Industrial Hemp in North America: Production, Politics and Potential

Abstract

:1. Introduction

2. North American History in Brief

3. Potential Uses for Hemp in North America

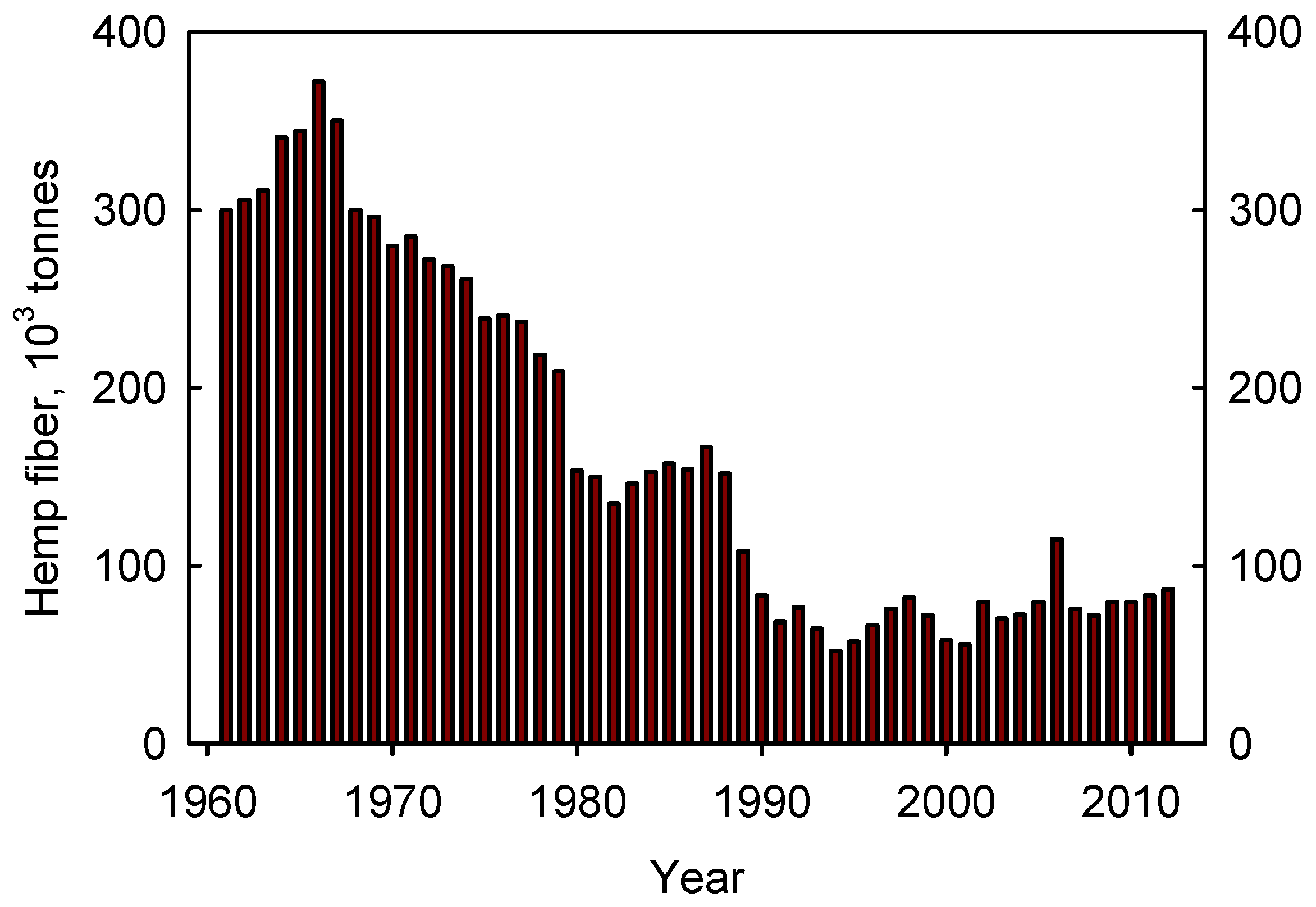

3.1. Fiber

3.2. Oilseed

3.3. Pharmaceuticals

4. Lessons from Novel Field Crops in North America in Recent Decades

5. Hemp Production in North America

6. Environmental Impact

6.1. Biodiversity

6.2. Environmental Sustainability

7. Economics

7.1. Economic Forecasts

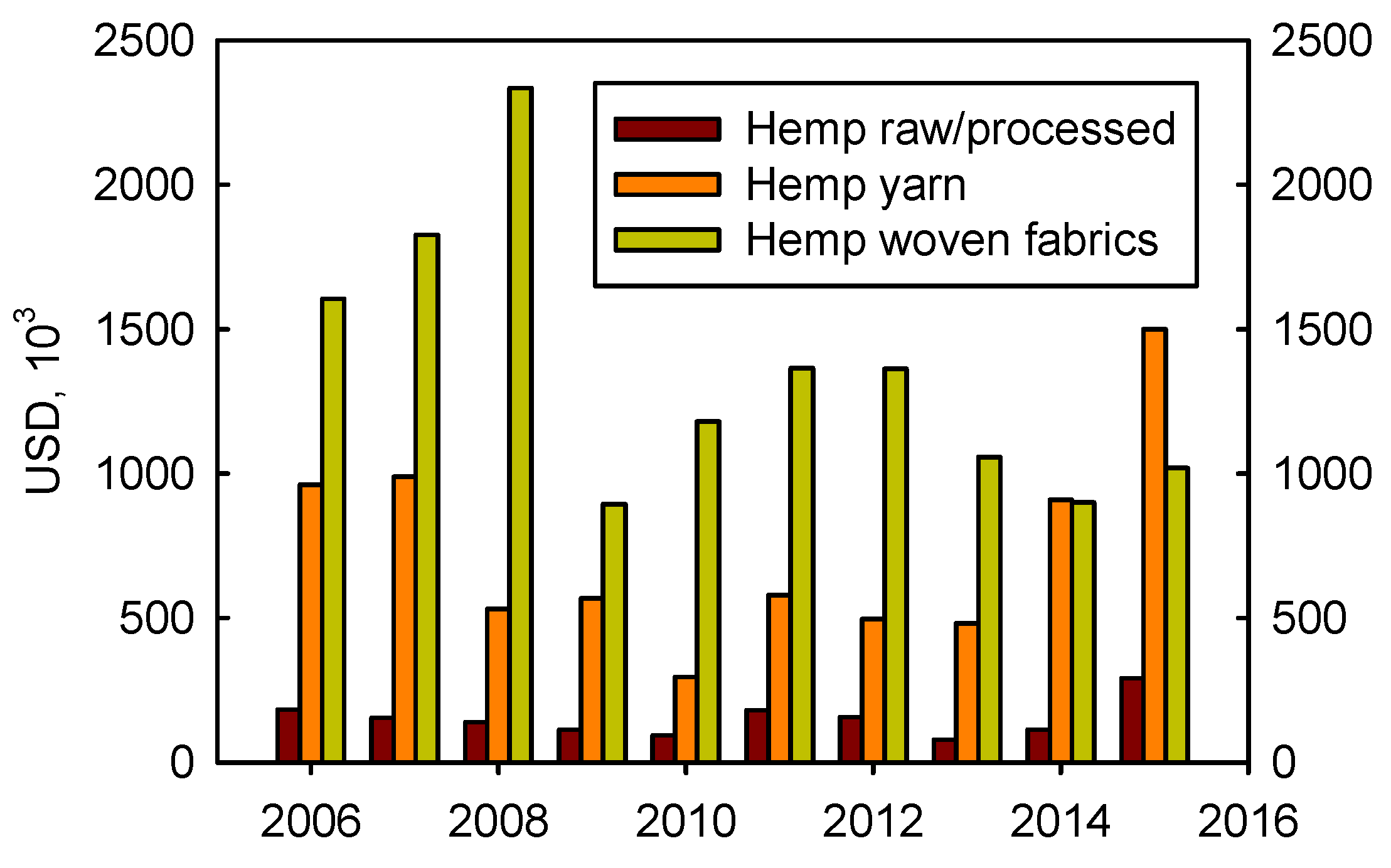

7.2. Fiber

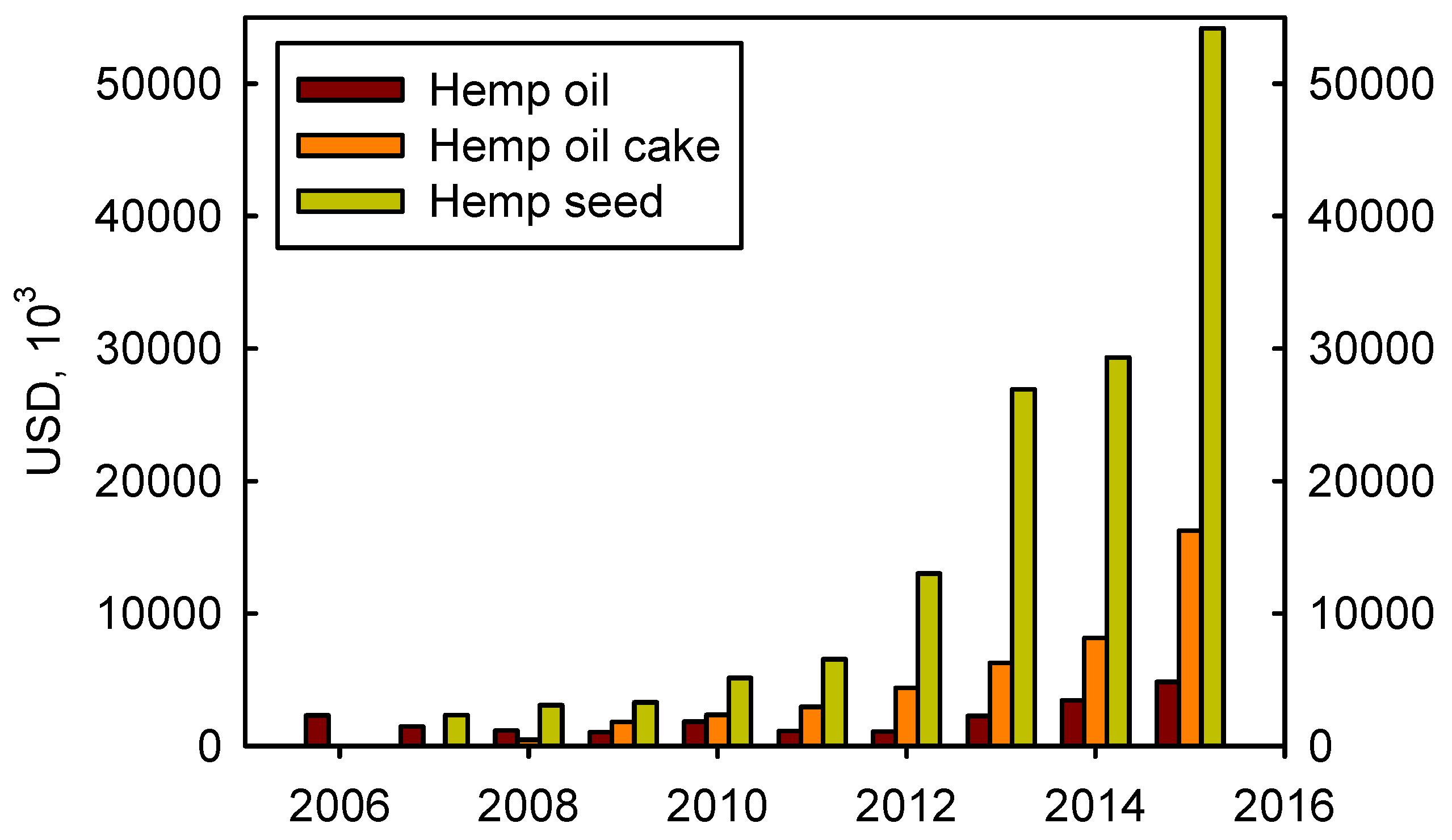

7.3. Oilseed

7.4. Cannabidiol

7.5. Biomass

8. Politics

8.1. Coupling and Decoupling of Hemp and Marijuana

8.2. Law Reviews

9. Current Status of Industrial Hemp

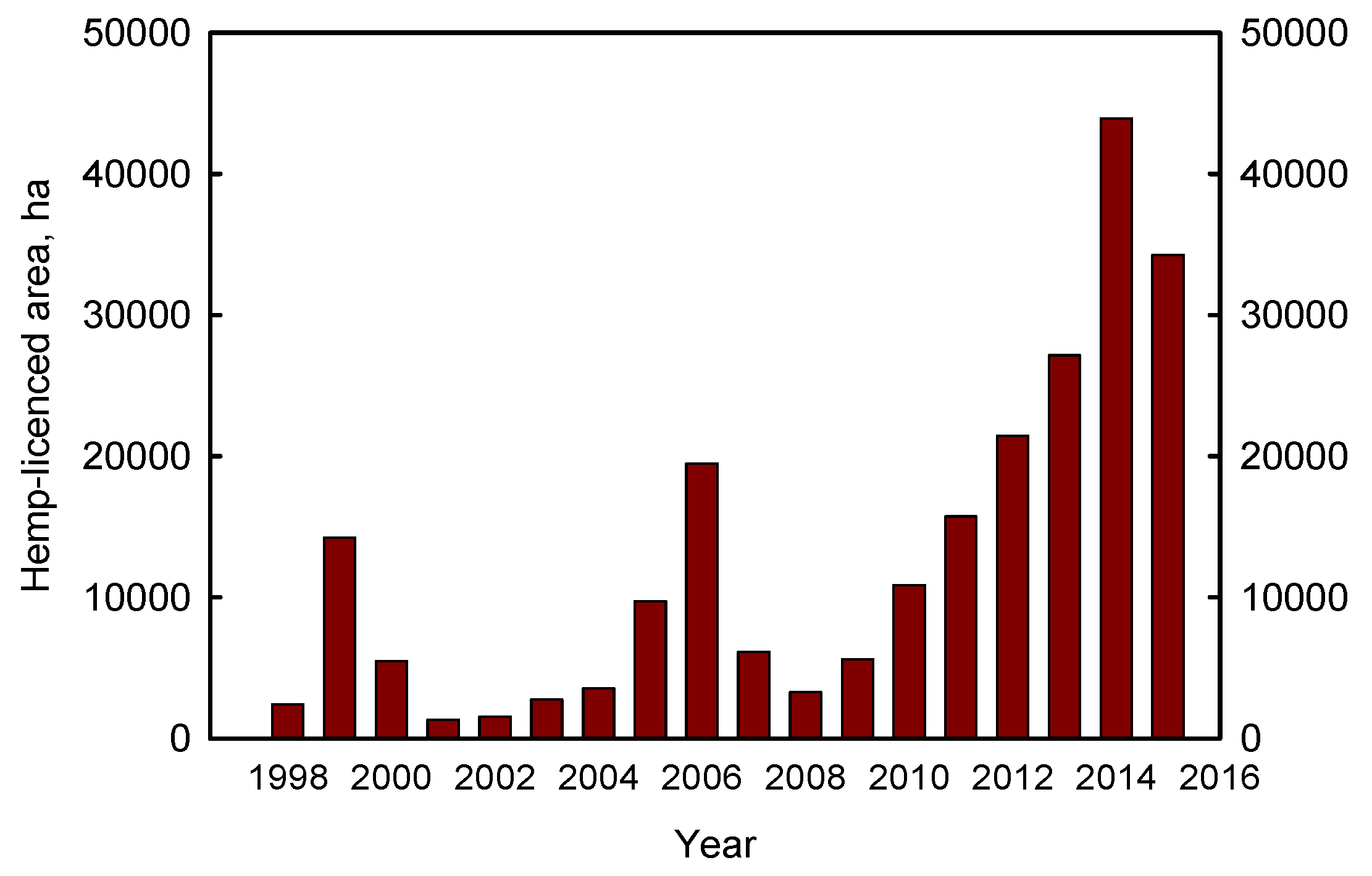

9.1. Canada

9.2. USA

9.2.1. State Reports on Hemp

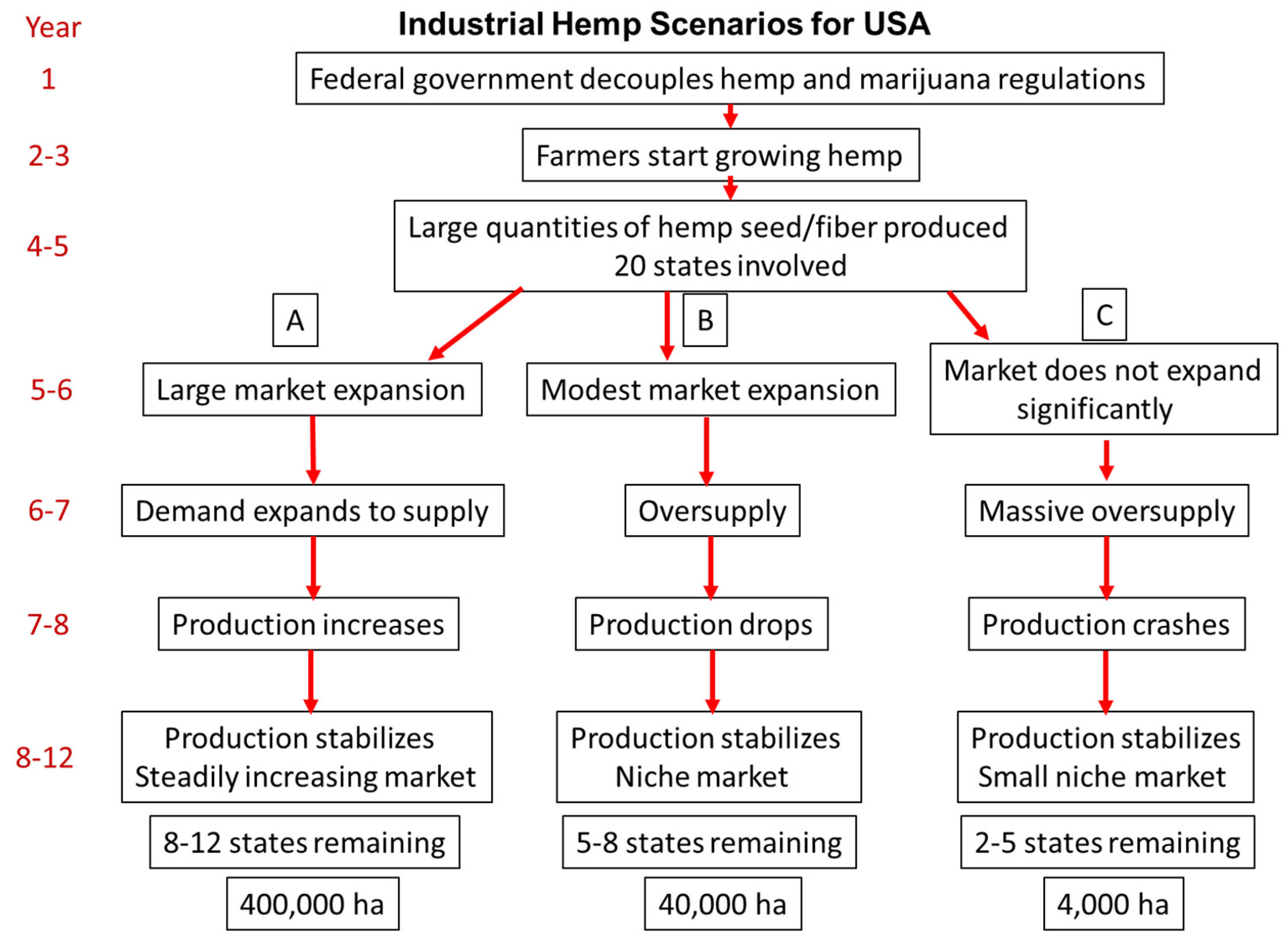

9.2.2. Possible Scenarios for the USA

10. Summary

Conflicts of Interest

References

- Industrialhemp.net. Available online: http://www.industrialhemp.net/ (accessed on 11 November 2016).

- Small, E. Cannabis: A Complete Guide; CRC Press: Boca Raton, FL, USA, 2016; in press. [Google Scholar]

- Small, E.; Cronquist, A. A practical and natural taxonomy for Cannabis. Taxon 1976, 25, 405–435. [Google Scholar] [CrossRef]

- Miller, R.L. Hemp as a Crop for Missouri Farmers: Markets, Economics, Cultivation, Law. Report to Agriculture Task Force, Missouri House of Representatives. 1991. Available online: www.naihc.org/hemp_information/content/millerhemp.html (accessed on 14 October 2016).

- Ehrensing, D.T. Feasibility of Industrial Hemp Production in the United States Pacific Northwest; Station Bulletin 681; Oregon State University: Corvallis, OR, USA, 1998. [Google Scholar]

- Small, E.; Marcus, D. Hemp—A new crop with new uses for North America. In Trends in New Crops and New Uses; Janick, J., Whipkey, A., Eds.; ASHS Press: Alexandria, Egypt, 2002; pp. 284–326. [Google Scholar]

- USDA-NRCS. Plants Database. Natural Resource and Conservation Service, U.S. Department of Agriculture. Available online: www.plants.usda.gov/core/profile?symbol = casa3 (accessed on 14 October 2016).

- Carus, M.; Sarmento, L. The European Hemp Industry: Cultivation, processing and applications for fibres, shivs, seed and flowers. European Industrial Hemp Association, May 2016; pp. 1–9. Available online: http://eiha.org/media/2016/05/16-05-17-European-Hemp-Industry-2013.pdf (accessed on 8 November 2016).

- Small, E.; Pocock, T.; Cavers, P.B. The biology of Canadian weeds. 119. Cannabis sativa L. Can. J. Plant Sci. 2003, 83, 217–237. [Google Scholar]

- Carus, M.; Karst, S.; Kauffmann, A.; Hobson, J.; Bertucelli, S. The European Hemp Industry: Cultivation, Processing and Applications for Fibres, Shives and Seeds; European Industrial Hemp Association: Hürth, Germany, 2013; pp. 1–9. [Google Scholar]

- Cochran, M.J.; Windham, T.E.; Moore, B. Feasibility of Industrial Hemp Production in Arkansas; Report SP102000; Department of Agricultural Economics and Agribusiness, University of Arkansas, Division of Agriculture: Fayetteville, AR, USA, 2000. [Google Scholar]

- FAOSTAT3. Statistics Division, Food and Agriculture Organization of the United Nations. Available online: http://faostat3.fao.org. (accessed on 14 October 2016).

- Small, E. Evolution and classification of Cannabis sativa (marijuana, hemp) in relation to human utilization. Bot. Rev. 2015, 81, 189–294. [Google Scholar] [CrossRef]

- Da Silva Vieira, R.; Canaveira, P.; da Simoes, A.; Domingos, T. Industrial hemp or eucalyptus paper? Int. J. Life Cycle Assess. 2010, 15, 368–375. [Google Scholar] [CrossRef]

- Suardana, N.P.G.; Piao, Y.; Lim, J.K. Mechanical properties of hemp fibres and hemp/PP composites: Effects of chemical surface treatment. Mater. Phys. Mech. 2011, 11, 1–8. [Google Scholar]

- Yallew, T.B.; Kumar, P.; Singh, I. Sliding behaviour of woven industrial hemp fabric reinforced thermoplastic polymer composites. Int. J. Plast. Technol. 2015, 19, 347–362. [Google Scholar] [CrossRef]

- Domke, P.V.; Mude, V.D. Natural fiber reinforced building materials. IOSR J. Mech. Civ. Eng. 2015, 12, 104–107. [Google Scholar]

- Duffy, E.; Lawrence, M.; Walker, P. Hemp-lime: Highlighting room for improvement. Civ. Environ. Res. 2013, 4, 16–21. [Google Scholar]

- Walker, R.; Pavia, S.; Mitchell, R. Mechanical properties and durability of hemp-lime concretes. Constr. Build. Mater. 2014, 61, 340–348. [Google Scholar] [CrossRef]

- Bouloc, P. The uses of hemp for domestic animals. In Hemp: Industrial Production and Uses; Bouloc, P., Allegret, S., Arnaud, L., Eds.; CAB International: Wallingford, UK; Boston, MA, USA, 2013; pp. 260–262. [Google Scholar]

- U.S. International Trade Commission (USITC). U.S. Import and Export Data on Dataweb; U.S. International Trade Commission: Washington, DC, USA, 2016. Available online: www.dataweb.usitc.gov (accessed on 14 October 2016).

- Huang, H.T. Science and Civilization in China, Vol. 6: Biology and Biological Technology, Part V: Fermentation and Food Science; Cambridge University: Cambridge, UK, 2000. [Google Scholar]

- Schultes, R.E. Random thoughts and queries on the botany of Cannabis. In The Botany and Chemistry of Cannabis; Joyce, R.B., Curry, S.H., Eds.; J. & A. Churchill: London, UK, 1970; pp. 11–38. [Google Scholar]

- Laakkonen, T.T.; Callaway, J.C. Update on FIN-314. J. Int. Hemp Assoc. 1998, 5, 34–35. [Google Scholar]

- Matthäus, B.; Brühl, L. Virgin hemp seed oil: An interesting niche product. Eur. J. Lipid Sci. Technol. 2008, 110, 655–661. [Google Scholar] [CrossRef]

- Mustafa, A.F.; McKinnon, J.J.; Christensen, D.A. The nutritive value of hemp meal for ruminants. Can. J. Anim. Sci. 1999, 79, 91–95. [Google Scholar] [CrossRef]

- Oomah, B.D.; Busson, M.; Godfrey, D.V.; Drover, J.C.G. Characteristics of hemp (Cannabis sativa L.) seed oil. Food Chem. 2002, 76, 33–43. [Google Scholar]

- Callaway, J.C.; Pate, D.W. Hempseed oil. In Gourmet and Health-Promoting Specialty Oils; Moreau, R., Kamal-Eldin, A., Eds.; AOCS Press: Urbana, IL, USA, 2009; pp. 185–214. [Google Scholar]

- Aladic, K.; Jarni, K.; Barbir, T.; Vidovic, S.; Vladic, J.; Bilic, M.; Jokic, S. Supercritical CO2 extraction of hemp (Cannabis sativa L.) seed oil. Ind. Crops Prod. 2015, 76, 472–478. [Google Scholar] [CrossRef]

- Callaway, J.C. Hempseed as a nutritional resource: An overview. Euphytica 2004, 140, 65–72. [Google Scholar] [CrossRef]

- Leson, G.; Pless, P. Hemp seed and hemp oil. In Cannabis and Cannabinoids. Pharmacology, Toxicology, and Therapeutic Potential; Grotenhermen, F., Russo, E., Eds.; Haworth Integrative Healing Press: Binghamton, NY, USA, 2002; pp. 411–425. [Google Scholar]

- Deferne, J.-L.; Pate, D.W. Hemp seed oil: A source of valuable essential fatty acids. J. Int. Hemp Assoc. 1996, 3, 4–7. [Google Scholar]

- Teh, S.-S.; Birch, J. Physicochemical and quality characteristics of cold-pressed hemp, flax and canola seed oils. J. Food Comp. Anal. 2013, 30, 26–31. [Google Scholar] [CrossRef]

- Mölleken, H.; Mothes, H.; Dudek, S. Quality of hemp fruits and hemp oil in relation to the maturity of the fruits. In Proceedings of the Bioresource Hemp & Other Fibre Crops: Proceedings of the Symposium, Wolfsburg, Germany, 13–16 September 2000; Nova Institute: Hürth, Germany, 2000. [Google Scholar]

- Vonapartis, E.; Aubin, M.-P.; Seguin, P.; Mustafa, A.F.; Charron, J.-B. Seed composition of ten industrial hemp cultivars approved for production in Canada. J. Food Comp. Anal. 2015, 39, 8–12. [Google Scholar] [CrossRef]

- Small, E.; Marcus, D. Hemp germplasm trials in Canada. Irregularly paginated. In Proceedings of the Third International Symposium Bioresource Hemp, Wolfsburg, Germany, 13–16 September 2000; Nova Corporation: Hürth, Germany, 2000. [Google Scholar]

- Chen, T.; He, J.; Zhang, J.; Zhang, H.; Qian, P.; Hao, J.; Li, L. Analytical characterization of hempseed (seed of Cannabis sativa L.) oil from eight regions in China. J. Diet. Suppl. 2010, 7, 117–129. [Google Scholar] [PubMed]

- Kriese, U.; Schumann, E.; Weber, W.E.; Beyer, M.; Brühl, L.; Matthäus, B. Oil content, tocopherol composition and fatty acid patterns of the seeds of 51 Cannabis sativa L. genotypes. Euphytica 2004, 137, 339–351. [Google Scholar] [CrossRef]

- Anwar, F.; Latif, S.; Ashraf, M. Analytical characterization of hemp (Cannabis sativa) seed oil from different agro-ecological zones of Pakistan. J. Am. Oil Chem. Soc. 2006, 83, 323–329. [Google Scholar] [CrossRef]

- Mihoc, M.; Pop, G.; Alexa, E.; Radulov, I. Nutritive quality of Romanian hemp varieties (Cannabis sativa L.) with special focus on oil and metal contents of seeds. Chem. Cent. J. 2012, 6, 122–133. [Google Scholar] [CrossRef] [PubMed]

- Callaway, J. Basic information on FINOLA Agronomy for 2016. Available online: http://finola.fi/Finola_basic_farming_info_2016.pdf (accessed on 10 November 2016).

- Official Journal of the European Union. Decisions. Off. J. Eur. Union 2016, 59, 7. [Google Scholar]

- Mölleken, H.; Theimer, R.R. Survey of minor fatty acids in Cannabis sativa L. fruits of various origins. J. Int. Hemp Assoc. 1997, 4, 13–17. [Google Scholar]

- De Meijer, E. The chemical phenotypes (chemotypes) of Cannibis. In Handbook of Cannabis; Pertwee, R.G., Ed.; Oxford University Press: Oxford, UK, 2014; pp. 89–110. [Google Scholar]

- Levin, D.A. The role of trichomes in plant defense. Q. Rev. Biol. 1973, 48, 3–15. [Google Scholar] [CrossRef]

- Wagner, G.J.; Wang, E.; Shepherd, W. New approaches for studying and exploiting an old proturberance, the plant trichome. Ann. Bot. 2004, 93, 3–11. [Google Scholar] [CrossRef] [PubMed]

- Potter, D.J. Cannabis horticulture. In Handbook of Cannabis; Pertwee, R.G., Ed.; Oxford University Press: Oxford, UK, 2014; pp. 65–88. [Google Scholar]

- Small, E.; Naraine, S.G.U. Size matters: Evolution of large drug-secreting resin glands in elite pharmaceutical strains of Cannabis sativa (marijuana). Genet. Resour. Crop Evol. 2016, 63, 349–359. [Google Scholar] [CrossRef]

- Grotenhermen, F.; Karus, M. Industrial hemp is not marijuana: comments on the drug potential of fiber Cannabis. J. Int. Hemp Assoc. 1998, 5, 96–101. [Google Scholar]

- Pertwee, R.G. The diverse CB1 and CB2 receptor pharmacology of three plant cannabinoids: Δ9-tetrahydrocannabinol, cannabidiol and Δ9-tetrahydrocannabivarin. Br. J. Pharmacol. 2008, 153, 199–215. [Google Scholar] [CrossRef] [PubMed]

- Piomelli, D.; Russo, E.B. The Cannabis sativa Versus Cannabis indica Debate: An Interview with Ethan Russo, MD. Cannabis Cannabinoid Res. 2016, 1.1, 44–46. [Google Scholar] [CrossRef]

- Mechoulam, R.; Hanus, L. Cannabidiol: An overview of some chemical and pharmacological aspects. Part I: Chemical aspects. Chem. Phys. Lipids 2002, 121, 35–43. [Google Scholar] [CrossRef] [PubMed]

- Pertwee, R.G. The pharmacology and therapeutic potential of cannabidiol. In Cannabinoids; Di Marzo, V., Ed.; Kluwer Academic/Plenum Publishers: New York, NY, USA, 2004; pp. 32–83. [Google Scholar]

- Pertwee, R.G. Pharmacological and therapeutic targets for Δ9-tetrahydrocannabinol and cannabidiol. Euphytica 2004, 140, 73–82. [Google Scholar] [CrossRef]

- Small, E. The Species Problem in Cannabis: Science and Semantics. Volume 2, Semantics; Corpus: Toronto, ON, Canada, 1979. [Google Scholar]

- Rock, E.M.; Sticht, M.A.; Parker, L.A. Effect of phytocannabinoids on nausea and vomiting. In Handbook of Cannabis; Pertwee, R.G., Ed.; Oxford University Press: Oxford, UK, 2014; pp. 435–454. [Google Scholar]

- Casler, M.D.; Vogel, K.P.; Harrison, M. Switchgrass germplasm resources. Crop Sci. 2015, 55, 2463–2478. [Google Scholar] [CrossRef]

- Cherney, J.H.; Cherney, D.J.R.; Akin, D.E.; Axtell, J.D. Potential of brown-midrib, low-lignin mutants for improving forage quality. In Advances in Agronomy; Sparks, D.L., Ed.; Academic Press, Inc.: Orlando, FL, USA, 1991; Chapter 4; Volume 46, pp. 157–198. [Google Scholar]

- Amato, J.A. The Great Jerusalem Artichoke Circus: The Buying and Selling of the Rural American Dream; University of Minnesota Press: Minneapolis, MN, USA, 1993. [Google Scholar]

- McMinimy, M.A. Biomass Crop Assistance Program (BCAP): Status and Issues; Congressional Research Service Report R41296; CRS: Washington, DC, USA, 2015. [Google Scholar]

- Vantreese, V.L. Industrial Hemp: Global Markets and Prices; Department of Agricultural Economics, University of Kentucky: Lexington, KY, USA, 1997. [Google Scholar]

- Williams, D.W.; Mundell, R. Agronomic Recommendations for Industrial Hemp Production in Kentucky—2016; University of Kentucky: Lexington, KY, USA, 2016; Available online: http://www.kyagr.com/marketing/documents/HEMP_UK-agronomic-recommendations.pdf (accessed on 14 October 2016).

- Meints, J. The hemp plant, humandkind’s savior–50,000 uses and counting. 23 January 2007. Available online: www.voteindustrialhemp.com/ (accessed on 10 November 2016).

- Baxter, W.J.; Scheifele, G. Growing Industrial Hemp in Ontario; Factsheet #67; Ontario Ministry of Agriculture, Food and Rural Affairs: Guelph, ON, Canada, 2009. Available online: http://www.omafra.gov.on.ca/english/crops/facts/00-067.htm (accessed on 14 October 2016).

- Desanlis, F.; Cerruti, N.; Warner, P. Hemp agronomics and cultivation. In Hemp: Industrial Production and Uses; Bouloc, P., Allegret, S., Arnaud, L., Eds.; CAB International: Wallingford, UK; Boston, MA, USA, 2013; pp. 98–124. [Google Scholar]

- Montford, S.; Small, E. Measuring harm and benefit: The biodiversity friendliness of Cannabis sativa L. Glob. Biodivers. 1999, 8, 2–13. [Google Scholar]

- Montford, S.; Small, E. A comparison of the biodiversity friendliness of crops with special reference to hemp (Cannabis sativa L.). J. Int. Hemp Assoc. 1999, 6, 53–63. [Google Scholar]

- Bouloc, P.; Van Der Werf, H.M.G. The role of hemp in sustainable development. In Hemp: Industrial Production and Uses; Bouloc, P., Allegret, S., Arnaud, L., Eds.; CAB International: Wallingford, UK; Boston, MA, USA, 2013; pp. 278–289. [Google Scholar]

- Kerckhoffs, H.; Kavas, Y.; Millner, J.; Anderson, C.; Kawana-Brown, E. Industrial hemp in New Zealand—Potential for cash cropping for a better environment in the Taranaki region. In Proceedings of the 17th Australian Society of Agronomy Conference, Hobart, Australia, 20–24 September 2015.

- Riddlestone, S.; Desai, P.; Evans, M.; Skyring, A. Bioregional Fibers, the Potential for a Sustainable Regional Paper and Textile Industry Based on Flax and Hemp; Bioregional Development Group, Sutton Ecology Centre: Carshalton, UK, 1994. [Google Scholar]

- Gehl, D. A Summary of Hemp Research in Canada Conducted by the Fibre Division of Agriculture Canada, 1923–1942; Agriculture and Agri-Food Canada: Indian Head, SK, Canada, 1995.

- McNulty, S. (Ed.) Report to the Governor’s Hemp and Related Fiber Crops Task Force; Commonwealth of Kentucky: Frankfort, KE, June 1995; Available online: http://www.globalhemp.com/1995/06/report-to-the-governors-hemp-and-related-fiber-crops-task-force.html (accessed on 14 October 2016).

- Kraenzel, D.G.; Petry, T.; Nelson, B.; Anderson, M.J.; Mathern, D.; Todd, R. Industrial Hemp as an Alternative Crop in North Dakota: A White Paper Study of the Markets, Profitability, Processing, Agronomics and History; Agricultural Economics Report No. 402; The Institute for Natural Resources and Economic Development, North Dakota State University: Fargo, ND, USA, 1998. [Google Scholar]

- Marcus, D. Commercial Hemp Cultivation in Canada: An Economic Justification. 1998. Available online: http://naihc.org/hemp_information/content/dmarcustx.html (accessed on 14 October 2016).

- Pinfold Consulting. A Maritime Industrial Hemp Product Marketing Study. Prepared for Nova Scotia Agriculture and Marketing (Marketing and Food Industry Development), and New Brunswick Agriculture & Rural Development (Marketing and Business Development). G. Pinfold Consulting Economists Ltd. and J. White, InfoResults Ltd. Irregularly Paginated. 1998. Available online: http://www.novascotia.ca/agri/marketing/research/hempms02.shtml (accessed on 14 October 2016).

- Thompson, E.C.; Berger, M.C.; Allen, S.N. Economic Impact of Industrial Hemp in Kentucky; Center for Business and Economic Research, University of Kentucky: Lexington, KY, USA, 1998. [Google Scholar]

- Johnson, P. Industrial hemp: A critical review of claimed potential for Cannabis sativa. Tappi J. 1999, 82, 77. [Google Scholar]

- USDA-ERS. Industrial Hemp in the United States: Status and Market Potential, AGES001E. January 2000; Economic Research Service, U.S. Department of Agriculture. Available online: http://www.ers.usda.gov/publications/ages001e/ages001em.pdf (accessed on 14 October 2016). [Google Scholar]

- Fortenbery, T.R.; Bennett, M. Opportunities for commercial hemp production. Rev. Agric. Econ. 2004, 26, 97–117. [Google Scholar] [CrossRef]

- Robbins, L.; Snell, W.; Halich, G.; Maynard, L.; Dillon, C.; Spalding, D. Economic Considerations for Growing Industrial Hemp: Implications for Kentucky’s Farmers and Agricultural Economy; Department of Agricultural Economics, University of Kentucky: Lexington, KY, USA, 2013. [Google Scholar]

- Johnson, R. Hemp as an Agricultural Commodity. CRS Report RL32725; Congressional Research Service: Washington, D.C., 26 January 2016; Available online: http://nationalaglawcenter.org/wp-content/uploads/assets/crs/RL32725.pdf (accessed on 14 October 2016).

- Illinois Industrial Hemp Investigative and Advisory Task Force. Report Submitted to the Illinois Hours of Representatives. 26 January 2000. Available online: http://www.globalhemp.com/2000/01/illinois-industrial-hemp-investigative-and-advisory-task-force-report.html (accessed on 14 October 2016).

- Bio-Based News. Growing Markets for Hemp Food and Pharmaceuticals—Potential Billion € Markets in Europe. 25 April 2016. Available online: www.news.bio-based.eu/growing-markets-for-hemp-food-and-pharmaceuticals-potential-billion-e-markets-in-europe/ (accessed on 14 October 2016).

- Van der Werf, H.M.G. Hemp facts and hemp fiction. J. Int. Hemp Assoc. 1994, 1, 58–59. [Google Scholar]

- Meijer, W.J.M.; Vanderwerf, H.M.G.; Mathijssen, E.W.J.M.; Vandenbrink, P.W.M. Constraints to dry-matter production in fiber hemp. Eur. J. Agron. 1995, 4, 109–117. [Google Scholar] [CrossRef]

- Biewinga, E.E.; Van der Bijl, G. Sustainability of Energy Crops in Europe. A Methodology Developed and Applied; Report No. 234; Centre for Agriculture and Environment: Utrecht, The Netherlands, 1996. [Google Scholar]

- Kuglarz, M.; Alvarado-Morales, M.; Karakashev, D.; Angelidaki, I. Integrated production of cellulosic bioethanol and succinic acid from industrial hemp in a biorefinery concept. Bioresour. Technol. 2016, 200, 639–647. [Google Scholar] [CrossRef] [PubMed]

- Sipos, B.; Kreuger, E.; Svensson, S.E.; Réczey, K.; Björnsson, L.; Guido, Z. Steam pretreatment of dry and ensiled industrial hemp for ethanol production. Biomass Bioenergy 2010, 34, 1721–1731. [Google Scholar] [CrossRef]

- González-García, S.; Luo, L.; Moreira, M.T.; Feijoo, G.; Huppes, G. Life cycle assessment of hemp hurds use in second generation ethanol production. Biomass Bioenergy 2012, 36, 268–279. [Google Scholar] [CrossRef]

- Prade, T.; Svensson, S.E.; and Mattson, J.E. Energy balances for biogas and solid biofuel production from industrial hemp. Biomass Bioenergy 2012, 40, 36–52. [Google Scholar] [CrossRef]

- Ragit, S.S.; Mohapatra, S.K.; Gill, P.; Kundu, K. Brown hemp methyl ester: Transesterification process and evaluation of fuel properties. Biomass Bioenergy 2012, 41, 14–20. [Google Scholar] [CrossRef]

- Li, S-Y.; Stuart, J.D.; Li, Y.; Parnas, R.S. The feasibility of converting Cannabis sativa L. oil into biodiesel. Bioresour. Technol. 2010, 101, 8457–8460. [Google Scholar]

- Ragit, S.S.; Mohapatra, S.K.; Kundu, K.; Karmakar, R. Methanolysis and ethanolysis of raw hemp oil: Biodiesel production and fuel characterization. Int. J. Eng. Res. Technol. 2013, 2. [Google Scholar]

- Herer, J. Hemp and the Marijuana Conspiracy: The Emperor Wears No Clothes, 10th ed.; Ahha Publishing: Austin, TX, USA, 1996. [Google Scholar]

- Survey Research Center. Survey Research Center Data Archive, University of Kentucky. 1995 Kentucky Spring Poll. Available online: www.research.uky.edu/survey/dataarchive.html (accessed on 14 October 2016).

- Chan Halbrendt, C.; Wang, Q.; Mole, M.C. Alternative agricultural strategies in Vermont: The case of industrial hemp. In Proceedings of the Vermont Agricultural Economic Development Conference, South Burlington, VT, USA, 16 December 1996.

- Cortilet, A. Industrial Hemp Research. Report to the Minnesota Department of Agriculture. Minnesota Law 2014: HF3172-3 (SF2785); Chapter 312: Article 12; Section 3. 15 January 2015. Available online: www.mda.state.mn.us (accessed on 14 October 2016).

- West, D.P. Hemp and Marijuana: Myths & Realities. North American Industrial Hemp Council, Inc., 1998. Available online: www.naihc.org (accessed on 14 October 2016).

- Callaway, J. Current status of FINOLA in the EU. Available online: http://finola.fi/DEFRA_prohibition_Cancelled_Oct2016.pdf (accessed on 10 November 2016).

- NORML and the NORML Foundation. Industrial use of marijuana. Washington DC, USA. Available online: http://norml.org/marijuana/industrial (accessed on 10 November 2016).

- Texas hemp Campaign. Austin, TX, USA. Available online: http://texashempcampaign.com/ (accessed on 14 October 2016).

- North American Industrial Hemp Council. Madison, WI, USA. Available online: http://naihc.org/ (accessed on 11 November 2016).

- Hempethics. Oroville, CA, USA. Available online: http://hempethics.weebly.com/ (accessed on 11 November 2016).

- Caulkins, J.P.; Hawken, A.; Kilmer, B.; Kleiman, M.A.R. Marijuana Legalization: What Everyone Needs to Know; Oxford University Press: New York, NY, USA, 2012. [Google Scholar]

- Brady, T.C. The argument for the legalization of industrial hemp. San Joaquin Agric. Law Rev. 2003, 13, 85–108. [Google Scholar]

- Kolosov, C.A. Evaluating the public interest: Regulation of industrial hemp under the Controlled Substances Act. UCLA Law Rev. 2009, 57, 237–274. [Google Scholar]

- Thedinger, S. Prohibition in the United States: International and U.S. regulation and control of industrial hemp. Colo. J. Int. Environ. Law Policy 2006, 17, 419–446. [Google Scholar]

- Keller, N.M. The legalization of industrial hemp and what it could mean for Indiana’s biofuel industry. Indiana Int. Comp. Law Rev. 2013, 23, 555–590. [Google Scholar]

- Dwyer, S.D. The hemp controversy: Can industrial hemp save Kentucky. Ky. Law J. 1997, 86, 1143–1182. [Google Scholar]

- Rogers, V. The future of hemp in Kentucky. Ky. J. Equine Agric. Nat. Resour. Law 2012, 4, 479–500. [Google Scholar]

- Shepherd, C.D. Lethal concentration of power: How the D.E.A. acts improperly to prohibit the growth of the industrial hemp. UMKC Law Rev. 1999, 68, 239–262. [Google Scholar]

- Duppong, T.A. Industrial Hemp: How the classification of industrial hemp as marijuana under the Controlled Substances Act has caused the dream of growing industrial hemp in North Dakota to go up in smoke. N. D. Law Rev. 2009, 85, 403–434. [Google Scholar]

- Lash, R. Industrial hemp: The crop for the Seventh Generation. Am. Indian Law Rev. 2002, 27, 313–356. [Google Scholar] [CrossRef]

- Moran, C.N. Industrial hemp: Canada exports, United States imports. Fordham Environ. Law Rev. 2015, 26, 383–449. [Google Scholar]

- Health Canada, Office of Controlled Substances. Ottawa, Ontario, Canada, 2016. Available online: www.hc-sc.gc.ca (accessed on 14 October 2016).

- Roth-Li, G. Industrial Hemp (Cannabis sativa)—Economic Viability and Political Concerns; White Paper Prepared for Representative Cynthia Thielen; Hawaiian State Legislature: Honolulu, HI, USA, 1996. Available online: http://www.globalhemp.com/1996/04/hawaiian-industrial-hemp-report.html (accessed on 14 October 2016).

- MAFES. An Assessment of Industrial Hemp Production in Maine; Maine Agricultural and Forest Experiment Station: Orono, ME, USA, 2016; Available online: www.votehemp.com/PDF/ME_Hemp_Study_2006.pdf (accessed on 14 October 2016).

| Region in | Research | 2015 | NA | Year of Peak | USA Federal | |||

|---|---|---|---|---|---|---|---|---|

| Field Crop | USA/Canada | Decades | Product | Most Optimistic Claims | Area, ha 1 | Status 2 | Production, ha 3 | Assistance |

| BMR Pearl millet, annual | USA | 1980/2000 | Forage | Highly digestible summer forage | 20,000 | 4 | 2015 | No |

| Pennisetum glaucum (L.) R.Br. | S Canada | NR | ||||||

| Camelina, annual | N USA | 1960/1980 | Oilseed | Omega-3 oil | 1392 | 2, 3, 4 | 2007: 9700 | Yes |

| Camelina sativa (L.) Crantz | S Canada | 2000 | NR | |||||

| Comfrey, annual | NC USA | 1910/1980 | Forage/medicinal | Tremendous yields/medicinal | NR | 1, 2, 3 | none | No |

| Symphytum spp. | Canada | value | NR | |||||

| Grain amaranth, annual | NC USA | 1970–1980 | Pseudo-grain | Food of the Aztecs | 153 | 1,3 | 1988: 1200 | No |

| Amaranthus spp. | S Ontario | 1990 | NR | |||||

| Industrial hemp, annual | N 3/4 USA | 1840/2010 | Oilseed/fiber | Humankind‘s savior | 621 | 1, 2, 3, 4 | 1943: 59,200 | No |

| Cannabis sativa L. | S Canada | 1920/2010 | 34,263 | 2014: 43,909 | ||||

| Jerusalem artichoke, annual | NC USA | 1930/1980 | Tuber | Manna of the plains | NR | 2,3 | 1982: 4000 | No |

| Helianthus tuberosus L. | SE Canada | 1980 | NR | |||||

| Kenaf, annual | S USA | 1940–1990 | Fiber/oilseed | Most promising non-wood fiber | 206 | 1, 2, 3 | 2000: 7300 | Yes |

| Hibiscus cannabinus L. | S Ontario | 2010 | NR | |||||

| Kura clover, perennial | N USA | 1910/1980 | Forage | Potential to be major forage | NR | 1 | none | No |

| Trifolium ambiguum M. Bieb. | Canada | 1990 | crop | NR | ||||

| Meadowfoam, annual | NW USA | 1980/2000 | Oilseed | Tremendous potential | 692 | 1, 3 | 2012: 789 | Yes |

| Limnanthes albal Benth. | SW Canada | NR | ||||||

| Miscanthus, perennial | E 1/2 USA | 2000–2010 | Biomass | Highest yielding biomass crop | 7400 | 1, 2, 3, 4 | 2015 | Yes |

| Miscanthus × giganteus | SE Canada | 2010 | 120 | |||||

| Quinoa, annual | NW USA | 1980/2010 | Pseudo-grain | Nutrient-dense superfood | 224 | 1, 2, 4 | 2015 | No |

| Chenopodium quinoa Willd. | SW Canada | 1990 | <2000 | |||||

| Spelt, annual | N 2/3 USA | 1890/1980 | Grain | Alternative to wheat | 6081 | 4 | 1980: 81,000 | No |

| Triticum aestivum var. spelta | S Canada | <5000 | ||||||

| Sunn hemp, annual | S 2/3 USA | 1930/1980 | Fiber | Excellent cover crop | 343 | 1 | 2015 | No |

| Crotalaria juncea L. | S Ontario | NR | ||||||

| Switchgrass, perennial | USA | 1980–2010 | Biomass/forage | Model bioenergy crop | >5000 | 2, 3, 4 | 2015 | Yes |

| Panicum virgatum L. | SE Canada | 2000–2010 | 1800 | |||||

| Teff, annual | USA | 1990 | Grain/forage | New superfood | 10,818 | 1, 2 , 3, 4 | 2015 | Yes |

| Eragrostis tef (Zucc.) Trotter | S Canada | NR |

| State Laws | Year | Study 1 | Provisions |

| Alabama | 2016 | No | Research only |

| Arizona | 2015 | In progress | Study authorized |

| Arkansas | 1999 | Yes | Study authorized |

| California | 2013 | In progress | License farmers 2 |

| Colorado | 2013 | No | License farmers |

| Connecticut | 2015 | In progress | Legalize hemp |

| Delaware | 2014 | No | Research only |

| Hawaii | 2014 | Yes | Research only |

| Illinois | 2014 | Yes | Research only |

| Indiana | 2014 | No | License farmers |

| Kentucky | 2013 | Yes | License farmers |

| Maine | 2009 | Yes | License farmers 2 |

| Maryland | 2014 | No | License farmers 2 |

| Michigan | 2014 | No | Research only |

| Minnesota | 2015 | No | Research only |

| Montana | 2001 | No | License farmers |

| Nebraska | 2014 | No | Research only |

| Nevada | 2015 | No | Research only |

| New Hampshire | 2015 | In progress | Research only |

| New York | 2014 | No | Research only |

| North Carolina | 2015 | No | Research only |

| North Dakota | 1999 | Yes | License farmers |

| Oregon | 2009 | Yes | License farmers |

| South Carolina | 2014 | No | License farmers |

| Tennessee | 2014 | No | License farmers |

| Utah | 2014 | No | Research only |

| Vermont | 2013 | Yes | License farmers |

| Virginia | 2015 | No | Research only |

| Washington | 2016 | In progress | Research only |

| West Virginia | 2002 | No | License farmers |

| Legislation | Year | Study | Status of Legislation |

| Alaska | 2016 | No | Sponsored |

| Arizona | 2015 | No | Stalled |

| Florida | 2016 | No | Failed |

| Georgia | 2016 | No | Sponsored |

| Idaho | 2007 | No | Failed |

| Iowa | 2016 | No | Stalled |

| Kansas | 2016 | No | Failed |

| Louisiana | 2016 | No | Sponsored |

| Massachusetts | 2016 | No | Stalled |

| Mississippi | 2015 | No | Failed |

| Missouri | 2016 | Yes | Sponsored |

| New Jersey | 2014 | No | Stalled |

| New Mexico | 2016 | No | Stalled |

| Oklahoma | 2014 | No | Stalled |

| Pennsylvania | 2016 | No | Sponsored |

| Rhode Island | 2016 | No | Sponsored 3 |

| South Dakota | 2016 | No | Failed |

| Texas | 2016 | No | Sponsored |

| Wisconsin | 2016 | No | Failed |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cherney, J.H.; Small, E. Industrial Hemp in North America: Production, Politics and Potential. Agronomy 2016, 6, 58. https://doi.org/10.3390/agronomy6040058

Cherney JH, Small E. Industrial Hemp in North America: Production, Politics and Potential. Agronomy. 2016; 6(4):58. https://doi.org/10.3390/agronomy6040058

Chicago/Turabian StyleCherney, Jerome H., and Ernest Small. 2016. "Industrial Hemp in North America: Production, Politics and Potential" Agronomy 6, no. 4: 58. https://doi.org/10.3390/agronomy6040058