The objective of the use of the balance sheet is to supply the minimum amount of N fertiliser needed to obtain the maximum crop yield for a given agricultural situation.

2.2.1. Crop N Requirements

The estimated crop N requirement is different between plants harvested for grain and plants harvested at a vegetative stage. The N uptake of plants harvested for grain is calculated as the product of the objective grain yield (Mg ha

−1) and the N requirement per unit of grain production (kg N Mg

−1 DM). The N requirement per unit of grain is calculated from the quantity of N accumulated by crop for a given grain yield, and these data are obtained from field experiments conducted by technical institutions. For other crops, the N requirement is considered constant per area unit (kg N ha

−1) and according to the crop, i.e., a potential yield is not considered when calculating the N requirements. For winter crops, whose growth cycle starts before the period in which the N balance sheet is calculated, the N that has already been taken up by the crop (which varies with the stage of crop development) is included in the term Pi and is subtracted from the total N required by the crop. The values used for the different variables characterising the crops, i.e., yield objective for plants harvested for grain, N requirements, maximum rooting depth, default date of crop harvest, and N uptake by the crop at the opening date of the balance sheet, are available in the crop catalogue of the software and are presented in

Table A1 in

Appendix A.

2.2.2. Mineralisation of Organic Sources

• Soil organic matter (Mh)

Humified organic matter is mineralised in the upper layer, the depth of which corresponds to the ploughing depth and ranges from 20 to 30 cm depending on the soil type. In soils in which organic matter accumulates below the ploughed layer, the extra N mineralisation is calculated as a fixed extra 10% of the N mineralised in the ploughed layer. The potential rate of mineralisation is calculated from the organic N pool of the considered soil layer (

Norg) and the rate of mineralisation of this pool (

k2), which depends on the clay and limestone concentrations in the soil [

21,

22,

23].

The organic N pool is divided into two fractions, an active fraction (

FNact) and an inert fraction (

Finert), and only the active fraction contributes to mineralisation (the ratio of the inert: active fractions is available in the soil catalogue). The mineralisation rate also considers the cultural history (

Fsyst) of the plot, such as the long-term effect of crop residue management; organic product application, frequency and nature; and catch crop species. The mineralisation rate (

Mh) of these layers is the product of the potential rate of mineralisation (

Vp), the

T (

f(

T)) and

W (

g(

W)) factors, and the

FNact and

Fsyst factors.

Therefore, AzoFert

® requires different variables, such as the clay (g 1000 g

−1 soil), limestone (g 1000 g

−1 soil) and total N (g 1000 g

−1 soil) contents, W at field capacity and wilting point, and parameters pertaining to “cultural history”. Some input data are provided by the farmer, while others are available in the soil catalogue (default data; see

Table A2 in

Appendix B).

• Organic products (Mr, Ma, Mcc, Mg)

The decay of crop residues (main crops, cover crops, plant residues from grassland ploughing) and organic products in the soil results in either the net mineralisation or the net immobilisation of soil N. The decay rate of these products depends on the nature of organic residues (chemical characteristics and C:N ratio) and the

T and

W soil conditions. The kinetics of mineralisation were determined using a large dataset of laboratory incubations conducted under controlled and optimal decomposition conditions (constant soil

W and

T; non-limiting N conditions) [

24,

25,

26] and using field experiments measuring the N mineralisation of crop residues or organic products. We used a single generic formalism that describes the dynamics of either the nitrogen (Equation (8)) or carbon (Equation (9)) of these various organic sources.

The net mineralisation rates of N and C are described by the following double exponential equations:

where

N and

C are the amounts of mineralised N and C, respectively, at time

t;

NRO and

CRO are the initial amounts of N and C in the crop residues or organic products, respectively; and

aN,

bN,

cN,

aC,

bC,

cC,

l and

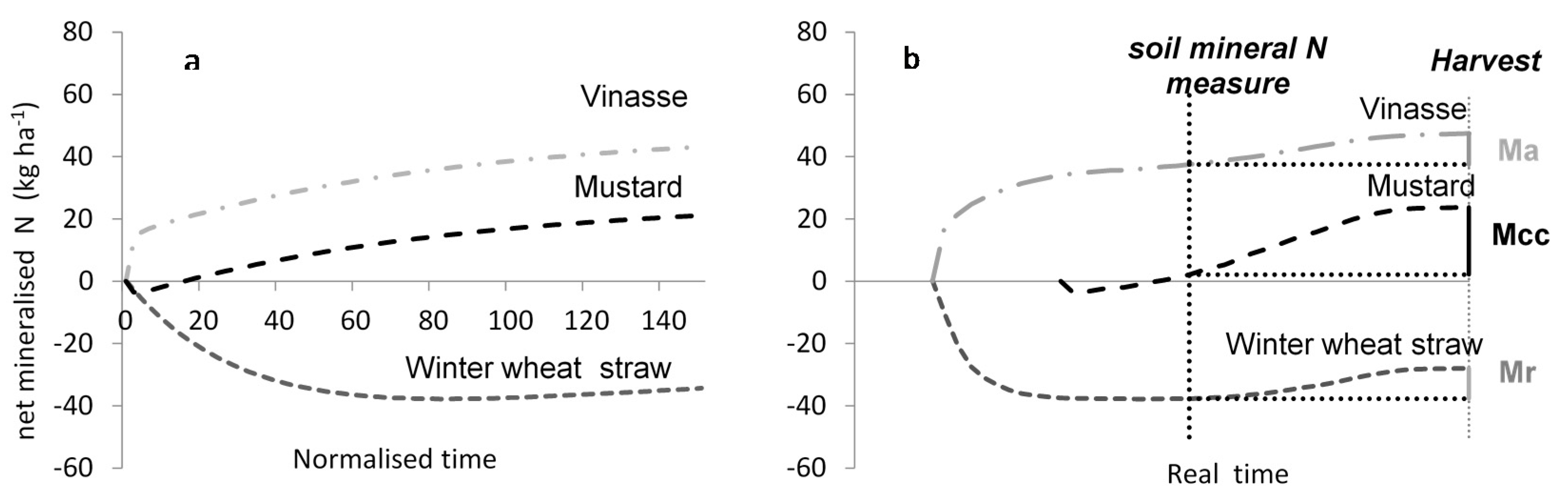

k are coefficients that describe the mineralisation kinetics of N and C of the crop residues and organic products. The coefficient values are expressed using normalised time. Three examples of the kinetics of net N mineralisation for crop residues and organic products are given in

Figure 1 to illustrate how the kinetics of potential mineralisation in the laboratory (expressed in normalised days,

Figure 1a) are used by AzoFert

® to dynamically determine the respective contribution of each organic source to the mineral N pool at balance opening and closing, with the net differences between the two dates being the values of the

Mr,

Ma or

Mcc terms of the calculation (

Figure 1b).

The equations have been parameterised for different types of crop residues, i.e., the straw of cereals, the tops of sugar beets and potatoes, and the residues of catch crops (see previous crop and catch crop catalogues,

Appendix C and

Appendix D). The parameters for organic products, such as solid and liquid manures, poultry droppings, agro-industry effluents and urban effluents, are available in the organic products catalogue (

Table A5 in

Appendix E). Because the kinetics of crop residue and organic product mineralisation are calculated over normalised time, their decomposition can be modelled over time. For example,

Table 1 shows the N contribution of vinasse applied before a sugar beet crop according to the date of application. Vinasse is a by-product of the sugar industry applied during the intercropping period between cereal harvest and the establishment of the sugar beet crop. The application rate was 3 Mg ha

−1 of vinasse, which had C and N contents of 16.4% and 2.4%, respectively. Earlier application dates correspond to lower Ma values in the balance sheet.

2.2.3. Processes affecting the Availability of Fertiliser N

AzoFert

® considers three processes that affect the availability of fertiliser N applied to a crop, i.e., nitrogen leaching, microbial N immobilisation and the volatilisation of ammonia from fertiliser; the denitrification losses from fertiliser N are not yet included in the model. This is due to the history of this balance sheet approach [

12,

13], which considered that N losses through gas emissions were generally compensated by non-symbiotic N fixation inputs. The scientific knowledge gained over the last decades has shown that farming practices and climate significantly change the losses resulting from volatilisation and denitrification, and these processes can no longer be considered negligible and/or compensated for by a fixed (and not adequately quantified) term of non-symbiotic fixation. While we have developed a simple module for volatilisation for this tool, we have not yet developed a module for denitrification, which remains a complex and difficult process to predict.

The functions used for N immobilisation and volatilisation of ammonia were derived from 15 N experiments that demonstrated the microbial immobilisation of added fertiliser N and the incomplete recovery of the added N by different crops in the temperate climate of northwestern Europe [

17,

18].

The amount of microbially immobilised fertiliser N depends on the N immobilisation capacity and the soil N availability [

27]. In AzoFert

®, the immobilisation capacity is calculated from the availability of C in the ploughed layer using Equation (9), which predicts the C evolution from crop residues and organic products, and an immobilisation ratio:

where

Y is the immobilisation ratio,

X is the amount of fertiliser N,

QC is the amount of decomposed organic C, and

Ix is the immobilised fertiliser N.

The immobilisation ratio, i.e., the immobilised N per decomposed C, varies with soil N availability. Mary et al. [

28] showed that microbial N immobilisation during wheat straw decomposition ranged from 13 kg N per ton of C for a N-“poor” environment (0 kg added N ha

−1) to 32 kg N per ton of C for a N-“rich” environment (up to 300 kg added N ha

−1). In AzoFert

®, the immobilisation ratio is linearly related to the amount of fertiliser N added, ranging from 13 to 25 kg N per ton of C.

The volatilisation of ammonia (

VOL) is estimated from the combined effects of soil factors (pH and cation exchange capacity), type of fertiliser considered as a whole (form of fertiliser marketed) and application method (on the soil surface or incorporated into the soil), and crop status at the time of fertiliser N application. VOL is nil if soil pH < 5.5, CEC > 40, fertiliser N is incorporated into the soil or fertiliser N is applied only as NO

3–N. For each type of fertiliser N, a maximum VOL rate (VMAX) is defined in the model. VMAX varies exponentially with soil pH between pH 5.5 and 8.5 [

29]. The VOL factor V is given by the relationship:

where

XNH4-N is the amount of fertiliser NH

4-N, and

Gx is the amount of volatilised fertiliser N. When fertiliser N is applied to a crop, the VOL rate decreases by 50% compared to that of bare soil, considering that the N uptake by a crop reduces the risk of volatilisation.

The losses of soil nitrate (

Ls) by leaching due to rain, beyond the rooting depth of the crop, concern soil inorganic N at the opening of the balance sheet (

Ri) and can occur between the opening of the balance sheet and the date of the end of the leaching period, which depends on crop type and climate. The proportion of mineral N leached is estimated using a simple approach: the transfer of water and nitrate into the soil is calculated for each elementary layer of 1 cm, by analogy with a reservoir. Incoming water fills the layer similar to a cascade, and the upper limit of each individual reservoir is the field capacity of the layer. Water and nitrate transfer then occurs after a homogeneous mixing of the layer with the underneath layer. Nitrate losses are dependent on effective rainfall and soil type (soil water content at field capacity). Effective rainfall (QPLUEFF) during the period (opening of the balance sheet and the end of leaching) is given by the relationship:

where QPLU is the amount of rainfall and ETP is potential evapotranspiration.

Unlike Ls, which can occur at the end of winter and can affect the residual mineral N (Ri), fertiliser N lost through leaching (Lx) is generally non-existent (end of the drainage period), and Lx = 0, which has been confirmed by 15N experiments.