Estimating Evapotranspiration of Processing Tomato under Plastic Mulch Using the SIMDualKc Model

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Site

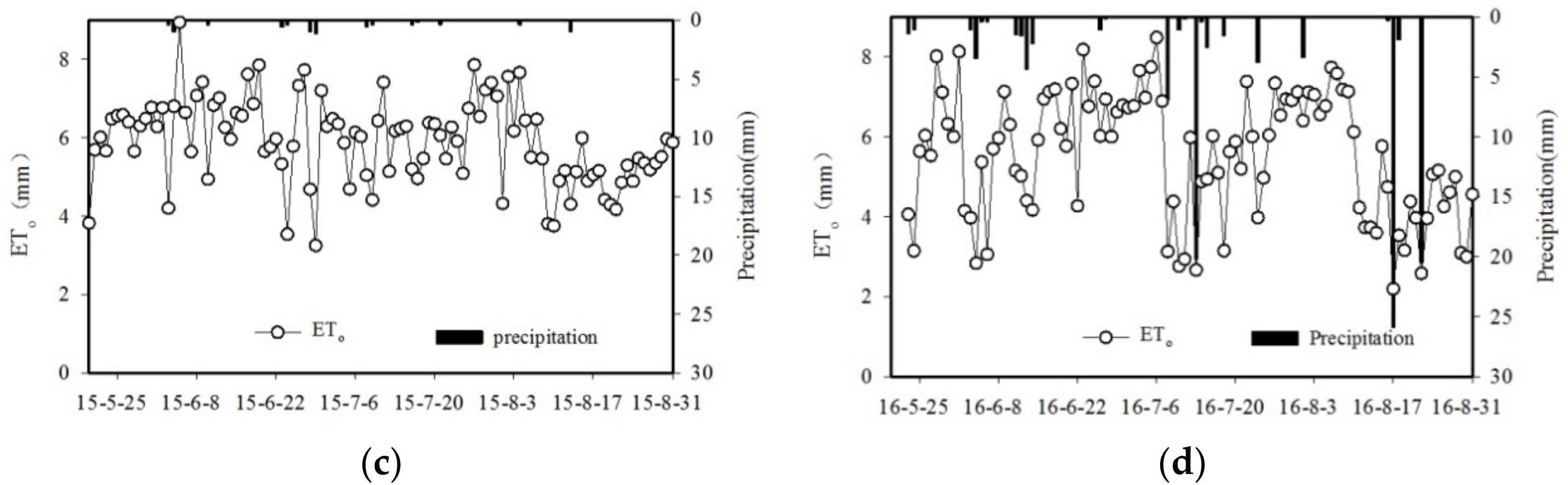

2.2. Weather Conditions

2.3. Experimental Design and Measurements

- drip irrigation treatment (DI), where the irrigation schedule was based upon soil moisture measurements. The treatment plots were irrigated with the lower and upper limits of the soil water content at the root zone for irrigation, being 70% and 80–90% of field capacity, respectively. The irrigation treatments for 2015 and 2016 are shown in Table 3.

- basin irrigation treatment (BI), where the treatment plots were irrigated during the development stage and mid-season stage with about 80 mm of water based on the experience of local farmers, whereas in 2016 only 50 mm of water were applied in the mid-season stage due to the relatively large rainfall that occurred during that stage (see Table 3).

- reduced drip irrigation treatment (RDI) and a reduced basin irrigation treatment (RBI) were considered in 2016. The RDI and RBI treatments were irrigated with 60% of the amount of water of the DI and BI treatments at the same time, respectively. The schematic experimental setup of the 2016 growing season is displayed in Figure 2.

2.4. Measurement

2.5. SIMDualKc Model and Data Requirements

2.6. Statistical Indicators for Model Performance

3. Results and Discussion

3.1. Model Calibration and Validation

3.2. Basal Crop Coefficient and Soil Evaporation Coefficient Dynamics

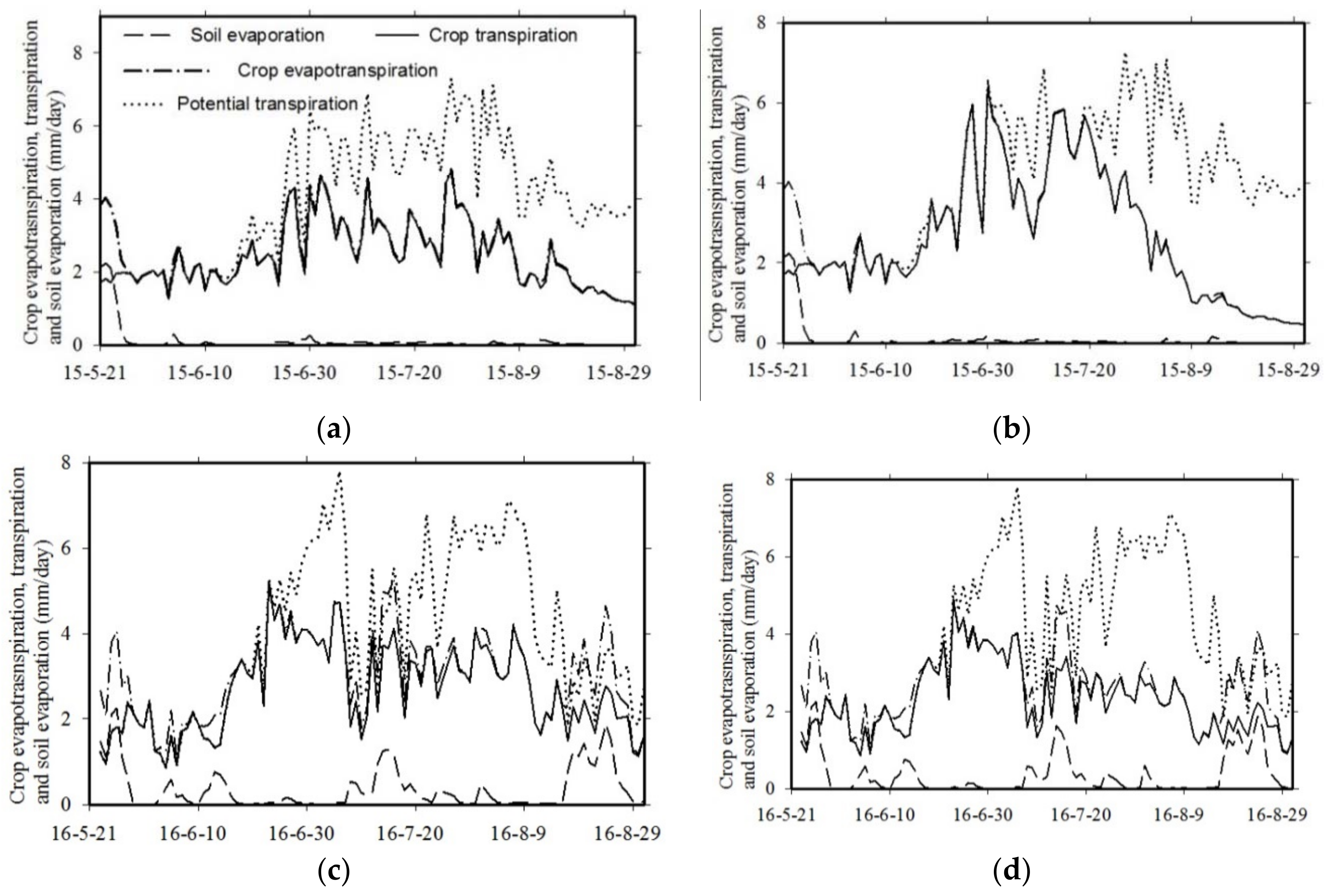

3.3. Crop Evapotranspiration Partitioning

3.4. Yield and Water Productivity

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Feng, Z.Z.; Wang, X.K.; Feng, Z.W. Soil N and salinity leaching after the autumn irrigation and its impact on groundwater in Hetao Irrigation District, China. Agric. Water Manag. 2005, 71, 131–143. [Google Scholar] [CrossRef] [Green Version]

- Lei, T.W.; Shainberg, I.; Yuan, P.J.; Huang, X.F.; Yang, P.L. Strategic considerations of efficient irrigation and salinity control on Hetao Plain in Inner Mongolia. Transf. CSAE 2001, 17, 48–52. [Google Scholar]

- Xu, X.; Sun, C.; Qu, Z.Y.; Huang, Q.Z.; Ramos, T.B.; Huang, G.H. Groundwater recharge and capillary rise in irrigated areas of the upper Yellow river basin assessed by an agro-hydrological model. Irrig. Drain. 2016, 64, 587–599. [Google Scholar] [CrossRef]

- Wu, Y.; Shi, X.H.; Li, C.Y.; Zhao, S.N.; Pen, F.; Green, T.R. Simulation of hydrology and nutrient transport in the Hetao Irrigation District, Inner Mongolia, China. Water 2017, 9, 169. [Google Scholar] [CrossRef]

- Yang, Y.T.; Shang, S.H.; Jiang, L. Remote sensing temporal and spatial patterns of evapotranspiration and the responses to water management in a large irrigation district of North China. Agric. For. Meteorol. 2012, 164, 112–122. [Google Scholar] [CrossRef]

- Szuvandzsiev, P.; Daood, H.G.; Posta, K.; Helyes, L.; Pék, Z. Application of VIS-NIR reflectance spectra for estimating soluble solid and lycopene content of open-field processing tomato fruit juice from irrigation and mycorrhiza treatments. Acta Hortic. 2017, 1159, 73–78. [Google Scholar] [CrossRef]

- Patanè, C.; Cosentino, S.L. Effects of soil water deficit on yield and quality of processing tomato under a Mediterranean climate. Agric. Water Manag. 2010, 97, 131–138. [Google Scholar] [CrossRef]

- Patane, C.; Saita, A. Biomass, fruit yield, water productivity and quality response of processing tomato to plant density and deficit irrigation under a semi-arid Mediterranean climate. Crop Pasture Sci. 2015, 66, 224–234. [Google Scholar] [CrossRef]

- Zhang, H.M.; Xiong, Y.W.; Huang, G.H.; Xu, X.; Huang, Q.Z. Effects of water stress on processing tomatoes yield, quality and water use efficiency with plastic mulched drip irrigation in sandy soil of the Hetao Irrigation District. Agric. Water Manag. 2017, 179, 205–214. [Google Scholar] [CrossRef]

- Xu, X.; Huang, G.H.; Qu, Z.Y.; Pereira, L.S. Assessing the groundwater dynamics and impacts of water saving in the Hetao Irrigation District, Yellow River basin. Agric. Water Manag. 2010, 98, 301–313. [Google Scholar] [CrossRef]

- Hunsaker, D.J.; Barnes, E.M.; Clarke, T.R.; Fitzgerald, G.J.; Pinter, P.J., Jr. Cotton irrigation scheduling using remotely sensed and FAO-56 basal crop coefficients. Trans. ASABE 2005, 48, 1395–1407. [Google Scholar] [CrossRef]

- Paredes, P.; D’Agostino, D.; Assif, M.; Todorovic, M.; Pereira, L.S. Assessing potato transpiration, yield and water productivity under various water regimes and planting dates using the FAO dual Kc approach. Agric. Water Manag. 2018, 195, 11–24. [Google Scholar] [CrossRef]

- Sezen, S.M.; Yazar, A.; Eker, S. Effect of drip irrigation regimes on yield and quality of field grown bell pepper. Agric. Water Manag. 2006, 81, 115–131. [Google Scholar] [CrossRef]

- Jensen, C.R.; Ørum, J.E.; Pedersen, S.M.; Andersen, M.N.; Plauborg, F.; Liu, F.; Jacobsen, S.E. A short overview of measures for securing water resources for irrigated crop production. J. Agron. Crop Sci. 2014, 200, 333–343. [Google Scholar] [CrossRef]

- Gerçek, S.; Demirkaya, M.; Işik, D. Water pillow irrigation versus drip irrigation with regard to growth and yield of tomato grown under greenhouse conditions in a semi-arid region. Agric. Water Manag. 2017, 180, 172–177. [Google Scholar] [CrossRef]

- Munoz-Carpena, R.; Bryan, H.; Klassen, W.; Dukes, M.D. Automatic soil moisture based drip irrigation for improving tomato production. Proc. Fla. State Hortic. Soc. 2003, 116, 80–85. [Google Scholar]

- Ngouajio, M.; Wang, G.Y.; Goldy, R. Withholding of drip irrigation between transplanting and flowering increases the yield of field-grown tomato under plastic mulch. Agric. Water Manag. 2007, 87, 285–291. [Google Scholar] [CrossRef]

- Sui, J.; Wang, J.D.; Gong, S.H.; Xu, D.; Zhang, Y.Q.; Qin, Q.M. Assessment of maize yield-increasing potential and optimum N level under mulched drip irrigation in the Northeast of China. Field Crops Res. 2018, 215, 132–139. [Google Scholar] [CrossRef]

- Fang, Q.; Zhang, X.Y.; Shao, L.W.; Chen, S.Y.; Sun, H.Y. Assessing the performance of different irrigation systems on winter wheat under limited water supply. Agric. Water Manag. 2018, 196, 133–143. [Google Scholar] [CrossRef]

- Hanson, B.R.; Schwankl, L.J.; Schulbach, K.F.; Pettygrove, G.S. A comparison of furrow, surface drip, and subsurface drip irrigation on lettuce yield and applied water. Agric. Water Manag. 1997, 33, 139–157. [Google Scholar] [CrossRef]

- Namara, R.E.; Nagar, R.K.; Upadhyay, B. Economics, adoption determinants, and impacts of micro-irrigation technologies: Empirical results from India. Irrig. Sci. 2007, 25, 283–297. [Google Scholar] [CrossRef]

- Burt, C.M.; Isbell, B. Leaching of accumulated soil salinity under drip irrigation. Trans. ASABE 2005, 48, 2115–2121. [Google Scholar] [CrossRef]

- Zheng, J.H.; Huang, G.H.; Wang, J.; Huang, Q.Z.; Pereira, L.S.; Xu, X.; Liu, H.J. Effects of water deficits on growth, yield and water productivity of drip-irrigated onion (Allium cepa L.) in an arid region of Northwest China. Irrig. Sci. 2013, 31, 995–1008. [Google Scholar] [CrossRef]

- Li, X.Y.; Shi, H.B.; Simunek, J.; Gong, X.W.; Peng, Z.Y. Modeling soil water dynamics in a drip-irrigated intercropping field under plastic mulch. Irrig. Sci. 2015, 33, 289–302. [Google Scholar] [CrossRef] [Green Version]

- Vazquez, N.; Pardo, A.; Suso, M.L.; Quemada, M. Drainage and nitrate leaching under processing tomato growth with drip irrigation and plastic mulching. Agric. Ecosyst. Environ. 2006, 112, 313–323. [Google Scholar] [CrossRef]

- Berihun, B. Effect of mulching and amount of water on the yield of tomato under drip irrigation. J. Hortic. For. 2011, 3, 200–206. [Google Scholar]

- Biswas, S.K.; Akanda, A.R.; Rahman, M.S.; Hossain, M.A. Effect of drip irrigation and mulching on yield, water-use efficiency and economics of tomato. Plant Soil Environ. 2015, 61, 97–102. [Google Scholar]

- Qin, S.J.; Li, S.E.; Kang, S.Z.; Du, T.S.; Tong, L.; Ding, R.S. Can the drip irrigation under film mulch reduce crop evapotranspiration and save water under the sufficient irrigation condition? Agric. Water Manag. 2016, 177, 128–137. [Google Scholar] [CrossRef]

- Rana, G.; Katerji, N. Measurement and estimation of actual evapotranspiration in the field under Mediterranean climate: A review. Eur. J. Agron. 2000, 13, 125–153. [Google Scholar] [CrossRef]

- Al-Omran, A.M.; Mohammad, F.S.; Al-Ghobari, H.M.; Alazba, A.A. Determination of evapotranspiration of tomato and squash using lysimeters in central Saudi Arabia. Int. Agric. Eng. J. 2004, 13, 27–36. [Google Scholar]

- Amayreh, J.; Al-Abed, N. Developing crop coefficients for field-grown tomato (Lycopersicon esculentum Mill.) under drip irrigation with black plastic mulch. Agric. Water Manag. 2005, 73, 247–254. [Google Scholar] [CrossRef]

- Hanson, B.R.; May, D.M. Crop evapotranspiration of processing tomato in the San Joaquin Valley of California, USA. Irrig. Sci. 2006, 24, 211–221. [Google Scholar] [CrossRef]

- Colaizzi, P.D.; O’Shaughnessy, S.A.; Evett, S.R.; Mounce, R.B. Crop evapotranspiration calculation using infrared thermometers aboard center pivots. Agric. Water Manag. 2017, 187, 173–189. [Google Scholar] [CrossRef] [Green Version]

- Howell, T.A.; Evett, S.R.; Tolk, J.A.; Schneider, A.D. Evapotranspiration of full-, deficit-irrigated and dryland cotton on the Northern Texas High Plains. J. Irrig. Drain. Eng. 2004, 130, 277–285. [Google Scholar] [CrossRef]

- Valdés-Gómez, H.; Ortega-Farías, S.; Argote, M. Evaluation of water requirements for a greenhouse tomato crop using the Priestley-Taylor method. Chil. J. Agric. Res. 2009, 69, 3–11. [Google Scholar]

- Zhao, P.; Li, S.E.; Li, F.S.; Du, T.S.; Tong, L.; Kang, S.Z. Comparison of dual crop coefficient method and Shuttleworth–Wallace model in evapotranspiration partitioning in a vineyard of Northwest China. Agric. Water Manag. 2015, 160, 41–56. [Google Scholar] [CrossRef]

- Abrisqueta, I.; Abrisqueta, J.M.; Tapia, L.M.; Munguía, J.P.; Conejero, W.; Vera, J.; Ruiz-Sánchez, M.C. Basal crop coefficients for early-season peach trees. Agric. Water Manag. 2013, 121, 158–163. [Google Scholar] [CrossRef]

- Allen, R.G.; Pereira, L.S.; Smith, M.; Raes, D.; Wright, J.L. FAO-56 dual crop coefficient method for estimating evaporation from soil and application extensions. J. Irrig. Drain. Eng. 2005, 131, 2–13. [Google Scholar] [CrossRef]

- Sumner, D.M.; Jacobs, J.M. Utility of Penman–Monteith, Priestley–Taylor, reference evapotranspiration, and pan evaporation methods to estimate pasture evapotranspiration. J. Hydrol. 2005, 308, 81–104. [Google Scholar] [CrossRef]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration: Guidelines for Computing Crop Water Requirements; FAO: Rome, Italy, 1998; p. 56. [Google Scholar]

- Zhang, B.Z.; Liu, Y.; Xu, D.; Zhao, N.N.; Lei, B.; Rosa, R.D.; Paredes, P.; Paço, T.A.; Pereira, L.S. The dual crop coefficient approach to estimate and partitioning evapotranspiration of the winter wheat–summer maize crop sequence in North China Plain. Irrig. Sci. 2013, 31, 1303–1316. [Google Scholar] [CrossRef]

- Bodner, G.; Loiskandl, W.; Kaul, H.-P. Cover crop evapotranspiration under semi-arid conditions using FAO dual crop coefficient method with water stress compensation. Agric. Water Manag. 2007, 93, 85–98. [Google Scholar] [CrossRef]

- Feng, Y.; Gong, D.Z.; Mei, X.R.; Cui, N.B. Estimation of maize evapotranspiration using extreme learning machine and generalized regression neural network on the China Loess Plateau. Hydrol. Res. 2017, 48, 1156–1168. [Google Scholar] [CrossRef]

- Paredes, P.; Rodrigues, G.C.; Alves, I.; Pereira, L.S. Partitioning evapotranspiration, yield prediction and economic returns of maize under various irrigation management strategies. Agric. Water Manag. 2014, 135, 27–39. [Google Scholar] [CrossRef]

- Zhao, N.N.; Liu, Y.; Cai, J.B.; Paredes, P.; Rosa, R.D.; Pereira, L.S. Dual crop coefficient modelling applied to the winter wheat-summer maize crop sequence in North China Plain: Basal crop coefficients and soil evaporation component. Agric. Water Manag. 2013, 117, 93–105. [Google Scholar] [CrossRef]

- Rosa, R.D.; Paredes, P.; Rodrigues, G.C.; Alves, I.; Fernando, R.M.; Pereira, L.S.; Allen, R.G. Implementing the dual crop coefficient approach in interactive software. 1. Background and computational strategy. Agric. Water Manag. 2012, 103, 8–24. [Google Scholar] [CrossRef]

- Paço, T.A.; Pôças, I.; Cunha, M.; Silvestre, J.C.; Santos, F.L.; Paredes, P.; Pereira, L.S. Evapotranspiration and crop coefficients for a super intensive olive orchard. An application of SIMDualKc and METRIC models using ground and satellite observations. J. Hydrol. 2014, 519, 2067–2080. [Google Scholar] [CrossRef] [Green Version]

- Qiu, R.J.; Du, T.S.; Kang, S.Z.; Chen, R.Q.; Wu, L.S. Assessing the SIMDualKc model for estimating evapotranspiration of hot pepper grown in a solar greenhouse in Northwest China. Agric. Syst. 2015, 138, 1–9. [Google Scholar] [CrossRef]

- Pereira, L.S.; Cordery, I.; Iacovides, I. Improved indicators of water use performance and productivity for sustainable water conservation and saving. Agric. Water Manag. 2012, 108, 39–51. [Google Scholar] [CrossRef]

- Pereira, L.S.; Paredes, P.; Rodrigues, G.C.; Neves, M. Modeling malt barley water use and evapotranspiration partitioning in two contrasting rainfall years. Assessing AquaCrop and SIMDualKc models. Agric. Water Manag. 2015, 159, 239–254. [Google Scholar] [CrossRef]

- Martins, J.D.; Rodrigues, G.C.; Paredes, P.; Carlesso, R.; Oliveira, Z.B.; Knies, A.E.; Petry, M.T.; Pereira, L.S. Dual crop coefficients for maize in southern Brazil: Model testing for sprinkler and drip irrigation and mulched soil. Biosyst. Eng. 2013, 115, 291–310. [Google Scholar] [CrossRef]

- Hanson, B.R.; May, D.M. Crop coefficients for drip-irrigated processing tomato. Agric. Water Manag. 2006, 81, 381–399. [Google Scholar] [CrossRef]

- Hanson, B.R.; May, D.M. Crop evapotranspiration of processing tomato under furrow and subsurface drip irrigation. Acta Hortic. 2004, 664, 303–307. [Google Scholar] [CrossRef]

- Aksic, M.; Gudzic, S.; Deletic, N.; Gudzic, N.; Stojkovic, S. Tomato fruit yield and evapotranspiration in the conditions of South Serbia. Bulg. J. Agric. Sci. 2011, 17, 150–157. [Google Scholar]

- Mukherjee, A.; Kundu, M.; Sarkar, S. Role of irrigation and mulch on yield, evapotranspiration rate and water use pattern of tomato (Lycopersicon esculentum L.). Agric. Water Manag. 2010, 98, 182–189. [Google Scholar] [CrossRef]

- Giuliani, M.M.; Nardella, E.; Gagliardi, A.; Gatta, G. Deficit irrigation and partial root-zone drying techniques in processing tomato cultivated under Mediterranean climate conditions. Sustainability 2017, 9, 2197. [Google Scholar] [CrossRef]

- Zaccaria, D.; Carrillo-Cobo, M.T.; Montazar, A.; Putnam, D.H.; Bali, K. Assessing the viability of sub-surface drip irrigation for resource-efficient alfalfa production in central and southern California. Water 2017, 9, 837. [Google Scholar] [CrossRef]

- Zheng, J.H.; Huang, G.H.; Jia, D.D.; Wang, J.; Mota, M.; Pereira, L.S.; Huang, Q.Z.; Xu, X.; Liu, H.J. Responses of drip irrigated tomato (Solanum lycopersicum L.) yield, quality and water productivity to various soil matric potential thresholds in an arid region of Northwest China. Agric. Water Manag. 2013, 129, 181–193. [Google Scholar] [CrossRef]

- Patanè, C.; Tringali, S.; Sortino, O. Effects of deficit irrigation on biomass, yield, water productivity and fruit quality of processing tomato under semi-arid Mediterranean climate conditions. Sci. Hortic. 2011, 129, 590–596. [Google Scholar] [CrossRef]

| Soil Depths (cm) | Soil Particle Fraction (%) | Soil Texture | Bulk Density (g/cm3) | Field Capacity (cm3/cm3) | Wilting Point (cm3/cm3) | ||

|---|---|---|---|---|---|---|---|

| Sand (>0.05 mm) | Silt (0.05–0.002 mm) | Clay (<0.002 mm) | |||||

| 0–20 | 12.18 | 60.98 | 26.84 | Silt loam | 1.47 | 0.33 | 0.16 |

| 20–40 | 21.84 | 56.87 | 21.29 | Silt loam | 1.53 | 0.35 | 0.15 |

| 40–60 | 18.46 | 54.81 | 26.73 | Silt loam | 1.49 | 0.35 | 0.13 |

| Crop Growth Stages | Initial Date in 2015 | Initial Date in 2016 | ||

|---|---|---|---|---|

| Drip Irrigation | Basin Irrigation | Drip Irrigation | Basin Irrigation | |

| Initial stage | 20 May 2015 | 20 May 2015 | 20 May 2016 | 20 May 2016 |

| Development stage | 15 June 2015 | 15 June 2015 | 13 June 2016 | 13 June 2016 |

| Midseason stage | 1 July 2015 | 1 July 2015 | 1 July 2016 | 1 July 2016 |

| Late stage | 10 August 2015 | 16 August 2015 | 12 August 2016 | 16 August 2016 |

| Harvest | 31 August 2015 | 31 August 2015 | 31 August 2016 | 31 August 2016 |

| Crop Growth Stages | Irrigation Depth in 2015 (mm) | Irrigation Depth in 2016 (mm) | ||||

|---|---|---|---|---|---|---|

| DI | BI | DI | RDI | BI | RBI | |

| Initial stage | 55.0 | 55.0 | 45.0 | 45.0 | 45.0 | 45.0 |

| Development stage | 15.0 | 80.0 | 15.0 | 9.0 | 80.0 | 48.0 |

| Midseason stage | 108.2 | 80.0 | 90.4 | 54.2 | 50.0 | 30.0 |

| Late stage | 19.0 | 0.0 | 17.8 | 10.7 | 0.0 | 0.0 |

| Harvest | 197.2 | 215.0 | 168.2 | 118.9 | 175.0 | 123.0 |

| Types | Parameters (Units) | Initial Value | Calibrated Value |

|---|---|---|---|

| Crop | Kcb,ini (/) | 0.15 | 0.30 |

| Kcb,mid (/) | 1.10 | 0.92 | |

| Kcb,end (/) | 0.60 | 0.60 | |

| pini (/) | 0.40 | 0.30 | |

| pdev (/) | 0.40 | 0.30 | |

| pmid (/) | 0.40 | 0.30 | |

| pend (/) | 0.40 | 0.30 | |

| Soil evaporation | REW (mm) | 8 | 10 |

| TEW (mm) | 25 | 37 | |

| Ze (m) | 0.10 | 0.15 |

| Years | Treatments | Y (t/ha) | ET (mm) | T (mm) | WPET (kg/m3) | WPT (kg/m3) | Es/ET |

|---|---|---|---|---|---|---|---|

| 2015 | DI | 99.4 ± 7.7 a | 266.3 | 253.2 | 37.3 ± 2.9 a | 39.2 ± 3.0 a | 4.9% |

| BI | 91.6 ± 6.8 a | 284.3 | 272.0 | 32.2 ± 2.4 b | 33.7 ± 2.5 b | 4.3% | |

| 2016 | DI | 107.9 ± 10.5 a | 309.7 | 272.5 | 34.8 ± 3.4 a | 39.6 ± 3.9 a | 11.9% |

| RDI | 88.4 ± 7.5 b | 270.9 | 233.3 | 32.6 ± 2.8 a | 37.9 ± 3.2 a | 13.8% | |

| BI | 105.1 ± 8.3 a | 331.2 | 295.0 | 31.7 ± 2.5 a | 35.6 ± 2.8 a | 10.9% | |

| RBI | 94.6 ± 7.8 ab | 283.9 | 246.9 | 33.3 ± 2.7 a | 38.3 ± 3.2 a | 12.9% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Huang, G.; Xu, X.; Xiong, Y.; Huang, Q. Estimating Evapotranspiration of Processing Tomato under Plastic Mulch Using the SIMDualKc Model. Water 2018, 10, 1088. https://doi.org/10.3390/w10081088

Zhang H, Huang G, Xu X, Xiong Y, Huang Q. Estimating Evapotranspiration of Processing Tomato under Plastic Mulch Using the SIMDualKc Model. Water. 2018; 10(8):1088. https://doi.org/10.3390/w10081088

Chicago/Turabian StyleZhang, Huimeng, Guanhua Huang, Xu Xu, Yunwu Xiong, and Quanzhong Huang. 2018. "Estimating Evapotranspiration of Processing Tomato under Plastic Mulch Using the SIMDualKc Model" Water 10, no. 8: 1088. https://doi.org/10.3390/w10081088