Ultrasound Assisted Extraction for the Recovery of Phenolic Compounds from Vegetable Sources

Abstract

:1. Introduction

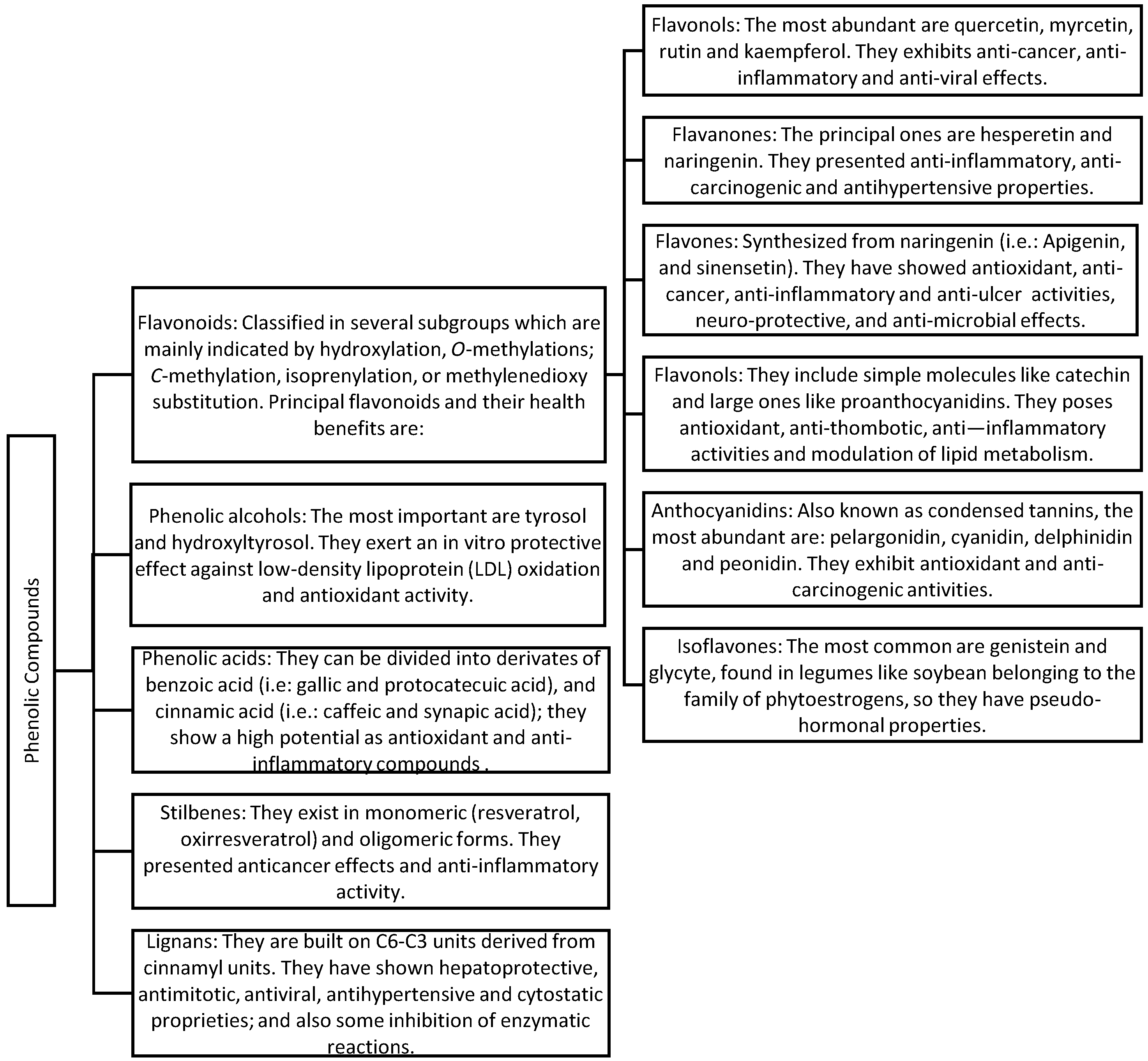

2. Phenolic Compounds: Characteristics and Biological Potential

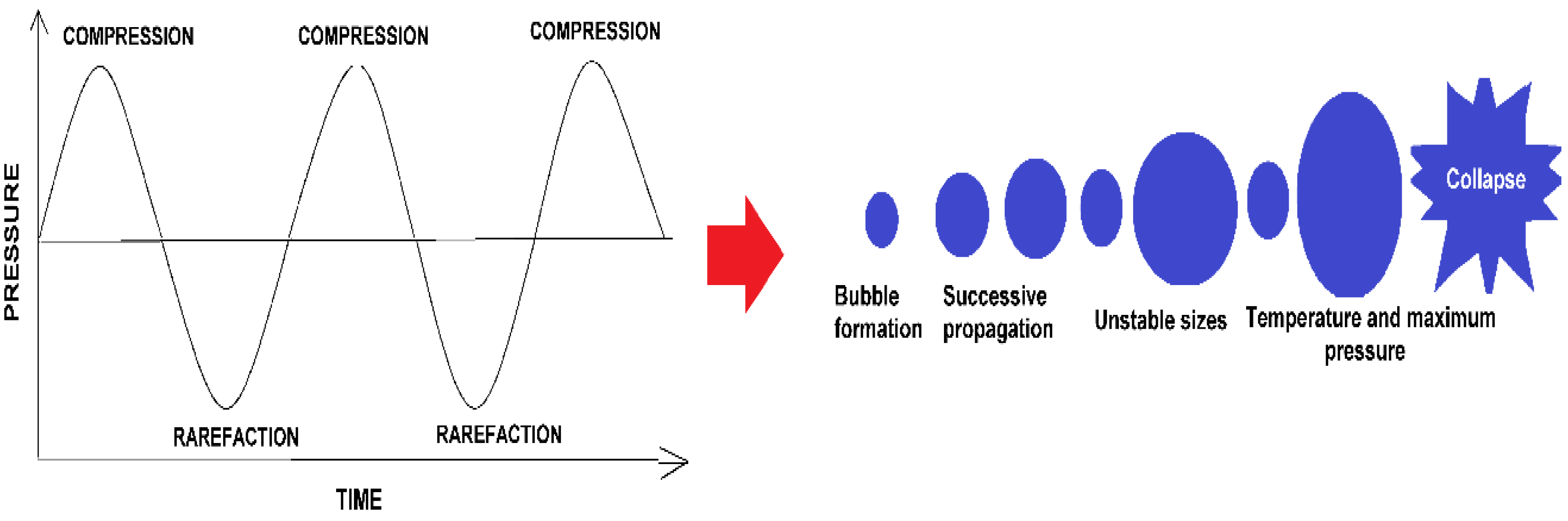

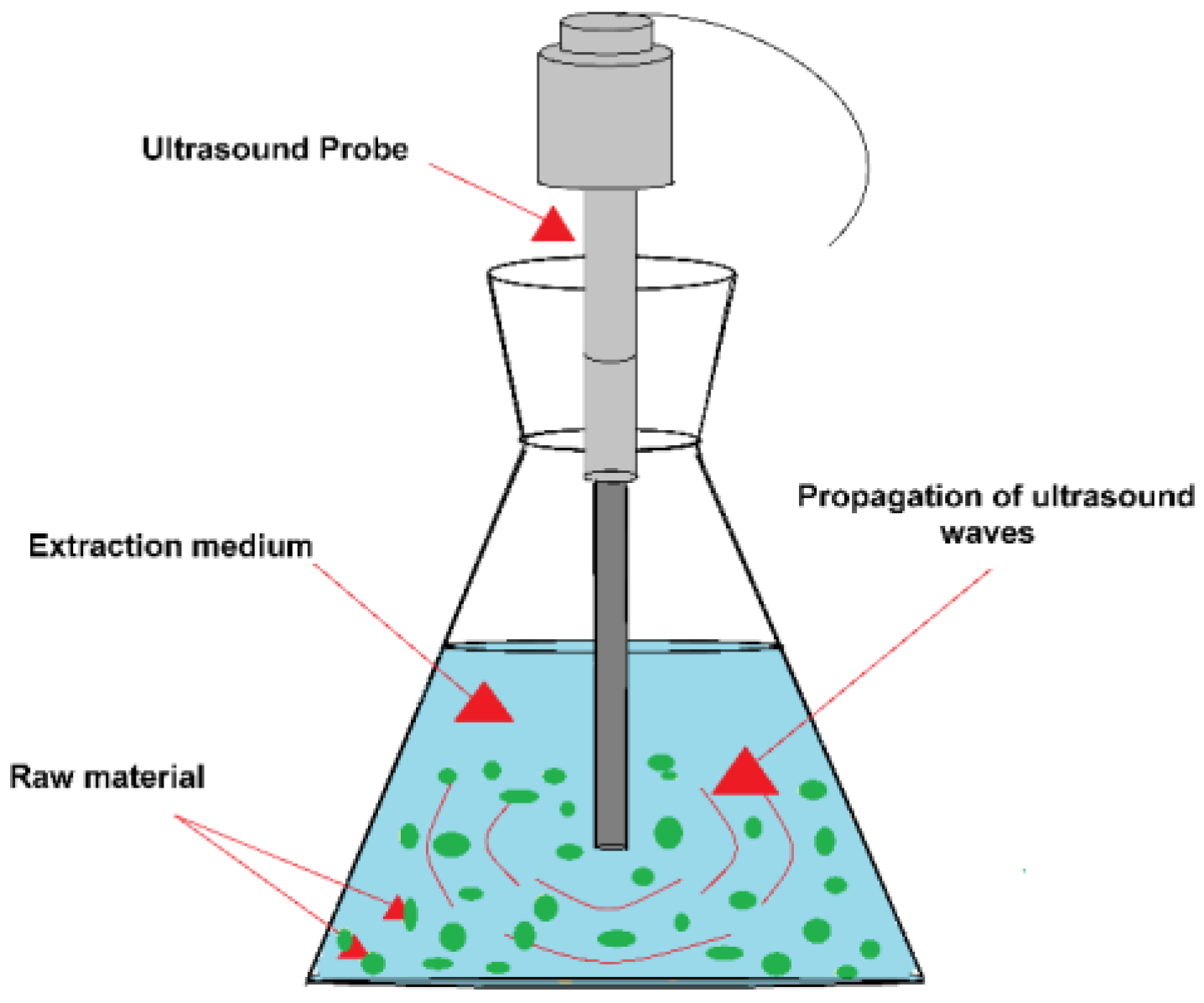

3. Ultrasonic Assisted Extraction (UAE) and Characteristics

- Length: distance between two points of compression or rarefaction.

- Amplitude: maximum height of a wave.

- Frequency (Hz): number of cycles per unit of time.

- Speed (m/s): product of frequency by wavelength.

- Power (W): ratio between the energy transported and the time considered.

- Intensity: ratio of a power unit across a unit area (W/cm2).

4. Effect of Involved Variables of UAE in Efficiency and Yield

4.1. Effect of Ultrasound System Characteristics

4.1.1. Operation Equipment Mode and Frequency

4.1.2. Ultrasound System and Amplitude

4.2. Effect of Sample Pretreatment

4.3. Effect of the Solvent

4.4. Temperature Effect

4.5. Effect of Solute/Solvent Ratio

4.6. Extraction Time

5. Optimization of Ultrasonic Assisted Extraction

6. Comparison UAE with Other Methods of Extraction

6.1. Comparison against Conventional Methods

6.2. Comparison against Non-Conventional Methods

7. Scale-Up UAE

8. UAE, Innovation-Driven to Environmental Sustainability

8.1. Use of Renewable Raw Materials

8.2. Reduction of the Use of Auxiliary Substances

8.3. Decreased Energy Consumption

9. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gil-ch, G.J.; Villa, A.; Ayala-zavala, J.F.; Heredia, J.B.; Sepulveda, D.; Yahia, E.M.; Gonz, G.A. Technologies for Extraction and Production of Bioactive Compounds to be Used as Nutraceuticals and Food Ingredients: An Overview. Compr. Rev. Food Sci. Food Saf. 2013, 12, 5–23. [Google Scholar]

- Da Porto, C.; Porretto, E.; Decorti, D. Ultrasonics Sonochemistry Comparison of ultrasound-assisted extraction with conventional extraction methods of oil and polyphenols from grape (Vitis vinifera L.) seeds. Ultrason. Sonochem. 2013, 20, 1076–1080. [Google Scholar] [CrossRef] [PubMed]

- Bendicho, C.; De La Calle, I.; Pena, F.; Costas, M.; Cabaleiro, N.; Lavilla, I. Ultrasound-assisted pretreatment of solid samples in the context of green analytical chemistry. TrAC Trends Anal. Chem. 2012, 31, 50–60. [Google Scholar] [CrossRef]

- Armenta, S.; Garrigues, S.; De Guardia, M. The role of green extraction techniques in Green Analyticla Chemistry. Trends Anal. Chem. 2015, 71, 2–8. [Google Scholar] [CrossRef]

- Chemat, F.; Khan, M.K. Applications of ultrasound in food technology: Processing, preservation and extraction. Ultrason. Sonochem. 2011, 18, 813–835. [Google Scholar] [CrossRef] [PubMed]

- Soria, A.C.; Villamiel, M. Effect of ultrasound on the technological properties and bioactivity of food: A review. Trends Food Sci. Technol. 2010, 21, 323–331. [Google Scholar] [CrossRef]

- Vieira, G.S.; Cavalcanti, R.N.; Meireles, M.A.A.; Hubinger, M.D. Chemical and economic evaluation of natural antioxidant extracts obtained by ultrasound-assisted and agitated bed extraction from jussara pulp (Euterpe edulis). J. Food Eng. 2013, 119, 196–204. [Google Scholar] [CrossRef]

- Tiwari, B.K. Trends in Analytical Chemistry Ultrasound: A clean, green extraction technology. TrAC Trends Anal. Chem. 2015, 71, 100–109. [Google Scholar] [CrossRef]

- Parisi, O.I.; Puoci, F.; Restuccia, D.; Iemma, F.; Picci, N. Polyphenols and Their Formulations: Different Strategies to Overcome the Drawbacks Associated with Their Poor Stability and Bioavailability. Polyphenols Hum. Health Dis. 2014, 4, 29–45. [Google Scholar] [CrossRef]

- Vilkhu, K.; Mawson, R.; Simons, L.; Bates, D. Applications and opportunities for ultrasound assisted extraction in the food industry—A review. Innov. Food Sci. Emerg. Technol. 2008, 9, 161–169. [Google Scholar] [CrossRef]

- Ignat, I.; Volf, I.; Popa, V.I. A critical review of methods for characterisation of polyphenolic compounds in fruits and vegetables. Food Chem. 2011, 126, 1821–1835. [Google Scholar] [CrossRef] [PubMed]

- Balasundram, N. Food Chemistry Phenolic compounds in plants and agri-industrial by-products: Antioxidant activity, occurrence, and potential uses. Food Chem. 2006, 99, 191–203. [Google Scholar] [CrossRef]

- Gutiérrez-grijalva, E.P.; Ambriz-pére, D.L.; Leyva-lópez, N.; Castillo-lópez, R.I.; Heredia, J.B. Review: Dietary phenolic compounds, health benefits and bioaccessibility. Arch. Latinoam. Nutr. 2016, 66, 87–100. [Google Scholar]

- Shahidi, F.; Ambigaipalan, P. Phenolics and polyphenolics in foods, beverages and spices: Antioxidant activity and health effects—A review. J. Funct. Foods 2015, 18, 820–897. [Google Scholar] [CrossRef]

- Paul, E.; Grijalva, G. Bioavailability of dietary phenolic compounds. Rev. Esp. Nutr. Hum. Diet. 2016, 20, 140–147. [Google Scholar] [CrossRef]

- Carocho, M.; Ferreira, I.C.F.R. The Role of Phenolic Compounds in the Fight against Cancer—A Review. Anti Cancer Agents Med. Chem. 2013, 13, 1236–1258. [Google Scholar] [CrossRef]

- Oroian, M.; Escriche, I. Antioxidants: Characterization, natural sources, extraction and analysis. Food Res. Int. 2015, 74, 10–36. [Google Scholar] [CrossRef] [PubMed]

- Musielak, G.; Mierzwa, D.; Kroehnke, J. Trends in Food Science & Technology Food drying enhancement by ultrasound—A review. Trends Food Sci. Technol. 2016, 56, 126–141. [Google Scholar]

- Awad, T.S.; Moharram, H.A.; Shaltout, O.E.; Asker, D.; Youssef, M.M. Applications of ultrasound in analysis, processing and quality control of food: A review. Food Res. Int. 2012, 48, 410–427. [Google Scholar] [CrossRef]

- Tippens, P.E.; Hernández, A.E.G. Física: Conceptos y Aplicaciones; Javier Neyra Bravo: Naucalpan, D.F., México, 2007. [Google Scholar]

- Kadam, S.U.; Tiwari, B.K.; Alvarez, C.; Donnell, C.P.O. Ultrasound applications for the extraction, identification and delivery of food proteins and bioactive peptides. Trends Food Sci. Technol. 2015, 46, 60–67. [Google Scholar] [CrossRef]

- Shirsath, S.R.; Sonawane, S.H.; Gogate, P.R. Intensification of extraction of natural products using ultrasonic irradiations—A review of current status. Chem. Eng. Process. Process Intensif. 2012, 53, 10–23. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Sicaire, A.; Meullemiestre, A.; Abert-vian, M. Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef] [PubMed]

- Pico, Y. Ultrasound-assisted extraction for food and environmental samples. TrAC Trends Anal. Chem. 2013, 43, 84–99. [Google Scholar] [CrossRef]

- Barba, F.J.; Zhu, Z.; Koubaa, M.; Sant, A.S. Green alternative methods for the extraction of antioxidant bioactive compounds from winery wastes and by-products: A review. Trends Food Sci. Technol. 2016, 49, 96–109. [Google Scholar] [CrossRef]

- Pan, Z.; Qu, W.; Ma, H.; Atungulu, G.G.; McHugh, T.H. Continuous and pulsed ultrasound-assisted extractions of antioxidants from pomegranate peel. Ultrason. Sonochem. 2012, 19, 365–372. [Google Scholar] [CrossRef] [PubMed]

- Galvan D’Alessandro, L.; Kriaa, K.; Nikov, I.; Dimitrov, K. Ultrasound assisted extraction of polyphenols from black chokeberry. Sep. Purif. Technol. 2012, 93, 42–47. [Google Scholar] [CrossRef]

- Tchabo, W.; Ma, Y.; Engmann, F.N.; Zhang, H. Ultrasound-assisted enzymatic extraction (UAEE) of phytochemical compounds from mulberry (Morus nigra) must and optimization study using response surface methodology. Ind. Crops Prod. 2015, 63, 214–225. [Google Scholar] [CrossRef]

- Al-dhabi, N.A.; Ponmurugan, K.; Maran, P. Development and validation of ultrasound-assisted solid-liquid extraction of phenolic compounds from waste spent coffee grounds. Ultrason. Sonochem. 2017, 34, 206–213. [Google Scholar] [CrossRef] [PubMed]

- Carrera, C.; Ruiz-rodríguez, A.; Palma, M.; Barroso, C.G. Ultrasound assisted extraction of phenolic compounds from grapes. Anal. Chim. Acta 2012, 732, 100–104. [Google Scholar] [CrossRef] [PubMed]

- Meullemiestre, A.; Petitcolas, E.; Maache-rezzoug, Z.; Chemat, F.; Rezzoug, S.A. Impact of ultrasound on solid-liquid extraction of phenolic compounds from maritime pine sawdust waste. Kinetics, optimization and large scale experiments. Ultrason. Sonochem. 2016, 28, 230–239. [Google Scholar] [CrossRef] [PubMed]

- Drosou, C.; Kyriakopoulou, K.; Bimpilas, A.; Krokida, M. A comparative study on different extraction techniques to recover red grape pomace polyphenols from vinification byproducts. Ind. Crops Prod. 2015, 75, 141–149. [Google Scholar] [CrossRef]

- Mane, S.; Bremner, D.H.; Tziboula-clarke, A.; Lemos, M.A. Effect of ultrasound on the extraction of total anthocyanins from Purple Majesty potato. Ultrason. Sonochem. 2015, 27, 509–514. [Google Scholar] [CrossRef] [PubMed]

- Tomšik, A.; Pavlic, B.; Vladic, J.; Ramic, M.; Brindza, J.; Vidovic, S. Optimization of ultrasound-assisted extraction of bioactive compounds from wild garlic (Allium ursinum L.). Ultrason. Sonochem. 2016, 29, 502–511. [Google Scholar] [CrossRef] [PubMed]

- Garcia-castello, E.M.; Rodriguez-lopez, A.D.; Mayor, L.; Ballesteros, R.; Conidi, C.; Cassano, A. Optimization of conventional and ultrasound assisted extraction of fl avonoids from grapefruit (Citrus paradisi L.) solid wastes. LWT Food Sci. Technol. 2015, 64, 1114–1122. [Google Scholar] [CrossRef]

- Muñiz-márquez, D.B.; Martínez-ávila, G.C.; Wong-paz, J.E.; Belmares-cerda, R.; Rodríguez-herrera, R.; Aguilar, C.N. Ultraso nics Sonoch emistry Ultrasound-assisted extraction of phenolic compounds from Laurus nobilis L. and their antioxidant activity. Ultrason. Sonochem. 2013, 20, 1149–1154. [Google Scholar] [CrossRef] [PubMed]

- Selin Sahin, R.S. Optimization of olive leaf extract obtained by ultrasound-assisted extraction with response surface methodology. Ultrason. Sonochem. 2013, 20, 595–602. [Google Scholar] [CrossRef] [PubMed]

- Katsampa, P.; Valsamedou, E.; Grigorakis, S.; Makris, D.P. A green ultrasound-assisted extraction process for the recovery of antioxidant polyphenols and pigments from onion solid wastes using Box-Behnken experimental design and kinetics. Ind. Crops Prod. 2015, 77, 535–543. [Google Scholar] [CrossRef]

- Corbin, C.; Fidel, T.; Leclerc, E.A.; Barakzoy, E.; Sagot, N.; Falguiéres, A.; Renouard, S.; Blondeau, J.P.; Ferroud, C.; Doussot, J.; et al. Development and validation of an efficient ultrasound assisted extraction of phenolic compounds from flax (Linum usitatissimum L.) seeds. Ultrason. Sonochem. 2015, 26, 176–185. [Google Scholar] [CrossRef] [PubMed]

- Celli, G.B.; Ghanem, A.; Brooks, M.S. Optimization of ultrasound-assisted extraction of anthocyanins from haskap berries (Lonicera caerulea L.) using Response Surface Methodology. Ultrason. Sonochem. 2015, 27, 449–455. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.B.; Brunton, N.P.; Patras, A.; Tiwari, B.; Donnell, C.P.O.; Martin-diana, A.B.; Barry-ryan, C. Optimization of ultrasound assisted extraction of antioxidant compounds from marjoram (Origanum majorana L.) using response surface methodology. Ultrason. Sonochem. 2012, 19, 582–590. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.; Zhang, Z.; Sun, D. Kinetic modeling of ultrasound-assisted extraction of phenolic compounds from grape marc: Influence of acoustic energy density and temperature. Ultrason. Sonochem. 2014, 21, 1461–1469. [Google Scholar] [CrossRef] [PubMed]

- Sousa, A.D.; Maia, A.I.V.; Rodrigues, T.H.S.; Canuto, K.M.; Ribeiro, P.R.V.; Pereira, R.D.C.A.; Vieira, R.F.; Brito, E.S.d. Ultrasound-assisted and pressurized liquid extraction of phenolic compounds from Phyllanthus amarus and its composition evaluation by UPLC-QTOF. Ind. Crops Prod. 2016, 79, 91–103. [Google Scholar] [CrossRef]

- Wong, J.E.; Muñiz, D.B.; Martínez, G.C.G.; Belmares, R.E.; Aguilar, C.N. Ultrasound-assisted extraction of polyphenols from native plants in the Mexican desert. Ultrason. Sonochem. 2015, 22, 474–481. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.; Wu, D.; Zhang, Q.; Sun, D. Ultrasound-assisted extraction of phenolics from wine lees: Modeling, optimization and stability of extracts during storage. Ultrason. Sonochem. 2014, 21, 706–715. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Zhao, Y.; Yu, S. Optimisation of ultrasonic-assisted extraction of phenolic compounds, antioxidants, and anthocyanins from sugar beet molasses. Food Chem. 2015, 172, 543–550. [Google Scholar] [CrossRef] [PubMed]

- Aybastıer, Ö.; Is, E.; Saliha, S. Optimization of ultrasonic-assisted extraction of antioxidant compounds from blackberry leaves using response surface methodology. Ind. Crops Prod. 2013, 44, 558–565. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Y.; Chen, G.; Yue, W.; Liang, Q.; Wu, Q. Optimisation of ultrasound assisted extraction of phenolic compounds from Sparganii rhizoma with response surface methodology. Ultrason. Sonochem. 2013, 20, 846–854. [Google Scholar] [CrossRef] [PubMed]

- González-centeno, M.R.; Knoerzer, K.; Sabarez, H.; Simal, S.; Rosselló, C.; Femenia, A. Effect of acoustic frequency and power density on the aqueous ultrasonic-assisted extraction of grape pomace (Vitis vinifera L.)—A response surface approach. Ultrason. Sonochem. 2014, 21, 2176–2184. [Google Scholar] [CrossRef] [PubMed]

- Heydari, M.; Rajaei, A.; Salar, D.; Ali, S.; Bolourian, S. Optimization of ultrasonic-assisted extraction of phenolic compounds from bovine pennyroyal (Phlomidoschema parviflorum) leaves using response surface methodology. Ind. Crops Prod. 2014, 57, 195–202. [Google Scholar] [CrossRef]

- Mkadmini, K.; Jdey, A.; Abdelly, C.; Majdoub, H.; Ksouri, R. Optimization of ultrasound-assisted extraction of antioxidant compounds from Tunisian Zizyphus lotus fruits using response surface methodology. Food Chem. 2015, 184, 80–89. [Google Scholar]

- Vidovic, S.; Zekovic, Z.; Vladic, J.; Cvejin, A.; Pavlic, B. Modeling and optimization of ultrasound-assisted extraction of polyphenolic compounds from Aronia melanocarpa by-products from filter-tea factory. Ultrason. Sonochem. 2015, 23, 360–368. [Google Scholar]

- Xu, J.; Wang, W.; Liang, H.; Zhang, Q.; Li, Q. Optimization of ionic liquid based ultrasonic assisted extraction of antioxidant compounds from Curcuma longa L. using response surface methodology. Ind. Crops Prod. 2015, 76, 487–493. [Google Scholar] [CrossRef]

- He, B.; Zhang, L.; Yue, X.; Liang, J.; Jiang, J.; Gao, X.; Yue, P. Optimization of Ultrasound-Assisted Extraction of phenolic compounds and anthocyanins from blueberry (Vaccinium ashei) wine pomace. Food Chem. 2016, 204, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Sharmila, G.; Nikitha, V.S.; Ilaiyarasi, S.; Dhivya, K.; Rajasekar, V.; Kumar, N.M.; Muthukumaran, K.; Muthukumaran, C. Ultrasound assisted extraction of total phenolics from Cassia auriculata leaves and evaluation of its antioxidant activities. Ind. Crops Prod. 2016, 84, 13–21. [Google Scholar] [CrossRef]

- Vázquez, M.F.B.; Comini, L.R.; Martini, R.E.; Montoya, S.C.N.; Bottini, S.; Cabrera, J.L. Comparisons between conventional, ultrasound-assisted and microwave-assisted methods for extraction of anthraquinones from Heterophyllaea pustulata Hook f. (Rubiaceae). Ultrason. Sonochem. 2014, 21, 478–484. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.; Qu, Z.; Lan, Y.; Zhao, S.; Ma, X.; Wan, Q.; Jing, P.; Li, P. Conventional, ultrasound-assisted, and accelerated-solvent extractions of anthocyanins from purple sweet potatoes. Food Chem. 2016, 197, 266–272. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Pérez, C.; Quirantes-Piné, R.; Fernández-Gutiérrez, A.; Segura-Carretero, A. Optimization of extraction method to obtain a phenolic compounds-rich extract from Moringa oleifera Lam leaves. Ind. Crops Prod. 2015, 66, 246–254. [Google Scholar] [CrossRef]

- Ledesma-escobar, C.A.; Priego-capote, F. Comparative study of the effect of auxiliary energies on the extraction of Citrus fruit components. Talanta 2015, 144, 522–528. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-rojo, S.; Visentin, A.; Maestri, D.; Cocero, M.J. Assisted extraction of rosemary antioxidants with green solvents. J. Food Eng. 2012, 109, 98–103. [Google Scholar] [CrossRef]

- Yildiz-ozturk, E.; Nalbantsoy, A.; Tag, O.; Yesil-celiktas, O. A comparative study on extraction processes of Stevia rebaudiana leaves with emphasis on antioxidant, cytotoxic and nitric oxide inhibition activities. Ind. Crops Prod. 2015, 77, 961–971. [Google Scholar] [CrossRef]

- M´hiri, N.; Ioannou, I.; Boudhrioua, N.; Ghoul, M. Processing Effect of different operating conditions on the extraction of phenolic compounds in orange peel. Food Bioprod. 2015, 6, 161–170. [Google Scholar] [CrossRef]

- Nayak, B.; Dahmoune, F.; Moussi, K.; Remini, H.; Dairi, S.; Aoun, O.; Khodir, M. Comparison of microwave, ultrasound and accelerated-assisted solvent extraction for recovery of polyphenols from Citrus sinensis peels. Food Chem. 2015, 187, 507–516. [Google Scholar] [CrossRef] [PubMed]

- Pingret, D.; Fabiano-Tixier, A.S.; Le Bourvellec, C.; Renard, C.M.; Chemat, F. Lab and pilot-scale ultrasound-assisted water extraction of polyphenols from apple pomace. J. Food Eng. 2012, 111, 73–81. [Google Scholar] [CrossRef]

- Alexandru, L.; Cravotto, G.; Giordana, L.; Binello, A.; Chemat, F. Ultrasound-assisted extraction of clove buds using batch- and flow-reactors: A comparative study on a pilot scale. Innov. Food Sci. Emerg. Technol. 2013, 20, 167–172. [Google Scholar] [CrossRef]

- Oniszczuk, A.; Olech, M. Optimization of ultrasound-assisted extraction and LC-ESI–MS/MS analysis of phenolic acids from Brassica oleracea L. var. sabellica. Ind. Crops Prod. 2016, 83, 359–363. [Google Scholar] [CrossRef]

- Goula, A.M.; Thymiatis, K.; Kaderides, K. Processing Valorization of grape pomace: Drying behavior and ultrasound extraction of phenolics. Food Bioprod. 2016, 100, 132–144. [Google Scholar] [CrossRef]

- Dahmoune, F.; Boulekbache, L.; Moussi, K.; Aoun, O.; Spigno, G. Valorization of Citrus limon residues for the recovery of antioxidants: Evaluation and optimization of microwave and ultrasound application to solvent extraction. Ind. Crops Prod. 2013, 50, 77–87. [Google Scholar] [CrossRef]

- Luis, J.; Reátegui, P.; Paula, A.; Barbero, G.F.; Rezende, C.A.; Martínez, J. Extraction of antioxidant compounds from blackberry (Rubus sp.) bagasse using supercritical CO2 assisted by ultrasound. J. Supercrit. Fluids 2014, 94, 223–233. [Google Scholar]

- Rabelo, R.S.; Machado, M.T.C.; Martínez, J.; Hubinger, M.D. Ultrasound assisted extraction and nano fi ltration of phenolic compounds from artichoke solid wastes. J. Food Eng. 2016, 178, 170–180. [Google Scholar] [CrossRef]

- Bosiljkov, T.; Dujmi, F. Processing Natural deep eutectic solvents and ultrasound-assisted extraction: Green approaches for extraction of wine lees anthocyanins. Food Bioprod. 2016, 2, 195–203. [Google Scholar]

- Tomaševic, M.; Kovac, K.; Bubalo, M.C.; Natka, C. Green extraction of grape skin phenolics by using deep eutectic solvents. Food Chem. 2016, 200, 159–166. [Google Scholar]

- Rodrigues, S.; Fernandes, F.A.N.; Sousa, E.; Brito, D.; Dutra, A.; Narain, N. Ultrasound extraction of phenolics and anthocyanins from jabuticaba peel. Ind. Crops Prod. 2015, 69, 400–407. [Google Scholar] [CrossRef]

- González-Centeno, M.; Comas-Serra, F.; Femenia, A.; Rosselló, C.; Simal, S. Effect of power ultrasound applicationon aqueous extraction of phenolic compounds and antioxidant capacity from grape pomace (Vitis vinifera L.): Experimental kinetics and modeling. Ultrasonics Sonochem. 2015, 22, 506–514. [Google Scholar] [CrossRef] [PubMed]

| Characteristic | Novel Extraction Technology | Conventional Methods | ||||

|---|---|---|---|---|---|---|

| Ultrasound-Assisted | Microwave-Assisted | Supercritical Fluids | Accelerated by Solvents | Mechanical Agitation | Soxhlet | |

| Driving force | Acoustic cavitation | Microwave power | Pressure in conjunction with supercritical fluid | Heat in conjunction with the solvent under pressure | Solvent contact | Heat |

| Extraction time | 10–60 min | 3–30 min | 10–60 min | 10–20 min | Several hours | 6–24 h |

| Sample size | 1–30 g | 1–10 g | 1–5 g | 1–30 g | 1–30 g | 1–30 g |

| Solvent amount | 50–200 mL | 10–40 mL | 30–60 mL | 15–60 mL | Large volume | 150–500 mL |

| Power Amount | Moderate | High | Moderate | Moderate | High | High |

| Advantage | Easy to handle, safe (atmospheric pressure and ambient temperature), moderate use of solvent, reproducible | Fast, easy to handle, moderate use of solvent | Fast, safe, no filtering required, high selectivity | Fast, safe, no filtering required | Not use o sophisticated equipment | Not use of sophisticated equipment |

| Disadvantages | Required filtration step, possible degradation of compounds at high frequencies | Risk of explosion (solvent must absorb microwave power), expensive, required filtration step | Many parameters to optimize | Possible degradation of thermo-labiles compounds | Risk of spills and exposure to organic vapors, degradation of thermos-labiles compounds, required filtration step | Exposure risk to organic vapors, degradation of thermos-labiles compounds |

| Polyphenol | Vegetal Source | |

|---|---|---|

| Flavonoids | Anthocyanins: Cyanidin, pelargonidin, petunidin | Bilberries, blackcurrant, cherries, cranberries, black berries, blueberries, strawberries, apricot, grapes, red cabbage, black bean, barley, pomegranate, onion, sweet potato, cocoa |

| Flavones: Apigenin, luteolin, rutin | Citric fruits, celery, parsley, spinach, artichoke, buckwheat, corn, sorghum, black rice, red cabbage, asparagus, olive, coffee, oregano, fenugreek seeds, nuts | |

| Isoflavones: Genistein, daidzein, glycitein | Soybean, black beans, green peas | |

| Flavanones: Naringenin, hesperitine, hesperidin, eriodictyn | Citric fruits: grapefruit, orange, lemon; tomato, sorghum, mint | |

| Flavonols: Quercetin, kaempferol, isoquercetine, myricetin | Apples, grapes, citric fruits, beans, blueberries, buckwheat, cranberries, endive, leeks, lettuce, onions, olive, pepper, tomato, moringa, sorghum, nuts, broccoli, potato, strawberries, blackwheat, cocoa, peach, raspberries, asparagus, lentils, oregano, rosemary, almonds, fenugreek seeds | |

| Flavanols (flavan-3-ols): (+)-catechin, (−)-epicatechin, (+)-gallocatechin, (−)-epigallocatechin | Apricots, apples, blueberries, grapes, onions, lettuce, buckwheat, hazelnut, cocoa, evening primrose, black tea, green tea, almonds | |

| Phenolic acids | Hydroxybenzoic acid: Gallic, p-hydroxy-benzoic, protocatechuic, vanillic and syringic acids | Grapes, blueberries, bilberries, blackberries, lentils, cranberries, oilseeds, apricots, blackwheat, carrot, onions, potato, sweet potato, soybean, rapeseed, borage, canola, evening primrose, sorghum, wheat, barley, millet rice, oat, peas, olive, coffee, nuts, almonds, ginger, turmeric, hazelnut |

| Hydroxycinnamic acid: Caffeic, ferulic, p-coumaric and sinapic acids | Blueberries, blackcurrant, apricot, blackberries, peas, grapes, rice, rye, buckwheat, millet, sorghum, cranberries, bilberries, oat, barley, broccoli, carrot, onion, potato, soybean, rapeseed, canola, flaxseed, hazelnut, borage, olive, almonds, black pepper, clove, turmeric | |

| Tannins | Proanthocyanidins (condensed tannins) | Berries, cocoa, barley, buckwheat, lentils, beans, peas, rapeseed, canola, evening primrose, blackcurrant, raspberries |

| Hydrolysable tannins | Grapes, blueberries, cranberries, blackberries, pomegranate, lentils, rapeseed, canola | |

| Stilbenes | Resveratrol | Grapes, peanuts, bilberries, nuts, blueberries |

| Lignans | Barley; flaxseed, sesame seed | |

| Variable Involved | Vegetable Source | Compounds | UAE Conditions | Performance/Remarks | Reference |

|---|---|---|---|---|---|

| Ultrasound irradiation | Pomegranate peel | Total polyphenols | Continuous irradiation | Increased yield of 24%, | Pan et al. [26] |

| Pomegranate peel | Total polyphenols | Pulsed irradiation of 5s | Increased yield of 22%, | Pan et al. [26] | |

| Frequency | Grape seeds | Phenolic compounds | 25 kHz–60 kHz | Low frequencies enhance extraction yield | Soria and Villamiel [6] |

| Grapes | Resveratrol | 47 kHz, 14 W | Increased yield of 24–28% | Barba et al. [25] | |

| Grapes by products | Polyphenols | 35 kHz | Increased yield of 50% | Barba et al. [25] | |

| Herbal extracts | Polyphenols | 20–24 kHz | Increases yield up to 34% | Vilkhu et al. [10] | |

| Ultrasonic power | Wild garlic | Bioactive compounds | 19.2 to 38.4 W/L | Low power resulted in better extraction | Tomšik et al. [34] |

| Amplitude | Grapes | Phenolic compounds | 20, 50 and 100% | Increased yield of 15%, higher cycles increases recovery | Meullemiestre et al. [31] |

| Purple Majesty potato | Anthocyanins | 30, 50 and 70% | Anthocyanins increased in all cases when higher amplitude values | Mane et al. [33] | |

| Pre-treatment | Grape pomace | Polyphenols | Solar dried | Increased extraction | Drosou et al. [32] |

| Purple Majesty potato | Anthocyanins | Freeze dried and Microwave | Increased anthocyanins extraction and decrease solvent used | Mane et al. [33] | |

| Solvent composition | Black chokeberry | Anthocyanins | Ethanol concentration of 0 and 50% | Ethanol at 50% showed 3-fold higher than water. | Galvan et al. [27] |

| Purple Majesty potato | Anthocyanins | Ethanol concentration 50 and 70% | Anthocyanins presented and increment when ethanol increases | Mane et al. [33] | |

| Grape pomace | Polyphenols | Water, water: ethanol (1:1) and ethanol 100% | Ethanol: water favor released of polyphenols | Drosou et al. [32] | |

| Herbal extracts | Polyphenols | Water–ethanol (1:1) | Increases yield up to 34% | Vilkhu et al. [10] | |

| Laurus nobilis L. | Phenolic compounds | Ethanol concentration at 0, 35, 70% | Extraction yield increases when ethanol concentration increases. | Muñiz-Márquez et al. [36] | |

| Wild garlic | Bioactive compounds | Ethanol concentration 30 to 70% | Higher ethanol concentration resulted in better extraction yield | Tomšik et al. [34] | |

| Temperature | Black chokeberry | Anthocyanins | 20–70 °C | Increment of temperatures improved polyphenol extraction | Galvan et al. [27] |

| Wild garlic | Bioactive compounds | 40–80 °C | Higher temperatures resulted in better extraction yield | Tomšik et al. [34] | |

| Grapefruit | Flavonoids | 25–70 °C | Higher temperature increases extraction yield | García-Castello et al. [35]. | |

| Grape marc | Phenolic compounds | 20–50 °C | Better extraction yield is obtained a higher temperatures | Tao et al. [42] | |

| Solid/liquid ratio | Laurus nobilis L. | Phenolic compounds | 1:4, 1:8, 1:12 | When solid/liquid ratio decreases polyphenol extract yield increases | Muñiz-Márquez et al. [36] |

| Time | Wild garlic | Bioactive compounds | 40 to 80 min | Higher time resulted in better extraction | Tomšik et al. [34] |

| Laurus nobilis L. | Phenolic compounds | 20, 40, 60 min | Presented lower effect in extraction yield | Muñiz-Márquez et al. [36] | |

| Black chokeberry | Anthocyanins | 0–24 min, | Higher at the beginning of the extraction, decreases considerably with time | Galvan et al. [27] | |

| Purple Majesty potato | Anthocyanins | 5, 30, 60, 120 min | A maximal increment of Anthocyanins was observed at 30 min | Mane et al. [33] |

| Optimization | ||||

|---|---|---|---|---|

| Reference | * Raw material * Solvent * Equipment | Optimization Methodology | Optimal Conditions | Results |

| Aybastıer et al. [47] | * Blackberry leaves. * Methanol. * Ultrasonic bath. | Box–Behnken. | (Sol.): 61%–64% T/°C: 66–68. T/M: 105–117. | TPC: 80.19 mg GAE/g DW. |

| Wang et al. [48] | * Rhizomes of S. (Stoloniferum Buch.-Ham). * Ethanol. * Ultrasound: 25 kHz, 300 W | Box–Behnken. | (Sol.): 75.3% T/M: 40 Solv/sol: 19.21 mL/g. | TPC: 881.12 μg/g DW. |

| González-centeno et al. [49] | * Grape skin (Vitis vinifera L.). * Water. * Ultrasound generator | Box–Behnken. | T/M: 25 Fc: 40 kHz. Pw: 150 W/L. | TPC: 32.31 mg GAE/g FW. AA: 53.47 mg Trolox/100 g FW |

| Majd et al. [50] | *Phlomidoschema parviflorum. * Methanol 80%. * Ultrasonic probe system: 200 W | Box–Behnken. | T/°C: 41.5 T/M: 49.3 pH: 6.5. | TPC: 15.4 mg GAE/g DB. |

| Celli et al. [40] | * Berries (Lonicera caerulea L.). * Ethanol. * Ultrasonic bath: 40 kHz, and 100 W. | Box–Behnken. | (Sol.): 80% T/°C: 35 T/M: 20 Solv/sol: 25/1 (mL/g). | Anthocyanins T: 22.73 mg cyanidin E/g DW. |

| Chen et al. [46] | * Sugar beet molasses. * Ethanol. * Ultrasonic bath: 40 kHz. | Central compound Design. | (Sol.): 57%–63% T/°C: 41–48 T/M: 66–73. | TPC: 17.36 mg GAE/100 mL. AA: 16.66 mg/g. |

| Hammi et al. [51] | * Azufaifo (Ziziphus lotus). * Ethanol. * Ultrasonic bath: 35 kHz. | Central Design Composite Rotatable | (Sol.): 50% T/°C: 63 T/M: 25 Solv/sol: 67 mL/g. | TPC: 40.782 mg GAE/g DW. AA: 0.289 mg/mL. |

| Ramić et al. [52] | * Black Aronia (Aronia melanocarpa). * Ethanol 50%. * Ultrasonic bath: 40 kHz. | Factorial complete (33) with three levels. | T/°C: 70 T/M: 80.1 Pw: 206.64 W. | TPC: 15.41 mg GAE/mL. |

| Tchabo et al. [28] | * Fruits of blackberry (Morus nigra). * Enzyme (Pectinex UF). * Ultrasonic probe (35.3 cm × 28.2 cm × 10.4 cm). | Box–Behnken. | (Sol.): 0.010% T/M: 11.58. Fc: 33.82 kHz. | TPC: 298.06 mg/100 mL. Totals Flavonoids: 379.24 mg/100 mL. |

| Xu et al. [53] | * Rhizomes of Curcuma longa L. * Bromine solution. * Ultrasonic bath: 40 kHz. | Box–Behnken. | (Sol.): 4.2 mol/L T/M: 90 Solv/sol: 30 mL/g. Pt: 250 W. | Totals Curcuminoids: 5.72 g/100 g. |

| He et al. [54] | * Blueberry wine waste (Vaccinium ashei). * Ethanol. * Ultrasonic bath: 40 kHz. | Box–Behnken. | T/°C: 61.3 T/M: 23.67 Solv/sol: 21.70 mL/g. | TPC: 16.41 mg GAE/g DW. |

| Sharmila et al. [55] | * Cassia flower (Cassia auriculata). * Methanol, Ethanol, and Water. * Ultrasonic generator. | Box–Behnken. | (Sol.): 60% T/M: 5 pH: 6.2. Pw: 50 W. | TPC: 15.41 mg GAE/g DW. Percent inhibition by DPPH: 90.5% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medina-Torres, N.; Ayora-Talavera, T.; Espinosa-Andrews, H.; Sánchez-Contreras, A.; Pacheco, N. Ultrasound Assisted Extraction for the Recovery of Phenolic Compounds from Vegetable Sources. Agronomy 2017, 7, 47. https://doi.org/10.3390/agronomy7030047

Medina-Torres N, Ayora-Talavera T, Espinosa-Andrews H, Sánchez-Contreras A, Pacheco N. Ultrasound Assisted Extraction for the Recovery of Phenolic Compounds from Vegetable Sources. Agronomy. 2017; 7(3):47. https://doi.org/10.3390/agronomy7030047

Chicago/Turabian StyleMedina-Torres, Nelly, Teresa Ayora-Talavera, Hugo Espinosa-Andrews, Angeles Sánchez-Contreras, and Neith Pacheco. 2017. "Ultrasound Assisted Extraction for the Recovery of Phenolic Compounds from Vegetable Sources" Agronomy 7, no. 3: 47. https://doi.org/10.3390/agronomy7030047