1. Introduction

Permeable pavement systems (PPS) have seen increasing adoption as a low impact development technology (LID) for use in low-traffic areas. PPS has been shown to not only mitigate stormwater water quantities [

1,

2,

3,

4,

5,

6,

7] but water quality as well [

1,

8,

9,

10]. Various types of PPS have seen increasing use in recent years including porous asphalt, porous concrete, and permeable interlocking concrete pavers [

11,

12]. Runoff reduction rate resulting from the very high surface infiltration rates (SIR) in PPS is one of the many benefits for using these systems [

4,

13,

14,

15]. Consequently, the maintenance of this hydraulic performance is critical to sustainable implementation of these systems in the long term. Once implemented, the SIR will immediately begin to degrade from clogging and degradation of the porosity [

16]. Maintaining the lifespan of PPS requires knowing when, and what type of maintenance should be conducted. Accurate methods for determining SIR in the field are key to understanding when maintenance should be performed.

SIR, which is inversely proportional to the clogging rate, is a largely surface phenomenon, which results from qualities within the top 0.25 m of the pavement [

17]. Several methods have been used over the years to determine SIR. Winston et al. [

18] succinctly summarizes the variety of methods used for measuring SIR. They range from single ring infiltrometers, or double ring infiltrometers (both are loosely based on conventional methods used in soil systems); simple and quick methods involving exposing the pavement to some volume of water; involve large-scale inundation of the pavement; or specially designed infiltrometers that employ a constant head or falling head [

18]. Several studies have attempted to determine, which of these methods is optimal given the variety of surfaces available and the conditions for testing [

19,

20].

The variety of methods and variability in results between methods points to the need for some kind of standard test method that could be used over time on a wide-scale. This lead the ASTM to develop two standards for performing infiltration tests on two types of permeable pavement systems: ASTM C1701 and C1781, developed for porous concrete and interlocking concrete pavers, respectively [

21,

22]. Both tests use single ring infiltrometers under a constant head and pre-wetting with 3.60 kg of water. If the pre-wetting time is less than 30 s, then 18.0 kg of water is used in the actual infiltration tests, but if the time is greater than 30 s, then 3.60 kg of water is used. The infiltration rate is calculated using the following equation:

where

I is the surface infiltration rate (mm/min),

K = 76,394,433.33 (mm

3∙s/(kg·min)),

M is the mass of infiltrated water (kg),

D is the ring’s inside diameter (mm), and

t is time required for the amount of water used in the test to infiltrate the surface (s). A larger diameter single ring infiltrometer is used as opposed to a double ring infiltrometer because of the large infiltration rates provided by these types of surfaces, and to reduce variability and repeatability between operators [

23]. The method is intended to give some measure of “

surface clogging potential” in the PPS. The developers recognized several issues with the C1701 test when it was introduced and suggested that the value obtained should be considered a starting point for infiltration leading to “early” evaluation of pavement permeability performance and the need for remediation [

23].

Since the introduction of this standard, a number of studies evaluating the accuracy of the ASTM standard tests, or comparing them to other methods for determining SIR, can be found in the literature [

16,

24,

25,

26,

27,

28,

29]. These comparisons are useful not only in judging the general use of such a method, but the precision by which it can provide a measure of SIR because of modeling needs and maintenance requirements [

30]. It should be noted that while there is currently no standard to test

porous asphalt or PPS

in general, numerous studies have been conducted using the ASTM C1701 test on both porous concrete and porous asphalt, or used modified versions to test infiltration rates of PPS on other types of systems [

6,

31,

32]. Brown and Borst [

16] recognized the need to select locations strategically on the surface as opposed to randomly. Li et al.’s [

25] comparison of the ASTM C1701 with the National Centre for Asphalt Technology (NCAT) permeameter (which uses a falling head) showed the latter to produce higher SIR magnitudes and greater variability because of the higher hydraulic head. This was confirmed by Qin et al. [

33]. Li et al. [

25] suggested using larger ring sizes to produce greater similarity in results. Winston et al. [

8] used a simple method based on the ASTM test for interlocking pavers that uses a falling head but over a larger surface area. They found their method provided comparable results to the ASTM test method. Other similar methods have been demonstrated to provide reasonable estimates of clogging levels in interlocking pavers [

24,

29]. Alternative instruments that simulate rainfall have produced SIR values comparable to double ring infiltrometers on interlocking pavers [

27]. Rainfall simulators and surface inundation methods [

26,

28] arguably provide as close a measure of clogging during a high rain event than most other tests. How this can be related to the ASTM standard used pervasively is difficult to say.

SIR is a measure of the degree of clogging, or decrease in porosity of the media

at the surface within a very small depth [

17]. Recent studies in the laboratory setting have used some form of imaging to obtain estimates of porosity [

17,

34,

35]. Obaidat et al. [

35] used image analysis on cell phone images to successfully determine volumetric parameters such as the amount of voids in an asphalt material. These studies suggest that capturing and analyzing imagery may produce useful surrogates for surface infiltration rates of permeable surfaces.

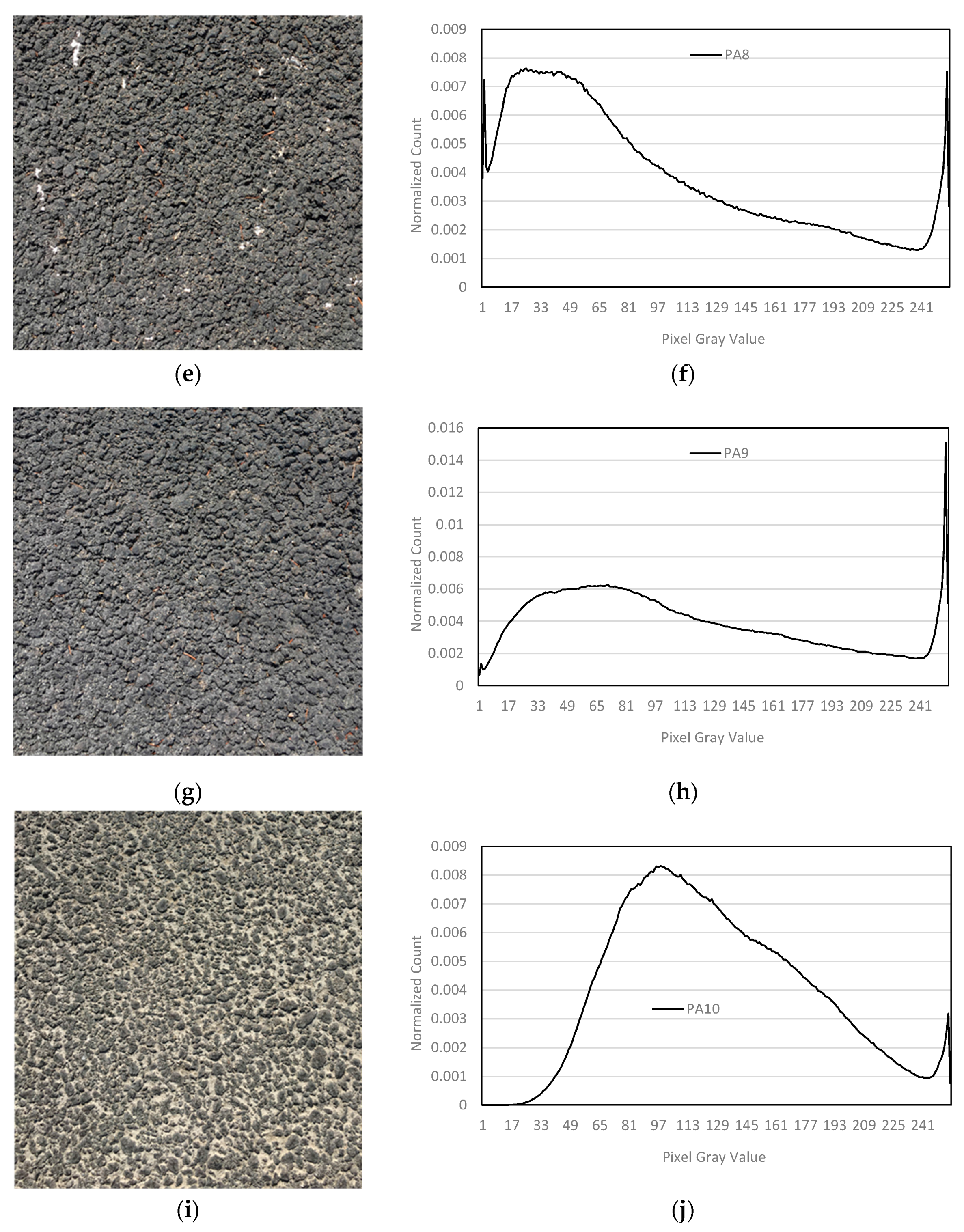

Given the continued diversity in SIR estimation methods and comparisons to the ASTM standards, the objectives of this work are to explore and demonstrate the possibilities provided by image analysis for providing comparable estimates of surface infiltration rate. Image analysis is a non-contact method that may help to alleviate problems with SIR estimation methods seen in the literature thus far. However, exploring such a method requires a comparison to an already established method such as the ASTM C1701 method. In addition, this study focuses on two permeable pavement surfaces that are not investigated in the literature as greatly as porous concrete and interlocking pavers. A fiber-reinforced porous asphalt and a new material called Porous Pave are tested in this research. Because ASTM C1701 is designed for porous concrete, and ASTM C1781 for interlocking pavers, the authors will draw on recommendations arising from the literature for determining SIR on the fiber-reinforced porous asphalt and Porous Pave surface (as no standard for determining SIR on these two types of surfaces as yet exists). Thus, this investigation will use the ASTM C1701 method and variations based on ring size, as well a falling head test, to explore the use of image analysis for estimating SIR. Image analysis of cell-phone photographs is used to develop relationships with SIR determined with these contact methods.

3. Results

3.1. Application of the ASTM C1701 Standard Test and Impact of Ring Size

The results of testing the three ring sizes with the ASTM C1701 test on the porous asphalt surface in the spring of 2016 are shown in

Table 1. The mean SIR and the range for each location are shown for each ring size along with the number of samples (

N) collected at that location and the dates these data were acquired. Results from location 4 on the porous asphalt were omitted for the smaller and largest ring sizes because the tests took longer than an hour to complete and insufficient data was collected to allow for meaningful analysis. Because of frequent rainfall during the spring, the data collection period spanned 10 weeks. Changes to surface permeability due to runoff within this period are likely very small as continued rainfall prevented significant build-up of clogging material.

The Shapiro-Wilk test was conducted on the pooled data and the results showed that for porous asphalt, the data collected for the 203 mm (N = 12, p = 0.08); and 305 mm (N = 14, p = 0.285) ring sizes are normally distributed. The data set collected with the 406 mm ring size is not normally distributed at the 0.05 significance level (N = 13, p = 0.023).

Because the 406 mm ring size data set for the porous asphalt surface was not normally distributed, the Sample Sign test for related samples (related by location) was used to determine if any significant differences existed between data sets. The pooled data set for each ring size was used (but related by location and pairs were compared based on the location) but because ring size 203 mm had only 12 points, only the first two infiltration test results collected at a specific location in the other two ring sizes, were used (thus, N = 12 for all sets for the pairwise comparison). Results for the porous asphalt showed no significant difference between the median of differences for the 203 mm and 305 mm ring sizes (p = 0.227), or between the 203 mm and the 406 mm ring sizes (p = 1.0), or between the 305 mm and 406 mm ring sizes (p = 0.227).

The results of testing the three ring sizes on the Porous Pave surface with the ASTM C1701 test in the spring of 2016 are shown in

Table 2. When the Shapiro-Wilk test was applied to the pooled data, none of the pooled data sets were found to be normally distributed: 203 mm ring size (

N = 15,

p = 0.031), 305 mm ring size (

N = 18,

p = 0.026), and 406 mm ring size (

N = 15,

p = 0.017). Using the Sample Sign test on the pooled data created in the manner done for the porous asphalt, (thus,

N = 15), there is a significant difference in the median of differences between the 203 mm ring size and the 305 mm ring size (

p = 0.007) and between the 203 mm and 406 mm ring sizes (

p < 0.000). However, there is no significant difference between the 305 mm and the 406 mm ring sizes for the Porous Pave (

p = 1.00) surface.

For both surfaces, the Sample Sign test did not seem to suggest that a 305 mm ring size should produce anything significantly different than a larger ring size. The results on the Porous Pave surface however, do suggest that a 203 mm ring size is likely too small (since the two larger ring sizes produce no significant difference) to capture a scalable infiltration rate. The tests suggest that the ASTM C1701 standard size of 300 m ± 10 mm is appropriate for porous asphalt and possibly for Porous Pave.

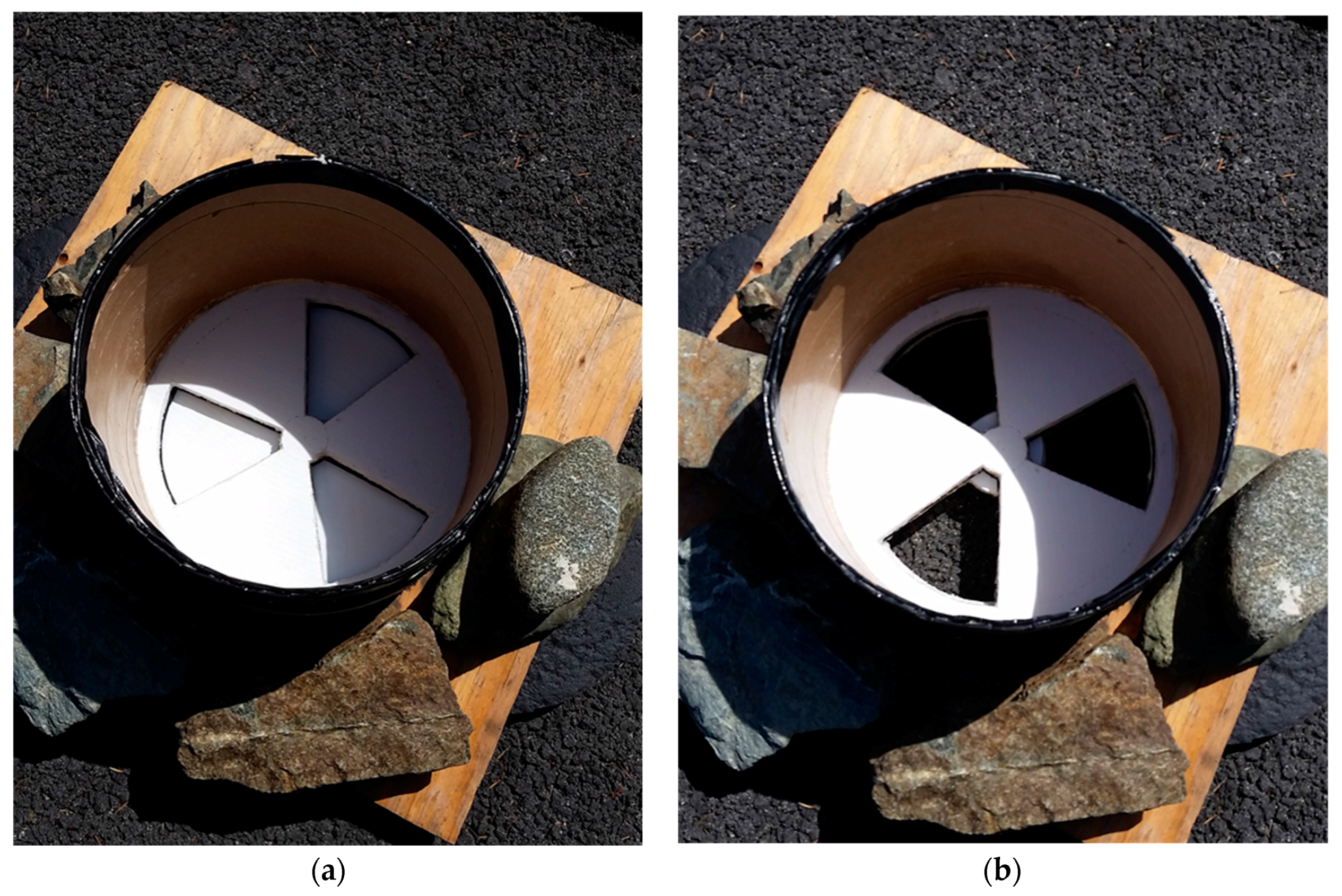

3.2. Application of the Falling Head Device in Comparison to the ASTM C1701 Test

In the spring of 2017, both the ASTM C1701 test and the falling head device were applied to locations 1 to 5 on the porous asphalt surface, and on the porous asphalt sample. These results are shown in

Table 3. The Shapiro-Wilk test showed that the pooled (

N = 12) ASTM data for these data were normally distributed (

p = 0.407) but the falling head data set rejected the null hypothesis (

N = 16,

p = 0.032) and is not considered to be normally distributed. The Sample Sign Test showed a significant difference (

N = 12 with the third value taken at any one location being thrown out in the falling head test) in the median of differences between the falling head test and the ASTM test (

p = 0.001).

While the data are insufficient to decide whether the falling head test is preferable to the ASTM test, the former produces a higher infiltration rate because of the higher hydraulic head involved but the variability (seen in the range of the three values at each location) is smaller than the range for the ASTM tests. This is a desirable characteristic to have in such a test and suggests at least, that the falling head test is worth exploring if such a permeability test is needed. For these reasons, both the ASTM test data and the falling head test data are used in the image analysis exploration.

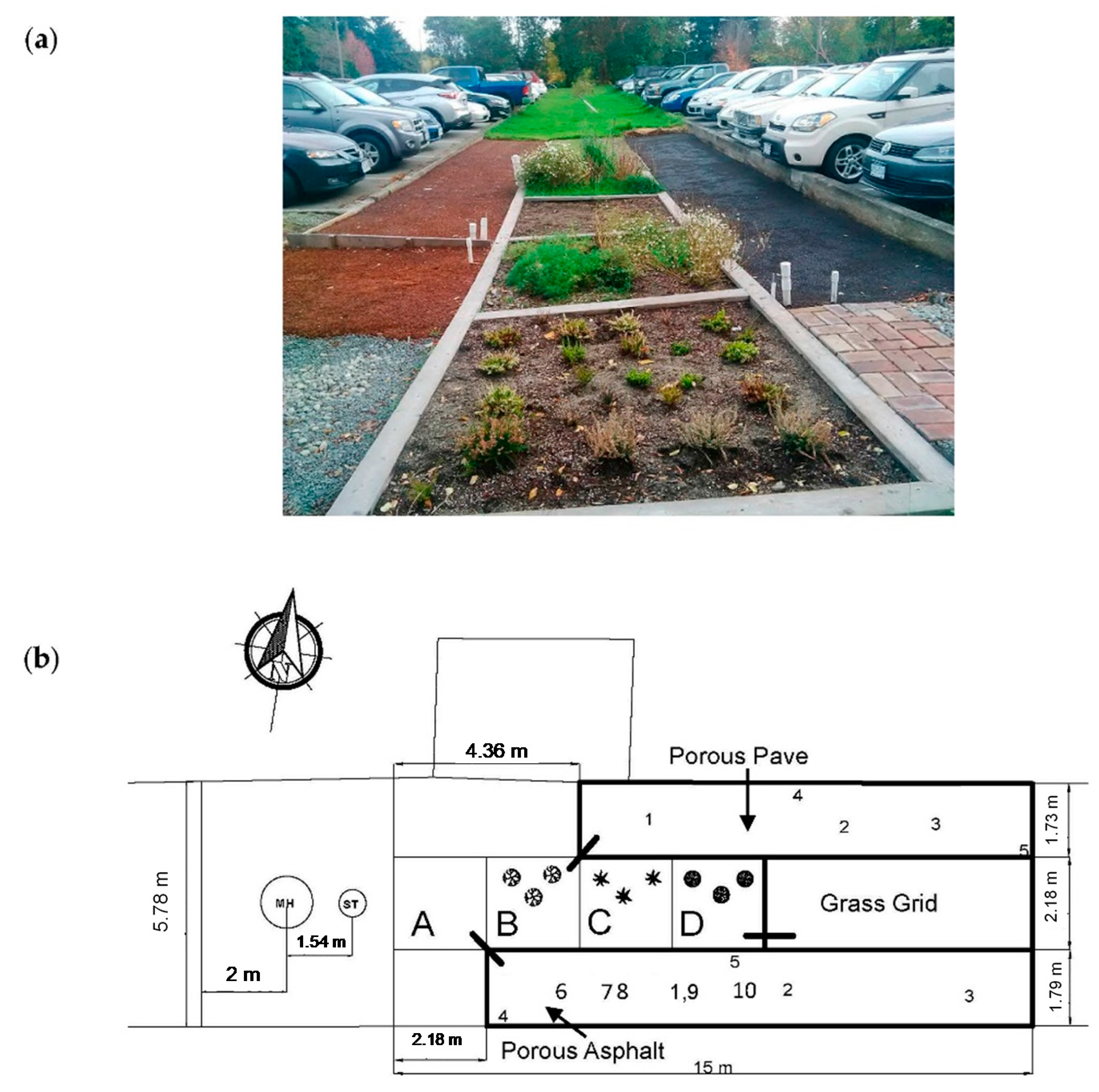

3.3. Image Analysis

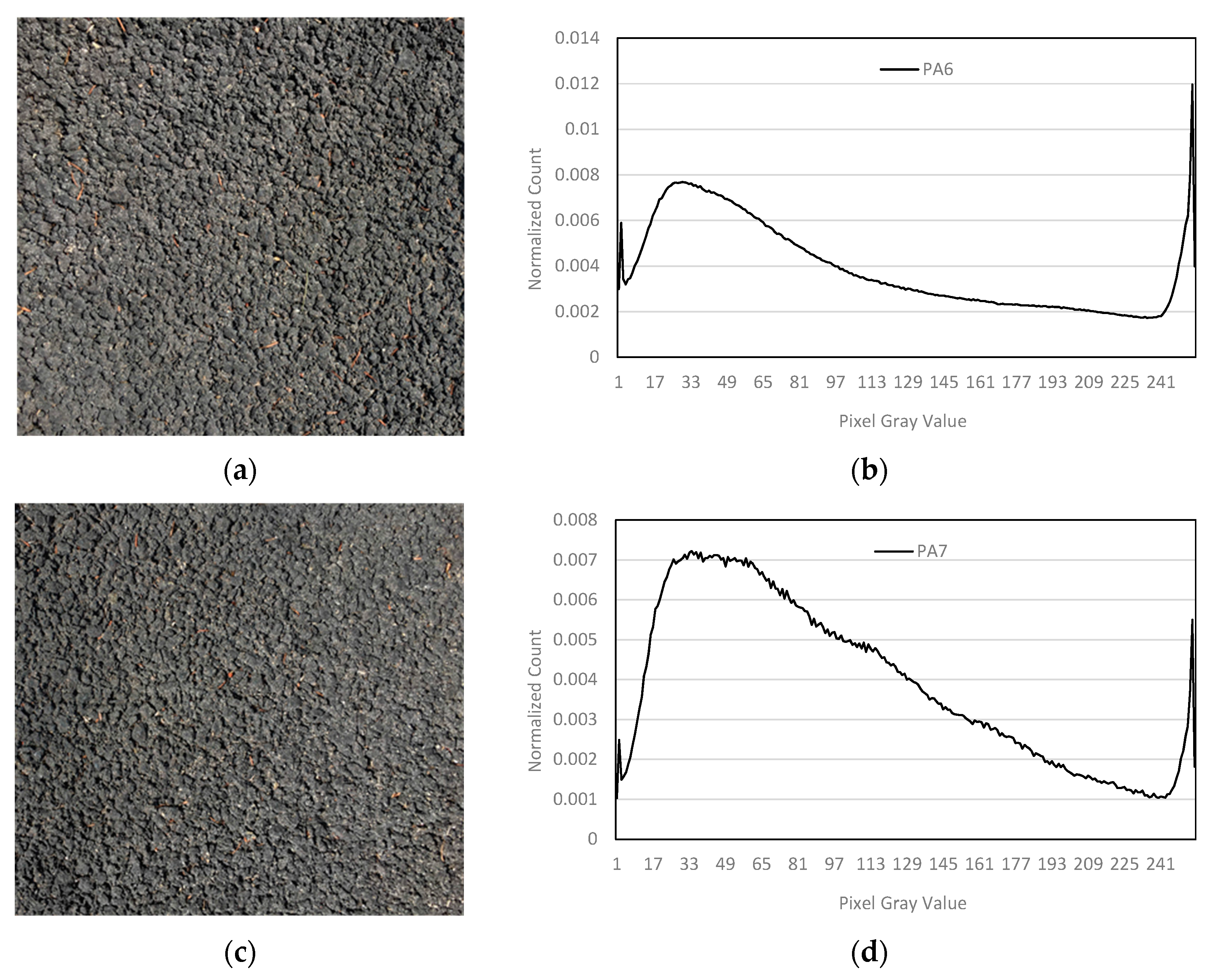

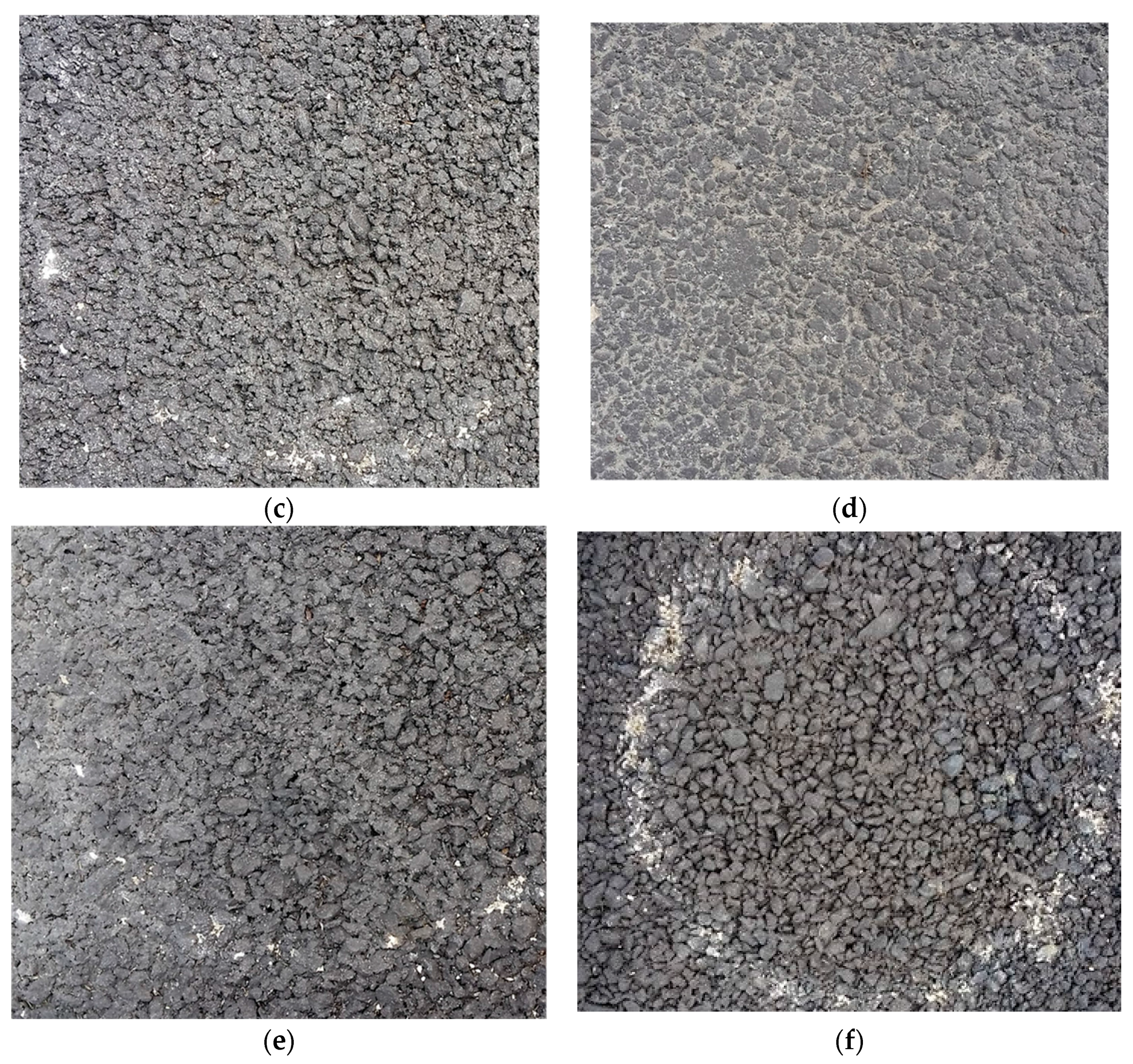

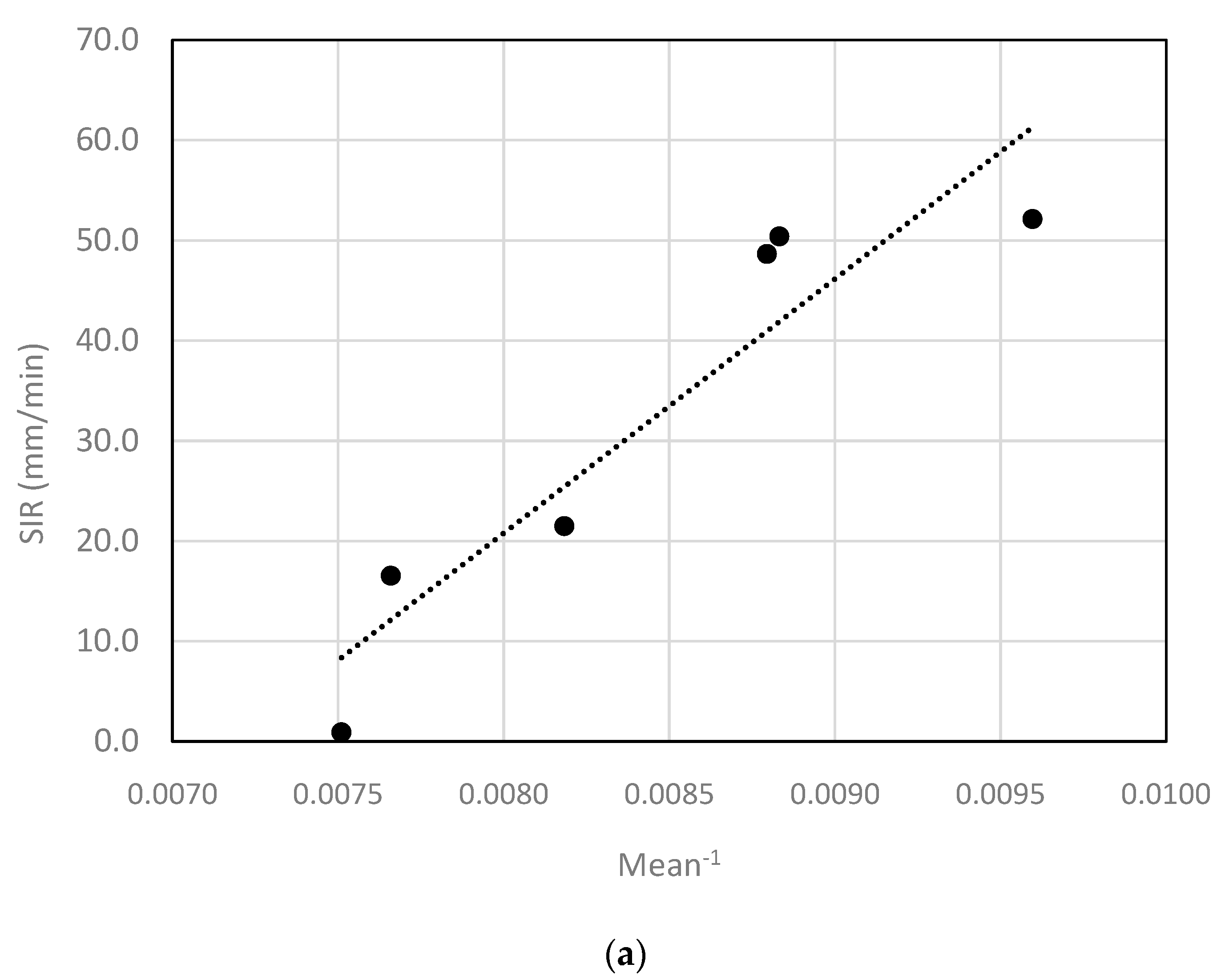

Figure 3 shows the images that were captured with a cellphone in the spring of 2017 of the dry porous asphalt before taking the SIR measurements at locations 1 to 5.

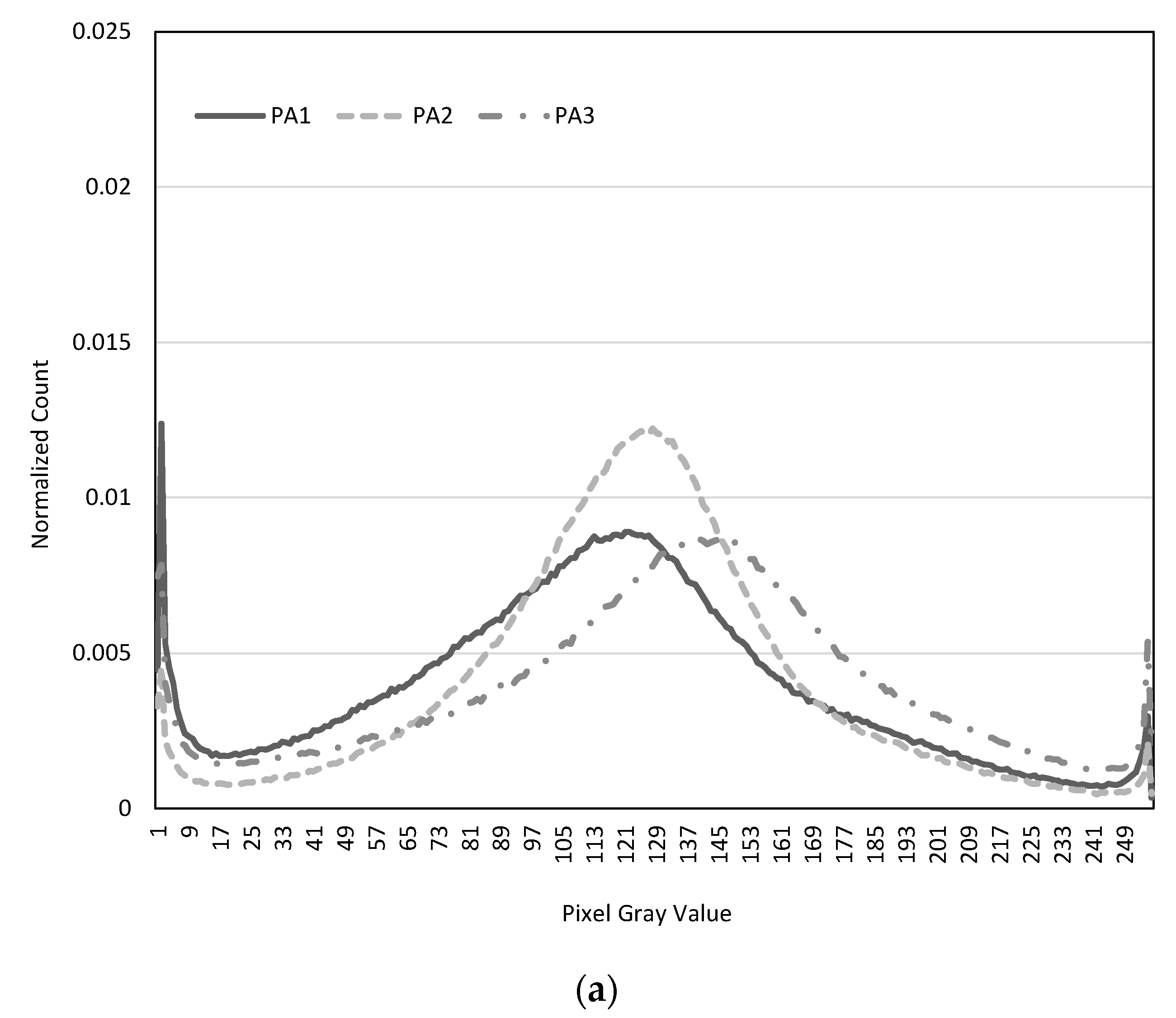

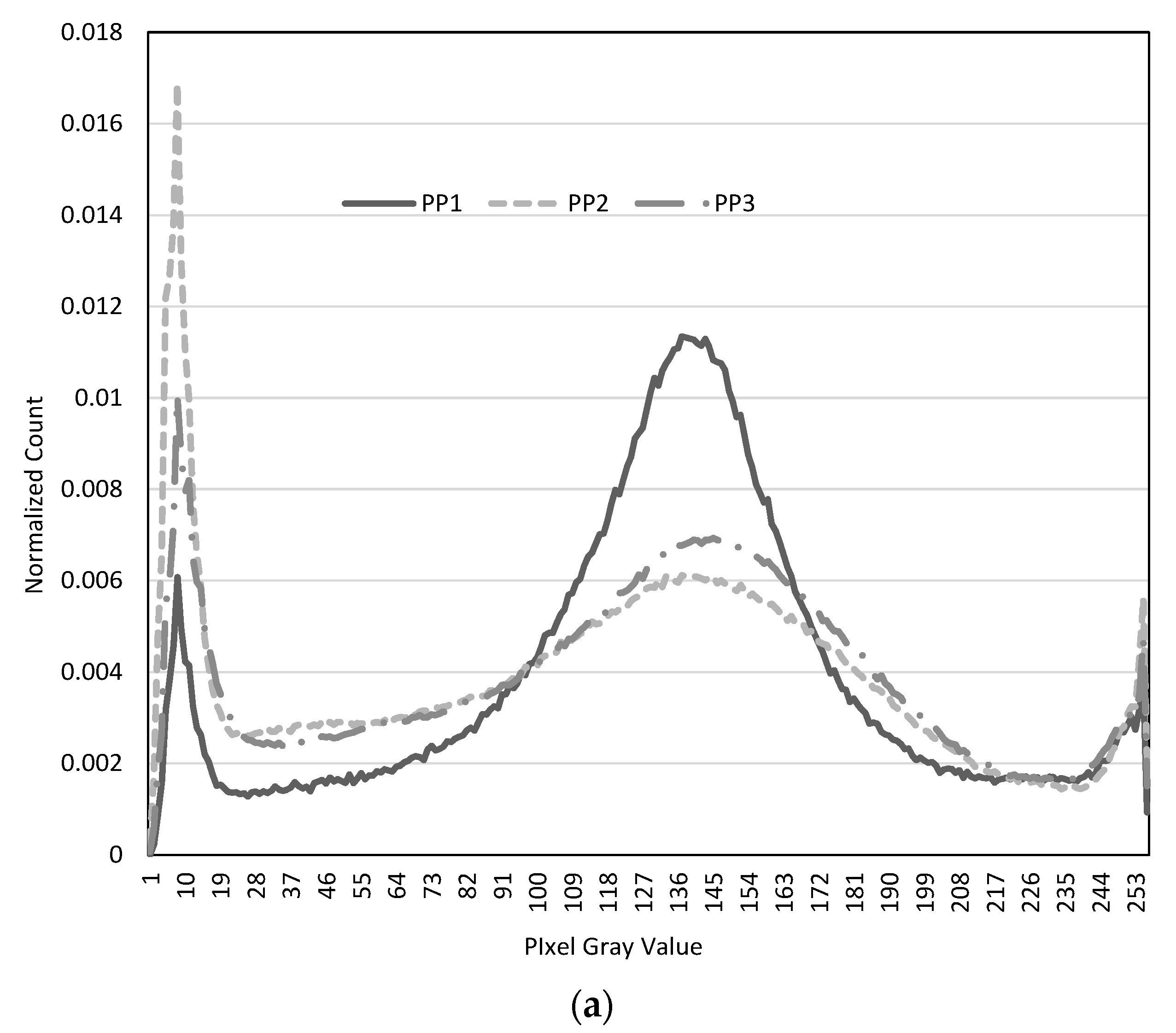

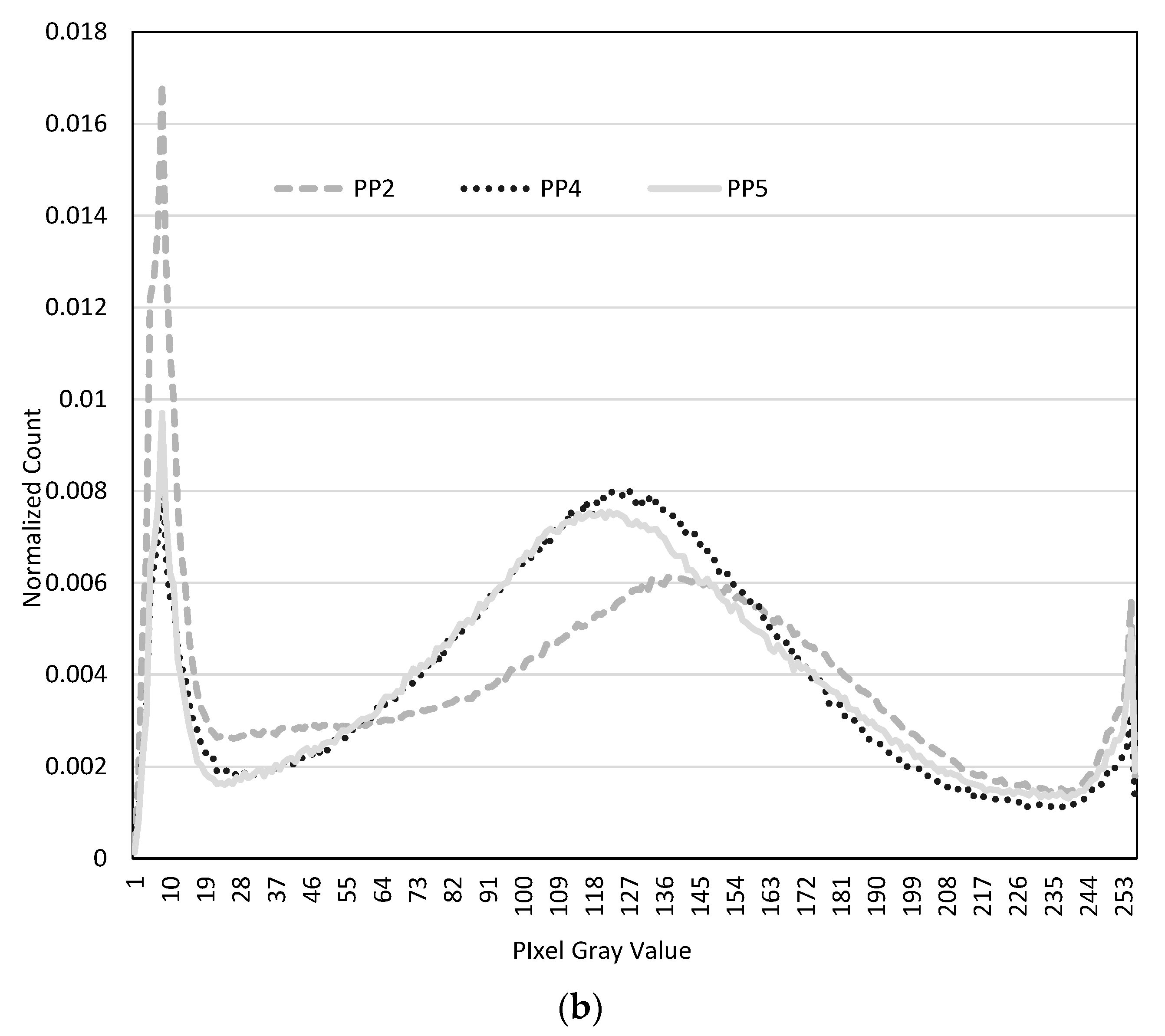

Figure 4 shows the distributions (histograms) produced by Matlab

® in the image processing of the gray level image.

The falling head test was conducted on locations 6–10 in the summer of 2017. Those images are shown in the

Appendix A with their respective gray level histograms. For locations 6–10, only one falling head test at each location was conducted. A Shapiro-Wilk test was conducted on the falling head data set that was used to create

Figure 5b. This data set was comprised of the single tests conducted on sites 6–10 in 2017 pooled with the average of the falling head tests conducted on locations 1 to 5 in 2016, and the average of the falling head results of the sample asphalt). In this data set,

N = 11 and

p = 0.841 showing that the data are normally distributed. Likewise the ASTM data set was tested and it too is normally distributed according to the Shapiro-Wilk test (

N = 6,

p = 0.197). Because the falling head data set of

Table 3 was shown to deviate from a normal distribution, one could argue that the median of the falling head test instead of the mean should have been tested. The authors tested this data set (that is, the same data set tested above but now for locations 1 to 5, the median of the 3 points taken in the falling head test is used in the pooled data set instead of the mean). This data set was also normally distributed (

N = 11,

p = 0.780).

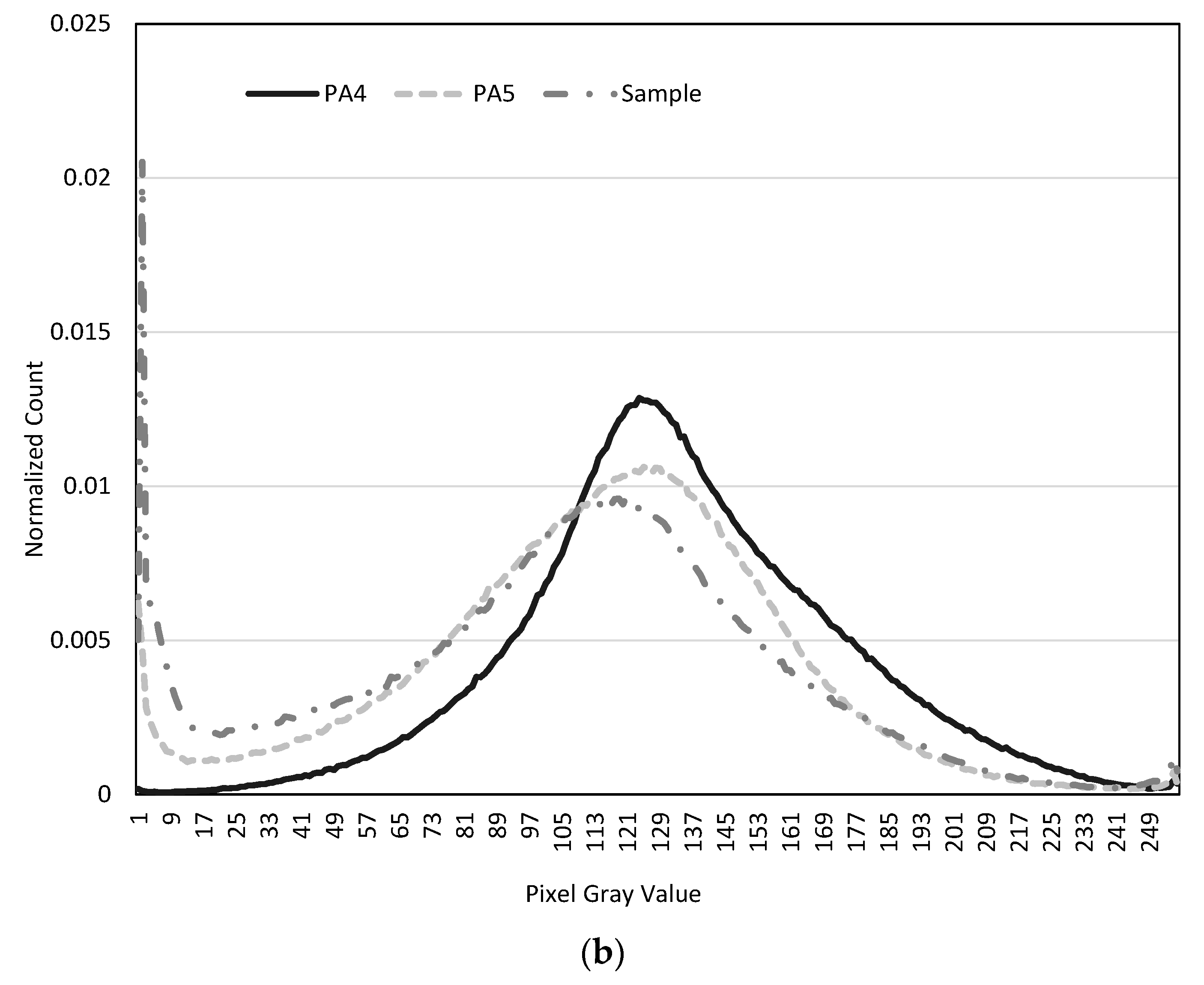

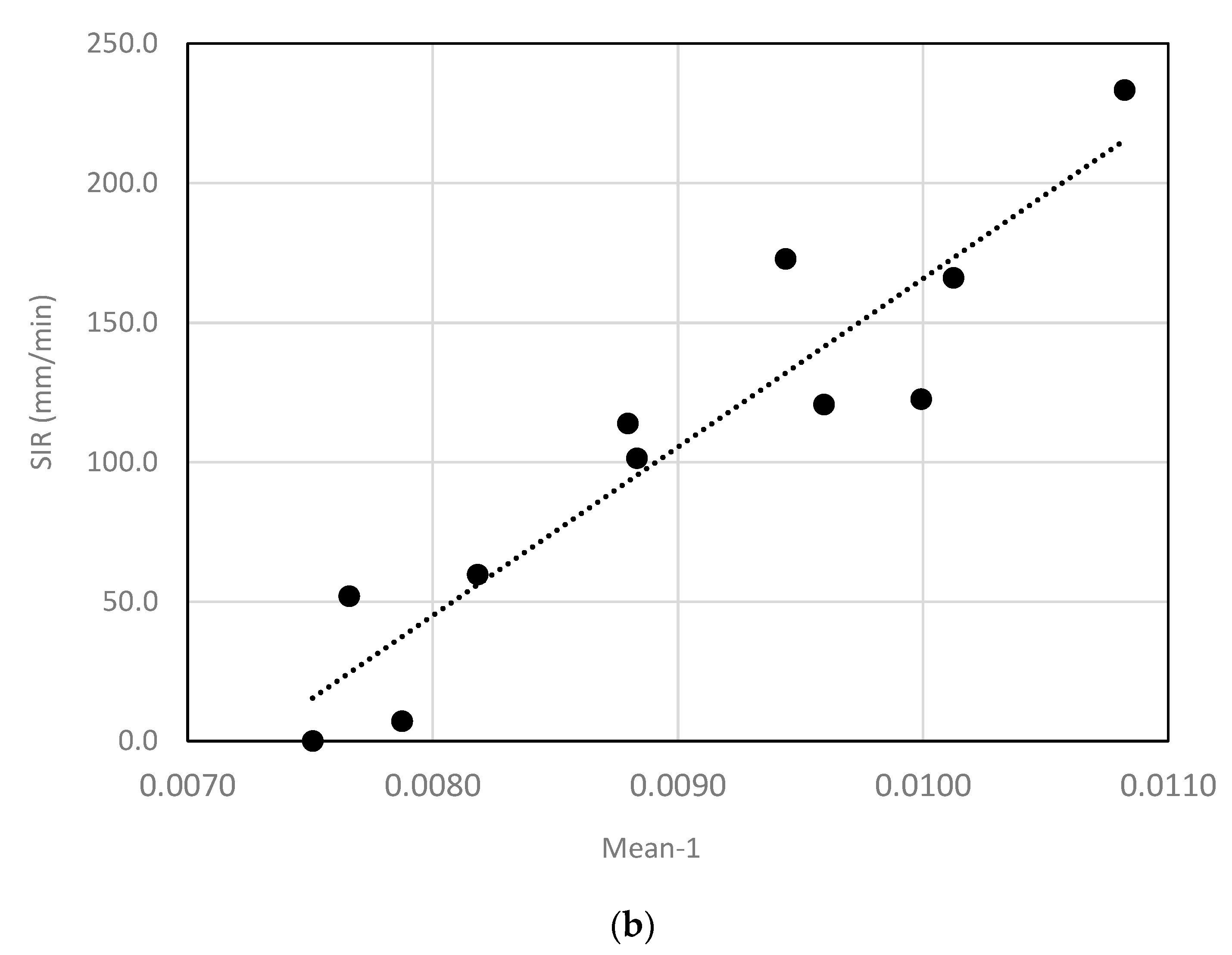

Figure 5a shows a simple linear regression between the inverse of the mean of each histogram and the mean surface infiltration rate measured by the ASTM C1701 method (

Table 3 data). A simple linear regression was conducted between the inverse of the mean of each histogram and the mean surface infiltration rate measured by the falling head method (

Table 3 data) in

Figure 5b. For simplicity, the mean is used as opposed to using the median of the falling head test. If the median were used, the regression coefficients are different but the adjusted coefficient of determination is nearly identical.

The following relationships were achieved for the dashed lines shown in

Figure 5a,b (as Equations (2) and (3), respectively). Note SIR

fh (the SIR determined using the falling head method) and SIR

astm (the SIR determined using the ASTM method) are in mm/minute and

is the mean gray level of the image.

The adjusted

R2 for SIR

astm is 0.84 and the standard error of the estimate is 8.74 mm/min. The ANOVA analysis indicates the regression is significant (

p = 0.007) as are the slope (

p = 0.007) and constant (

p = 0.012). The adjusted

R2 on SIR

fh in Equation (3) is 0.85 and the standard error of the estimate is 27.3 mm/min. The regression is significant according to ANOVA with

p < 0.000 as are the slope and constant (

p < 0.000 for both). The residual statistics for both regressions are shown in

Table 4. The key values to examine in

Table 4 are the standardized residuals. If the data are normal, and the relationship between the dependent and independent variable is truly linear, then all the standardized residuals values should be between +2 and −2. The table shows that this is true for both linear regressions equations.

3.4. Application of the ASTM C1701 Test and Image Analysis on the Porous Pave Site

No falling head testing was conducted on the Porous Pave site because of the high infiltration rate. Thus, all image analysis relies on the ASTM C1701 testing conducted in the spring of 2016. Images of the test locations 1–5 on the Porous Pave surface shown in

Figure 1b were taken on a dry day in the spring of 2017 and are shown in

Figure 6.

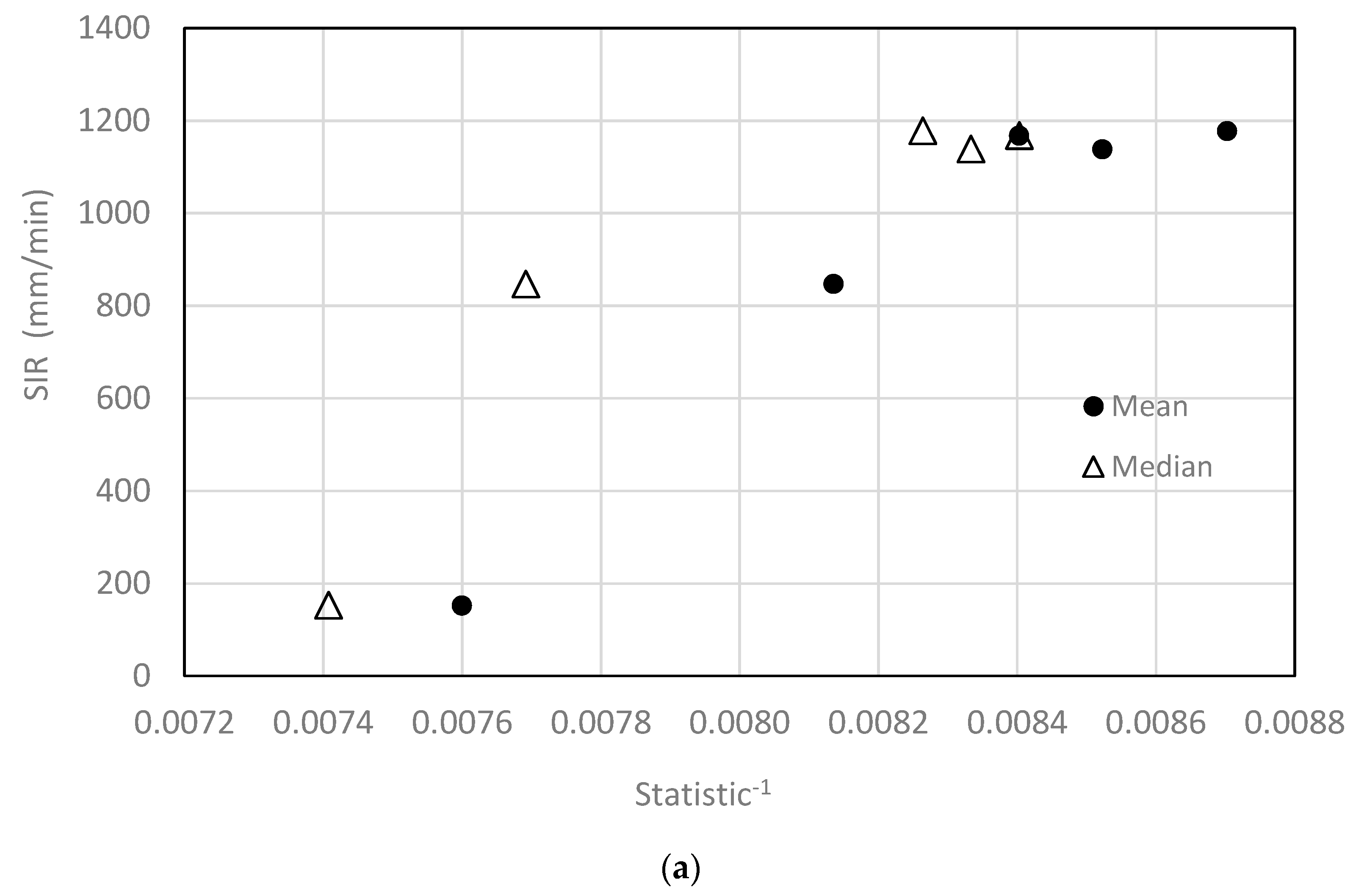

Figure 7 shows the histograms obtained for these images and

Figure 8a shows the SIR measured with the ASTM C1701 test in the Spring of 2016 (a year before the images were taken) plotted against the inverse of the mean and the inverse of the median, of each image’s gray level. A plot using the median gray level is considered because the surface has a great deal of red color and red values tend to convert to lower gray values, thus, creating a distribution skewed to lower values. The median is not as affected by skewness as the mean.

The data sets used to create

Figure 8 (the mean SIR data shown in

Table 2) were tested with the Shapiro-Wilk test. The data for the 305 mm ring significantly deviated from a normal distribution (

N = 5,

p = 0.03) while the five data points for each of ring 203 mm and 406 mm ring sizes were normally distributed according to the test (

p = 0.55 and

p = 0.38, respectively).

Figure 8b shows the same image analysis data but now related to the SIR values in

Table 2 for the smaller and larger rings sizes. Thus,

Figure 8b shows linear regression lines for the 203 mm and 406 mm ring sizes, but no line is shown for the 305 mm ring size in either

Figure 8a,b.

Because the 305 mm ring size SIR measurements observed on the Porous Pave surface are not normally distributed, StadDirect

® was used to conduct nonparametric linear regression on the medians of all gradients of the data to produce the following expressions:

where

refers to the median and again SIR is in mm/min. Note that the slope coefficient seen in these two equations are medians. According to Kendall’s tau-

b correlation procedure, the inverse mean gray level is significantly correlated with SIR

305 (

τb = 0.8,

p = 0.05 for Equation (4)) but not for the inverse median gray level median (

τb = 0.6,

p = 0.142 for Equation (5)).

Equation (6) is the expression for the best-fit linear regression line in

Figure 8b for the 203 mm ring (using data from

Table 2) and Equation 7 corresponds to the 406 mm ring. Equations (8) and (9) are the nonparametric linear formulae.

The adjusted R2 for SIR203 in Equation (6) is 0.92 and the standard error of the estimate is 225 mm/min. The ANOVA analysis indicates the regression is significant (p = 0.007) as are the slope (p = 0.007) and constant (p = 0.009). The adjusted R2 on SIR406 in Equation (7) is 0.90 and the standard error of the estimate is 152 mm/min. This regression is also significant according to ANOVA with p = 0.01 as are the slope and constant (p = 0.013 and p = 0.01, respectively). The standardized residual statistics for Equations (6) and (7) are all within ±2 (results not shown here). Kendall’s tau-b correlation procedure showed that the inverse mean gray level is significantly correlated with SIR203 and SIR406 (τb = 0.8, p = 0.05 for both Equations (8) and (9)).

5. Conclusions

This research investigated the impact of in situ, contact test methods for measuring SIR on two highly permeable pavement surfaces—a fiber-reinforced porous asphalt and a highly permeable surface material known as Porous Pave. The methods tested were the ASTM C1701 with a 305 mm ring size, a 203 mm ring size and a 406 mm ring size. In addition, a simple falling head test device was created but only tested on the porous asphalt. All the results indicate that the ASTM C1701 standard test that was originally devised for porous concrete can produce reasonable estimates of SIR for both these two types of surfaces, which corroborates with results from the literature [

25].

The ASTM C1701 method is still a contact method that is cumbersome to use, and thus, acquiring numerous estimates of SIR over large surface areas is often impractical. Because surface infiltration is largely the result of surface clogging, visual inspection should be a suitable method for providing information on the degree of clogging in certain contexts (pavement color and sediment color). Cell-phone photographs were taken of both surfaces investigated in this work and the inverse of the mean gray level was shown to be highly correlated with mean SIR determined using the ASTM method and the falling head test in the porous asphalt surface. The falling head test and the ASTM method proved to be significantly different but the fact that both methods produced very good linear relationships with image parameters over a number of locations on the surface, indicates that a visual, non-contact method can reproduce the sensitivity of both methods. In both linear regressions, the coefficient of determination was quite high thus suggesting that the mean gray level is a suitable image analysis parameter to indicate level of surface clogging. However, it should be recognized that the inverse of the mean was used because SIR was calculated. An easier approach would be to simply correlate the mean itself with the time in seconds to drain, which in turn is directly proportional to porosity (if this measure can be obtained in the field). This would avoid the large regression coefficients that result when using the inverse of a mean of the distribution with so many pixels and the mean SIR in mm/minute.

The ASTM C1701 test method was used on the Porous Pave material, which is a different type of material with one of the highest infiltration rates available for permeable pavements. The image analysis using photos taken a year after the tests were conducted, also produced a high coefficient of determination of 0.95 when using a ring size of 406 mm. This could lead to the development of a cellphone application by which a homeowner interested in implementing permeable pavements in their homestead can simply use their cellphone camera to monitor the degradation in surface infiltration over time. This can potentially lead to a simple cell phone application that allows any user to determine the maintenance requirements of their low impact development.

The limitations of the investigation arise from the low numbers of data collected and the fact that testing was conducting on only one surface in the field of each type. Therefore, it is highly recommended that future work collect further image analysis data in conjunction with in situ SIR measurements with the ASTMC1701 method over numerous locations, a variety of pavement surfaces and over long periods of time in order to monitor the impact on degradation of SIR and change in image parameters. Other image analysis parameters should be investigated to determine if a more sensitive parameter is more appropriate depending on the surface type, color and clogging sediment characteristics.