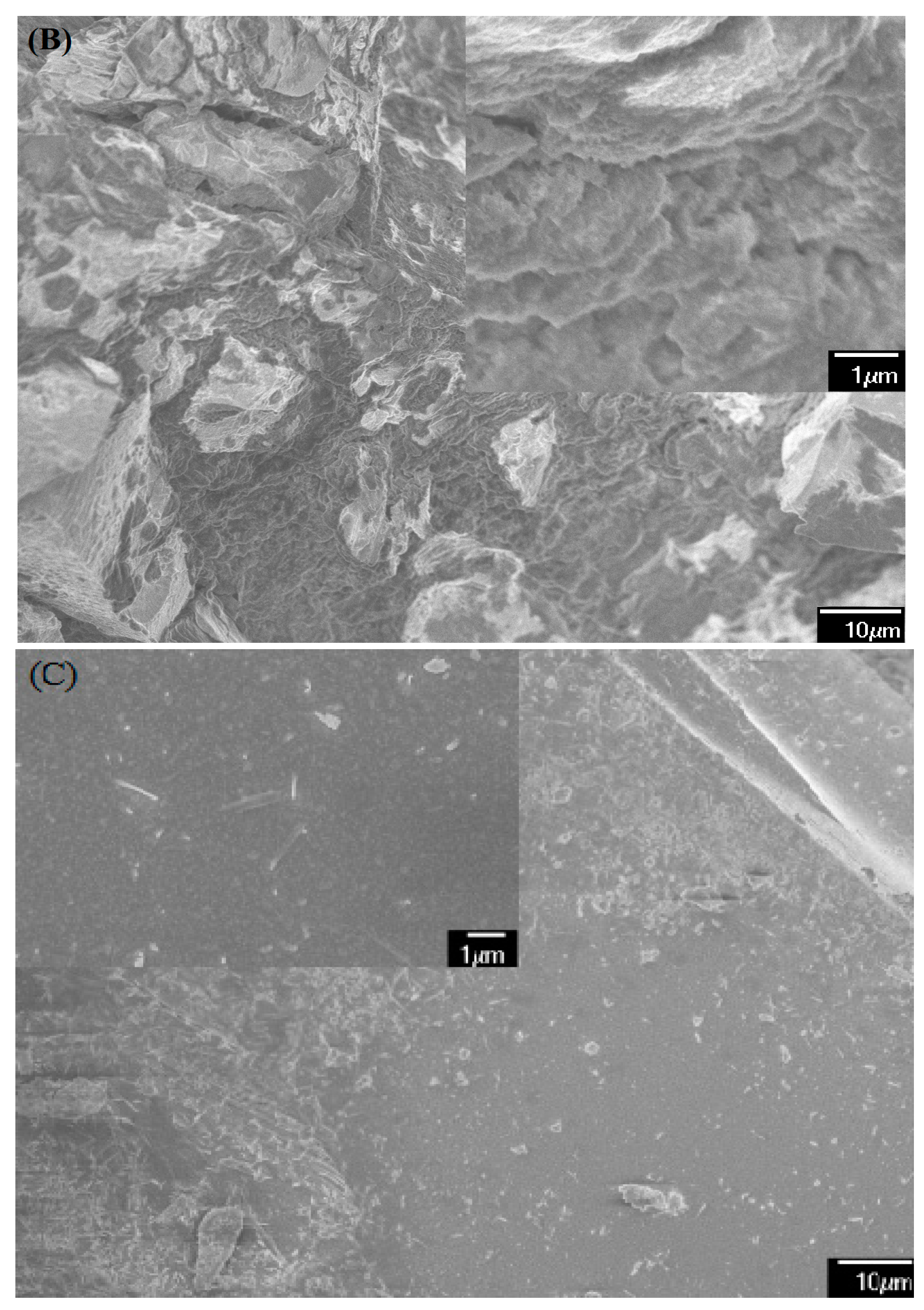

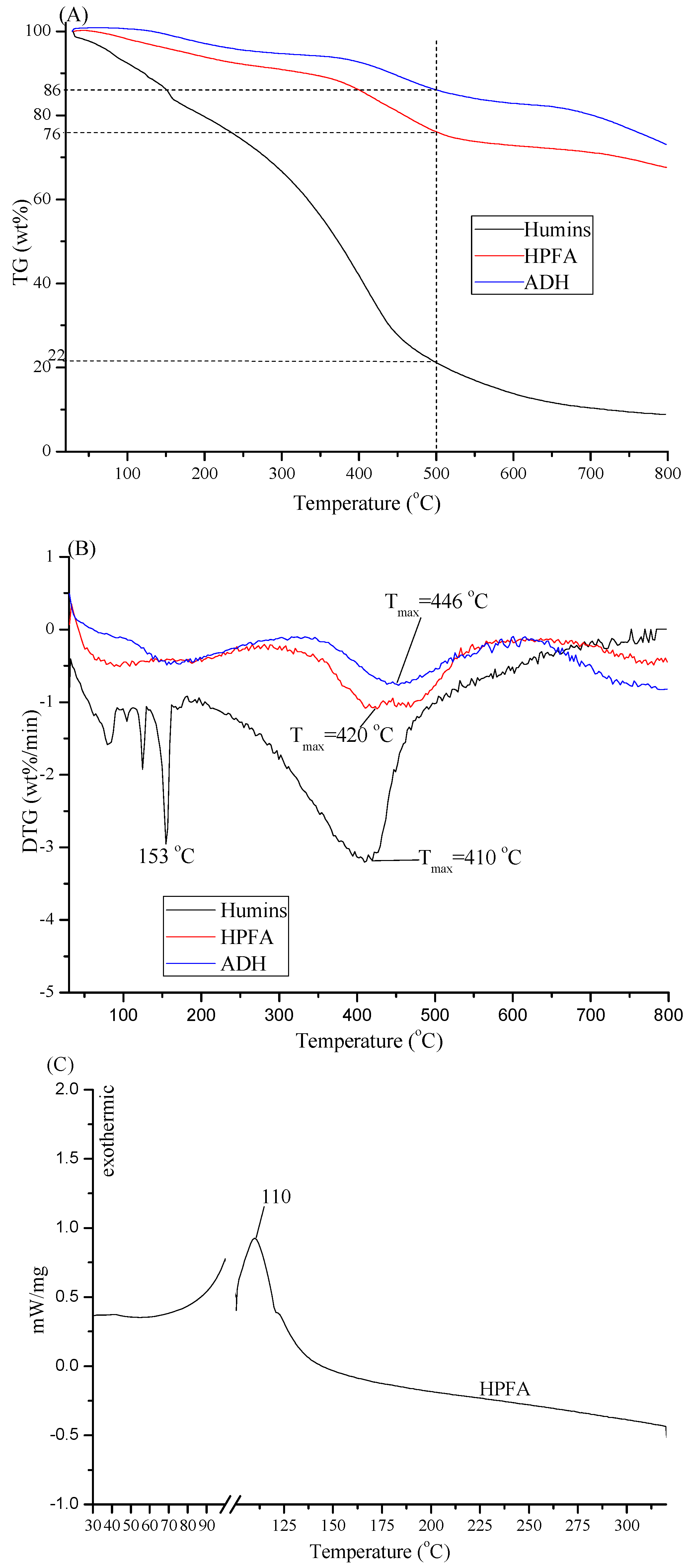

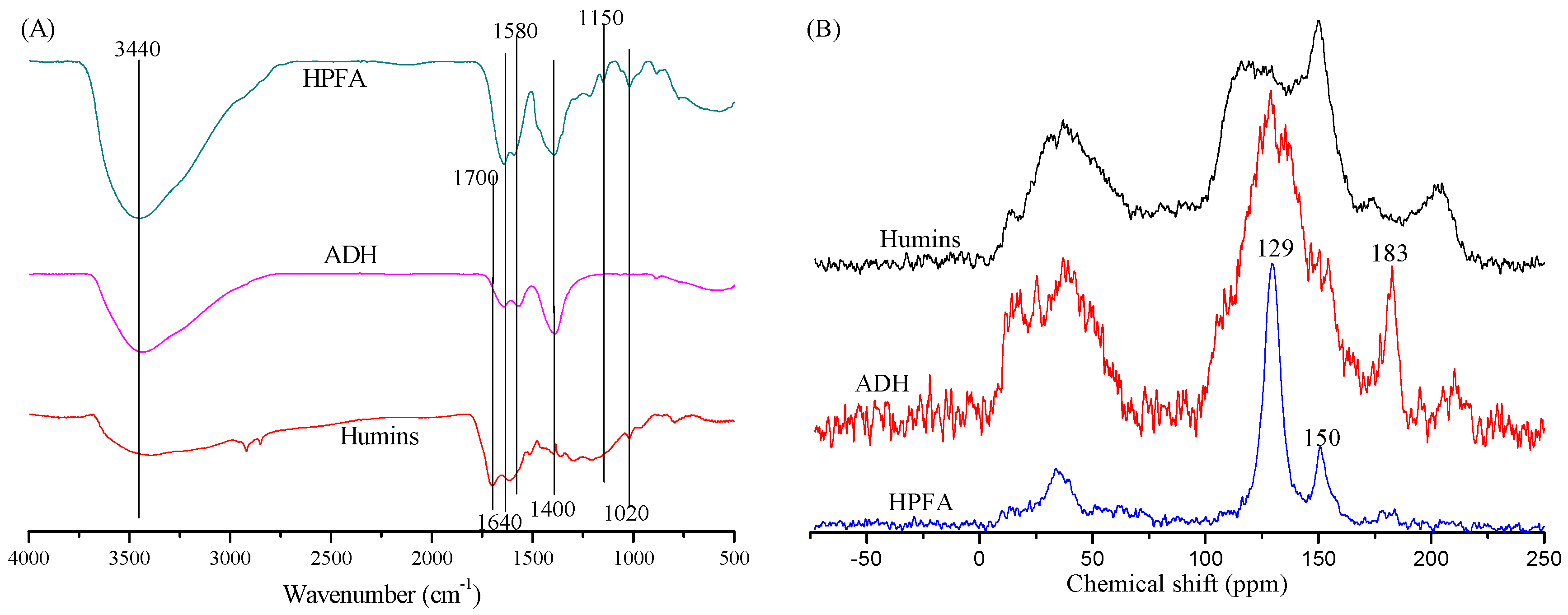

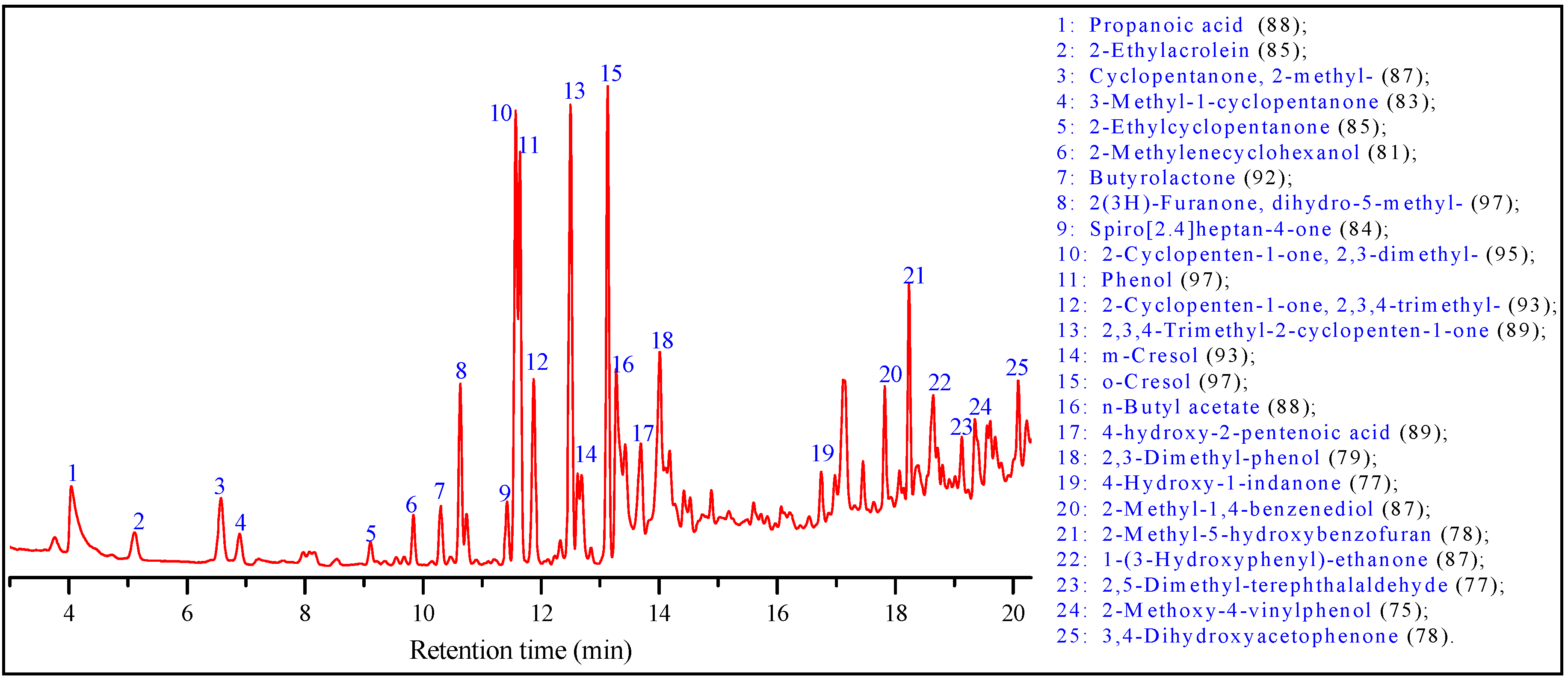

3.1. Hydrothermal Treatment

3.2. Polycondensation Reaction

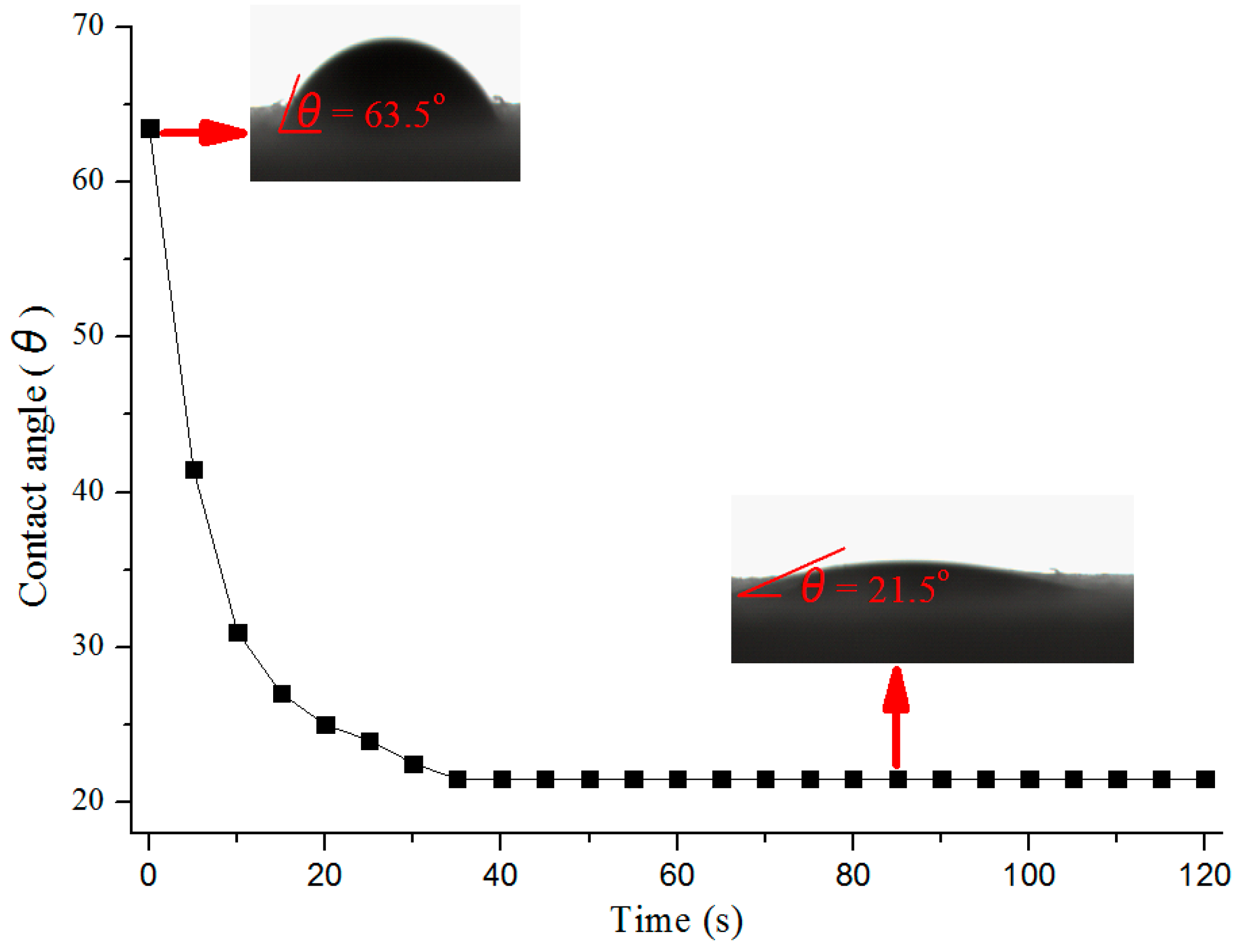

3.3. Characterization of HPFA

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- De, S.; Saha, B.; Luque, R. Hydrodeoxygenation processes: Advances on catalytic transformations of biomass-derived platform chemicals into hydrocarbon fuels. Bioresour. Technol. 2015, 178, 108–118. [Google Scholar] [CrossRef] [PubMed]

- Elumalai, S.; Agarwal, B.; Sangwan, R.S. Thermo-chemical pretreatment of rice straw for further processing for levulinic acid production. Bioresour. Technol. 2016, 218, 232–246. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.; Zhang, G.; Yang, X.; Yin, H.Y.; Fu, X.F.; Liao, J.; Tu, J.T.; Huang, X.; Qin, F.G.F.; Xu, Y. Effects of p-toluenesulfonic acid in the conversion of glucose for levulinic acid and sulfonated carbon production. Energy Fuels 2017, 31, 2847–2854. [Google Scholar] [CrossRef]

- Galletti, A.M.R.; Antonetti, C.; Luise, V.D.; Licursi, D.; Nasso, N.N.D. Levulinic acid production from waste biomass. BioResources 2012, 7, 1824–1835. [Google Scholar]

- Van Zandvoort, I. Towards the Valorization of Humin By-Products: Characterization, Solubilization and Catalysis. Ph.D. Thesis, Utrecht University, Utrecht, The Netherlands, 2015. [Google Scholar]

- Sumerskii, I.V.; Krutov, S.M.; Zarubin, M.Y. Humin-like substances formed under the conditions of industrial hydrolysis of wood. Russ. J. Appl. Chem. 2010, 83, 320–327. [Google Scholar] [CrossRef]

- Kang, S.; Zhang, G.; Yang, Q.; Tu, J.; Guo, X.; Qin, F.G.F.; Xu, Y. A new technology for utilization of biomass hydrolysis residual humins for acetic acid production. BioResources 2016, 11, 9496–9505. [Google Scholar] [CrossRef]

- Weingarten, R.; Conner, W.C.; Huber, G.W. Production of levulinic acid from cellulose by hydrothermal decomposition combined with aqueous phase dehydration with a solid acid catalyst. Energy Environ. Sci. 2012, 5, 7559–7574. [Google Scholar] [CrossRef]

- Inamdar, S.S.; Rathod, K.K. Study of characteristics of partial replacement of phenol by coconut shell flour in a phenol formaldehyde resin. Int. J. Res. Eng. Technol. 2013, 2, 314–320. [Google Scholar]

- Jin, Y.Q.; Cheng, X.S.; Zheng, Z.B. Preparation and characterization of phenol-formaldehyde adhesives modified with enzymatic hydrolysis lignin. Bioresour. Technol. 2010, 101, 2046–2048. [Google Scholar] [CrossRef] [PubMed]

- Shahid, S.A.; Ali, M.; Zafar, Z.I. Cure kinetics, bonding performance, thermal degradation, and biocidal studies of phenolformaldehyde resins modified with crude bio-oil prepared from Ziziphus mauritiana endocarps. Bioresources 2014, 10, 105–122. [Google Scholar] [CrossRef]

- Vithanage, A.E.; Chowdhury, E.; Alejo, L.D.; Pomeroy, P.C.; Desisto, W.J.; Frederick, B.G.; Gramlich, W.M. Renewably sourced phenolic resins from lignin bio-oil. J. Appl. Polym. Sci. 2017, 134, 44827. [Google Scholar] [CrossRef]

- Van Zandvoort, I.; Eck, E.R.H.V.; Peinder, P.D.; Heeres, H.J.; Bruijnincx, P.C.A.; Weckhuysen, B.M. Full, reactive solubilization of humin byproducts by alkaline treatment and characterization of the alkali-treated humins formed. ACS Sustain. Chem. Eng. 2015, 3, 533–543. [Google Scholar] [CrossRef]

- GB/T 14732-2006: Adhesives: Urea Formaldehyde, Phenol Formaldehyde and Melamine Formaldehyde Resins (English Version). Available online: http://www.codeofchina.com/standard/GBT14732-2006.html (accessed on 15 October 2006).

- Smith, G.D.; Hutson, M.S.; Lu, Y.; Tierney, M.T.; Grinstaff, M.W.; Palmer, R.A. Step-scan FT-IR time-resolved spectroscopy in the solid state. Appl. Spectrosc. 2001, 55, 637–642. [Google Scholar] [CrossRef]

- Herzfeld, J.; Rand, D.; Matsuki, Y.; Daviso, E.; Mark-Jurkauskas, M.; Mamajanov, I. Molecular structure of humin and melanoidin via solid state NMR. J. Phys. Chem. B 2011, 115, 5741–5745. [Google Scholar] [CrossRef] [PubMed]

- Blanksby, S.J.; Ellison, G.B. Bond dissociation energies of organic molecules. Acc. Chem. Res. 2003, 36, 255–263. [Google Scholar] [CrossRef] [PubMed]

- Sugimura, Y.; Tsuge, S. Studies on thermal degradation of aromatic polyesters by pyrolysis-gas chromatography. J. Chromatogr. Sci. 1979, 17, 269–272. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.; Li, X.; Fan, J.; Chang, J. Classified separation of lignin hydrothermal liquefied products. Ind. Eng. Chem. Res. 2011, 50, 11288–11296. [Google Scholar] [CrossRef]

- Orella, M. Understanding Humins: Molecular Characterization and Growth Rates. Bachelor's Thesis, University of Delaware, Newark, DE, USA, 2014. [Google Scholar]

- Tsilomelekis, G.; Orella, M.J.; Lin, Z.; Cheng, Z.; Zheng, W.; Nikolakis, V.; Vachos, D.G. Molecular structure, morphology and growth mechanisms and rates of 5-hydroxymethyl furfural (HMF) derived humins. Green Chem. 2016, 18, 1983–1993. [Google Scholar] [CrossRef]

- Pin, J.M.; Guigo, N.; Mija, A.; Vincent, L.; Sbirrazzuoli, N.; van der Waal, J.C.; de Jong, E. Valorization of biorefinery side-stream provalorization of biorefinery side-stream products: Combination of humins with polyfurfuryl alcohol for composite elaboration. ACS Sustain. Chem. Eng. 2014, 2, 2182–2190. [Google Scholar] [CrossRef]

- Patil, S.K.R.; Heltzel, J.; Lund, C.R.F. Comparison of structural features of humins formed catalytically from glucose, fructose, and 5-hydroxymethylfurfuraldehyde. Energy Fuels 2012, 26, 5281–5293. [Google Scholar] [CrossRef]

- Tyagi, R. Organic Reactions: Mechanism with Problems; Discovery Publishing House: New Delhi, India, 2005. [Google Scholar]

- Kang, S.; Li, X.; Fan, J.; Chang, J. Characterization of hydrochars produced by hydrothermal carbonization of lignin, cellulose, D-Xylose, and wood meal. Ind. Eng. Chem. Res. 2012, 51, 9023–9031. [Google Scholar] [CrossRef]

- Poljansek, I.; Krajnc, M. Characterization of phenol-formaldehyde prepolymer resins by in line FT-IR spectroscopy. Acta Chim. Slov. 2005, 52, 238–244. [Google Scholar]

- Lei, H.; Wu, Z.; Cao, M.; Du, G. Study on the soy protein-based wood adhesive modified by hydroxymethyl phenol. Polymers 2016, 8, 256–266. [Google Scholar] [CrossRef]

- Cui, Y.; Chang, J.; Wang, W. Fabrication of glass fiber reinforced composites based on bio-oil phenol formaldehyde resin. Materials 2016, 9, 886. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Jing, J.; Zhu, Y.; Yang, X.; Wang, X.; Wang, Z. Preparation and performance of lignin–phenol–formaldehyde adhesives. Int. J. Adhes. Adhes. 2015, 64, 163–167. [Google Scholar] [CrossRef]

- Wang, X.; Li, J.Z.; Zhou, W.R.; Zhang, D.R. Study on the phenol-formaldehyde resin adhesive modified with lac. China Adhes. 2006, 15, 19–22. [Google Scholar]

- Sun, F.; Li, X. Technologies of liquefaction of bamboo and preparation of adhesive. Chem. Ind. For. Prod. 2007, 27, 65–70. [Google Scholar] [CrossRef]

- Frihart, C.R.; Hunt, C.G. Adhesives with Wood Materials Bond Formation and Performance; General Technical Report FPL–GTR–190; US Department of Agriculture: Washington, DC, USA, 2010.

- Wahab, N.H.A.; Tahir, P.M.; Hoong, Y.B.; Ashaari, Z.; Yunus, N.Y.M.; Uyup, M.K.A.; Shahri, M.H. Adhesion characteristics of phenol formaldehyde pre-preg oil palm stem veneers. BioResources 2012, 7, 4545–4562. [Google Scholar] [CrossRef]

- Tang, L.; Yang, X.; Chen, M.; Wang, X.; Zhou, X. Surface characterization of plasma-modified poplar veneer: Dynamic wettability. BioResources 2014, 10, 369–381. [Google Scholar] [CrossRef]

- Shi, S.Q.; Gardner, D.J. Dynamic adhesive wettability of wood. Wood Fiber Sci. 2007, 33, 58–68. [Google Scholar]

| Properties | ADH Solution | HPFA | Chinese National Standard (GB/T 14732-2006) |

|---|---|---|---|

| pH | 13.2 | 9.4 | ≥7 |

| Viscosity (mPa·s) | 12.5 | 112 | ≥60 |

| Solid content (wt %) | 31.2 | 45 | ≥35.0 |

| Bonding strength (MPa) | 0.29 | 0.83 | ≥0.7 |

| Free formaldehyde level (wt %) | - | 0.2 | ≤0.3 |

| Free phenol level (wt %) | - | 0.2 | ≤6 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, S.; Fu, J.; Zhang, G.; Zhang, W.; Yin, H.; Xu, Y. Synthesis of Humin-Phenol-Formaldehyde Adhesive. Polymers 2017, 9, 373. https://doi.org/10.3390/polym9080373

Kang S, Fu J, Zhang G, Zhang W, Yin H, Xu Y. Synthesis of Humin-Phenol-Formaldehyde Adhesive. Polymers. 2017; 9(8):373. https://doi.org/10.3390/polym9080373

Chicago/Turabian StyleKang, Shimin, Jinxia Fu, Gang Zhang, Wentao Zhang, Huibin Yin, and Yongjun Xu. 2017. "Synthesis of Humin-Phenol-Formaldehyde Adhesive" Polymers 9, no. 8: 373. https://doi.org/10.3390/polym9080373