Identification of Factors That Influence Energy Performance in Water Distribution System Mains

Abstract

:1. Introduction

- What hydraulic parameters have the largest influence on the energy performance for water mains data in distribution systems?

- What combinations of hydraulic parameters can better distinguish highly efficient water mains from those with low efficiency?

- How aligned are the simplified rehabilitation approaches, for example those based on pipe age or break rate, with energy efficiency in water mains?

2. Methods

2.1. Pipe-Level Energy Metrics

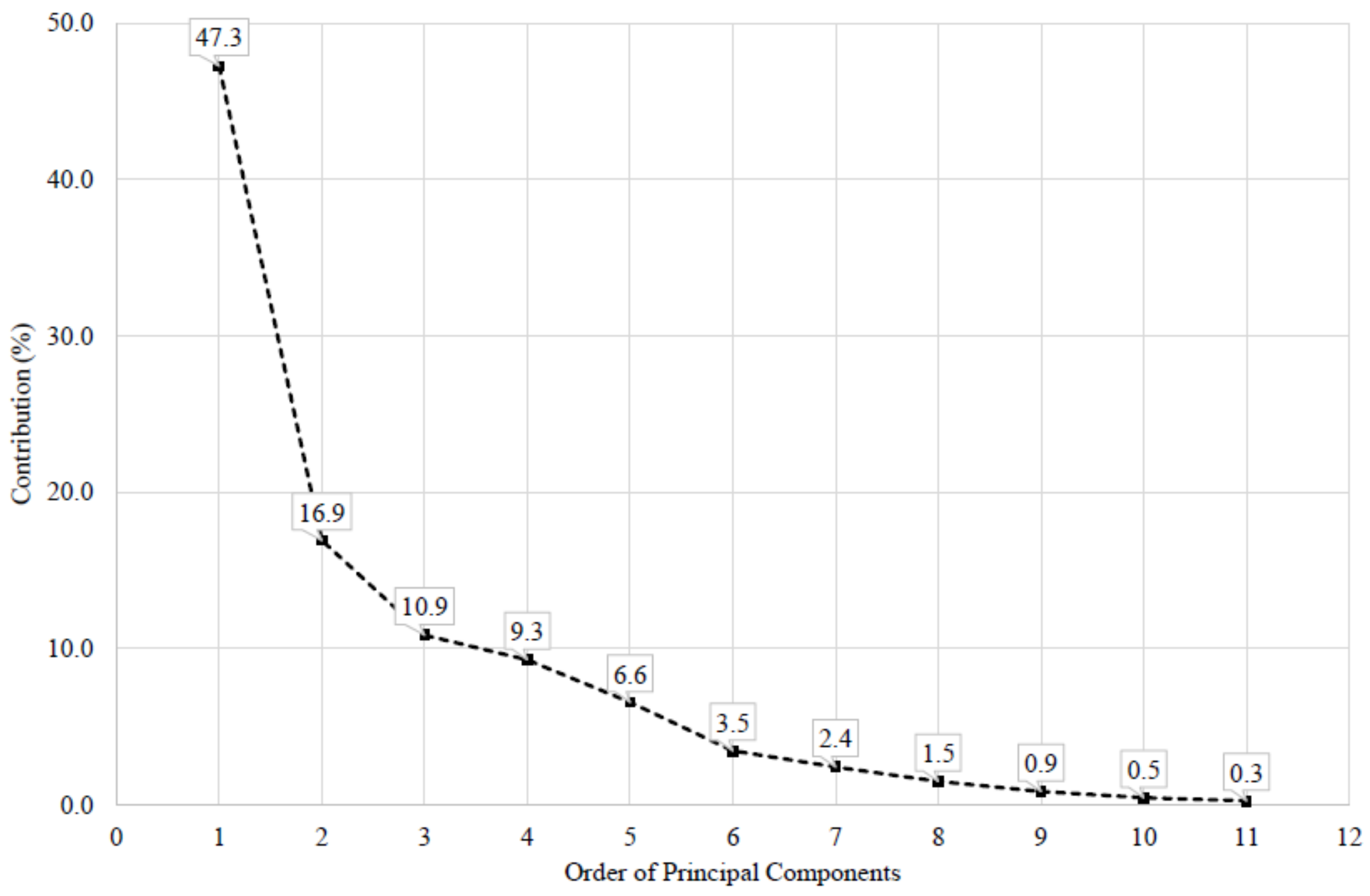

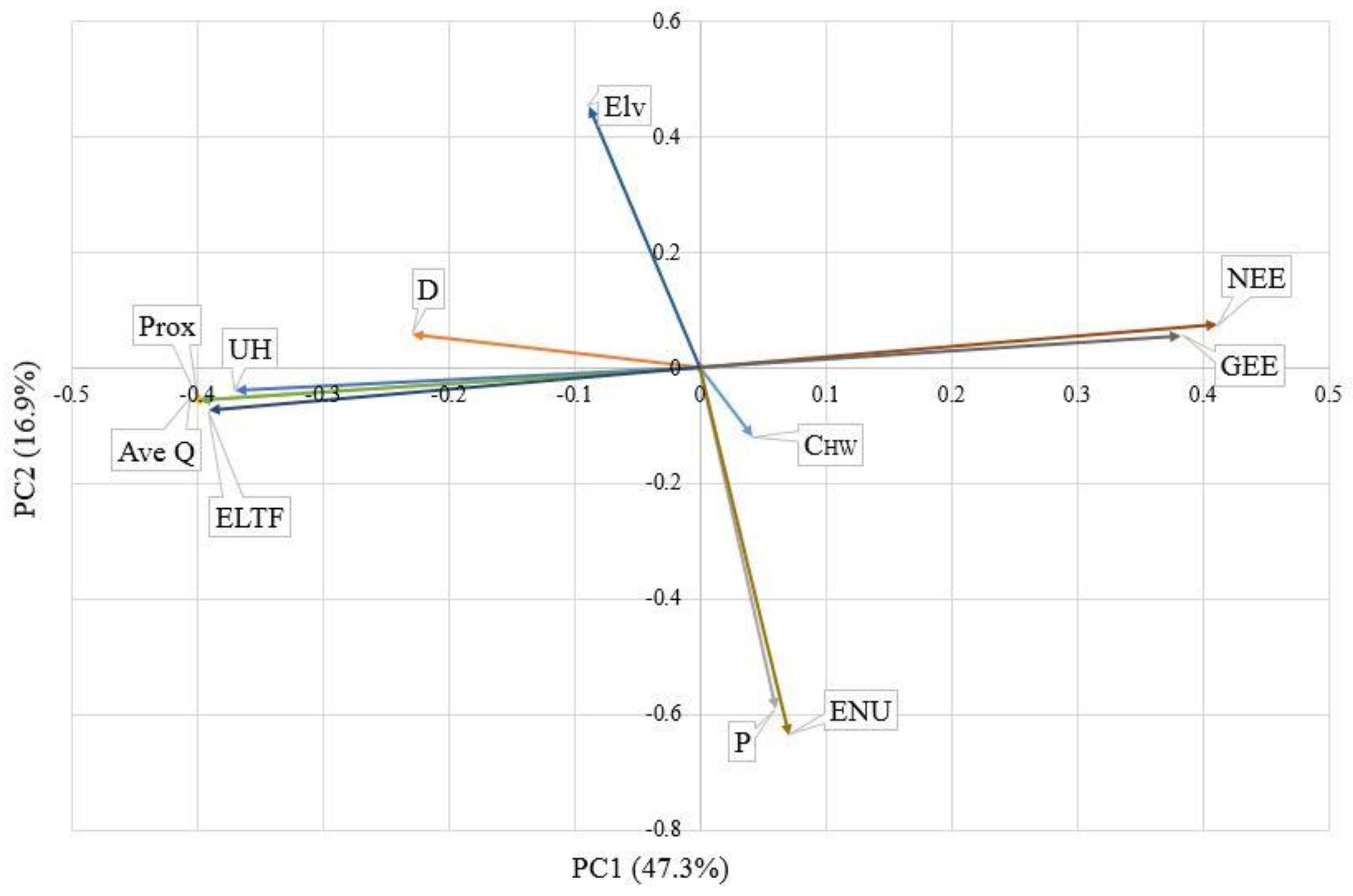

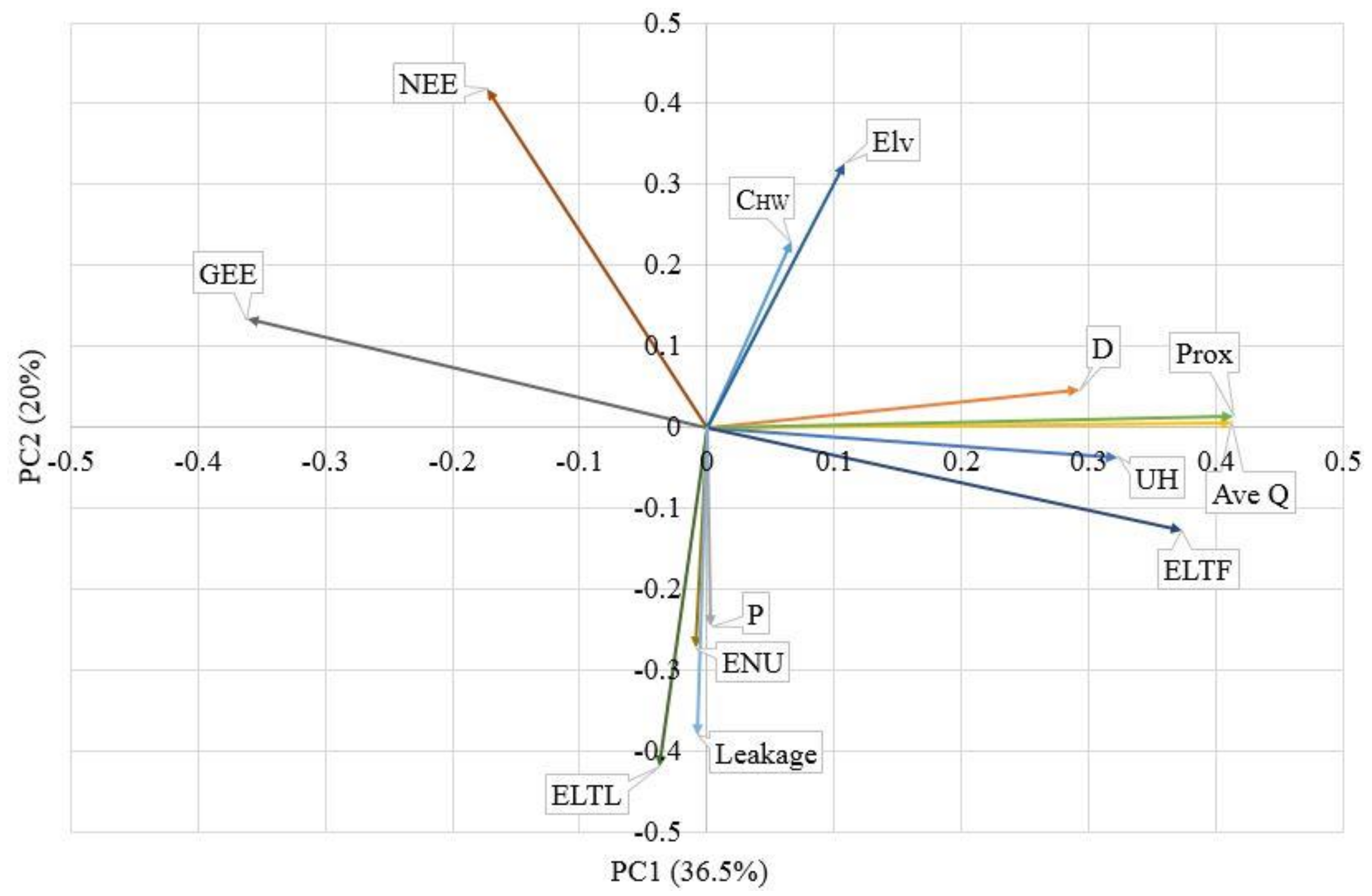

2.2. Principal Components Analysis (PCA)

PCA Mono-Plots and Bi-Plots

3. Application of Multivariate Statistical Analyses in Large WDSs

4. Results

4.1. Hierarchical Importance of Parameters in Energy-Based Decision Making

4.1.1. Non-Leaky Ensemble

4.1.2. Leaky Ensemble

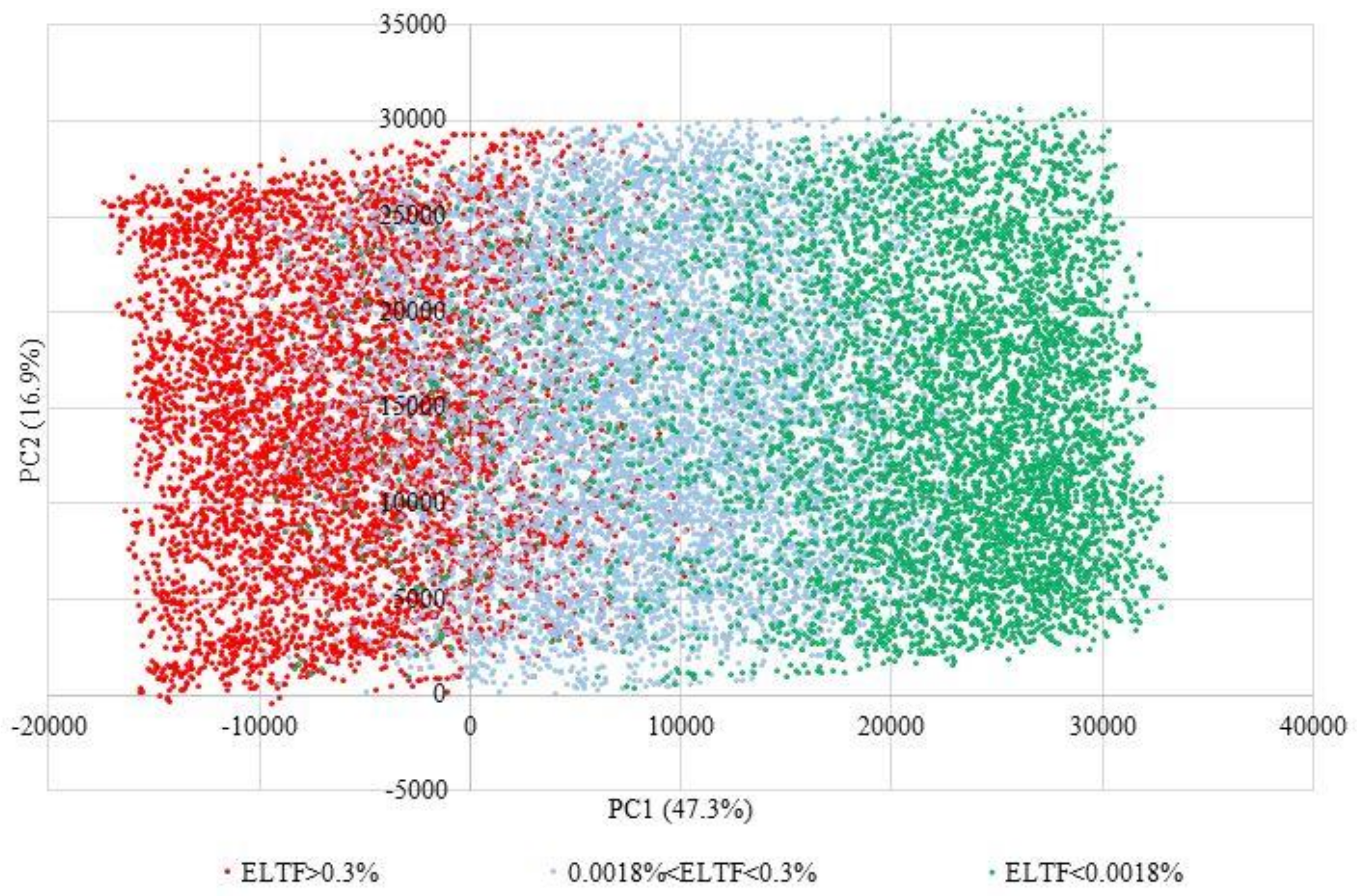

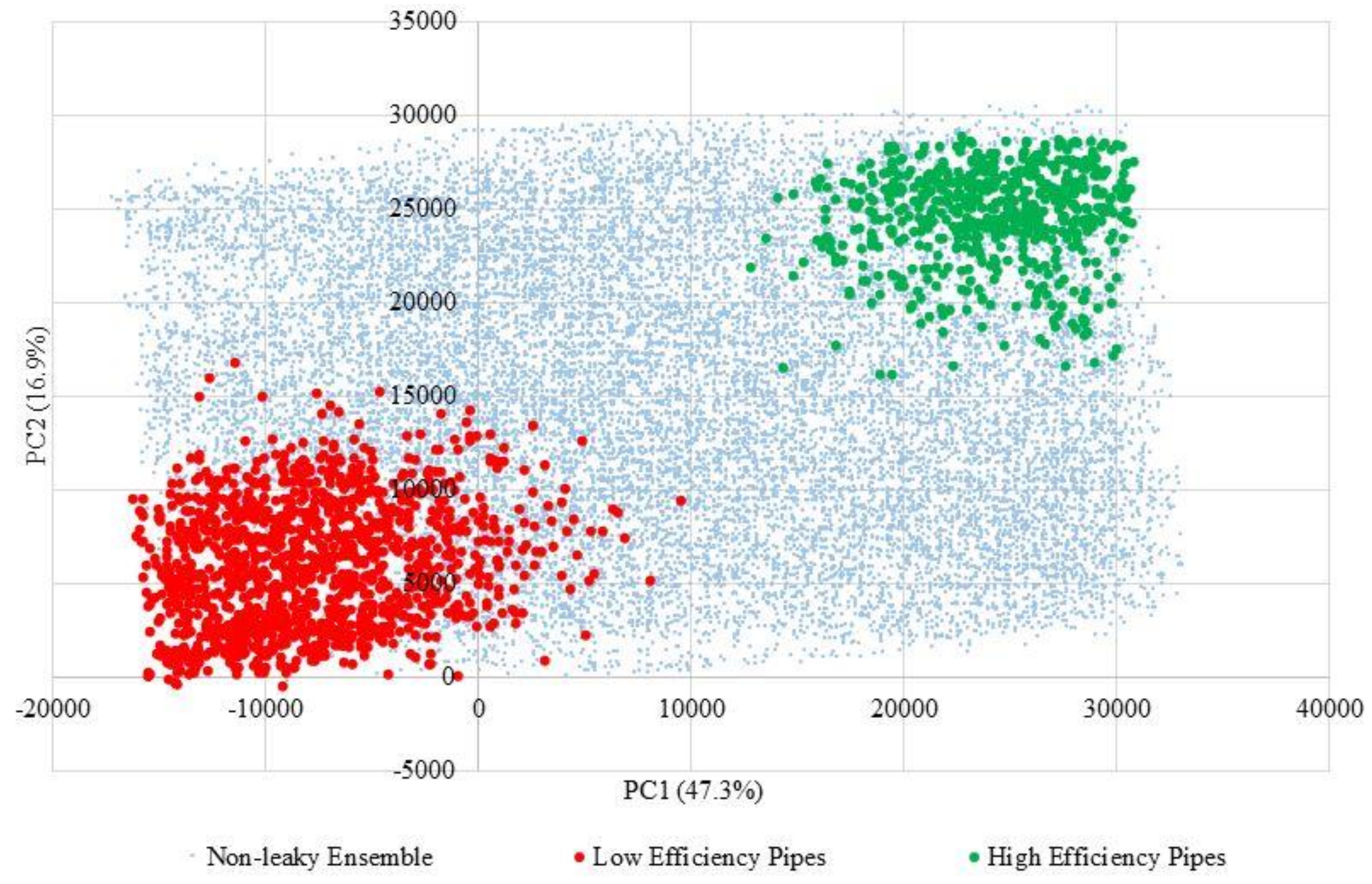

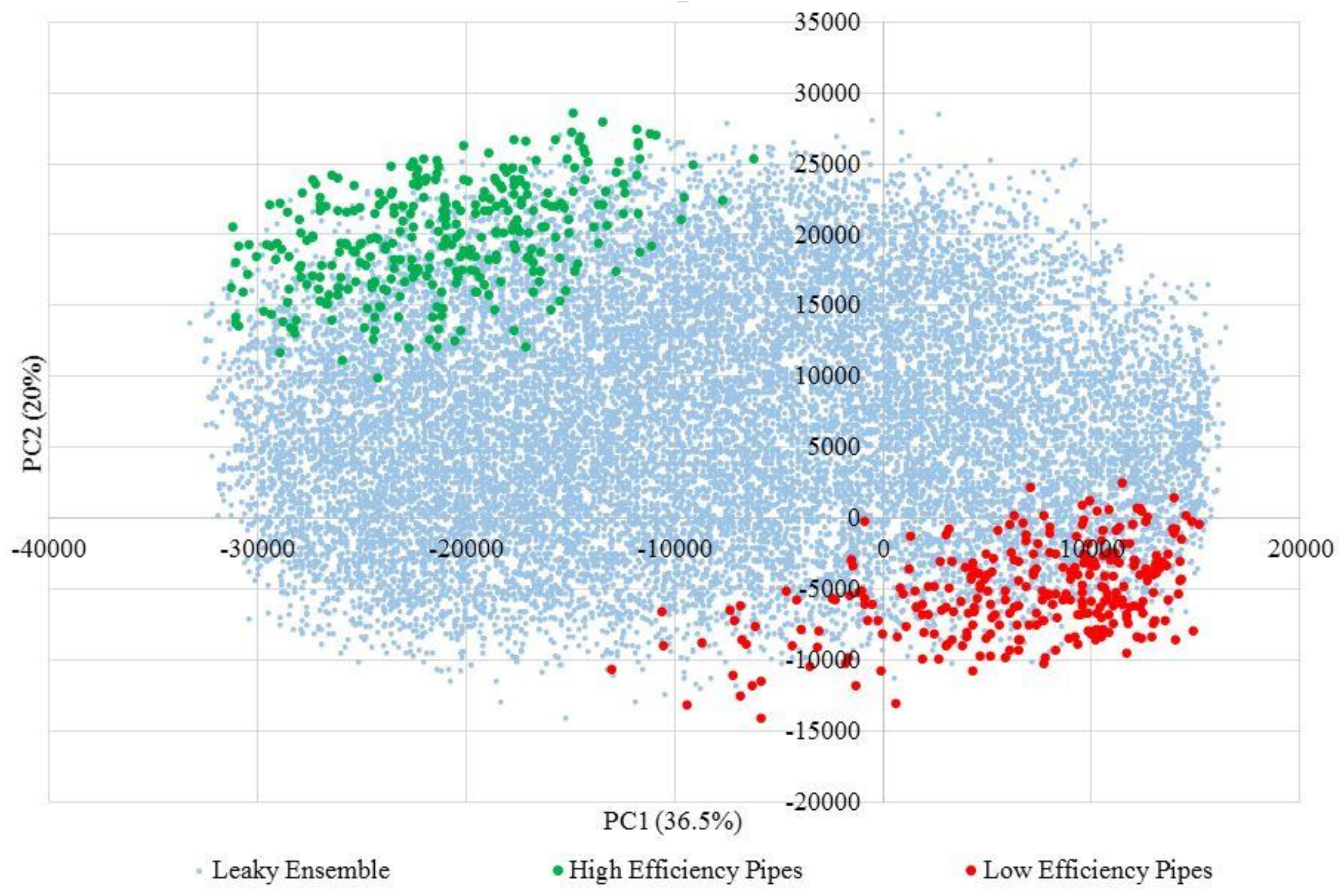

4.2. Clusters of High Efficiency Versus Low Efficiency Pipes

4.2.1. Non-Leaky Ensemble

4.2.2. Leaky Ensemble

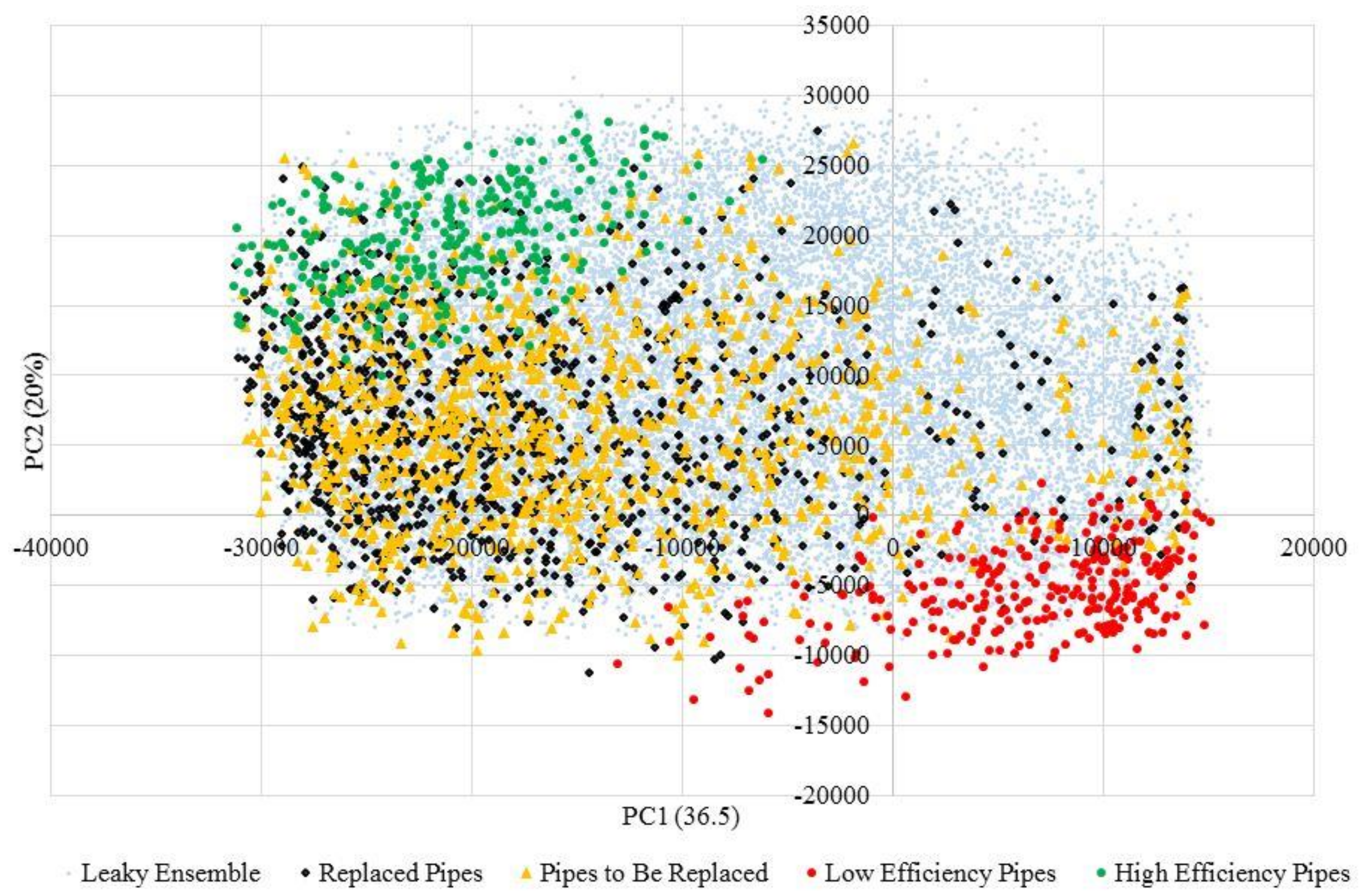

4.3. Examining Current-Practice Pipe Rehabilitations

5. Discussion

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Roshani, E.; Filion, Y.R. Event-based approach to optimize the timing of water main rehabilitation with asset management strategies. J. Water Resour. Plan. Manag. 2013, 6, 04014004. [Google Scholar] [CrossRef]

- Rajani, B.; Kleiner, Y. Comprehensive review of structural deterioration of water mains: Physically based models. Urban Water 2001, 3, 151–164. [Google Scholar] [CrossRef]

- Kleiner, Y.; Rajani, B. Comprehensive review of structural deterioration of water mains: Statistical models. Urban Water 2001, 3, 131–150. [Google Scholar] [CrossRef]

- Engelhardt, M.O.; Skipworth, P.J.; Savic, D.A.; Saul, A.J.; Walters, G.A. Rehabilitation strategies for water distribution networks: A literature review with a UK perspective. Urban Water 2000, 2, 153–170. [Google Scholar] [CrossRef]

- Lansey, K.E.; Basnet, C.; Mays, L.W.; Woodburn, J. Optimal maintenance scheduling for water distribution systems. Civ. Eng. Syst. 1992, 3, 211–226. [Google Scholar] [CrossRef]

- Scanlan, M.; Filion, Y.R. Influence of Topography, Peak Demand, and Topology on Energy Use Patterns in four Small to Medium-Sized Systems in Ontario, Canada. Water Resour. Manag. 2017, 4, 1361–1379. [Google Scholar] [CrossRef]

- Pelli, T.; Hitz, H.U. Energy indicators and savings in water supply. J. AWWA 2000, 92, 55. [Google Scholar] [CrossRef]

- Cabrera, E.; Pardo, M.A.; Cobacho, R.; Cabrera, E., Jr. Energy audit of water networks. J. Water Resour. Plan. Manag. 2010, 6, 669–677. [Google Scholar] [CrossRef]

- Cabrera, E.; Gómez, E.; Cabrera, E., Jr.; Soriano, J.; Espert, V. Energy assessment of pressurized water systems. J. Water Resour. Plan. Manag. 2014, 8, 04014095. [Google Scholar] [CrossRef]

- Dziedzic, R.M.; Karney, B.W. Water distribution system performance metrics. Procedia Eng. 2014, 89, 363–369. [Google Scholar] [CrossRef]

- Hashemi, S.; Filion, Y.R.; Speight, V.L. Examining the relationship between unit headloss and energy performance of water mains with statistical analyses across an ensemble of water distribution systems. J. AWWA 2018, in press. [Google Scholar]

- Hashemi, S.; Filion, Y.R.; Speight, V.L. Energy Metrics to Evaluate the Energy Use and Performance of Water Main Assets. J. Water Resour. Plan. Manag. 2017, 2, 04017094. [Google Scholar] [CrossRef]

- Jolliffe, I.T. Principal Component Analysis and Factor Analysis. Principal Component Analysis; Springer: New York, NY, USA, 1986; pp. 115–128. [Google Scholar]

- Krzanowski, W.J. Principles of Multivariate Analysis: A User’s Perspective; Clarendon: Oxford, UK, 1988. [Google Scholar]

- Jolly, M.D.; Lothes, A.D.; Sebastian Bryson, L.; Ormsbee, L. Research database of water distribution system models. J. Water Resour. Plan. Manag. 2013, 4, 410–416. [Google Scholar] [CrossRef]

- Prosser, M.E.; Speight, V.L.; Filion, Y.R. Life-cycle energy analysis of performance-versus age-based pipe replacement schedules. J. AWWA 2013, 105, E721–E732. [Google Scholar] [CrossRef]

- Wong, H.G.; Speight, V.L.; Filion, Y.R. Impact of Urban Development on Energy Use in a Distribution System. J. AWWA 2017, 109, E10–E18. [Google Scholar] [CrossRef]

- Rossman, L.A. Epanet 2 User’s Manual; US Environmental Protection Agency; Water Supply and Water Resources Division, National Risk Management Research Laboratory: Cincinnati, OH, USA, 2000; p. 45268.

- Toolbox, Global Optimization. User’s Guide (r2011b); MathWorks Inc.: Natick, MA, USA, 2011. [Google Scholar]

- City of Toronto. Design Criteria for Sewers and Water Mains; Engineering and Construction Services: Toronto, ON, Canada, 2009. [Google Scholar]

- Region of Peel. Public Works Design. In Specifications and Procedures Manual; Region of Peel: Mississauga, ON, Canada, 2010. [Google Scholar]

- Denver Water. Engineering Standards, 14th ed.; Denver Water: Denver, CO, USA, 2012. [Google Scholar]

- Hashemi, S.; Filion, Y.R.; Speight, V.L. An Energy Evaluation of Common Hydraulic Thresholds in Water Mains. In Proceedings of the 15th International Computing and Control for Water Industry Conference, Sheffield, UK, 5–7 September 2017. [Google Scholar]

- American Water Works Association. AWWA Manual M32-Distribution Network Analysis for Water Utilities; American Water Works Association: Denver, CO, USA, 2017. [Google Scholar]

| Item | Definition |

|---|---|

| Esupplied | Energy supplied to the upstream end of the pipe |

| Edelivered | Energy delivered to the user to satisfy downstream demand Qd at pressure head Hd |

| Eds | Energy flowing out of the pipe to meet downstream user demands |

| Eleak | Energy directly lost to leakage |

| Efriction | Friction energy loss incurred along the pipe |

| Elocal | Local energy losses through valves, appurtenances, and blockages |

| Eneed | Energy needed/required by the downstream node according to standards |

| Efriction (leak) | Friction energy loss incurred along the pipe as a result of leakage |

| GEE | Gross Energy Efficiency |

| NEE | Net Energy Efficiency |

| ENU | Energy Needed by User |

| ELTF | Energy Lost to Friction |

| ELEL | Energy Lost to Leakage |

| Proximity | Hydraulic proximity to major components of the network based on pressure head and pipe flow |

| Q | Pipe flow (m3/s) |

| Hs | Head supplied at the upstream node of a pipe |

| Network | State/Province | No. of Pipes | Pipes Length (km) | No. of Model Junctions | Difference in Elevations (m) a | No. of Pumps | No. of Tanks | Average Daily Demand (MLD) | Average Daily Pressure (m) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | ON1 b | 12,189 | 627 | 11,177 | 50 | 31 | 10 | 69.07 | 44.86 |

| 2 | ON2 | 405 | 56 | 349 | 46 | 6 | 3 | 3.54 | 46.71 |

| 3 | KY1 c | 984 | 67 | 856 | 37 | 1 | 2 | 7.52 | 33.07 |

| 4 | KY2 | 1124 | 152 | 811 | 29 | 1 | 3 | 7.92 | 46.07 |

| 5 | KY3 | 366 | 91 | 271 | 43 | 5 | 3 | 15.19 | 41.76 |

| 6 | KY4 | 1156 | 260 | 959 | 75 | 2 | 4 | 5.65 | 48.02 |

| 7 | KY5 | 496 | 96 | 420 | 75 | 9 | 3 | 8.58 | 134 |

| 8 | KY6 | 644 | 123 | 543 | 96 | 2 | 3 | 6.19 | 60.2 |

| 9 | KY7 | 603 | 137 | 481 | 70 | 1 | 3 | 5.80 | 55.32 |

| 10 | KY8 | 1614 | 247 | 1325 | 135 | 4 | 5 | 9.32 | 54.15 |

| 11 | KY9 | 1270 | 972 | 1242 | 138 | 17 | 15 | 5.07 | 94 |

| 12 | KY10 | 1043 | 435 | 920 | 96 | 13 | 13 | 8.18 | 68 |

| 13 | KY11 | 846 | 464 | 802 | 248 | 21 | 28 | 6.61 | 97.11 |

| 14 | KY12 | 2426 | 655 | 2347 | 145 | 15 | 7 | 5.18 | 111 |

| 15 | KY13 | 940 | 155 | 778 | 95 | 4 | 5 | 8.92 | 50.78 |

| 16 | KY14 | 548 | 105 | 377 | 65 | 5 | 3 | 3.94 | 53.9 |

| 17 | OH1 d | 1183 | 166 | 956 | 100 | 15 | 4 | 10.13 | 57 |

| 18 | OH2 e | 27,231 f | 5500 | 19,618 | 154 | 28 | 27 | 531.49 | 53 |

| CHW | D (mm) | P (m) | Avg. Q (L/s) | Avg. Unit Headloss (m/km) | Prox (m4/s) | Elv. (m) | GEE (%) | NEE (%) | ENU (%) | ELTF (%) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CHW 1 | 1 | −0.20 | 0.05 | 0.05 | −0.13 | 0.05 | −0.10 | 0.11 | 0.06 | 0.05 | −0.10 |

| D (mm) 2 | −0.20 | 1 | −0.07 | 0.53 | 0.09 | 0.55 | 0.26 | −0.57 | −0.30 | −0.01 | 0.29 |

| P (m) 3 | 0.05 | −0.07 | 1 | −0.02 | −0.08 | −0.05 | −0.24 | 0.10 | 0.08 | 0.66 | −0.10 |

| Avg. Q (MLD) 4 | 0.05 | 0.53 | −0.02 | 1 | 0.73 | 0.96 | 0.16 | −0.75 | −0.81 | −0.13 | 0.73 |

| Avg. Unit Headloss (m/km) 5 | −0.13 | 0.09 | −0.08 | 0.73 | 1 | 0.69 | 0.10 | −0.64 | −0.88 | −0.14 | 0.82 |

| Prox (m4/s) 6 | 0.05 | 0.55 | −0.05 | 0.96 | 0.69 | 1 | 0.18 | −0.73 | −0.78 | −0.08 | 0.71 |

| Elv. (m) 7 | −0.10 | 0.26 | −0.24 | 0.16 | 0.10 | 0.18 | 1 | −0.09 | −0.08 | −0.41 | 0.06 |

| GEE (%) 8 | 0.11 | −0.57 | 0.10 | −0.75 | −0.64 | −0.73 | −0.09 | 1 | 0.80 | 0.04 | −0.76 |

| NEE (%) 9 | 0.06 | −0.30 | 0.08 | −0.81 | −0.88 | −0.78 | −0.08 | 0.80 | 1 | 0.10 | −0.92 |

| ENU (%) 10 | 0.05 | −0.01 | 0.66 | −0.13 | −0.14 | −0.08 | −0.41 | 0.04 | 0.10 | 1 | −0.07 |

| ELTF (%) 11 | −0.10 | 0.29 | −0.10 | 0.73 | 0.82 | 0.71 | 0.06 | −0.76 | −0.92 | −0.07 | 1 |

| Energy Metric | Threshold Value to Define Low Efficiency Pipes (%) | Threshold Value to Define High Efficiency Pipes (%) |

|---|---|---|

| GEE | GEE < 15 | GEE > 20 |

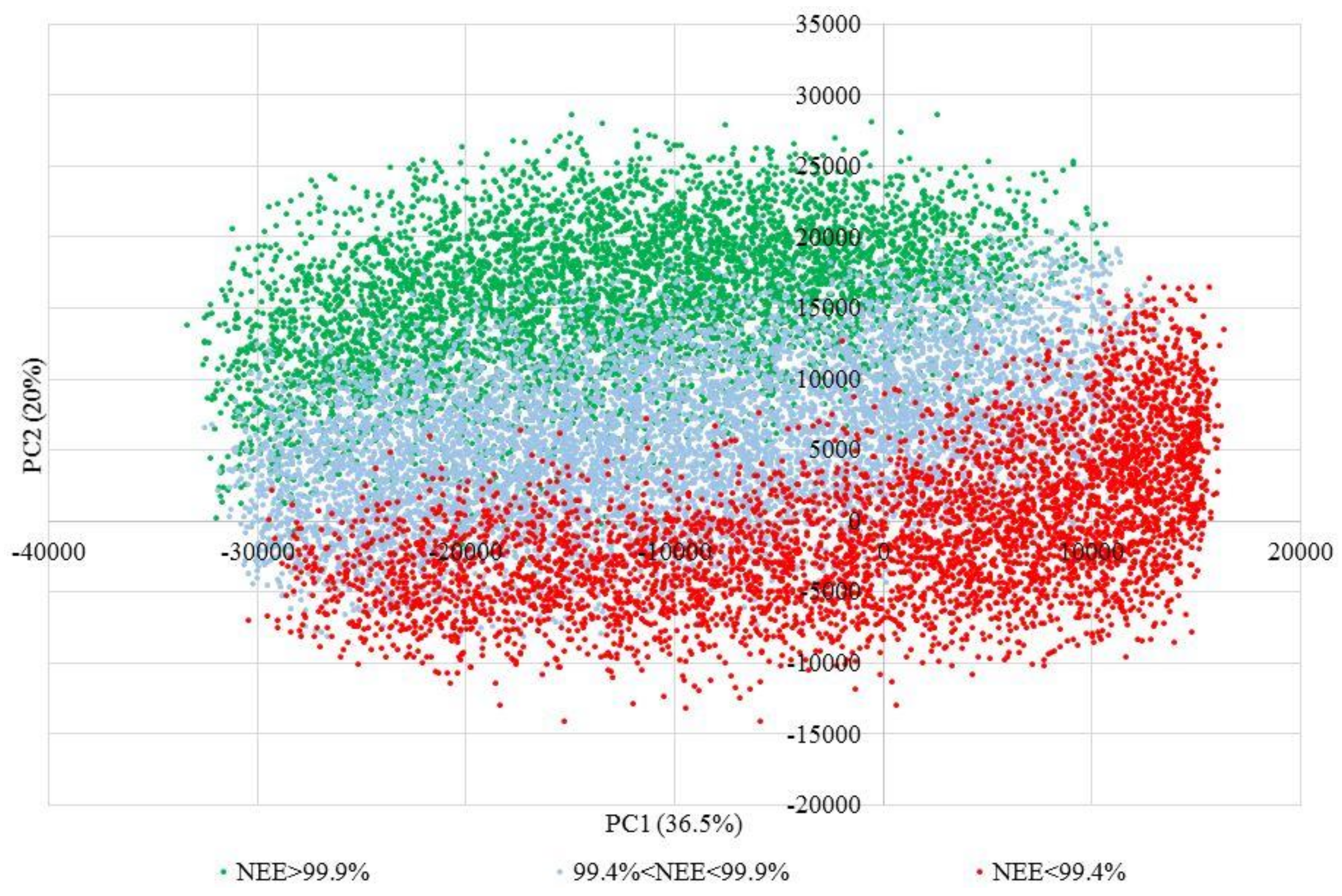

| NEE | NEE < 99.4 | NEE > 99.9 |

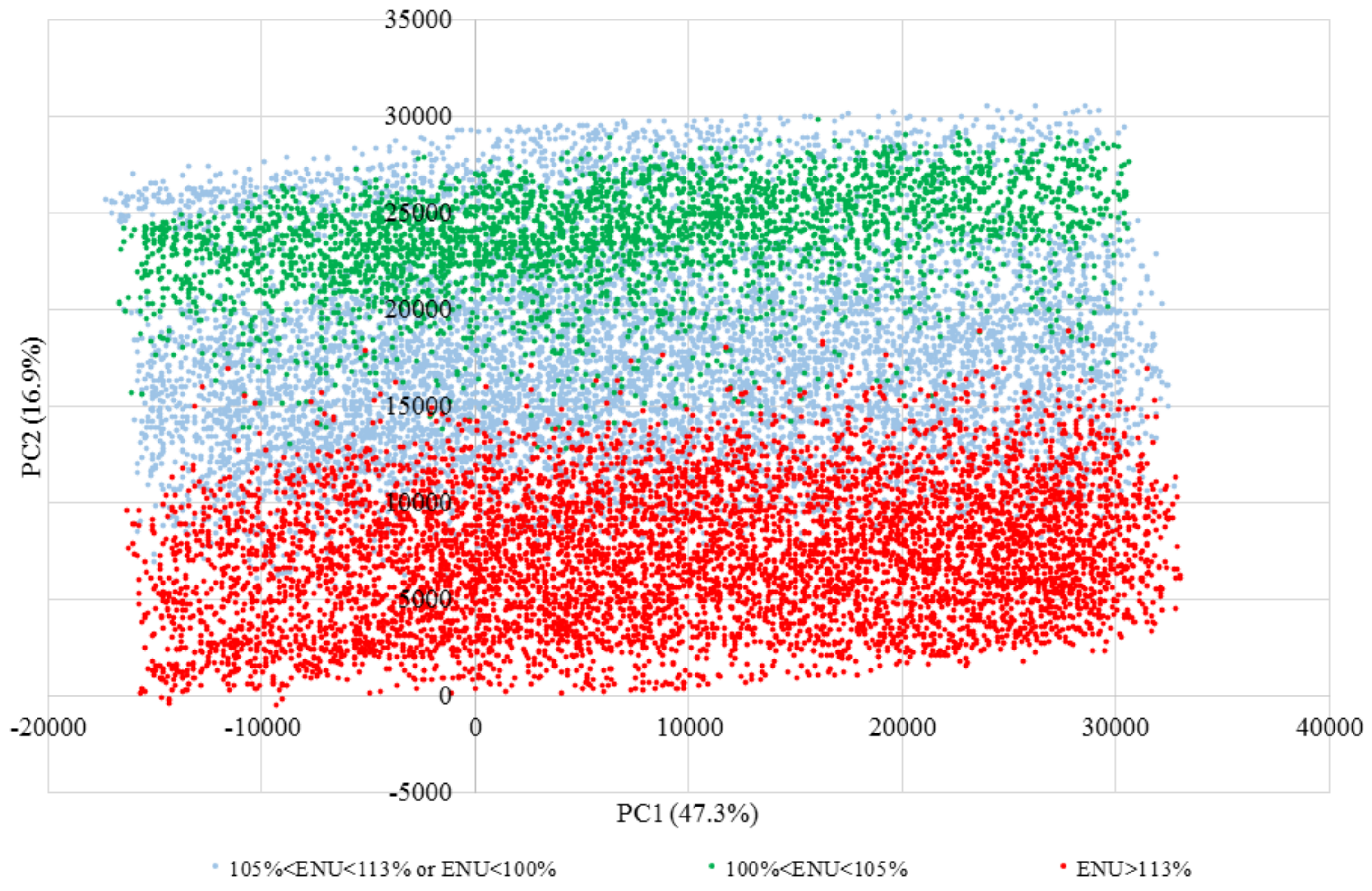

| ENU | ENU > 113 | 100 < ENU < 105 |

| ELTF | ELTF > 0.3 | ELTF < 0.0018 |

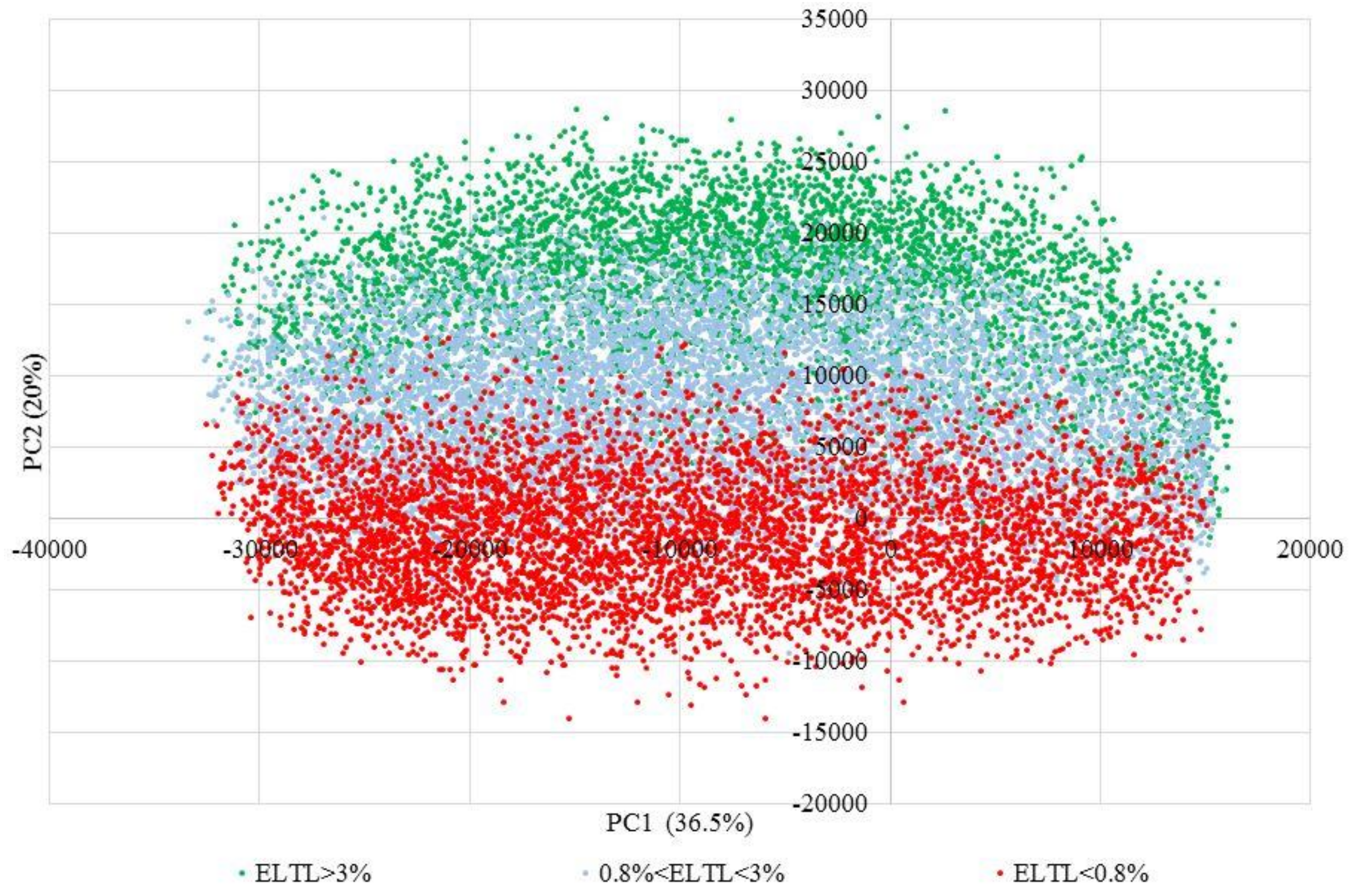

| ELTL * | ELTL > 3 | ELTL < 0.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hashemi, S.; Filion, Y.; Speight, V. Identification of Factors That Influence Energy Performance in Water Distribution System Mains. Water 2018, 10, 428. https://doi.org/10.3390/w10040428

Hashemi S, Filion Y, Speight V. Identification of Factors That Influence Energy Performance in Water Distribution System Mains. Water. 2018; 10(4):428. https://doi.org/10.3390/w10040428

Chicago/Turabian StyleHashemi, Saeed, Yves Filion, and Vanessa Speight. 2018. "Identification of Factors That Influence Energy Performance in Water Distribution System Mains" Water 10, no. 4: 428. https://doi.org/10.3390/w10040428