The study was conducted for two consecutive years (2010 and 2011) on a commercial farm in Georgia, USA. Georgia is the leading peanut-producing state in the USA. During each year a field with sloped land and field rows with varying degrees of curvature was selected for the study. In addition, both fields contained steep earthen terraces installed decades ago to reduce erosion. These terraces were not parallel to each other nor were they parallel to the row pattern currently used by the farmer. As a result, the tractor and implement were required to cross these terraces at various angles during all field operations. The fields were adjacent to each other (

Figure 1) and were irrigated with center pivot irrigation systems. Field size was 5 ha in 2010 and 10 ha in 2011. The fields were divided into alternating strips representing treatments.

Figure 1.

Google Earth image of the two fields used in the study. The field used in 2011 was expanded to the black boundaries shown in the figure to accommodate a new center pivot irrigation system. The tear drop-shaped area in the middle of the field was not used for the study. Non-parallel earthen terraces used to control erosion are clearly seen in both fields.

Figure 1.

Google Earth image of the two fields used in the study. The field used in 2011 was expanded to the black boundaries shown in the figure to accommodate a new center pivot irrigation system. The tear drop-shaped area in the middle of the field was not used for the study. Non-parallel earthen terraces used to control erosion are clearly seen in both fields.

2.1. Treatments

In 2010 there were two treatments—conventional and auto-steer (

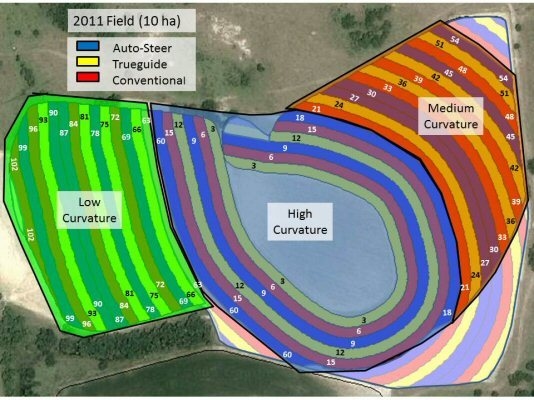

Figure 2). In 2011 there were three treatments—conventional, auto-steer, and auto-steer with passive implement guidance (

Figure 3). Each strip consisted of three passes of four row equipment (12 rows, 4 rows per pass). The same farm equipment (tractor, planter, and inverter) were used for all treatments—the auto-steer was either engaged or not engaged depending on the treatment. The tractor belonged to the University of Georgia (UGA) Precision Agriculture Team while the implements belonged to the cooperating farmer. Conventional treatments were planted and inverted without using GNSS guidance. Auto-steer treatments were planted and inverted using a Trimble AgGPS Autopilot™ auto-steer system with tower-based RTK correction and ±2.5 cm (1 in) accuracy and ±2.5 cm (1 in) year-to-year repeatability. The RTK tower-based correction system is maintained by Ag Technologies LLC (Cordele, GA, USA). The auto-steer with passive implement guidance treatments were planted and inverted using the Trimble AgGPS Autopilot™ auto-steer system with AgGPS Trueguide™ implement guidance. A single A–B line created prior to planting along the innermost curve of the field (

Figure 2 and

Figure 3) was used for all subsequent auto-steer passes during planting and inverting.

Figure 2.

Experimental design used in 2010. Each replicate (colored strip) = 12 rows of peanuts or three 4-row passes. Numbers indicate strips used during data analysis.

Figure 2.

Experimental design used in 2010. Each replicate (colored strip) = 12 rows of peanuts or three 4-row passes. Numbers indicate strips used during data analysis.

Figure 3.

Experimental design used in 2011. Each replicate (colored strip) = 12 rows of peanuts or three 4-row passes. Numbers indicate strips used during data analysis.

Figure 3.

Experimental design used in 2011. Each replicate (colored strip) = 12 rows of peanuts or three 4-row passes. Numbers indicate strips used during data analysis.

The Trueguide™ system is a “passive” guidance system that affects the position of the implement by adjusting the path of the tractor to place the implement on the centerline. Implement guidance is particularly useful when working on sloped lands with curvature where the implement tends to drift off the centerline. To be fully effective, the Trueguide™ system requires the implement to be towed rather than mounted. This allows the tractor’s longitudinal axis to be in a different orientation from that of the implement’s and permits the automated steering system to adjust the direction of travel of the tractor in order to place the implement on the centerline. In our study, both implements (planter, inverter) were mounted to the tractor with a 3-point hitch which limited the effectiveness of the Trueguide™ system.

2.2. Planting and Harvest

Peanuts were planted using strip tillage. Tillage and planting were done as a single operation. The Georgia-06G peanut cultivar was used during both years. Peanuts were inverted (

Figure 4) and allowed to dry for two to three days before harvest. During the 2010 harvest, the “middle” pass of each strip within each treatment was harvested individually. The two “outside” passes in each strip were considered buffer passes and not harvested individually. The peanuts harvested from the middle pass were emptied by the harvester into a peanut wagon mounted on four load scales and the mass of peanuts recorded (

Figure 5). During 2011, all three passes in each strip were harvested individually and their yield recorded individually. The measured mass of peanuts was corrected for foreign material content and moisture content using grading data from the United States Department of Agriculture grading office at the buying point to which the cooperating farmer sold his peanuts.

Figure 4.

Inverting peanuts with a 4-row KMC (Kelley Manufacturing Company, Tifton, GA, USA) peanut inverter pulled by the University of Georgia (UGA) tractor equipped with a Trimble® AgGPS Autopilot™ auto-steer system.

Figure 4.

Inverting peanuts with a 4-row KMC (Kelley Manufacturing Company, Tifton, GA, USA) peanut inverter pulled by the University of Georgia (UGA) tractor equipped with a Trimble® AgGPS Autopilot™ auto-steer system.

Figure 5.

Peanut harvester emptying a load of peanuts into a peanut wagon (left) and load scales used to record weight of peanuts harvested from a pass (right). A load scale is located under each wheel of the wagon.

Figure 5.

Peanut harvester emptying a load of peanuts into a peanut wagon (left) and load scales used to record weight of peanuts harvested from a pass (right). A load scale is located under each wheel of the wagon.

2.3. Data Analysis

The experimental design was entered into the Farm Works™ software which was used to measure and verify strip length and area. In addition, the strips were grouped into low, medium, and high curvature rows. Curvature was estimated by using the radius of curvature formula [

10]

where:

r = the radius of curvature in units of length

c = the length of the chord, and

h = the height

These variables are illustrated in

Figure 6. The formula was applied to the middle pass of each strip using a 150 m (500 ft) arc length as shown in

Figure 6. The Farm Works™ software was used to superimpose the arc over the strip. The chord (

c) was snapped to the endpoints of the arc and its length measured. The height line (

h) was then placed at the midpoint of the chord at a right angle and its length to the arc measured. Using English units, the measurements were entered into Equation (1) and the radius of curvature (

r) calculated—the smaller the calculated radius of curvature, the higher the curvature of the strip. Strips with a radius of curvature of less than 400 ft were designated as high curvature, those between 400 ft and 1000 ft as medium curvature, and those above 1000 ft as low curvature. The 2010 field contained only medium and high curvature strips (

Figure 7) while the 2011 field contained low, medium, and high curvature strips (

Figure 8).

Figure 6.

Screenshot from the The Farm Works™ software showing how the radius of curvature analysis was conducted. We superimposed an arc of 121 m (500 ft) over the center of each strip. The chord (c) was snapped to the endpoints of the arc and its length measured. The height line (h) was then placed at the midpoint of the chord at a right angle and its length measured. The measurements were entered into the formula on the right and the radius of curvature (r) calculated—the smaller the calculated radius of curvature, the higher the curvature of the strip.

Figure 6.

Screenshot from the The Farm Works™ software showing how the radius of curvature analysis was conducted. We superimposed an arc of 121 m (500 ft) over the center of each strip. The chord (c) was snapped to the endpoints of the arc and its length measured. The height line (h) was then placed at the midpoint of the chord at a right angle and its length measured. The measurements were entered into the formula on the right and the radius of curvature (r) calculated—the smaller the calculated radius of curvature, the higher the curvature of the strip.

Figure 7.

The 2010 field was divided into high and medium curvature areas.

Figure 7.

The 2010 field was divided into high and medium curvature areas.

Figure 8.

The 2011 field was divided into high, medium, and low curvature areas. Strip 20 is included in the medium curvature area.

Figure 8.

The 2011 field was divided into high, medium, and low curvature areas. Strip 20 is included in the medium curvature area.

Data were analyzed two different ways: (1) they were grouped together by treatment and compared; and (2) they were grouped by curvature of the rows harvested and treatment and compared. To be consistent with 2010, only data from the middle pass in 2011 were used for comparisons. Treatments were compared statistically using the t-test. We used an alpha level of 0.05 for all statistical tests.